Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

149 results about "Heusler compound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

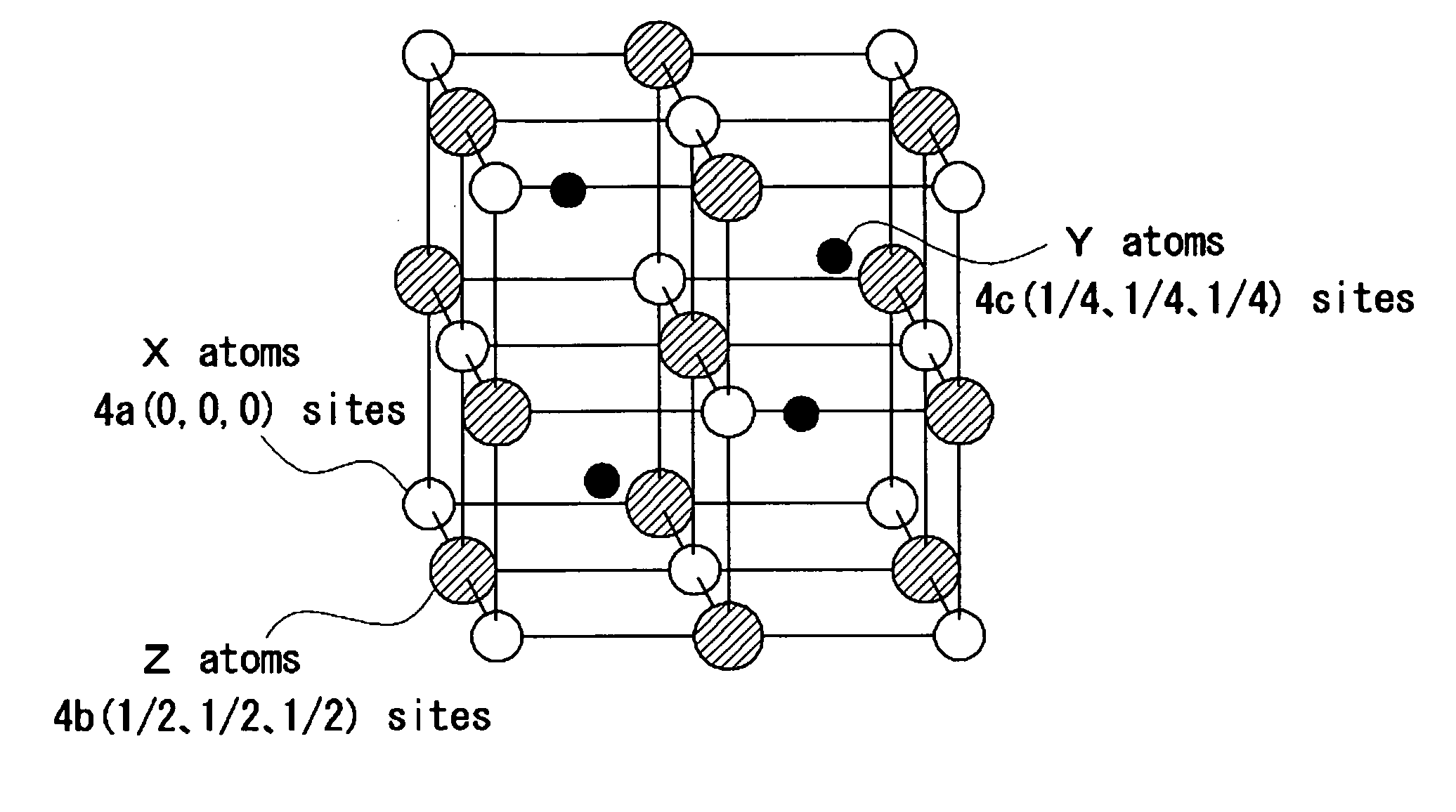

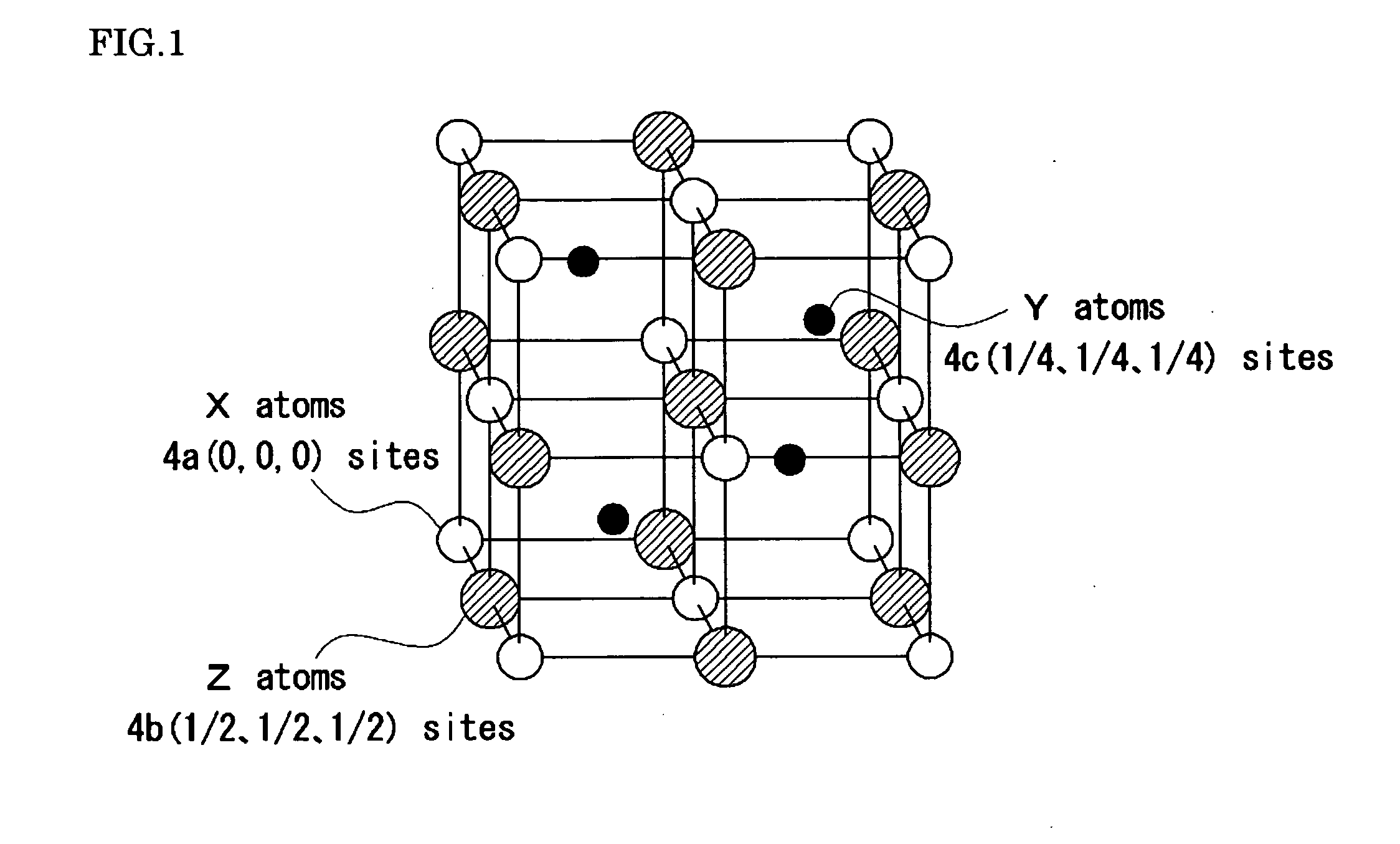

Heusler compounds are magnetic intermetallics with face-centered cubic crystal structure and a composition of XYZ (half-Heuslers) or X₂YZ (full-Heuslers), where X and Y are transition metals and Z is in the p-block. Many of these compounds exhibit properties relevant to spintronics, such as magnetoresistance, variations of the Hall effect, ferro-, antiferro-, and ferrimagnetism, half- and semimetallicity, semiconductivity with spin filter ability, superconductivity, and topological band structure. Their magnetism results from a double-exchange mechanism between neighboring magnetic ions. Manganese, which sits at the body centers of the cubic structure, was the magnetic ion in the first Heusler compound discovered. (See the Bethe–Slater curve for details of why this happens.)

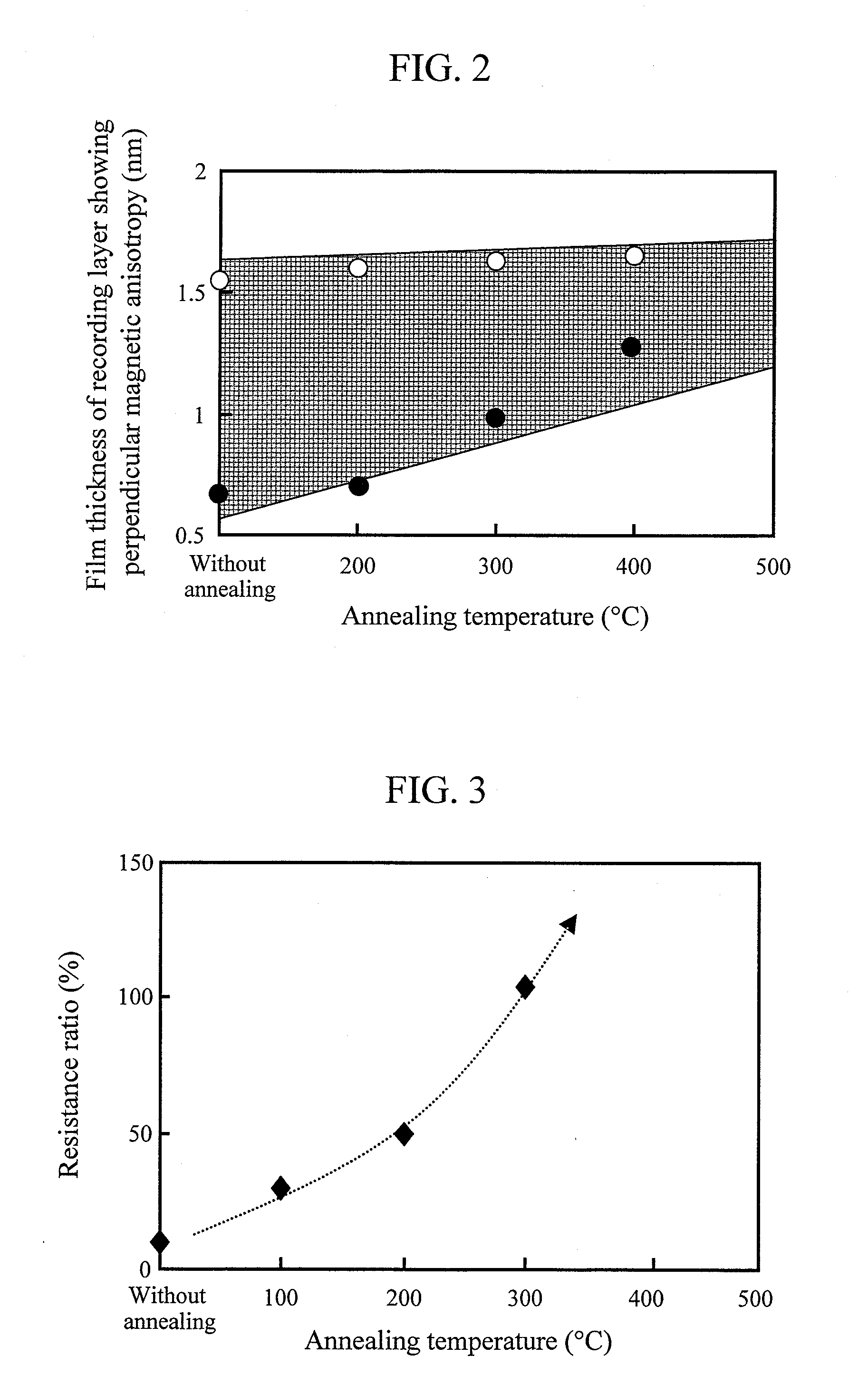

Thin seeded Co/Ni multilayer film with perpendicular anisotropy for spintronic device applications

ActiveUS20090257151A1Raise the ratioNot to damageMagnetic measurementsVacuum evaporation coatingPerpendicular anisotropySpins

A spin valve structure for a spintronic device is disclosed and includes a composite seed layer made of at least Ta and a metal layer having a fcc(111) or hcp(001) texture to enhance perpendicular magnetic anisotropy (PMA) in an overlying (Co / Ni)x multilayer. The (Co / Ni)x multilayer is deposited by a low power and high Ar pressure process to avoid damaging Co / Ni interfaces and thereby preserving PMA. As a result, only a thin seed layer is required. PMA is maintained even after annealing at 220° C. for 10 hours. Examples of GMR and TMR spin valves are described and may be incorporated in spin transfer oscillators and spin transfer MRAMs. The free layer is preferably made of a FeCo alloy including at least one of Al, Ge, Si, Ga, B, C, Se, Sn, or a Heusler alloy, or a half Heusler alloy to provide high spin polarization and a low magnetic damping coefficient.

Owner:TDK CORPARATION +1

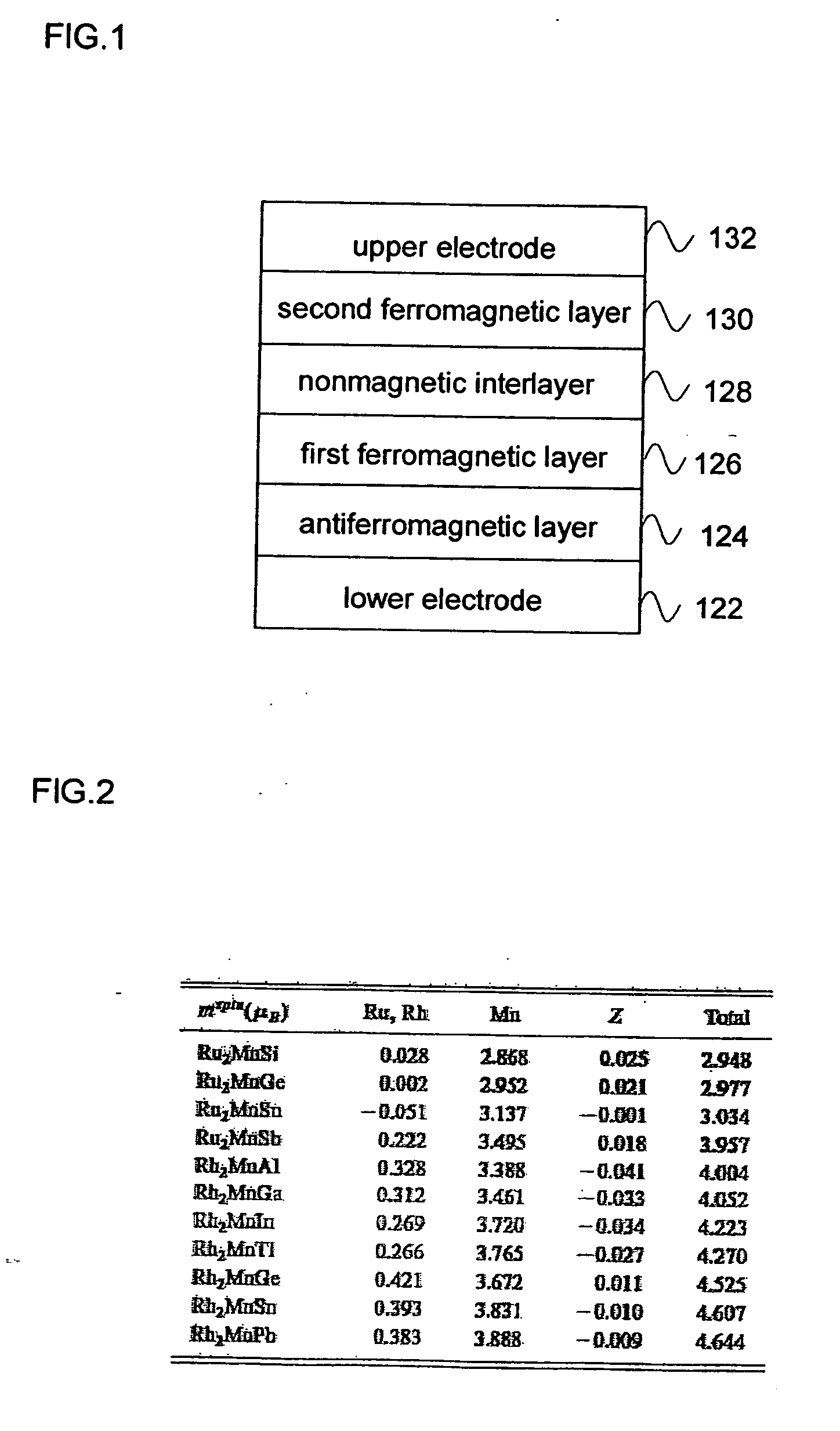

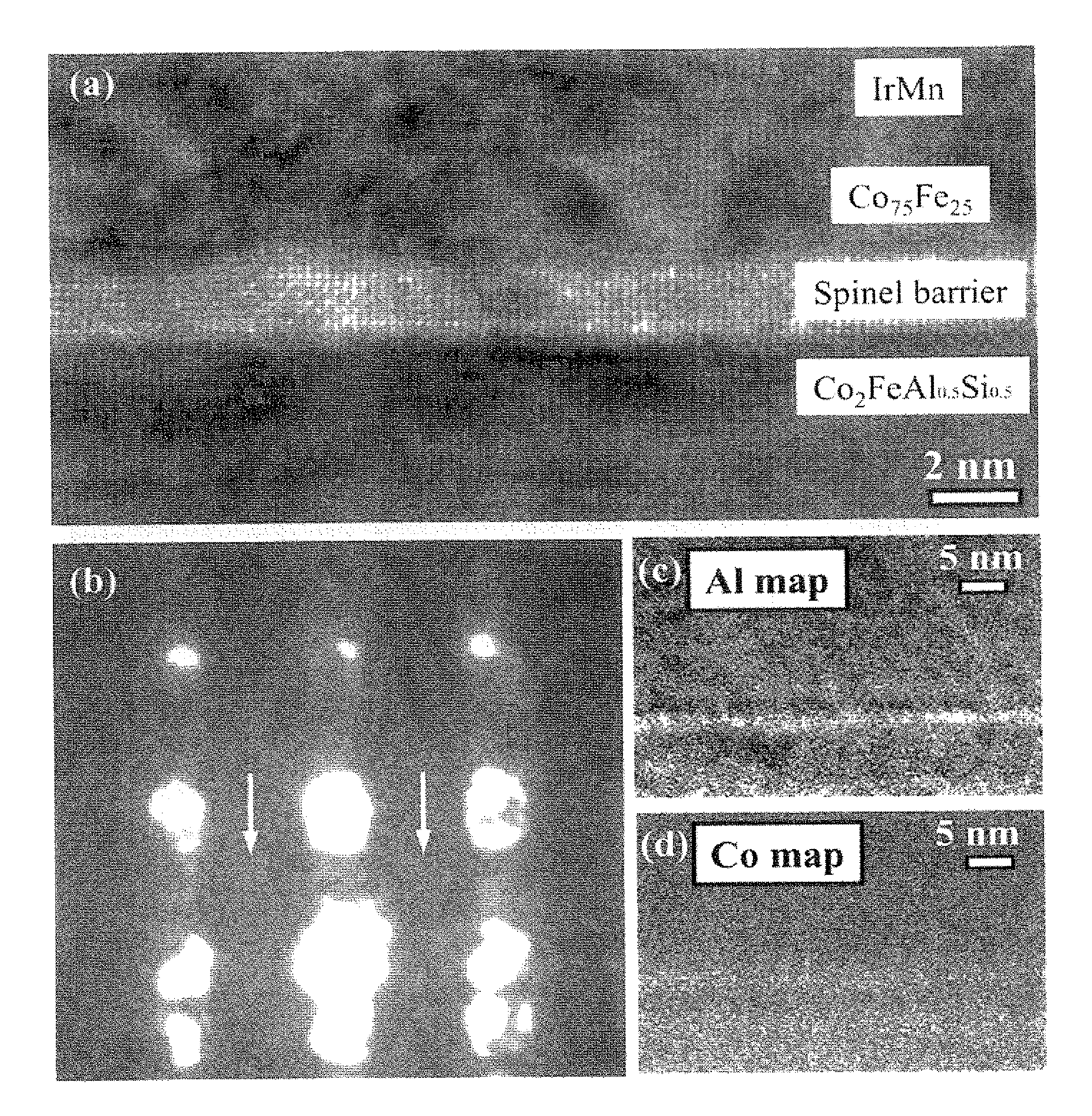

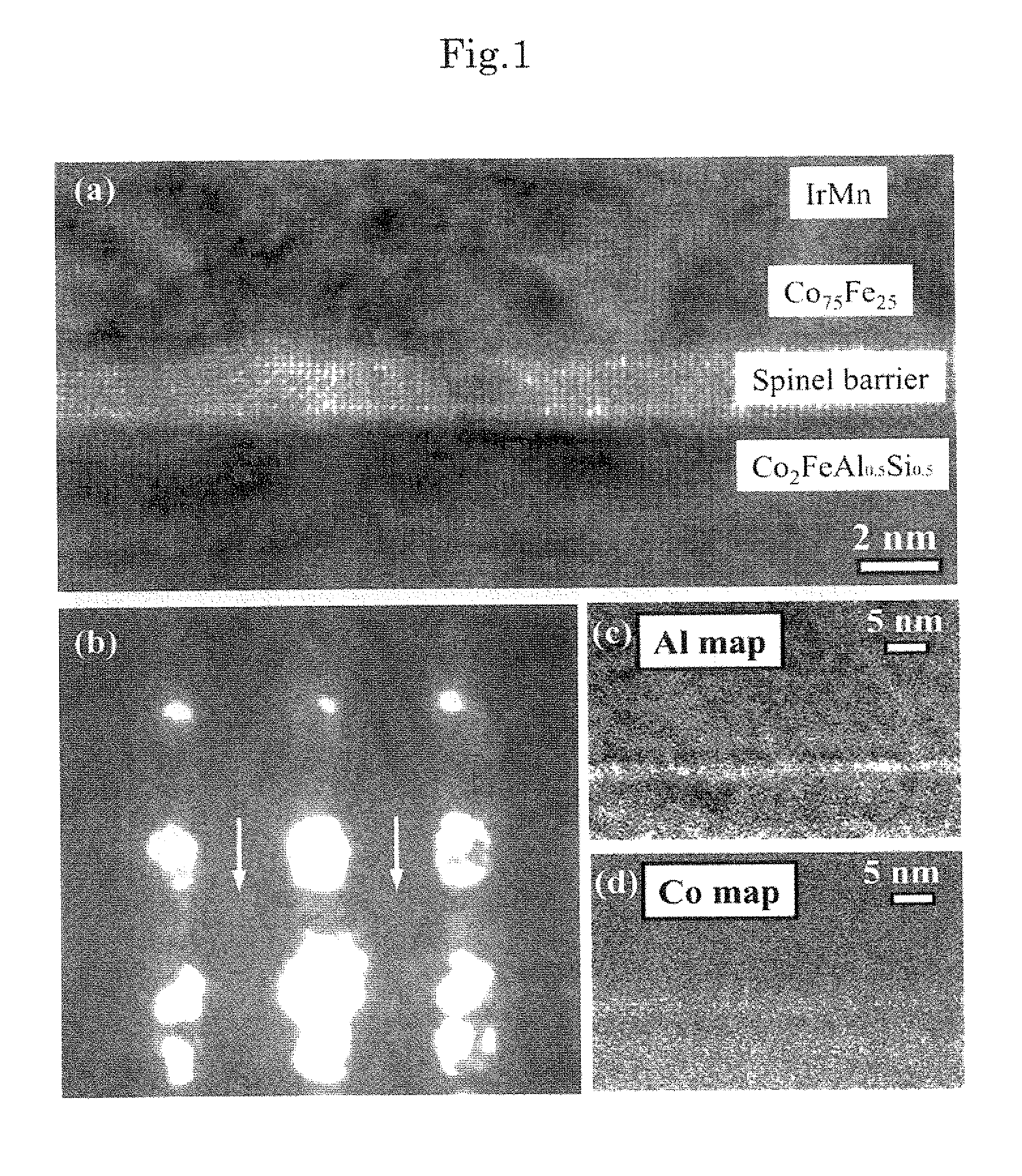

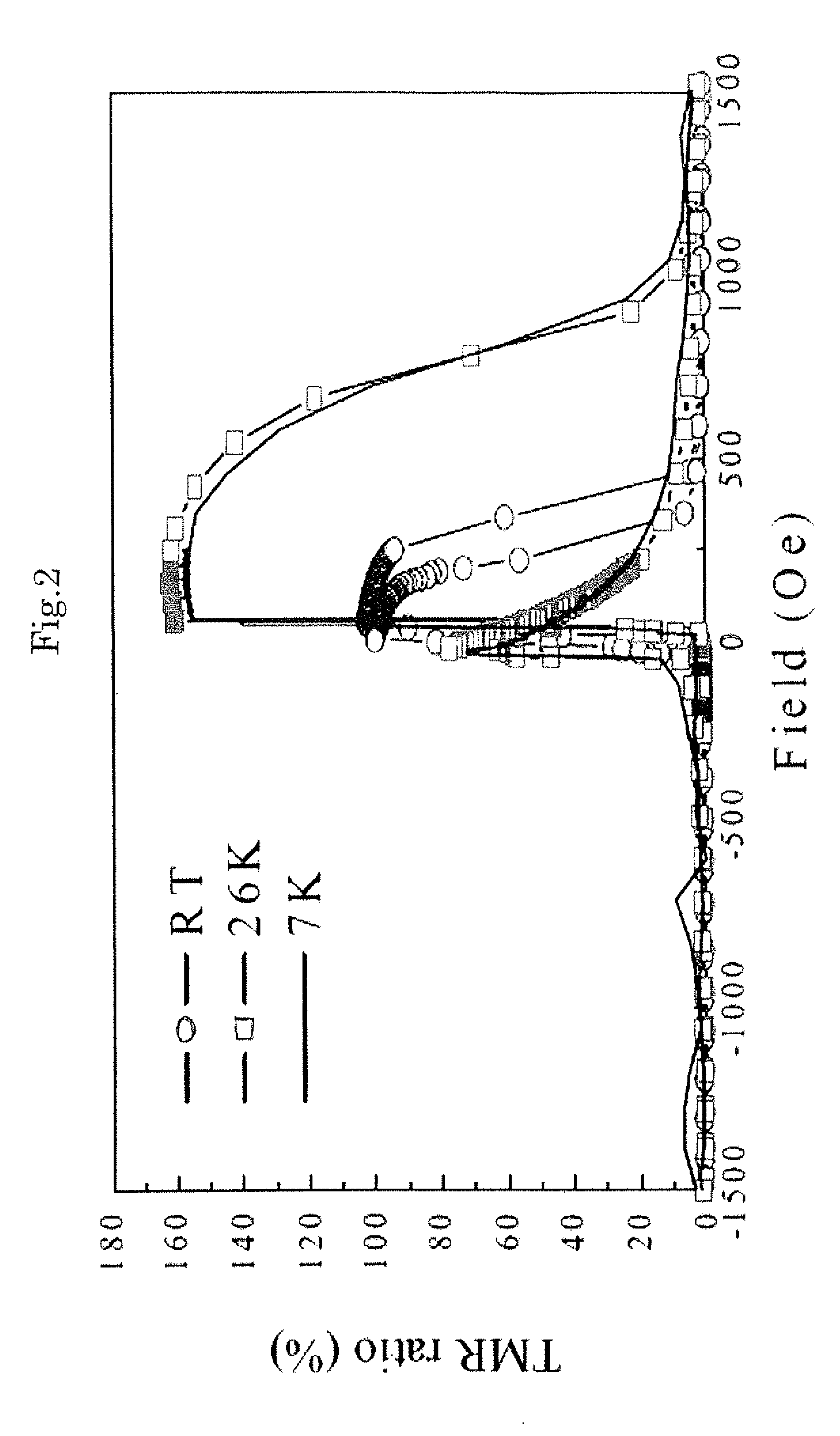

Ferromagnetic tunnel junction structure, and magneto-resistive element and spintronics device each using same

ActiveUS20120091548A1Quality improvementLarge TMRNanomagnetismMagnetic measurementsMagnetic reluctanceAlloy

Disclosed is a ferromagnetic tunnel junction structure which is characterized by having a tunnel barrier layer that comprises a non-magnetic material having a spinel structure. The ferromagnetic tunnel junction structure is also characterized in that the non-magnetic material is substantially MgAl2O4. The ferromagnetic tunnel junction is also characterized in that at least one of the ferromagnetic layers comprises a Co-based full Heusler alloy having an L21 or B2 structure. The ferromagnetic tunnel junction structure is also characterized in that the Co-based full Heusler alloy comprises a substance represented by the following formula: Co2FeAlxSi1-x (0≦x≦1). Also disclosed are a magnetoresistive element and a spintronics device, each of which utilizes the ferromagnetic tunnel junction structure and can achieve a high TMR value, that cannot be achieved by employing conventional tunnel barrier layers other than a MgO barrier.

Owner:NAT INST FOR MATERIALS SCI

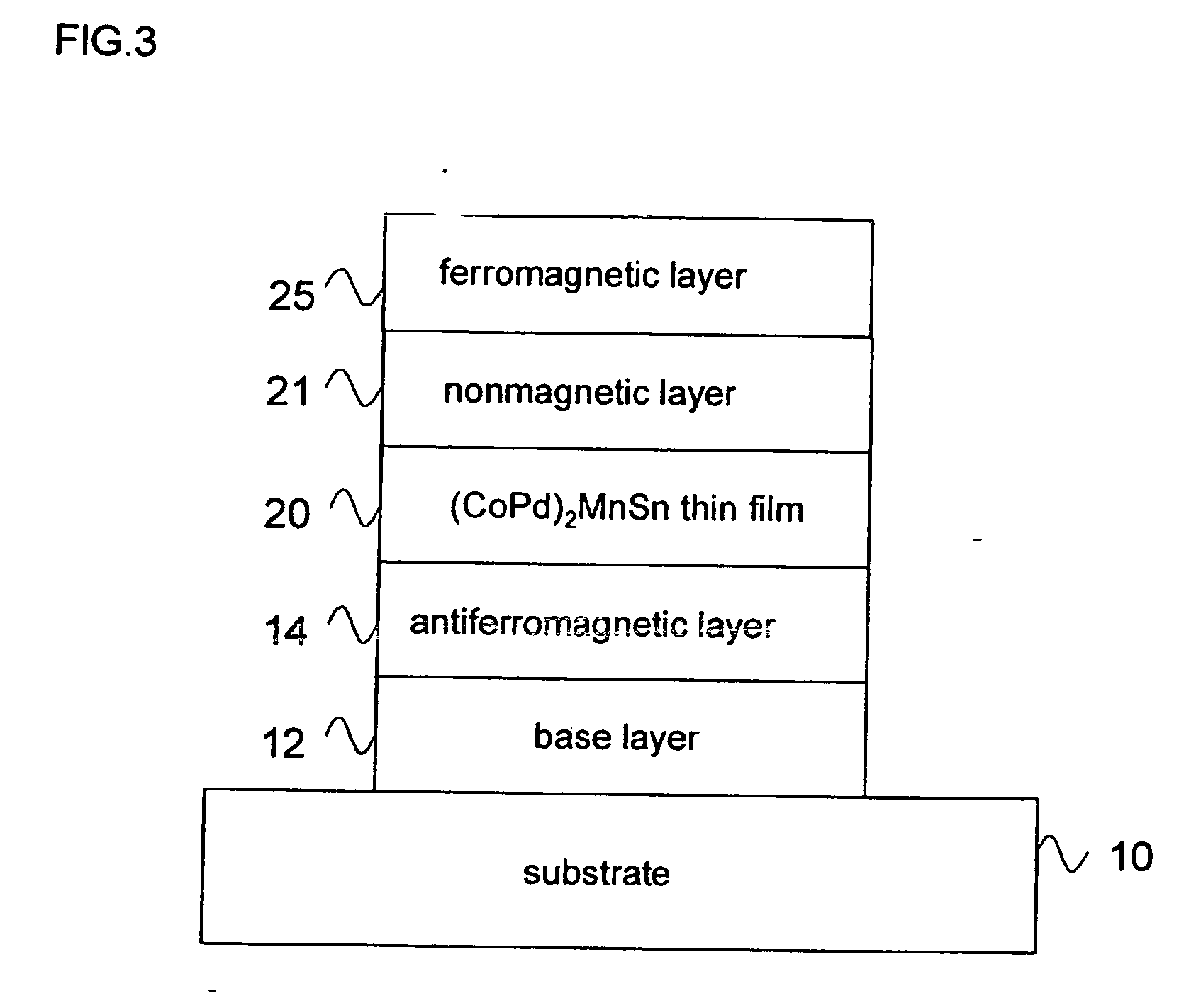

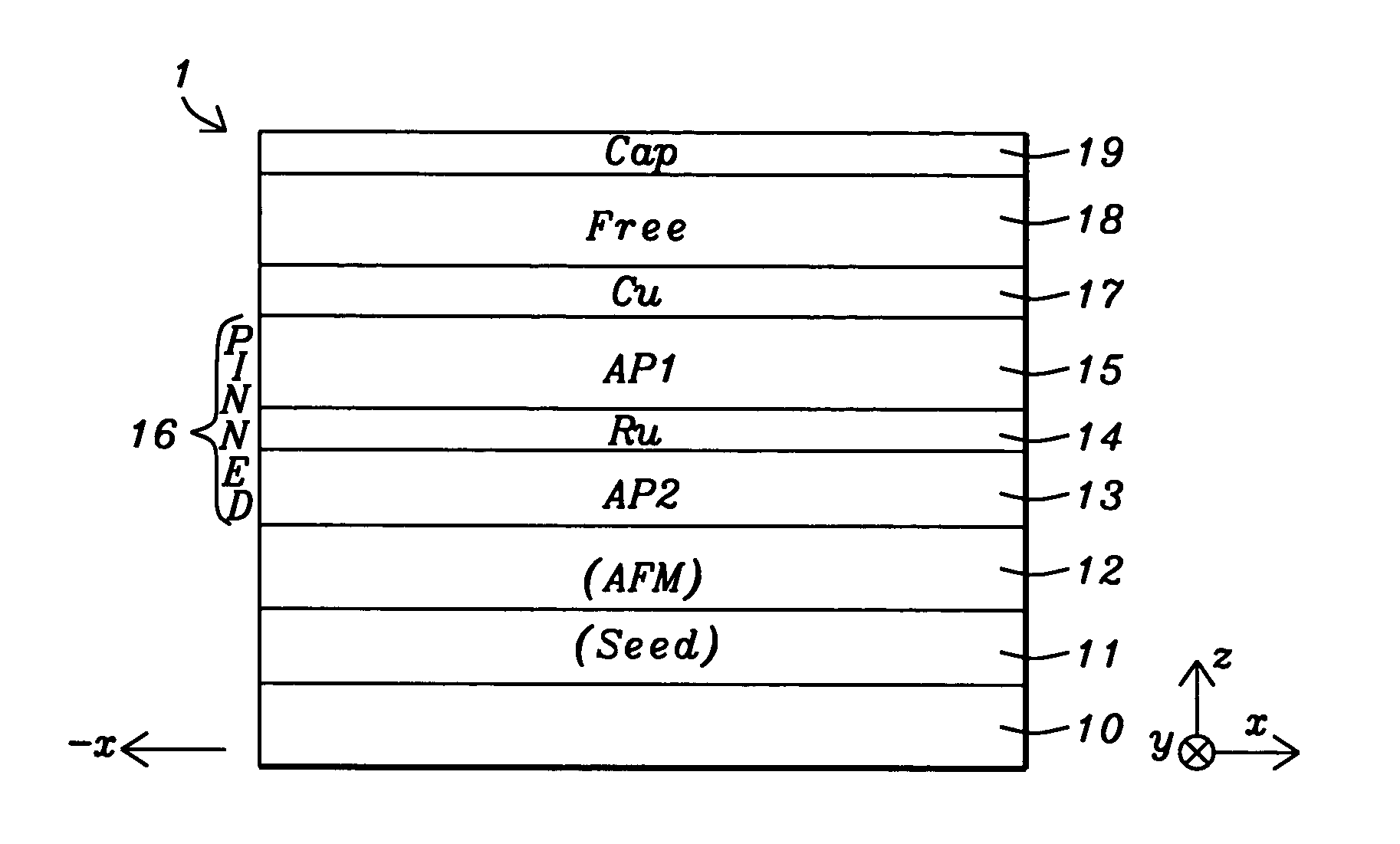

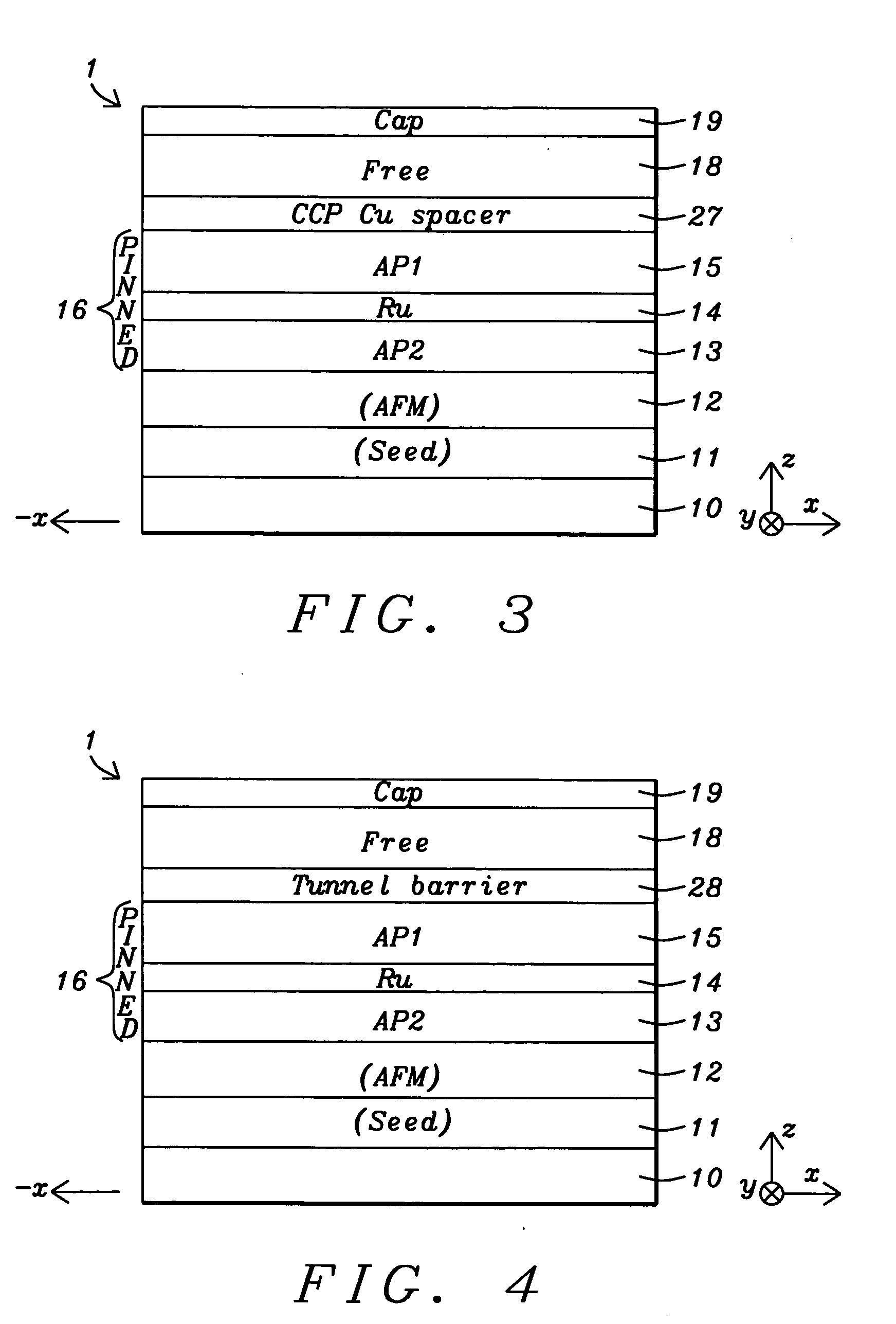

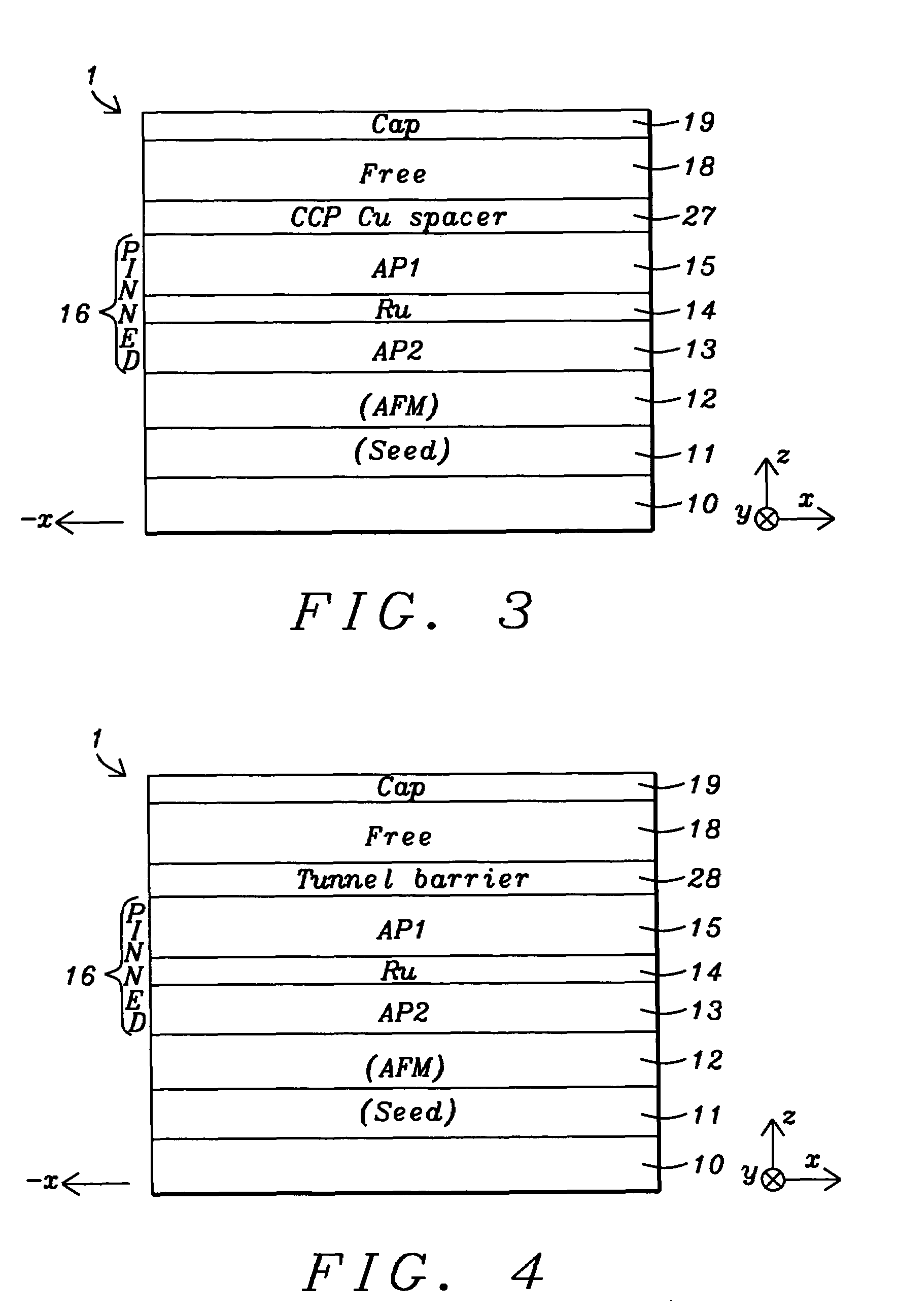

Novel way to reduce the ordering temperature for Co2MnSi-like Heusler alloys for CPP, TMR, MRAM, or other spintronics device applications

ActiveUS20070297103A1Decreased ordering temperatureReduce the temperatureNanomagnetismMagnetic measurementsAlloySpin valve

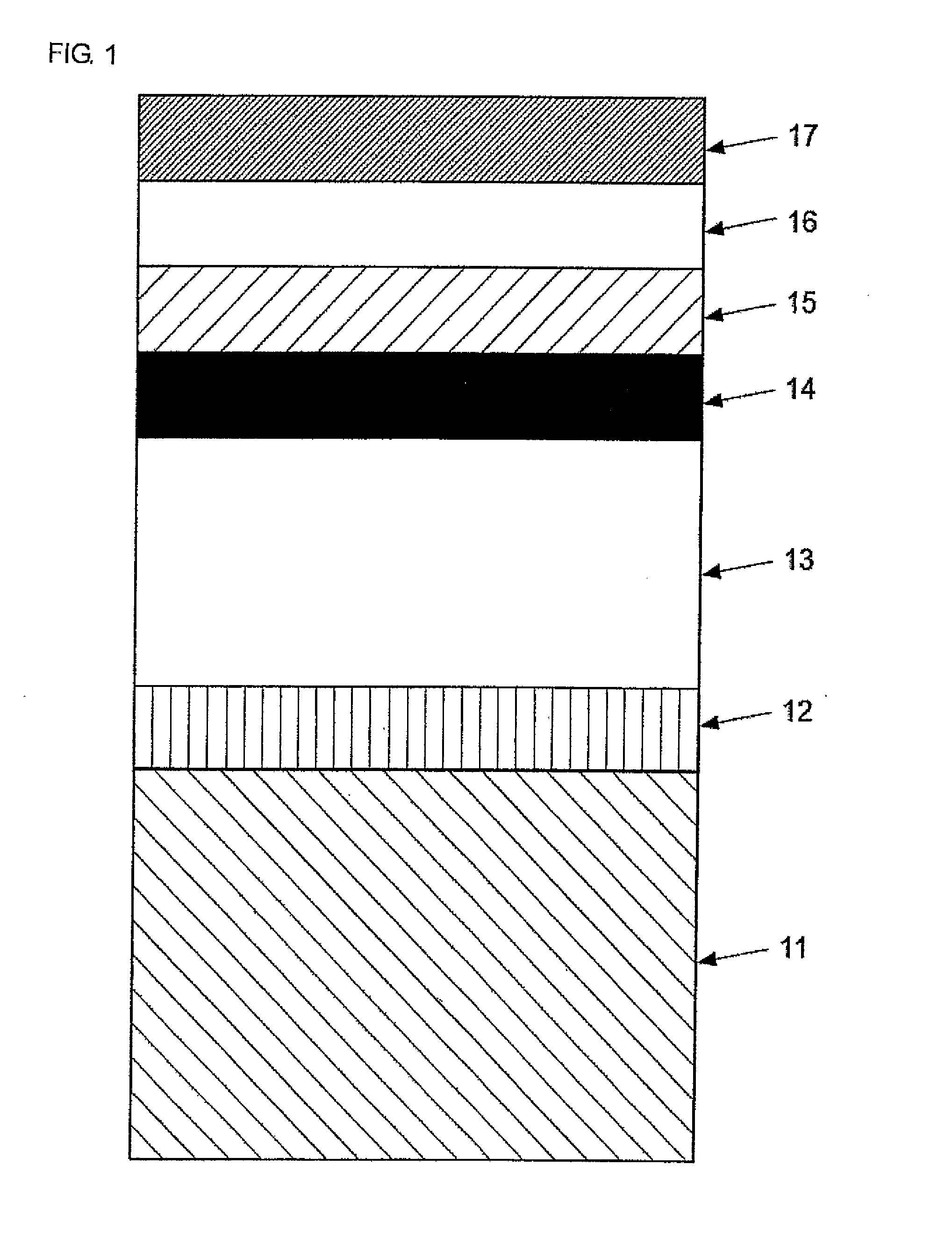

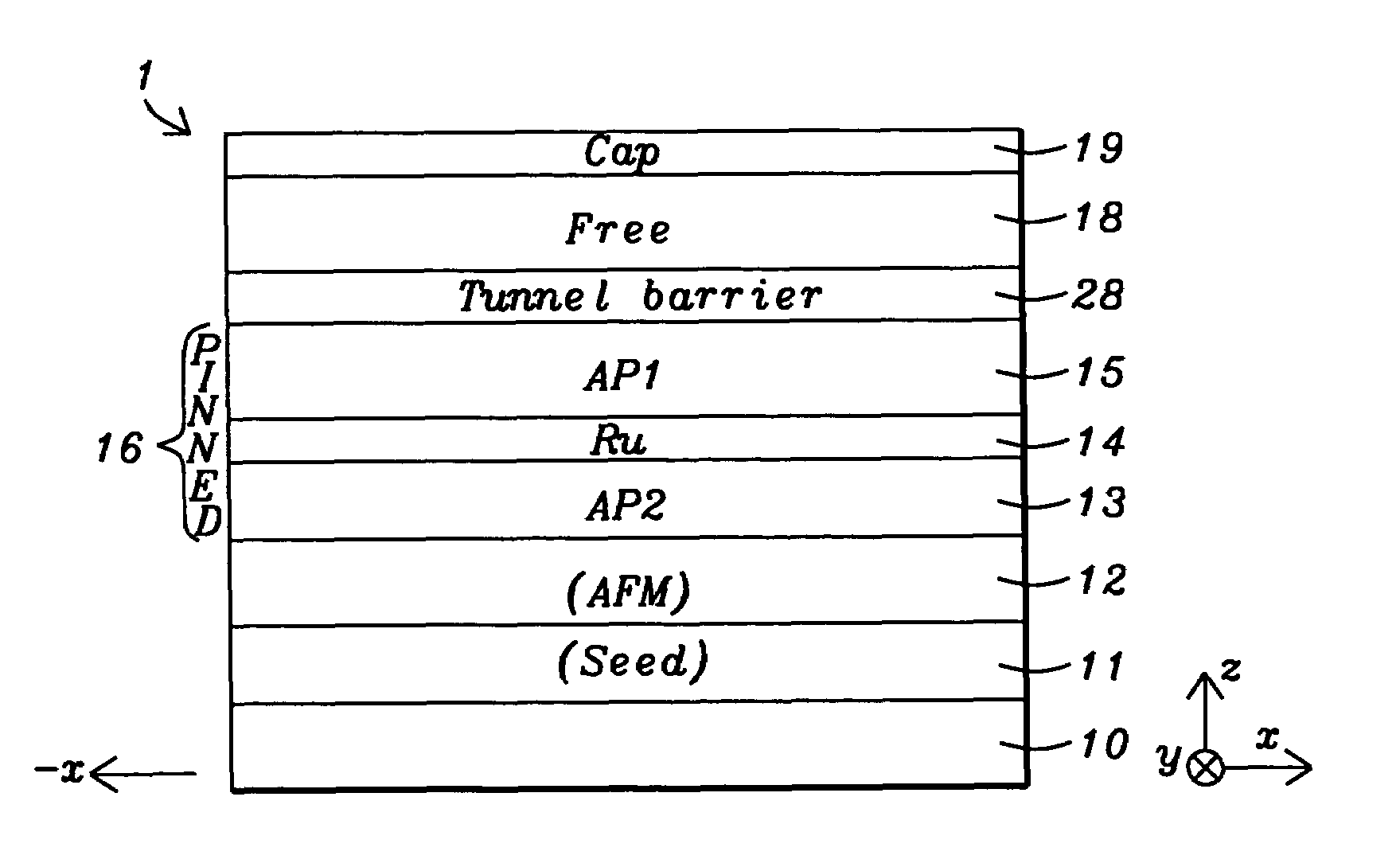

A spin valve structure is disclosed in which an AP1 layer and / or free layer are made of a laminated Heusler alloy having Al or FeCo insertion layers. The ordering temperature of a Heusler alloy such as Co2MnSi is thereby lowered from about 350° C. to 280° C. which becomes practical for spintronics device applications. The insertion layer is 0.5 to 5 Angstroms thick and may also be Sn, Ge, Ga, Sb, or Cr. The AP1 layer or free layer can contain one or two additional FeCo layers to give a configuration represented by FeCo / [HA / IL]nHA, [HA / IL]nHA / FeCo, or FeCo / [HA / IL]nHA / FeCo where n is an integer≧1, HA is a Heusler alloy layer, and IL is an insertion layer. Optionally, a Heusler alloy insertion scheme is possible by doping Al or FeCo in the HA layer. For example, Co2MnSi may be co-sputtered with an Al or FeCo target or with a Co2MnAl or Co2FeSi target.

Owner:HEADWAY TECH INC

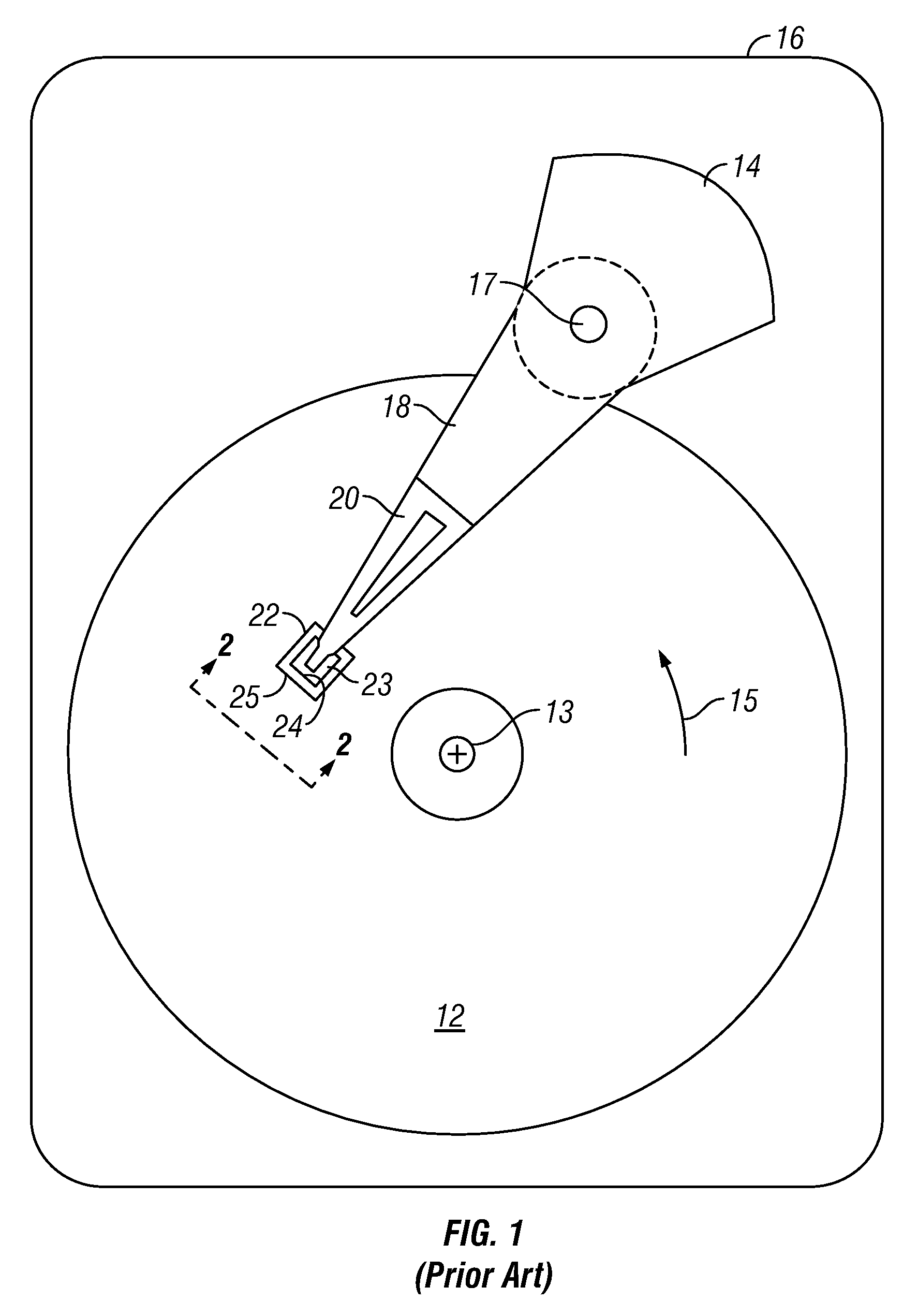

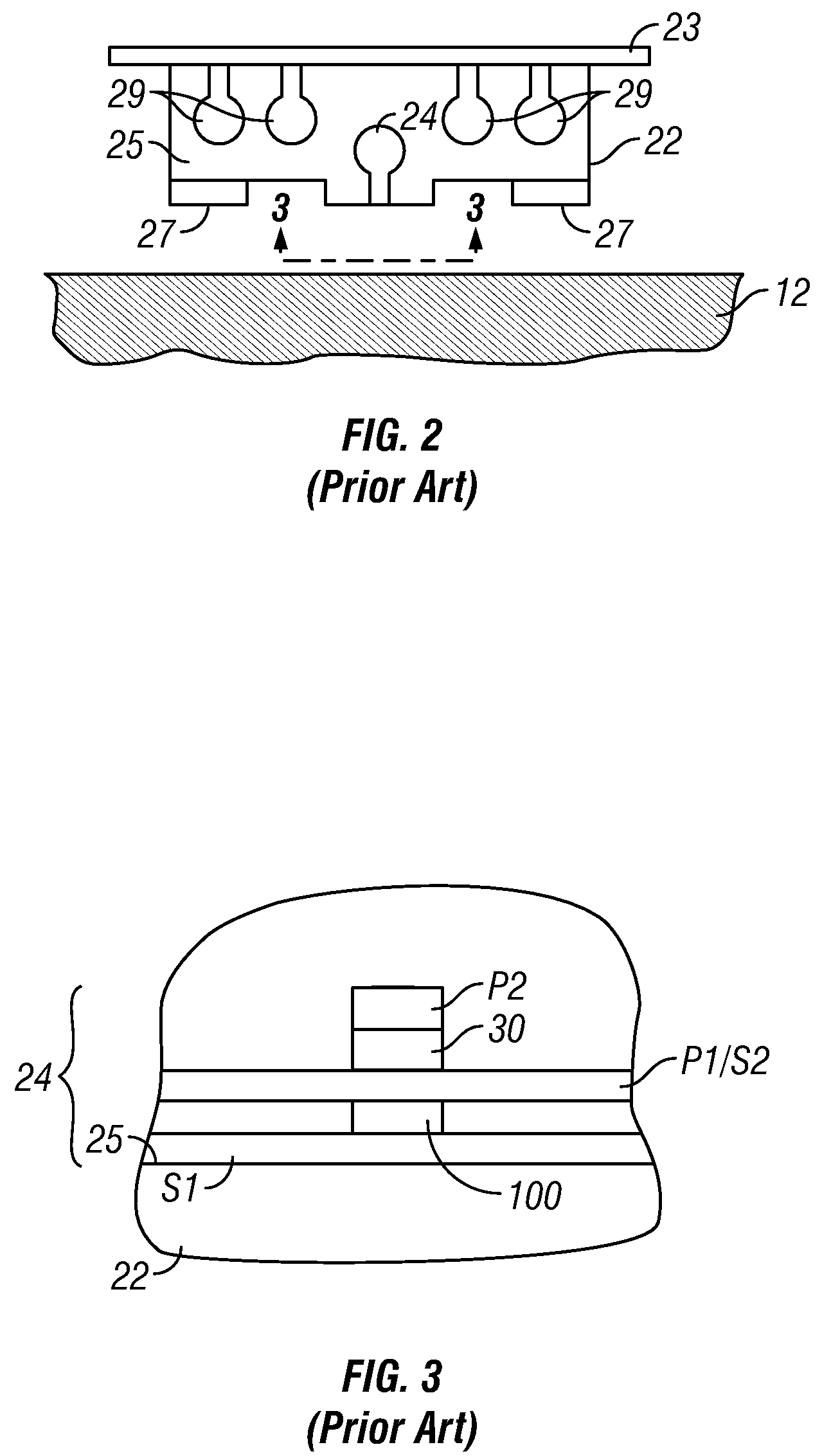

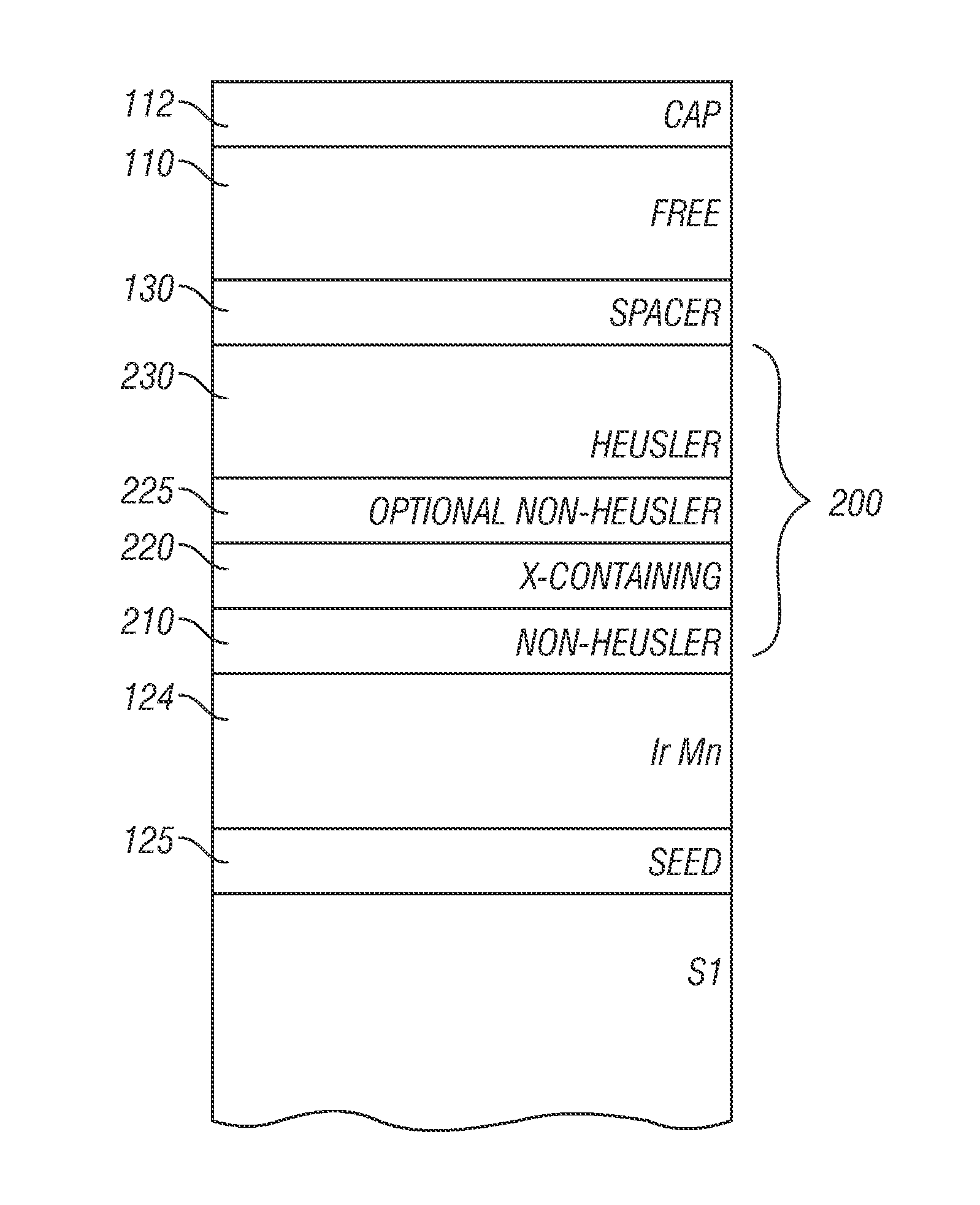

Method for making a current-perpendicular-to-the-plane (CPP) magnetoresistive sensor containing a ferromagnetic alloy requiring post-deposition annealing

InactiveUS20130236639A1Improve microstructureMagnetic measurementsMagnetic-field-controlled resistorsGiant magnetoresistanceAlloy

A method for making a current-perpendicular-to the-plane giant magnetoresistance (CPP-GMR) sensor with a Heusler alloy pinned layer on the sensor's Mn-containing antiferromagnetic pinning layer uses two annealing steps. A layer of a crystalline non-Heusler alloy ferromagnetic material, like Co or CoFe, is deposited on the antiferromagnetic pinning layer and a layer of an amorphous X-containing ferromagnetic alloy, like a CoFeBTa layer, is deposited on the Co or CoFe crystalline layer. After a first in-situ annealing of the amorphous X-containing ferromagnetic alloy, the Heusler alloy pinned layer is deposited on the amorphous X-containing ferromagnetic layer and a second high-temperature annealing step is performed to improve the microstructure of the Heusler alloy pinned layer.

Owner:WESTERN DIGITAL TECH INC

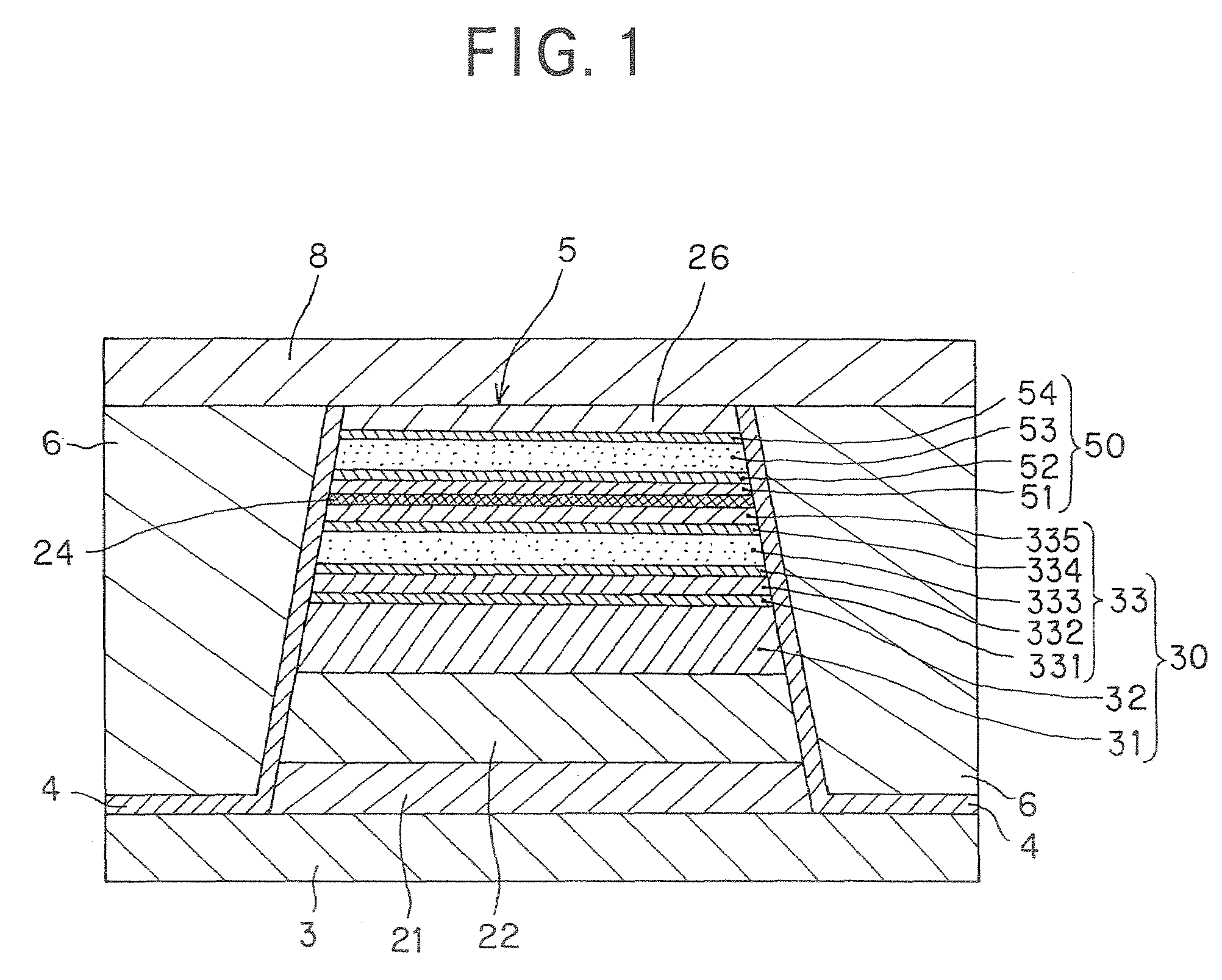

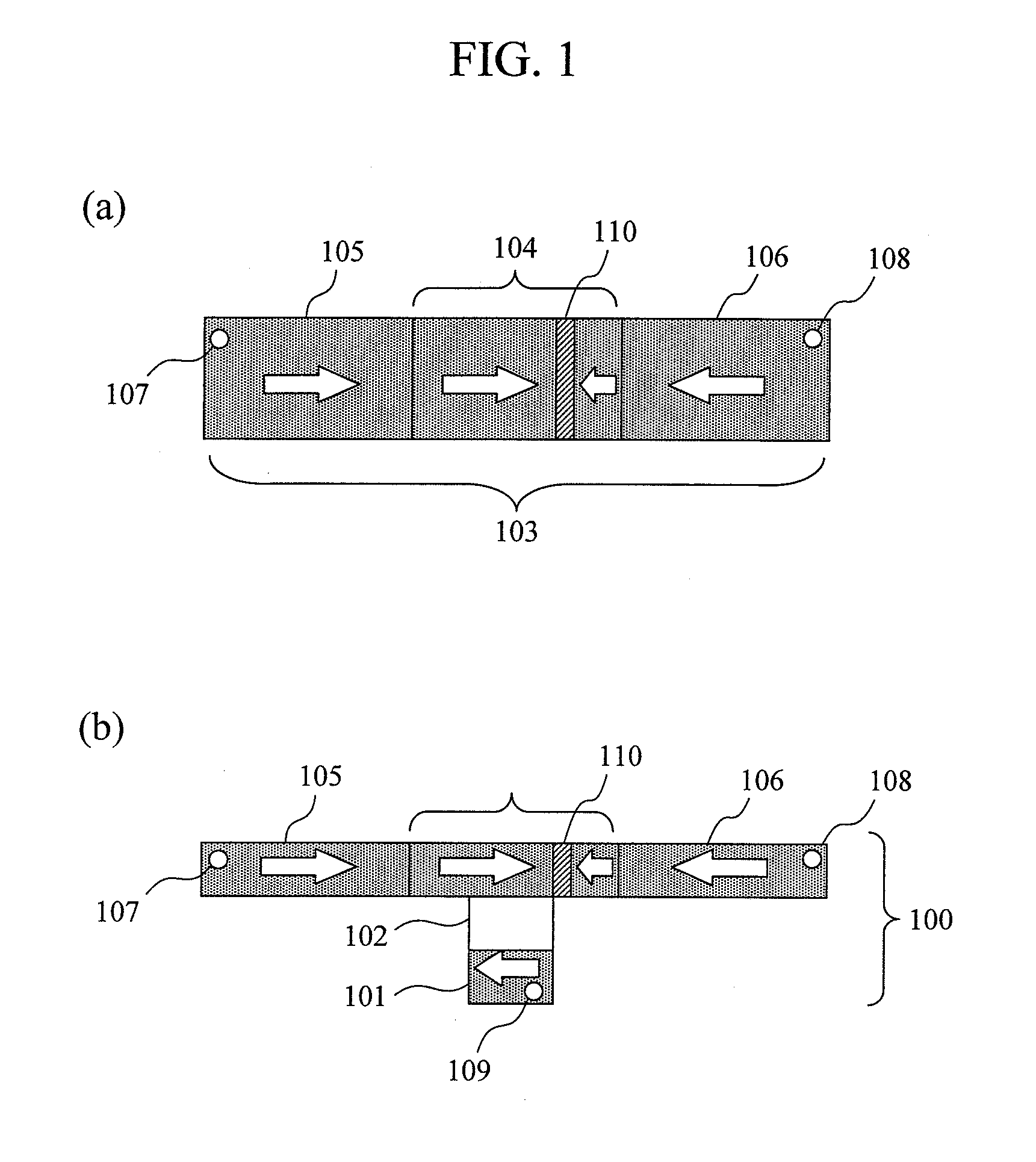

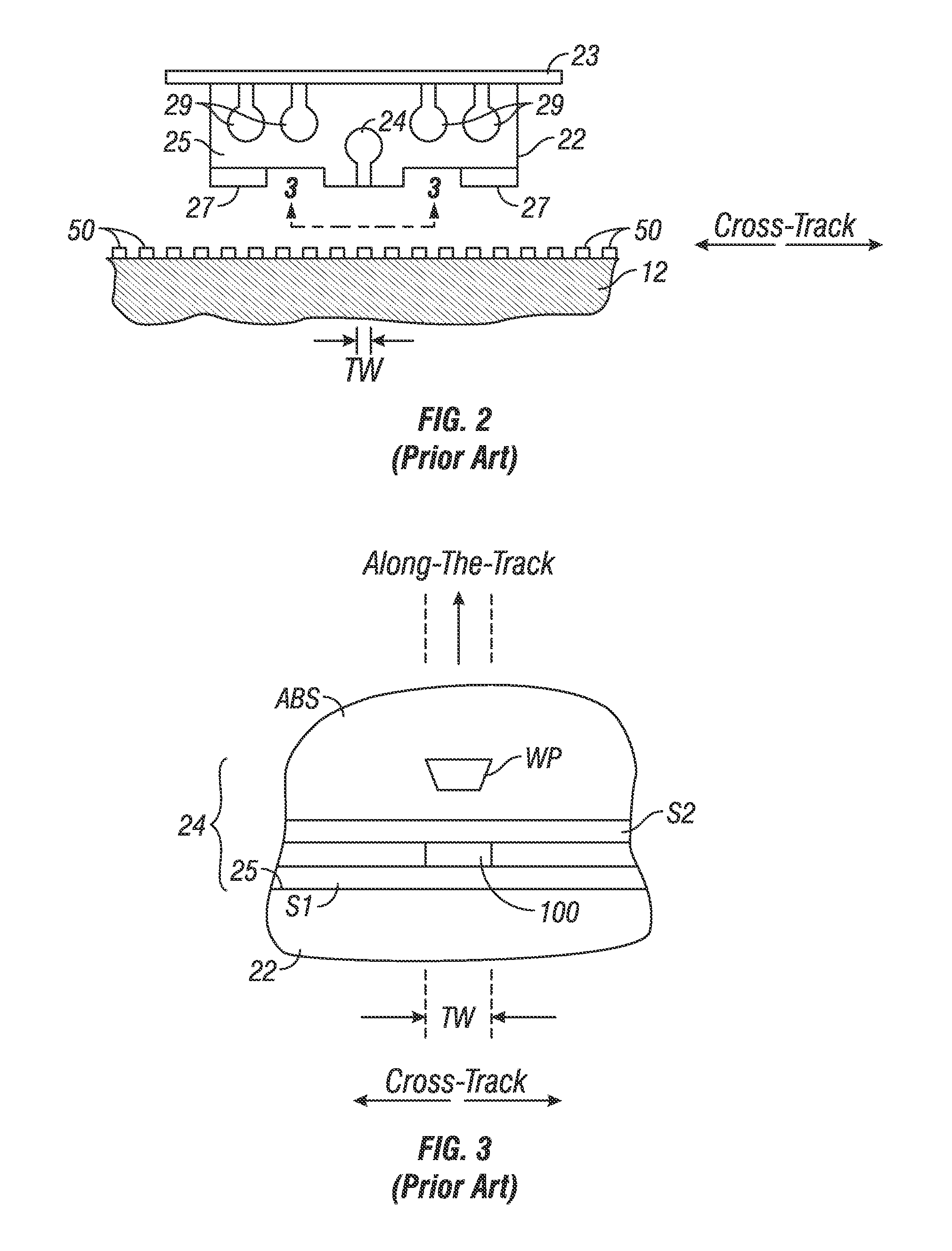

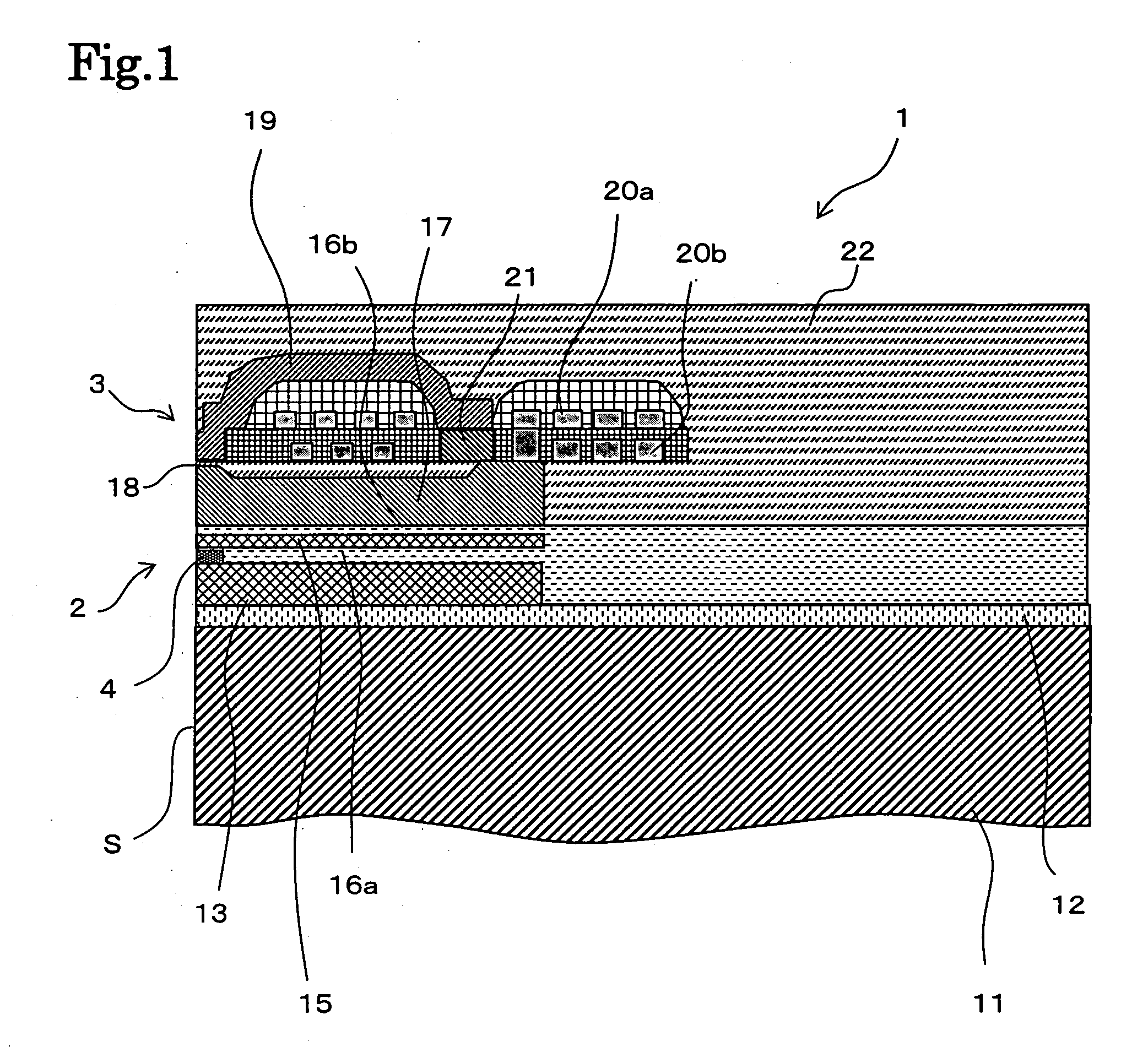

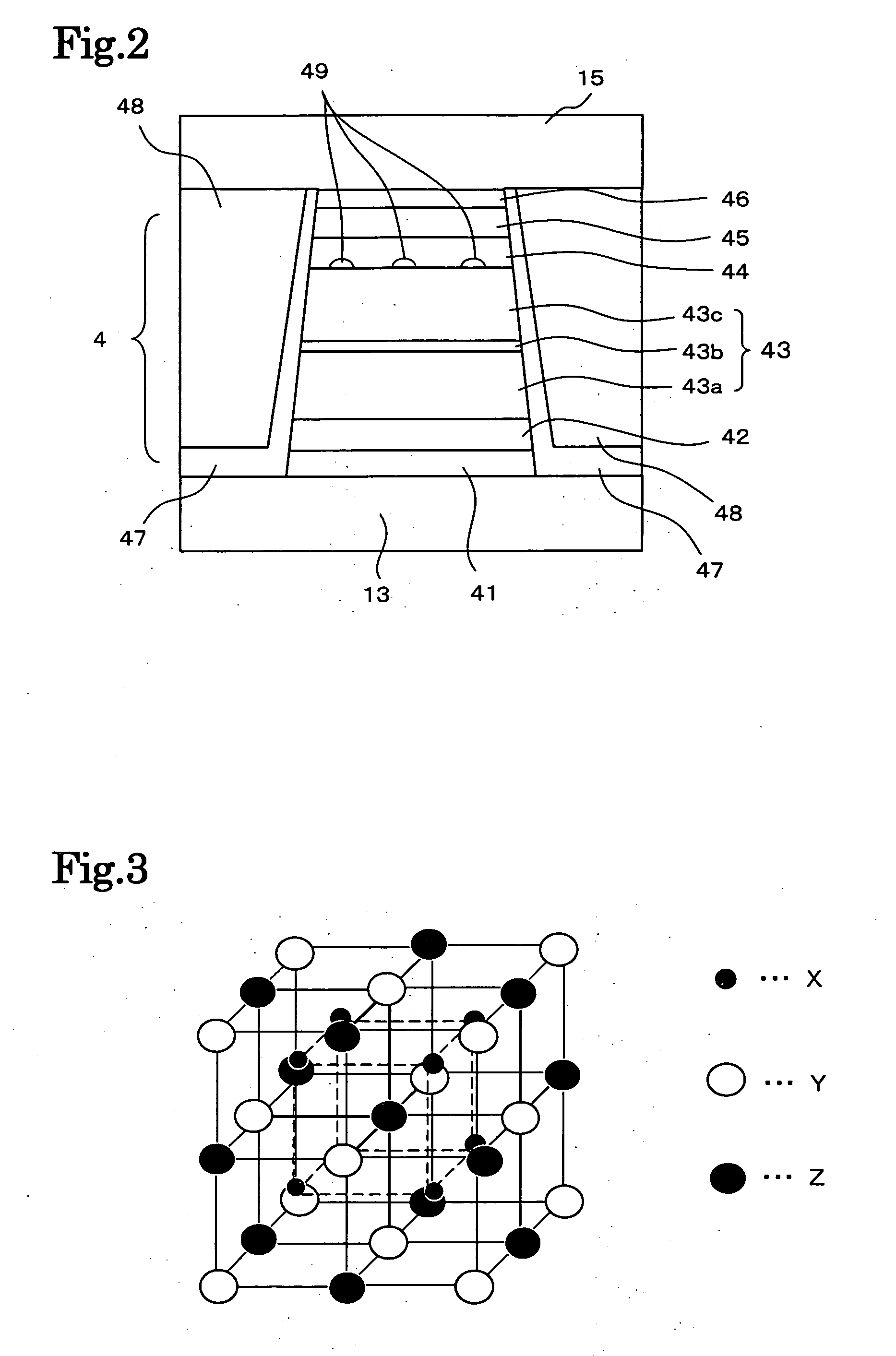

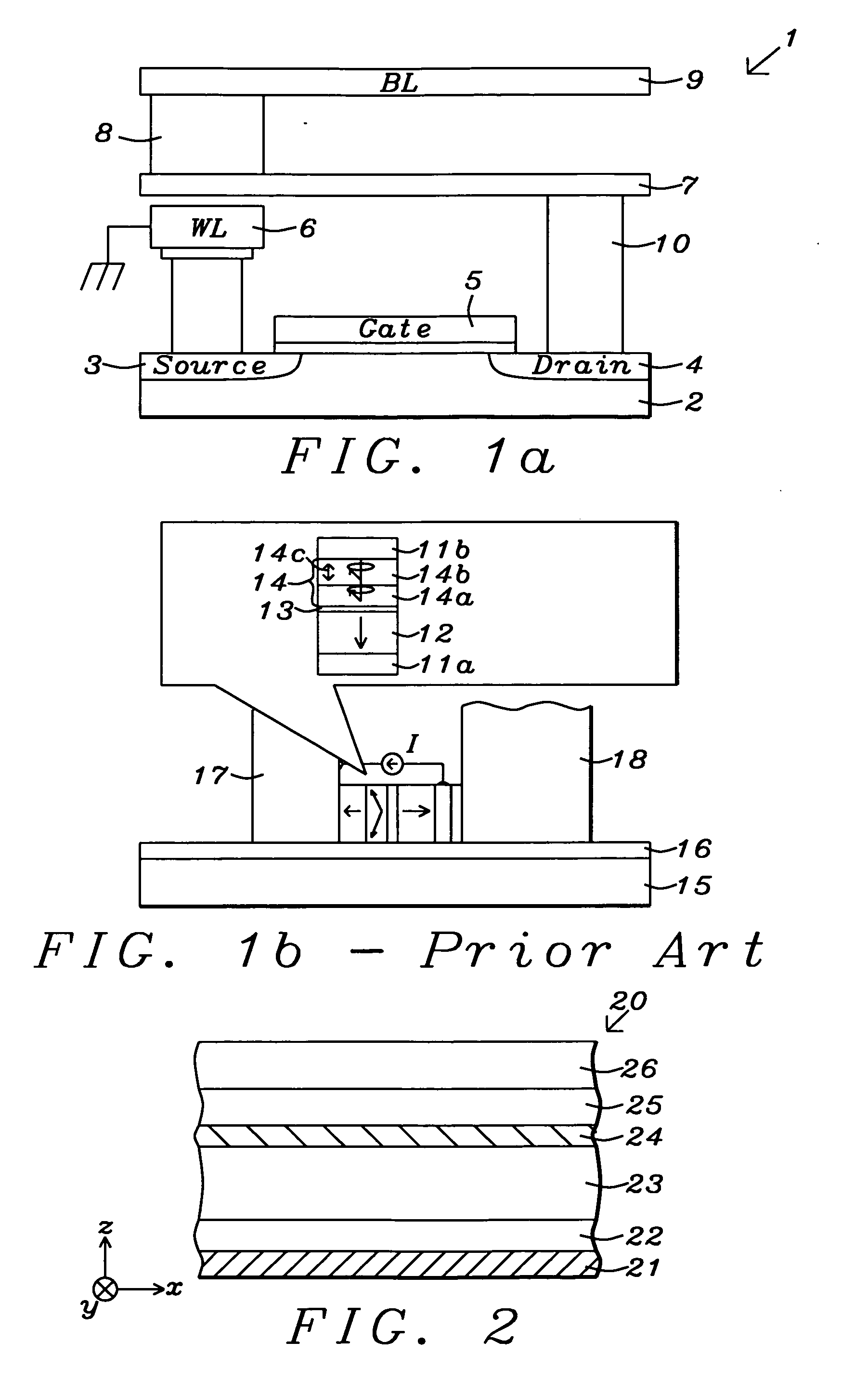

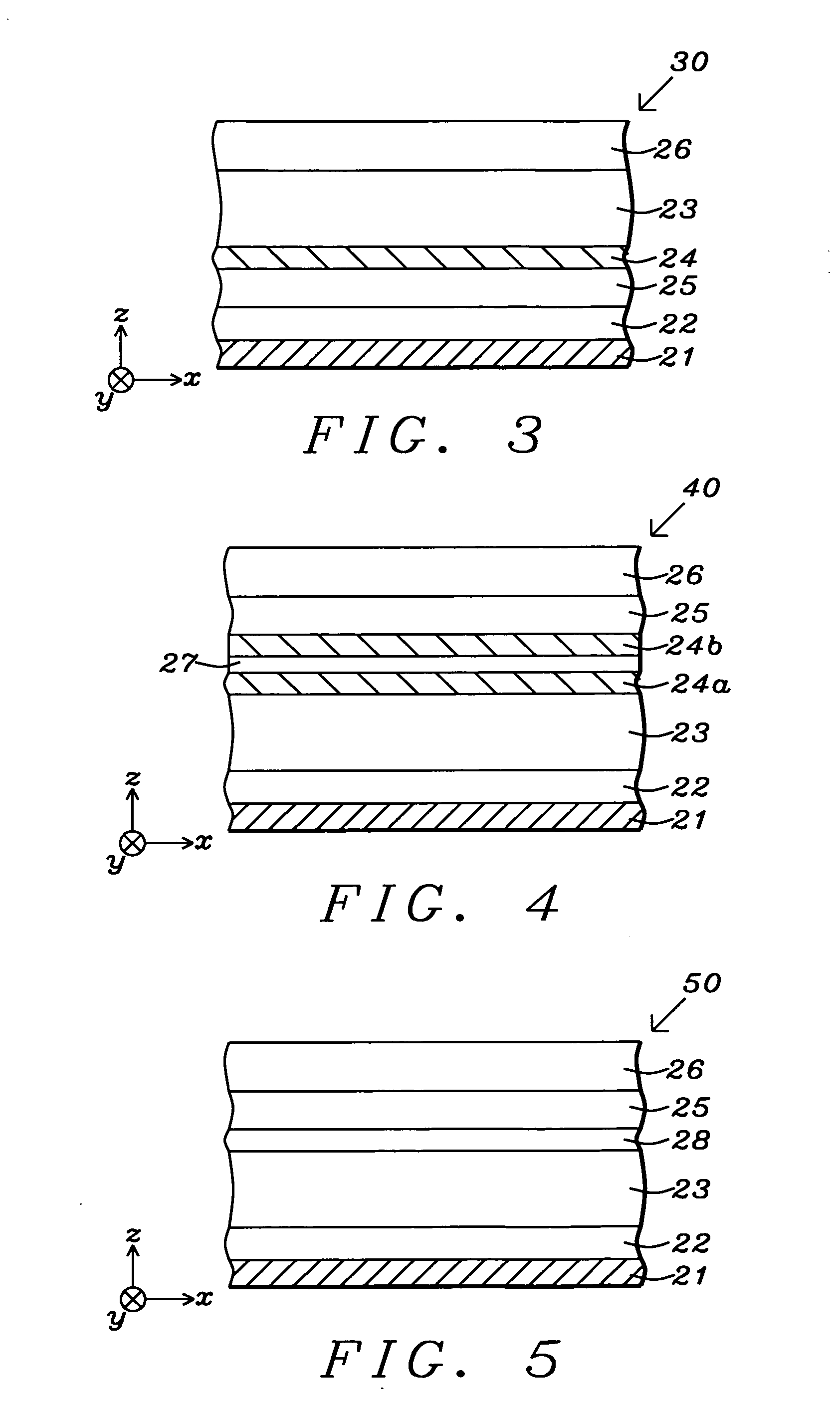

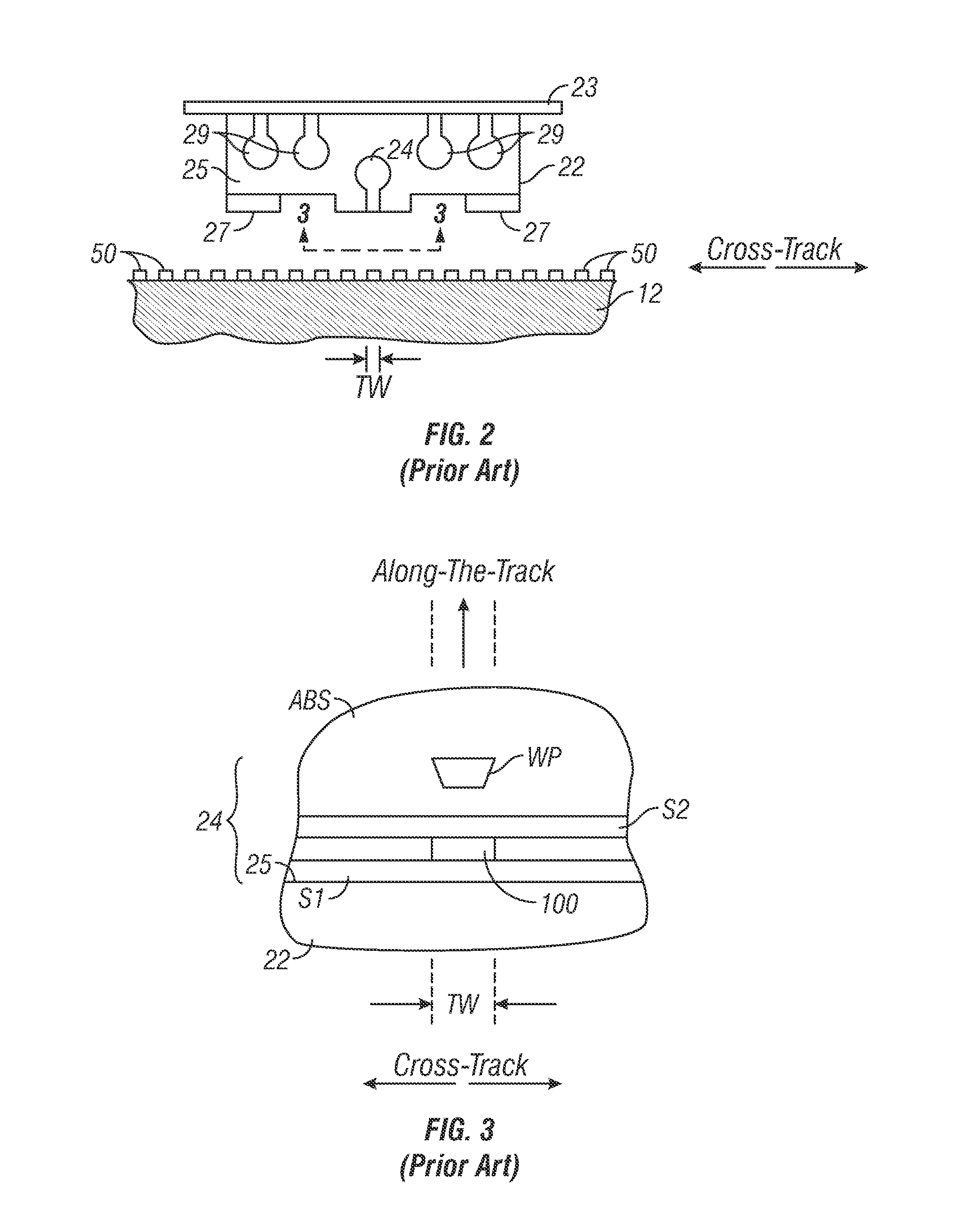

Magnetic sensing element including pinned layer and/or free layer composed of [110] crystal planes-oriented Heusler alloy

InactiveUS7336453B2Raise the ratioSufficient crystalline structureMagnetic-field-controlled resistorsHeads using thin filmsAlloyCrystal plane

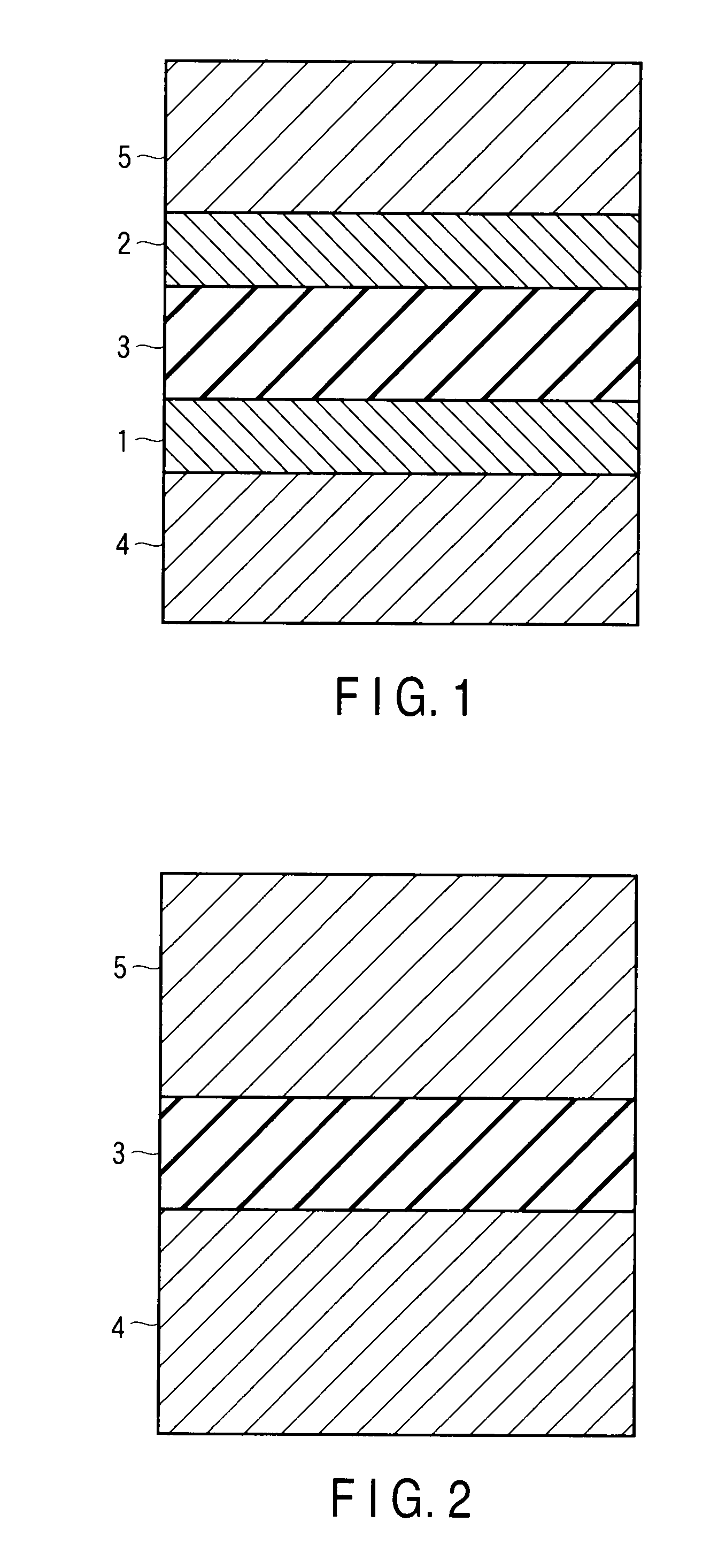

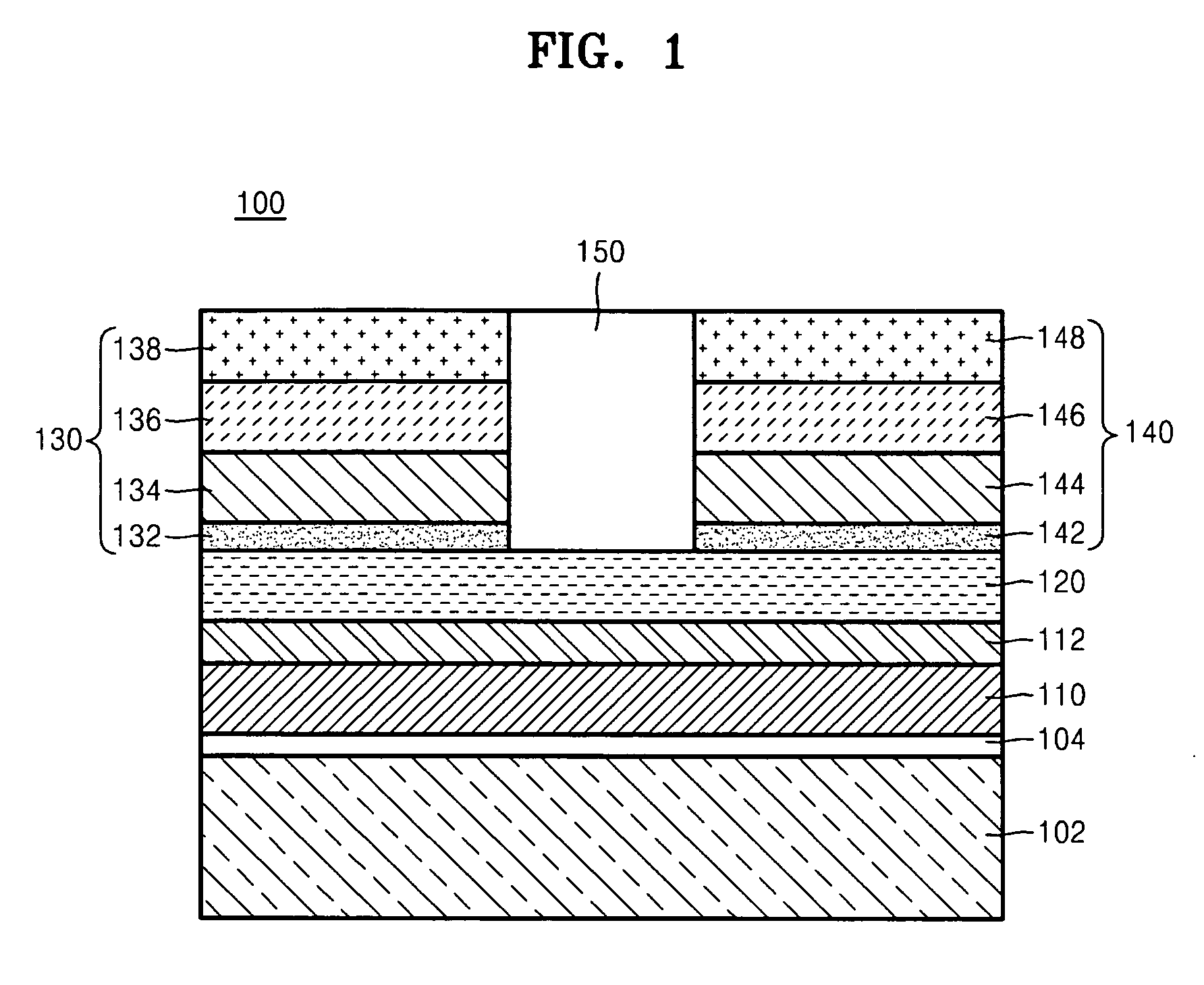

A magnetic sensing element using a thin film composed of an adequately crystallized Heusler alloy is provided. At least one of free magnetic layer and pinned magnetic layer includes a Heusler alloy layer. The Heusler alloy layer has a body-centered cubic (bcc) structure, in which equivalent crystal planes represented as [220] planes are preferentially oriented in the direction parallel to the layer surface. The Heusler alloy layer is disposed on a bcc layer having a body-centered cubic (bcc) structure, in which equivalent crystal planes represented as [110] planes are preferentially oriented in the direction parallel to the layer surface.

Owner:ALPS ALPINE CO LTD

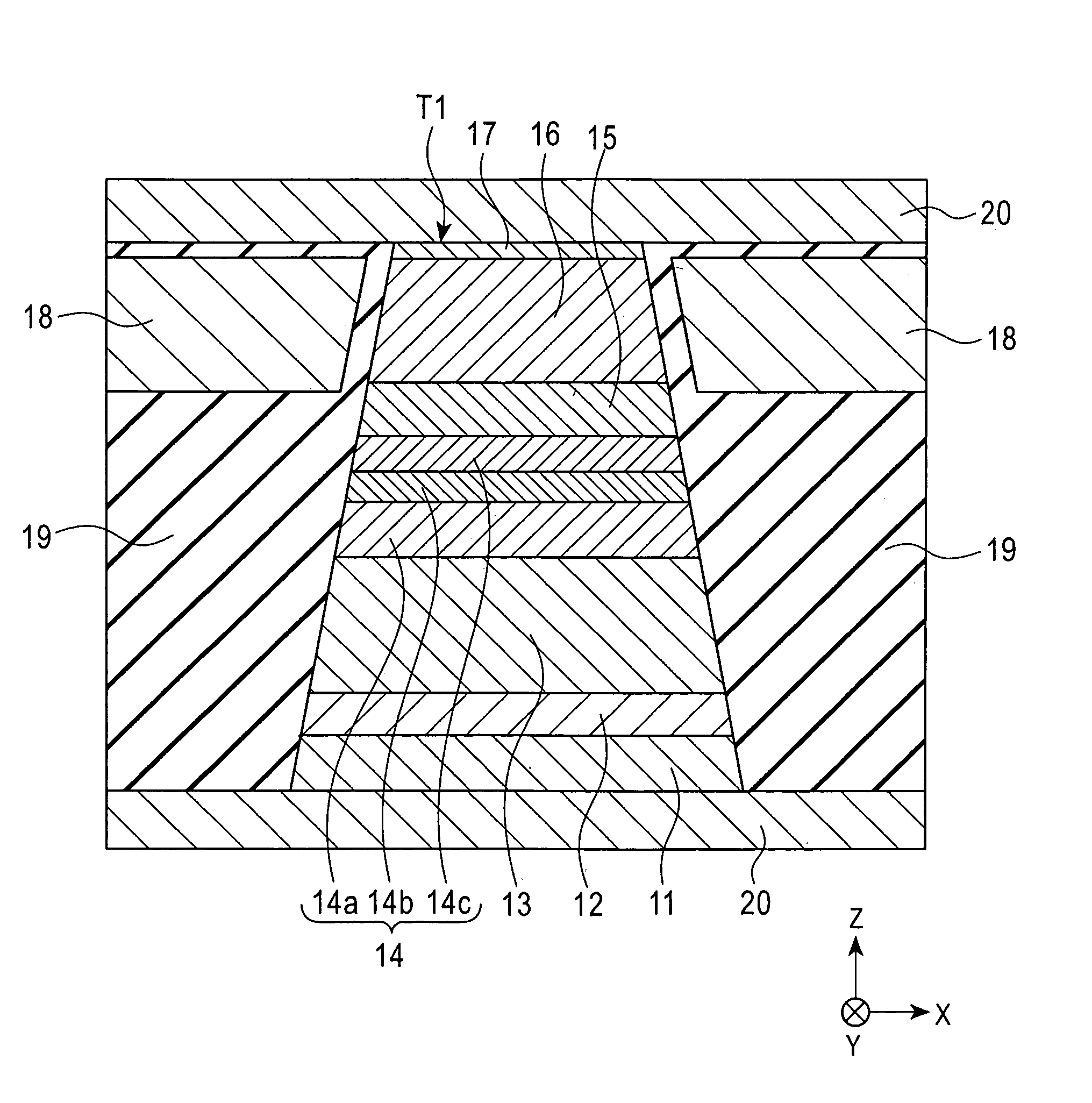

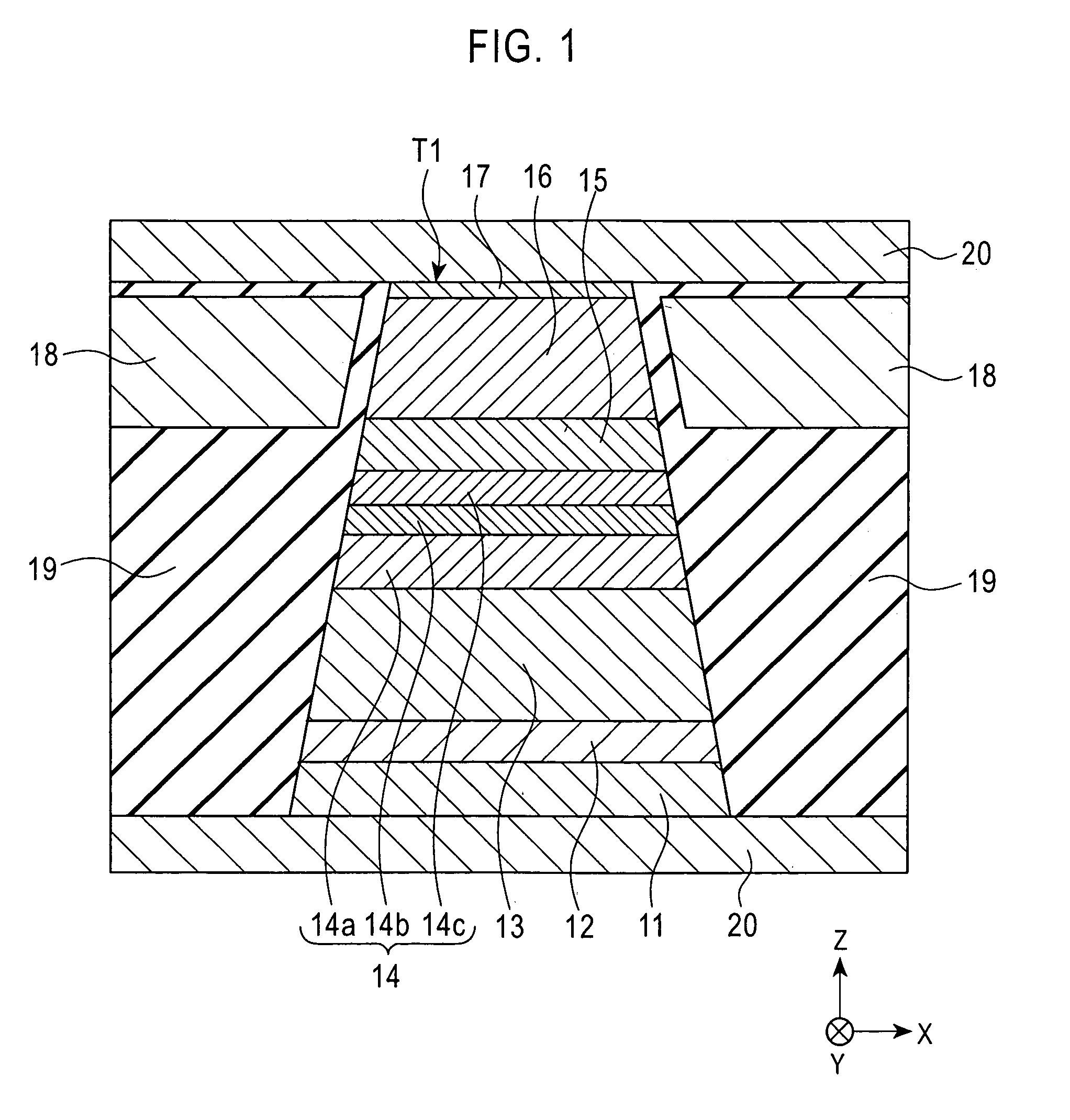

Current-perpendicular-to-plane magneto-resistance effect element

InactiveUS20160019917A1Maintain good propertiesInexpensive and high in performanceMagnetic measurementsNanoinformaticsGiant magnetoresistanceMagneto

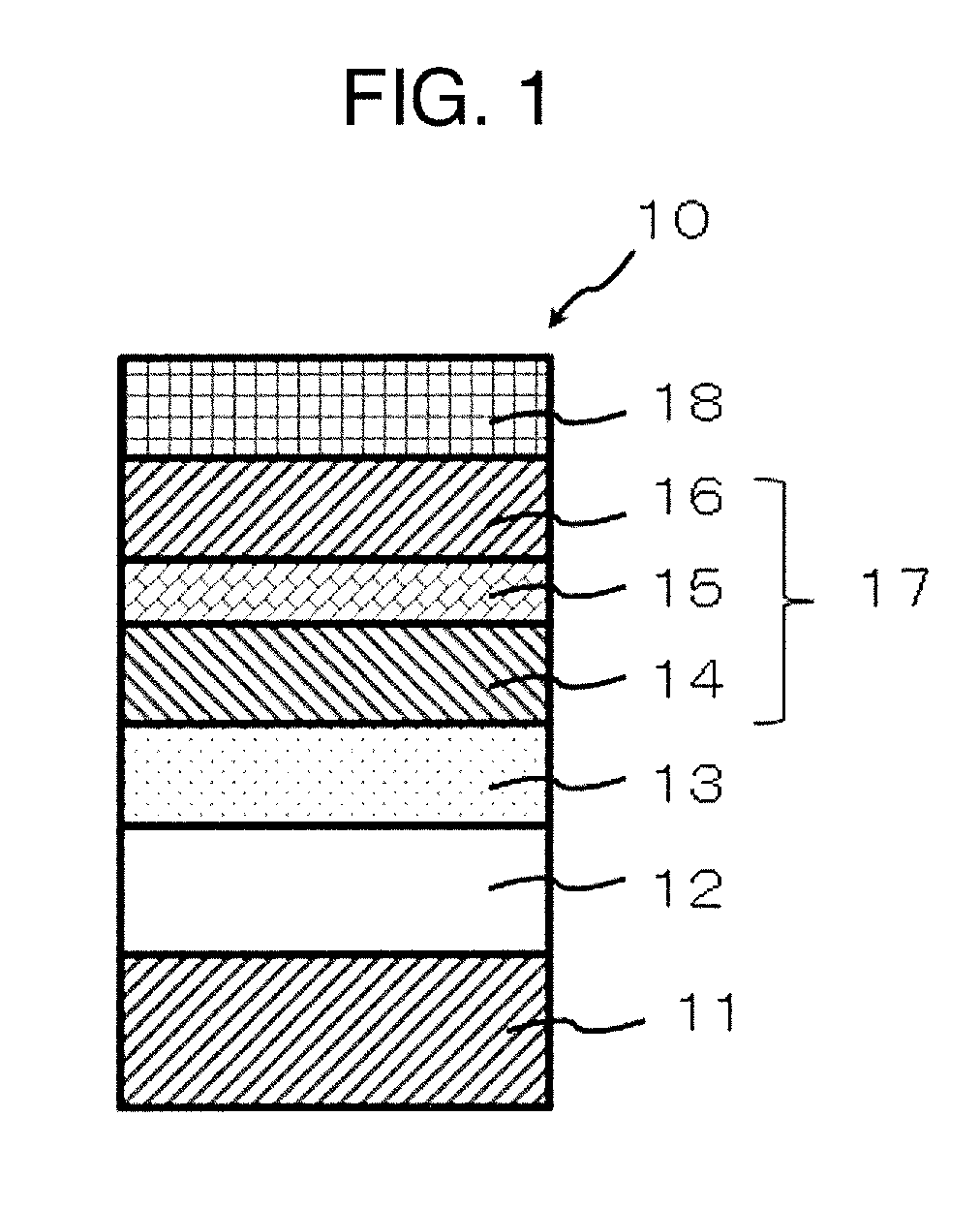

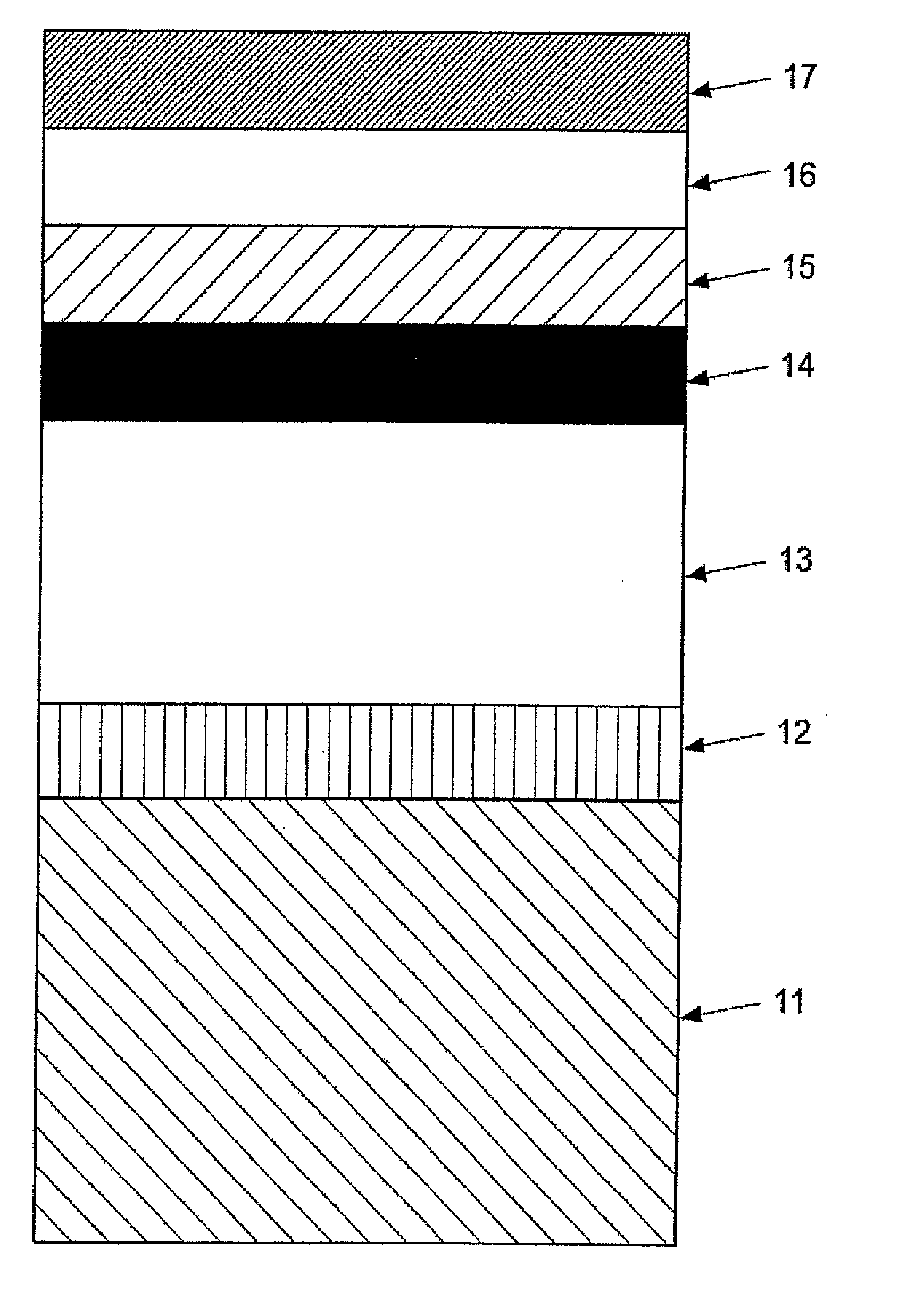

The CPPGMR element of the present invention has an orientation layer 12 formed on a substrate 11 to texture a Heusler alloy into a (100) direction, an underlying layer 13 that is an electrode for magneto-resistance measurement stacked on the orientation layer 12, a lower ferromagnetic layer 14 and an upper ferromagnetic layer 16 each stacked on the underlying layer 13 and made of a Heusler alloy, a spacer layer 15 sandwiched between the lower ferromagnetic layers 14 and the upper ferromagnetic layers 16, and a cap layer 17 stacked on the upper ferromagnetic layer 16 for surface-protection. This manner makes it possible to provide, inexpensively, an element using a current-perpendicular-to-plane giant magneto-resistance effect (CPPGMR) of a thin film having a trilayered structure of a ferromagnetic metal / a nonmagnetic metal / a ferromagnetic metal, thereby showing excellent performances.

Owner:NAT INST FOR MATERIALS SCI

Heusler alloy with insertion layer to reduce the ordering temperature for CPP, TMR, MRAM, and other spintronics applications

A spin valve structure is disclosed in which an AP1 layer and / or free layer are made of a laminated Heusler alloy having Al or FeCo insertion layers. The ordering temperature of a Heusler alloy such as Co2MnSi is thereby lowered from about 350° C. to 280° C. which becomes practical for spintronics device applications. The insertion layer is 0.5 to 5 Angstroms thick and may also be Sn, Ge, Ga, Sb, or Cr. The AP1 layer or free layer can contain one or two additional FeCo layers to give a configuration represented by FeCo / [HA / IL]nHA, [HA / IL]nHA / FeCo, or FeCo / [HA / IL]nHA / FeCo where n is an integer ≧1, HA is a Heusler alloy layer, and IL is an insertion layer. Optionally, a Heusler alloy insertion scheme is possible by doping Al or FeCo in the HA layer. For example, Co2MnSi may be co-sputtered with an Al or FeCo target or with a Co2MnAl or Co2FeSi target.

Owner:HEADWAY TECH INC

GMR spin valve structure using heusler alloy

A giant magnetoresistive spin valve sensor is provided in which first and second ferromagnetic layers comprise a Heusler alloy. A non-ferromagnetic spacer layer is positioned between the first and second ferromagnetic layers. The non-magnetic spacer layer has an energy band which is similar to the energy bands of the Heusler alloy of the first and second ferromagnetic layers to allow a giant magnetoresistive effect to occur.

Owner:SEAGATE TECH LLC

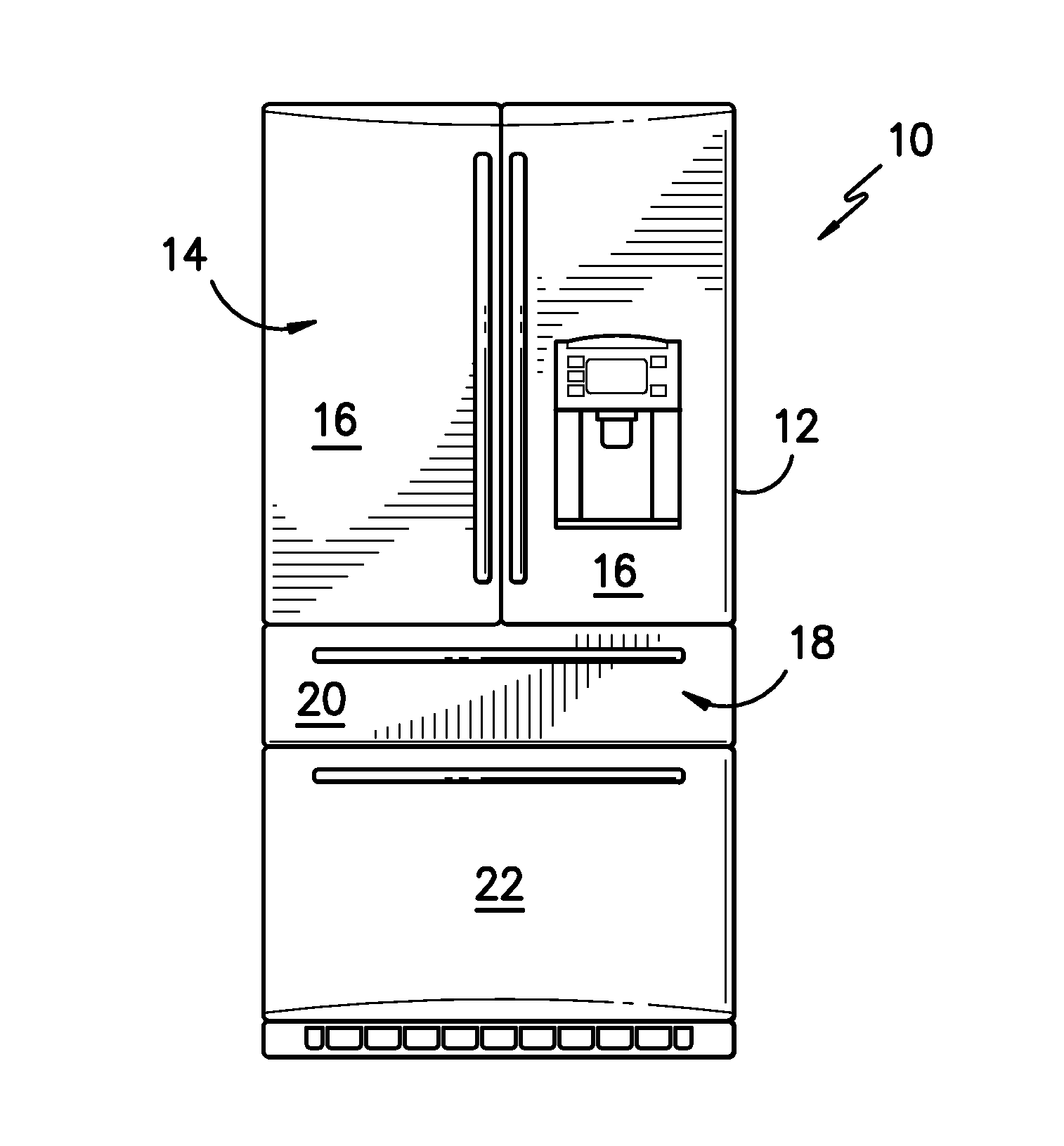

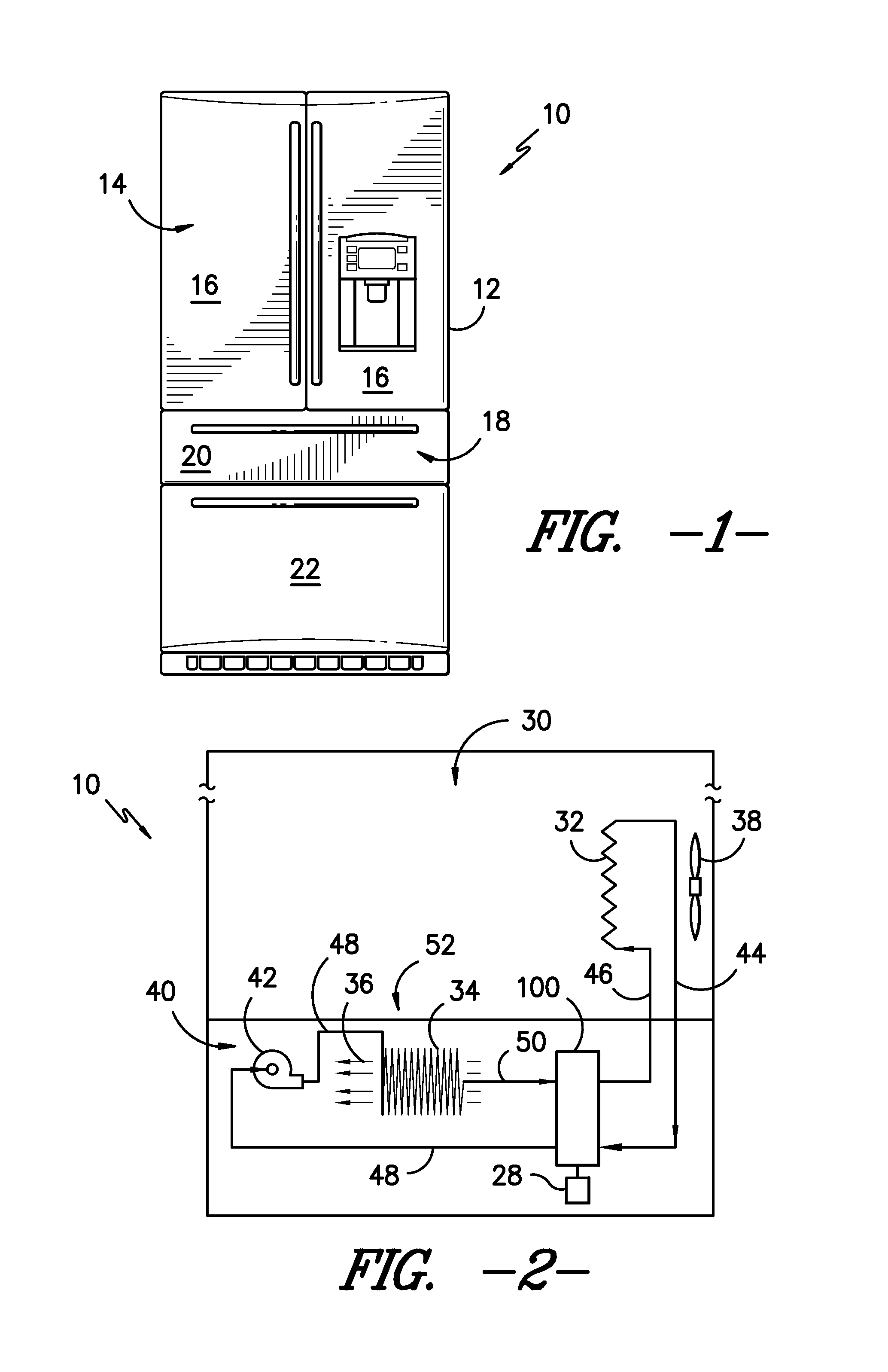

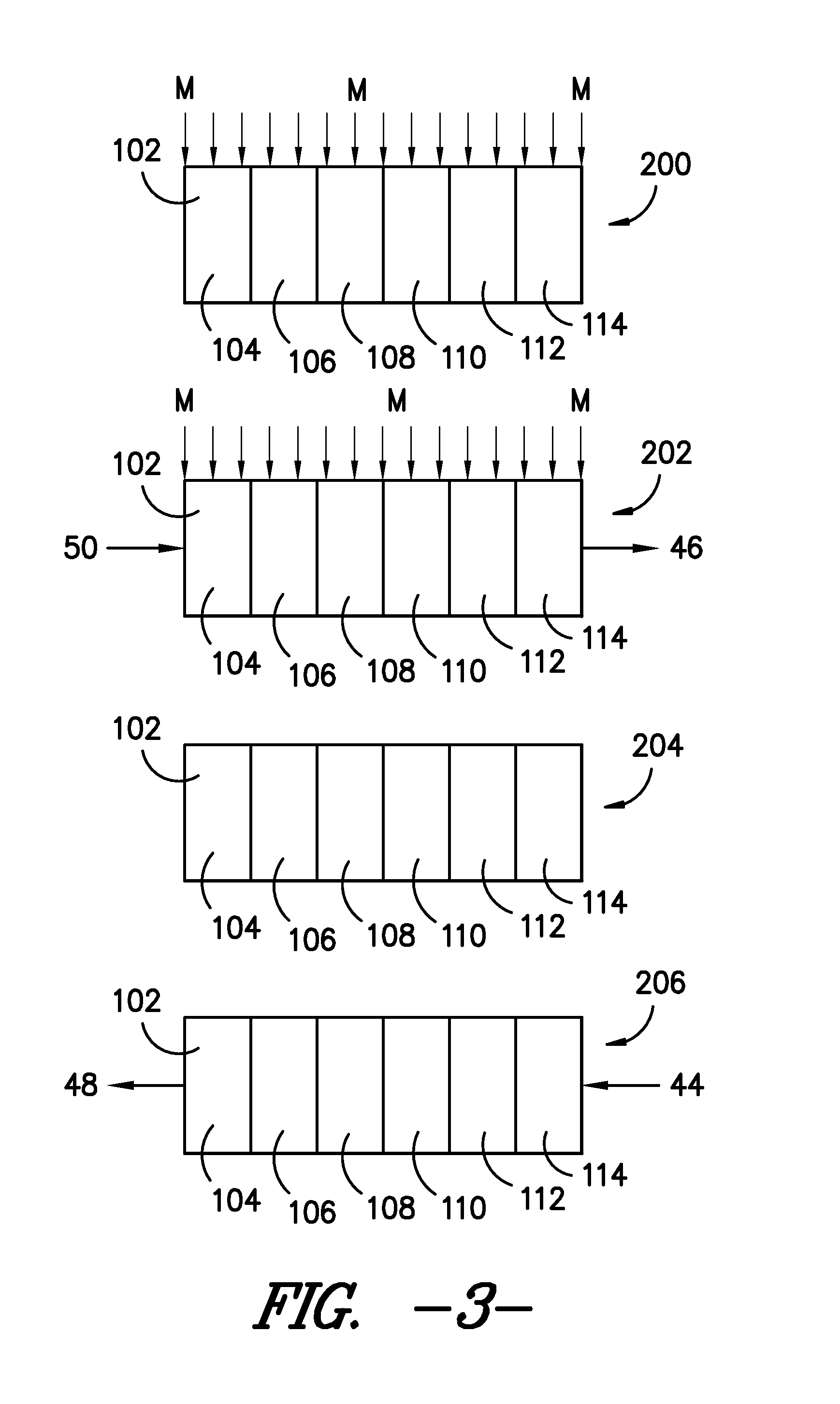

Novel magnetic refrigerant materials

InactiveUS20140157793A1Domestic refrigeratorsMachines using electric/magnetic effectsMagnetizationAlloy

A novel magneto caloric material (MCM) is provided that can be used in, for example, a regenerator of a heat pump, appliance, air conditioning system, and other heating and / or cooling devices. The MCM is a type of Heusler alloy, has an L21 crystal structural prototype, and can undergo a reversible phase transformation between a low temperature, low magnetization Martensite phase and a high temperature, high magnetization Austenite phase to exhibit an inverse magneto caloric effect upon application of a sufficient magnetic field. A process of annealing of the alloy is also provided that can be used to adjust the temperature at which this phase transformation occurs. The present invention includes the alloy as subjected to such annealing.

Owner:HAIER US APPLIANCE SOLUTIONS INC

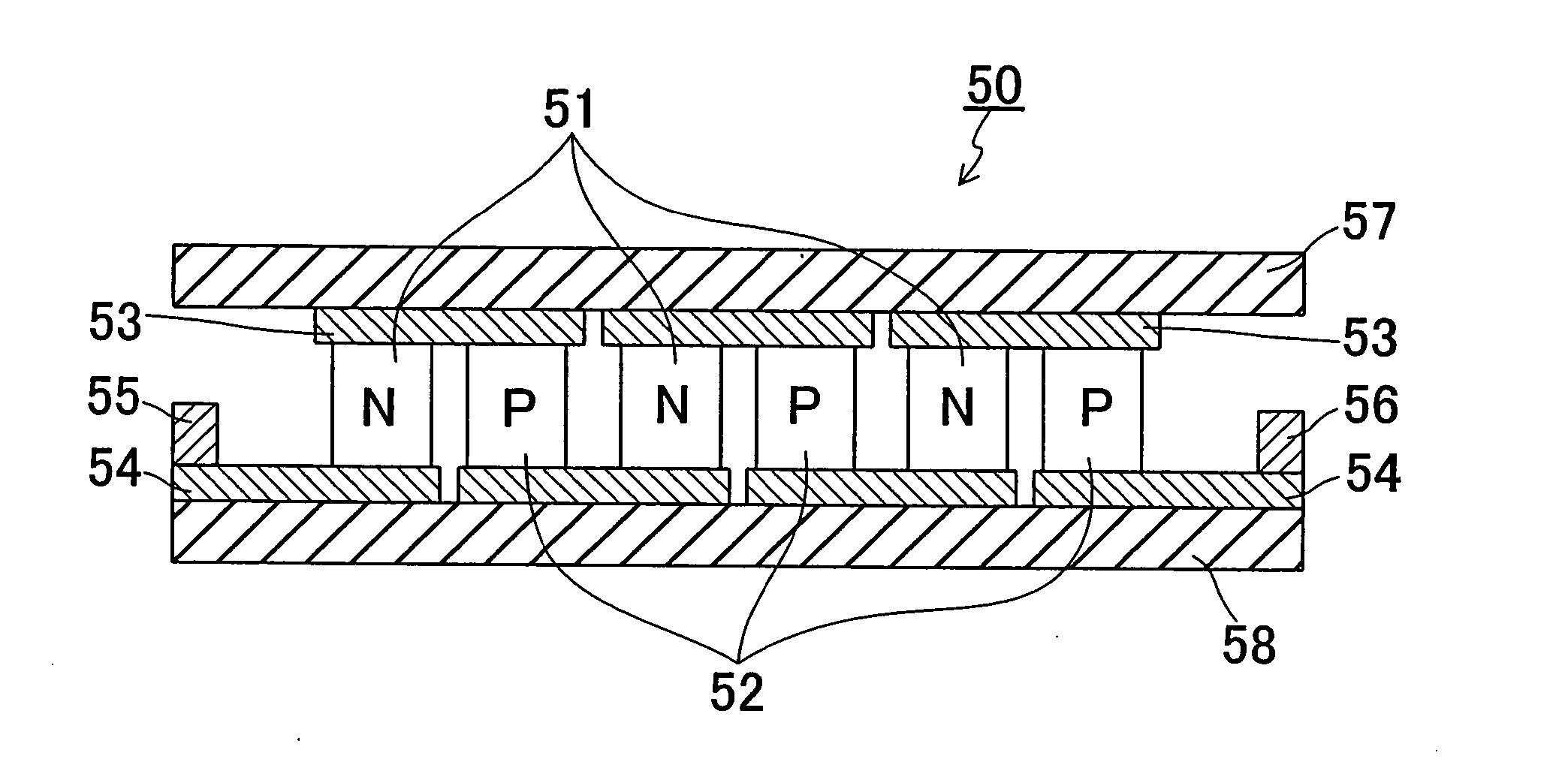

Thermoelectric conversion material, thermoelectric conversion element using the material, and electric power generation method and cooling method using the element

InactiveUS20040261833A1Improve featuresImprove thermoelectric performanceThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentIridiumIndium

The present invention provides a thermoelectric conversion material including a half-Heusler alloy represented by the formula QR(L1-pZp), where Q is at least one element selected from group 5 elements, R is at least one element selected from cobalt, rhodium and iridium, L is at least one element selected from tin and germanium, Z is at least one element selected from indium and antimony, p is a numerical value that is equal to or greater than 0 and less than 0.5. A preferable example of the half-Heusler alloy is NbCo(Sn1-pSbp). The thermoelectric conversion material according to the present invention is n-type, and therefore, it is desired that the material is combined with a p-type thermoelectric conversion material to make a thermoelectric conversion element.

Owner:PANASONIC CORP

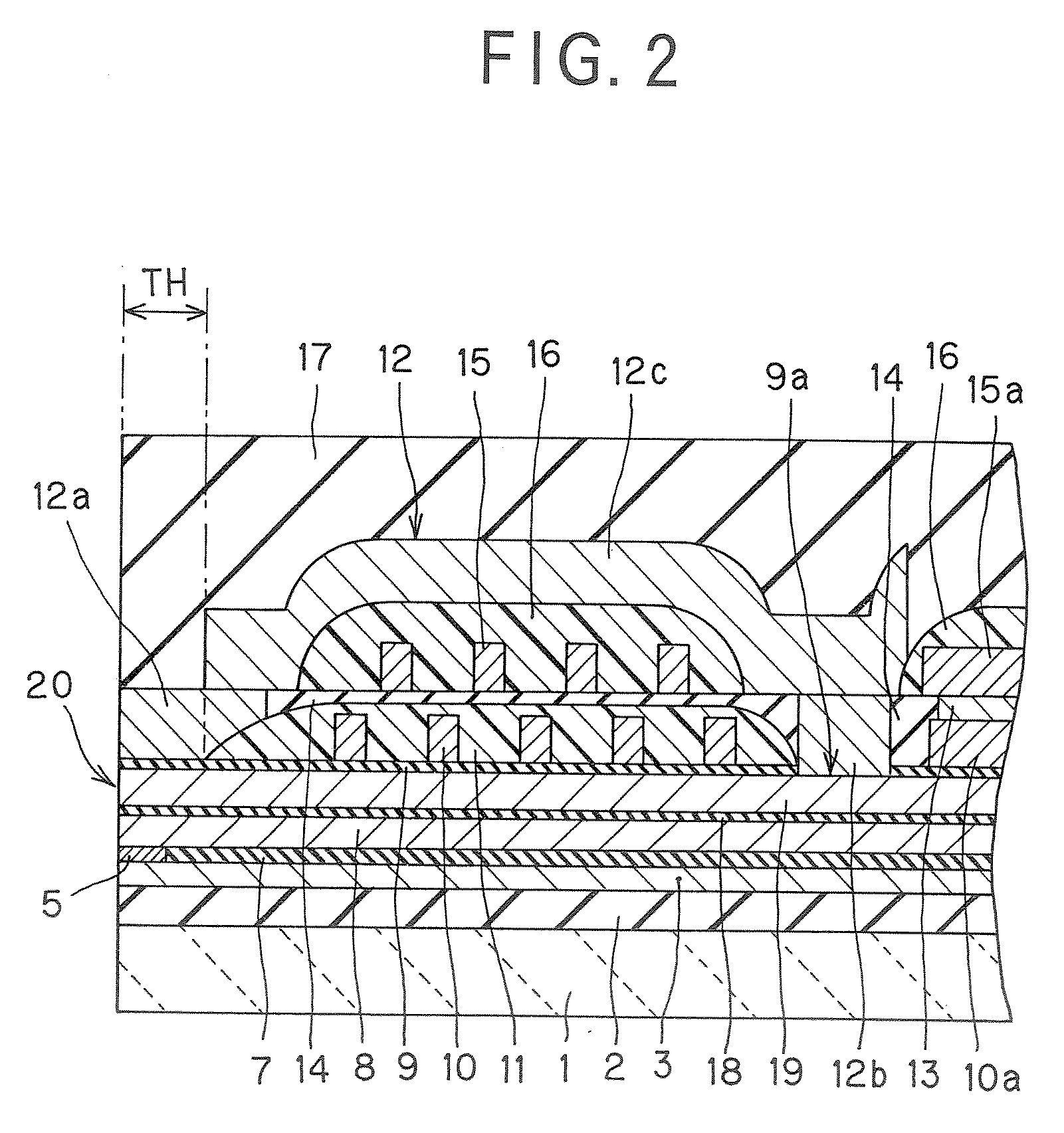

Magnetic sensing element including pinned layer and/or free layer composed of [110] crystal planes-oriented heusler alloy

InactiveUS20050074634A1Raise the ratioSufficient crystalline structureMagnetic-field-controlled resistorsHeads using thin filmsAlloyCrystal plane

A magnetic sensing element using a thin film composed of an adequately crystallized Heusler alloy is provided. At least one of free magnetic layer and pinned magnetic layer includes a Heusler alloy layer. The Heusler alloy layer has a body-centered cubic (bcc) structure, in which equivalent crystal planes represented as [220] planes are preferentially oriented in the direction parallel to the layer surface. The Heusler alloy layer is disposed on a bcc layer having a body-centered cubic (bcc) structure, in which equivalent crystal planes represented as [110] planes are preferentially oriented in the direction parallel to the layer surface.

Owner:ALPS ALPINE CO LTD

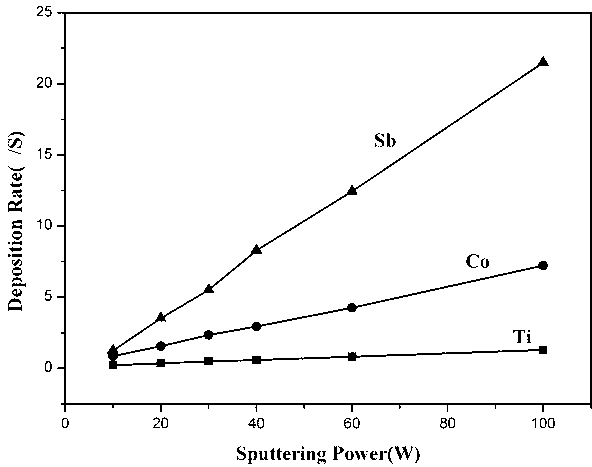

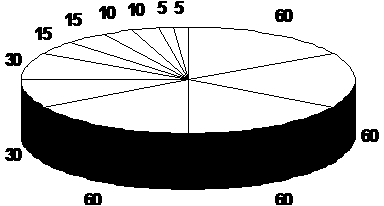

Design method for composite target for magnetron sputtering

InactiveCN103255385AReduce manufacturing costThe composition of the film is uniformVacuum evaporation coatingSputtering coatingSputteringComposite film

The invention discloses a design method for a composite target for magnetron sputtering and relates to the fields of magnetron sputtering techniques and preparation techniques of functional films of inorganic compounds. The composite target is formed by uniformly and alternatively splicing simple-substance sheet targets, being divided into 5-degree, 10-degree, 30-degree and 60-degree fan-shaped sections, of each component according to certain angles, wherein the components are uniform in ingredient proportion, are stable and are easy to change; and the ingredients of the composite target can be adjusted by adjusting the angles of the fan-shaped sections of each component so as to adjust the stoichiometric ratio of a compound film, and the ingredients of the compound film obtained by utilizing sputtering are uniform. The design method is especially suitable for film preparation of Heusler compounds and half Heusler compounds which have brittleness and are difficultly prepared into the compound targets accordant with the stoichiometric ratio because the differences among the melting points of the components are relatively large or the ingredients of the partial components are easy to segregate and is a novel composite target design method for co-sputtering growing of the compound film or the composite film without utilizing a multi-target co-sputtering method.

Owner:SHANGHAI UNIV

Thermoelectric material and method of manufacturing the material

ActiveUS20100147352A1Reduce compoundingReduce conductivityThermoelectric device junction materialsThermoelectric materialsRare-earth element

The present invention provides a thermoelectric material and a method of manufacturing it. The thermoelectric material contains a half-Heusler compound including a composition represented by: (Ti1-aAa)1+x(Ni1-bBb)1+y(Sn1-cCc) where 0≦a<0.1, 0≦b<0.1 and 0≦c<0.1; −0.1≦x≦0.2 and 0<y≦0.2; A is one or more elements selected from the group consisting of group IIIa elements, group IVa elements (excluding Ti), group Va elements and rare earth elements; B is one or more elements selected from the group consisting of group VIIIa elements (excluding Ni) and group Ib elements; and C is one or more elements selected from the group consisting of group IIIb elements, group IVb elements (excluding Sn) and group Vb elements, wherein amounts of Zr substitution and Hf substitution at Ti sites of the half-Heusler compound are less than 1 at %, respectively.

Owner:TOYOTA CENT RES & DEV LAB INC

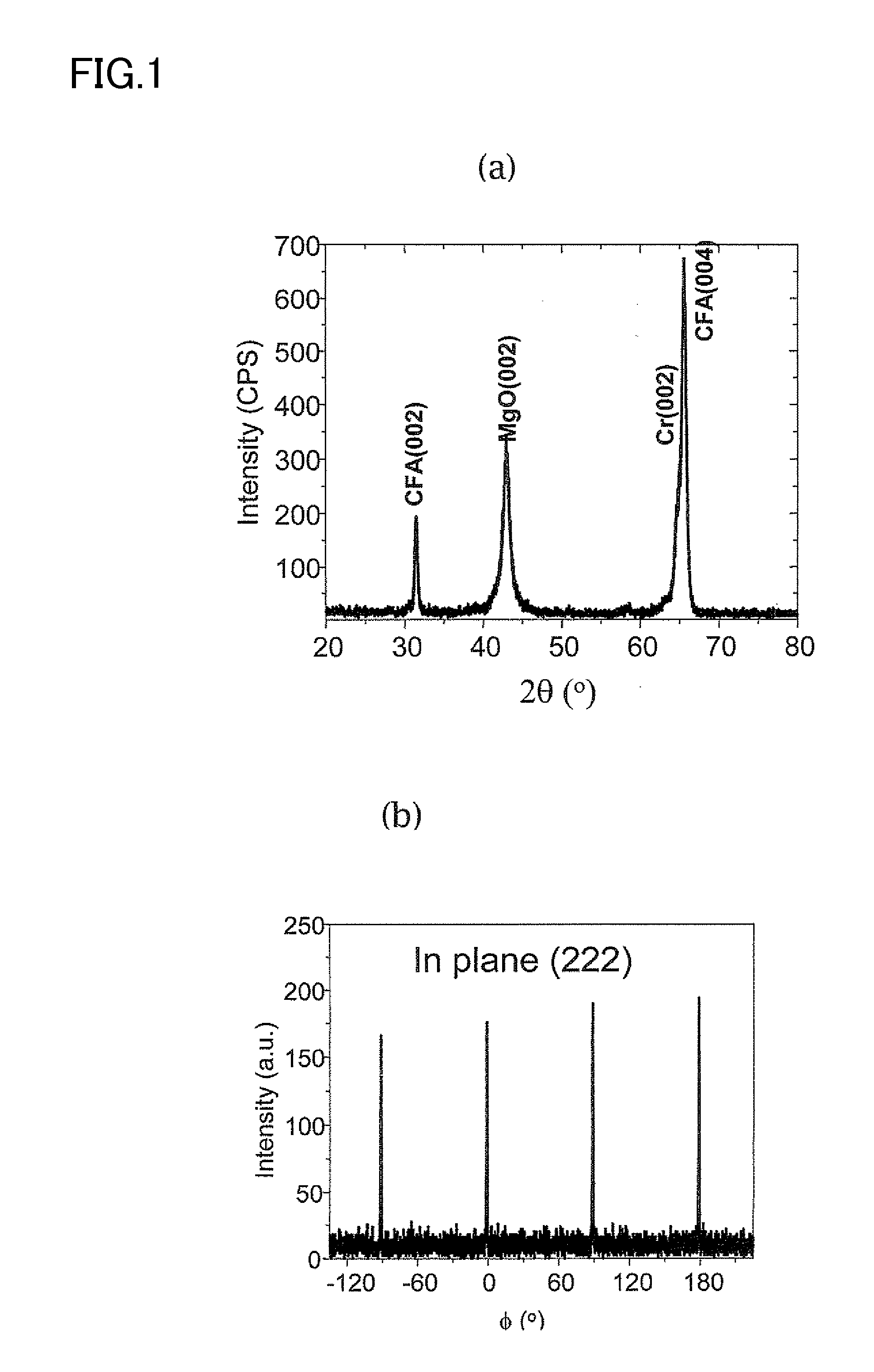

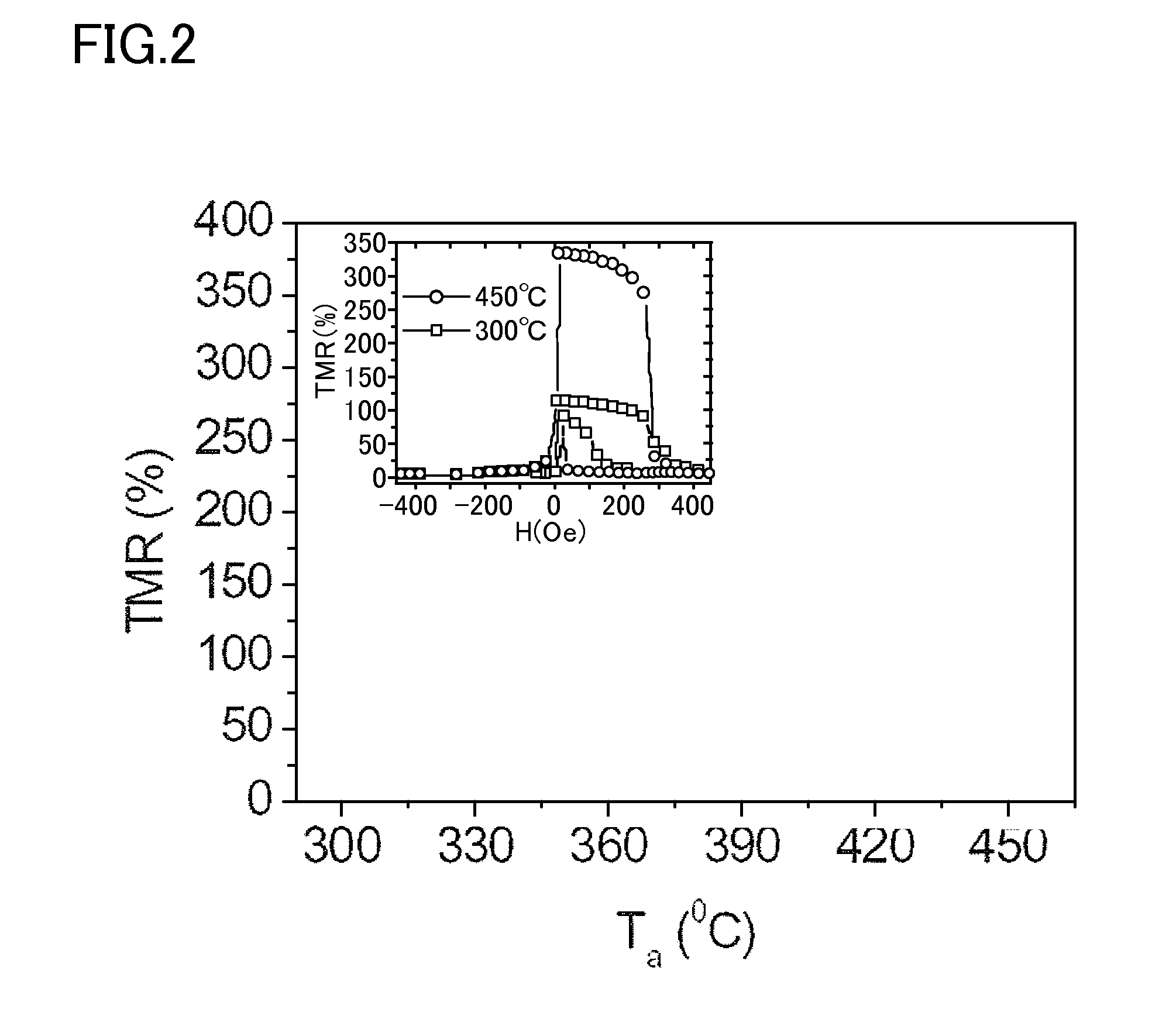

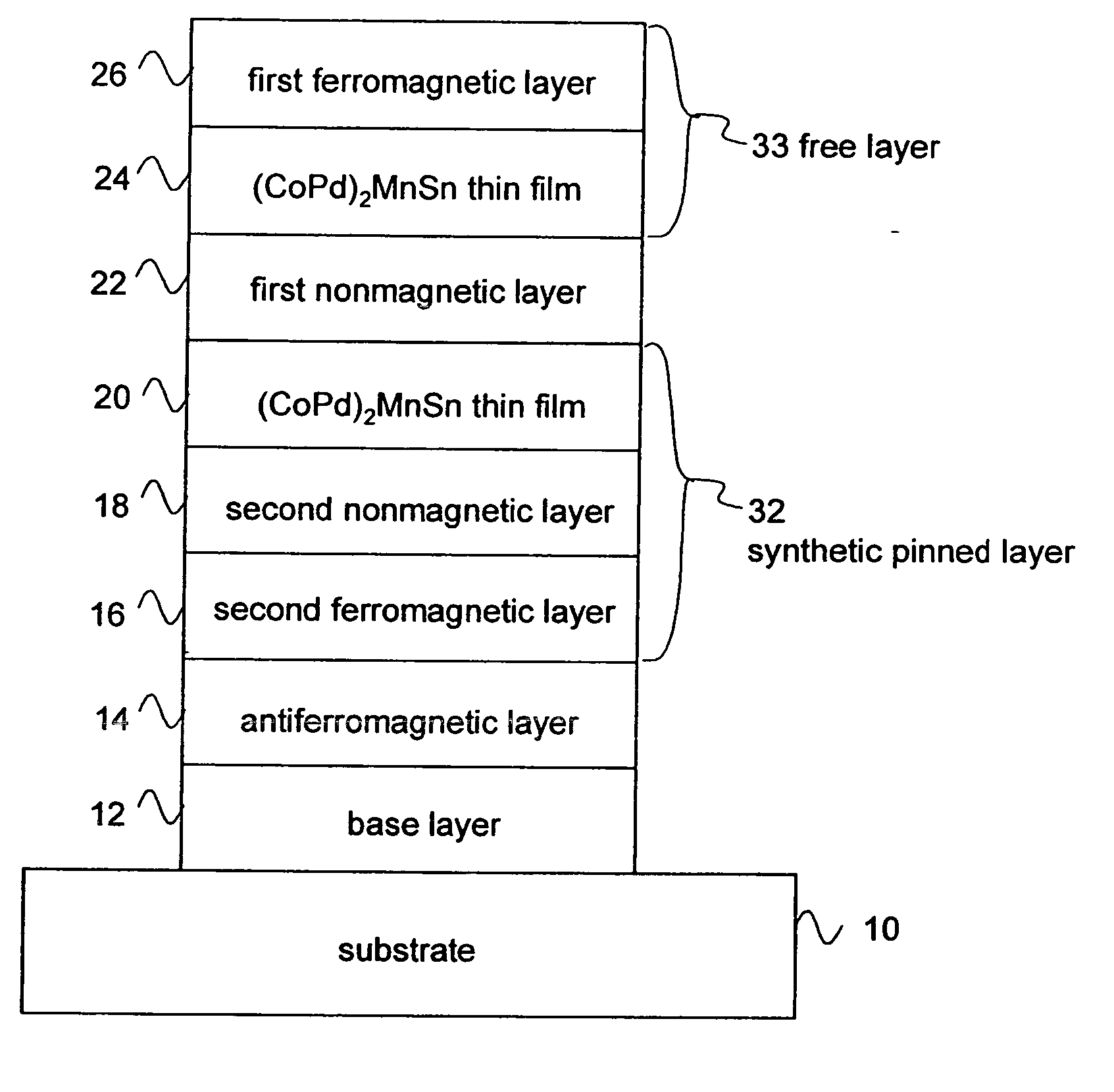

Ferromagnetic tunnel junction structure and magnetoresistive element using the same

InactiveUS20120112299A1Large TMRGood lattice misfitNanomagnetismMagnetic measurementsHalf-metalMagnetic reluctance

For the present ferromagnetic tunnel junction structure, employed is a means characterized by using an MgO barrier and using a Co2FeAl full-Heusler alloy for any of the ferromagnetic layers therein. The ferromagnetic tunnel junction structure is characterized in that Co2FeAl includes especially a B2 structure and one of the ferromagnetic layers is formed on a Cr buffer layer. The magnetoresistive element is characterized in that the ferromagnetic tunnel junction structure therein is any of the above-mentioned ferromagnetic tunnel junction structure. Accordingly, a large TMR, especially a TMR over 100% at room temperature can be attained, using Co2FeAl having a smallest α though not a half-metal.

Owner:NAT INST FOR MATERIALS SCI

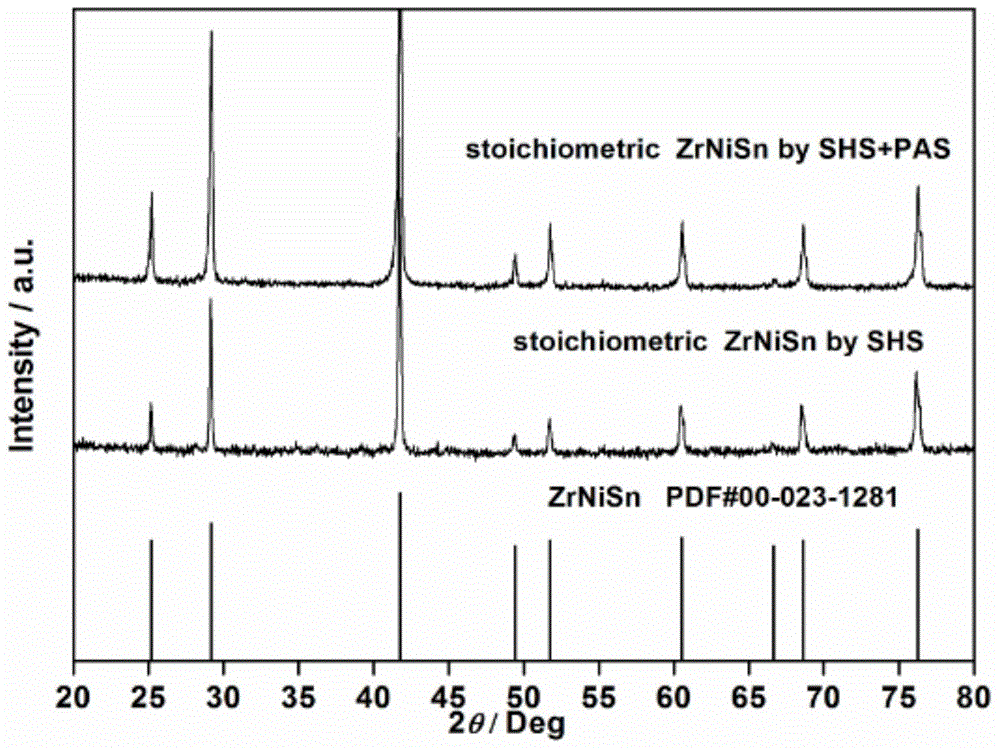

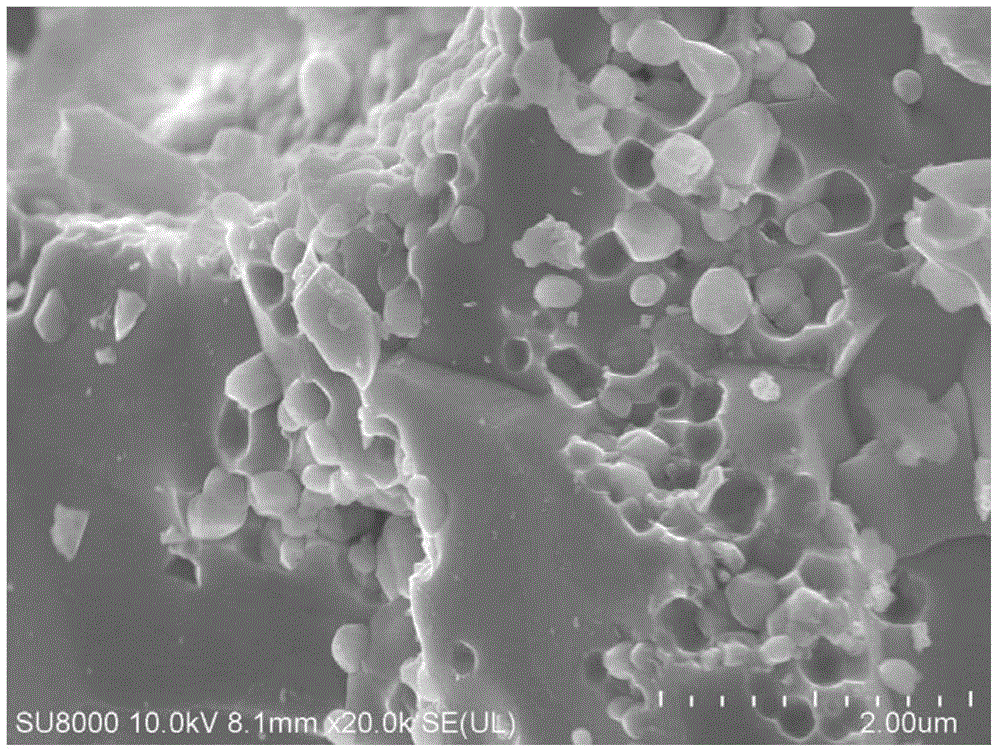

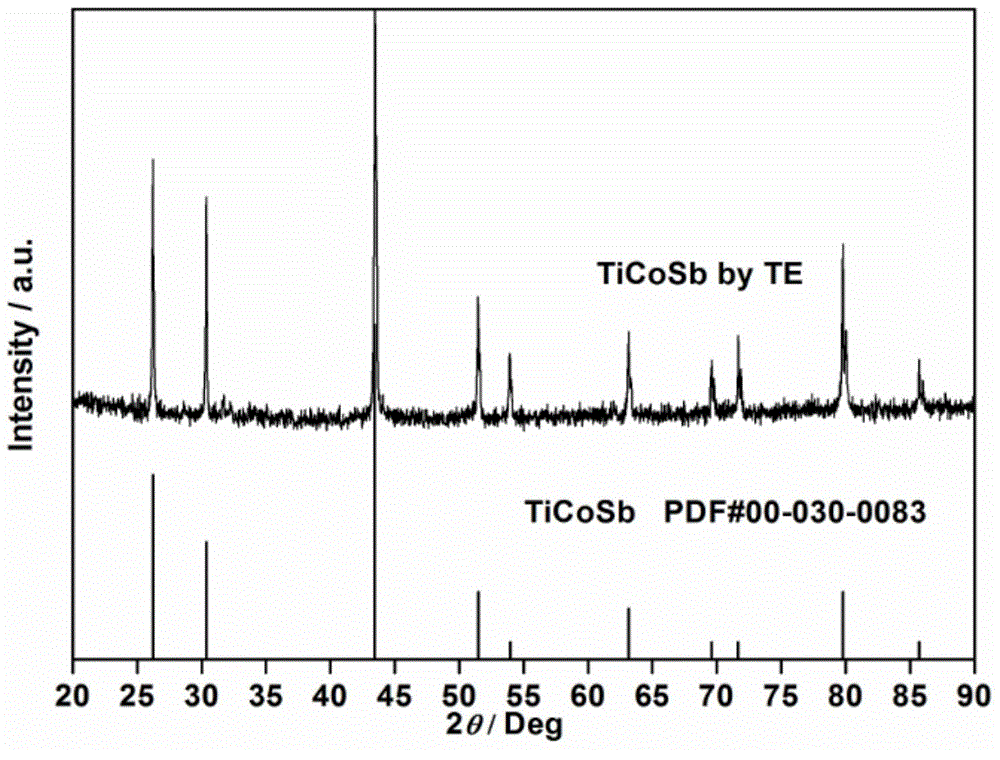

Method for preparing high-performance Half-Heusler block thermoelectric materials at ultrahigh speed and low cost

ActiveCN103934459AImprove performanceShort preparation timeThermoelectric device junction materialsThermoelectric materialsCombustion

The invention provides a method for preparing high-performance Half-Heusler block thermoelectric materials at ultrahigh speed and low cost. The method particularly includes the steps that firstly, according to the general formula ABX of Half-Heusler compounds, powder A, powder B and powder X are weighed at the chemical stoichiometric ratio of 1:1:1, used as raw materials and uniformly mixed, and then an reactant is acquired; secondly, the reactant generates a combustion synthesis reaction, and cooling or quenching is conducted after the reaction is finished; thirdly, a product acquired through the second step is ground into fine powder, then PAS is conducted, and then the high-performance Half-Heusler block thermoelectric materials are acquired. According to the method, by the combination of the combustion synthesis reaction with the PAS process, the high-performance Half-Heusler block thermoelectric materials can be prepared within 15 min, and the method has the advantages that preparation time is short, energy consumption is low, the process is simple, the requirement for equipment is low, repeatability is good, and the method is suitable for large-scale production.

Owner:WUHAN UNIV OF TECH

Magnetic sensing element including magnetic layer composed of Heusler alloy disposed on underlayer having {111}-oriented fcc structure

InactiveUS7310207B2Reduce interfaceDecrease spin-independent scatteringNanomagnetismMagnetic measurementsAlloyCrystal plane

A magnetic sensing element using a Heusler alloy is provided. In the magnetic sensing element, a free magnetic layer composed of a Heusler alloy layer is disposed on a nonmagnetic layer that corresponds to an fcc layer having the face-centered cubic (fcc) structure. Equivalent crystal planes represented as [111] planes in the fcc structure, which are the closest packed planes, are exposed on the surface of the nonmagnetic layer.

Owner:ALPS ALPINE CO LTD

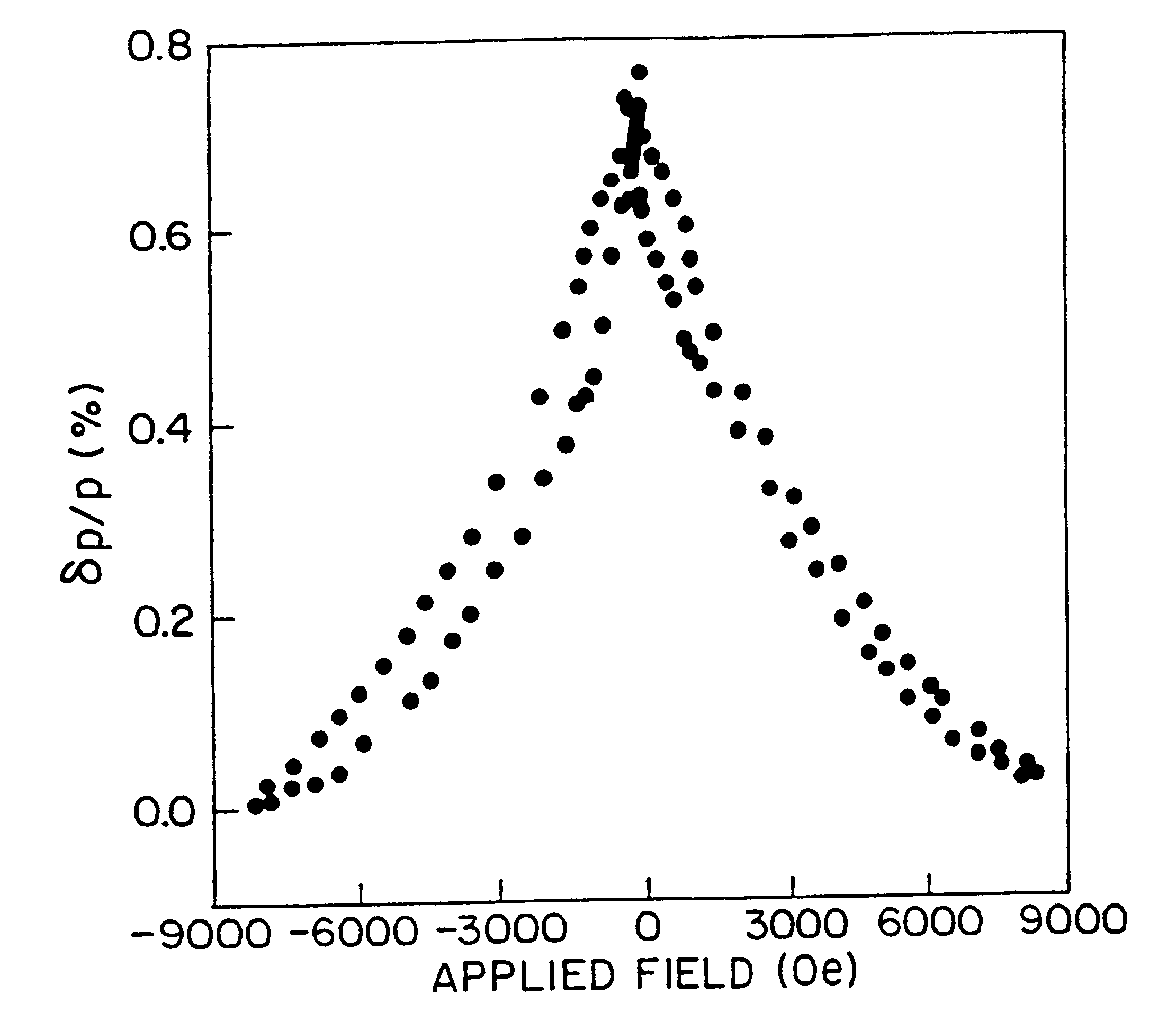

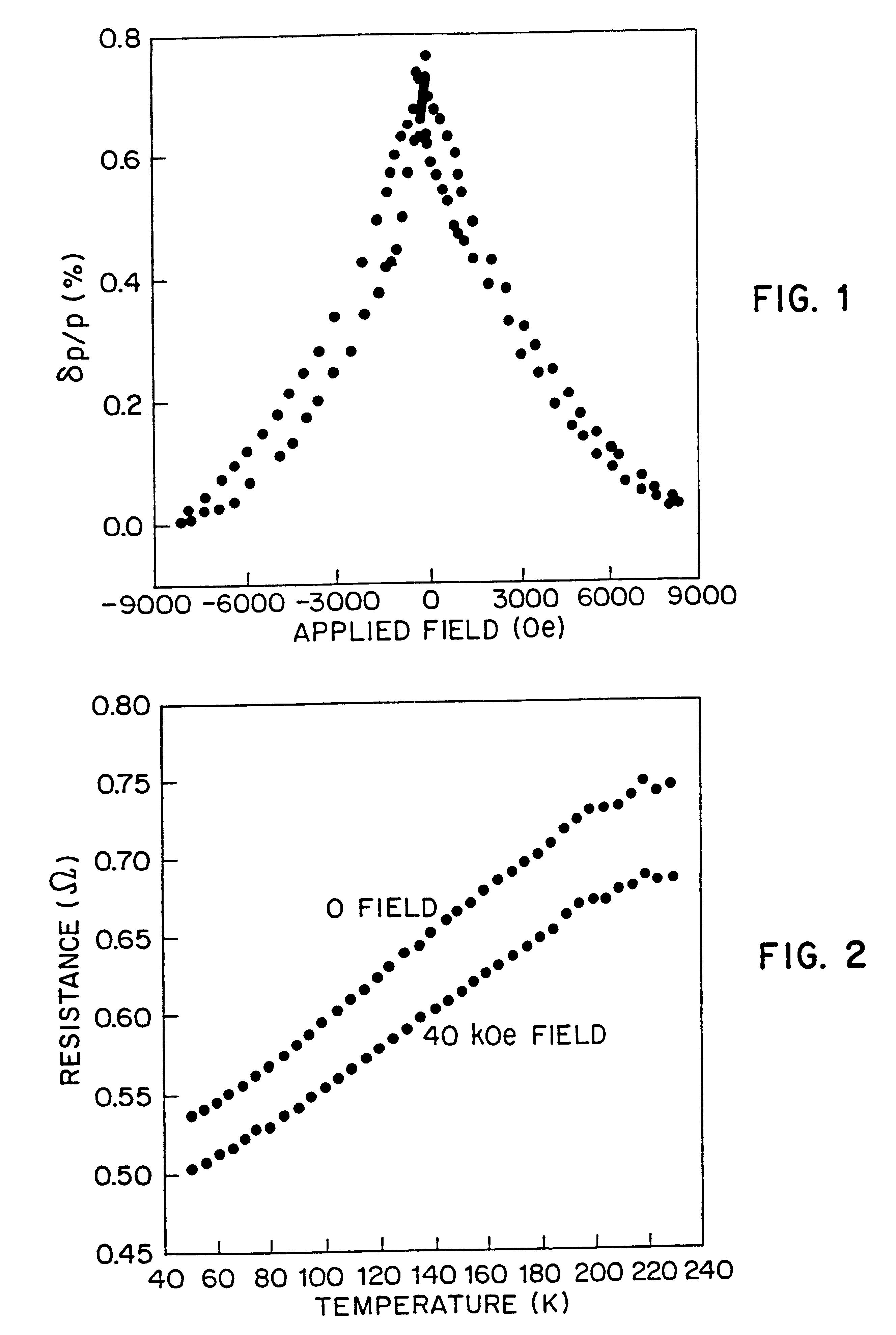

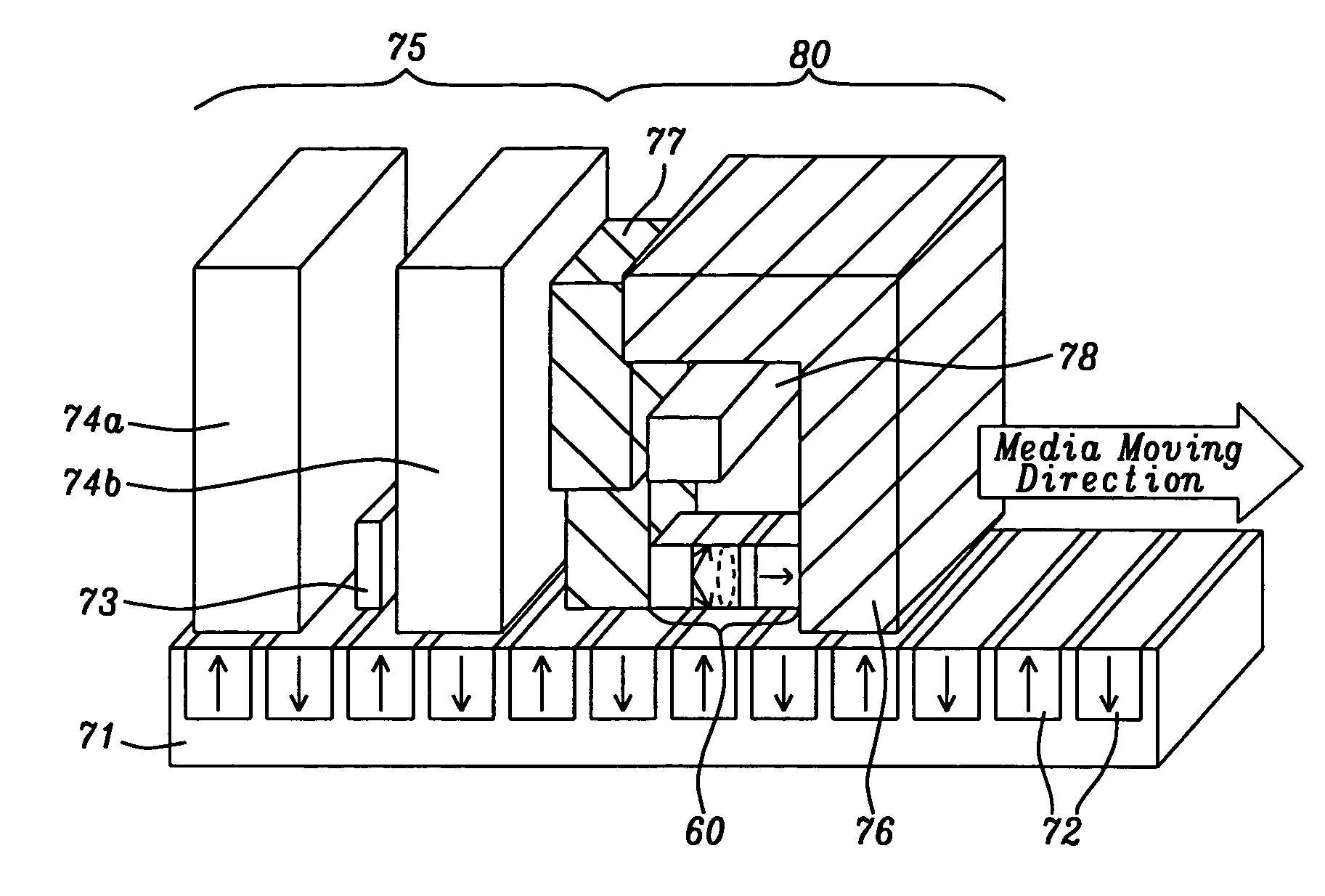

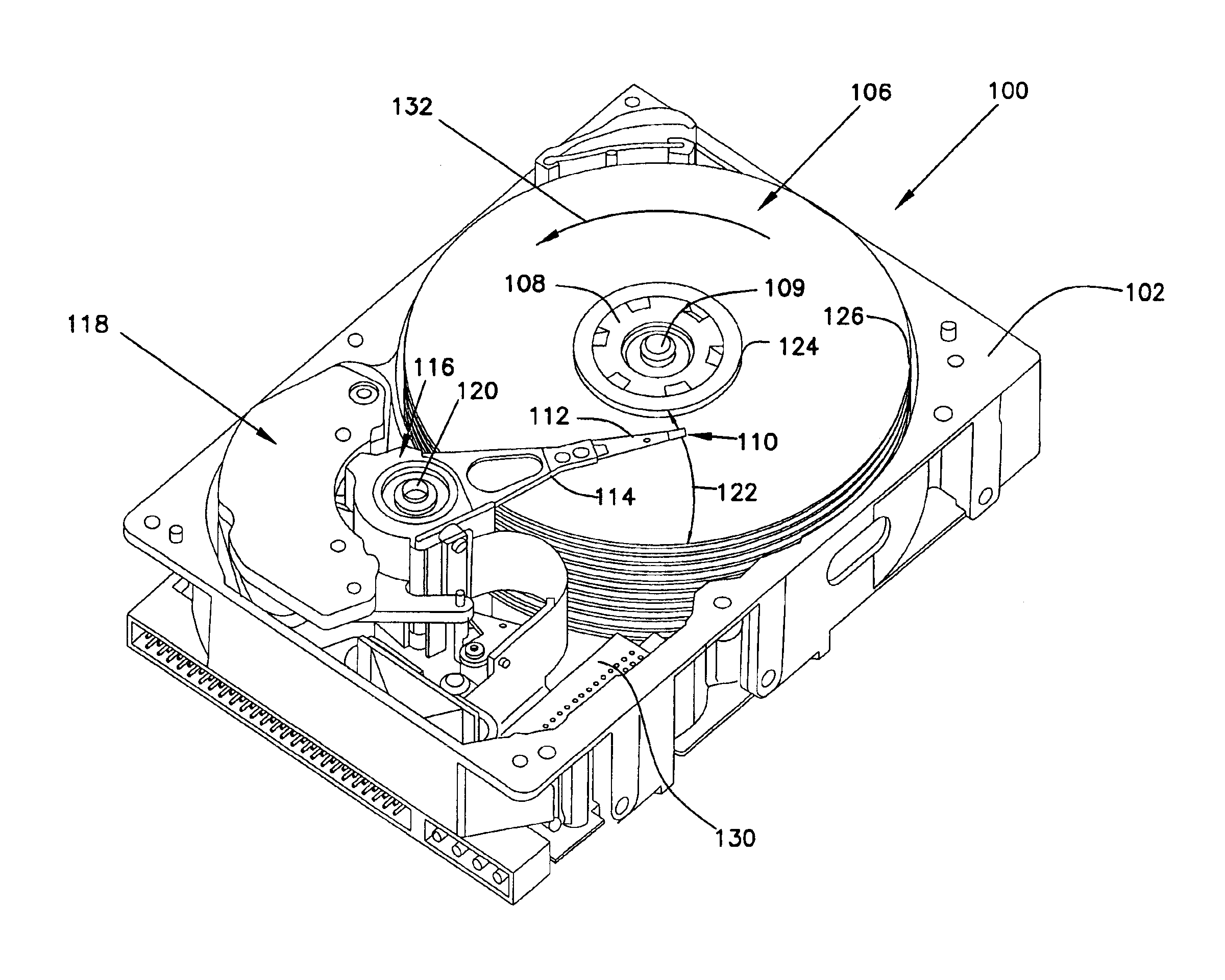

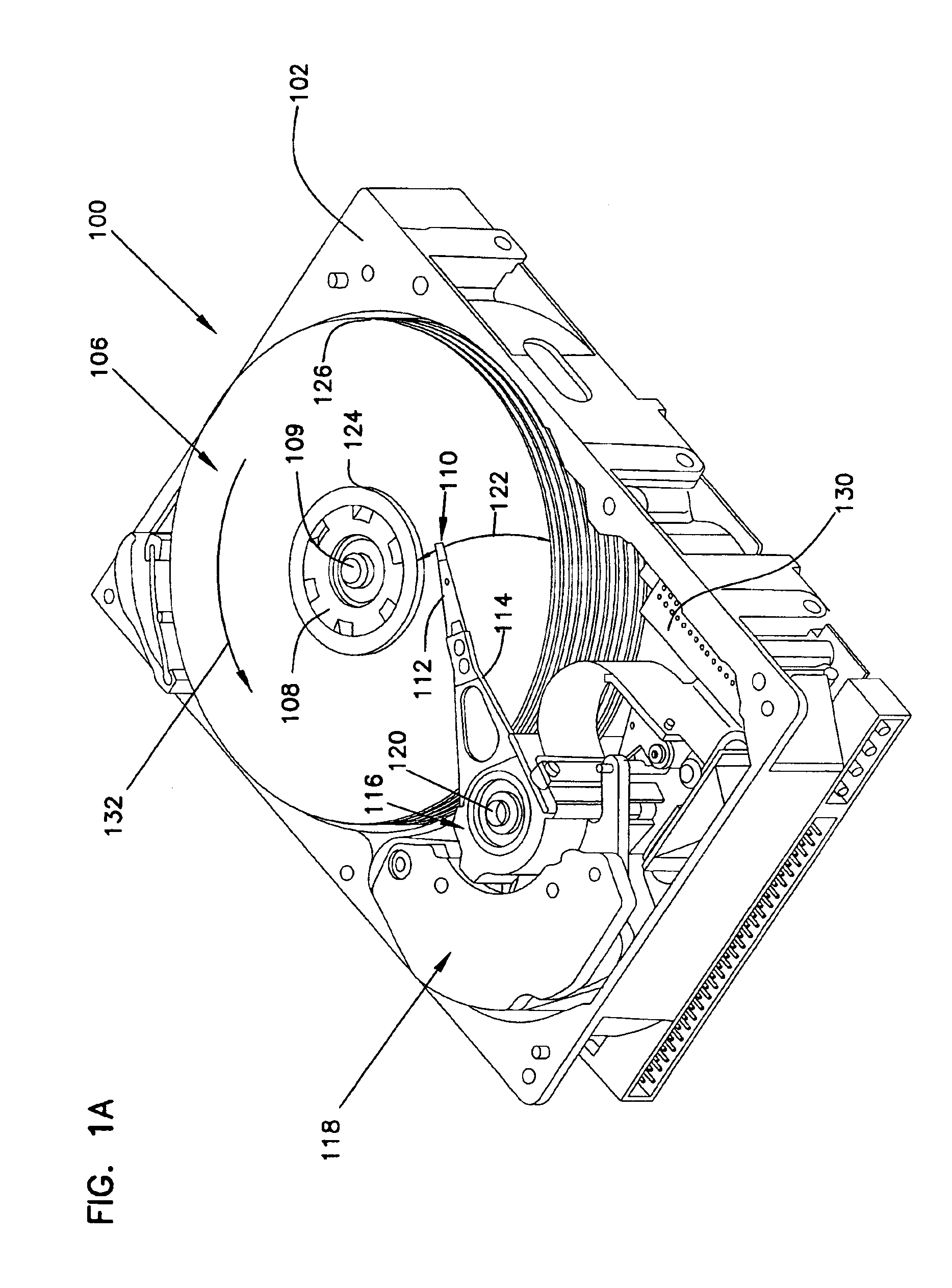

Magnetoresistive material with two metallic magnetic phases

A magnetoresistive material with two metallic magnetic phases. The material exhibits the giant magnetoresistance effect (GMR). A first phase of the material includes a matrix of an electrically conductive ferromagnetic transition metal or an alloy thereof. A second precipitate phase exhibits ferromagnetic behavior when precipitated into the matrix and is antiferromagnetically exchange coupled to the first phase. The second precipitate phase can be electrically conductive rare earth pnictide or can be a Heusler alloy. A method of manufacturing magnetoresistive materials according to the present invention employs facing targets magnetron sputtering. The invention also includes a method of detecting magnetic field strength by providing a read head including a portion of one of the magnetoresistive materials according to the invention, exposing the read head to the magnetic field of a magnetic recording medium, sensing electrical resistivity of the portion of material associated with the magnetic field of the magnetic recording medium, and converting the electrical resistivity into a signal which is indicative of the magnetic field strength of the magnetic field associated with the magnetic recording medium. A digital magnetic recording system, according to the present invention, is adapted for use with a magnetic recording medium having a characteristic coercive force and a plurality of stored bits thereon. The bits are stored by magnetic field strength levels of a magnetic field associated with the medium. The system can include a conventional write head and a controller. The system can also include a read head including a portion of magnetoresistive material according to the present invention which is located in proximity to the medium and a suitable resistivity sensor.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

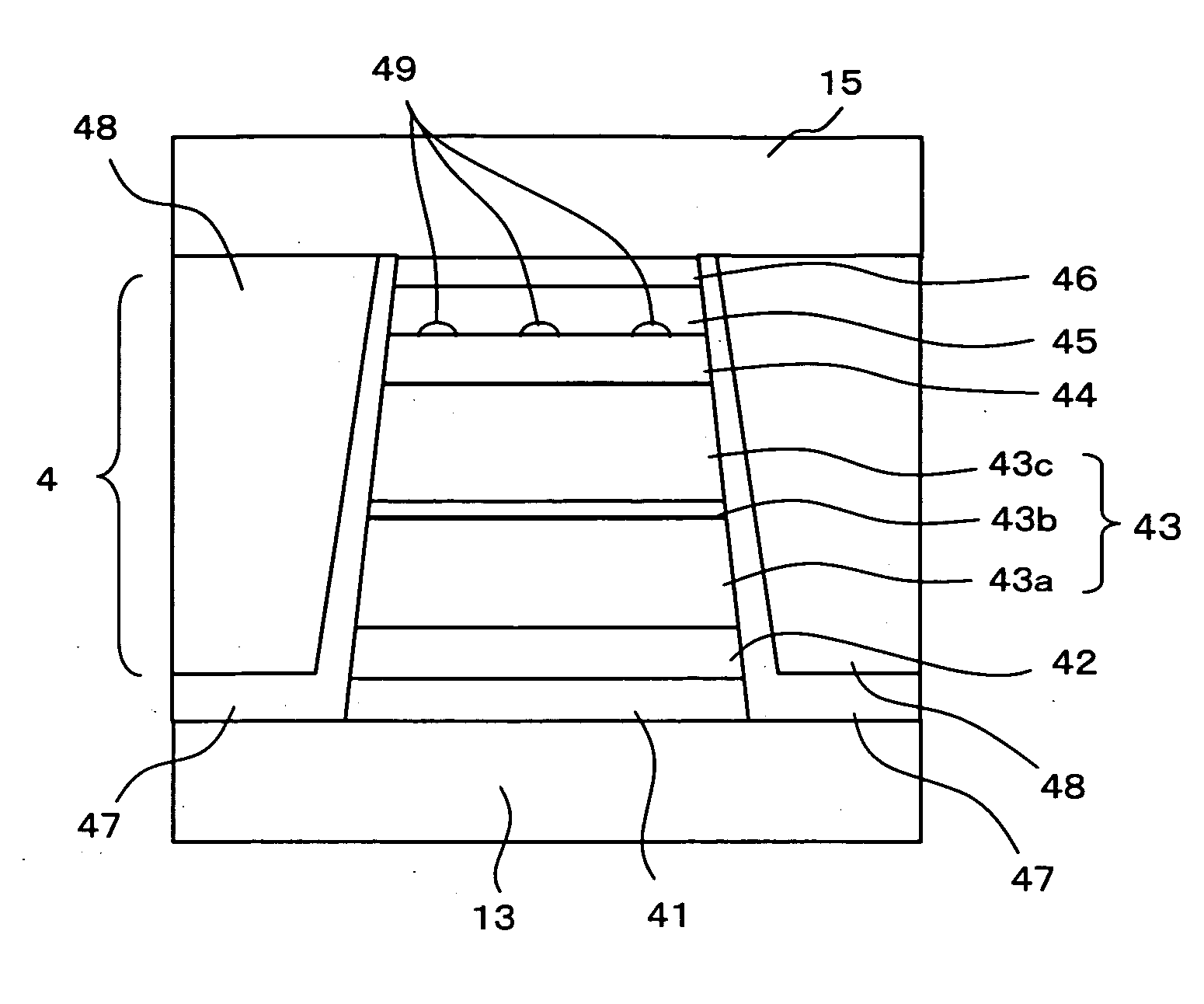

Magneto-resistive effect device, thin-film magnetic head, head gimbal assembly, and hard disk system

ActiveUS20080019060A1Inhibited DiffusionReduce polarizabilityNanomagnetismMagnetic measurementsDiffusionMagnetization

The invention provides a magneto-resistive effect device having a CPP (current perpendicular to plane) structure comprising a nonmagnetic spacer layer, and a fixed magnetized layer and a free layer stacked one upon another with said nonmagnetic spacer layer sandwiched between them, with a sense current applied in a stacking direction, wherein said free layer functions such that its magnetization direction changes depending on an external magnetic field, and is made up of a multilayer structure including a Heusler alloy layer, wherein an Fe layer is formed on one of both planes of said Heusler alloy layer in the stacking direction, wherein said one plane is near to at least a nonmagnetic spacer layer side, and said fixed magnetization layer is made up of a multilayer structure including a Heusler alloy layer, wherein Fe layers are formed on both plane sides of said Heusler alloy layer in the stacking direction with said Heusler alloy layer sandwiched between them. It is thus possible to prevent diffusion of Co atoms contained in the CoFe layer into the Heusler alloy layer, enabling the decrease in the spin polarizability of the Heusler alloy layer to be hold back and achieving a high MR ratio.

Owner:TDK CORPARATION

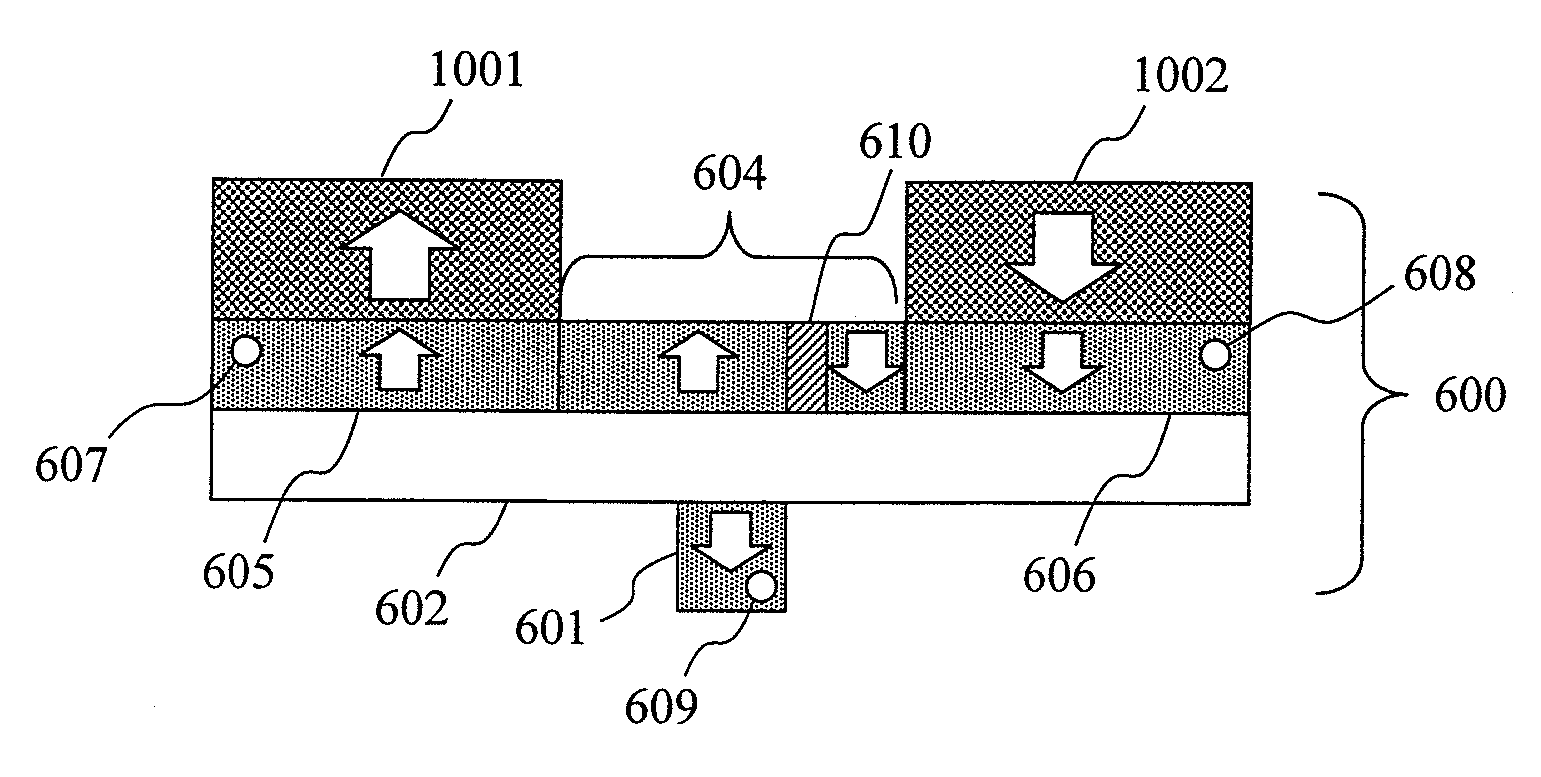

Magnetoresistance effect element and magnetic memory

ActiveUS20130141966A1High magneto-resistive ratioLow constantMagnetic-field-controlled resistorsSolid-state devicesFilm planeMagnetic memory

Provided are a magnetoresistance effect element with a stable magnetization direction perpendicular to film plane and a controlled magnetoresistance ratio, in which writing can be performed by magnetic domain wall motion, and a magnetic memory including the magnetoresistance effect element. The magnetoresistance ratio is controlled by forming a ferromagnetic layer of the magnetoresistance effect element from a ferromagnetic material including at least one type of 3d transition metal or a Heusler alloy. The magnetization direction is changed from a direction in the film plane to a direction perpendicular to the film plane by controlling the film thickness of the ferromagnetic layer on an atomic layer level.

Owner:TOHOKU UNIV

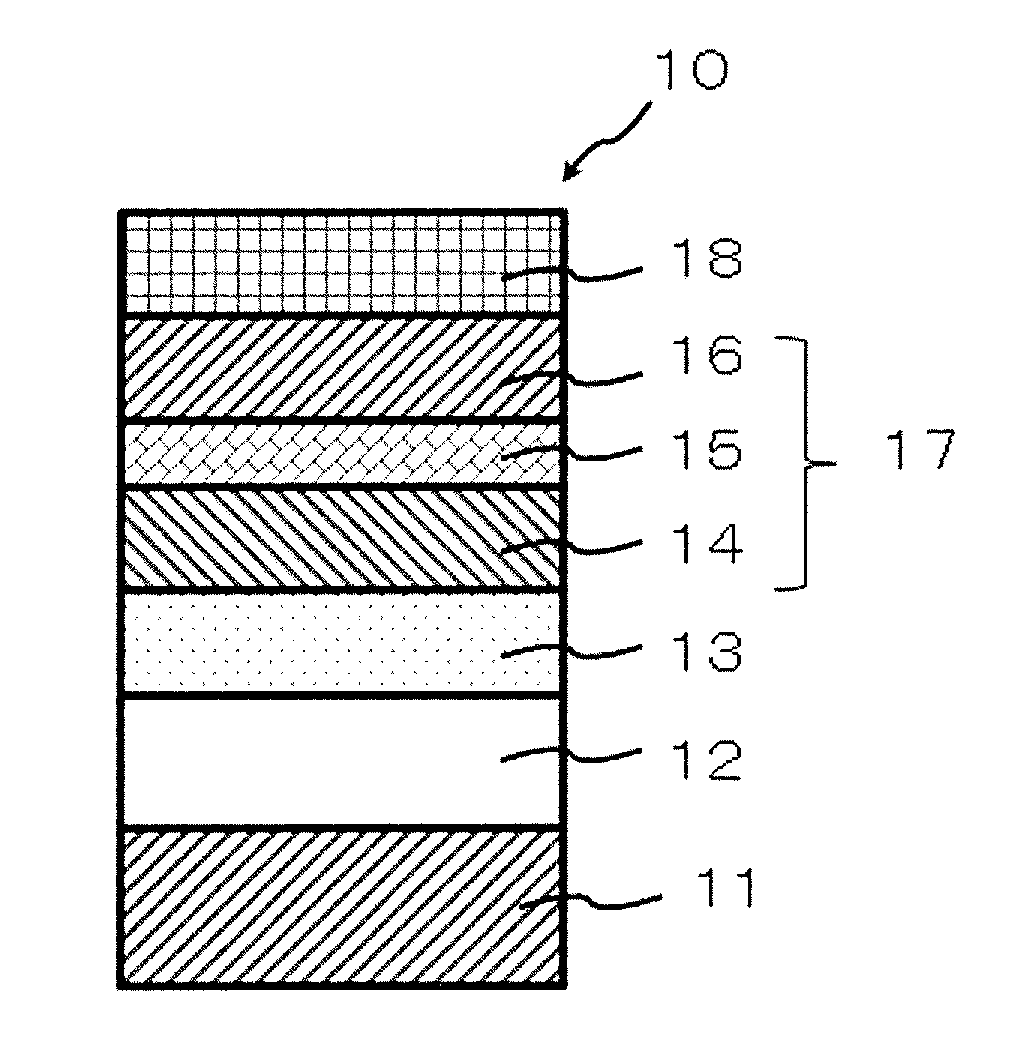

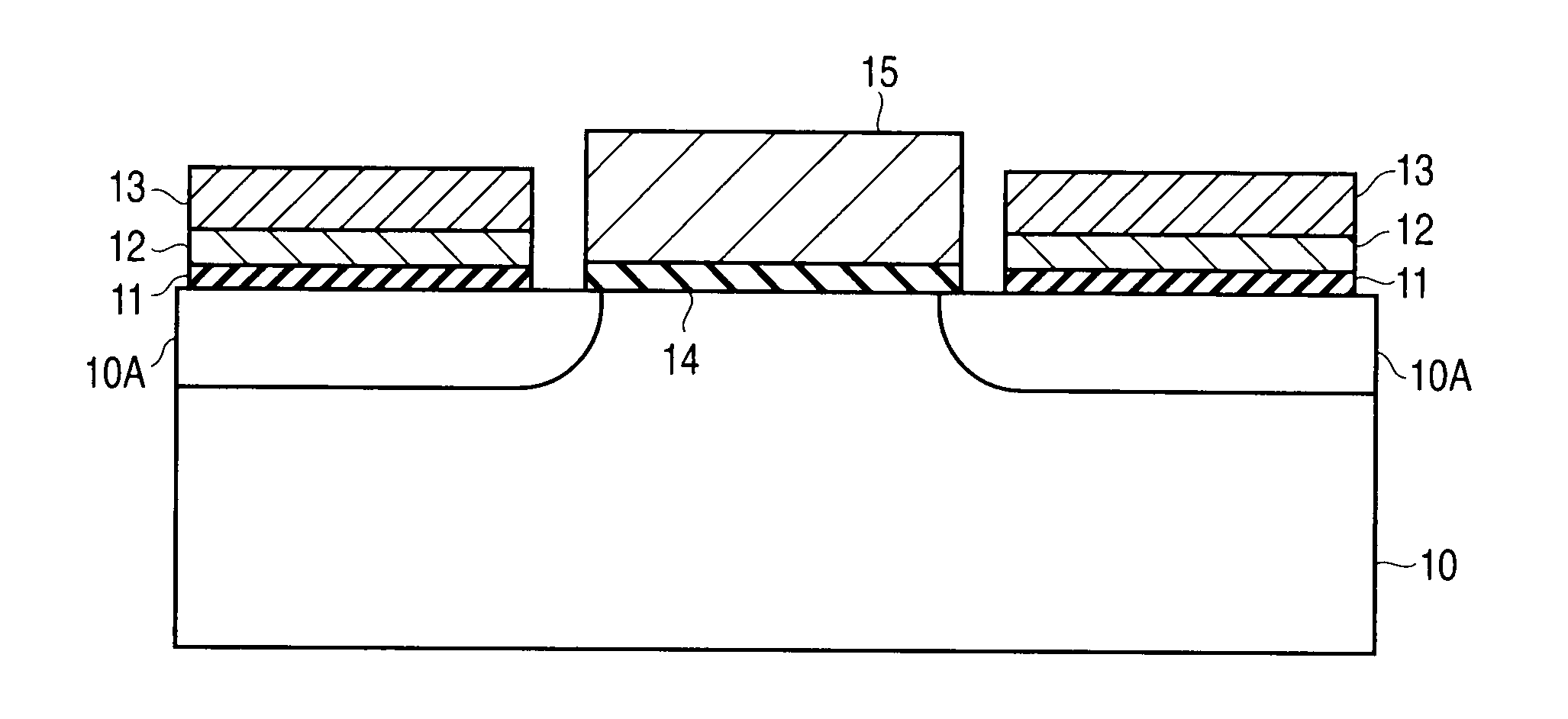

Monocrystalline magneto resistance element, method for producing the same and method for using same

ActiveUS20170229643A1Low costMass productivityMagnetic-field-controlled resistorsGalvano-magnetic material selectionGiant magnetoresistanceAlloy

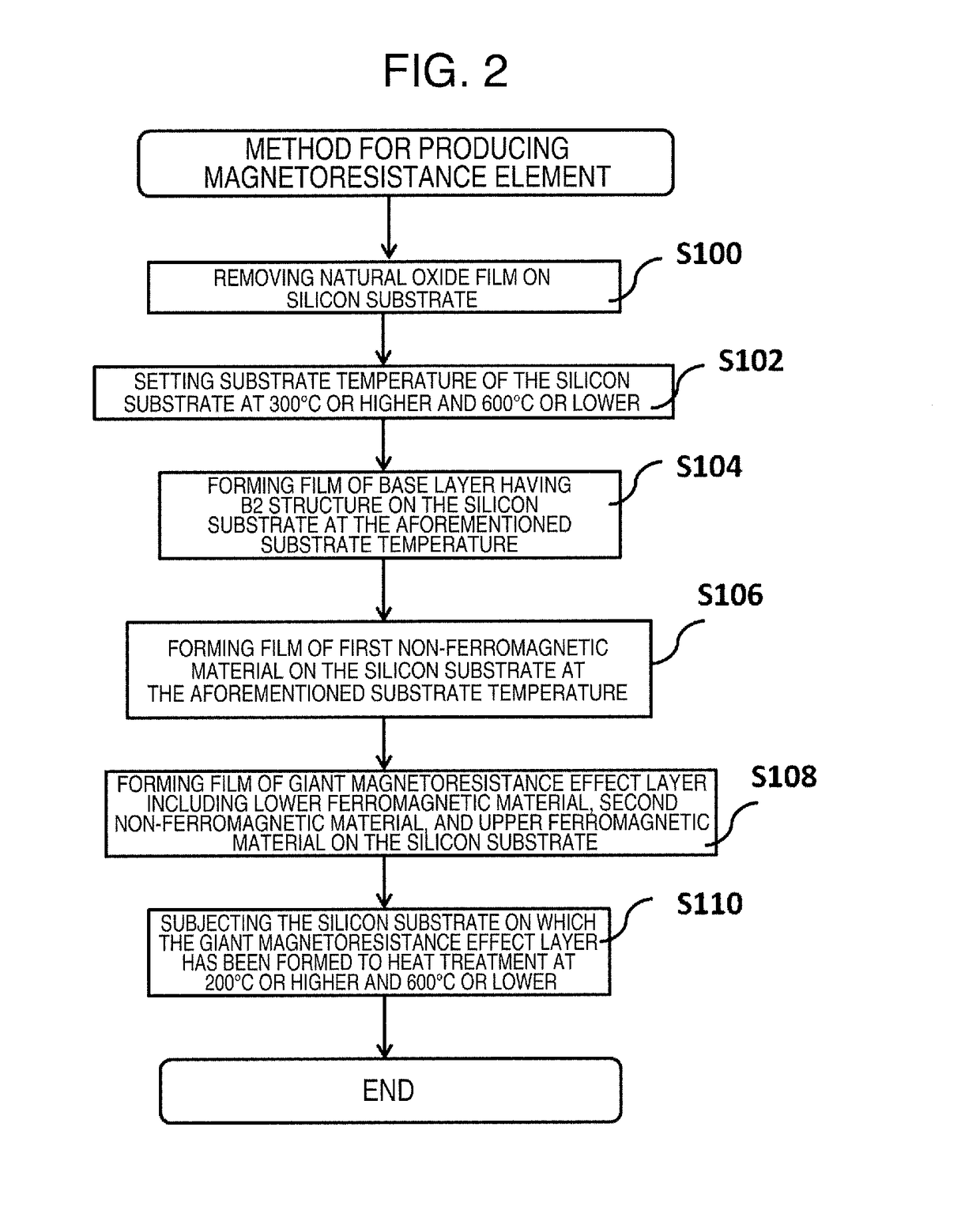

To provide a key monocrystalline magnetoresistance element necessary for accomplishing mass production and cost reduction for applying a monocrystalline giant magnetoresistance element using a Heusler alloy to practical devices. A monocrystalline magnetoresistance element of the present invention includes a silicon substrate 11, a base layer 12 having a B2 structure laminated on the silicon substrate 11, a first non-magnetic layer 13 laminated on the base layer 12 having a B2 structure, and a giant magnetoresistance effect layer 17 having at least one laminate layer including a lower ferromagnetic layer 14, an upper ferromagnetic layer 16, and a second non-magnetic layer 15 disposed between the lower ferromagnetic layer 14 and the upper ferromagnetic layer 16.

Owner:NAT INST FOR MATERIALS SCI

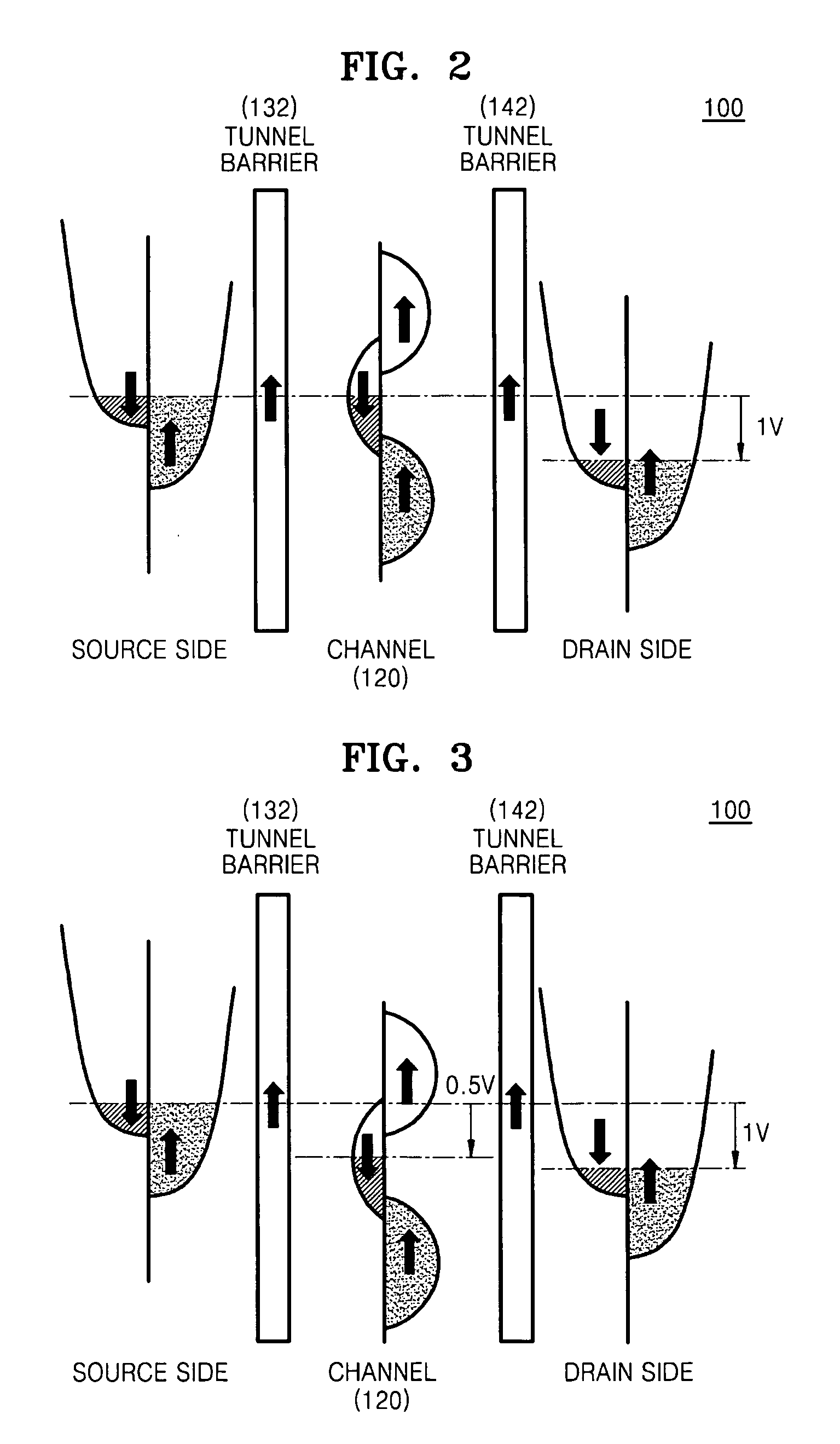

Stack having Heusler alloy, magnetoresistive element and spin transistor using the stack, and method of manufacturing the same

Owner:KK TOSHIBA

Spin field effect transistor using half metal and method of manufacturing the same

ActiveUS20090121267A1Increase charge mobilityReduce the amount requiredNanomagnetismSemiconductor/solid-state device manufacturingHalf-metalAlloy

A spin field effect transistor may include at least one gate electrode, a channel layer, a first stack and a second stack separate from each other on a substrate, wherein the channel layer is formed of a half metal. The half metal may be at least one material selected from the group consisting of chrome oxide (CrO2), magnetite (Fe3O4), a double perovskite structure material, a Heusler alloy, NiMnSb, La(1-x)AxMnO3 (A=Ca, Ba, Sr, x˜0.3), and GaN doped with Cu, and the double perovskite structure material is expressed as a chemical composition of A2BB′O6, and a material corresponding to A is Ca, Sr, or Ba, a material corresponding to B is a 3d orbital transition metal, and a material corresponding to B′ is a 4d orbital transition metal. The 3d orbital transition metal may be Fe or Co, and the 4d orbital transition metal is Mo or Re.

Owner:SAMSUNG ELECTRONICS CO LTD

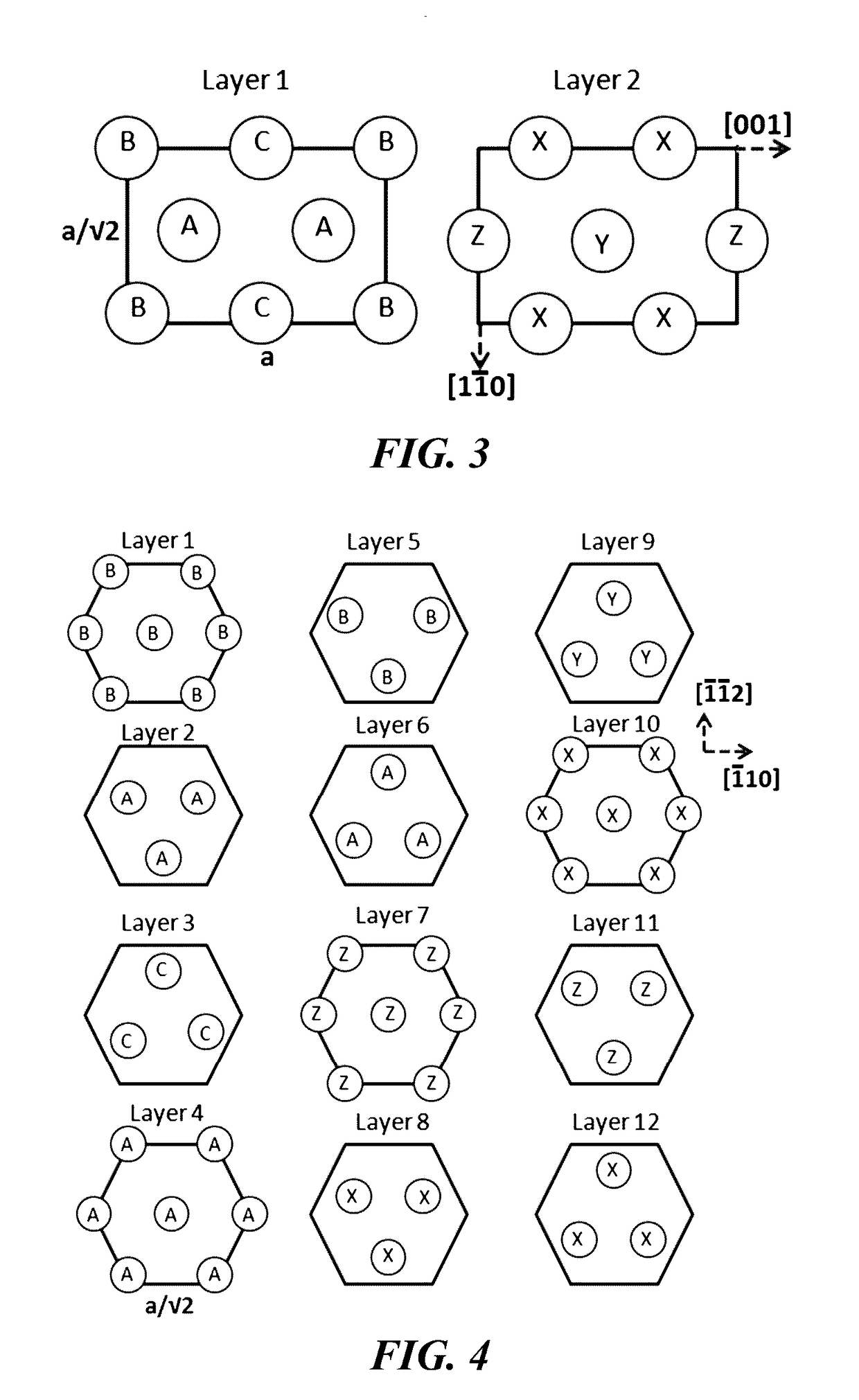

Layered heusler alloys and methods for the fabrication and use thereof

ActiveUS9643385B1High spin polarizationLow dampingSpin-exchange-coupled multilayersElectrical equipmentMetallurgyCrystal structure

Disclosed herein are layered Heusler alloys. The layered Heusler alloys can comprise a first layer comprising a first Heusler alloy with a face-centered cubic (fcc) crystal structure and a second layer comprising a second Heusler alloy with a fcc crystal structure, the second Heusler alloy being different than the first Heusler alloy, wherein the first layer and the second layer are layered along a layering direction, the layering direction being the [110] or [111] direction of the fcc crystal structure, thereby forming the layered Heusler alloy.

Owner:UNIVERSITY OF ALABAMA

Stack having heusler alloy, magnetoresistive element and spin transistor using the stack, and method of manufacturing the same

InactiveUS20100072529A1Solid-state devicesGalvano-magnetic material selectionMetallurgySpin transistor

Owner:KK TOSHIBA

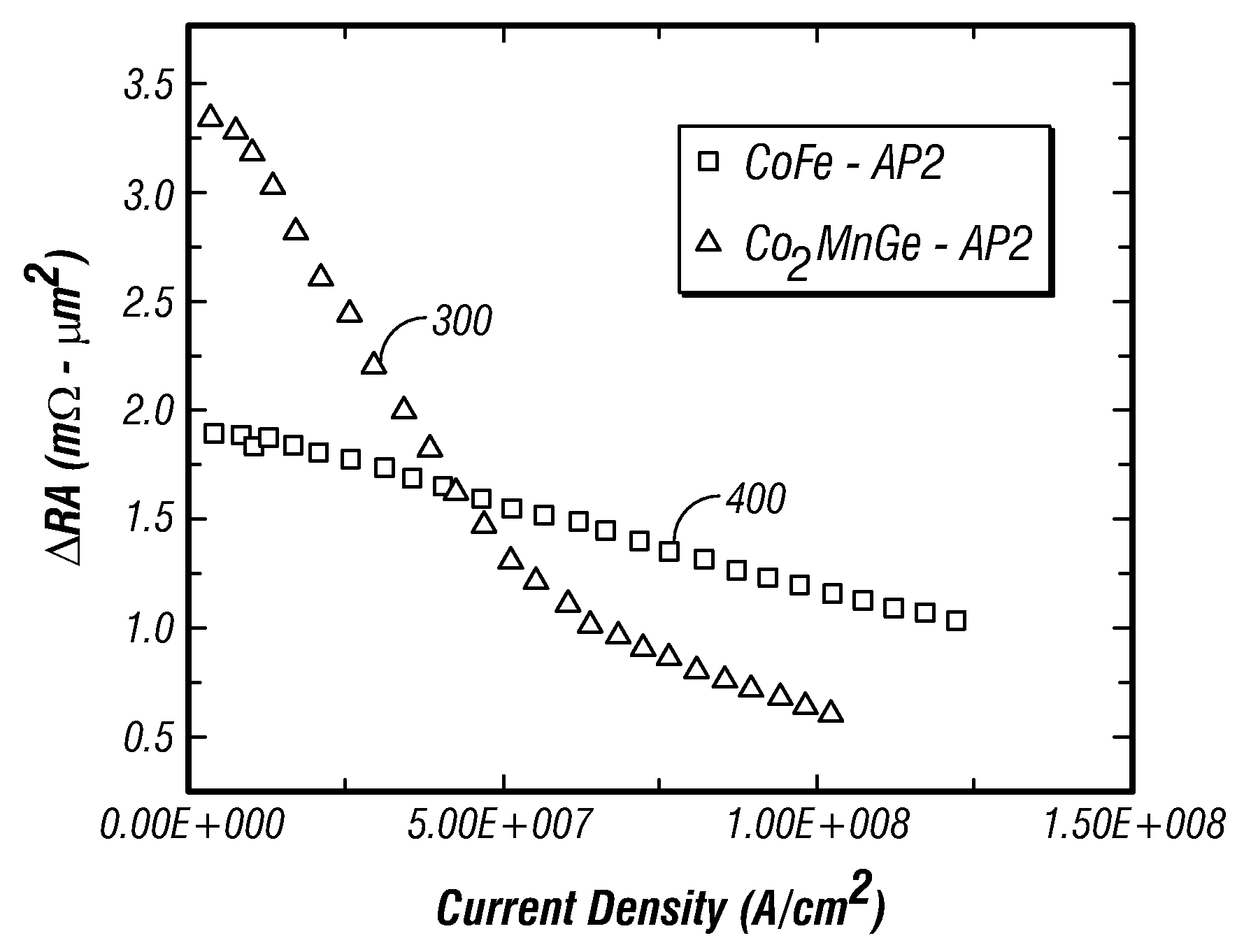

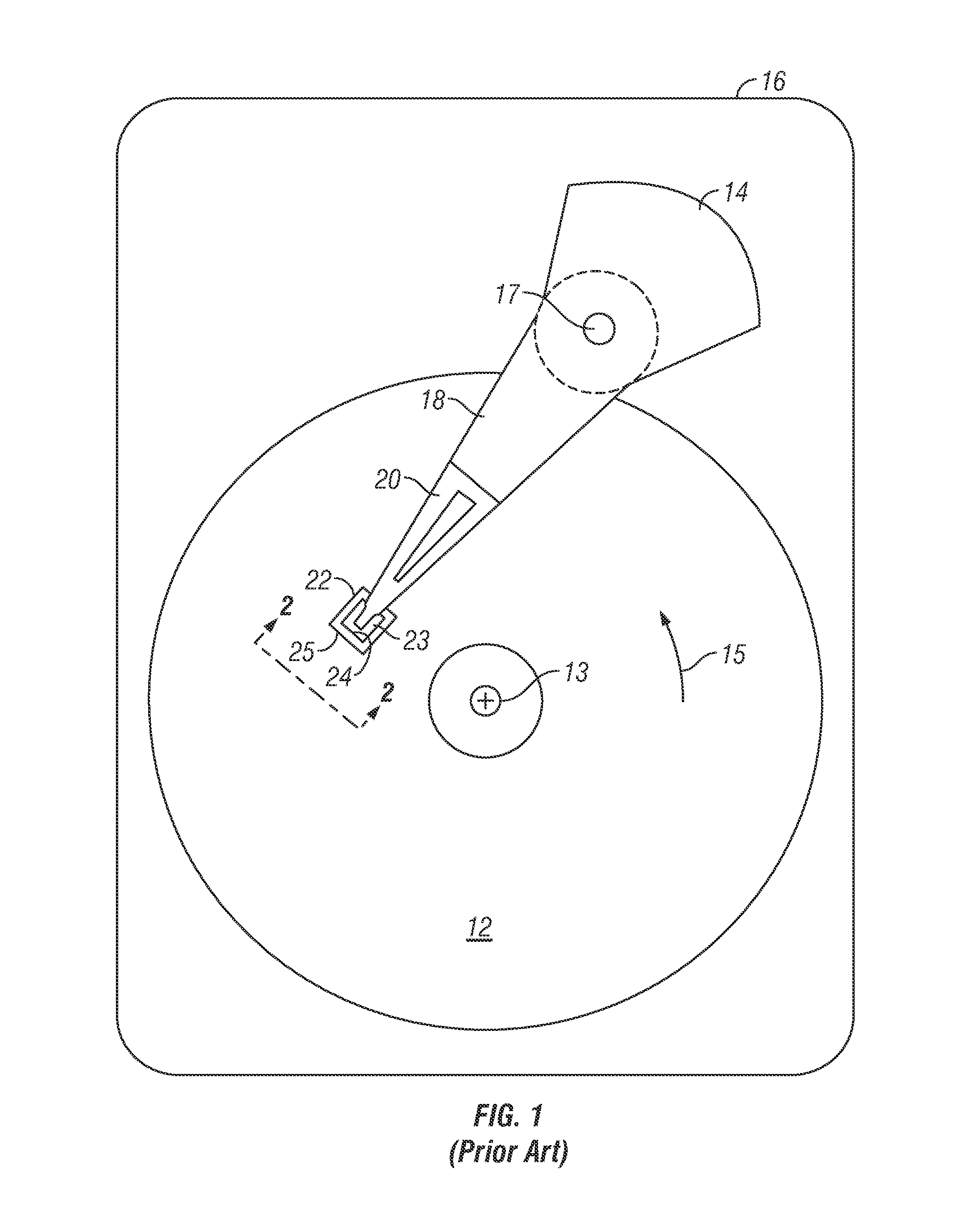

Dual current-perpendicular-to-the-plane (CPP) magnetoresistive sensor with heusler alloy free layer and minimal current-induced noise

InactiveUS20080112095A1Increased reluctanceEnhanced spin polarizationNanomagnetismMagnetic measurementsMagnetizationSpins

A dual current-perpendicular-to-the-plane (CPP) magnetoresistive sensor has a free ferromagnetic layer formed of a Heusler alloy and each of the pinned ferromagnetic layers formed of a ferromagnetic material other than a Heusler alloy, like a conventional CoFe or NiFe material. The Heusler alloy material in the free layer may be a known Heusler alloy material or an alloy with a composition substantially the same as that of a known Heusler alloy, and which results in high magnetoresistance due to enhanced spin polarization and / or enhanced spin-dependent scattering compared to conventional ferromagnetic materials. Each of the two pinned ferromagnetic layers may be an antiparallel (AP) pinned structure wherein first (AP1) and second (AP2) ferromagnetic layers are separated by a nonmagnetic antiparallel coupling (APC) layer with the magnetization directions AP1 and AP2 layers oriented substantially antiparallel. Each AP2 layer is adjacent one of the two nonmagnetic spacer layers in the dual CPP sensor and is formed of a ferromagnetic material other than a Heusler alloy.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

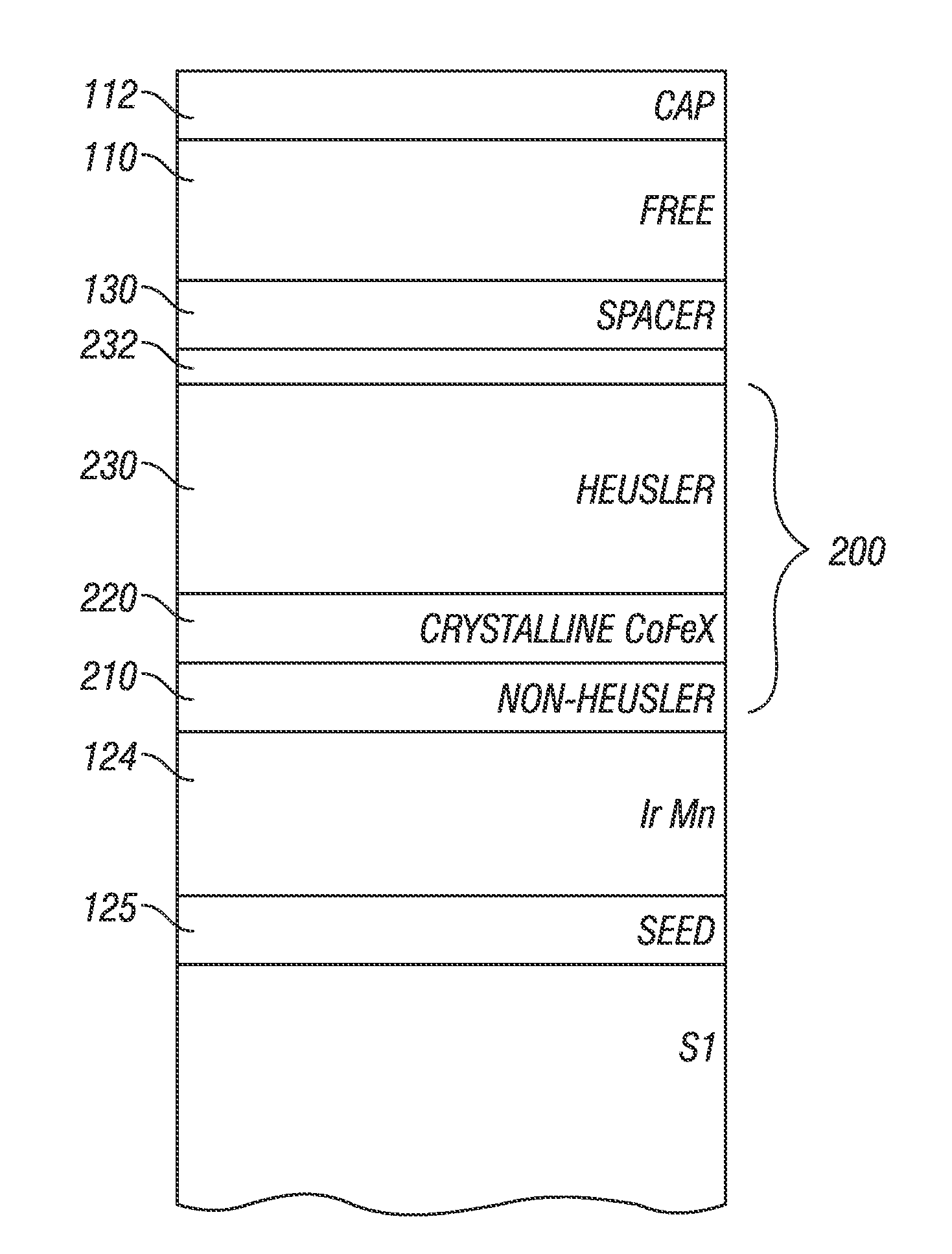

CURRENT-PERPENDICULAR-TO-THE-PLANE (CPP) MAGNETORESISTIVE SENSOR WITH MULTILAYER REFERENCE LAYER INCLUDING A CRYSTALLINE CoFeX LAYER AND A HEUSLER ALLOY LAYER

ActiveUS20150010780A1Easy to fixReduce the possibilityRecord information storageManufacture of flux-sensitive headsGiant magnetoresistanceInstability

A current-perpendicular-to-the-plane giant magnetoresistance (CPP-GMR) has a multilayer reference layer containing a Heusler alloy. The multilayer reference layer includes a crystalline non-Heusler alloy ferromagnetic layer on an antiferromagnetic layer, a Heusler alloy layer, and an intermediate crystalline non-Heusler alloy of the form CoFeX, where X is one or more of Ge, Al, Si and Ga, located between the non-Heusler alloy layer and the Heusler alloy layer. The CoFeX alloy layer has a composition (CoyFe(100-y))zX(100-z) where y is between about 10 and 90 atomic percent, and z is between about 50 and 90 atomic percent. The CoFeX alloy layer induces very strong pinning, which greatly lessens the likelihood of magnetic instability by the spin polarized electron flow from the free layer to the reference layer.

Owner:WESTERN DIGITAL TECH INC

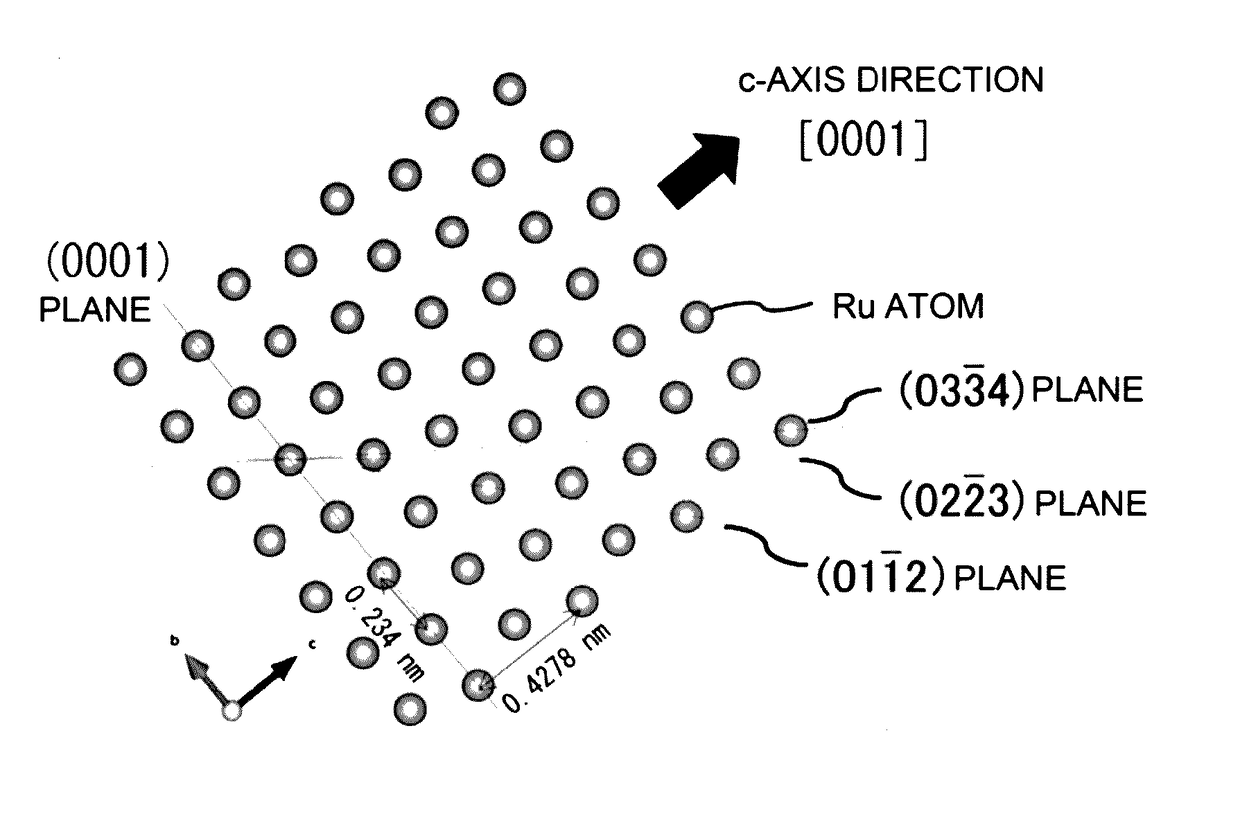

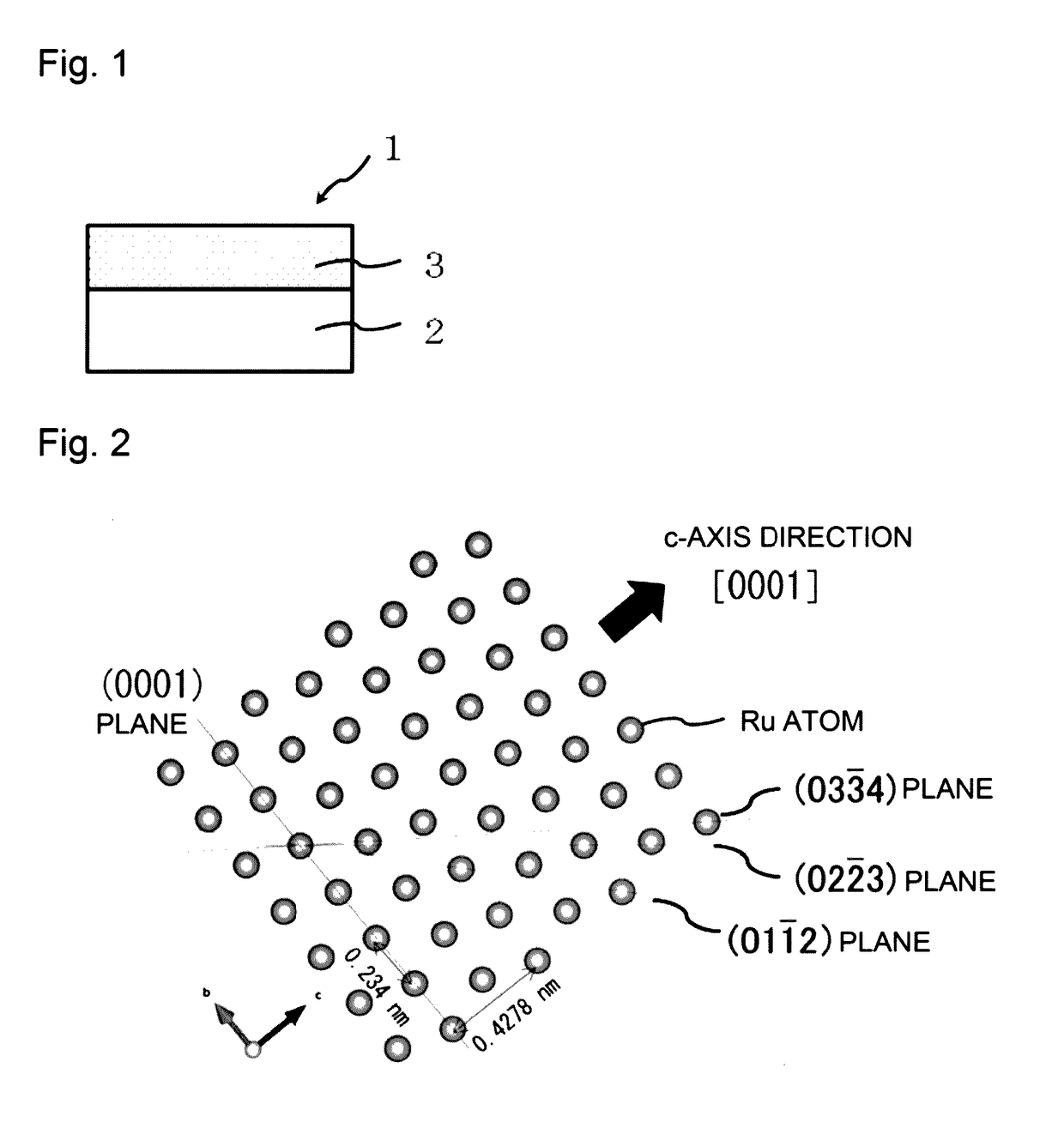

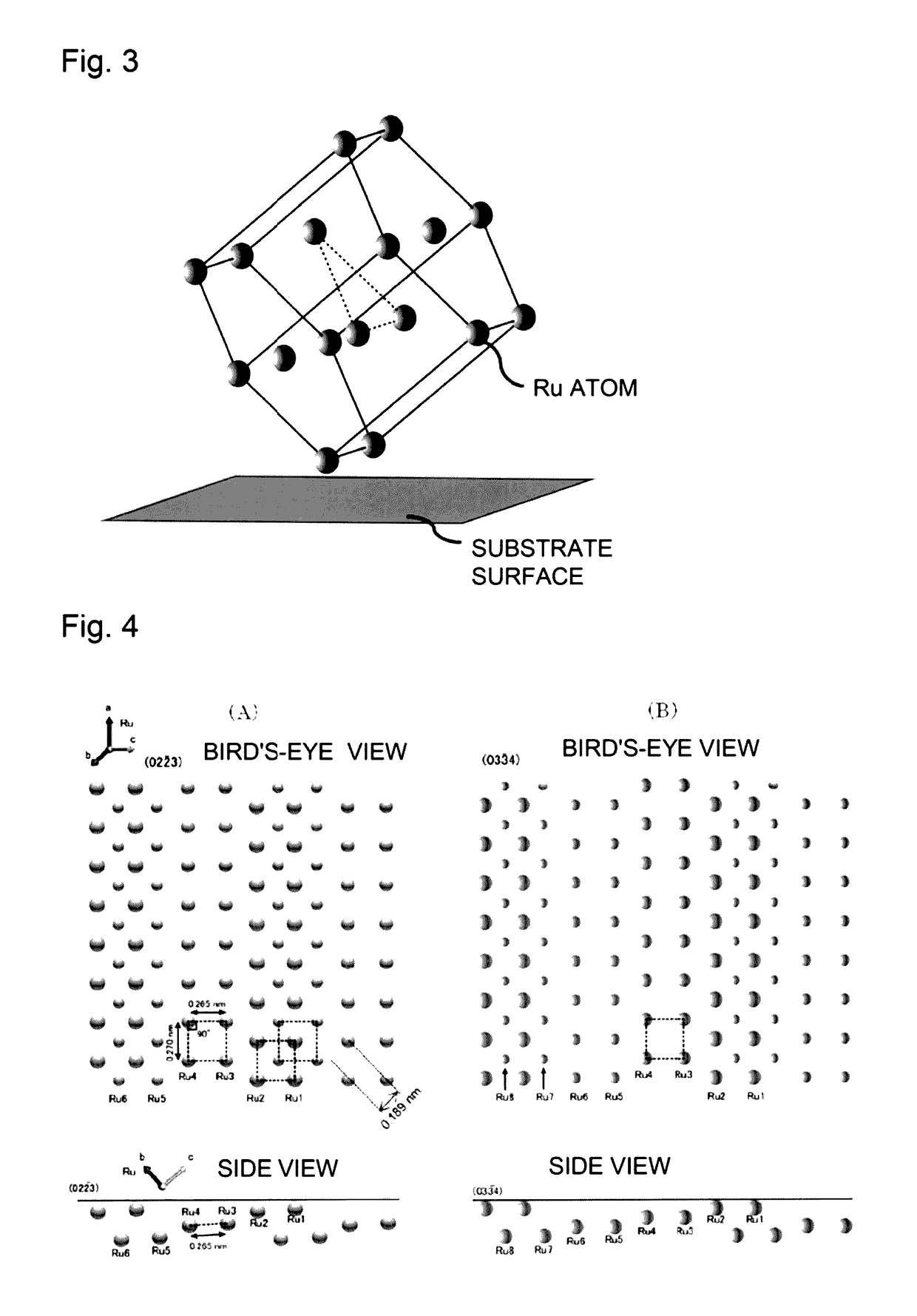

Underlayer for perpendicularly magnetized film, perpendicularly magnetized film structure, perpendicular mtj element, and perpendicular magnetic recording medium using the same

ActiveUS20170140784A1High indexImprove heat resistanceBase layers for recording layersRecord information storageThin metalSingle crystal substrate

Disclosed is a perpendicularly magnetized film structure that uses a highly heat resistant underlayer film on which a cubic or tetragonal perpendicularly magnetized film can grow with high quality, the structure comprising any one substrate (5) of a cubic single crystal substrate having a (001) plane, or a substrate having a cubic oriented film that grows to have the (001) plane; an underlayer (6) formed on the substrate (5) from a thin film of a metal having an hcp structure, such as Ru or Re, in which the [0001] direction of the thin metal film forms an angle in the range of 42° to 54° with respect to the <001> direction or the (001) orientation of the substrate (5); and a perpendicularly magnetized layer (7) located on the metal underlayer (6) and formed from a cubic material selected from the group consisting of a Co-based Heusler alloy, a cobalt-iron (CoFe) alloy having a bcc structure, and the like, as a constituent material, and grown to have the (001) plane.

Owner:NAT INST FOR MATERIALS SCI

Magneto-resistance effect element having Heusler alloy compounds adjacent to spacer layer

InactiveUS20070121255A1Increase polarizabilityBig ratioNanomagnetismMagnetic measurementsMagnetizationAlloy

A magneto-resistance effect element according to the present invention comprises a pinned layer whose magnetization direction is fixed; a free layer whose magnetization direction varies in accordance with an external magnetic field; and a nonmagnetic spacer layer that is arranged between said pinned layer and said free layer. At least either said pinned layer or said free layer includes a Heusler alloy layer that is disposed adjacent to said spacer layer, and compounds are arranged in a dotted pattern at an interface between said spacer layer and at least said spacer layer and said pinned layer or said spacer layer and said free layer, said compounds including material that is included in said Heusler alloy layer.

Owner:TDK CORPARATION

Thermoelectric composite and preparation method thereof

InactiveCN101942577ALower lattice thermal conductivityImprove thermoelectric performanceMaterial nanotechnologyThermoelectric device manufacture/treatmentLiquid mediumSkutterudite

The invention provides a preparation method of a composite, comprising: providing a suspension of a solid thermoelectric material which disperses in a liquid medium, wherein the solid thermoelectric material is filled and / or doped with skutterudite, half-Heusler alloy, a cagelike material and other thermoelectric ordered alloy or thermoelectric disordered alloy or a thermoelectric intermetallic compound; contacting the suspension with a solution formed by dissolving a metallic oxide precursor into solvent to obtain a reaction mixture; forming a metallic oxide by hydrolyzing the metallic oxide precursor in the presence of water; obtaining the compound of the metallic oxide and the solid thermoelectric material which are evenly dispersed in liquid phase; and separating the compound of the metallic oxide and the solid thermoelectric material from the liquid phase to obtain the separated composite. The invention can dramatically improve the thermoelectric performance of the composite.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

Magneto-resistance element and thin film magnetic head with improved heat reliability

ActiveUS20070058301A1Increase rate of changeImprove thermal reliabilityNanomagnetismMagnetic measurementsMagnetizationAlloy

A magneto-resistance element according to the present invention has a pinned layer whose magnetization direction is fixed; a free layer whose magnetization direction varies in accordance with an external magnetic field; and a nonmagnetic spacer layer that is arranged between the pinned layer and the free layer, at least the pinned layer or the free layer includes a layer having Heusler alloy represented by composition formula X2YZ (where X is a precious metal element, Y is a transition metal of Mn, V, or Ti group, Z is an element from group III to group V), and a part of composition X is replaced with Co, and an atomic composition ratio of Co in composition X is from 0.5 to 0.85.

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Magnetic sensing element including pinned layer and/or free layer composed of [110] crystal planes-oriented Heusler alloy Magnetic sensing element including pinned layer and/or free layer composed of [110] crystal planes-oriented Heusler alloy](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/71302996-470d-4e17-b945-ce0039b3a82e/US07336453-20080226-D00000.png)

![Magnetic sensing element including pinned layer and/or free layer composed of [110] crystal planes-oriented Heusler alloy Magnetic sensing element including pinned layer and/or free layer composed of [110] crystal planes-oriented Heusler alloy](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/71302996-470d-4e17-b945-ce0039b3a82e/US07336453-20080226-D00001.png)

![Magnetic sensing element including pinned layer and/or free layer composed of [110] crystal planes-oriented Heusler alloy Magnetic sensing element including pinned layer and/or free layer composed of [110] crystal planes-oriented Heusler alloy](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/71302996-470d-4e17-b945-ce0039b3a82e/US07336453-20080226-D00002.png)

![Magnetic sensing element including pinned layer and/or free layer composed of [110] crystal planes-oriented heusler alloy Magnetic sensing element including pinned layer and/or free layer composed of [110] crystal planes-oriented heusler alloy](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d6766aa4-675a-4122-b133-ed522fc8bedf/US20050074634A1-20050407-D00000.png)

![Magnetic sensing element including pinned layer and/or free layer composed of [110] crystal planes-oriented heusler alloy Magnetic sensing element including pinned layer and/or free layer composed of [110] crystal planes-oriented heusler alloy](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d6766aa4-675a-4122-b133-ed522fc8bedf/US20050074634A1-20050407-D00001.png)

![Magnetic sensing element including pinned layer and/or free layer composed of [110] crystal planes-oriented heusler alloy Magnetic sensing element including pinned layer and/or free layer composed of [110] crystal planes-oriented heusler alloy](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d6766aa4-675a-4122-b133-ed522fc8bedf/US20050074634A1-20050407-D00002.png)