Abutment applied to dental implant and abutment taking machine

A technology for dental implants and abutments, applied in dental implants, dentistry, prosthetics, etc., can solve problems such as lack of matching equipment, and achieve the effects of avoiding bacterial infection, quickly and effectively taking out and screwing in, and reducing micro-gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

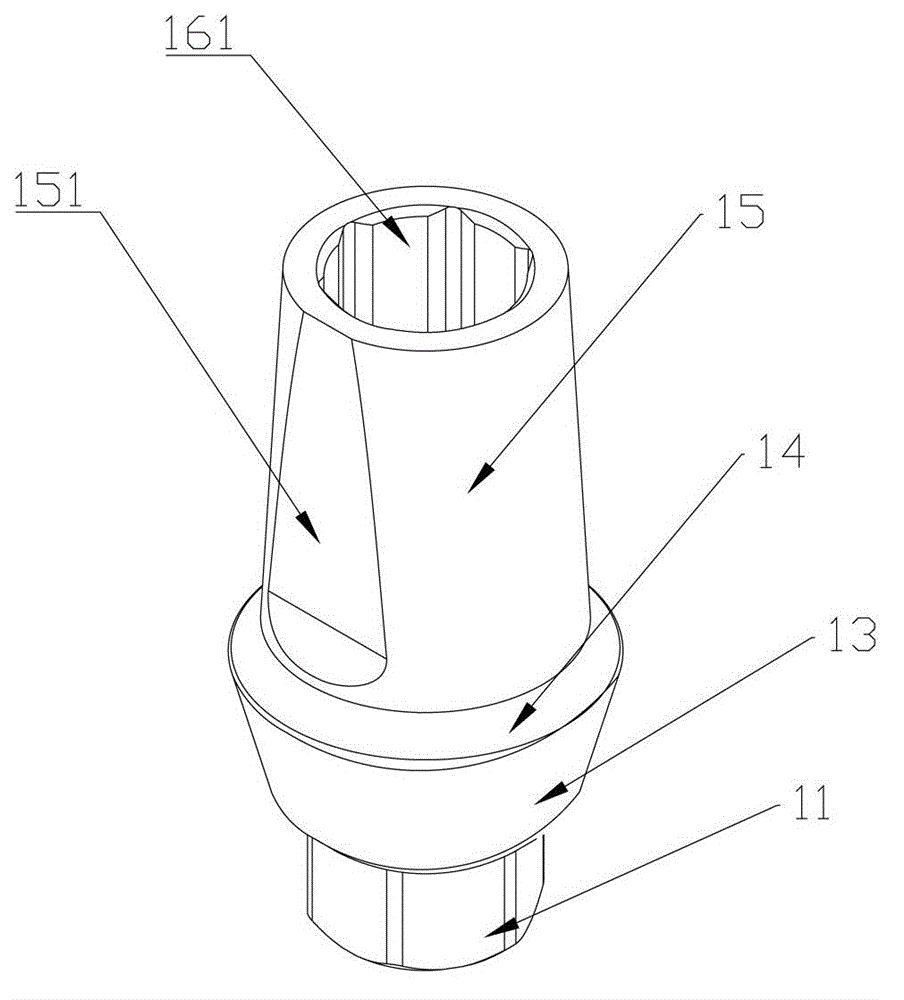

[0031] like Figure 1 to Figure 3 As shown, it is the abutment for dental implants according to the present invention, including the abutment main body 1 .

[0032] The abutment main body 1 is sequentially provided with a positioning anti-rotation part 11 , a sealing part 12 , a gingival part 13 , a connecting part 14 and a main body bonding part 15 from bottom to top.

[0033] The positioning and anti-rotation part 11 is a regular polygon boss; the sealing part 12 is an inverted truncated cone; the gingival part 13 is an inverted truncated cone; the connecting part 14 is a truncated cone with a slightly concave surface formed on the outer surface; There is a cutout 151 on one side of the main body bonding part 15 .

[0034] The central axis of the positioning anti-rotation part 11, the sealing part 12, the gingival part 13 and the connecting part 14 are coincident, and the central axis of the main body bonding part 15 is coincident with the central axis of the gingival part ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com