Three-axis numerically-controlled milling machine milling method and device for semi-open type impeller of variable-cross-section twisted blades

A twisted blade, CNC milling machine technology, applied in the direction of automatic control device, feeding device, milling machine equipment, etc., can solve the problems of large cost input, long processing cycle, low efficiency, etc., to reduce the total cost input, high processing efficiency, operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

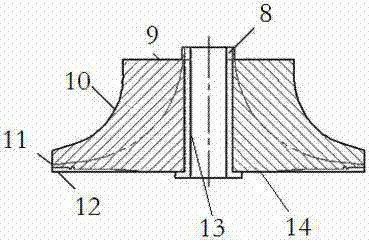

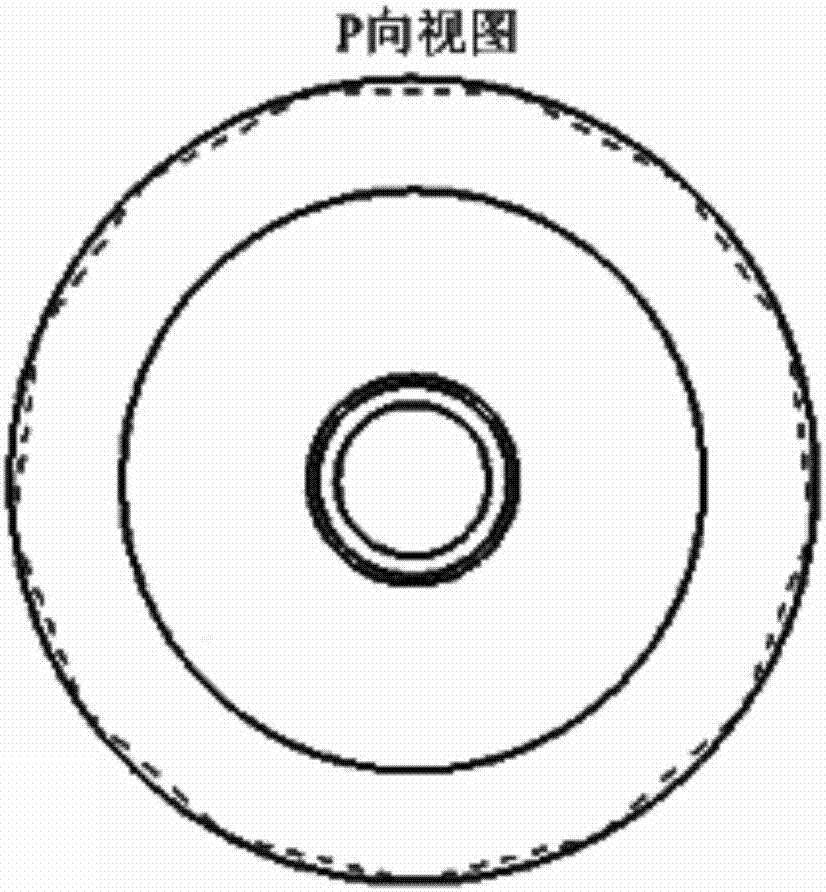

[0033] The present invention is directed to a method and device for milling semi-open impellers with an ordinary three-axis CNC milling machine. The auxiliary parts mainly include: one dividing head, one adapter disc, and one mandrel. For details, refer to the attached Figure 1-9 , the present invention is described in further detail, the steps are as follows:

[0034] The specific dimensions, materials and processing parameters of the semi-open ternary impeller in this example are as follows:

[0035] (1) The maximum rotation diameter of the impeller: Φ600mm

[0036] (2) Number of blades: 13, evenly distributed around the circumference

[0037] (3) The maximum thickness of the blade tip: 6.5mm

[0038] (4) The maximum thickness of the blade: 12.83mm

[0039] (5) The inlet width of the impeller: 121.37mm

[0040] (6) The outlet width of the impeller: 39.76mm

[0041] (7) Impeller material: LD10

[0042] Step 1: Use the point metadata of the blade pressure surface and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com