Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

150 results about "Equilateral polygon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In geometry, three or more than three straight lines (or segment of a line) make a polygon and an equilateral polygon is a polygon which has all sides of the same length. Except in the triangle case, it need not be equiangular (need not have all angles equal), but if it does then it is a regular polygon. If the number of sides is at least five, an equilateral polygon need not be a convex polygon: it could be concave or even self-intersecting.

Method and system for statistical filters and design of statistical filters

InactiveUS7184938B1Less dataLess signalDigital variable displayNoise figure or signal-to-noise ratio measurementFrequency spectrumFilter system

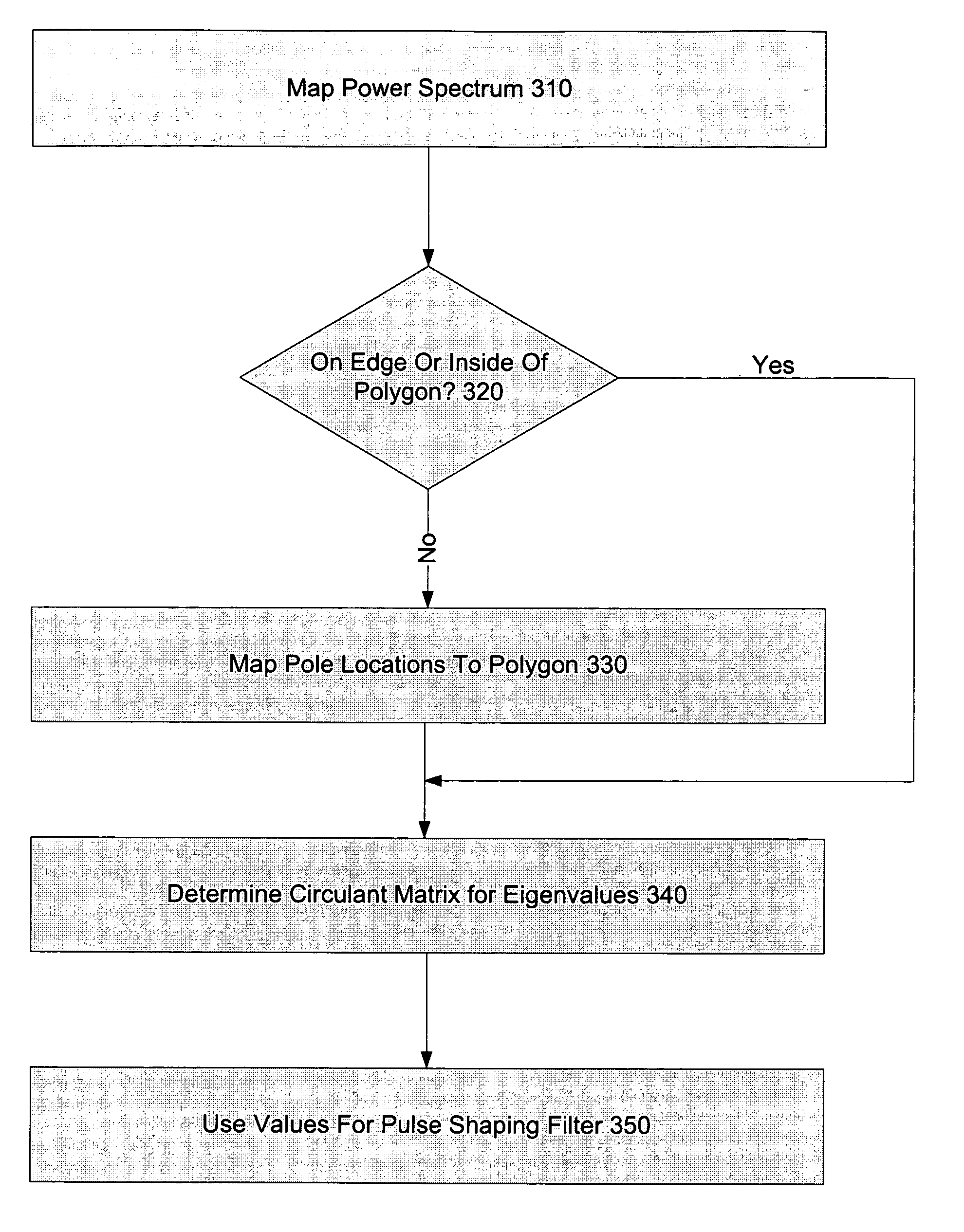

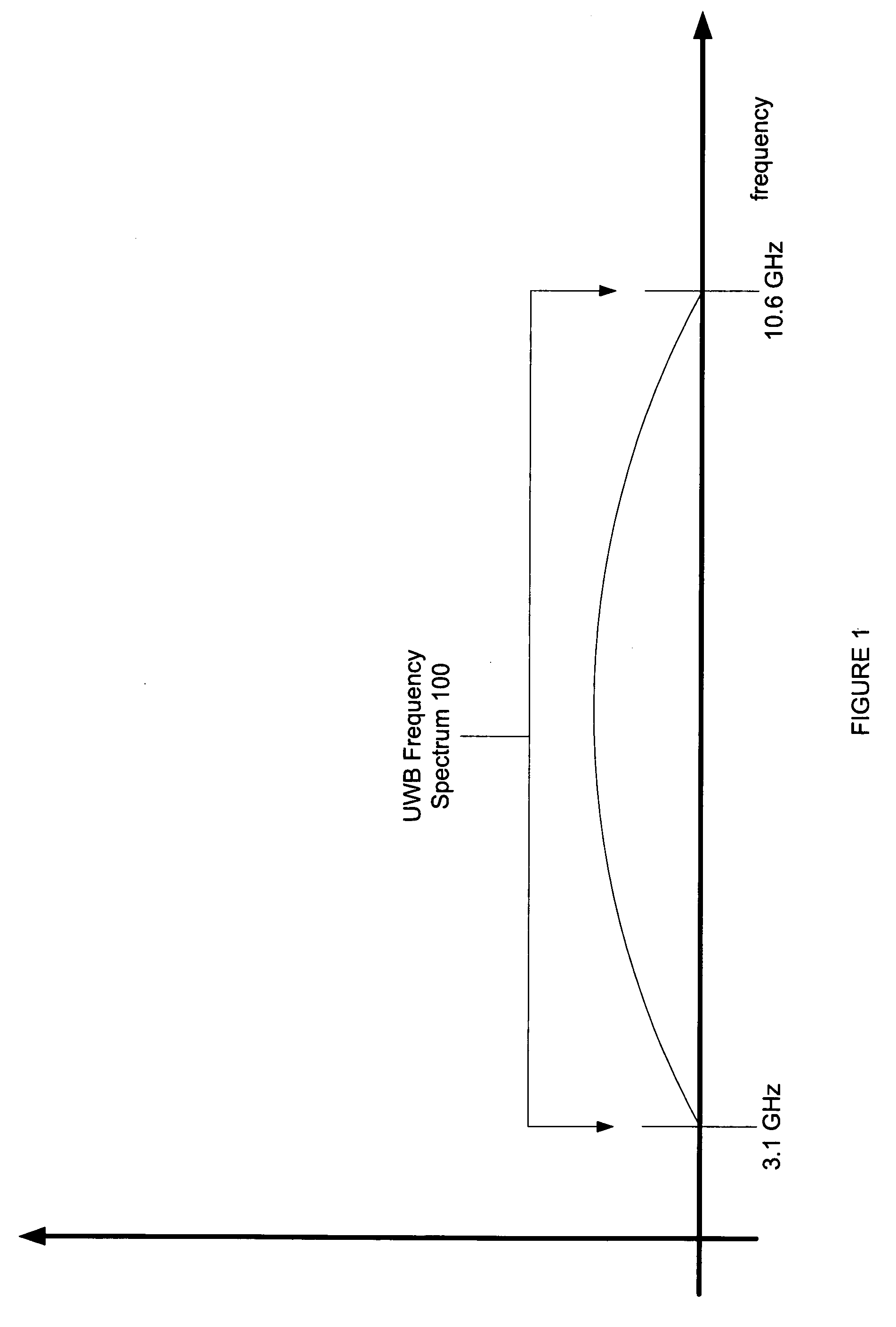

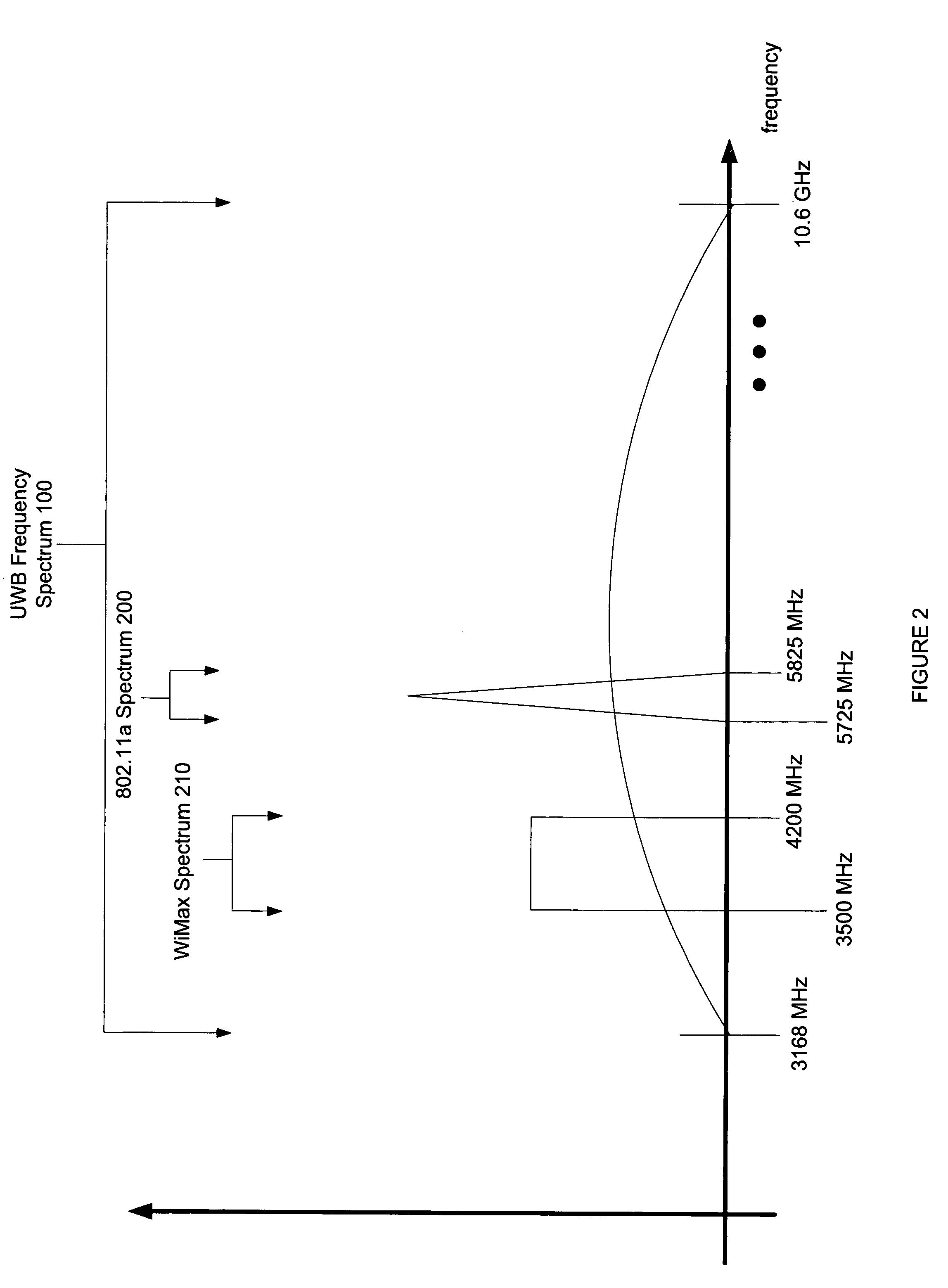

Systems and methods for the design or implementation of statistical filters for use in the spectral shaping of transmissions are disclosed. A desired power spectrum may be mapped to find pole locations that approximate the desired spectrum. These pole locations may then be mapped to the edge or inside of an equilateral polygon lying inside a unit circle, the equilateral polygon having the same number of sides as the order of the statistical filter desired and one vertex mapped to unity, to yield a set of eigenvalues. These eigenvalues may be the eigenvalues of a stochastic matrix the elements of which may be the Markov transition probabilities for use in a statistical filter designed to achieve the desired power spectrum. Use of a statistical filter employing these Markov transition values may be utilized to shape UWB or other signals to achieve the desired power spectrum.

Owner:ALEREON

Optical fibres with special bending and dispersion properties

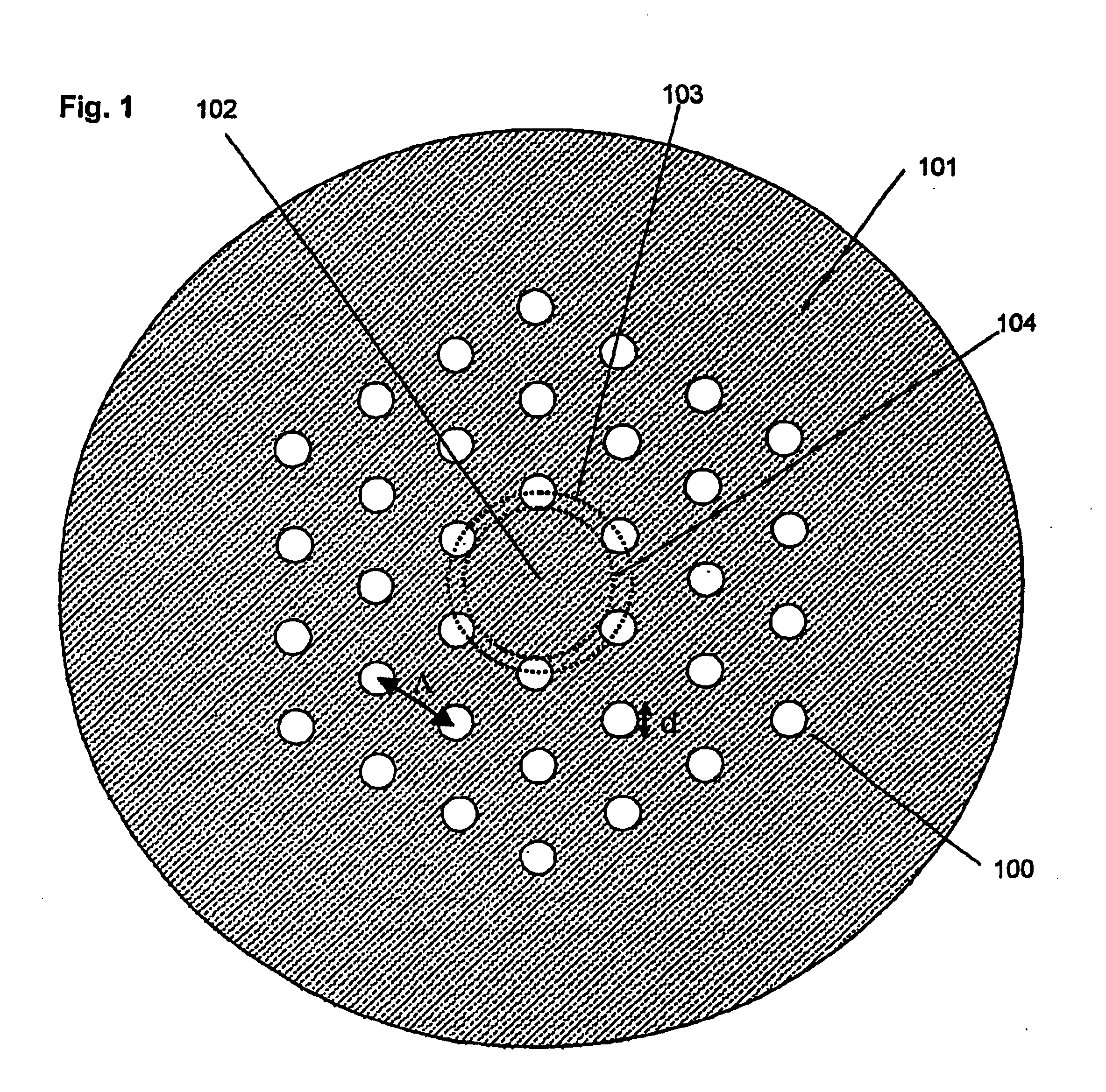

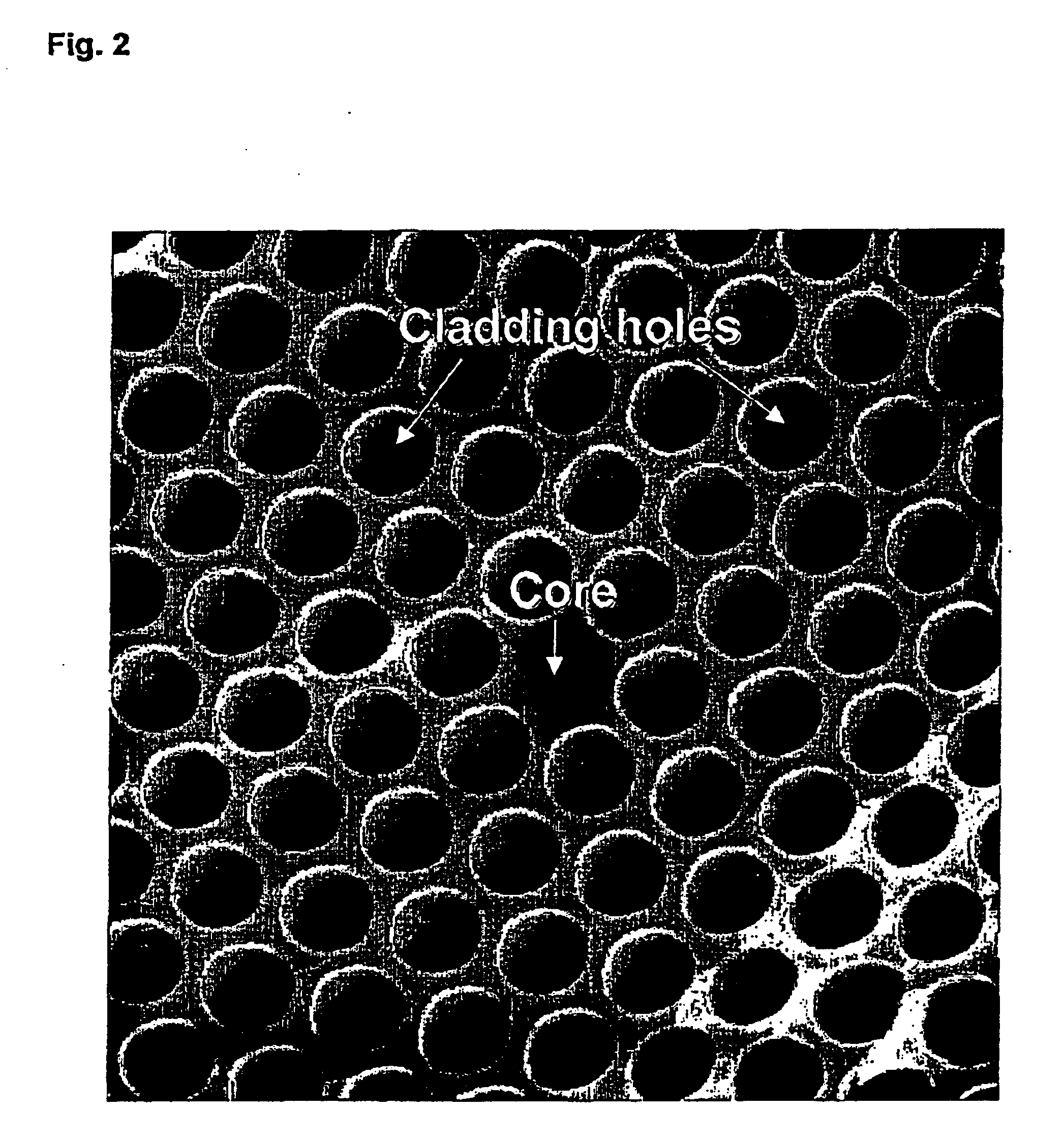

InactiveUS6856742B2Improve the cutoff effectGlass making apparatusOptical fibre with polarisationEngineeringEquilateral polygon

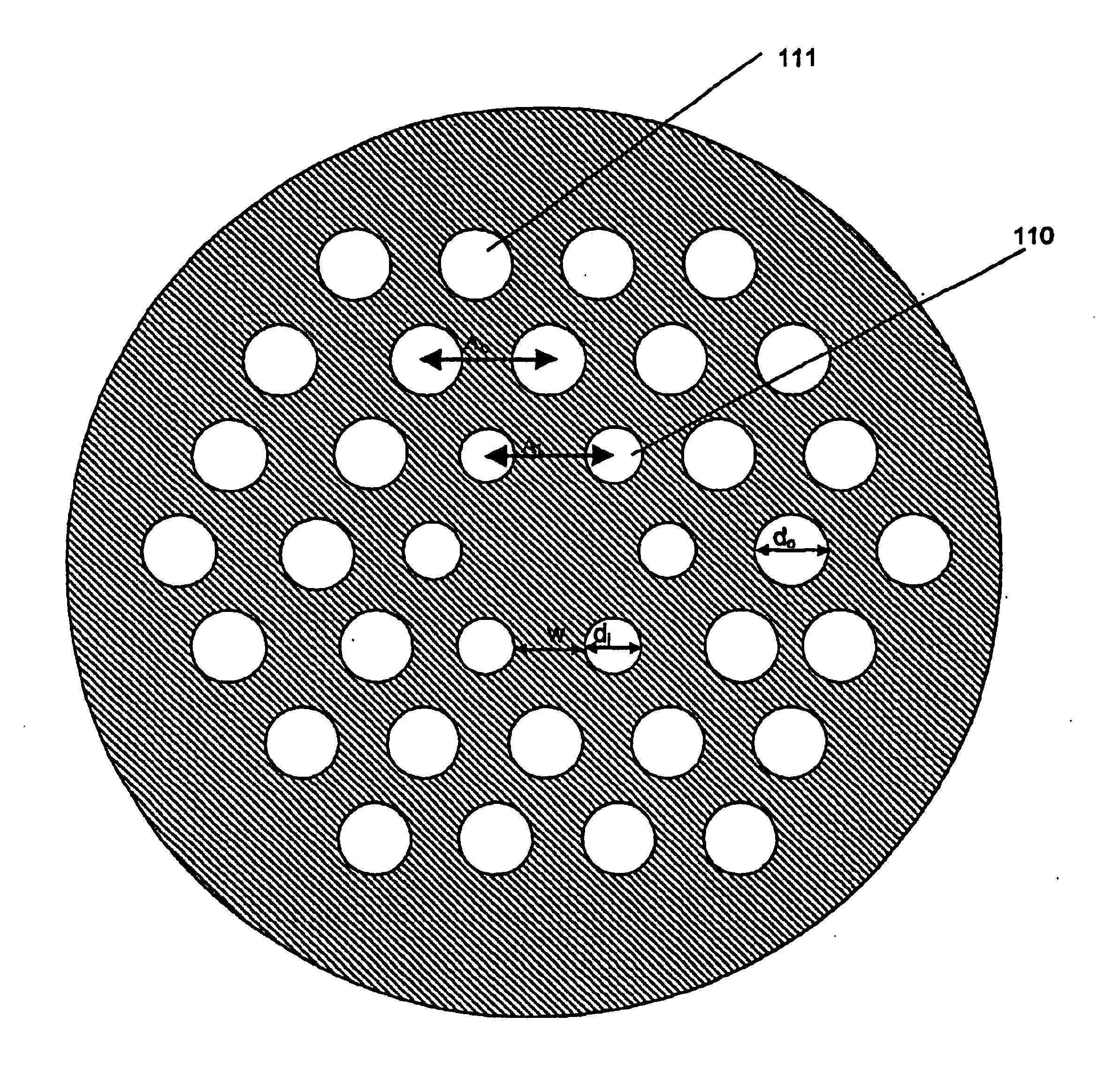

A microstructured optical fiber having a specially designed cladding to provide single mode waveguidance and low sensitivity to bending losses. In one aspect the optical fiber has an inner and an outer cladding each comprising elongated features. The inner cladding features have normalized dimensions in the range from 0.35 to 0.50 and the outer cladding features have normalized dimensions in the range from 0.5 to 0.9, where the normalization factor is a typical feature spacing. The fiber is further characterized by a feature spacing of the inner cladding larger than 2.0 micron. In a second aspect, the fiber has a special non-circular and non-equilateral-polygonial outer cross-sectional shape to mechanically ensure bending in predetermined directions that are favourable with respect to low bending losses. The present invention provides fibers, which are less sensitive to macro-bending losses than presently known single-mode fibers with similar sized mode areas, and provides robust, single-mode, large-mode area fibers for long-distance optical transmission and fibers with special dispersion properties.

Owner:CRYSTAL FIBRE AS

Wear part for a crusher

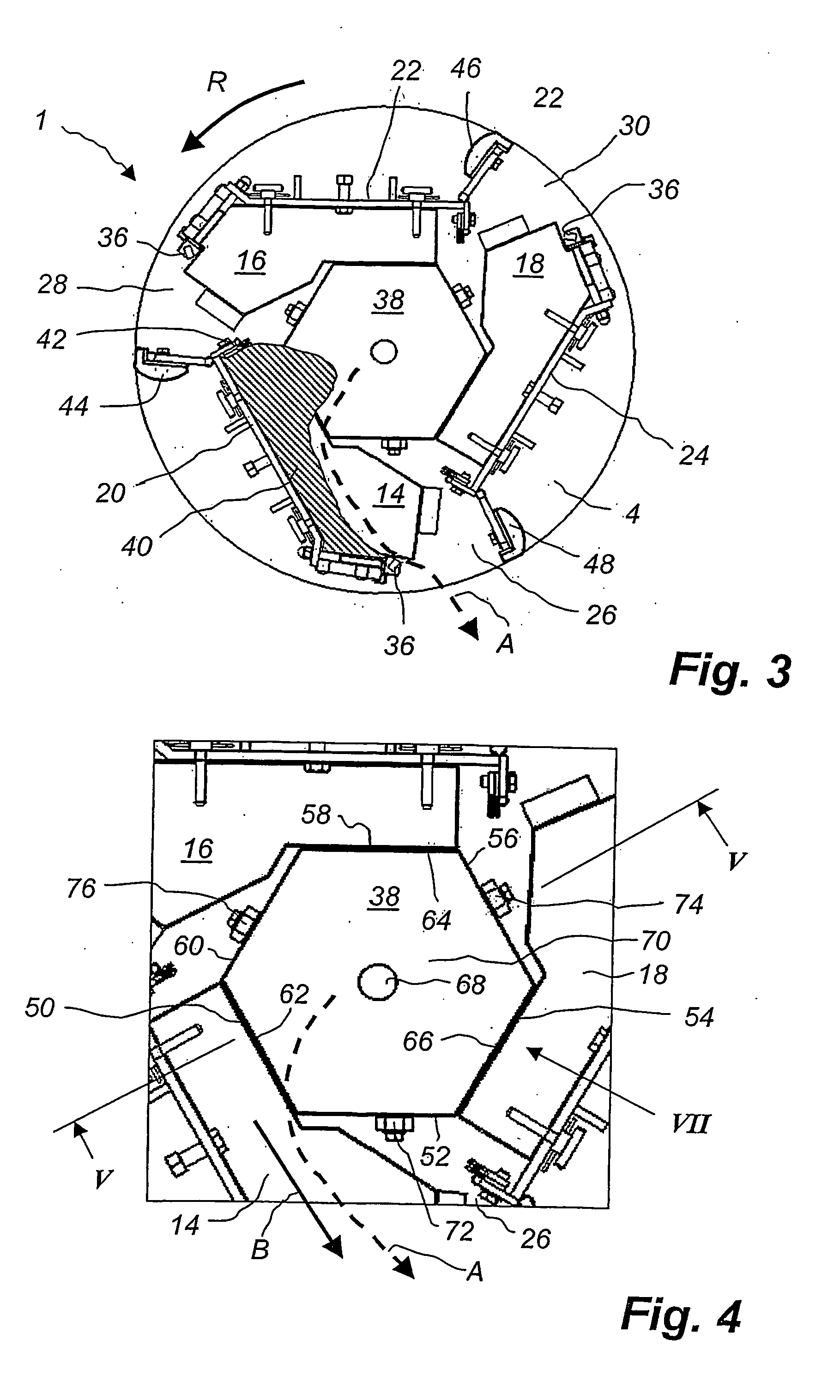

ActiveUS20060011762A1Solution to short lifeReduce downtimeGrinding machine componentsCocoaCrusherDistributor

A distributor plate adapted to be releasably mounted on a horizontal lower disc of a rotor of a vertical shaft impact crusher. The rotor has an opening for the intake of material to be crushed and at least one outflow opening for material leaving the rotor. The distributor plate is an equilateral polygon as seen from above.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

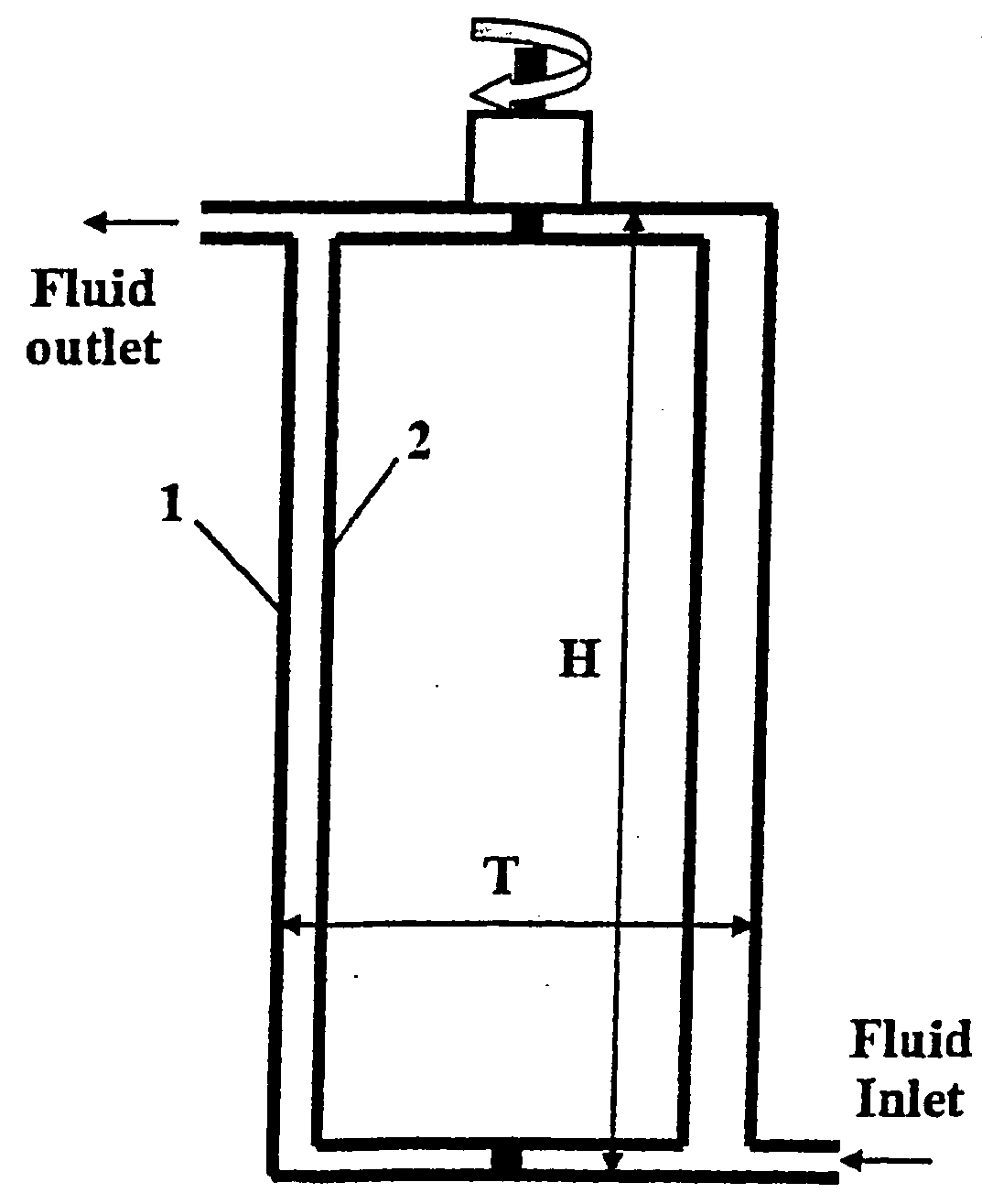

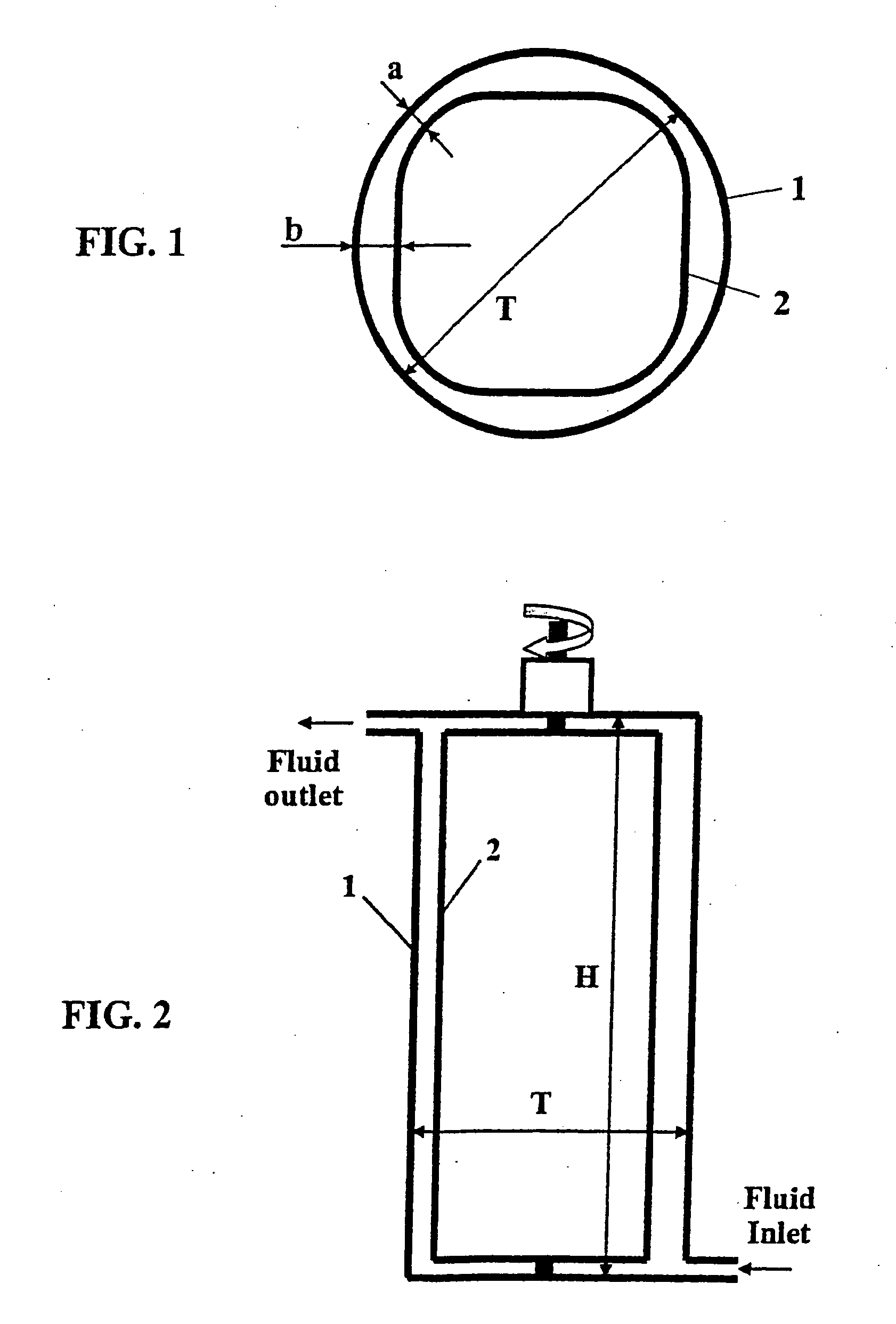

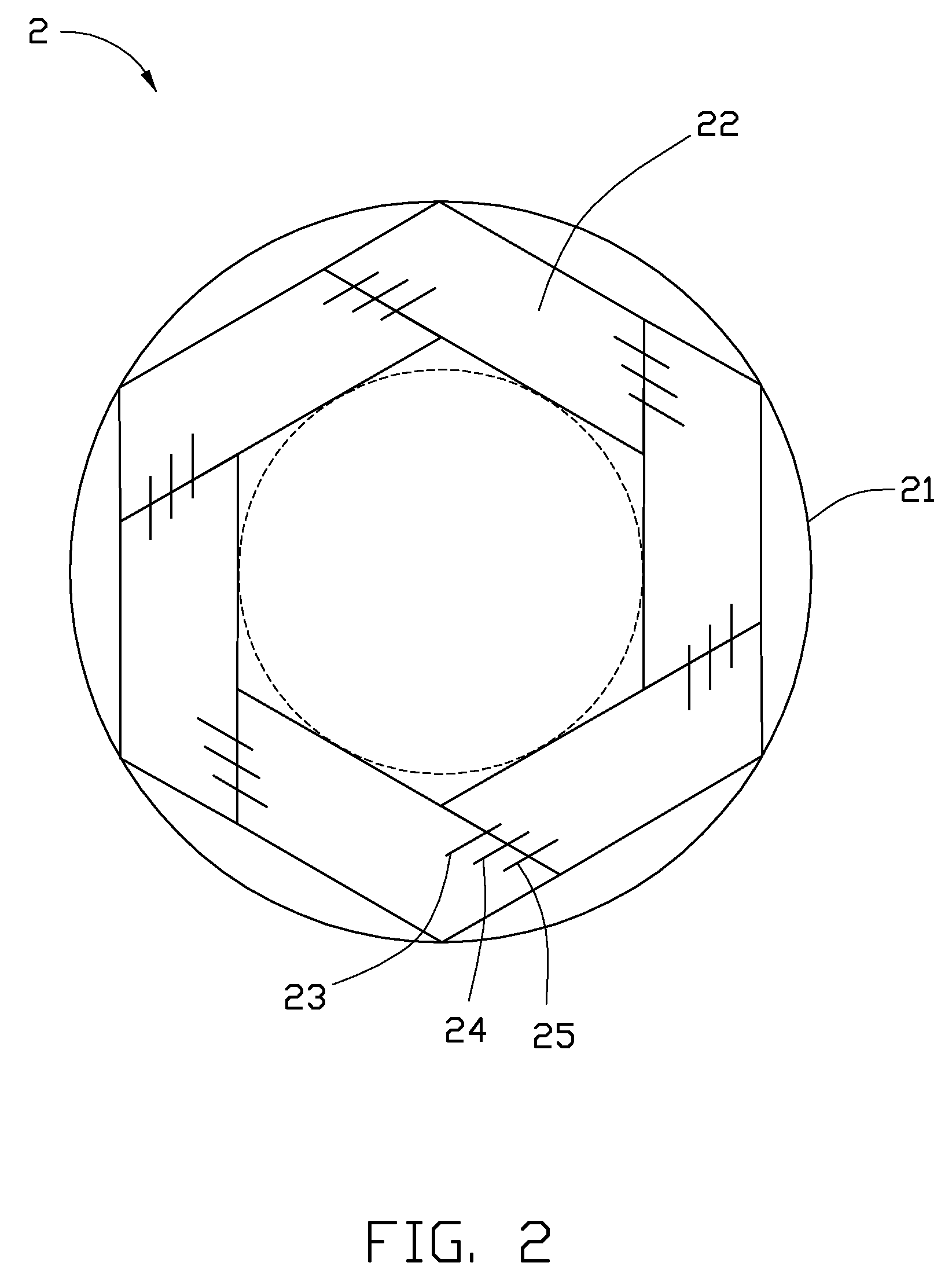

Rotating Stirring Device with Substantially Narrow Distribution of Energy Dissipation Rate

InactiveUS20080226513A1Rotary stirring mixersTransportation and packagingShear rateVolumetric Mass Density

A rotating stirring device for generating substantially narrow distribution of energy dissipation rate and avoiding presence of Taylor vortices is disclosed. The device includes an outer member (1) such as a cylinder with cross-section of circular shape and an inner member (2) with cross-section of equilateral or inequilateral polygon shape with curved cusps. The inner member is preferably concentrically placed within the outer cylinder and rotates. Such device is particularly advantageous as a reactor or mixer for processes where chemical and physical properties are sensitive to the variations in the shear rate and for processes that involve fragile components. The device can be also used to replace Taylor Couette device for the purposes of improving mass transfer and of avoiding separate of components in the gap in the case of presence of differences in density among components.

Owner:ETH ZZURICH

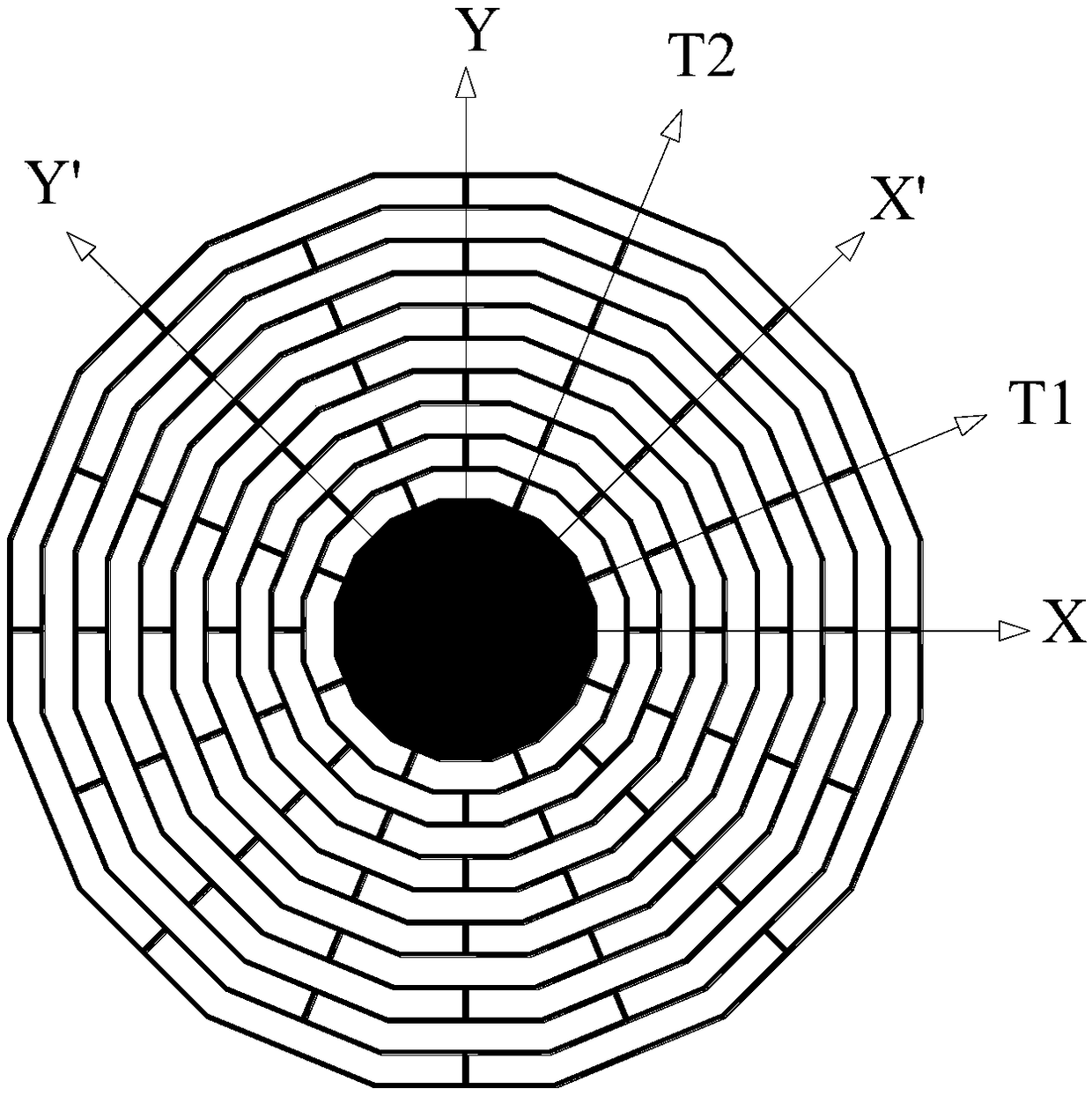

Equilateral polygon discal MEMS resonant gyro

ActiveCN108613669AImprove structural asymmetryHigh precisionSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesAnchor pointEquilateral polygon

The invention discloses an equilateral polygon discal MEMS resonant gyro which comprises a sensitive structure, wherein the sensitive structure includes a harmonic oscillator, fixed anchor points forfixing the entire harmonic oscillator are arranged in the center of the harmonic oscillator, the harmonic oscillator takes the shape of an equilateral polygon disc which is in axial symmetry entirely,the harmonic oscillator includes a plurality of concentric equilateral polygon resonant rings, the concentric equilateral polygon resonant rings are connected through spokes, the fixed anchor pointsare connected with adjacent concentric equilateral polygon resonant rings through the spokes, the plurality of concentric equilateral polygon resonant rings are radially distributed by taking centersof the fixed anchor points as centers, grooves are formed between adjacent equilateral polygon resonant rings and spokes, and electrodes are arranged in the grooves. The equilateral polygon structuresare entirely in line connection without arc line, thereby having a small edge error effect and a relatively smaller symmetry error. Therefore, the resonant frequency of two operating modes are smallin splitting.

Owner:SUZHOU WENZHIXIN MICRO SYST TECH

Asymmetrical hammock shelter

InactiveUS6865757B2Improve comfortImprove fitTravelling sacksSofasEquilateral polygonMechanical engineering

A hammock includes a bed made of a piece of flexible material gathered by folding at opposite ends. Ropes are attached to the gathered ends whereby the bed can be suspended from trees. The edges of the bed are drawn apart along a tension axis which is diagonal to the suspension axis, giving the bed the shape of a non-equilateral polygon so that one can lie diagonally across the suspension axis, whereby the back is well supported.

Owner:HENNESSY HLDG

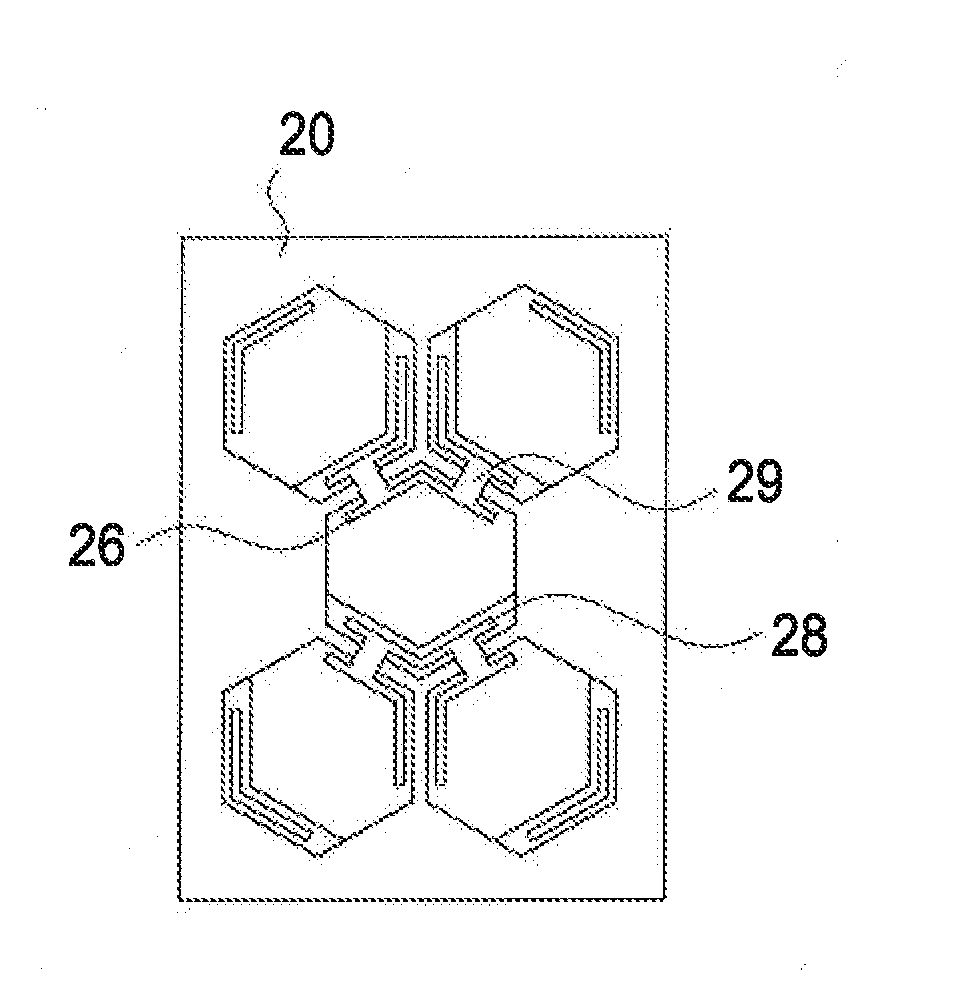

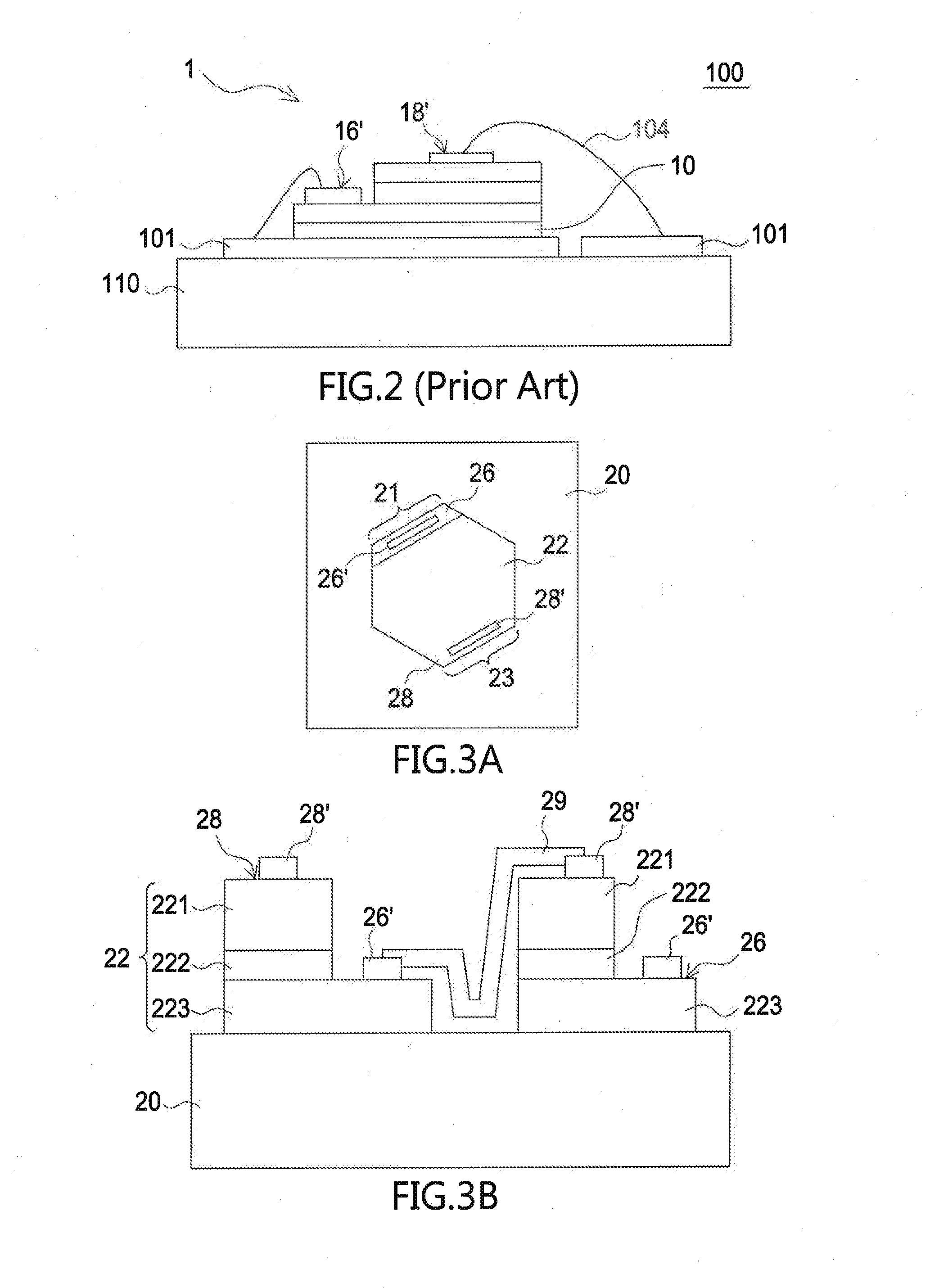

Light-emitting device

InactiveUS20140034974A1Improve reliabilitySolid-state devicesSemiconductor devicesEngineeringEquilateral polygon

A light-emitting diode device is disclosed, which includes a substrate; a plurality of light-emitting diode units, each of the light-emitting diode units being an equilateral polygon with more than four sides, are disposed on the substrate; wherein each of the light-emitting diode units includes a first electrical connecting area disposed along a first side of the light-emitting diode unit, a second electrical connecting area disposed along a second side of the light-emitting diode unit, and a conductive connecting structure disposed on each of the electrical connecting areas; wherein each of the electrical connecting area electrically connects to one another light-emitting diode unit through the conductive connecting structure.

Owner:EPISTAR CORP

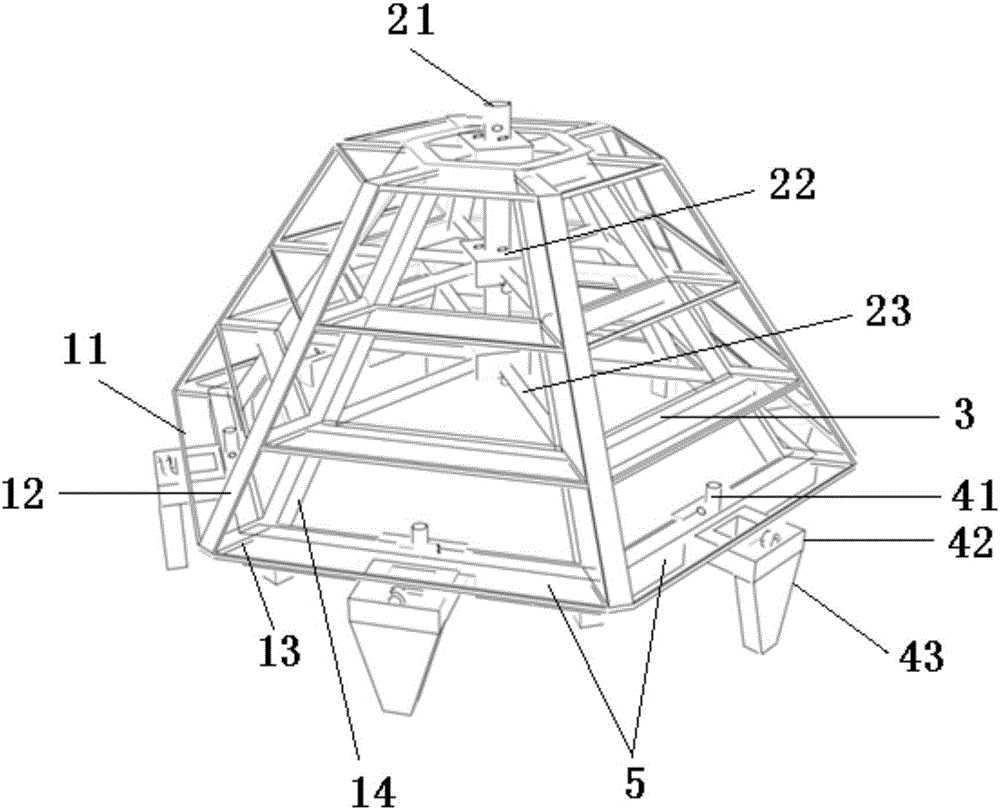

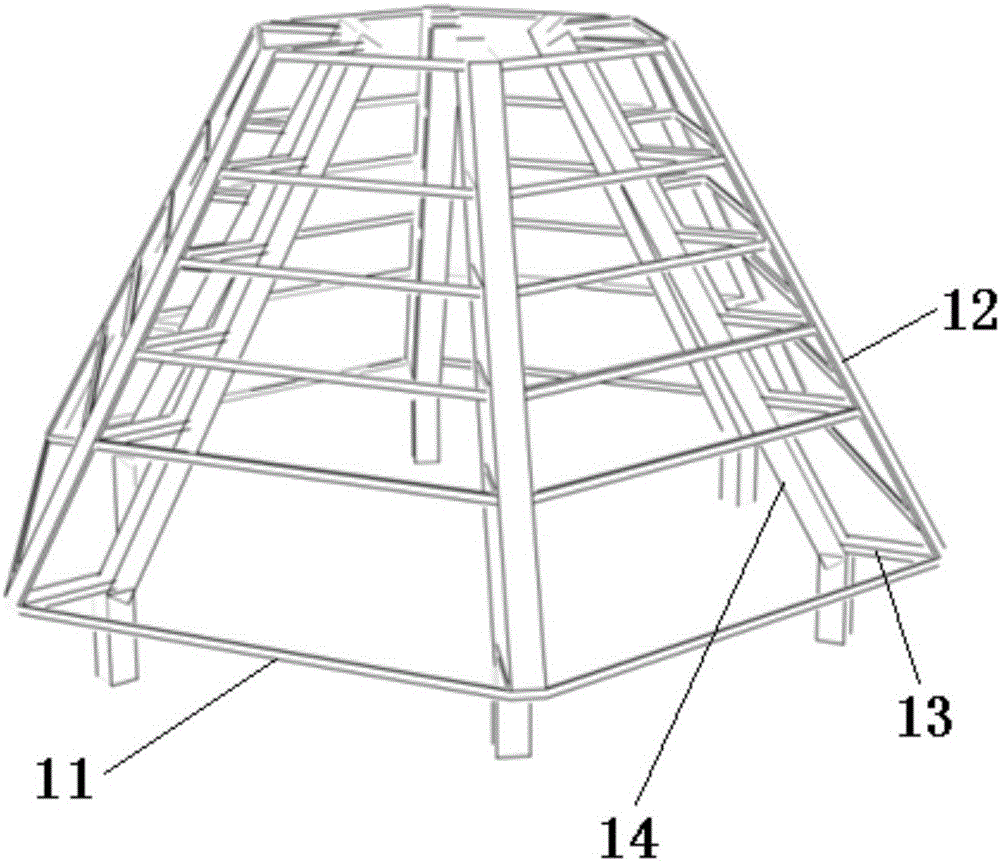

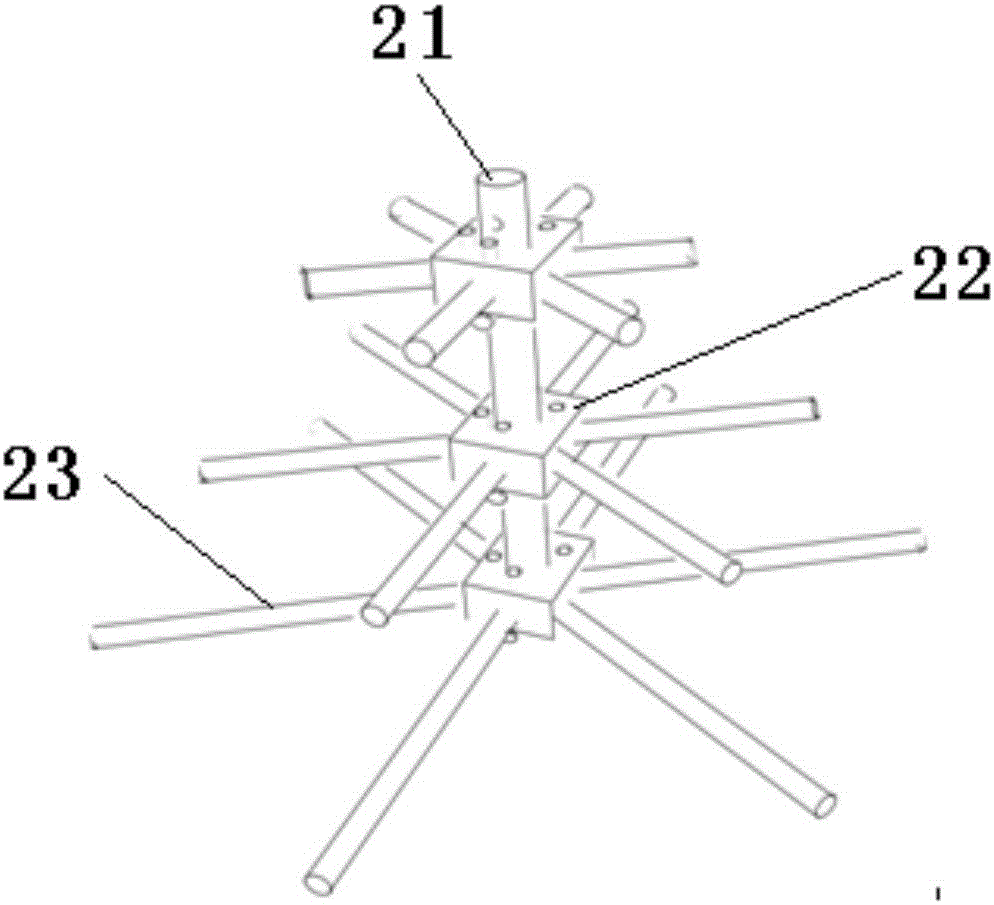

Basalt fiber cay ecological restoration multi-dimensional reef

InactiveCN105994091AImprove mechanical propertiesImprove corrosion resistanceClimate change adaptationPisciculture and aquariaEcological environmentApposition

The invention discloses a basalt fiber cay ecological restoration multi-dimensional reef which comprises a polygonal prismatic platform frame or a circular platform frame, a central supporting component and a polygonal connector, wherein the polygonal prismatic platform frame comprises a plurality of equilateral polygonal components with side length being gradually increased, an outer inclined stay bar and an inner inclined stay bar from top to bottom; the polygonal connector is arranged on the inner side of the inner inclined stay bar and is fixedly connected with the inner inclined stay bar; and the central supporting component comprises a plurality of central connectors from top to bottom, horizontal supporting rods in uniform outward radial connection with the central connectors and central vertical columns connected with the central connectors from top to bottom. The basalt fiber cay ecological restoration multi-dimensional reef has the advantages of environment friendliness, high strength, long service life, corrosion resistance, plant modular production, short construction cycle, strong storm resistance, construction and mounting under various complex cay geological environments, benefit in coral apposition growth and capability of effectively repairing marine ecological environments.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI +1

Semiconductor radiation sensing device and manufacturing method thereof

InactiveCN102214723AHigh-resolutionLow detection limitFinal product manufactureSemiconductor devicesLower limitSemiconductor sensor

The invention relates to the field of semiconductor sensors and discloses a semiconductor radiation sensing device and a manufacturing method thereof. The sensing device comprises at least one radiation sensing unit, wherein each radiation sensing unit comprises a first substrate, a first columnar electrode and a second columnar electrode; the first substrate comprises a first surface and a second surface; the first columnar electrode comprises first metal posts and N-type doped silicon surrounding the first metal posts; the second columnar electrode comprises more than two second metal postsand P-type doped silicon surrounding the second metal posts; the first columnar electrode and the second columnar electrode are embedded into the first substrate and pass through the first surface and the second surface of the substrate; the more than two metal posts are arranged in an equilateral polygon mode; and the first columnar electrode is arranged at the geometric center of the equilateral polygon. According to the invention, the thin dead layer thickness of the sensing device, the smaller equivalent capacitance and the shorter signal drifting process can be realized, thus improving the energy resolution, reducing the response time and decreasing the lower limit of energy detection.

Owner:PEKING UNIV

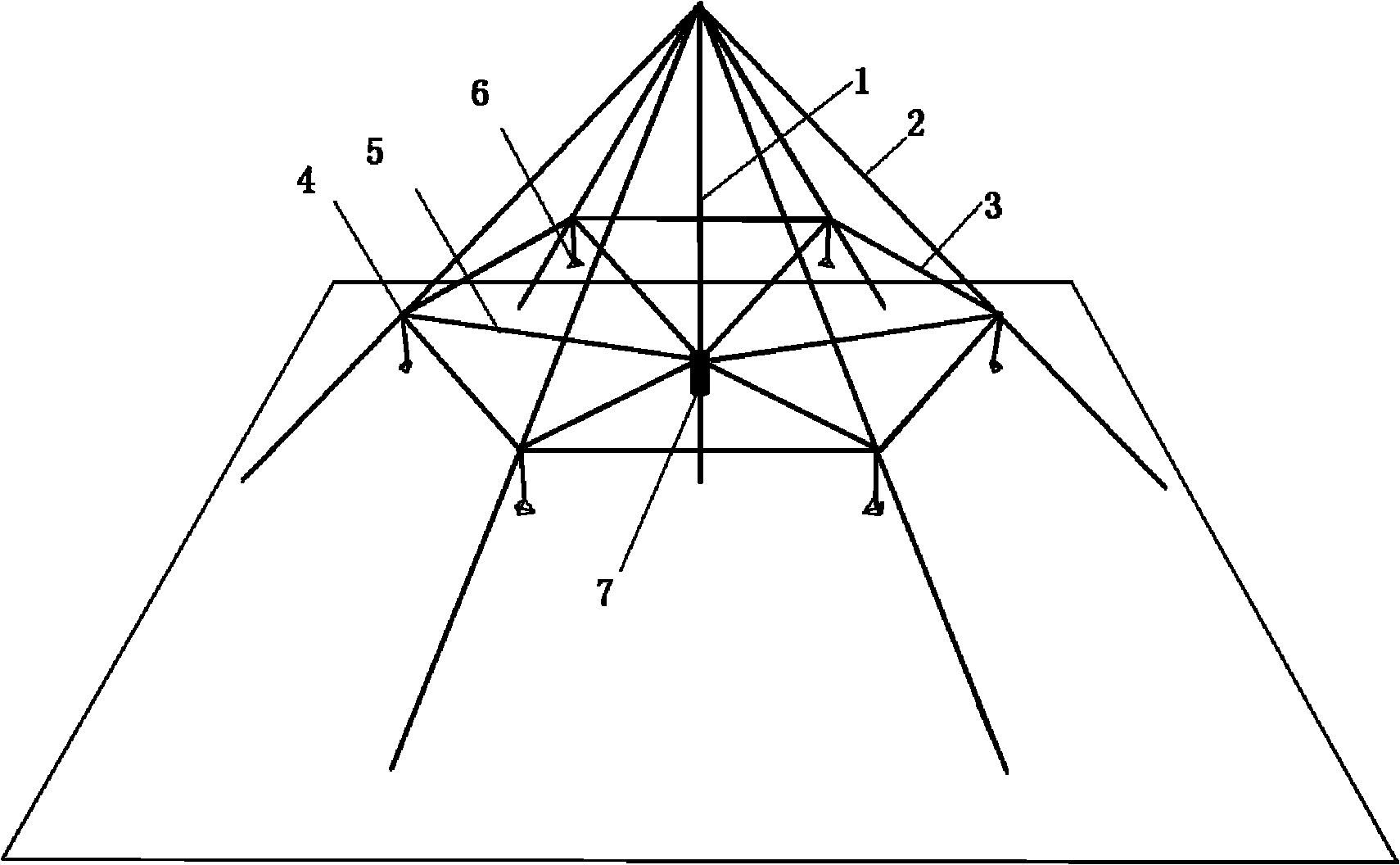

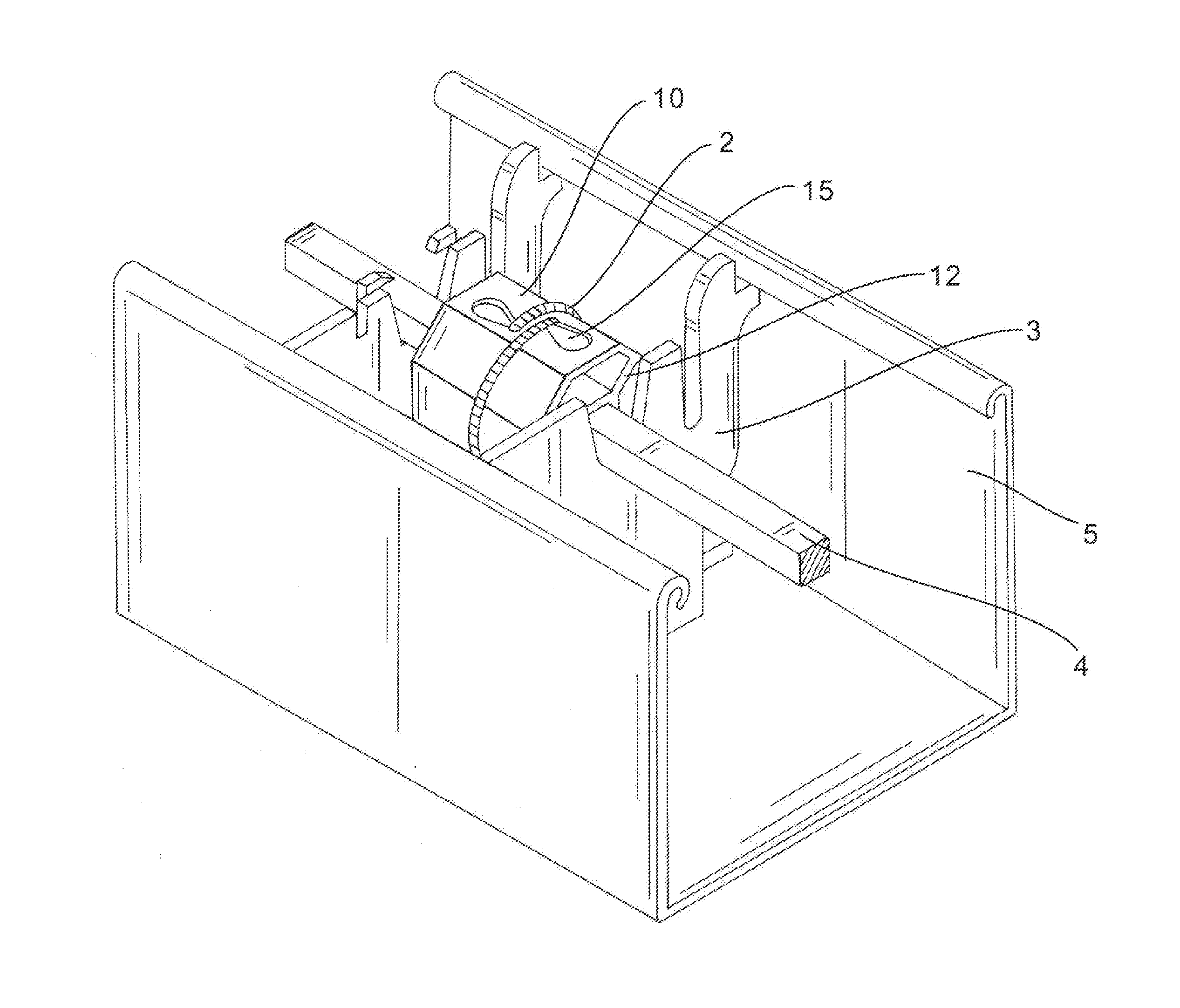

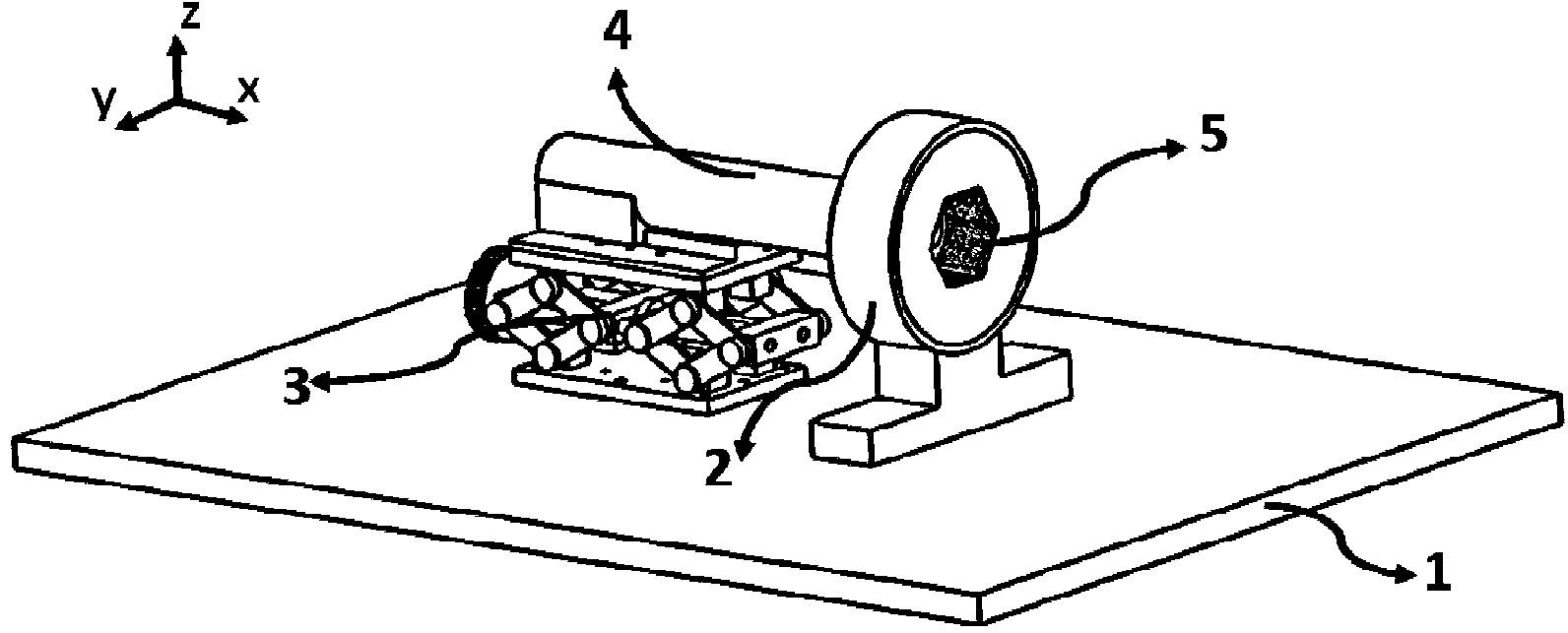

Hoisting system of large-sized extensible antenna

InactiveCN102050409ANot limited by test spaceConvenient multi-point uninstallationLifting devicesEngineeringZero gravity

The invention discloses a hoisting system for a large-sized extensible antenna, and in particular relates to a ground testing system for the extensible antenna. The hoisting system provided by the invention mainly solves the problem that the existing testing system can not simulate the space zero gravity extension for the extensible antenna in the ground stimulation. The system provided by the invention comprises a lifting rod (1), a positioning cable (2), a supporting cable (3), a hoisting ring (4), a pulling cable (5) and a counter weight (6), wherein the supporting cable (3) is an equilateral polygon parallel to the opening surface of the extensible antenna (7); the hoisting ring (4) is arranged in each cross position of the radially arranged positioning cable (2) and supporting cable (3); the pulling cable (5) passes through the hoisting ring (4) and is respectively connected with the counter weight (6) and the extensible antenna (7); and one end of the positioning cable (2) is connected with the upper end of the lifting rod (1), and the other end of the positioning cable and the other end of the lifting rod are fixed with the ground so as to form a circular conical surface extensible supporting structure with the lifting rod (1) as the center. The hoisting system provided by the invention is convenient in gravity unloading, is not limited by the testing space and can be used for the ground extension test of the extensible antenna.

Owner:XIDIAN UNIV

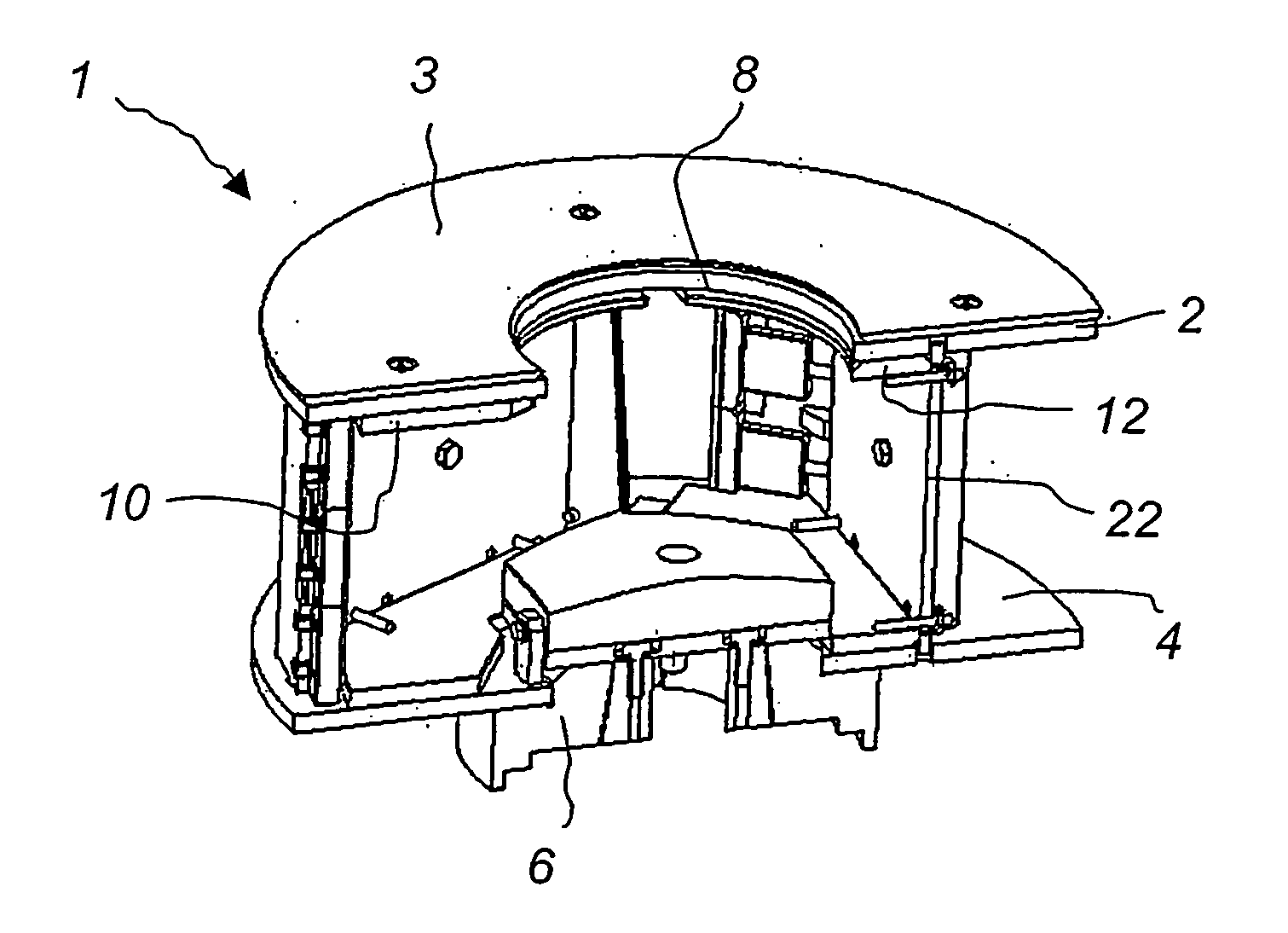

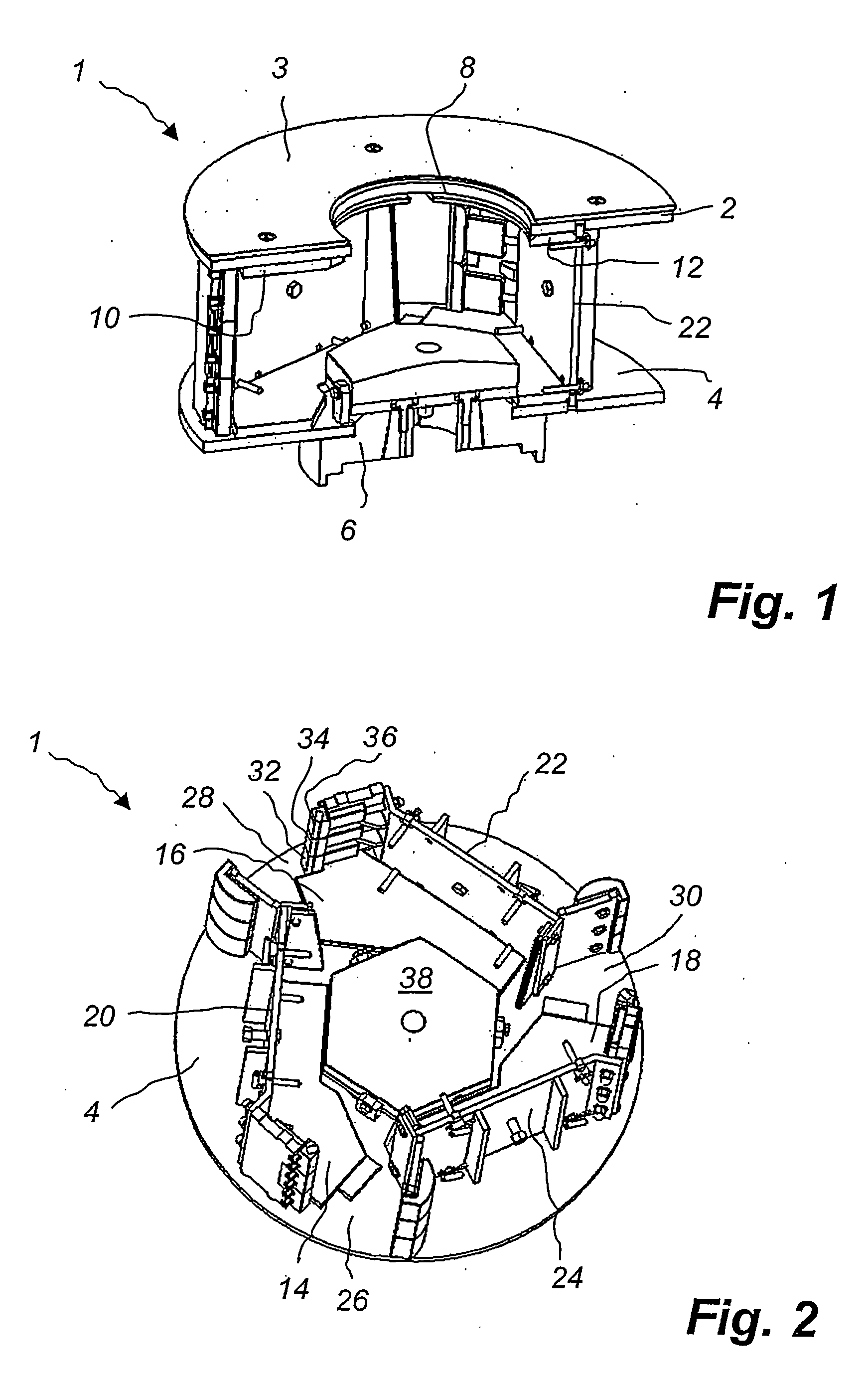

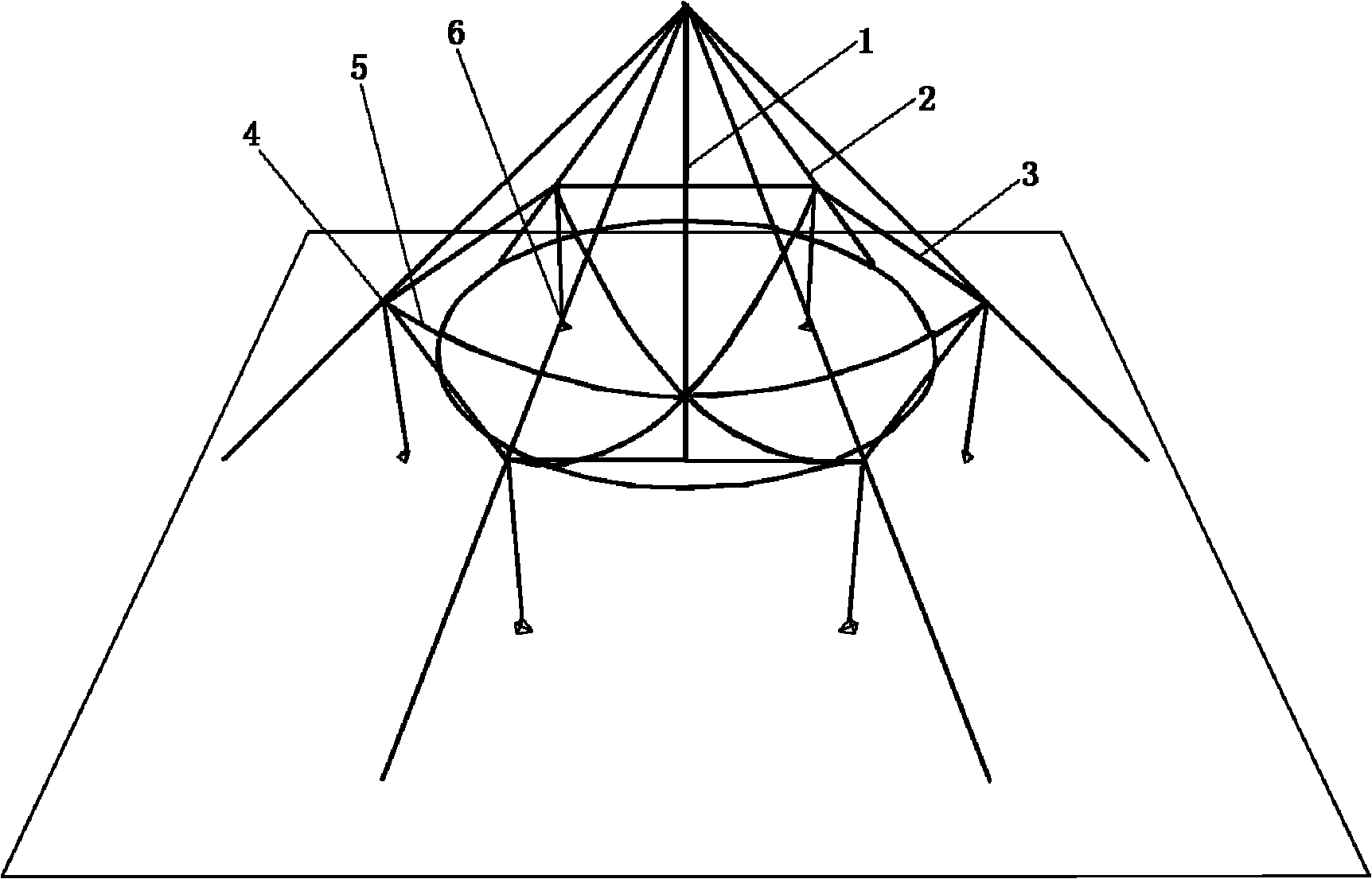

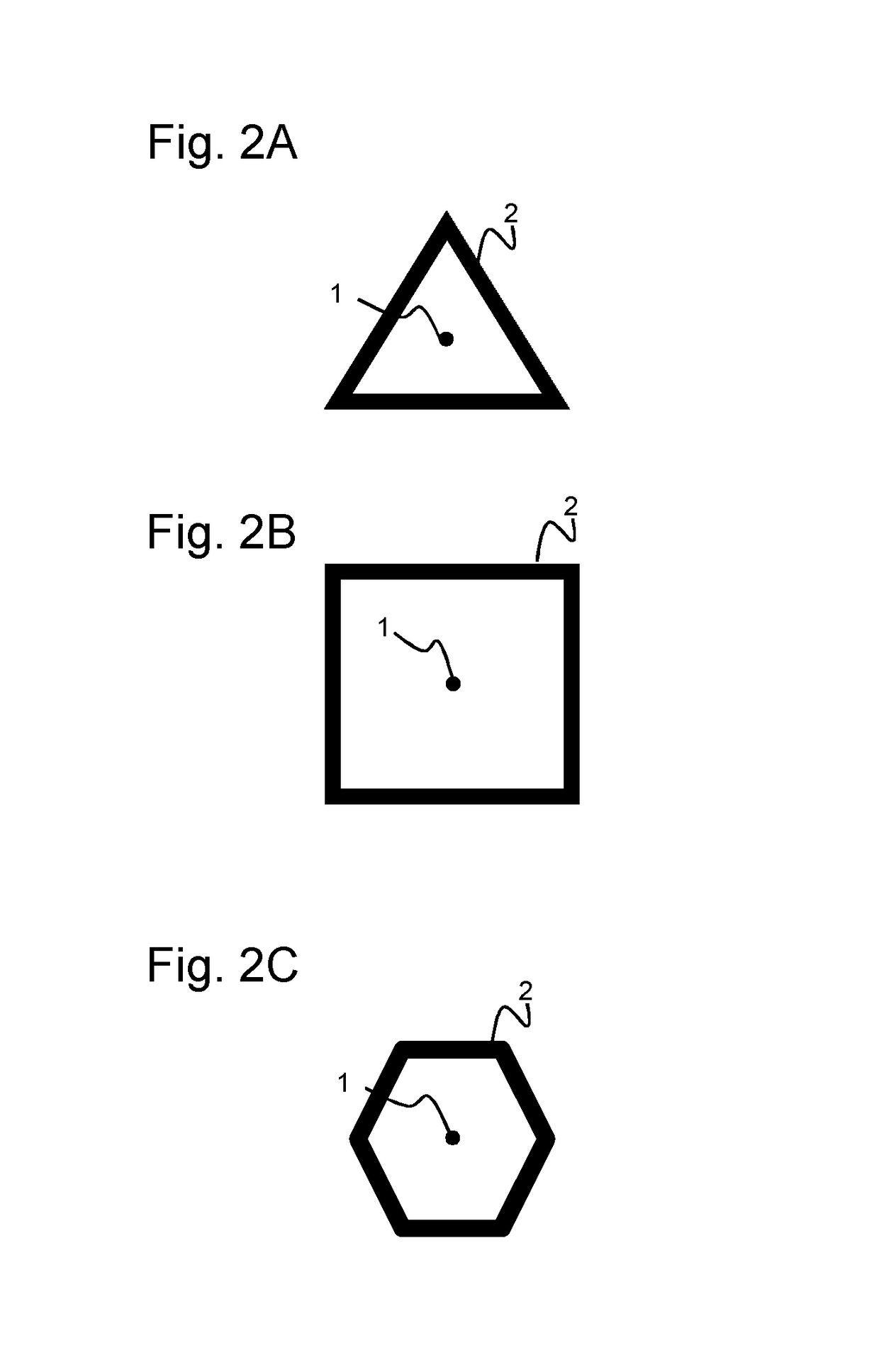

Modular multi-channel coil array for an MRI having decoupling of next but one neighbors

ActiveUS20120268133A1Reduced space requirementsReduce spacingMagnetic measurementsElectric/magnetic detectionTransceiverCoil array

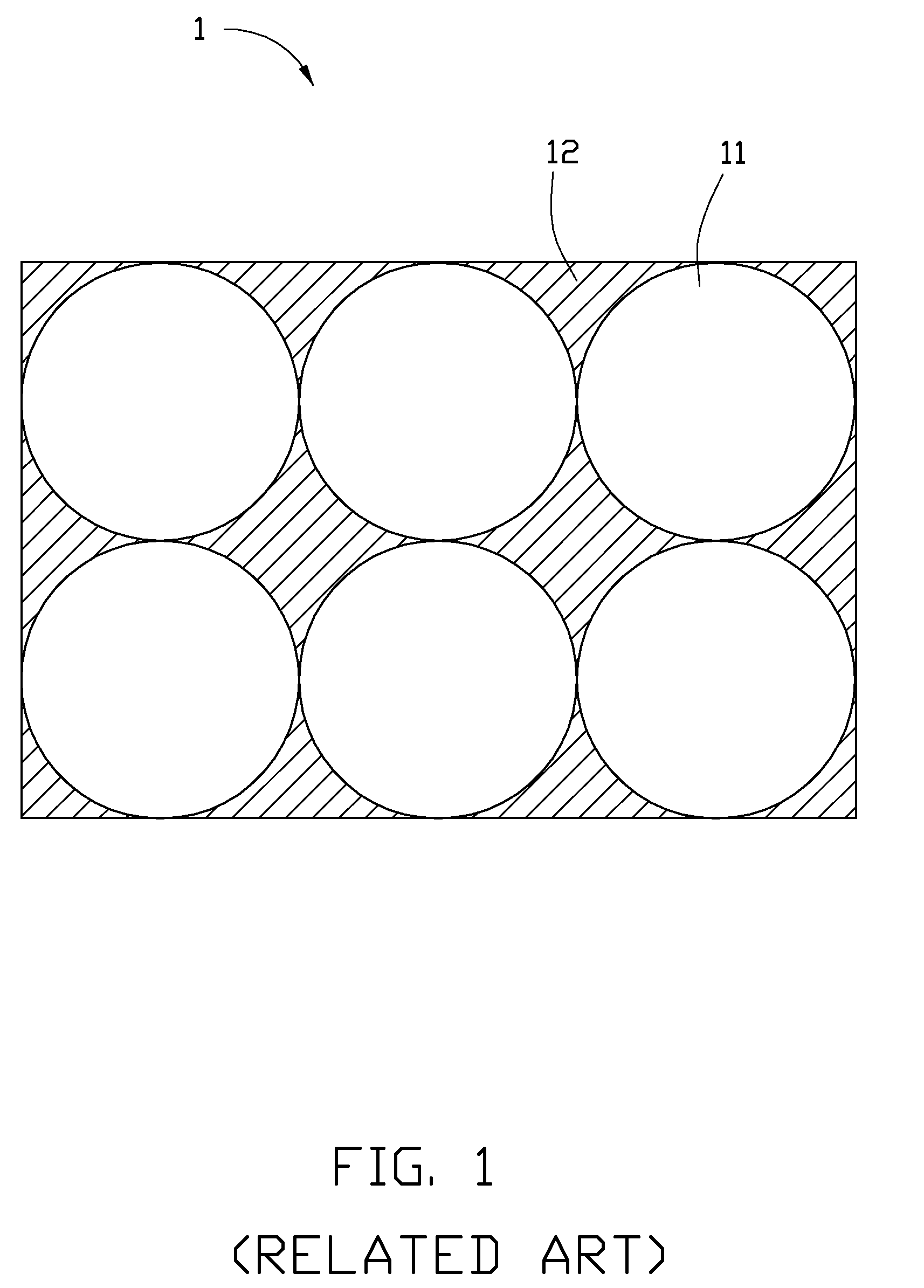

A multi-channel coil array for use as a transceiver in magnetic resonance imaging (MRI) has a plurality of radio frequency (RF) coils disposed next to one another, devices for electromagnetically decoupling the RF coils and coil elements which are applied onto a planar carrier element (5). The carrier elements (5) have a regular, equilateral polygonal outer contour and the shape of the individual coils (2) corresponds to the outer contour of the carrier element (5). An individual coil (2) has a loop-shaped structure (1), which leads to a decoupling of individual coils (2) not immediately adjacent to each other when a plurality of individual elements are arranged. The space requirement for adding new coils is reduced, and the modular design makes it possible to easily implement any three-dimensional or two-dimensional shape.

Owner:ALBERT LUDWIGS UNIV FREIBURG

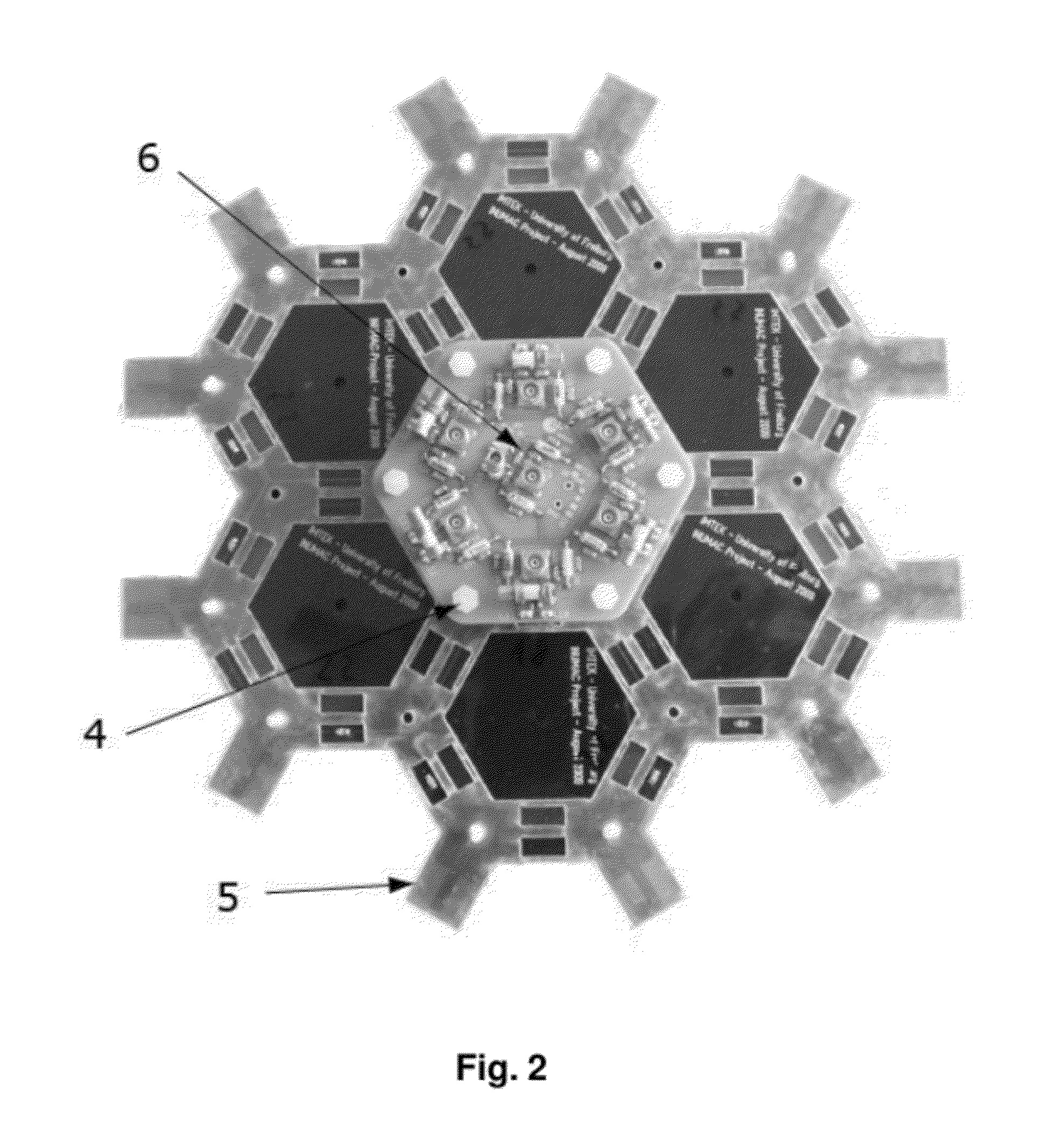

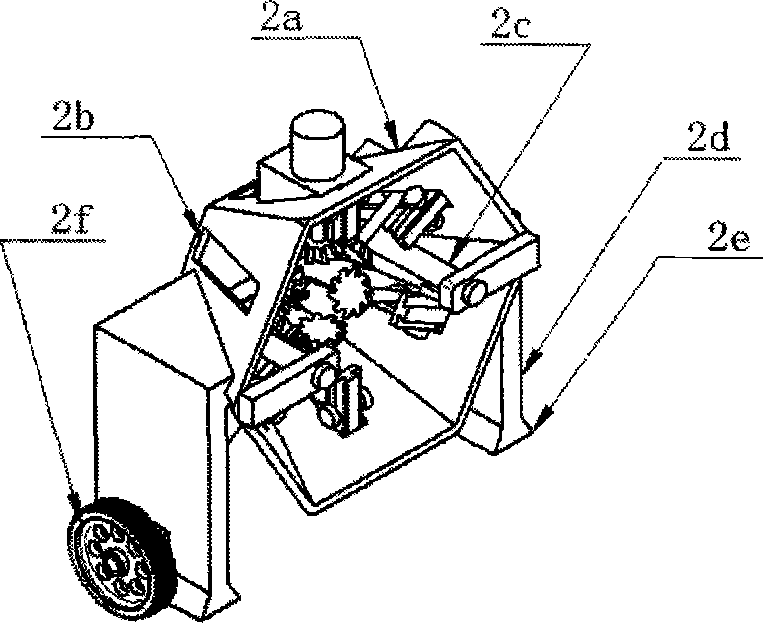

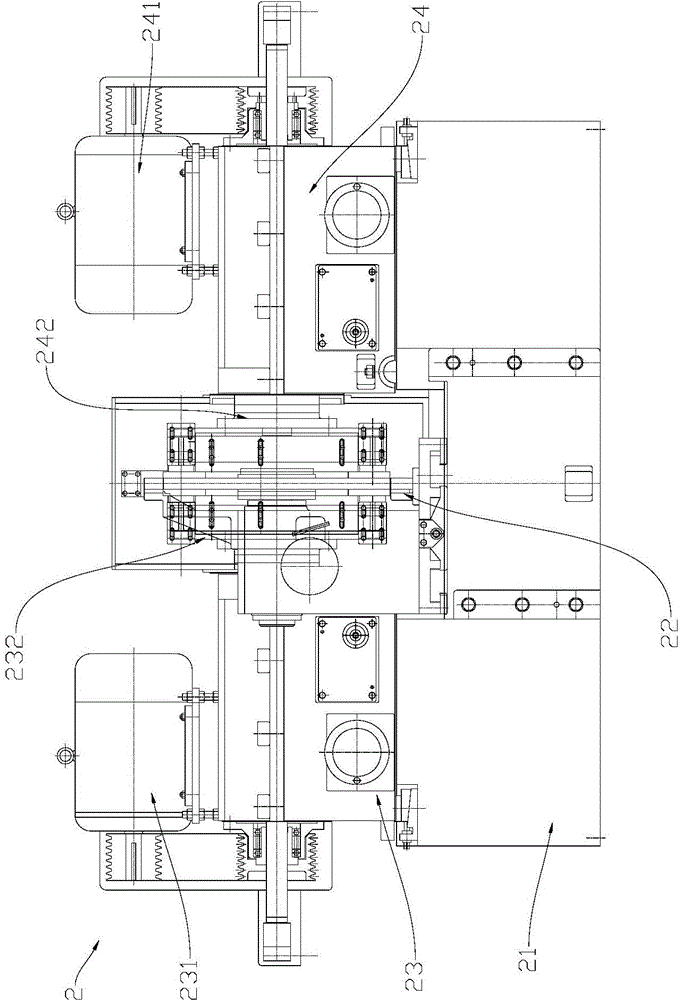

Bamboo and wood equilateral polygon milling machine

InactiveCN104128970AImprove uniformitySimple structureFlat surfacing machinesEngineeringEquilateral polygon

The invention relates to a bamboo and wood equilateral polygon milling machine which has effect of milling bamboo or log into equilateral polygon materials, such as regular hexagon or regular octagon and the like. The milling machine specifically contains a pedestal, a cutter mounting table, a cutter regulating disk, a fixed top claw and a top claw support. The cross section of the pedestal is shaped as a groove; upward sides of two ends of the pedestal are provided with dovetail slots; and two side surfaces of the pedestal are provided with racks. Several cutters are installed on the cutter mounting table, and the cutters are driven to slide on the pedestal so as to cut bamboo into an equilateral polygon bamboo material. The cutter regulating disk has dovetail slots which are uniformly arranged in one side surface of the cutter regulating disk, and the cutters connected with the cutter regulating disk can be driven to regulate position. The fixed top claw stretches from inner sides of two ends of the bamboo, and the bamboo is fixed and the axis is maintained horizontal. The top claw support has an effect of installing the fixed top claw and regulating height and horizontal position of the fixed top claw.

Owner:BEIJING FORESTRY MACHINERY RES INST OF STATE FORESTRY ADMINISTRATION

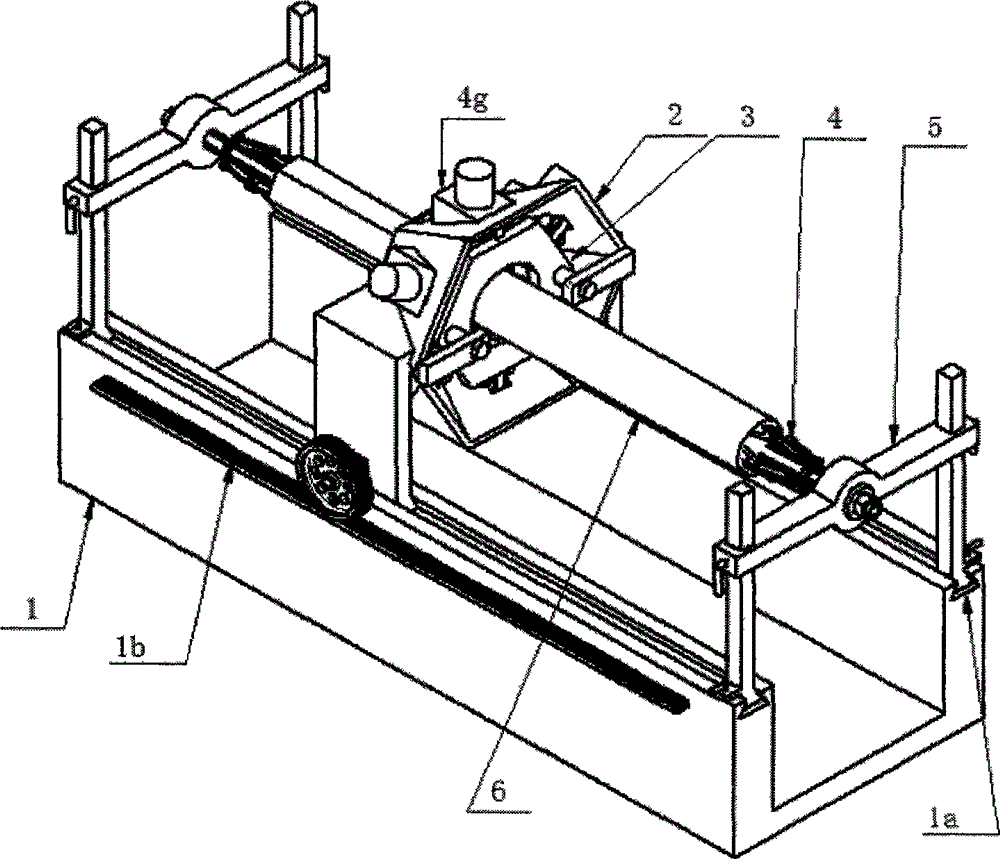

Three-axis numerically-controlled milling machine milling method and device for semi-open type impeller of variable-cross-section twisted blades

InactiveCN107052419AEasy to operateImprove processing efficiencyAutomatic control devicesFeeding apparatusImpellerSemi open

The invention discloses a three-axis numerically-controlled milling machine milling method and device for a semi-open type impeller of variable-cross-section twisted blades. The method comprises the following steps that 1, a three-dimensional model of the semi-open type impeller is made through software (Solidworks) and stored in the IGS format, and UG4.0 is introduced for programming; 2, machining before milling is conducted on a forge piece through a lathe; 3, the piece obtained through machining before milling is vertically placed on a milling machine workbench in the mode that the piece is axially parallel to the Z-axis direction of a milling machine and the shaft disc surface is upward and then unloaded after an equilateral polygon of which the edge number is equal to the number of the blades is milled, and a central spindle and a connecting disc are installed and then fixed after being leveled and aligned; 4, a first program and a second program are introduced for machining; 5, a blank obtained through the first program and the second program is fixed to an indexing disc through the connecting disc, leveling and aligning are conducted through an impeller chuck, the indexing disc and the equilateral polygon arranged on a shaft disc, and machining achieved through a third program is completed; 6, a reserved technological face of the shaft disc and the technological chuck are removed, and then impeller machining is completed. Compared with a method for machining the semi-open type impeller through a five-axis milling machine, the milling method has the advantages that the machining cost is greatly reduced while the machining precision is guaranteed.

Owner:NORTHEASTERN UNIV

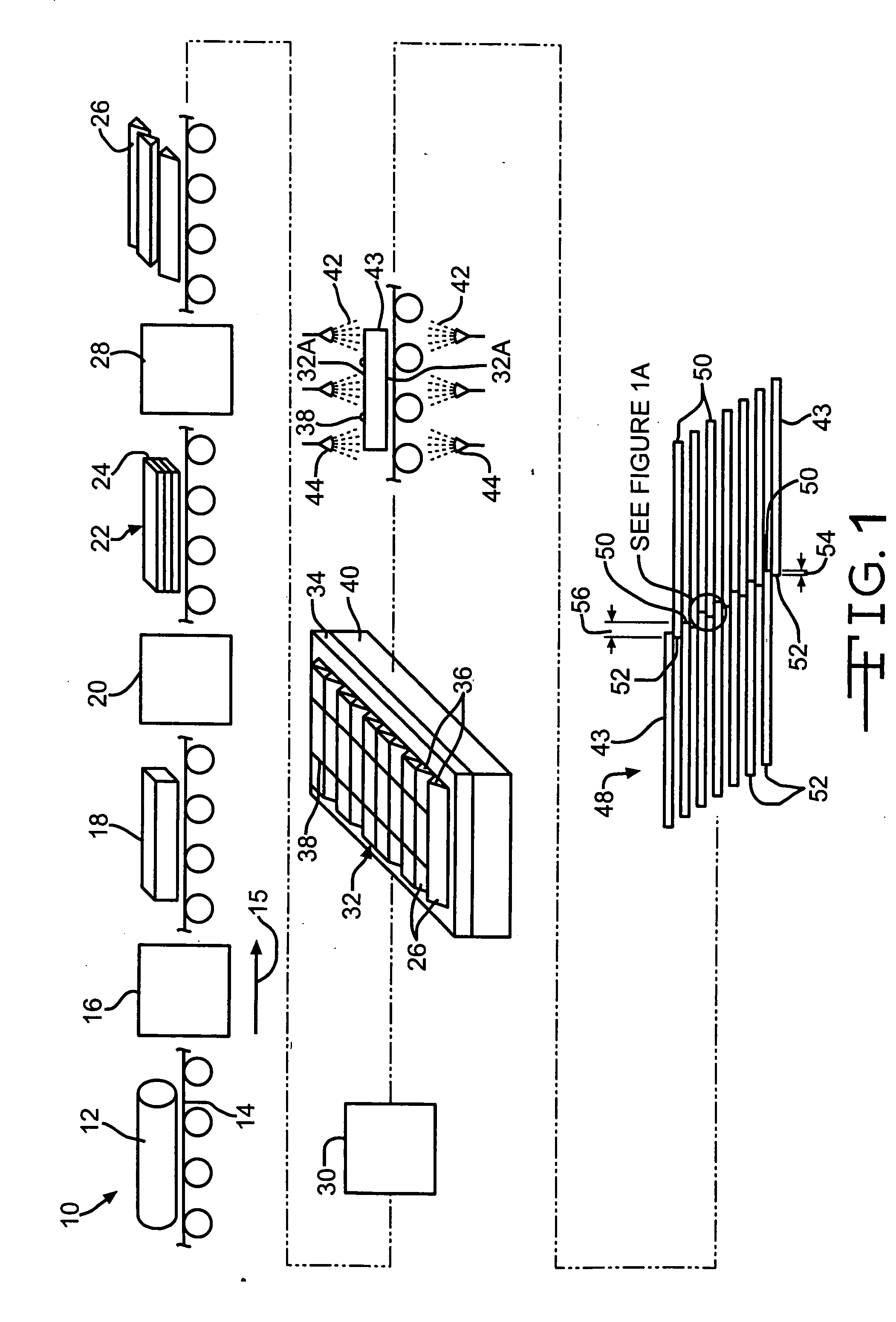

Equilateral strand composite lumber and method of making same

InactiveUS20050000185A1Simple methodLoad-supporting elementsNon-woven fabricsEngineeringComposite lumber

A method of forming a composite beam includes cutting an elongated piece of wood to produce strands having cross sections with a substantially symmetrical equilateral polygonal shape. Resin is then applied to the strands, and the strands are formed into a composite beam.

Owner:UNIVERSITY OF MAINE

Centrosymmetric radio frequency electrode configuration for skin treatment

PendingUS20170189668A1Improve securityLarge cross-sectional dimensionSurgical instruments for heatingExternal electrodesSkin treatmentsSkin contact

The invention relates to a device (100) for RF skin treatment comprising an outer electrode (2) arranged on an operational side (15) of the device. The outer electrode has an annular or equilateral polygonal shape. An inner electrode (1) is arranged at a center of the outer electrode and is surrounded by the outer electrode. An RF generator (21) is arranged to supply an RF treatment voltage between the inner electrode (1) and the outer electrode (2). A skin contact surface of the inner electrode has a largest cross-sectional dimension in a range of 200-500 μm, and the RF treatment voltage is less than 50 V. The invention provides a device with improved safety in that it enables the creation of non-ablative fractionated skin lesions, particularly using a relatively low RF treatment voltage for treating the skin as compared to known devices and without the necessity of a feedback or monitoring system.

Owner:KONINKLJIJKE PHILIPS NV

Polygonal drum for controlling blind slats

InactiveUS20120227913A1Enhanced blind slat control effectGuaranteed uptimeLight protection screensWindow shutterEngineering

Owner:CHOU TSER WEN

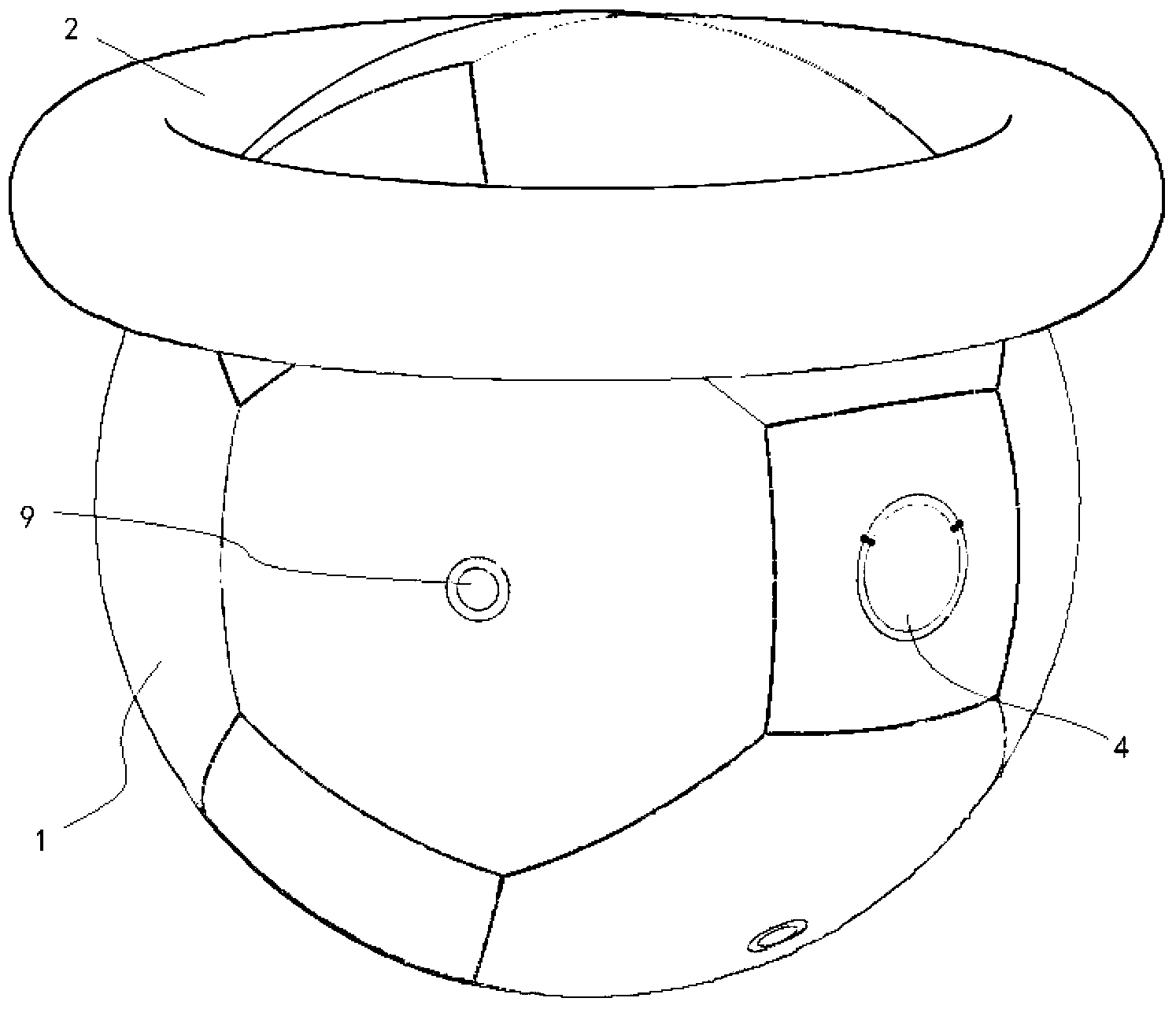

Inflatable polycystic emergency evacuation device

The invention discloses an inflatable polycystic emergency evacuation device which comprises a spherical gasbag unit and a gas filling device, wherein sealed protecting spaces are formed in the center of each spherical gasbag unit, the spherical gasbag unit is composed of prismatic gasbags, the bottom surfaces and the top surfaces of the prismatic gasbags form coaxial spherical equilateral polygons, and the side surfaces of the prismatic gasbags are sectors; an opening for in and out of outer layer workers and an opening for the in and out of inner layer workers are formed in the spherical gasbag unit; and the gas filling device is further arranged on the spherical gasbag unit. The device provided by the invention makes full use of aerodynamic resistance to realize aerial deceleration, and a gas filling structure absorbs shock kinetic energy, so as to realize the purpose of safe landing. The device provided by the invention is foldable to store, saves space, is easy to place, light in weight, and convenient to carry, and can be used for emergency escape in high-rise buildings and super high-rise buildings.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Plant transplanting cultivation device capable of treating municipal wastewater

InactiveCN103733909AImprove transplant survivalFertilize wellWatering devicesCultivating equipmentsVertical tubeDecomposition

A plant transplanting cultivation device capable of treating municipal wastewater comprises a spiral tube coil, a coil-mouth ring, a clamping structure and vertical tubes, wherein the spiral tube coil is formed by tightly spiraling a water pipe. An interface arranged on the upper part of the water pipe is communicated with the coil-mouth ring and an interface arranged on the lower part of the water pipe is communicated with the bottom ends of the vertical tubes. The coil-mouth ring is of a circular or an equilateral polygon shape and positioned above the spiral tube coil in a fixed clamping manner by the clamping structure. The vertical tubes are positioned in the area which is enclosed by the spiral tube coil and small holes are formed in the wall of the water pipe close to the inner wall of the spiral tube coil. The plant transplanting cultivation device can be used for transplanting and cultivating plants such as trees and the like to reduce damages to root hairs, improve the survival rate of plants such as trees and the like, and decrease the probabilities of plants such as trees and the like being blown down and frozen to death. At the same time, municipal wastewater can be purified by plants functions of absorption, decomposition and purification to promote plants growing.

Owner:刘尧臣

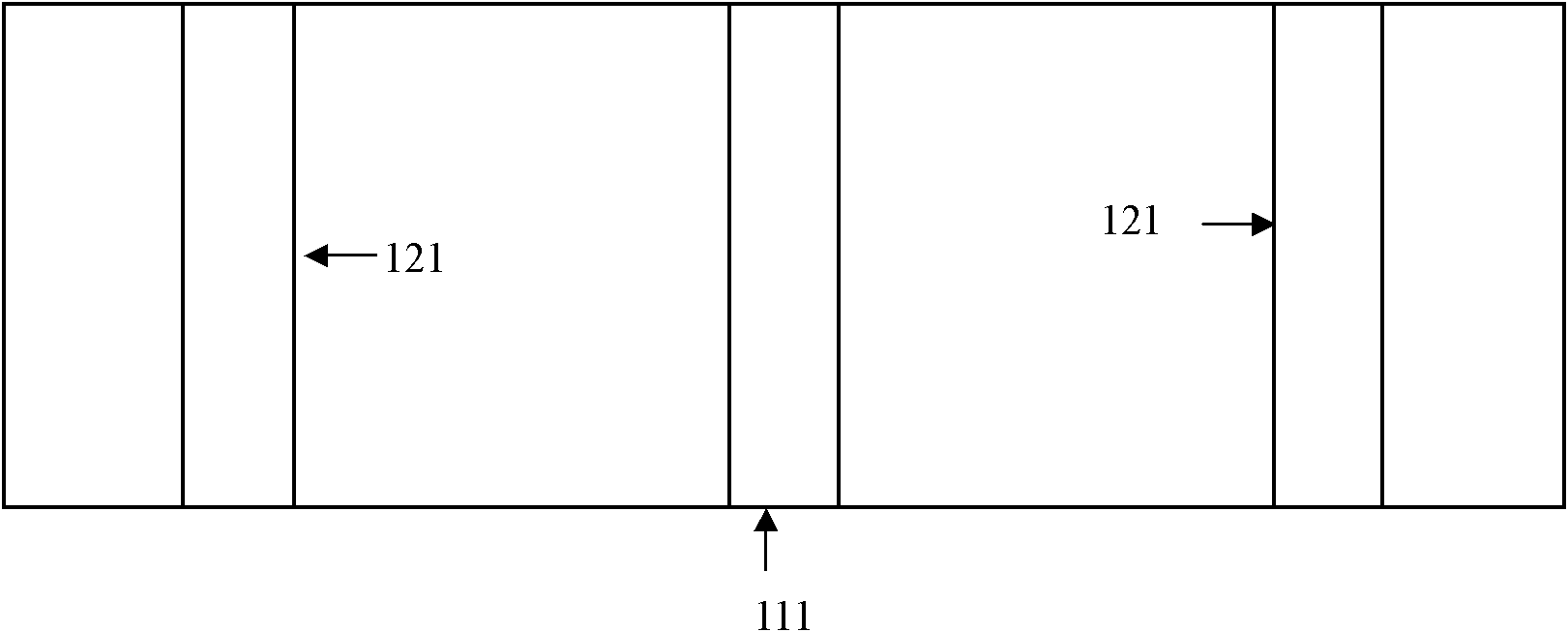

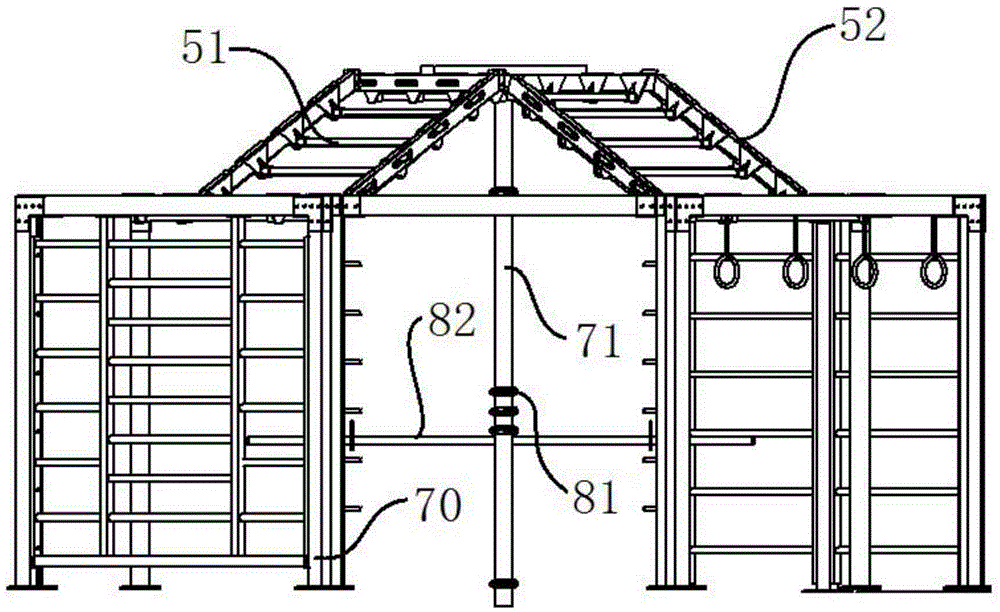

Polygonal extension fitness frame and corresponding comprehensive fitness combination frame

ActiveCN104436523AMeeting exercise needsImprove space utilizationGymnastic exercisingEngineeringEquilateral polygon

The invention provides a polygonal extension fitness frame and a corresponding comprehensive fitness combination frame. The polygonal extension fitness frame comprises a plurality of first-layer crossbeams, at least one layer of outer-layer crossbeams, a plurality of layer-to-layer transition beams, a plurality of stand columns and various fitness mechanisms or instruments, wherein the two ends of each first-layer crossbeam are located on a first-layer circumference by taking the center of the polygonal extension fitness frame as the circle center, so that one side of an equilateral polygon is formed, and the endpoints of one side are located on the first-layer circumference; the two ends of each outer-layer crossbeam are located on the outer-layer circumference outside the first-layer circumference and correspond to vacant positions formed because the first-layer crossbeams are separated; the crossbeams in all layers are connected in series through the layer-to-layer transition beams; one end of each stand column is fixed to a base or the ground, and the other ends of the stand columns are connected with connecting points among the first-layer crossbeams, the outer-layer crossbeams and the layer-to-layer transition beams; the fitness mechanisms or instruments are arranged among the first-layer crossbeams or the outer-layer crossbeams or the layer-to-layer transition beams or the stand columns. More detailed function division is carried out, more people can be allowed to take exercise without mutual influences, and security, privacy, interestingness and comfort of exercise are increased.

Owner:SHENZHEN GOOD FAMILY ENTERPRISE

Calibration plate of double-camera system for DIC (Digital Image Correlation) measurement and calibration method thereof

InactiveCN103278104AImprove calibration accuracySimple designUsing optical meansTotal stationEngineering

The invention discloses a calibration plate of a double-camera system for DIC (Digital Image Correlation) measurement and a calibration method thereof and belongs to the technical field of digital images. The calibration plate comprises a calibration plate base plate and a target group, wherein the front face of the calibration plate base plate is provided with speckles; and the target group is arranged on the front face of the calibration plate base plate and consists of a plurality of targets; the centers of a plurality of double-total station targets form an equilateral polygon. Due to the adoption of the method of precisely measuring three-dimensional coordinates of the centers of the targets by double total stations and a geometric construction method, the size is precisely selected to calibrate space points, corresponding points on an image are precisely matched, and the size calibration precision is improved. A calibration plate which is provided by a seller is used for respectively calibrating the parameters of two cameras, the calibration plate provided by the invention is used for relating the two cameras, and the needed precision of calibrating the cameras when a large-size space object is measured is ensured. According to the invention, the calibration precision is higher, the manufacture is simple, and the carry is simple, which is of great importance for measuring the deformation of a large-size high precision object.

Owner:HARBIN INST OF TECH

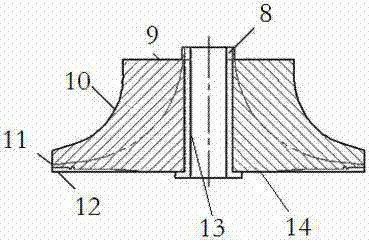

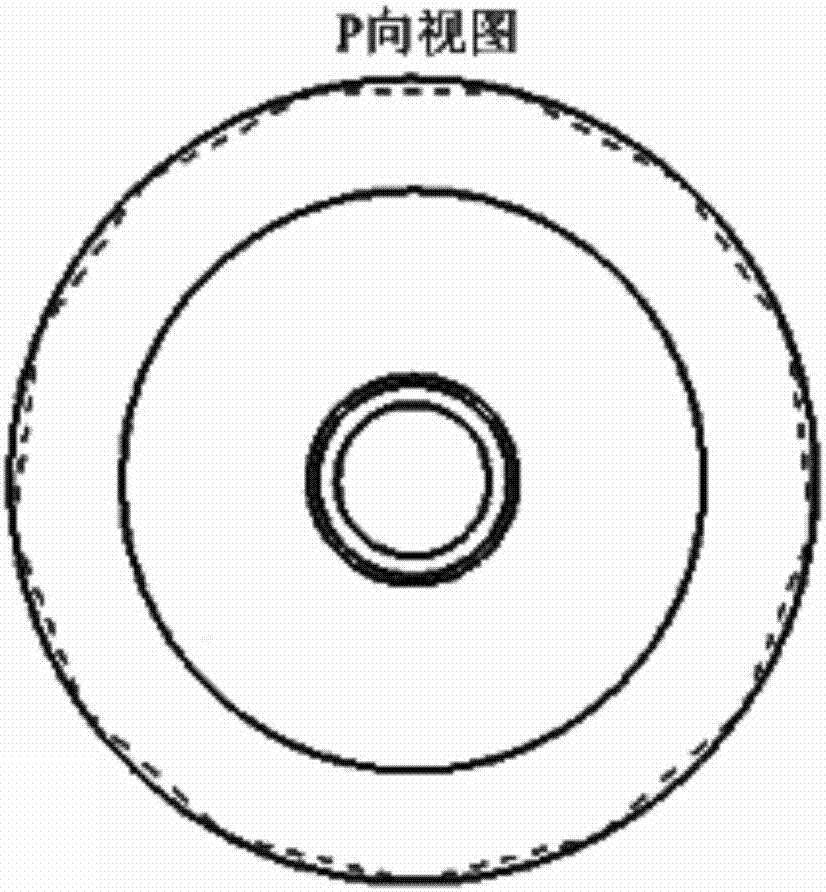

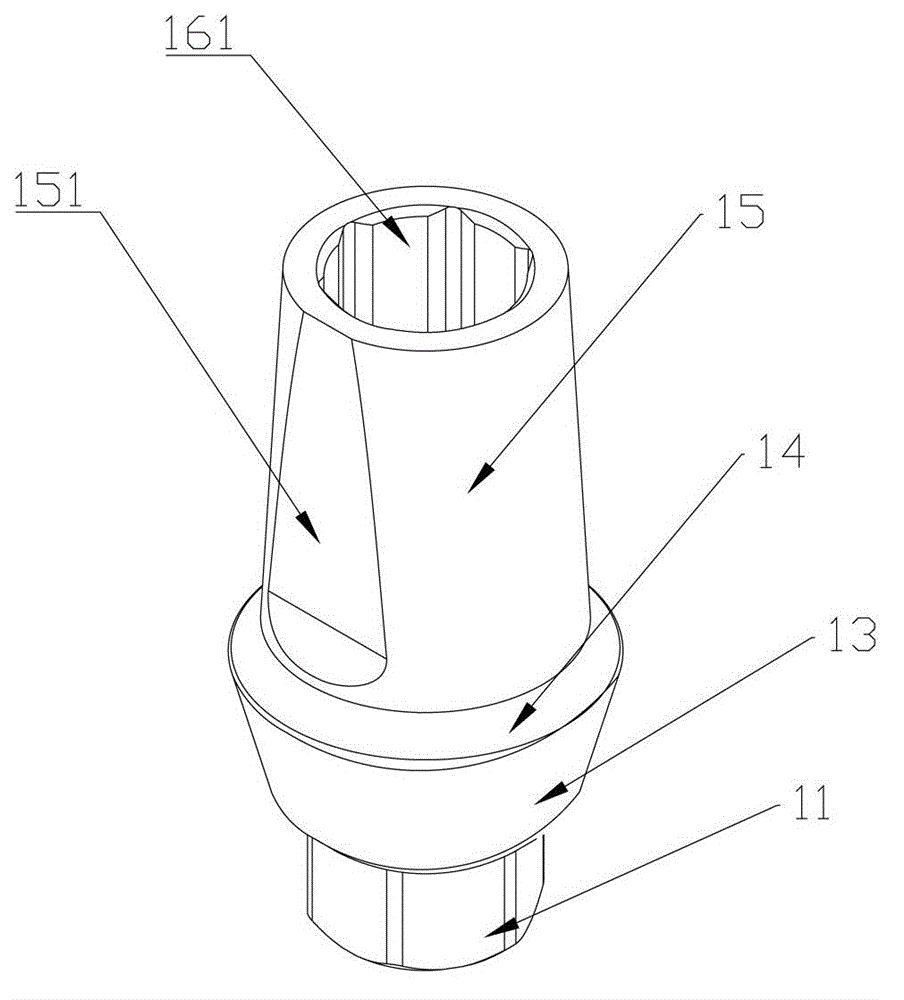

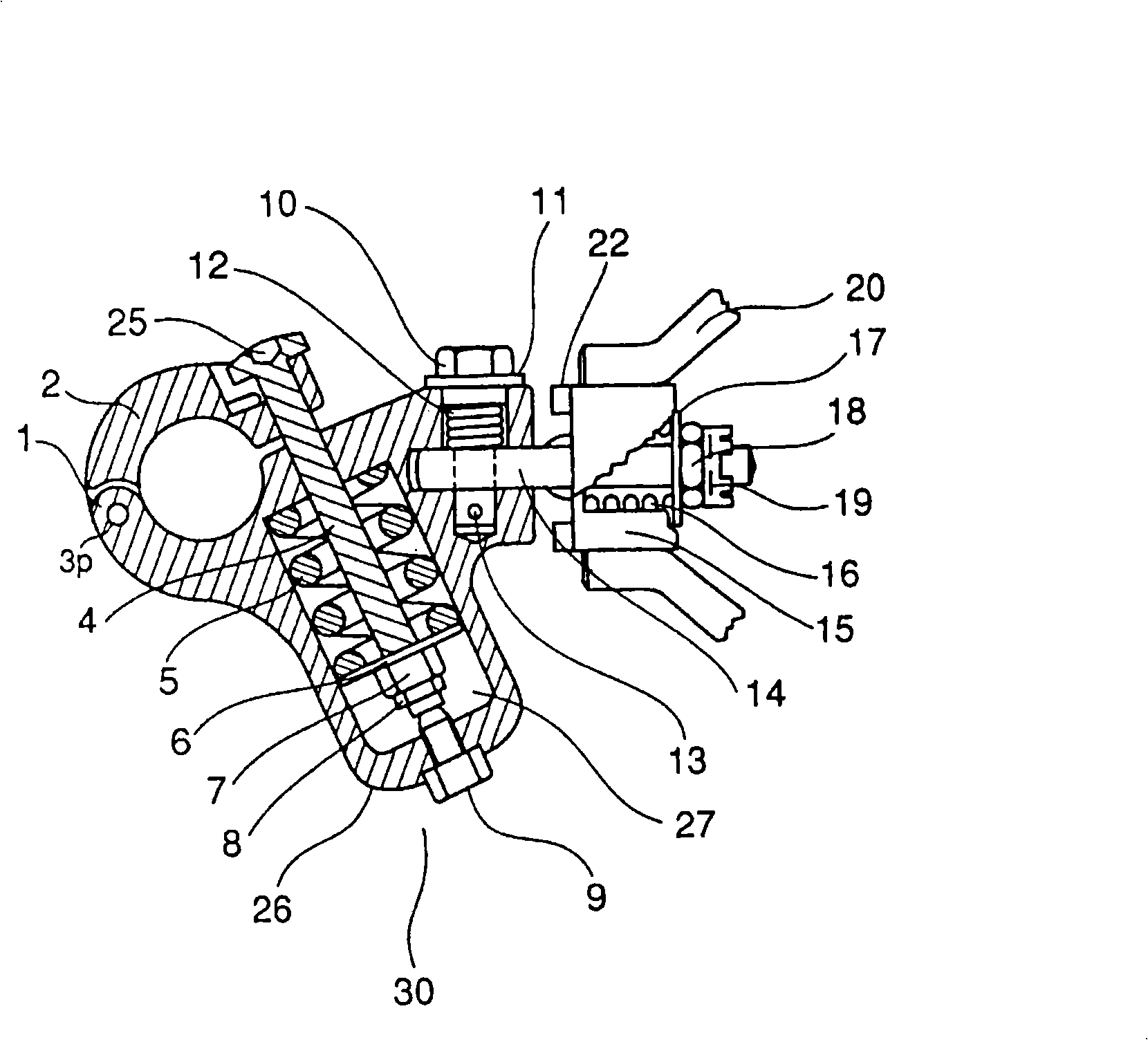

Abutment applied to dental implant and abutment taking machine

ActiveCN104055589AMeet the functional requirements of clinical restorationReduce MicrogapDental implantsAbutmentEngineering

The invention provides an abutment applied to a dental implant. The abutment comprises an abutment main body, wherein the abutment main body is provided with a positioning anti-rotating part, a sealing part, a gingiva passing-through part, a connecting part and a main body bonding part which are arranged successively from bottom to top; the abutment main body is provided with a through hole in a vertical penetration mode, the through hole is a two-layer step circular through hole, the diameter of the upper layer of the two-layer step circular through hole is greater than that of the lower layer, and the two layers of the two-layer step circular through hole are connected through an inverted cone surface; an equilateral polygon through hole is formed in the upper part of the first layer of the two-layer step circular through hole. The invention also provides an abutment taking machine. The abutment taking machine comprises a connection rod, wherein the upper end of the connection rod is a standard wedge-shaped opening; the lower part of the connection rod is provided with a positioning part and an annular clamping slot which are closely adjacent from top to bottom. The function requirements of clinical rehabilitation of the abutment can be met; meanwhile, the abutment has both an aesthetic effect and a repairing effect; and the assorted abutment taking machine can be taken out or screwed into the abutment quickly and effectively, so that bacterial infection of the dental implant process is avoided.

Owner:广东健齿生物科技有限公司

Double-end-face grinding machine for automobile oil pump valve spools

InactiveCN103600273AGuaranteed quality and accuracyGood synchronizationGrinding work supportsPlane surface grinding machinesEngineeringGrinding wheel

The invention discloses a double-end-face grinding machine for automobile oil pump valve spools. The double-end-face grinding machine comprises a machine body, a clamp, a first grinding device and a second grinding device. The clamp can rotate around the self axis and comprises a body extending radially, the body is in the shape of an equilateral polygon in the radial cross section thereof and capable of rotating around a central axis of the equilateral polygon, a plurality of grooves are formed in the outer wall surface of the body, a pressing plate corresponding to each groove is arranged on the same, the first side of each pressing plate is hinged to the body, the second side of each pressing plate is connected with the first end of an elastic element, a plurality of sliding grooves corresponding to the pressing plates are formed in the body, and the second end of each elastic element is slidably arranged in the corresponding sliding groove. The first grinding device comprises a first motor and a first grinding wheel driven by the first motor, the second grinding device comprises a second motor and a second grinding wheel driven by the second motor, and the first grinding wheel and the second grinding wheel are bilaterally symmetrical along a center line of the clamp.

Owner:SUZHOU KELIAN PRECISION MACHINERY

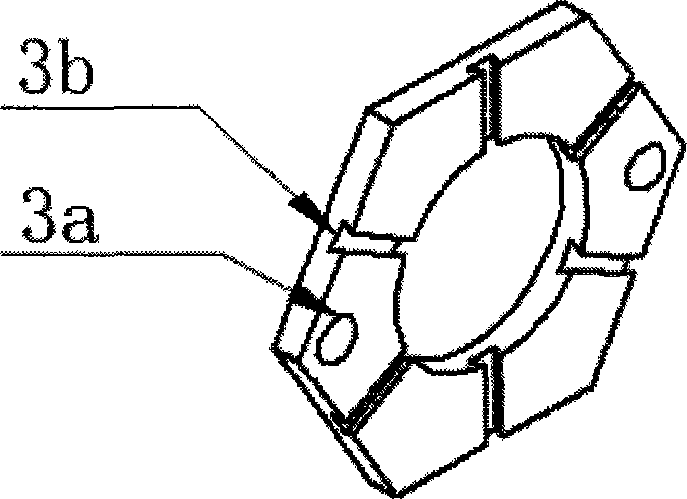

Escapement for electric power line without bolt

InactiveCN101345402ASmooth movementBeautiful installationMaintaining distance between parallel conductorsElectrical conductorElectric power system

The invention provides a spacer frame configuration structure of bolt-free wire holding part and spacer for light-weight and cheap transmission line capable of largely reducing wave interference resulting from corona discharge of radio and TV or relatively high potential gradient such as UHV transmission line, and corona discharge noise resulting from water drip forming around bolt-free wire holding part in rain. The bolt-free wire holding part is axially symmetrical and mounted radially for performing gyratory motion corresponding to equilateral polygon, then connected with lead terminal, assembled on chamber; the gyration-proof block for keeping regular assembling posture of bolt-free wire holding part is oppositely disposed at two positions of outer plane, the wire clamp connector of bolt-free wire holding part changes its position in about + / - theta degree from multi-conductor symmetrical axis of maximum potential gradient for positioning bolt-free spacer suitable for UHV transmission line.

Owner:FURUKAWA ELECTRIC POWER SYST

Equilateral polygon patch circular polarized antenna

PendingCN107645051ARealize circularly polarized directional radiationSimple structureRadiating elements structural formsAntenna earthingsCapacitanceCircularly polarized antenna

The invention discloses an equilateral polygon patch circular polarized antenna. The antenna comprises an equilateral N-gonn metal patch, a microstrip feed line connected with the feeding port of themetal patch, a PCB board located under the metal patch, and a floor located under the PCB board. The floor is provided with a hollowed equilateral N-gonn empty slot. A rectangular patch is arranged inthe empty. The side of the empty slot is longer than the side of the metal patch, and the empty slot is located directly under the metal patch. A circular seam between the empty slot and the metal patch forms a capacitive load. The metal patch and the rectangular patch are coupled and short-circuited to form an inductive load. N is a positive integer greater than or equal to 6. According to the invention, the circular seam is formed between the empty slot and the metal patch to form the capacitive load; the metal patch and the rectangular patch are coupled and short-circuited to form the inductive load; the antenna can realize circularly polarized directional radiation in a working frequency band; in addition, the antenna adopts single-point feeding design; the structure is simple; an external circular polarization feeding network is not needed; and a great circularly polarized radiation effect is formed.

Owner:GUANGDONG UNIV OF TECH

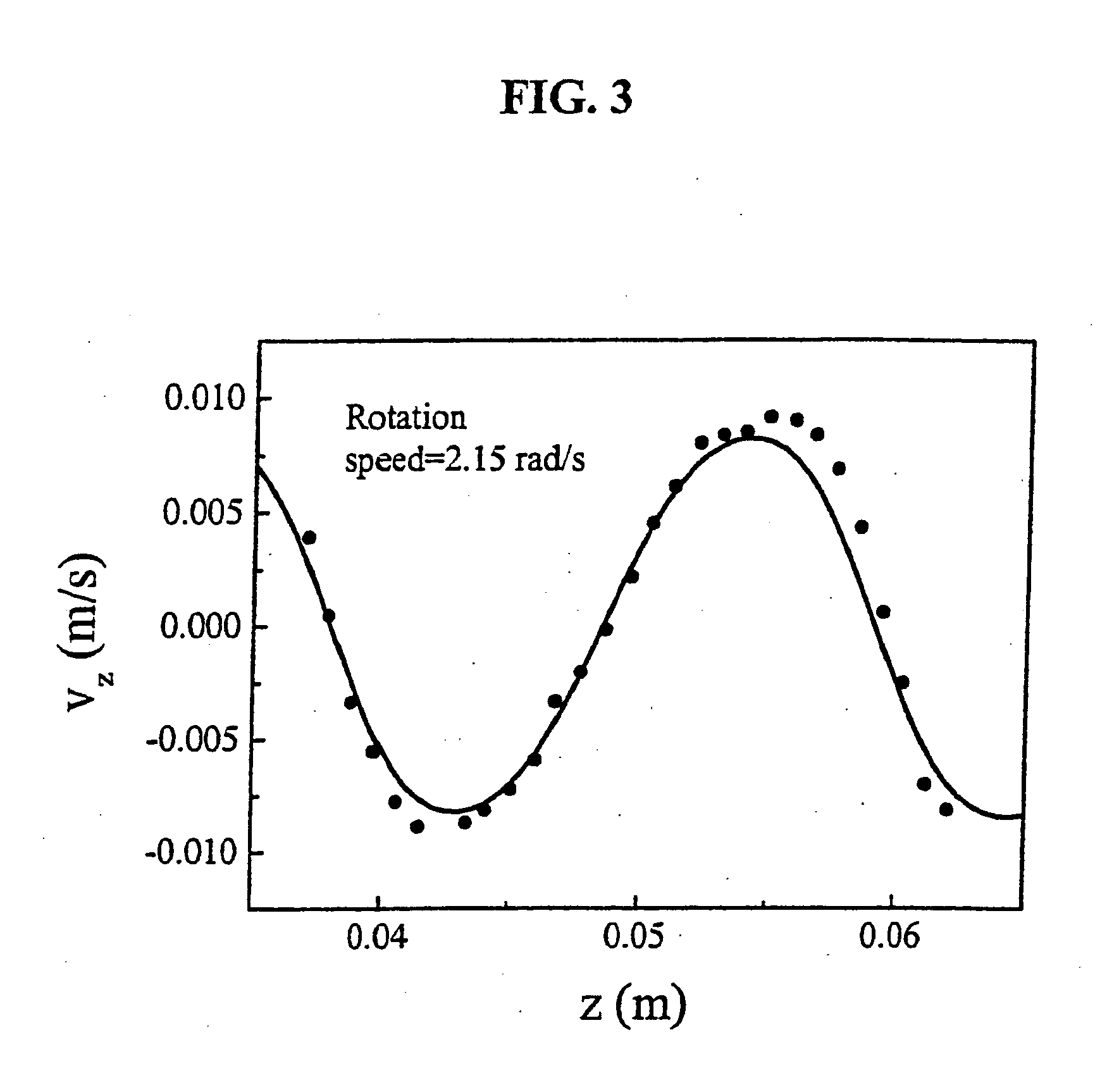

SPECT (single-photon emission computed tomography) imaging method based on ordered subset algorithm

ActiveCN104027129AReduce demandReduce photon countComputerised tomographsTomographyAcquisition timeImage resolution

The invention discloses a SPECT (single-photon emission computed tomography) imaging method based on an ordered subset algorithm. The SPECT imaging method includes that a SPECT detector and a collimator are arranged in an equilateral polygon arranged on the periphery of a through hole of a rotating frame, the number of edges of the polygon corresponds to the number of angles in one subset, the rotating frame is rotated to have data collected, each time of data collection is accompanied with OS-EM iteration once, and after multiple iterations, images meeting requirements of image resolution are reestablished through a computer. The SPECT detector and the collimator are in polygon arrangement matched with the ordered subset algorithm, the advantages of the algorithm can be effectively exerted by means of hardware grouping, collecting full 360 angles is not needed, unnecessary photon counting is effectively reduced, and collecting time is shortened; besides, quantity demanded on the detectors and the collimators is decreased by adopting the rotating frame, and economical efficiency is high.

Owner:PEKING UNIV

Circular electronic apparatus

InactiveUS8149588B2Insulating layers/substrates workingElectrical connection printed elementsIsosceles trapezoidEngineering

The present invention provides a circular electronic apparatus. The circular electronic apparatus includes a circular crust and a plurality of isosceles trapezoid circuit boards. The isosceles trapezoid circuit boards are put together to form an equilateral polygon. Each isosceles trapezoid circuit board is connected with an adjacent isosceles trapezoid circuit board by a plurality of electrical lines and all the isosceles trapezoid circuit boards are connected together. The circular crust covers the equilateral polygon circuit board.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Vibration isolator outer sleeve

The invention discloses a vibration isolator outer sleeve which comprises a sleeve body integrally formed. The cross section of the sleeve body is of a non-equilateral polygon cylindrical structure. T-shaped support holes are formed in the side walls, corresponding to at lest two relatively-long edges, of the sleeve body. Each T-shaped support hole comprises a horizontal hole extending towards two sides and a vertical hole extending downwards from the middle of the horizontal hole. A jacking hole is formed in the side wall, above each support hole, of the sleeve body. The outside of the sleeve body is provided with a boss extending outwardly from each support hole and the corresponding jacking hole. Each boss recesses towards one side of the center of the sleeve body to form a pit. The sleeve is simple in structure, integrally formed, good in mechanical performance, long in service life, convenient to operate and good in limit effect, no special limit parts are needed, and a vibration isolator can be rotated into the sleeve from two directions and limited by the T-shaped support holes.

Owner:易科路通轨道设备有限公司

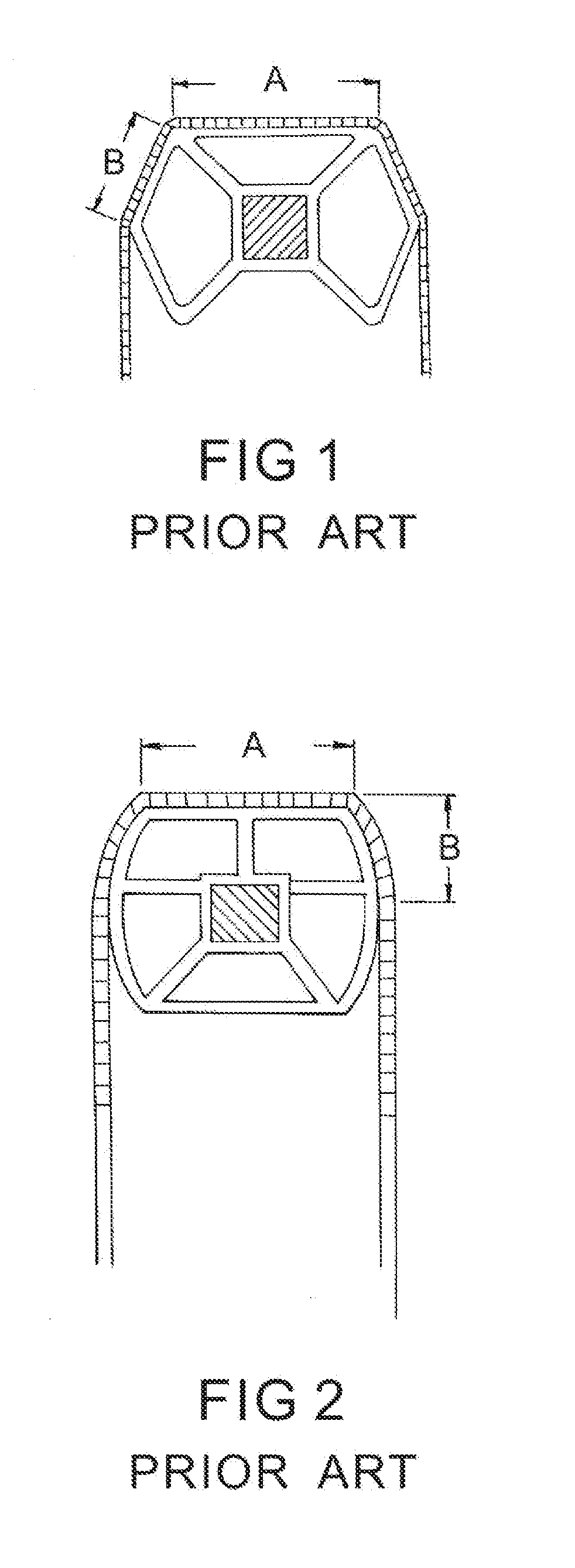

Wear part for a crusher

ActiveUS7677484B2Solution to short lifeReduce downtimeGrinding machine componentsCocoaEngineeringCrusher

A distributor plate adapted to be releasably mounted on a horizontal lower disc of a rotor of a vertical shaft impact crusher. The rotor has an opening for the intake of material to be crushed and at least one outflow opening for material leaving the rotor. The distributor plate is an equilateral polygon as seen from above.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

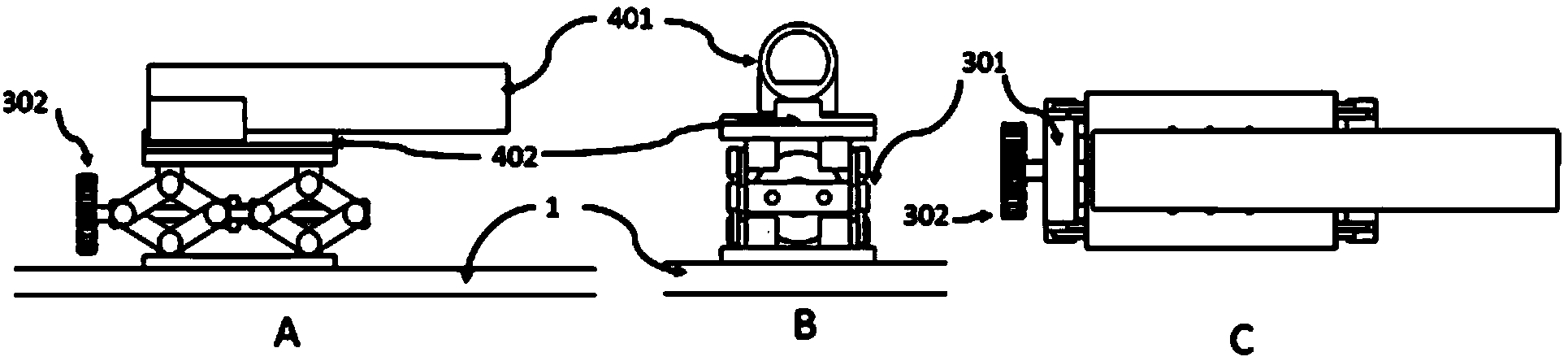

Automatic rod connecting system for cable probing rods and static penetration test method

ActiveCN106638539AImprove performanceSimple and fast operationIn situ soil foundationHydraulic motorRoller screw

The invention provides an automatic rod connecting system for cable probing rods. The automatic rod connecting system for the cable probing rods includes a static penetration probe, a cable probing rod, an equilateral-polygon-shaped cylindrical capstan, a capstan roller screw rod, a support, a hydraulic motor, a rod connecting or folding converter and a data collector. The cable probing rod is formed by connecting a plurality of probing rod units in a hinged mode in sequence, and can wind round the equilateral-polygon-shaped cylindrical capstan at a certain inclination angle. The capstan roller screw rod is supported by the support and driven by the hydraulic motor, and when the hydraulic motor drives the equilateral-polygon-shaped cylindrical capstan to rotate, the capstan roller screw rod drives the equilateral-polygon-shaped cylindrical capstan to move in the axial direction of the capstan roller screw rod so as to assure that the cable probing rod passes through the rod connecting or folding converter in a fixed position in the rotation process of the equilateral-polygon-shaped cylindrical capstan. The static penetration probe is connected with the data collector through a data acquisition cable. The automatic rod connecting system has the advantages of being stable in performance, simple in operation and low in system cost, and can greatly improve the in-situ testing speed of underwater geotechnical engineering and reduce the test cost of underwater in-situ testing.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Straight wire PCB plane spiral coil primary current sensor

InactiveCN101677031AEase of mass productionHigh measurement accuracyTransformersVolume meteringUltra high voltageCurrent sensor

The invention discloses a primary straight wire PCB plane spiral coil primary current sensor, a primary coil thereof is a straight wire with a circular or rectangular cross section, a secondary coil comprises two layers or an even number of layers of PCB circuit boards, the even number of same plane spiral coils above 4 are arranged on each layer of the PCB board, and the magnetic center of each spiral coil is arranged like an equilateral quadrilateral or an equilateral polygon. The adjacent coils in each layer are in sequential reverse-polarity series-connection, the spiral coils between thelayers are connected by through holes, the first end and the last end are used as output ends, and the spiral coils at the sides of the PCB boards are embedded in a cuneate groove of the central axisline of the straight wire or tightly bonded above, below or on two sides of the wire and fastened by using bolts. The primary straight wire PCB plane spiral coil primary current sensor can eliminate the interference of an external electromagnetic field, and the secondary coil can simultaneously sensitively respond to primary current in the straight wire and generate a secondary voltage signal which changes in direct proportion to the primary current, thereby having great linearity, measurement precision and anti-electromagnetic interference ability, and being applicable to being used as the current sensor for electronic current transformers of ultra-high voltage and various voltage levels therebelow.

Owner:周有庆

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com