Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35 results about "Niobium monoxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Niobium monoxide is the inorganic compound with the formula NbO. It is a grey solid with metallic conductivity.

Production of high-purity niobium monoxide and capacitor production therefrom

The present invention relates to high-purity niobium monoxide powder (NbO) produced by a process of combining a mixture of higher niobium oxides and niobium metal powder or granules; heating and reacting the compacted mixture under controlled atmosphere to achieve temperatures greater than about 1800° C., at which temperature the NbO is liquid; solidifying the liquid NbO to form a body of material; and fragmenting the body to form NbO particles suitable for application as e.g., capacitor anodes. The NbO product is unusually pure in composition and crystallography, highly dense, and can be used for capacitors and for other electronic applications. The method of production of the NbO is robust, does not require high-purity feedstock, and can reclaim value from waste streams associated with the processing of NbO electronic components.

Owner:READING ALLOYS

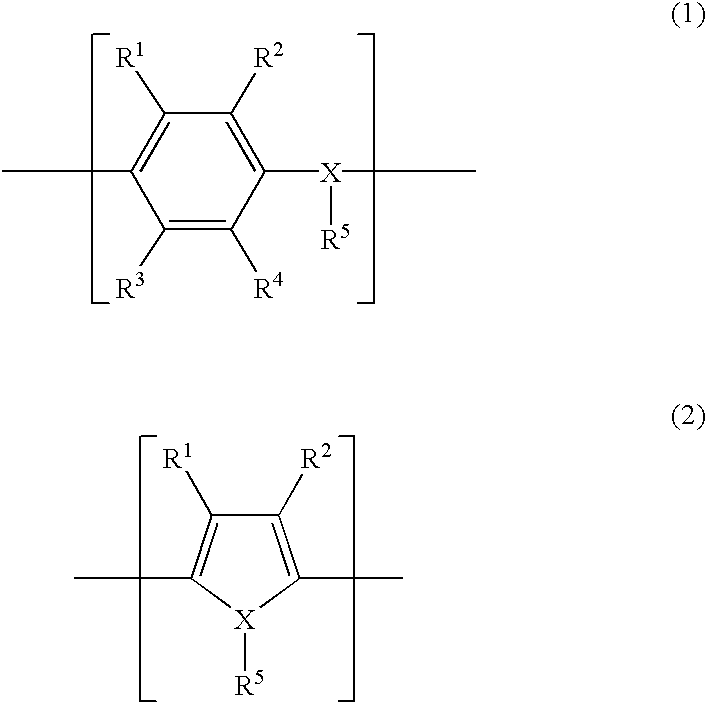

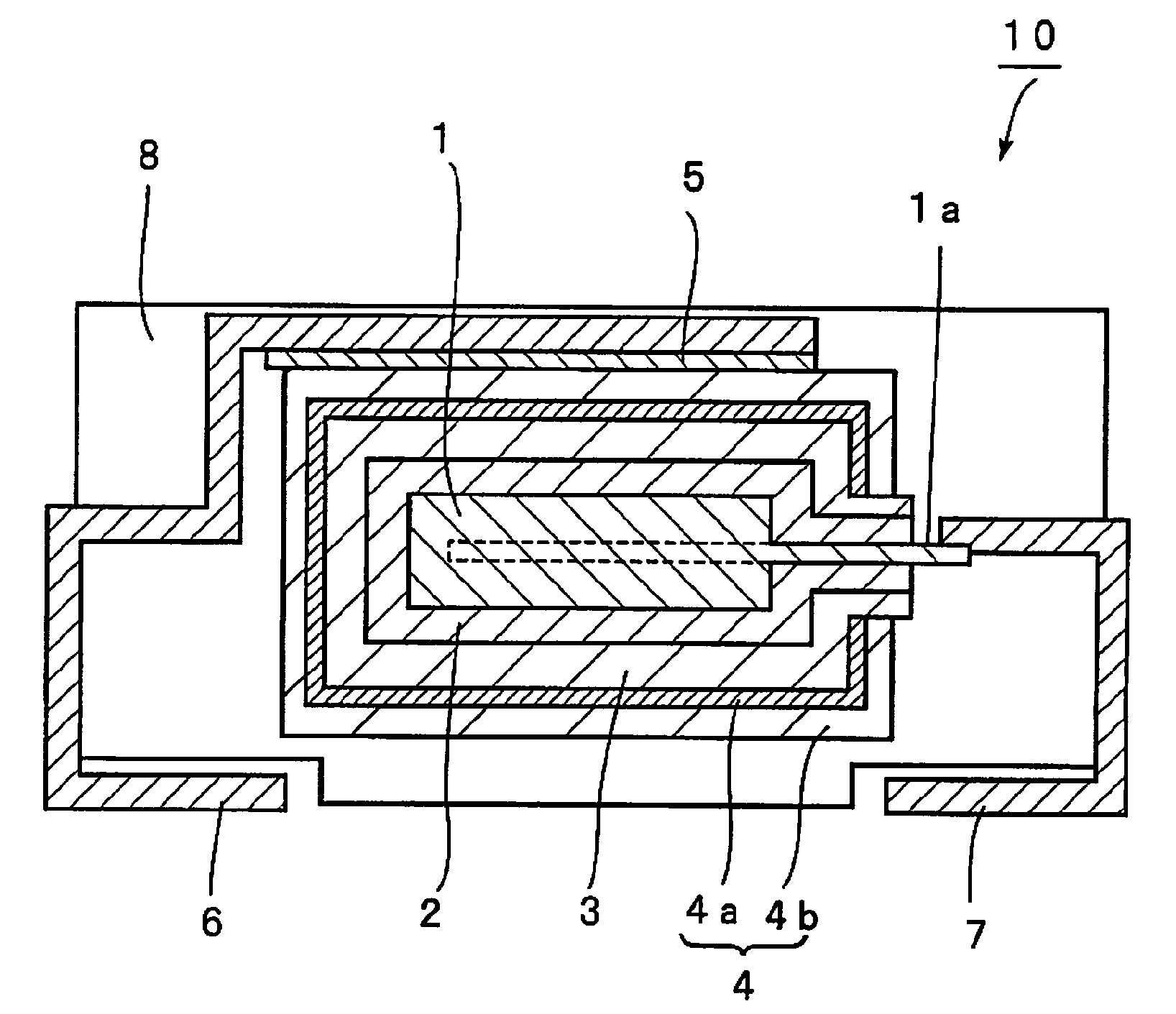

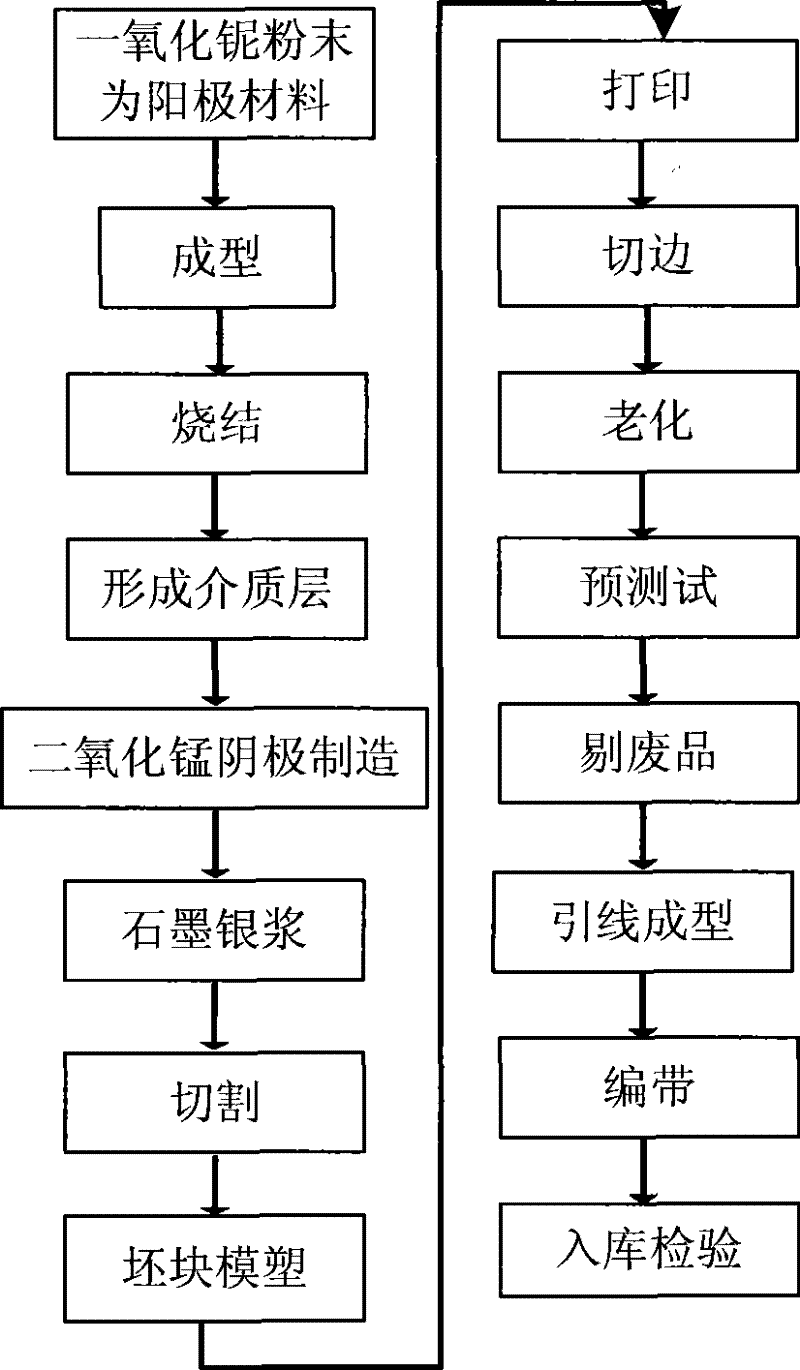

Production method of solid electrolytic capacitor

ActiveUS6882522B2Good electrical contactHybrid capacitor electrolytesHybrid capacitor electrodesElectrolysisAlloy

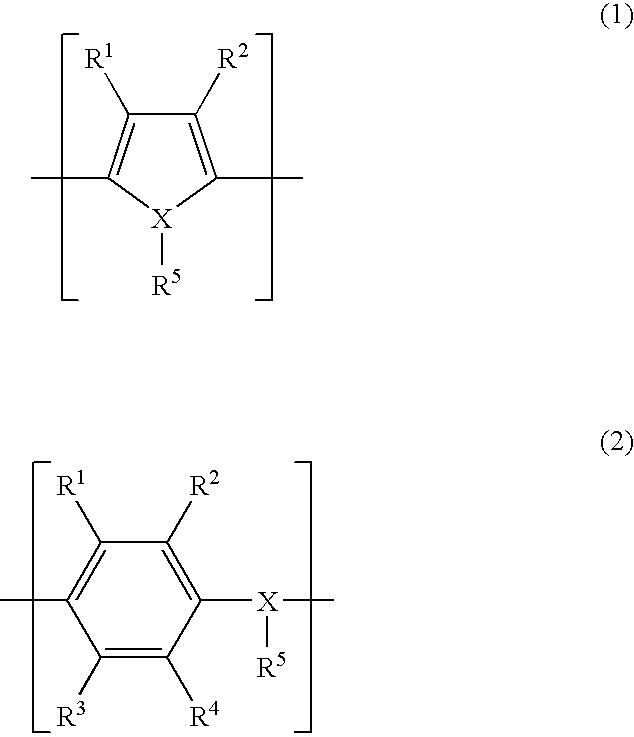

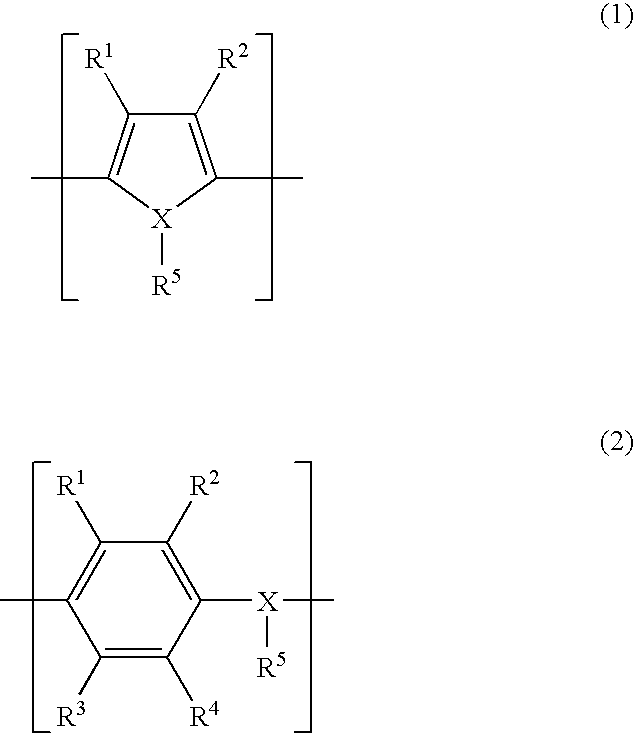

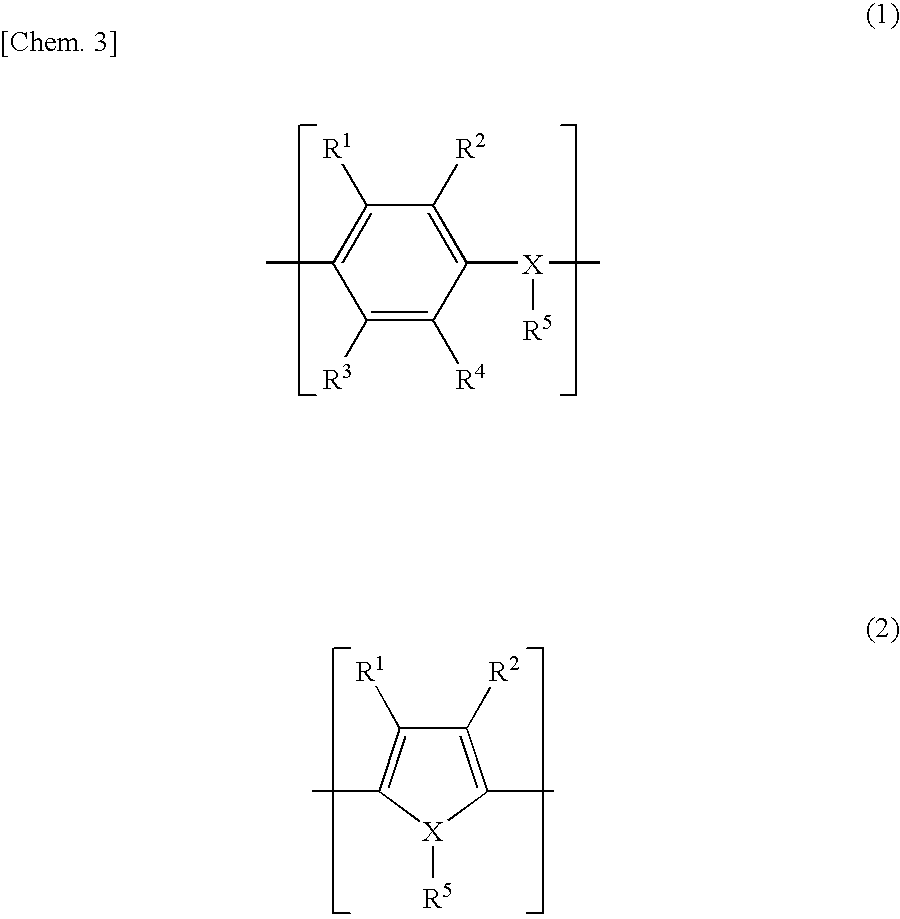

The present invention relates to a method for producing a niobium-oxide solid electrolytic capacitor having an anode being at least one member selected from niobium monoxide, niobium and an alloy mainly comprising niobium, or a mixture of niobium monoxide with niobium or an alloy mainly comprising niobium, which capacitor formed by the electrolytic oxidation (electrochemical formation) of the anode; and the method including sequentially repeating twice or more a step of exposing a dielectric layer to a temperature to 1,000° C. before formation of a cathode and a step of re-electrochemically forming the dielectric layer. The niobium solid electrolytic capacitor obtained by the present invention improved in the leakage current value after mounting and excellent in reliability.

Owner:SHOWA DENKO KK

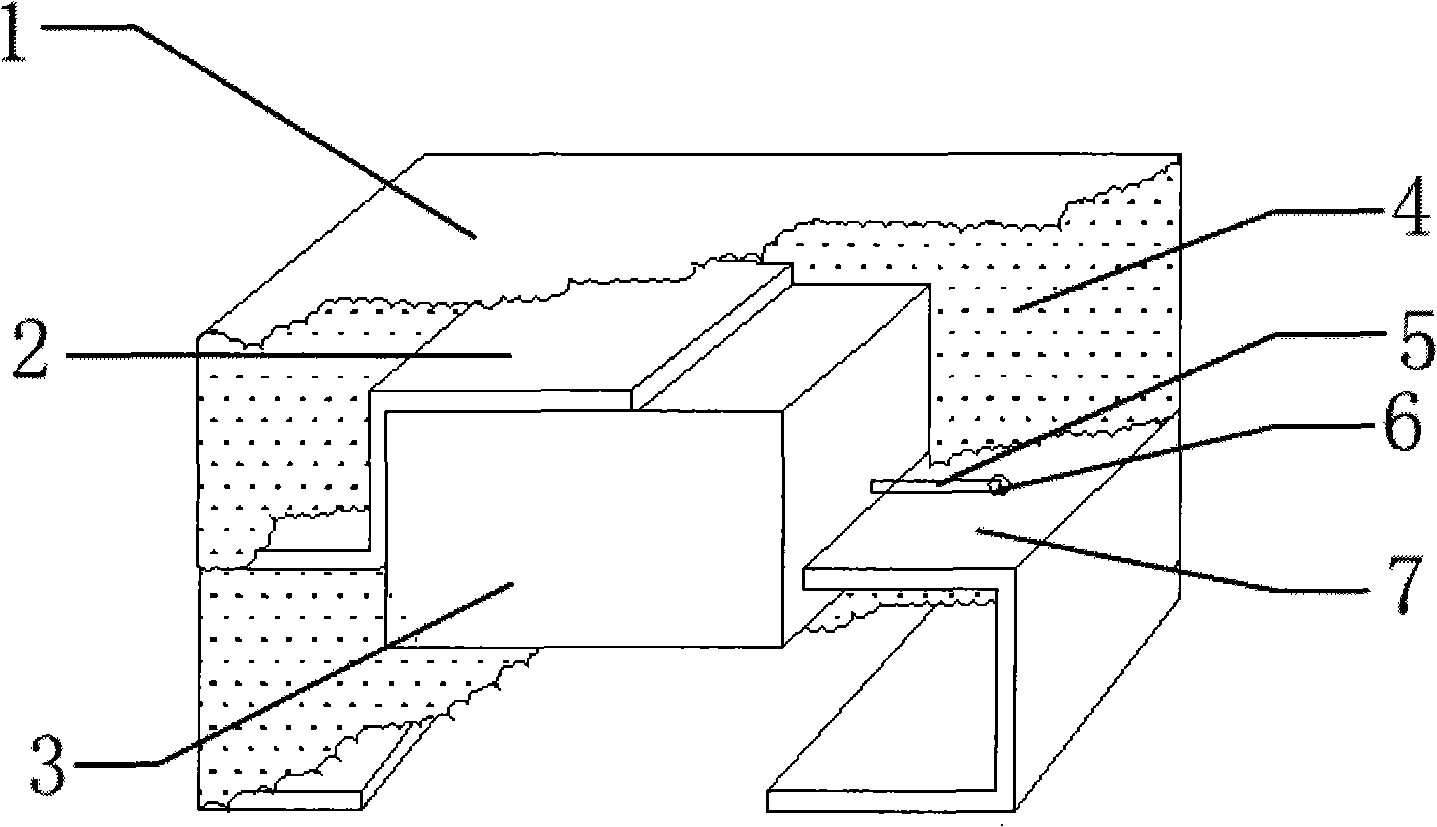

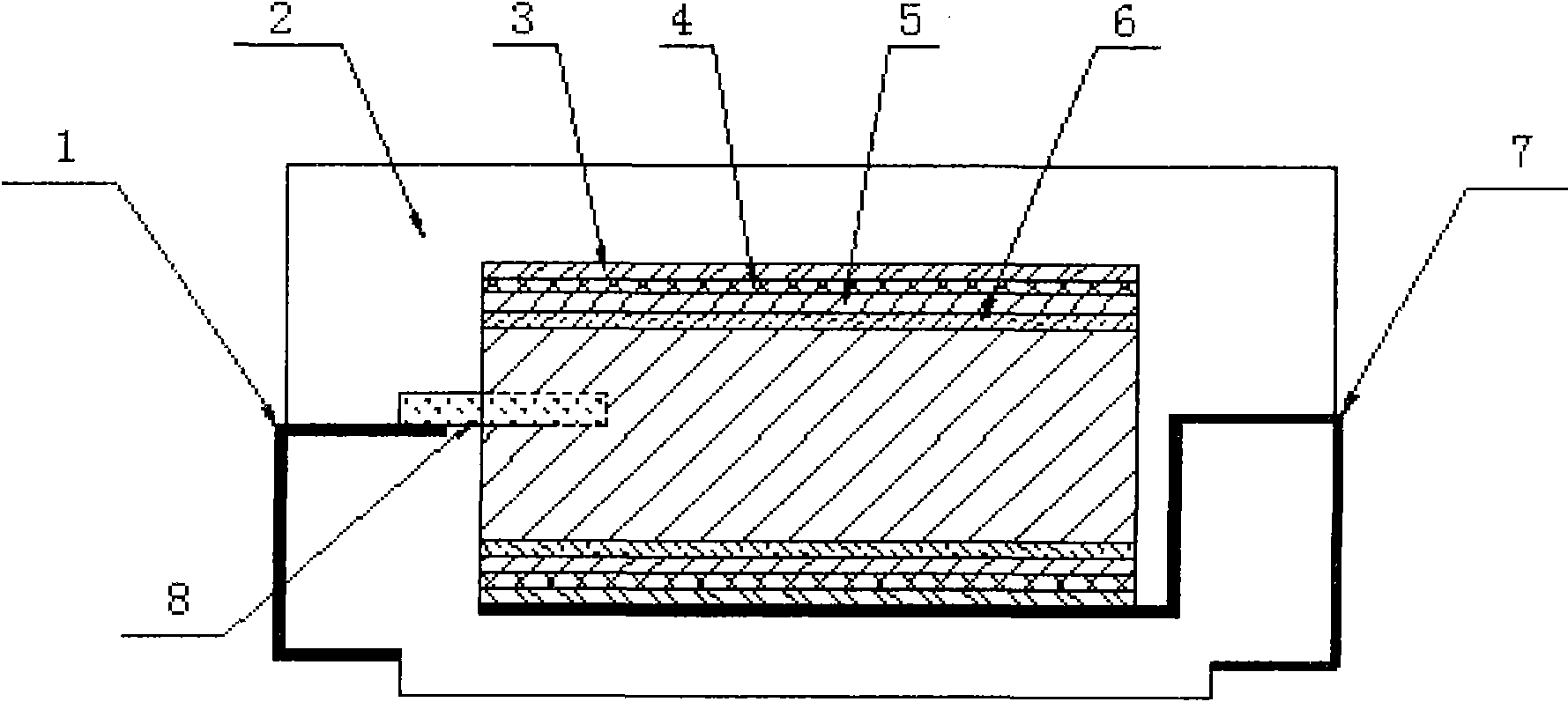

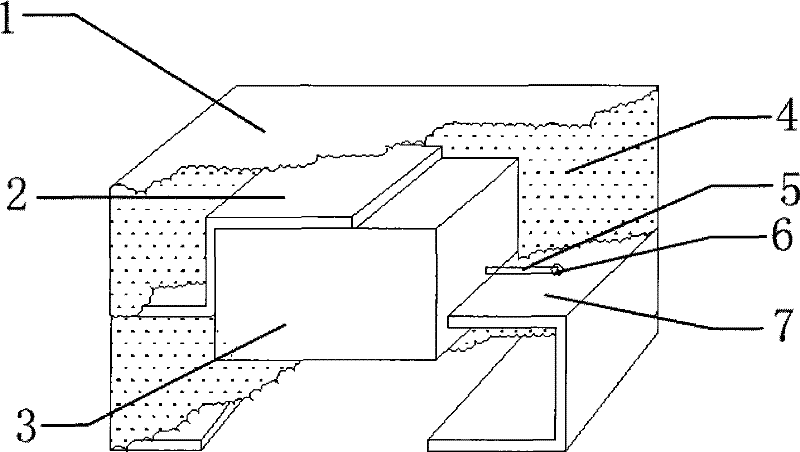

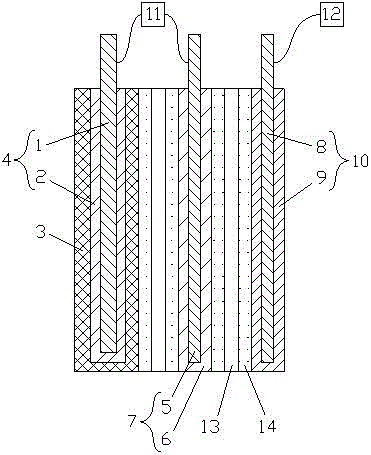

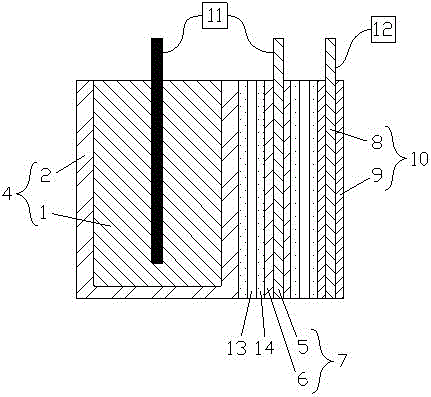

Sheet type niobium oxide solid electrolyte capacitor and its manufacturing method

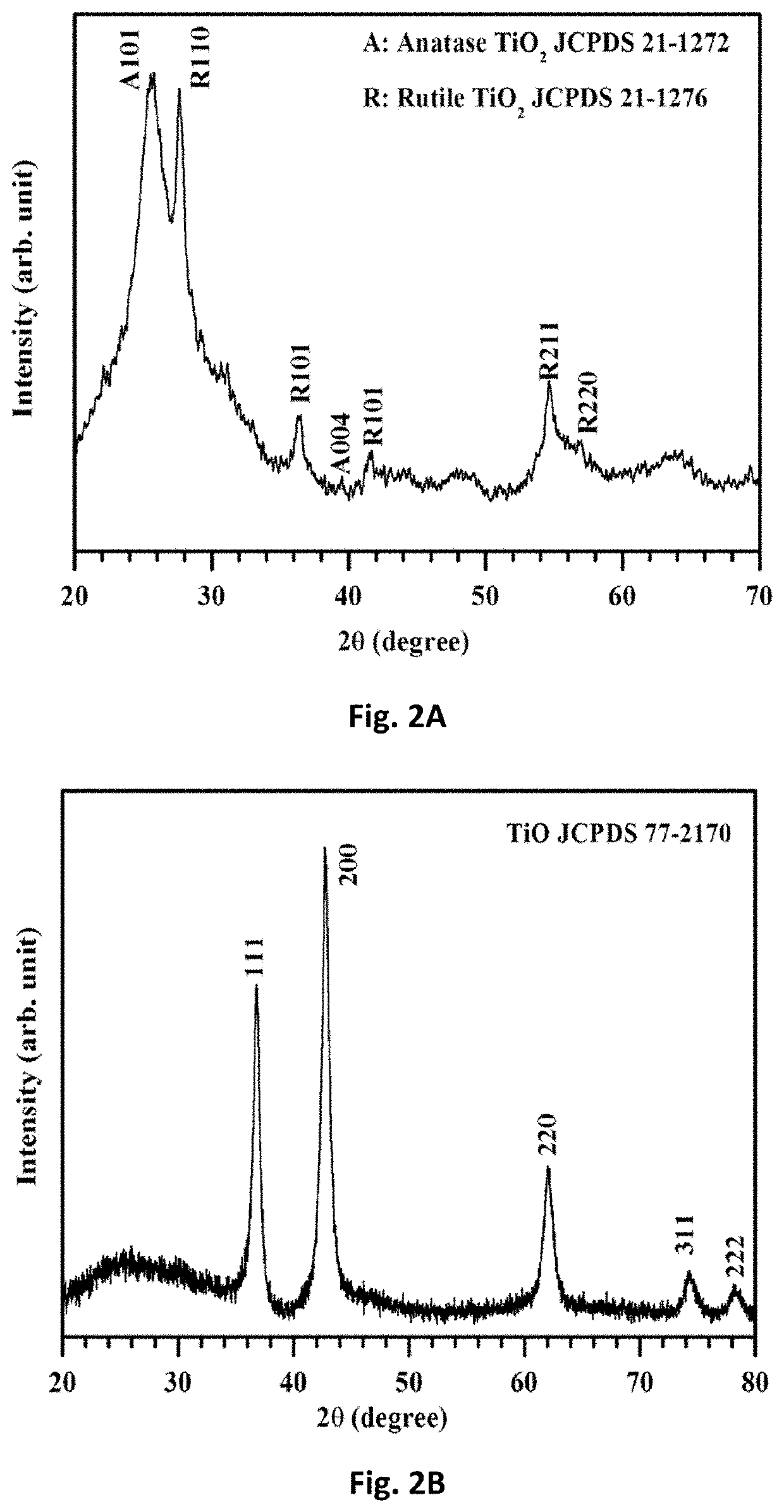

ActiveCN101404212ASimple structureSimple preparation processSolid electrolytic capacitorsCapacitor terminalsEpoxyElectrolysis

The invention discloses a slice-typed niobium oxide solid electrolytic capacitor and a preparation method thereof; the capacitor comprises an epoxy resin encapsulation shell which is internally provided with a niobium monoxide capacitor substrate, a nickel-based tinning cathode eduction slice and a nickel-based tinning anode eduction slice; the niobium monoxide capacitor substrate is internally provided with an anode and the surface thereof is a cathode; the anode is internally provided with a Ta-wire eduction wire; the cathode of the niobium monoxide capacitor substrate is electrically connected with the nickel-based tinning cathode eduction slice; the Ta-wire anode eduction wire in the niobium monoxide capacitor substrate is welded on the nickel-based tinning anode eduction slice to form electric connection. The niobium oxide solid electrolytic capacitor has simple structure and convenient manufacture process; the prepared niobium oxide capacitor can be applied to various circuits such as switch power circuit for large surge voltage and current and the like; when accidental breakdown occurs, combustion or explosion does not occur; furthermore, continuous breakdown can be effectively avoided; compared with the Ta capacitor or pure Nb capacitor, the niobium oxide solid electrolytic capacitor is greatly improved on the reliability and safety.

Owner:BEIJING 718 YOUYI ELECTRONICS

Processes for the production of niobium oxides with controlled tantalum content and capacitors made therefrom

InactiveUS20050225927A1Increase capacitanceReduce leakage currentElectrolytic capacitorsTantalum compoundsCapacitanceNiobium dioxide

The present invention relates to niobium oxides having a controlled tantalum content and processes for producing such niobium oxides. The tantalum content can be homogenous or heterogeneous and can be obtained using various process, including co-precipitation, impregnation, deposition, and mixing processes. Niobium pentoxide having a controlled tantalum content can further be reduced to niobium monoxide with controlled tantalum content using a single step reduction process, or can first be reduced to niobium-dioxide with controlled tantalum content using a two step process. The niobium monoxide with controlled tantalum content produced according to such processes can exhibit a high surface area and an appropriate morphology, and can be used to make capacitors with a high capacitance and a low leakage current.

Owner:CIA BRASILEIRA DE METALURGIA E MINERCAO

Solid electrolyte tantalum-niobium composite capacitor and preparation method thereof

ActiveCN101859649ATake advantage of stabilityReduce leakage currentSolid electrolytic capacitorsElectrochemistryNiobium monoxide

The invention discloses a solid electrolyte tantalum-niobium composite capacitor and a preparation method thereof. The tantalum-niobium composite capacitor is prepared by mixing tantalum and niobium. The preparation method comprises the following steps: firstly, uniformly mixing tantalum power and niobium power or the tantalum power and pure columbium monoxide according to certain ratio, wherein the content of tantalum is 5-95 percent and the balance of niobium; pressing the mixture to form to obtain an anode block of compound metal; vacuum sintering to obtain an anode of the composite capacitor; electrochemically oxidizing the anode to form a medium film compounded by tantalum oxide and niobium oxide and using the medium film as the anode of the tantalum-niobium composite capacitor; and preparing the anode from solid manganese dioxide. The appearance of a product is similar to the appearance of the platy solid electrolyte tantalum-niobium composite capacitor. The preparation method comprises the working procedures of mixing, forming, sintering, energizing and enveloping the tantalum power and the niobium power or the columbium monoxide.

Owner:ZHUZHOU HONGDA ELECTRONICS

Niobium powder for capacitor, sintered body thereof and capacitor using the sintered body

A nobium powder for capacitors, which contains from 0.05 to 20% by mass of niobium monoxide crystal and from 0.05 to 20% by mass of hexaniobium monoxide crystal; a sintered body thereof; and a capacitor fabricated from the sintered body as one part electrode, a dielectric material formed on the surface of the sintered body, and another part provided on the dielectric material. A capacitor manufactured from a sintered body of a niobium powder of the present invention is favored with good high-temperature characteristics.

Owner:SHOWA DENKO KK

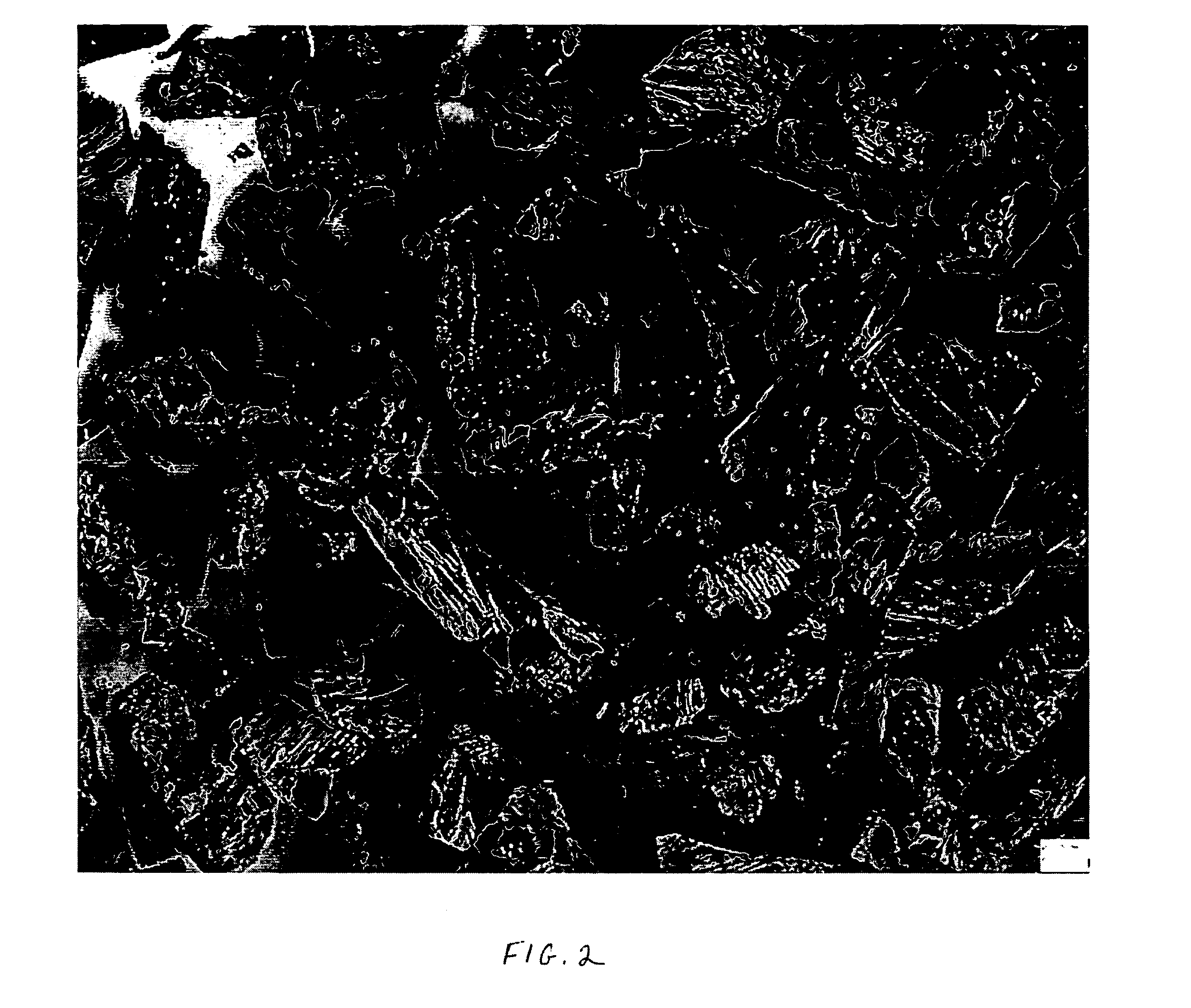

Production of high-purity niobium monoxide and capacitor production therefrom

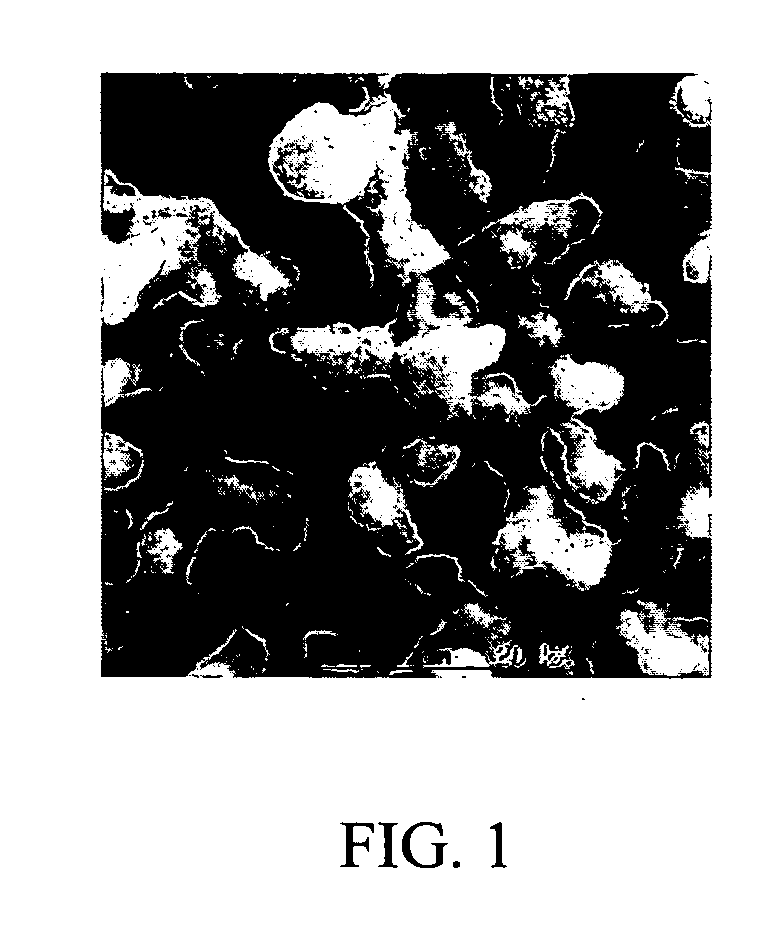

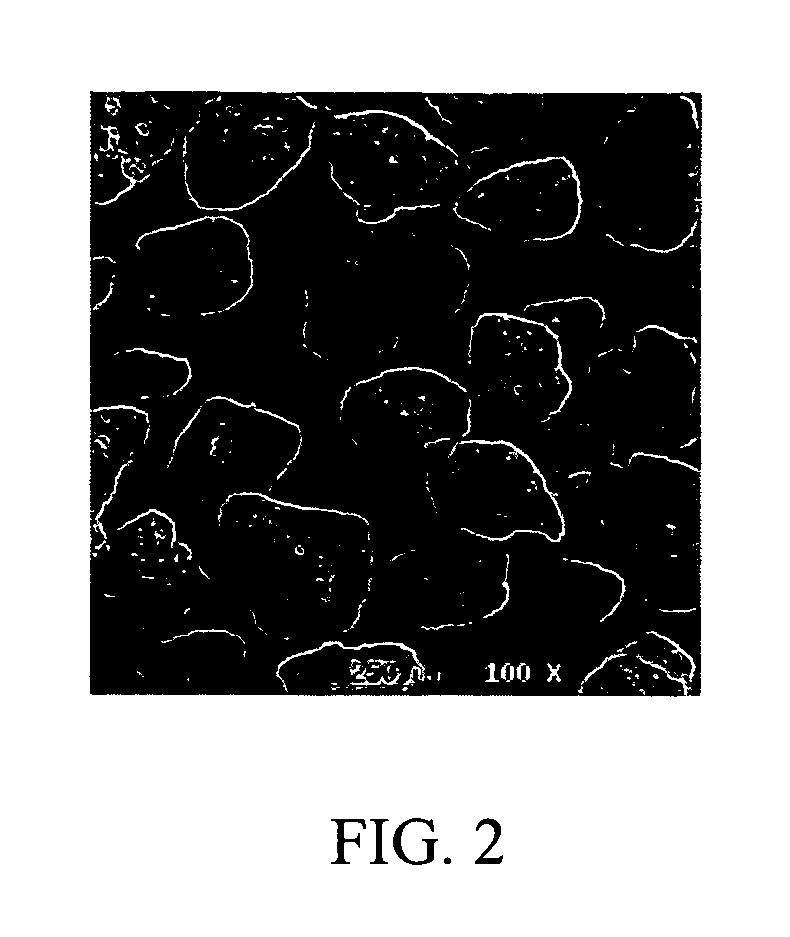

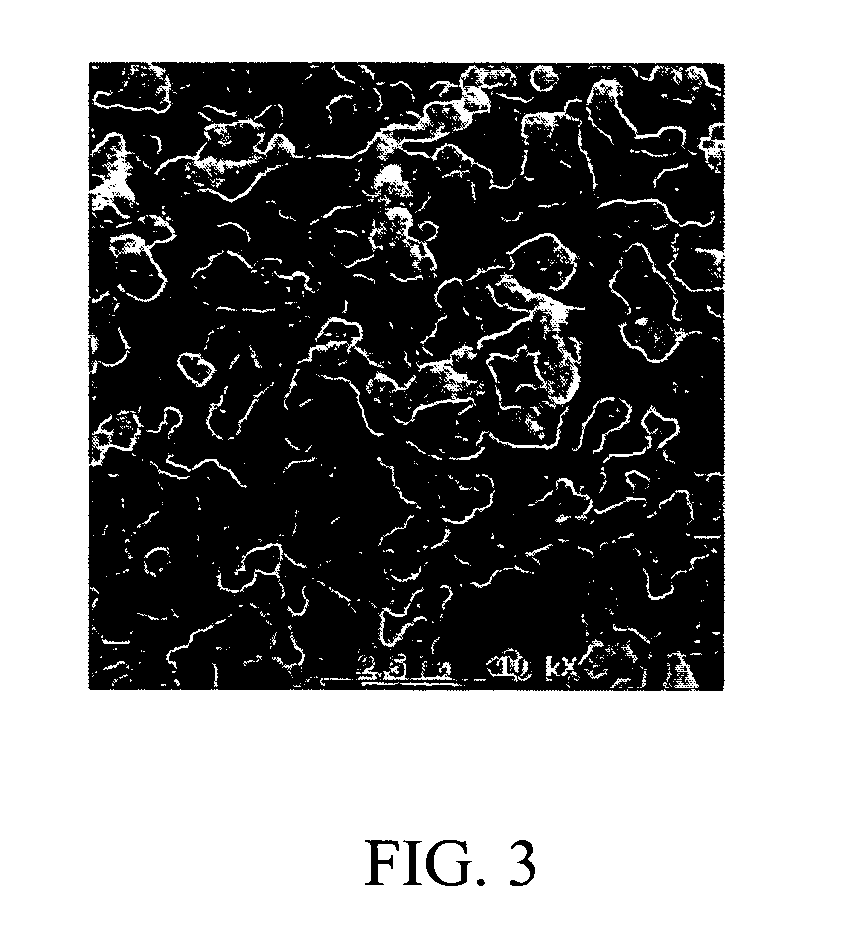

The present invention relates to high-purity niobium monoxide powder (NbO) produced by a process of combining a mixture of higher niobium oxides and niobium metal powder or granules; heating and reacting the compacted mixture under controlled atmosphere to achieve temperature greater than about 1945° C., at which temperature the NbO is liquid; solidifying the liquid NbO to form a body of material; and fragmenting the body to form NbO particles suitable for application as capacitor anodes. The NbO product is unusually pure in composition and crystallography, and can be used for capacitors and for other electronic applications. The method of production of the NbO is robust, does not require high-purity feedstock, and can reclaim value from waste streams associated with the processing of NbO electronic components. The method of production also can be used to make high-purity NbO2 and mixtures of niobium metal / niobium monoxide and niobium monoxide / niobium dioxide. The method further is ideal for doping of the product oxides to enhance particular characteristics of the materials. The method further allows the production of single crystal or directionally-solidified ingots. In contrast to the spongy, highly porous agglomerates produced by other techniques, the present invention produces solid, non-porous ingots that can be fragmented to fine, non-porous angular particles suitable for electronic applications.

Owner:READING ALLOYS

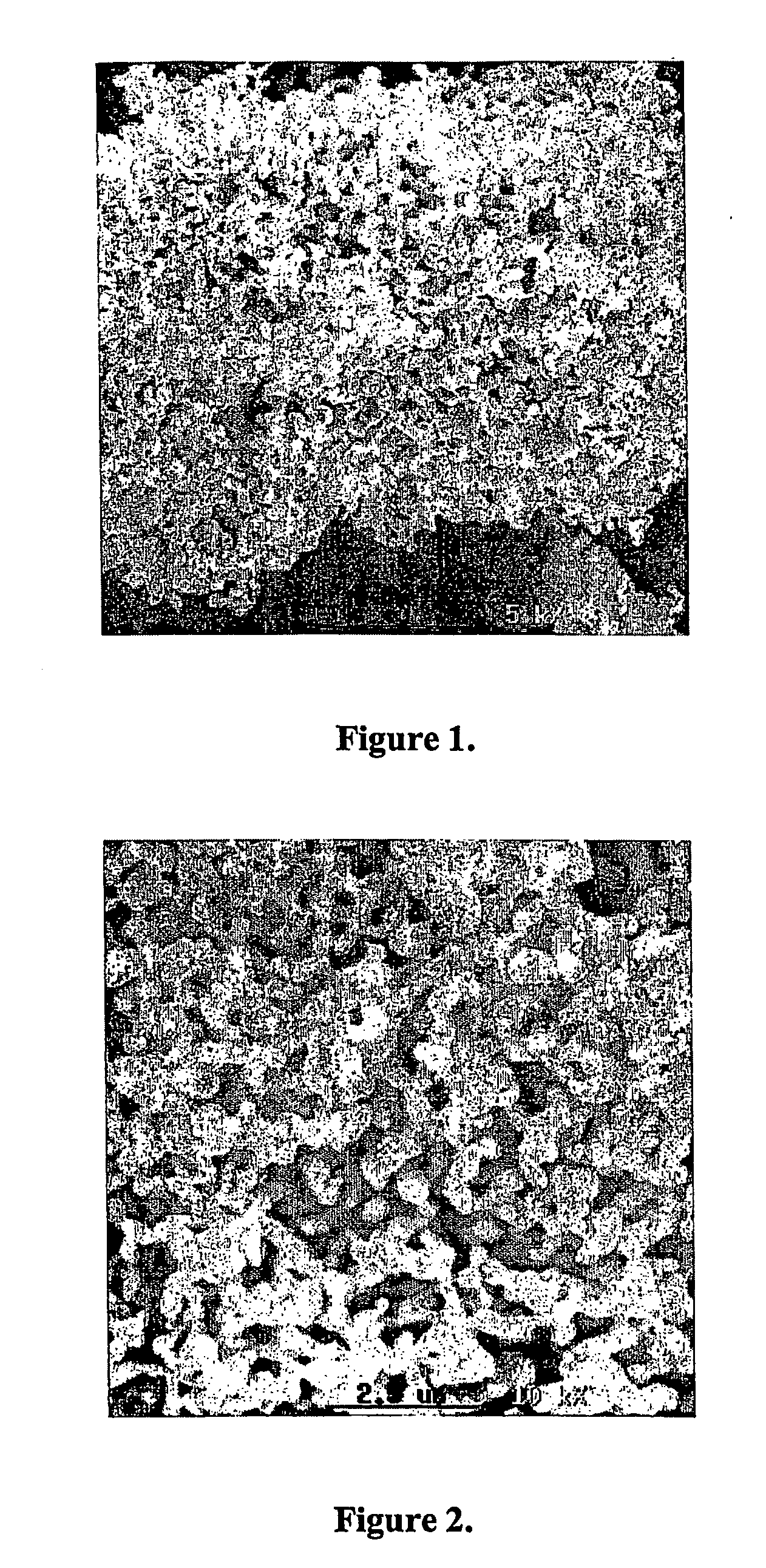

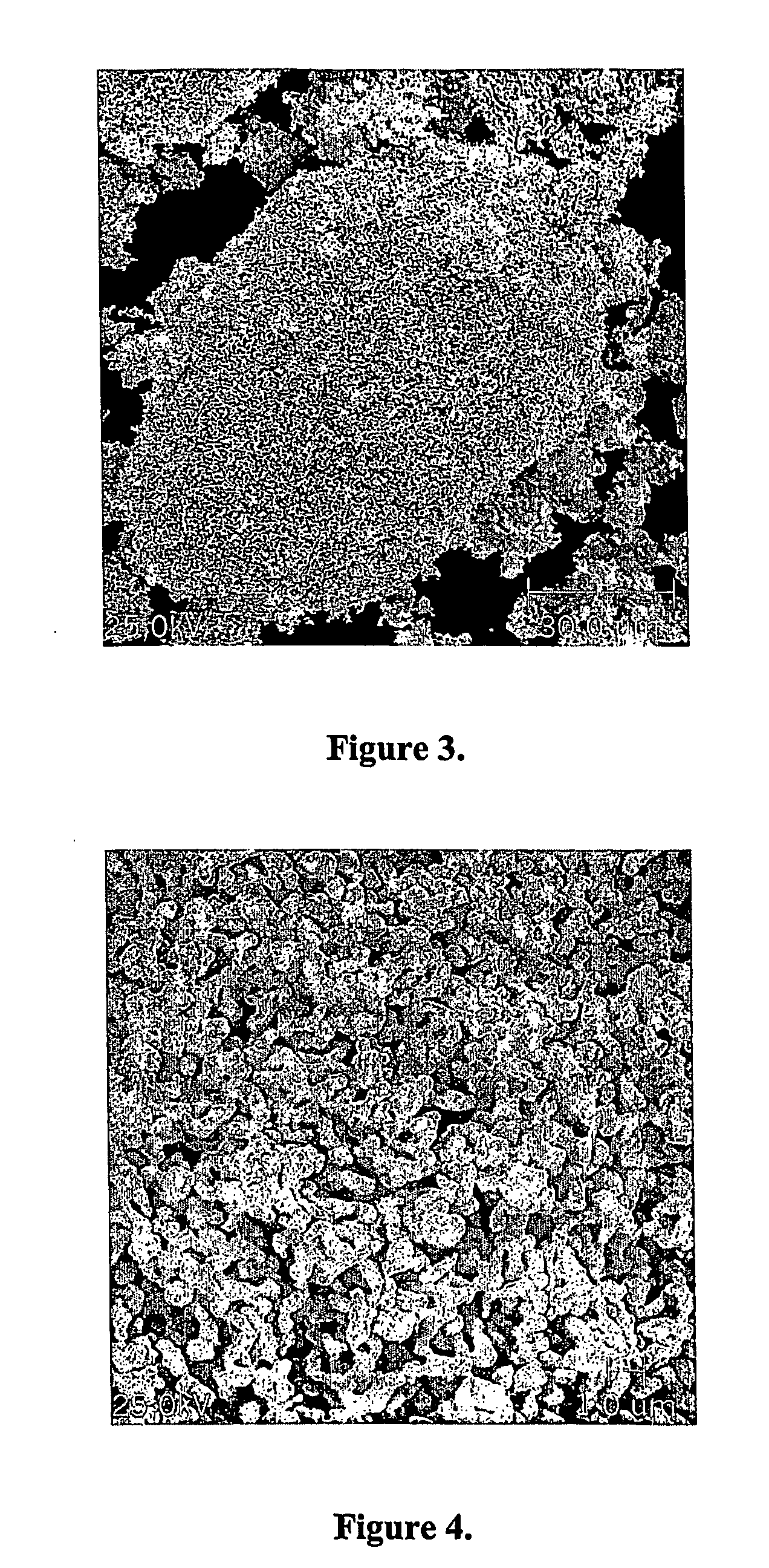

Process for the production of niobium oxide powder for use in capacitors

InactiveUS20060275204A1Low production costEasy to controlElectrolytic capacitorsTantalum compoundsHydrogenMetallurgy

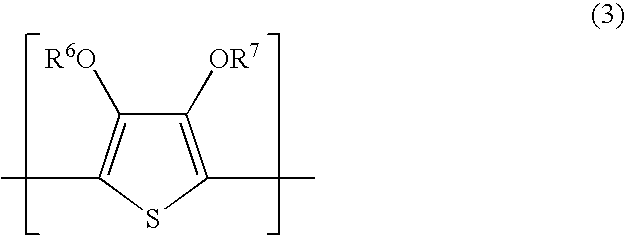

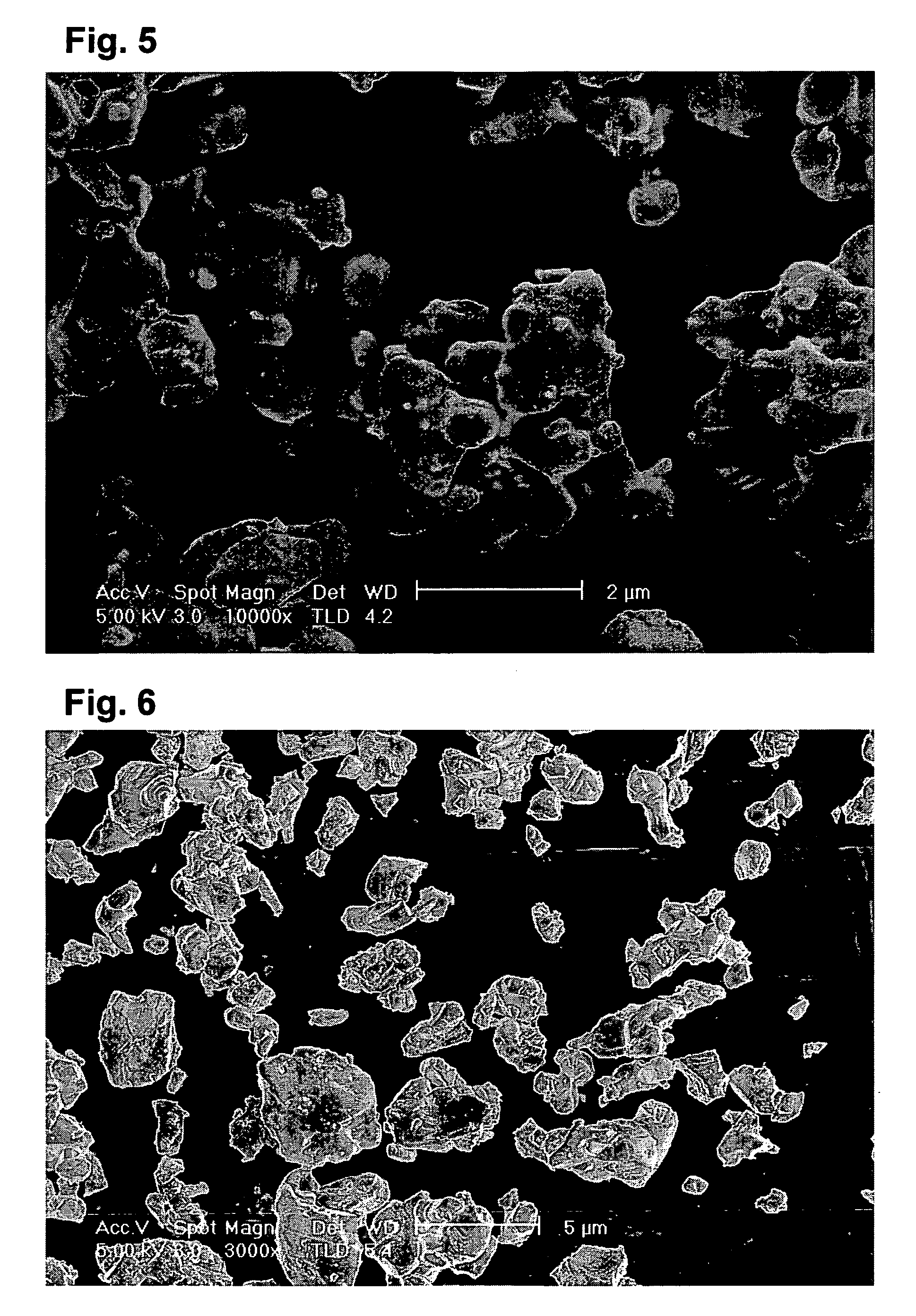

The present invention is related to a process for the production of a powder of niobium monoxide (NbO) having a high purity, large specific surface area, controlled oxygen and nitrogen contents and a morphology adequate for use in the manufacture of capacitors, characterized by comprising two niobium pentoxide (Nb2O5) reduction steps, the first step comprising reducing, by hydrogen, the niobium pentoxide (Nb2O5) to niobium dioxide (NbO2), and the second step comprising reducing niobium dioxide (NbO2) to niobium monoxide (NbO), by using an oxygen getter material in a convenient atmosphere which permits the transfer of the oxygen atoms from the niobium oxide (NbO2) to the getter material, under adequate conditions of time and temperature to form the niobium monoxide (NbO). The particles of powder of niobium monoxide (NbO) produced using the instant process are small, have a large surface area and an appropriate morphology, and are adequate for the production of capacitors.

Owner:CIA BRASILEIRA DE METALURGIA E MINERCAO +1

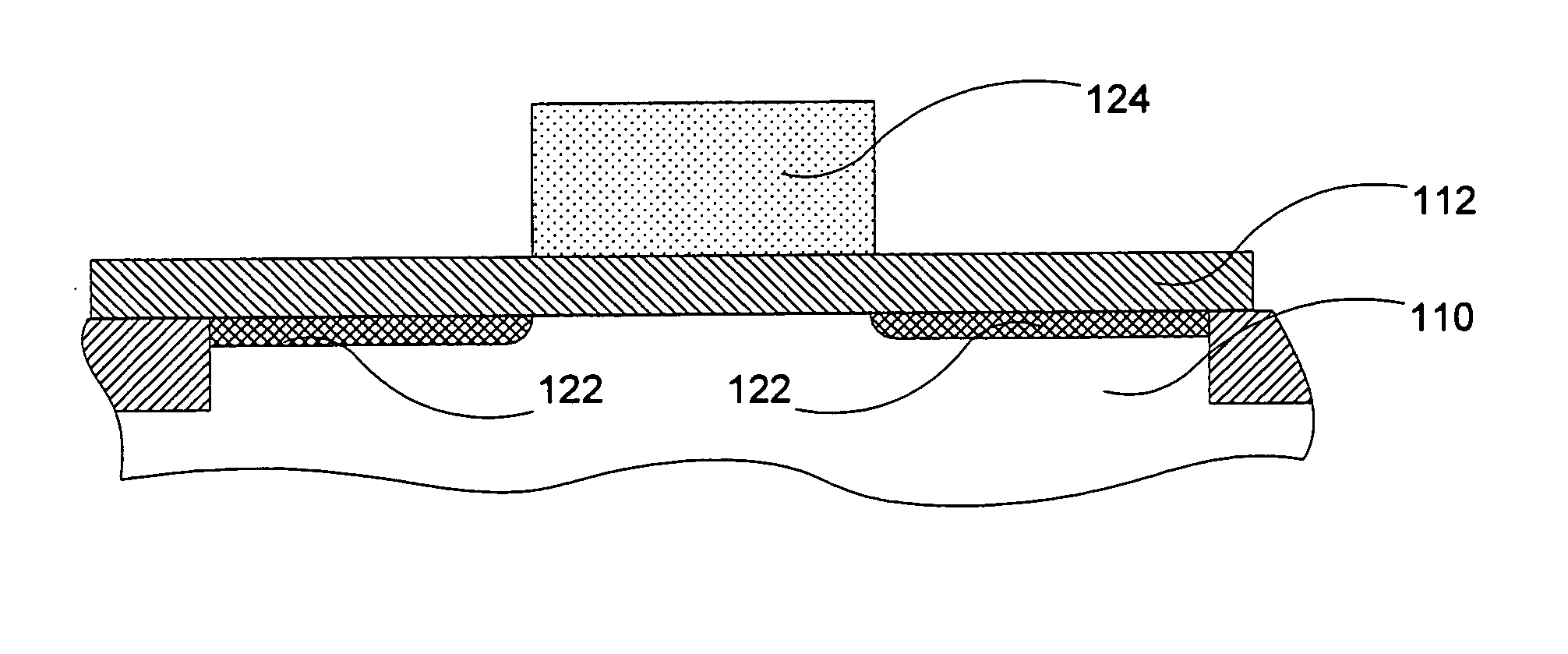

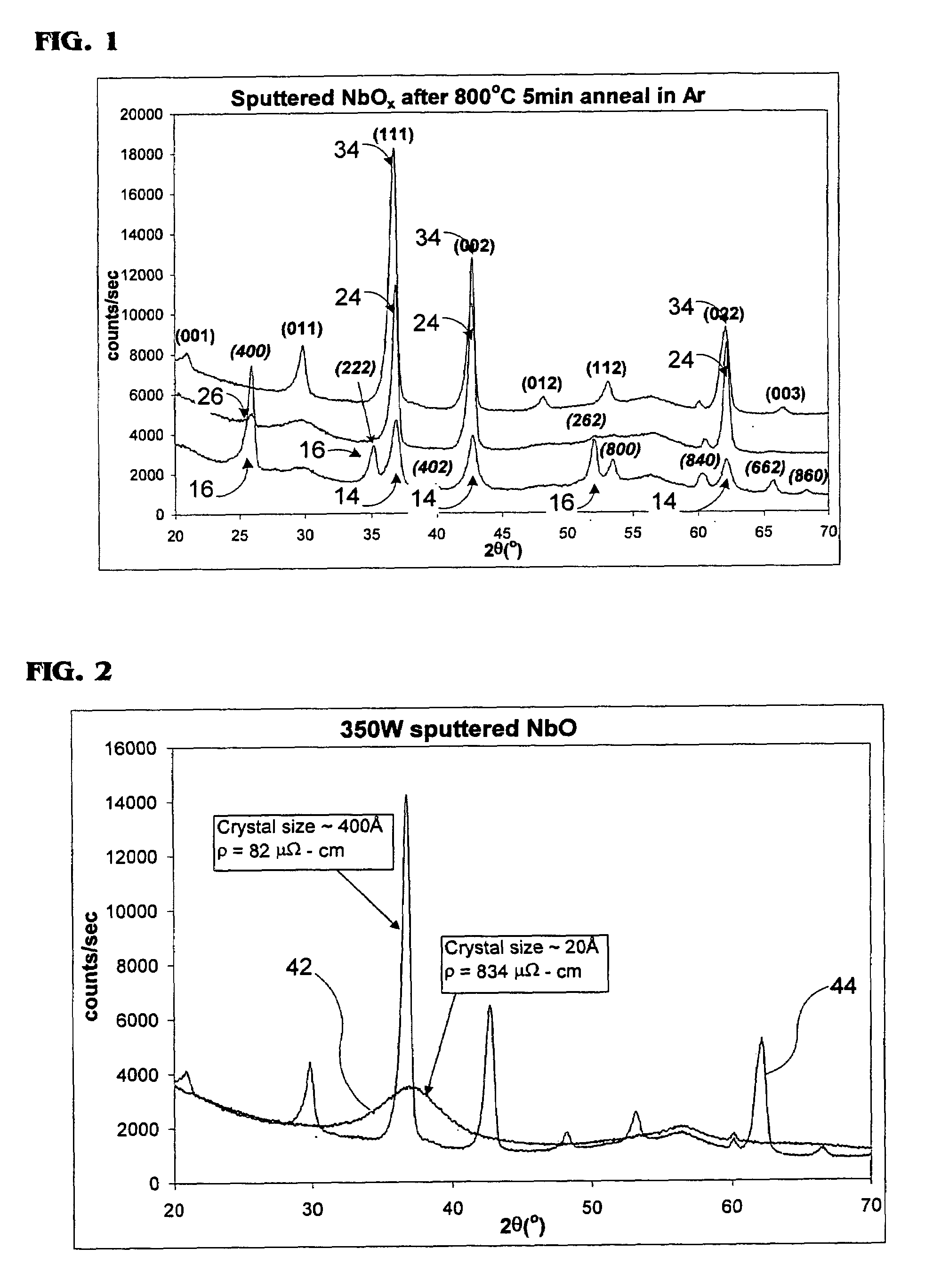

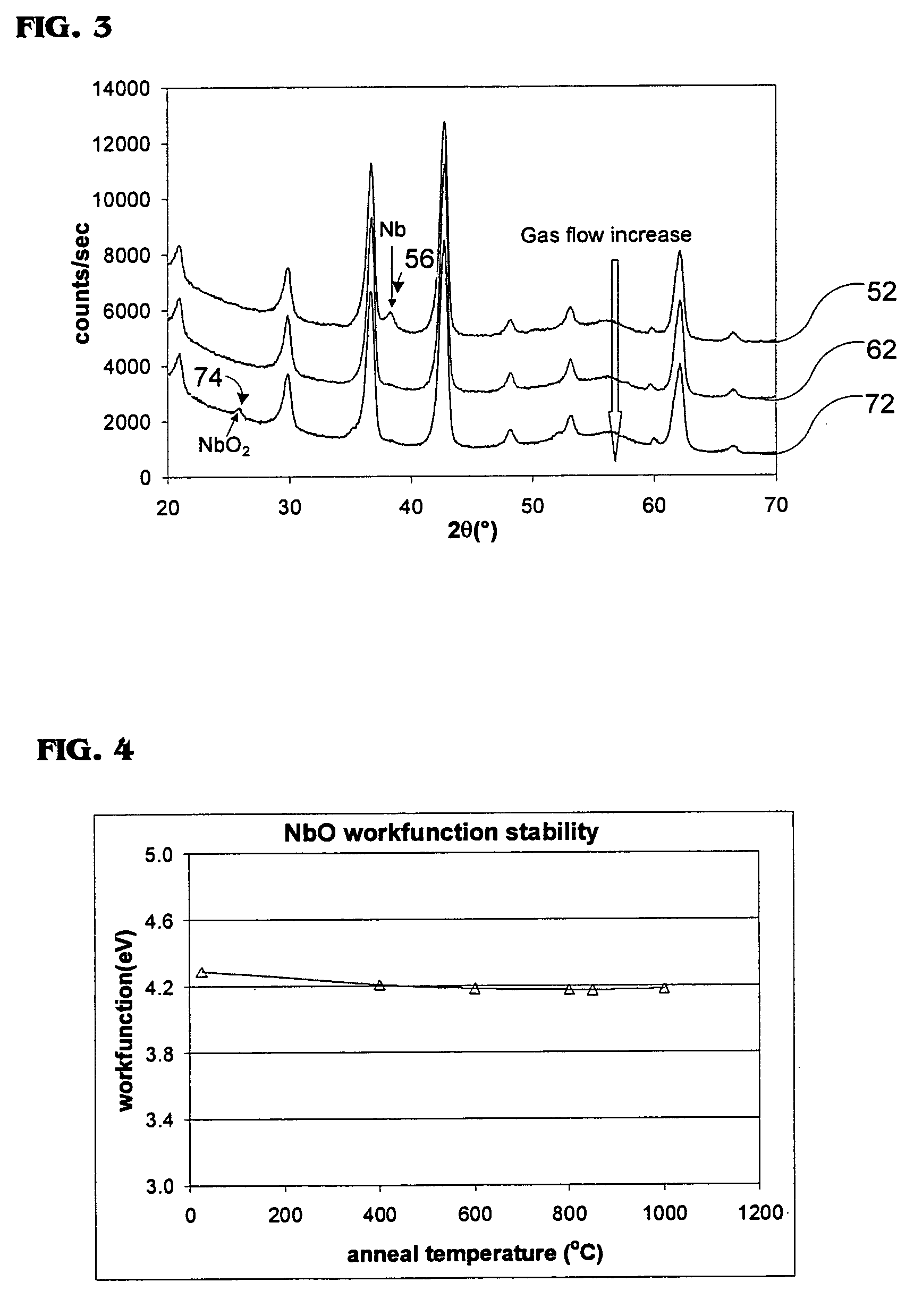

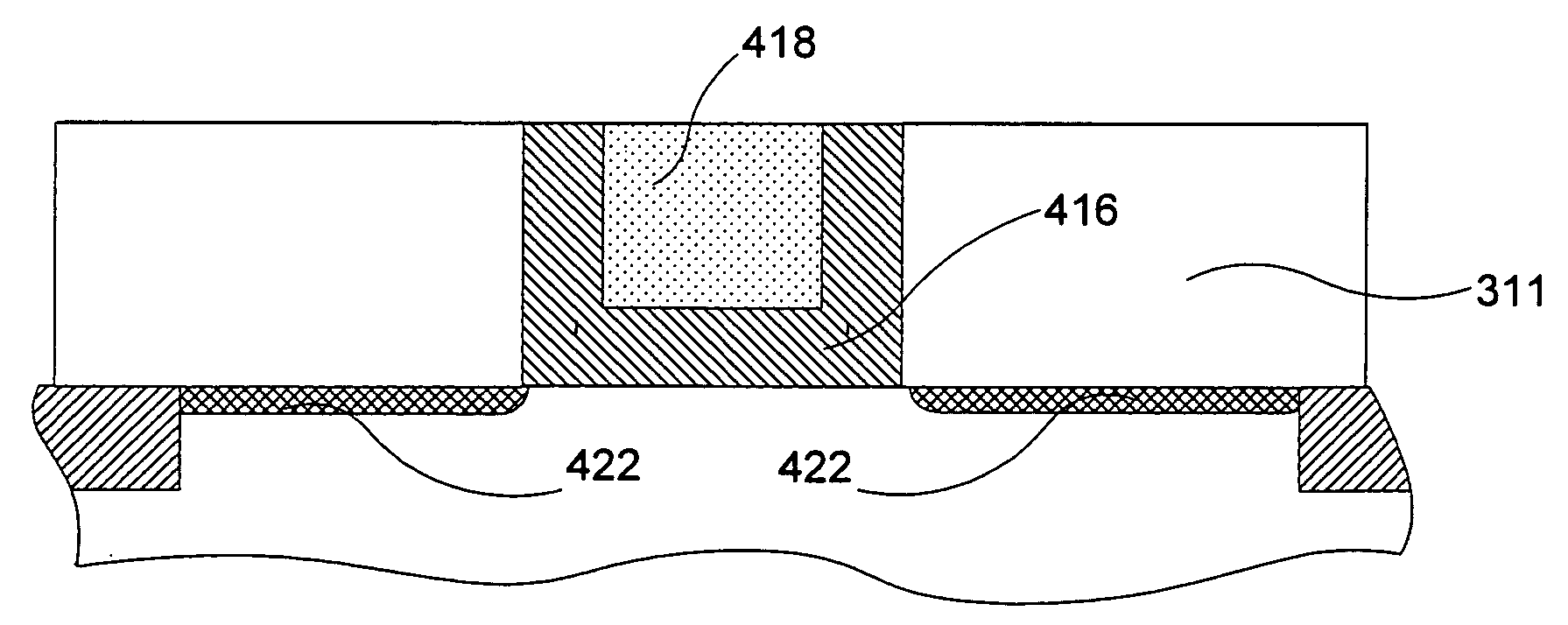

MOSFET structures with conductive niobium oxide gates

InactiveUS7129552B2Semiconductor/solid-state device manufacturingSemiconductor devicesMOSFETGate dielectric

Owner:SHARP KK

Powdered niobium, sintered body thereof, capacitor using the sintered body and production method of the capacitor

Owner:SHOWA DENKO KK

Niobium monoxide powder, niobium monoxide sintered body and capacitor using the sintered body

InactiveUS7737066B2Solve the large leakage currentImprove reliabilityOxide/hydroxide preparationTantalum compoundsPore distributionRelative intensity

(1) A niobium monoxide powder for a capacitor represented by formula: NbOx (x=0.8 to 1.2) and optionally containing other elements in an amount of 50 to 200,000 ppm, having a tapping density of 0.5 to 2.5 g / ml, an average particle size of 10 to 1000 μm, angle of repose from 10° to 60°, the BET specific surface area from 0.5 to 40 m2 / g and a plurality of pore diameter peak tops in the pore distribution, and a producing method thereof; (2) a niobium monoxide sintered body, which is obtained by sintering the above niobium monoxide powder and, having a plurality of pore diameter peak tops in a range of 0.01 μm to 500 μm, preferably, the peak tops of two peaks among the plurality of pore diameter peak tops having a highest relative intensity are present in the range of 0.2 to 0.7 μm and in the range of 0.7 to 3 μm, respectively, and a producing method thereof; (3) a capacitor using the above sintered body and a producing method thereof; and (4) an electronic circuit and electronic device using the above capacitor.

Owner:SHOWA DENKO KK

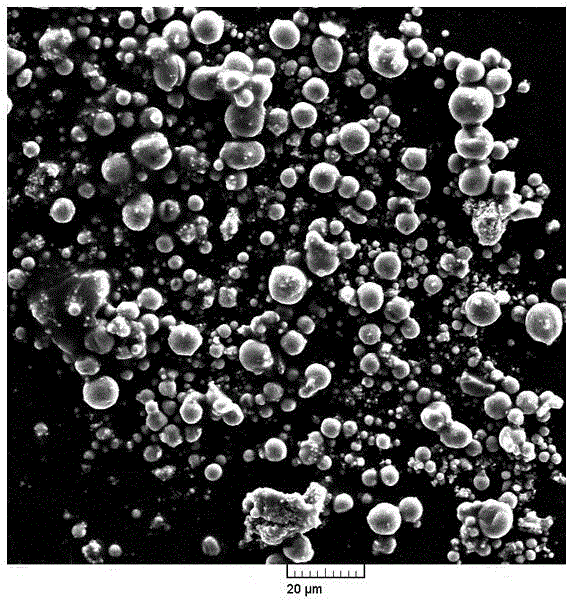

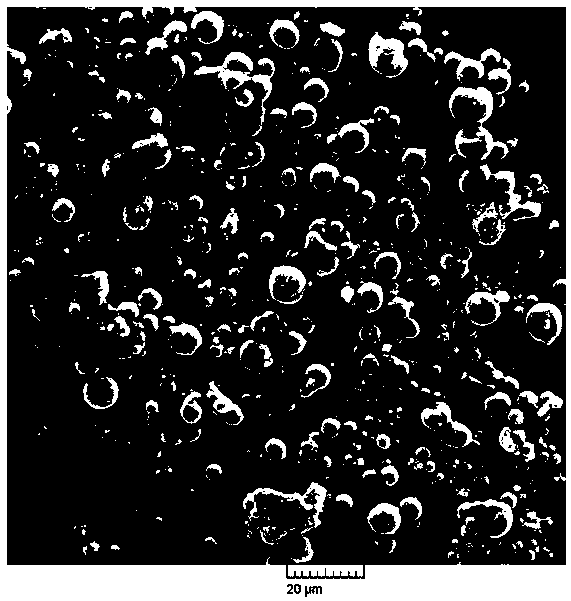

Method for preparing niobium monoxide and niobium powder mixture through plasma decomposition

Te invention discloses a method for preparing a niobium monoxide and niobium powder mixture through plasma decomposition. According to the method for preparing the niobium monoxide and niobium powder mixture through plasma decomposition, niobium pentoxide is used as a raw material, high-temperature plasma decomposition is conducted on the niobium pentoxide, and then the niobium monoxide and niobium powder mixture is prepared. The method for preparing the niobium monoxide and niobium powder mixture through plasma decomposition comprise the specific steps that the niobium pentoxide is poured into a plasma gun, the decomposition action is conducted through the high temperature of a plasma flame, and then the niobium monoxide and niobium powder mixture is obtained, wherein the power is controlled to be in the range of 10-100 kw; and the niobium monoxide and niobium powder mixture obtained through decomposition falls into a cooling device. The method for preparing the niobium monoxide and niobium powder mixture through plasma decomposition achieves simple and rapid reparation of the niobium monoxide and niobium powder mixture and is low in energy consumption and free of pollution. Besides, the particle shape of the obtained niobium monoxide and niobium powder mixture is sphere, the sphere particle shape is an ideal particle shape for manufacturing of a capacitor, and the niobium monoxide and niobium powder mixture is low in cost and good in quality. The method for preparing the niobium monoxide and niobium powder mixture through plasma decomposition has important significance in the aspects of replacing tantalum with niobium, replacing a tantalum capacitor and an aluminum capacitor with the niobium capacitor, manufacturing of a supercapacitor and the like.

Owner:江西波德新材料研究有限公司

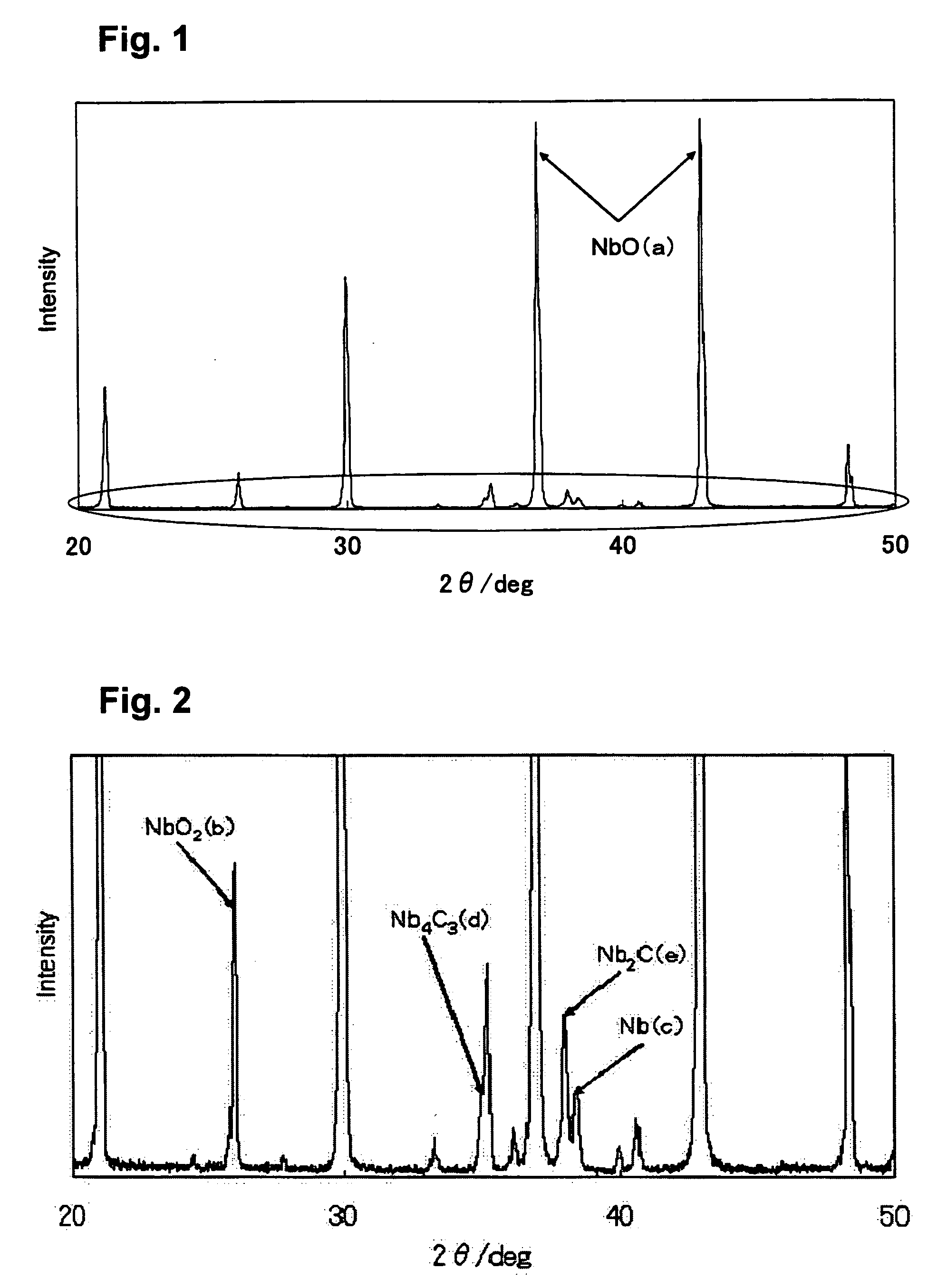

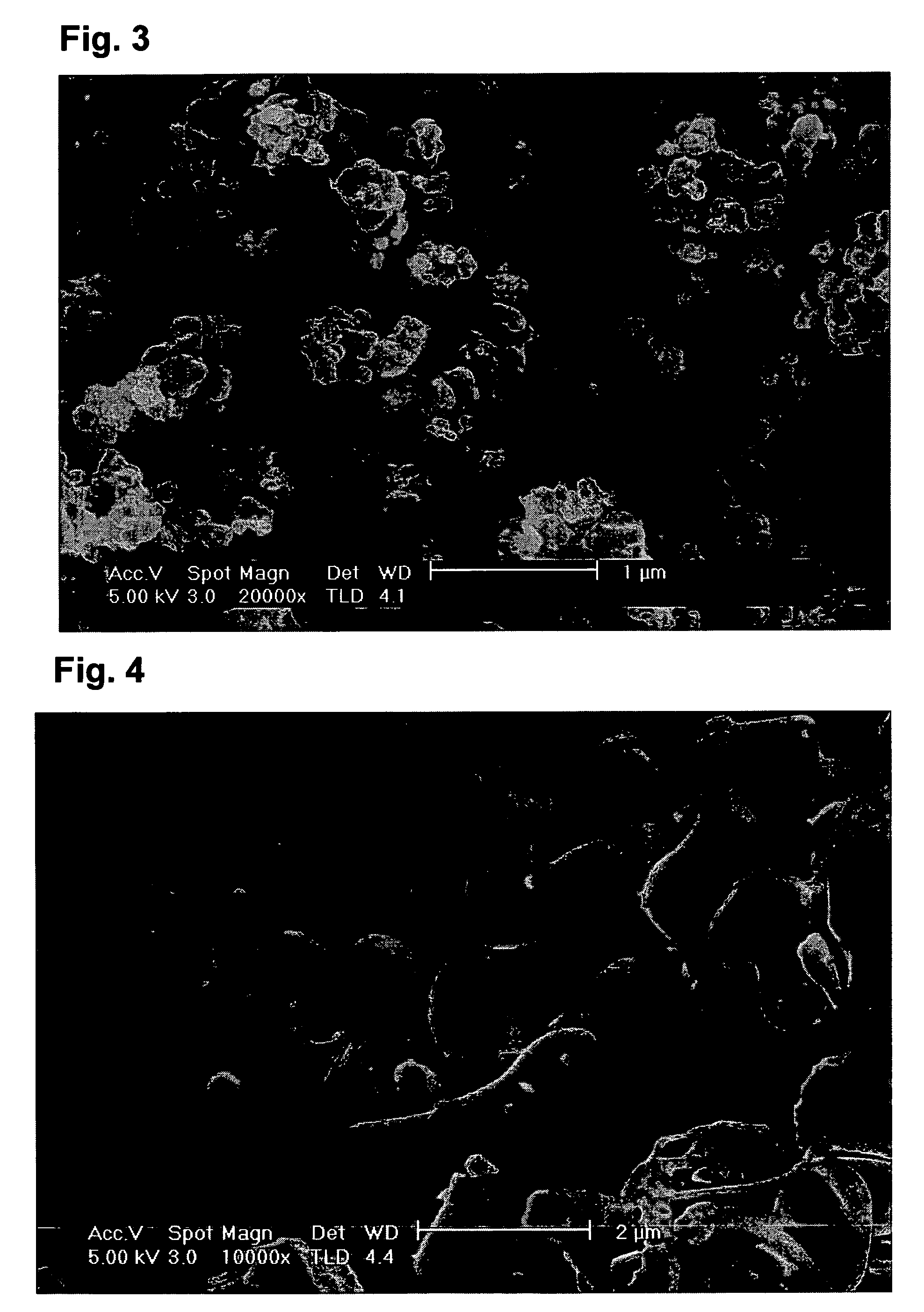

Niobium oxide and method for producing the same

InactiveUS20070031324A1Efficient productionTantalum compoundsVanadium oxidesReduction treatmentMetallurgy

An object of the present invention is to provide a niobium oxide that is suitable for application to capacitors, high in purity, large in specific surface area and small in particle size. The present invention also provides a method for producing such a high-purity niobium oxide. The present invention provides a niobium oxide that is a low oxidation number niobium oxide obtained from a high oxidation number niobium oxide, characterized in that the niobium oxide has a specific surface area (BET value) of 2.0 m2 / g to 50.0 m2 / g. The production method comprising dry reducing niobium pentoxide to produce niobium monoxide is characterized in that the reduction treatment is carried out stepwise in two steps. In the stepwise reduction, it is preferable that a carbon-containing reducing agent be used at least in any one of the two steps, and the temperature and the ambient pressure be maintained in a predetermined range in each of the steps.

Owner:MITSUI MINING & SMELTING CO LTD

Niobium powder for capacitor, sintered body thereof and capacitor using the sintered body

InactiveUS20030007313A1Fixed capacitor electrodesLiquid electrolytic capacitorsNiobiumNiobium monoxide

A nobium powder for capacitors, which contains from 0.05 to 20% by mass of niobium monoxide crystal and from 0.05 to 20% by mass of hexaniobium monoxide crystal; a sintered body thereof; and a capacitor fabricated from the sintered body as one part electrode, a dielectric material formed on the surface of the sintered body, and another part provided on the dielectric material. A capacitor manufactured from a sintered body of a niobium powder of the present invention is favored with good high-temperature characteristics.

Owner:SHOWA DENKO KK

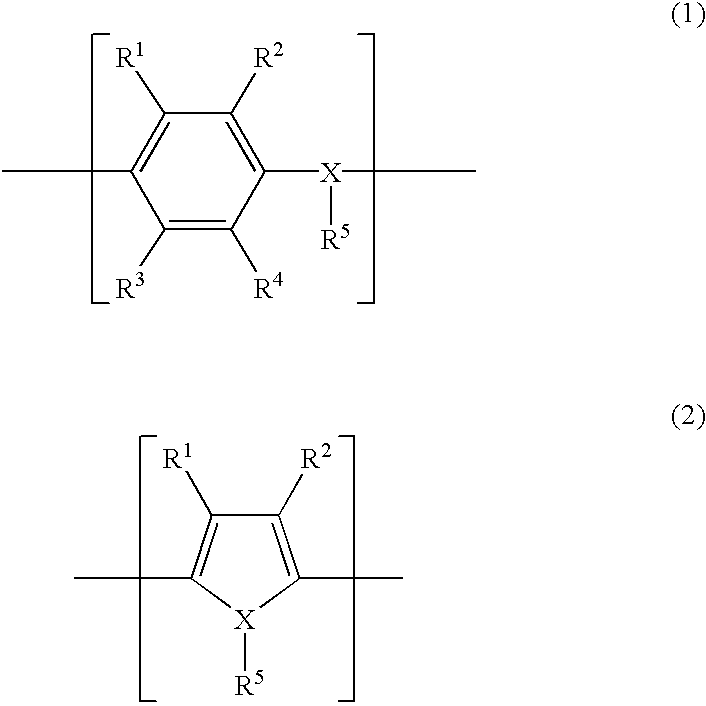

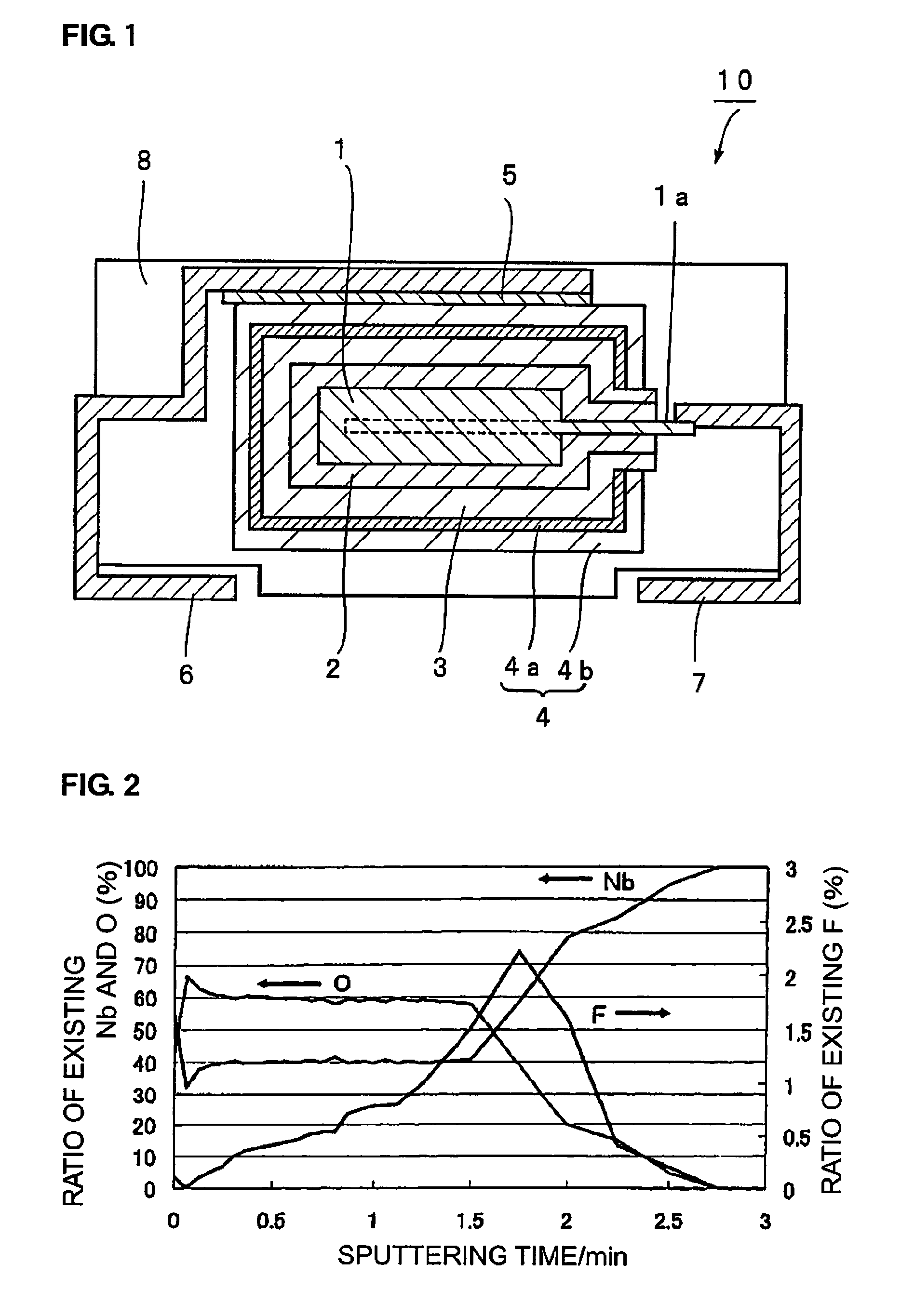

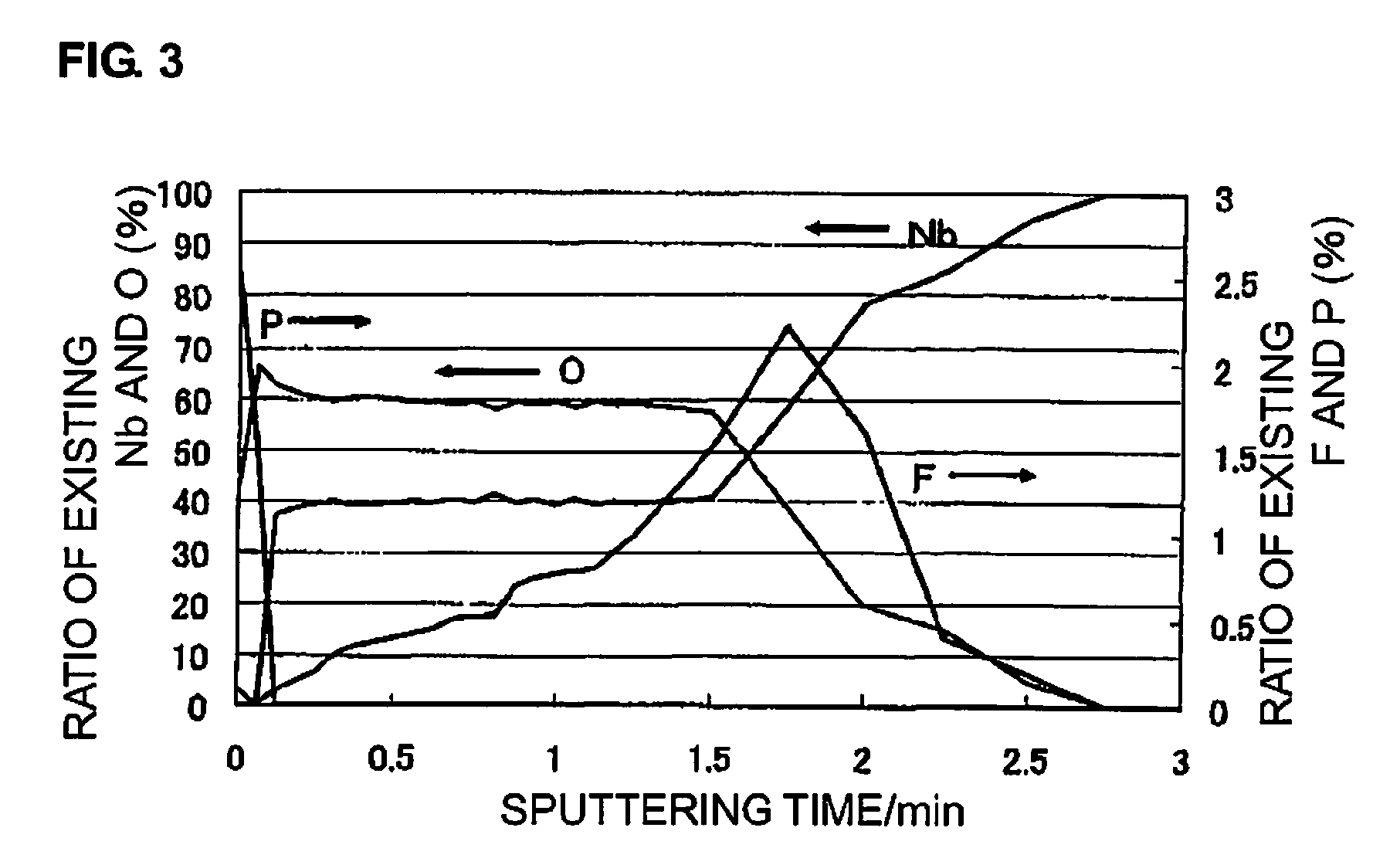

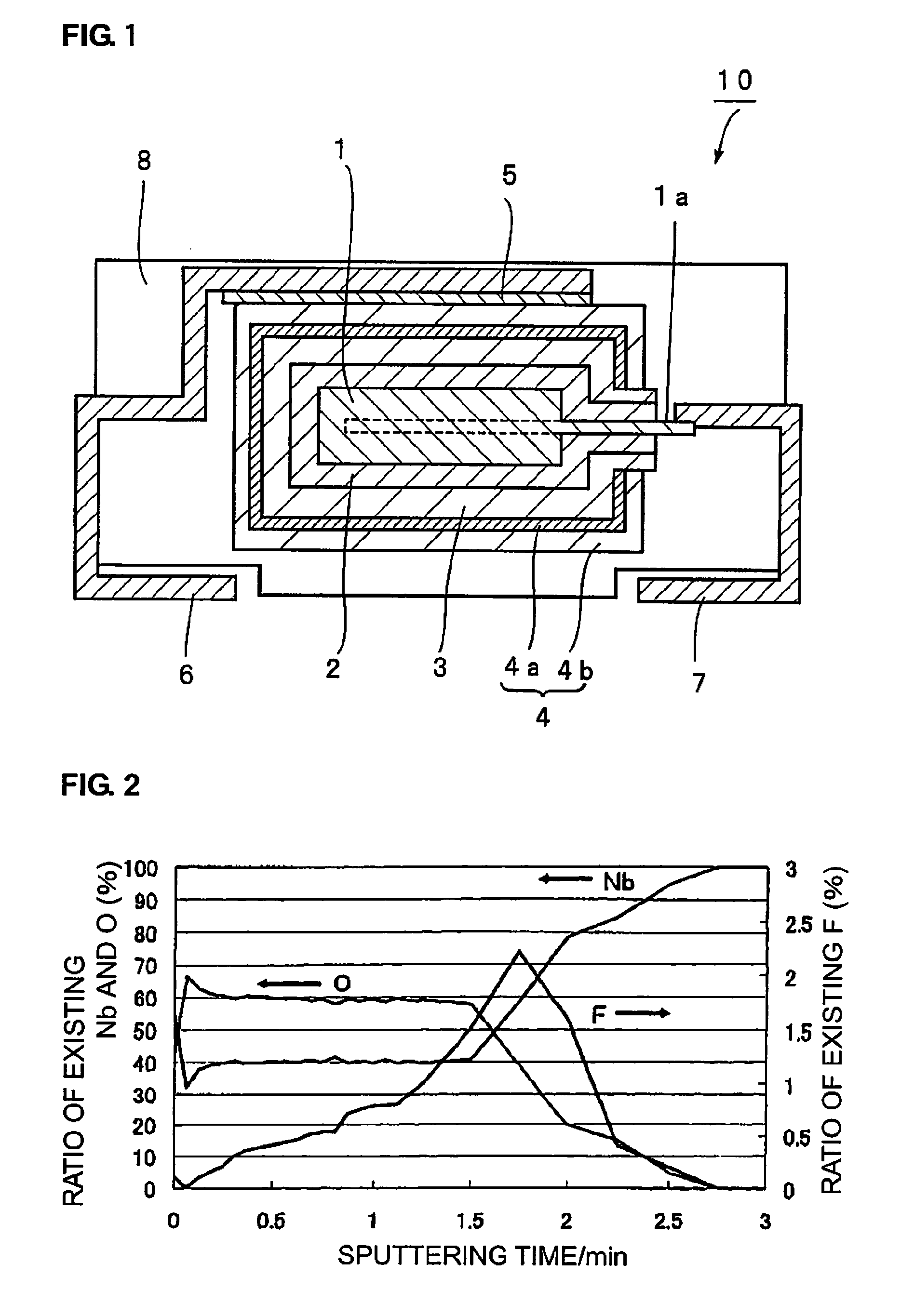

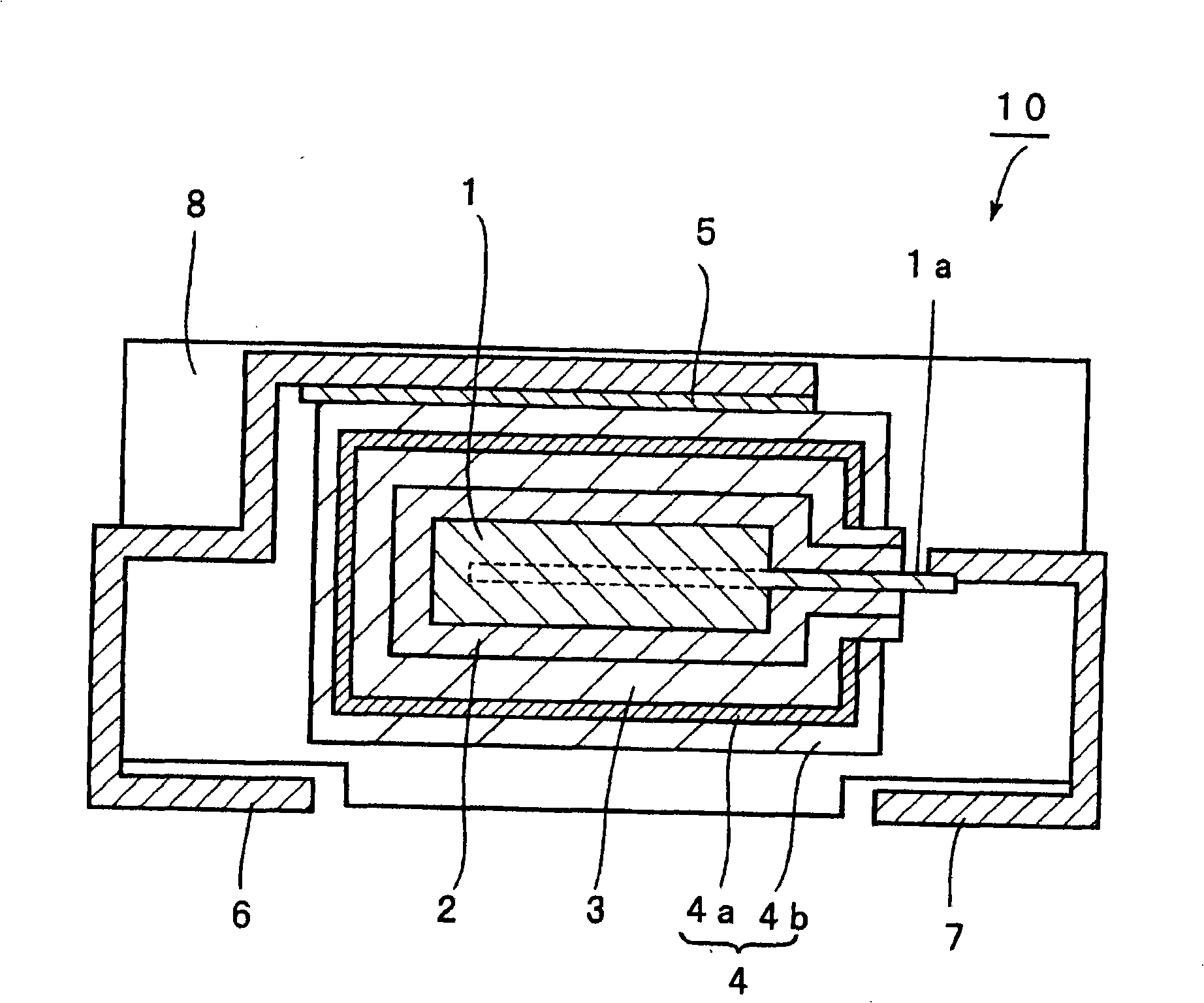

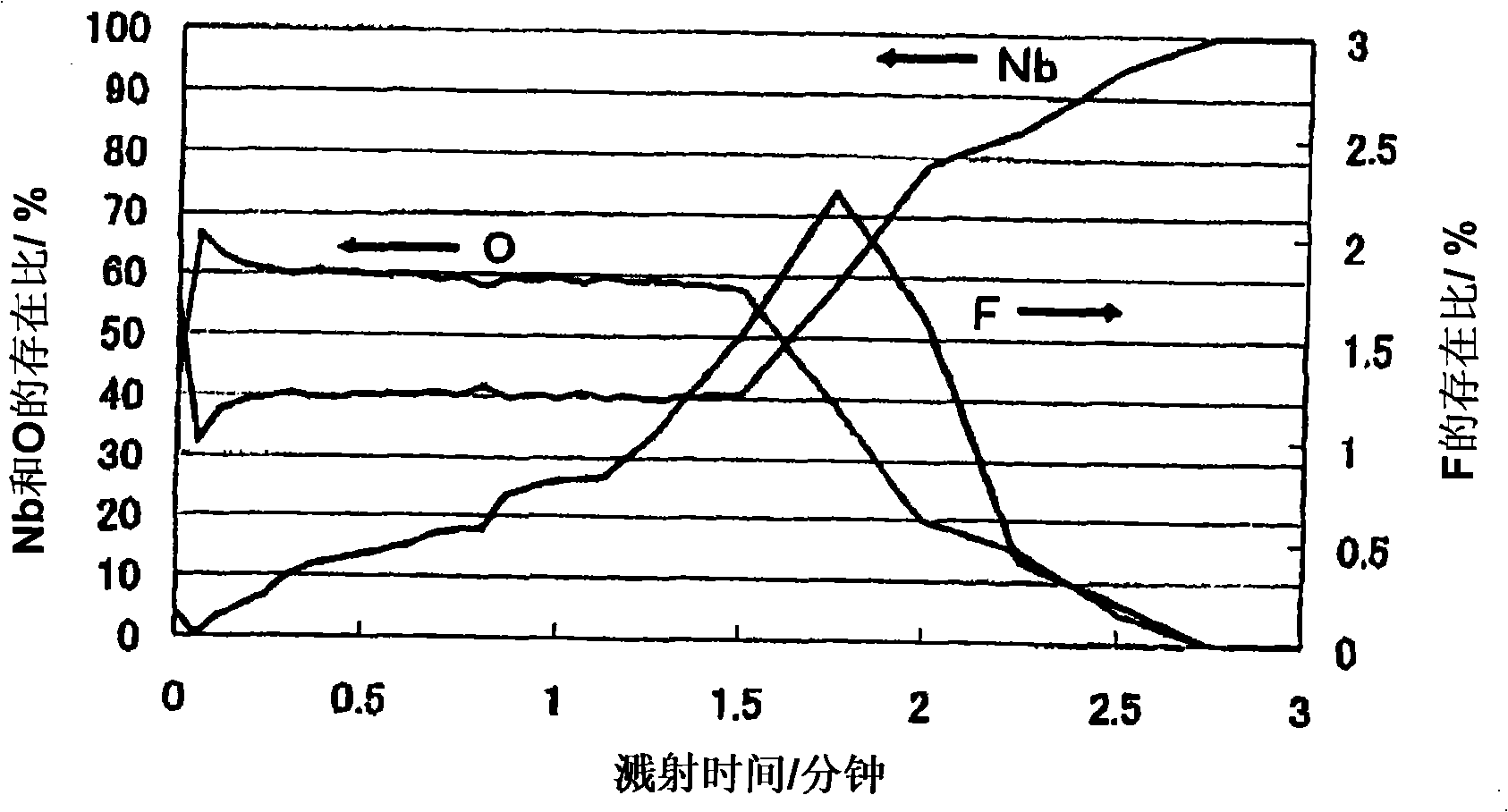

Niobium solid electrolytic capacitor and its production method

InactiveUS7876548B2Total current dropPreserving capacityLiquid electrolytic capacitorsFixed capacitor dielectricElectrolysisNiobium dioxide

Disclosed are a niobium solid electrolytic capacitor capable of reducing leak current that may occur in high heat treatment in a reflow process and capable of preserving the capacity before and after heat treatment, and a method for producing it. The niobium solid electrolytic capacitor comprises an anode containing an oxide of niobium monoxide or niobium dioxide and a metal of niobium or a niobium alloy, a dielectric layer formed on the surface of the anode, and a cathode formed on the dielectric layer, wherein the dielectric layer contains fluorine.

Owner:SANYO ELECTRIC CO LTD

Niobium solid electrolytic capacitor and its production method

InactiveUS20080259527A1Leakage currentHigh heat treatmentSolid electrolytic capacitorsLiquid electrolytic capacitorsElectrolysisNiobium dioxide

Disclosed are a niobium solid electrolytic capacitor capable of reducing leak current that may occur in high heat treatment in a reflow process and capable of preserving the capacity before and after heat treatment, and a method for producing it. The niobium solid electrolytic capacitor comprises an anode containing an oxide of niobium monoxide or niobium dioxide and a metal of niobium or a niobium alloy, a dielectric layer formed on the surface of the anode, and a cathode formed on the dielectric layer, wherein the dielectric layer contains fluorine.

Owner:SANYO ELECTRIC CO LTD

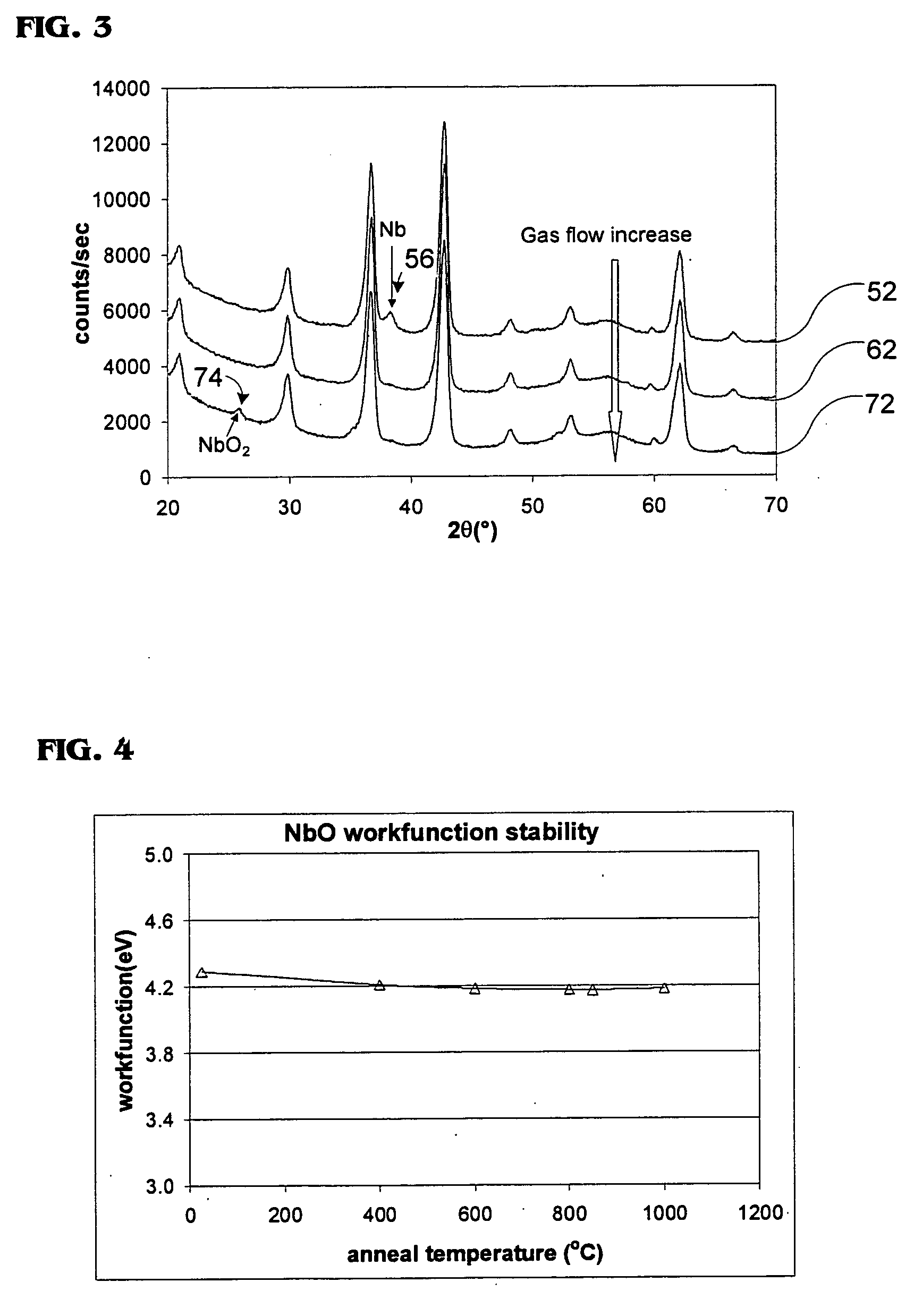

MOSFET structures with conductive niobium oxide gates

InactiveUS20050067664A1Semiconductor/solid-state device manufacturingSemiconductor devicesMOSFETGate dielectric

MOSFET gate structures are provided comprising a niobium monoxide gate, overlying a gate dielectric. The niobium monoxide gate may have a low work function suitable for use as an NMOS gate.

Owner:SHARP KK

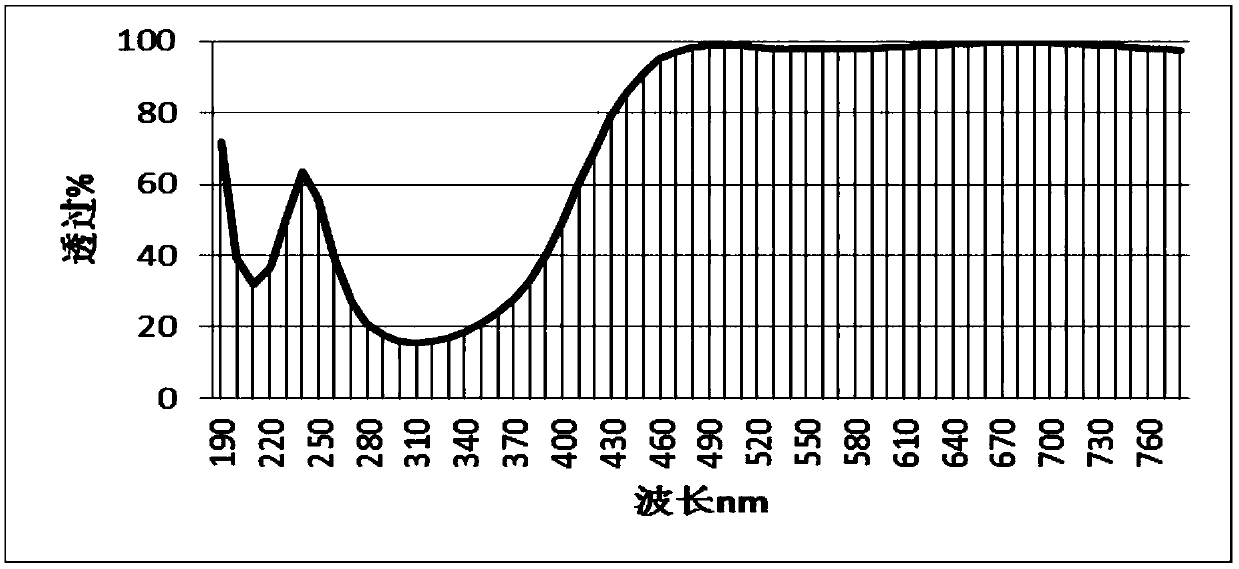

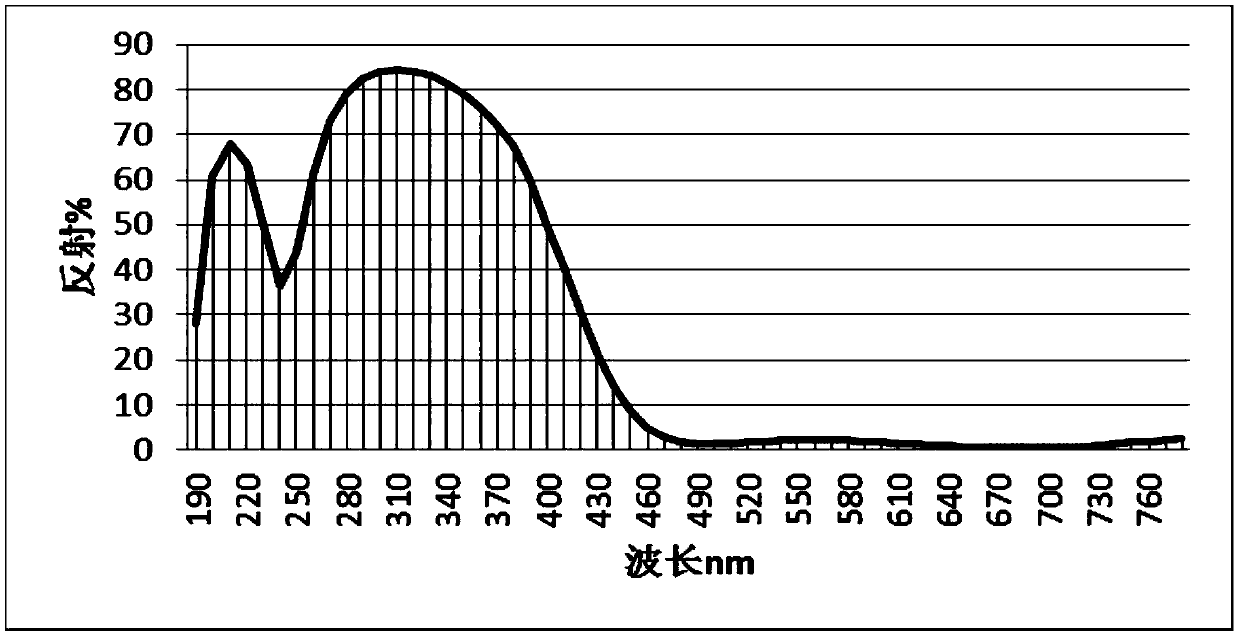

AR glass with ultraviolet-proof function, and production process thereof

The invention discloses AR glass with an ultraviolet-proof function. The AR glass comprises a glass substrate, wherein a first niobium oxide layer, a first silicon dioxide layer, a second niobium oxide layer, a second silicon dioxide layer and a first carbon nitride layer are sequentially plated on the front surface of the glass substrate from inside to outside, and a third niobium oxide layer, athird silicon dioxide layer, a fourth niobium oxide layer, a fourth silicon dioxide layer and a second carbon nitride layer are sequentially plated on the back surface of the glass substrate from inside to outside. According to the invention, Nb2O5, SiO2 and a carbon nitride material form a double-sided five-layer film system structure, and one-sided film coating is completed at one time by usingcontinuous film coating line, so that an AR glass structure with low film thickness and low material cost is obtained; and compared with the prior art, the AR glass of the invention has the characteristics of high hardness, scratch resistance, ultraviolet resistance, permeability increase, antireflection performance and the like.

Owner:SHENZHEN SANXIN JMT GLASS

Sheet type niobium oxide solid electrolyte capacitor and its manufacturing method

ActiveCN101404212BSimple structureSimple preparation processSolid electrolytic capacitorsCapacitor terminalsEpoxyElectrolysis

The invention discloses a slice-typed niobium oxide solid electrolytic capacitor and a preparation method thereof; the capacitor comprises an epoxy resin encapsulation shell which is internally provided with a niobium monoxide capacitor substrate, a nickel-based tinning cathode eduction slice and a nickel-based tinning anode eduction slice; the niobium monoxide capacitor substrate is internally provided with an anode and the surface thereof is a cathode; the anode is internally provided with a Ta-wire eduction wire; the cathode of the niobium monoxide capacitor substrate is electrically connected with the nickel-based tinning cathode eduction slice; the Ta-wire anode eduction wire in the niobium monoxide capacitor substrate is welded on the nickel-based tinning anode eduction slice to form electric connection. The niobium oxide solid electrolytic capacitor has simple structure and convenient manufacture process; the prepared niobium oxide capacitor can be applied to various circuits such as switch power circuit for large surge voltage and current and the like; when accidental breakdown occurs, combustion or explosion does not occur; furthermore, continuous breakdown can be effectively avoided; compared with the Ta capacitor or pure Nb capacitor, the niobium oxide solid electrolytic capacitor is greatly improved on the reliability and safety.

Owner:BEIJING 718 YOUYI ELECTRONICS

Niobium solid electrolytic capacitor and its production method

InactiveCN101290834AInhibited DiffusionSuppression of defectsSolid electrolytic capacitorsCapacitor electrolytes/absorbentsCapacitanceElectrolysis

Disclosed are a niobium solid electrolytic capacitor capable of reducing leak current that may occur in high heat treatment in a reflow process and capable of preserving the capacity before and after heat treatment, and a method for producing it. The niobium solid electrolytic capacitor comprises an anode containing an oxide of niobium monoxide or niobium dioxide and a metal of niobium or a niobium alloy, a dielectric layer formed on the surface of the anode, and a cathode formed on the dielectric layer, wherein the dielectric layer contains fluorine.

Owner:SANYO ELECTRIC CO LTD

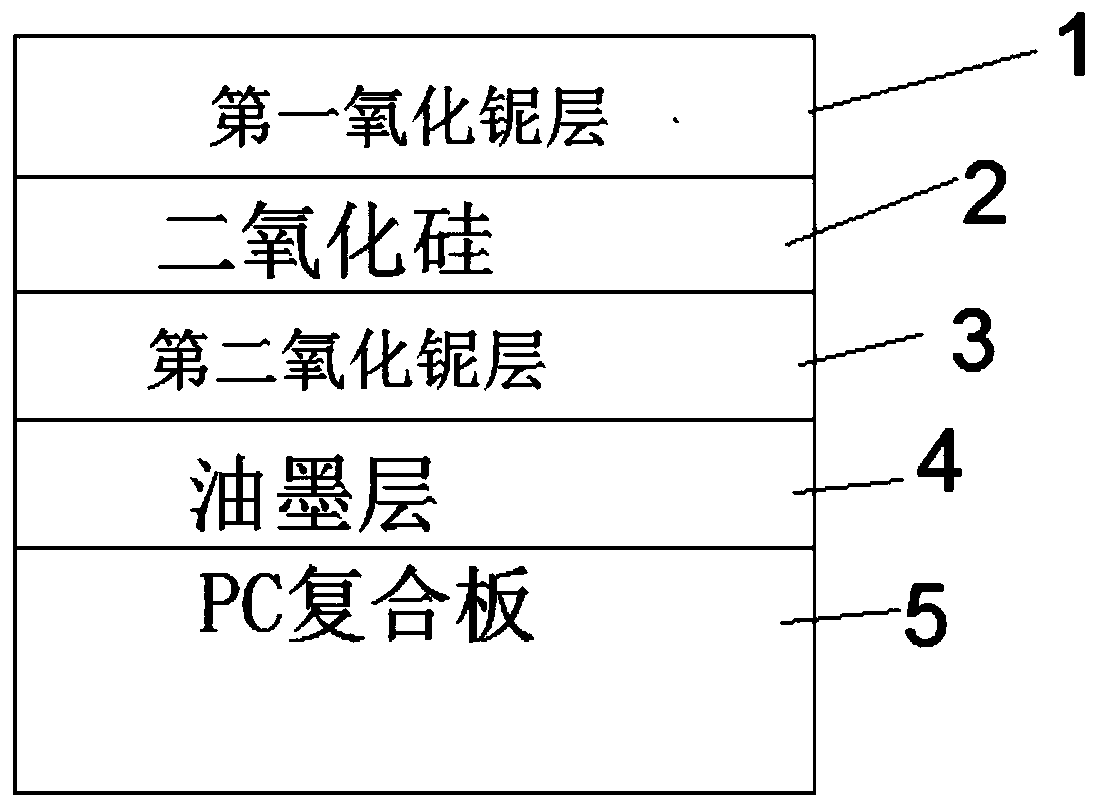

Coated PC composite board and manufacturing process thereof

PendingCN111020476AImprove adhesionVacuum evaporation coatingSputtering coatingSilicon oxideComposite plate

The invention relates to a coated PC composite board and a manufacturing process thereof. The PC composite board sequentially comprises a first niobium oxide layer, a silicon dioxide layer, a second niobium oxide layer, an ink layer and a PC composite board body from top to bottom. The process comprises the following steps: mounting a niobium oxide target material and a silicon dioxide target material in a coated box body, closing the box body, continuously vacuumizing to remove water vapor and miscellaneous gas in the box body, when the local vacuum degree reaches 5*10<-4> pa, feeding oxygenand argon with the purity of 99.99% to working pressure of 0.3-0.8 Pa, turning on an ion source, turning on a target material power supply, starting coating, carrying out magnetron sputtering in the vacuum box body, bombarding the surface of the target material by Ar, and sequentially plating 58+ / -8nm niobium oxide, 25+ / -5nm silicon dioxide and 38+ / -8nm niobium oxide on the PC composite board which is treated by the ion source and is printed with the ink. According to the invention, the composite film layer is plated on the PC composite board coated with the ink, so that the adhesive force ofthe film layer is optimized.

Owner:安徽立光电子材料股份有限公司

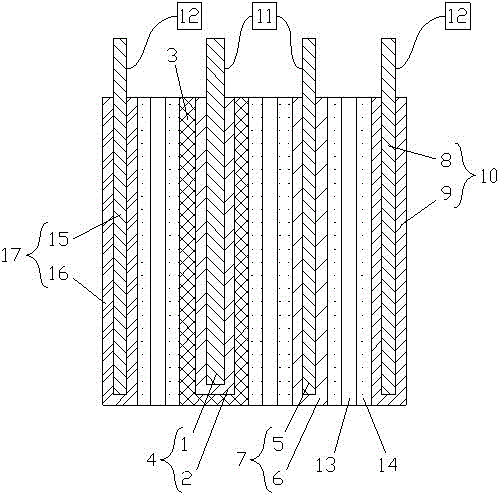

Hybrid capacitor and manufacturing method thereof

InactiveCN104599848ALarge capacityLower equivalent series resistanceHybrid capacitor electrodesCapacitor collector combinationsElectrolysisSupercapacitor

The invention relates to a hybrid capacitor composed of a positive electrode, a negative electrode, a membrane, and an electrolyte. The positive electrode is connected with a super capacitor positive plate and an electrolytic capacitor positive plate. The super capacitor positive plate is composed of a positive current collector and a positive active layer covering the surface of the positive current collector and containing positive active materials. The electrolytic capacitor positive plate is composed of valve metal or niobium monoxide and an oxide of valve metal or an oxide of niobium monoxide covering the surface of valve metal or niobium monoxide. The super capacitor positive plate is not in direct contact with the oxide of valve metal or the oxide of niobium monoxide of the electrolytic capacitor positive plate. The negative electrode is at least connected with a super capacitor negative plate which is composed of a negative current collector and a negative active layer covering the surface of the negative current collector and containing negative active materials. The hybrid capacitor of the invention has the advantages of large capacity, low equivalent series resistance, and excellent frequency characteristics.

Owner:张彩欣

Niobium powder for capacitor, sintered body thereof and capacitor using the sintered body

InactiveUS20050257642A1Fixed capacitor electrodesCapacitor electrolytes/absorbentsNiobiumNiobium monoxide

A niobium powder for capacitors, which contains niobium monoxide crystal or hexaniobium monoxide crystal; a sintered body thereof; and a capacitor fabricated from the sintered body as one part electrode, a dielectric material formed on the surface of the sintered body, and another part electrode provided on the dielectric material.

Owner:RESONAC HOLDINGS CORPORATION

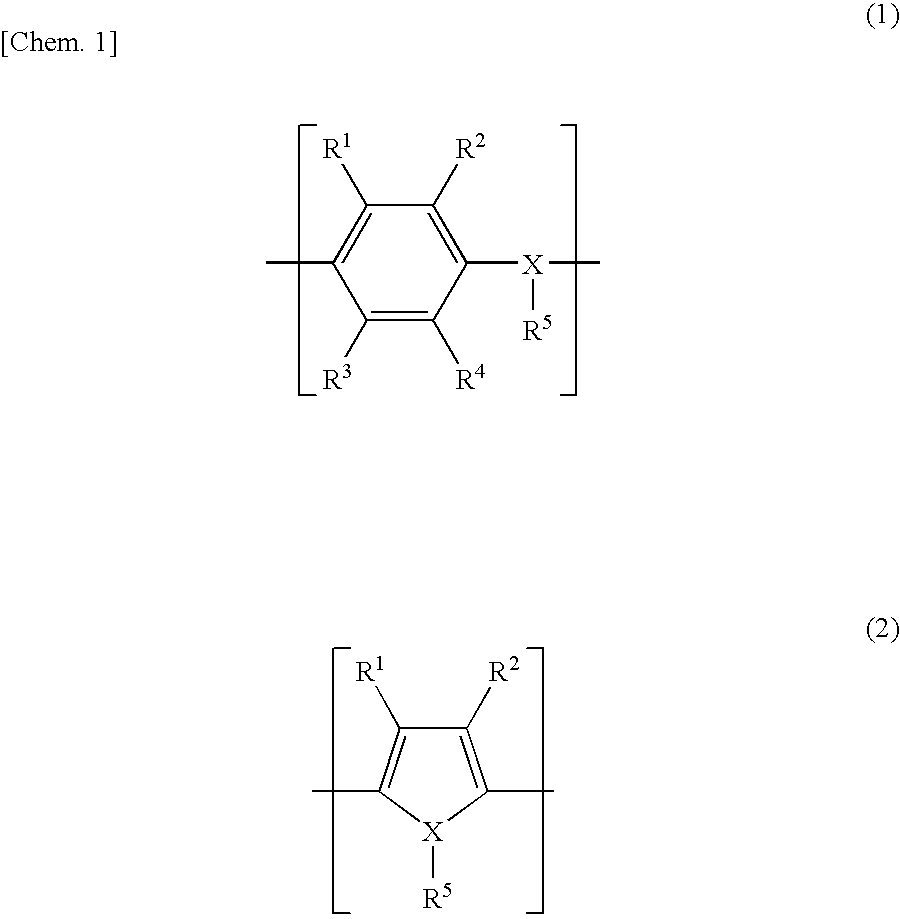

Free-standing, binder-free metal monoxide/suboxide nanofiber as cathodes or anodes for batteries

ActiveUS10886525B2Electrode thermal treatmentNegative electrodesMetal oxide nanoparticlesManganese oxide

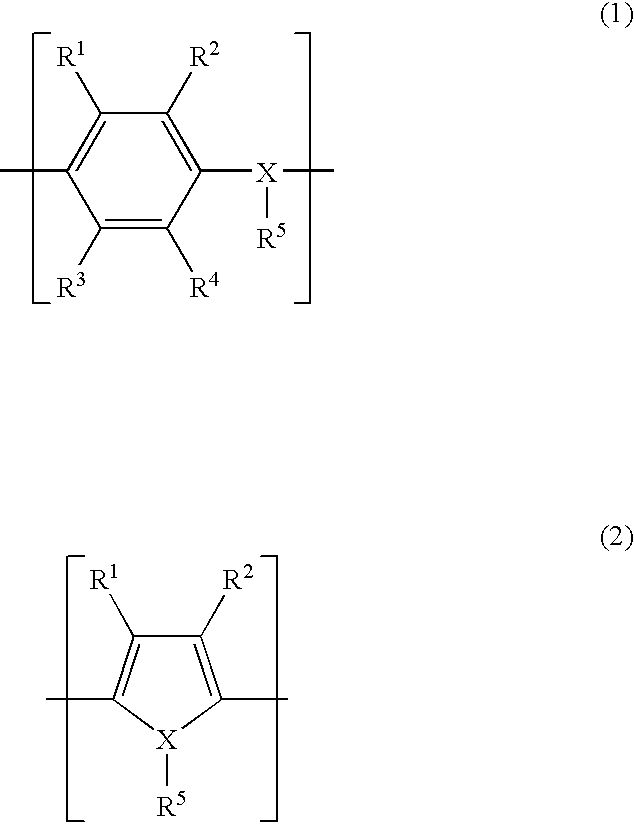

A nanofiber mat comprises metal oxide nanoparticles distributed on surface of metal oxide nanofibers, wherein the nanofiber mat has a surface area at least 150 m2 / g, and the metal oxide is selected from titanium monoxide TiOx, wherein 0.65<x<1.25, niobium monoxide NbOx, wherein 0.982<x<1.008, vanadium (II) oxide VOx, wherein 0.79<x<1.29, iron (II) oxide FexO, wherein 0.833<x<0.957, manganese (II) oxide MnxO, wherein 0.848<x<1.000, titanium suboxide, TinO2n-1, wherein n>1, molybdenum suboxide, MonO3n-1, wherein n>1, MonO3n-2, wherein n>1, and vanadium suboxide, VnO2n-1, wherein n>1. Cathodes, anodes and batteries are made using the nanofiber mat. Processes for producing the metal oxide nanofiber mat and an electrode including it are also provided.

Owner:DREXEL UNIV

Free-standing, binder-free metal monoxide/suboxide nanofiber as cathodes or anodes for batteries

ActiveUS20210111390A1Electrode thermal treatmentNegative electrodesMetal oxide nanoparticlesManganese

A nanofiber mat comprises metal oxide nanoparticles distributed on surface of metal oxide nanofibers, wherein the nanofiber mat has a surface area at least 150 m2 / g, and the metal oxide is selected from titanium monoxide TiOx, wherein 0.65<x<1.25, niobium monoxide NbOx, wherein 0.982<x<1.008, vanadium (II) oxide VOx, wherein 0.79 <x <1.29, iron (II) oxide FexO, wherein 0.833<x<0.957, manganese (II) oxide MnxO, wherein 0.848<x<1.000, titanium suboxide, TiOnO2n-1, wherein n>1, molybdenum suboxide, MonO3n-1, wherein n>1, MonO3n-2, wherein n>1, and vanadium suboxide, VnO2n-1, wherein n>1. Cathodes, anodes and batteries are made using the nanofiber mat. Processes for producing the metal oxide nanofiber mat and an electrode including it are also provided.

Owner:DREXEL UNIV

Solid electrolyte tantalum-niobium composite capacitor and preparation method thereof

ActiveCN101859649BTake advantage of stabilityReduce leakage currentSolid electrolytic capacitorsElectrochemistryNiobium monoxide

The invention discloses a solid electrolyte tantalum-niobium composite capacitor and a preparation method thereof. The tantalum-niobium composite capacitor is prepared by mixing tantalum and niobium. The preparation method comprises the following steps: firstly, uniformly mixing tantalum power and niobium power or the tantalum power and pure columbium monoxide according to certain ratio, wherein the content of tantalum is 5-95 percent and the balance of niobium; pressing the mixture to form to obtain an anode block of compound metal; vacuum sintering to obtain an anode of the composite capacitor; electrochemically oxidizing the anode to form a medium film compounded by tantalum oxide and niobium oxide and using the medium film as the anode of the tantalum-niobium composite capacitor; and preparing the anode from solid manganese dioxide. The appearance of a product is similar to the appearance of the platy solid electrolyte tantalum-niobium composite capacitor. The preparation method comprises the working procedures of mixing, forming, sintering, energizing and enveloping the tantalum power and the niobium power or the columbium monoxide.

Owner:ZHUZHOU HONGDA ELECTRONICS

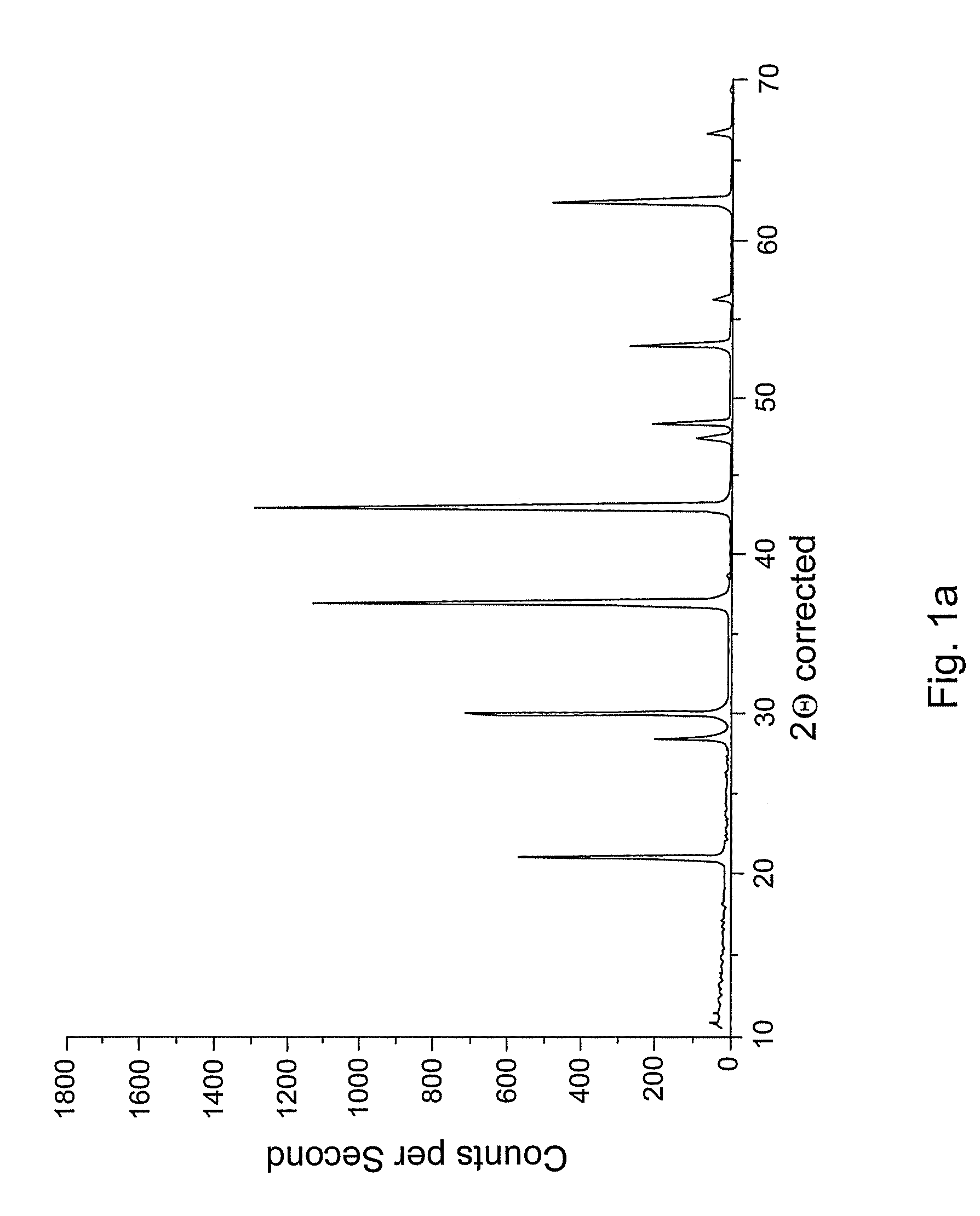

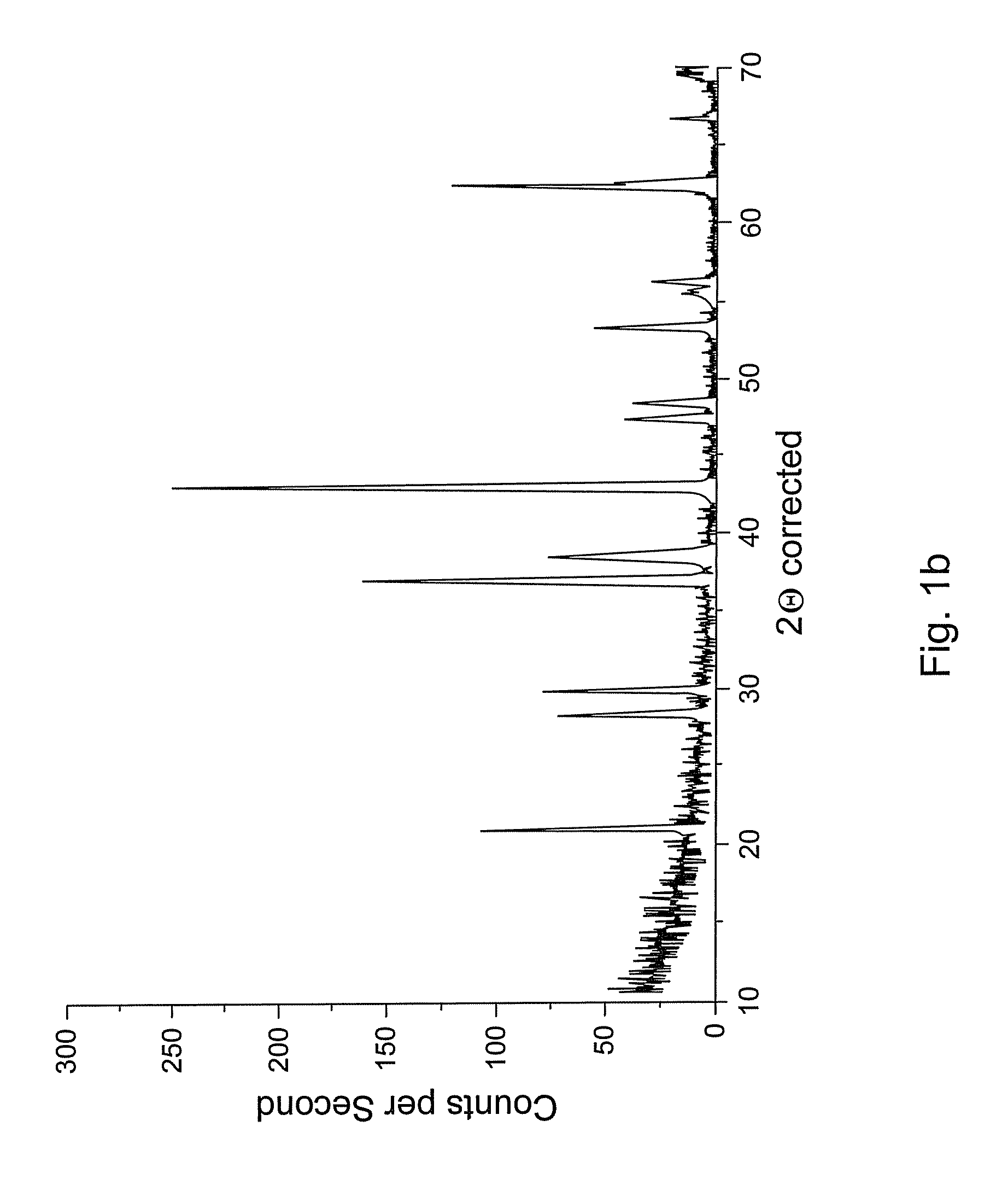

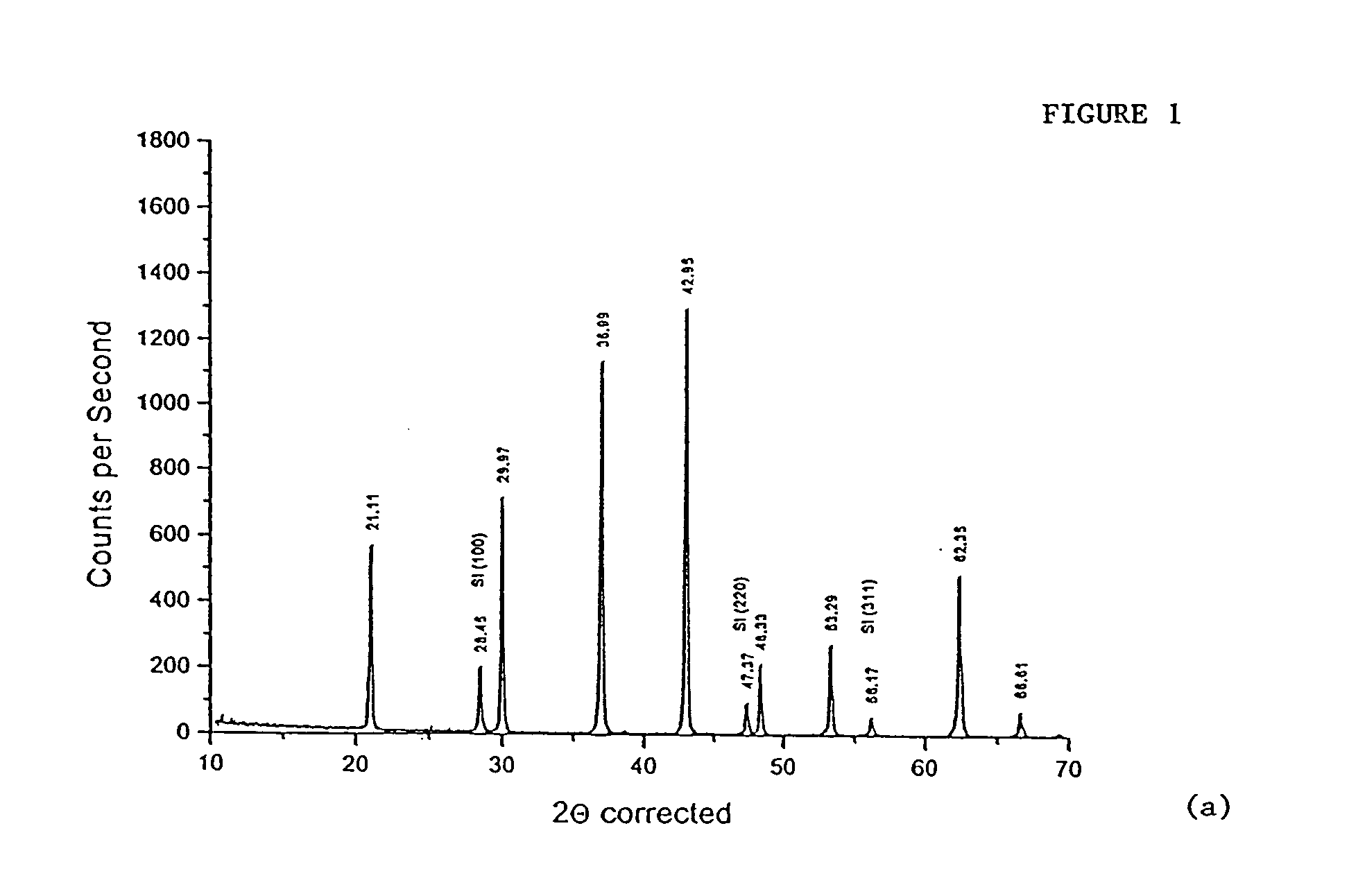

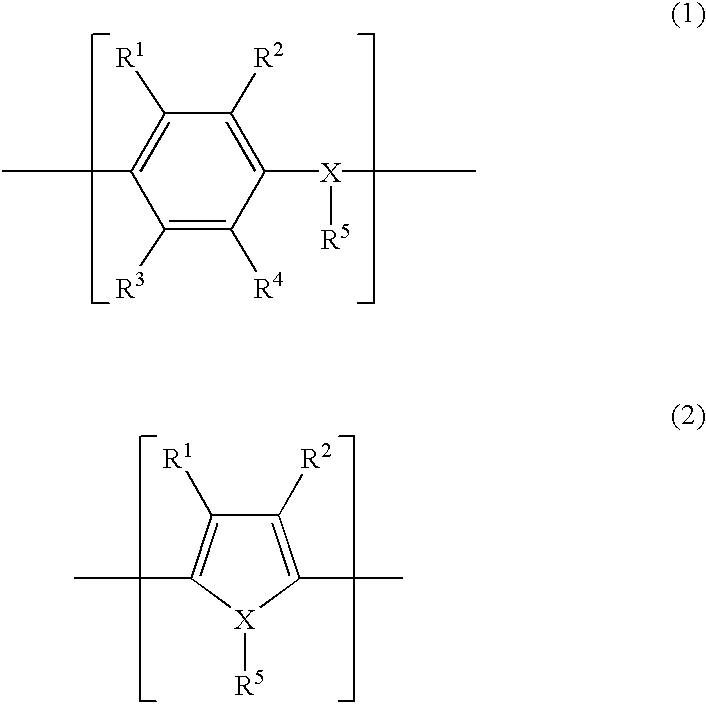

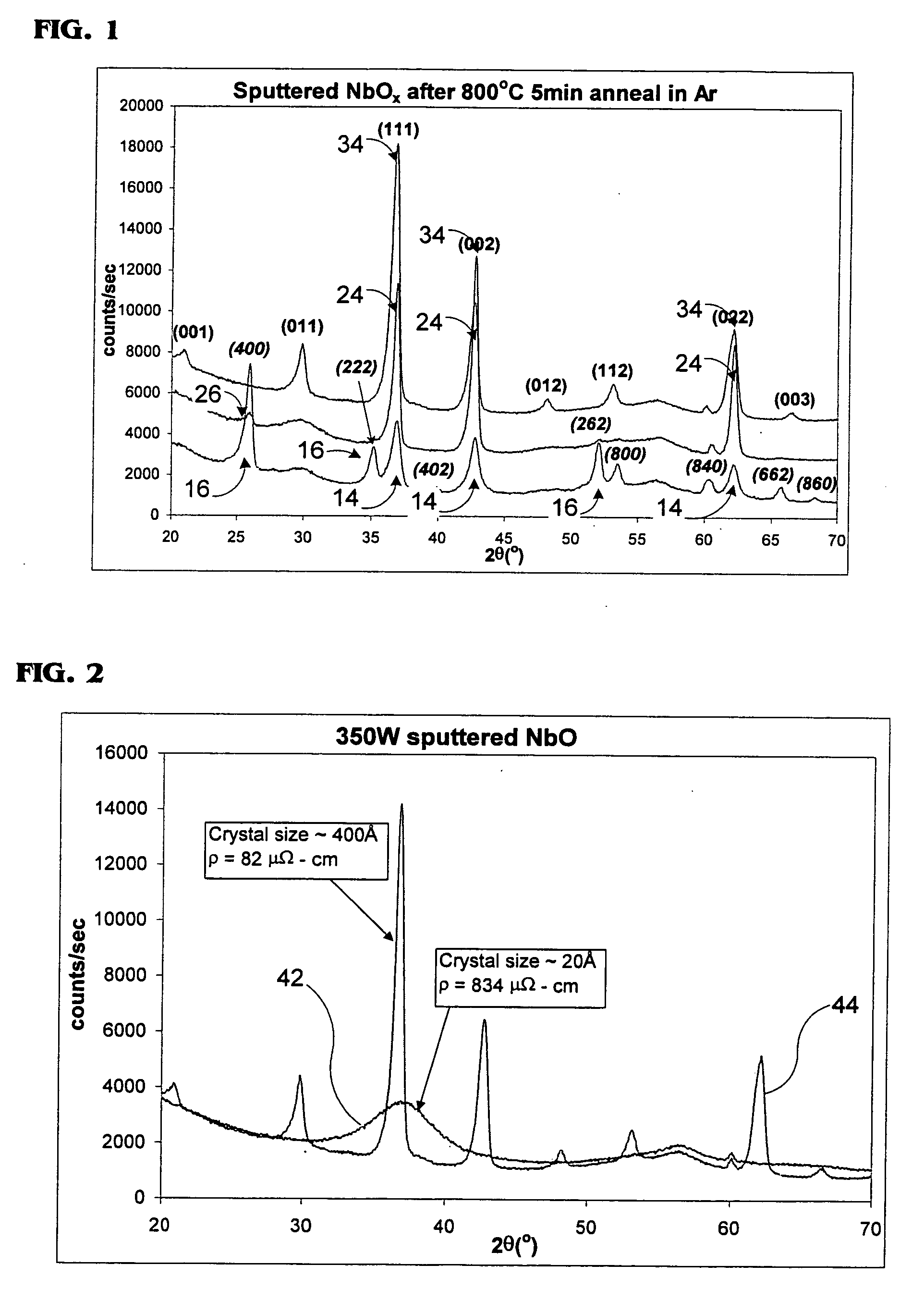

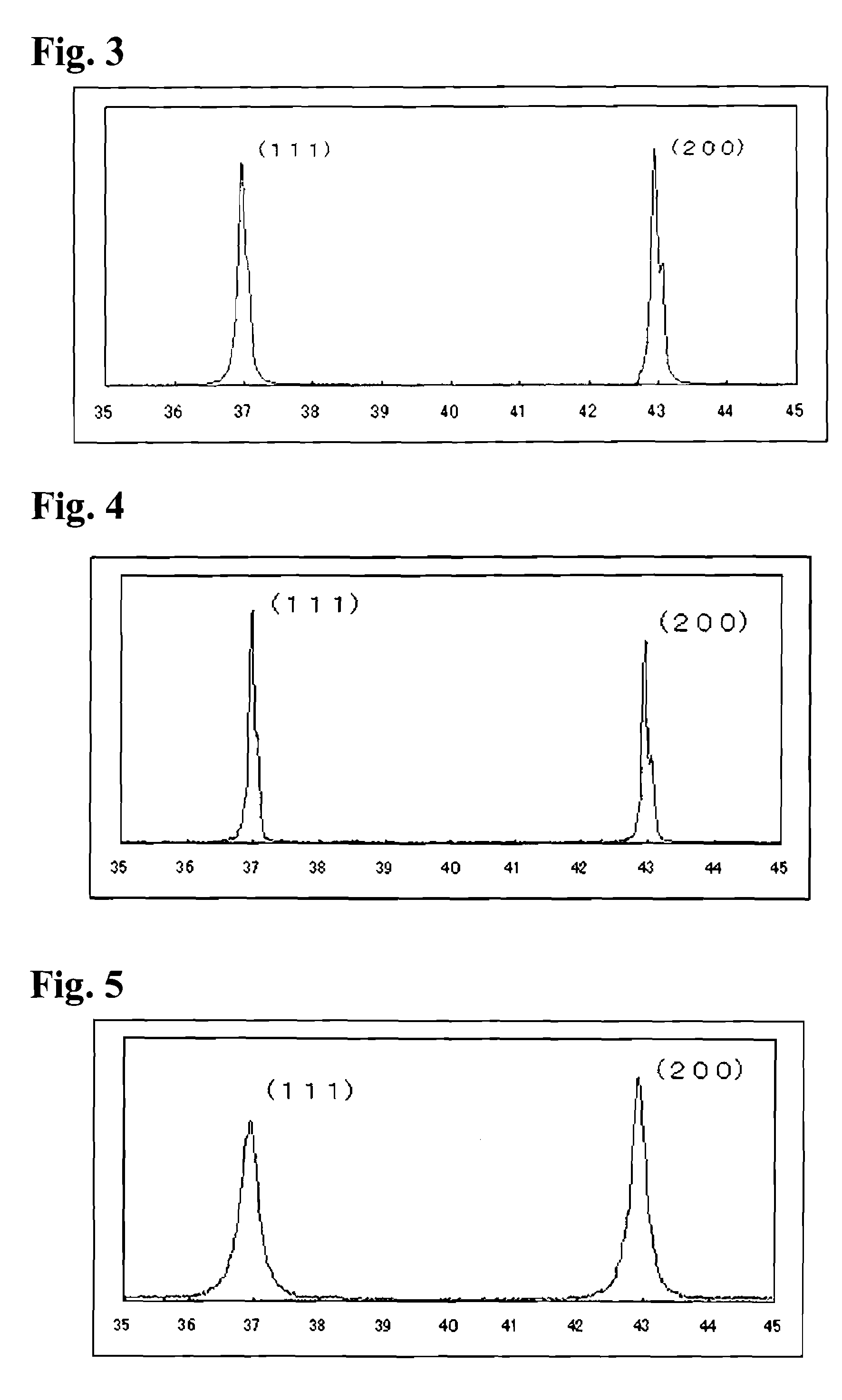

Niobium monoxide

InactiveUS7988945B2Improve performanceElectrolytic capacitorsTantalum compoundsCrystallographyCapacitance

An object of the present invention is to provide a niobium monoxide able to realize large capacitance in a miniature sized capacitor. The invention relates to a niobium monoxide having a porous structure comprising particles, characterized in that the niobium monoxide has a full-width at half maximum of an X-ray diffraction peak corresponding to a (111) plane or an X-ray diffraction peak corresponding to a (200) plane of 0.21° to 1.0°. The niobium monoxide has a large specific surface area and porosity, and is especially suitable for use in a capacitor.

Owner:MITSUI MINING & SMELTING CO LTD

Low-resistivity niobium pentoxide hot-pressed target material and preparation method thereof

InactiveCN111606708ALow resistivityImprove conductivityVacuum evaporation coatingSputtering coatingElectrical conductorHigh density

The invention provides a low-resistivity niobium pentoxide hot-pressed target material and a preparation method thereof, and belongs to the technical field of coating materials. Vacuum presintering iscarried out on a mixture of niobium pentoxide powder and niobium powder, part of niobium pentoxide reacts with niobium to generate niobium monoxide and niobium dioxide, meanwhile, niobium pentoxide generates niobium dioxide in a vacuum oxygen loss state, niobium oxide containing niobium monoxide is obtained, and then hot-pressed sintering is carried out to obtain the niobium pentoxide hot-pressedtarget material with high density. The niobium pentoxide hot-pressed target material contains a niobium monoxide conductor and a niobium dioxide semiconductor, so that the resistivity of the target material is effectively reduced, and the conductivity is improved.

Owner:FUJIAN ACETRON NEW MATERIALS CO LTD

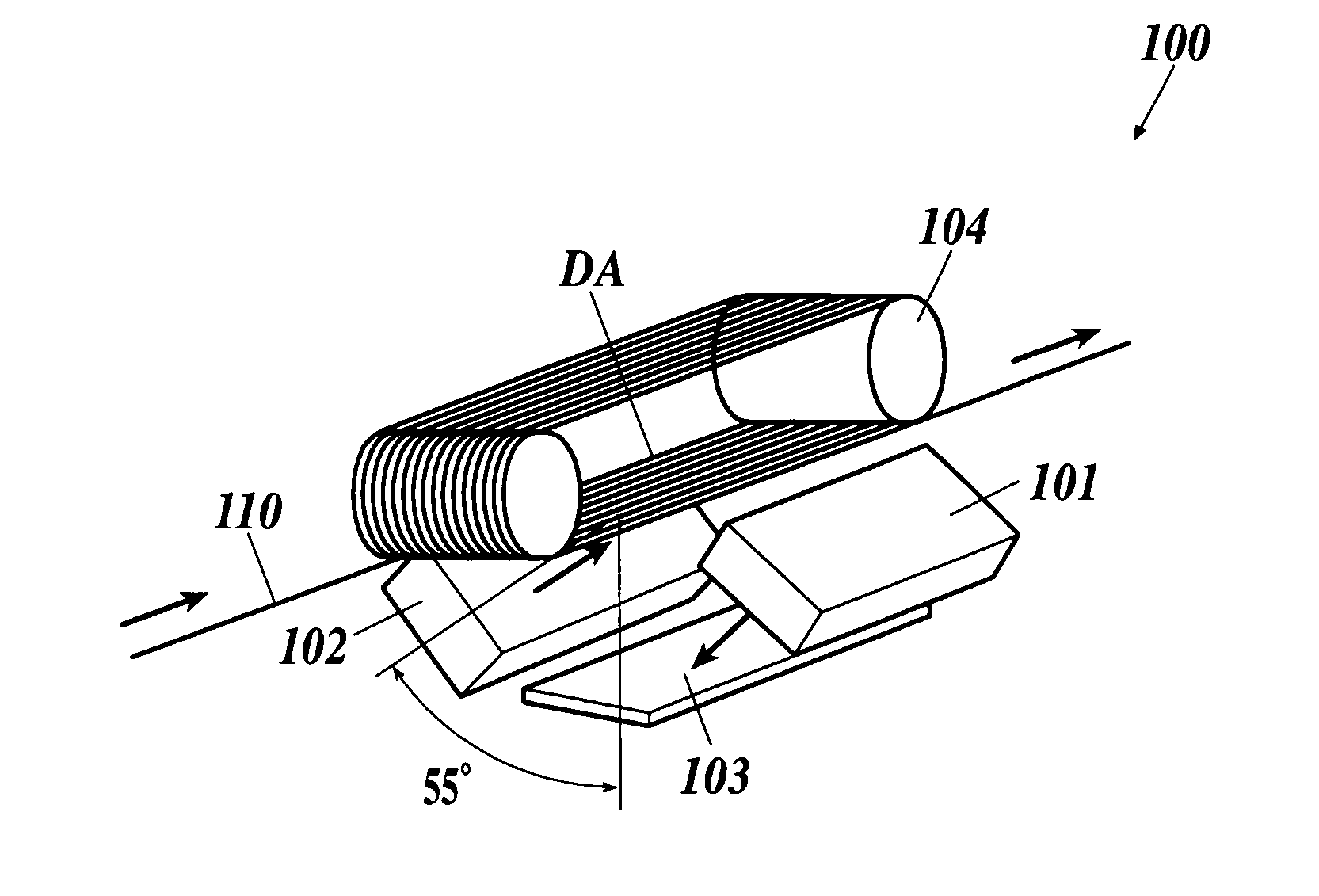

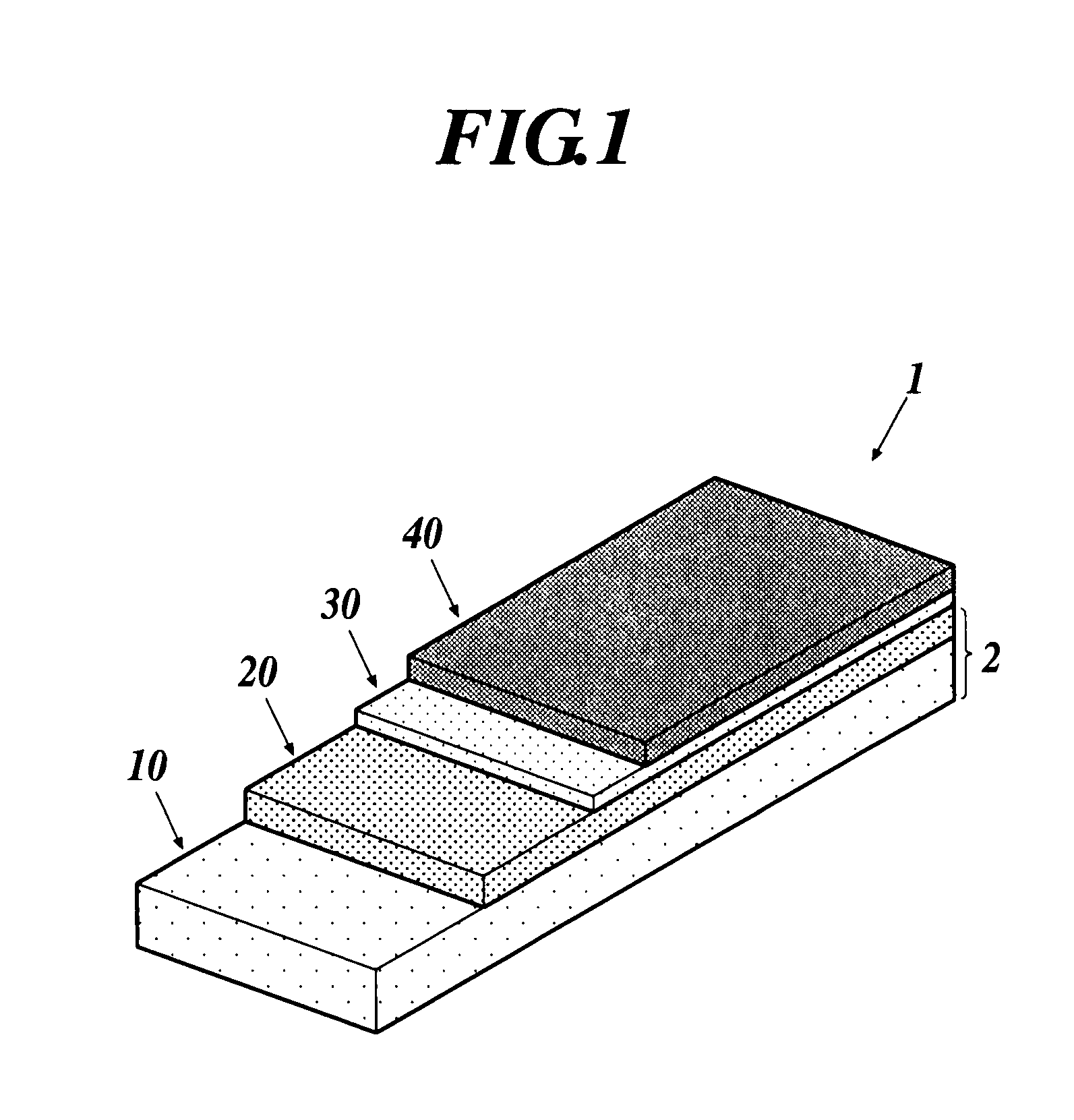

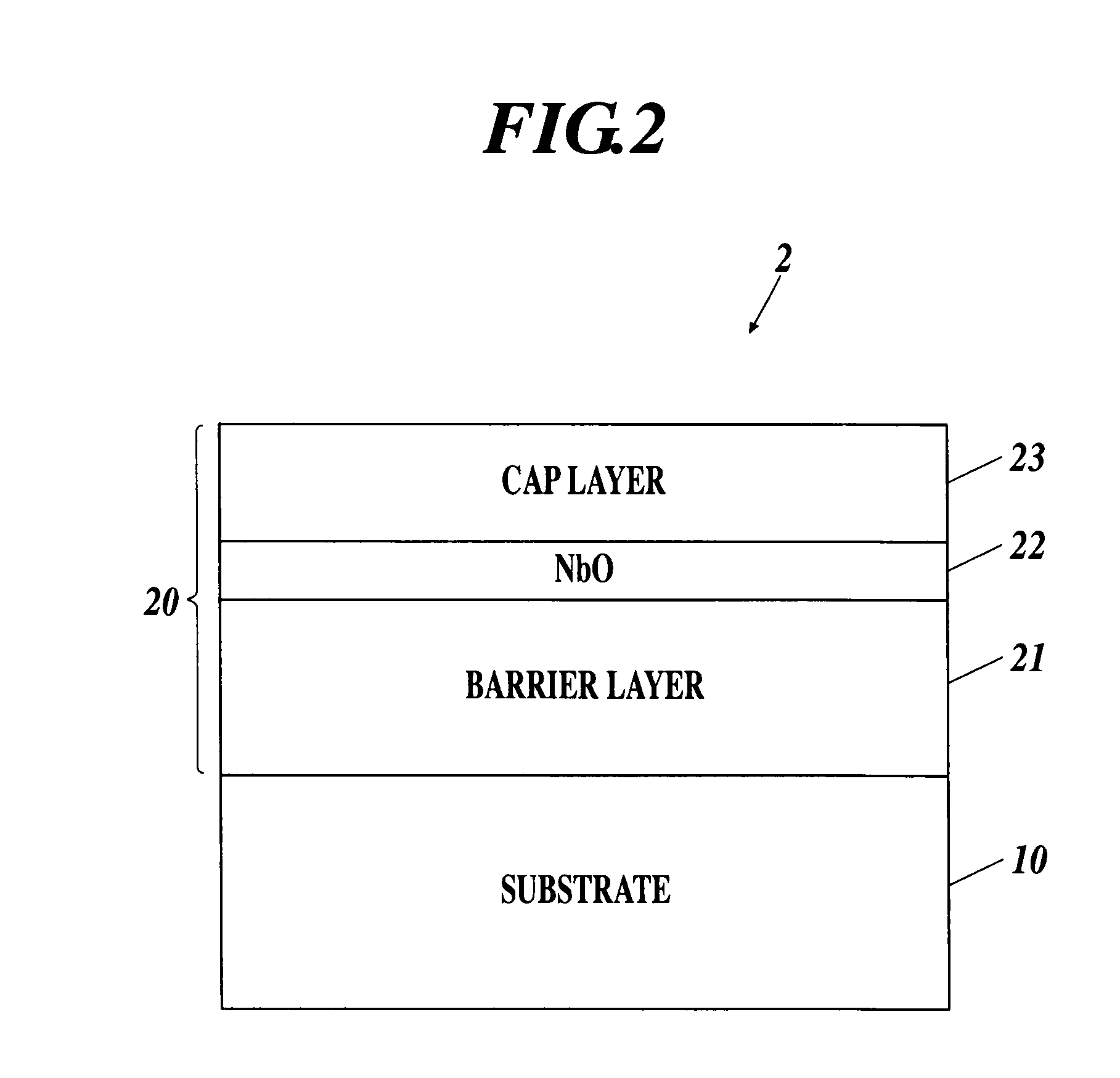

Tape base for superconducting wire, and superconducting wire

ActiveUS20120165199A1Corrosion resistanceHigh strengthVacuum evaporation coatingSputtering coatingWire rodNiobium monoxide

A tape-shaped base for a superconducting wire, which simplifies the intermediate layer and thus enables production of a superconducting wire at lower cost, and which is capable of improving the characteristics (such as electrical conduction and handling properties) of a superconducting wire; and a superconducting wire. Specifically disclosed is a tape-shaped base for a superconducting wire, which is obtained by forming an intermediate layer on a metal substrate. In the tape-shaped base for a superconducting wire a biaxially oriented layer of the intermediate layer is configured of a niobium monoxide (NbO) layer that is formed by depositing vapor deposition particles from a vapor deposition source on a film formation surface.

Owner:FURUKAWA ELECTRIC CO LTD

A method for preparing niobium monoxide and niobium powder mixture by plasma decomposition

Te invention discloses a method for preparing a niobium monoxide and niobium powder mixture through plasma decomposition. According to the method for preparing the niobium monoxide and niobium powder mixture through plasma decomposition, niobium pentoxide is used as a raw material, high-temperature plasma decomposition is conducted on the niobium pentoxide, and then the niobium monoxide and niobium powder mixture is prepared. The method for preparing the niobium monoxide and niobium powder mixture through plasma decomposition comprise the specific steps that the niobium pentoxide is poured into a plasma gun, the decomposition action is conducted through the high temperature of a plasma flame, and then the niobium monoxide and niobium powder mixture is obtained, wherein the power is controlled to be in the range of 10-100 kw; and the niobium monoxide and niobium powder mixture obtained through decomposition falls into a cooling device. The method for preparing the niobium monoxide and niobium powder mixture through plasma decomposition achieves simple and rapid reparation of the niobium monoxide and niobium powder mixture and is low in energy consumption and free of pollution. Besides, the particle shape of the obtained niobium monoxide and niobium powder mixture is sphere, the sphere particle shape is an ideal particle shape for manufacturing of a capacitor, and the niobium monoxide and niobium powder mixture is low in cost and good in quality. The method for preparing the niobium monoxide and niobium powder mixture through plasma decomposition has important significance in the aspects of replacing tantalum with niobium, replacing a tantalum capacitor and an aluminum capacitor with the niobium capacitor, manufacturing of a supercapacitor and the like.

Owner:江西波德新材料研究有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com