Sheet type niobium oxide solid electrolyte capacitor and its manufacturing method

A technology of solid electrolysis and manufacturing method, applied in solid electrolytic capacitors, electrolytic capacitors, capacitors and other directions, can solve the problems of poor temperature characteristics and sensitivity of tantalum capacitors, and achieve the effects of improved safety, convenient manufacturing process and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

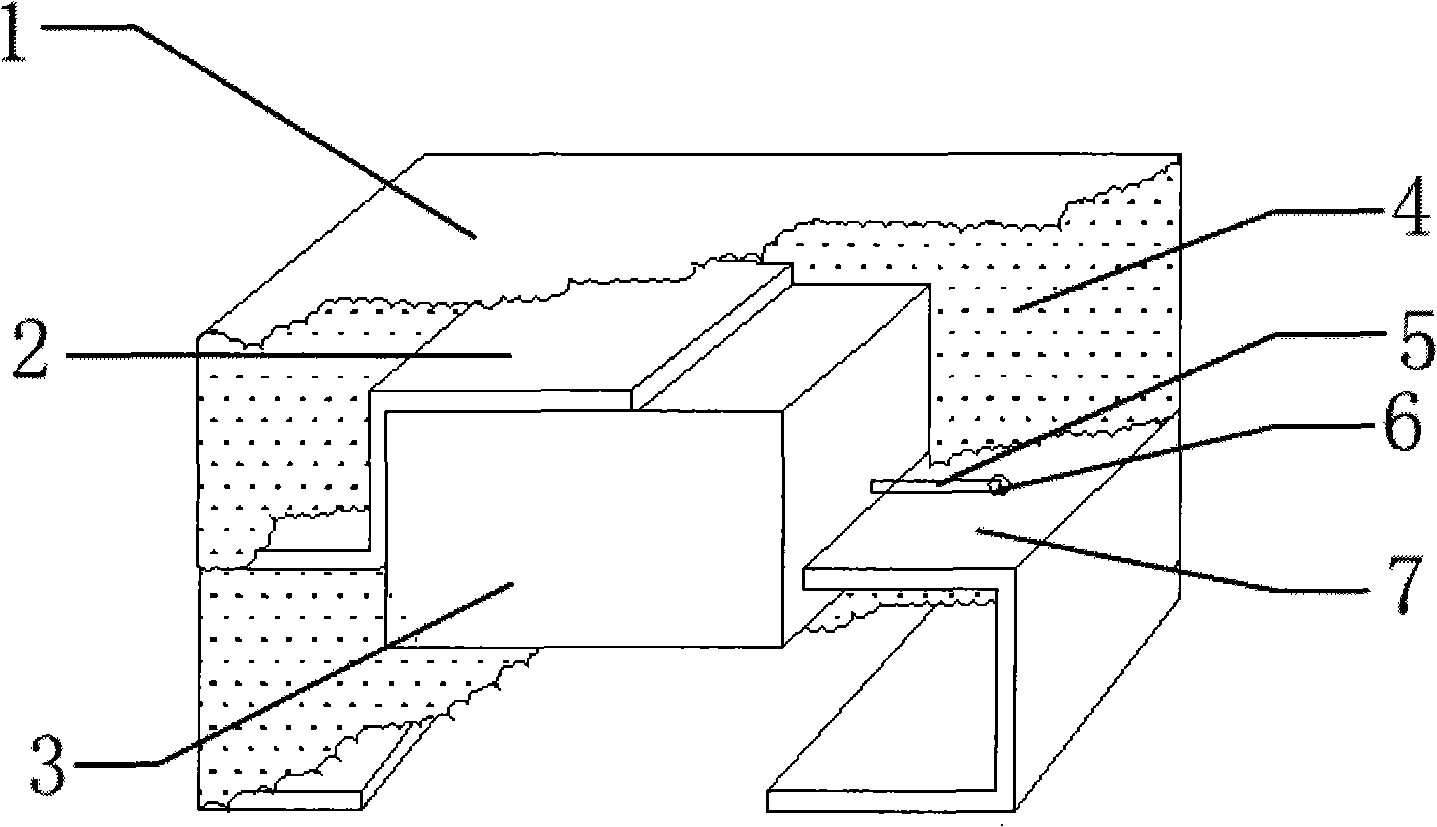

[0025] The embodiment of the present invention provides a chip-type niobium oxide solid electrolytic capacitor and its manufacturing method. The specific volume is 60,000-120,000 UuF.V / g, and the niobium monoxide powder with an oxygen content of 14.5-15.5% is used as a raw material. / CC pressing density is pressed into a compact, and the anode compact is formed by vacuum sintering, and then a chip-type niobium oxide electrolytic capacitor is prepared by forming a DC voltage dielectric layer, cathode preparation and packaging. Compared with tantalum capacitors or pure niobium capacitors, this niobium oxide electrolytic capacitor has greatly improved performance and safety, and can be used in various circuits, such as switching power supply circuits with large surge voltage and current. , will not burn and explode, and the capacity and loss parameters remain basically unchanged, and the large current passing through can be limited. Continuous breakdown can be effectively avoided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com