Hoisting system of large-sized extensible antenna

An antenna and large-scale technology, applied in the field of hoisting systems and temporary awnings, can solve the problems of high manufacturing cost of frictionless cylinders, rare large-scale deployable devices, and inability to meet the requirements of complex motion trajectories of deployed antennas, and reduce the number of tests. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

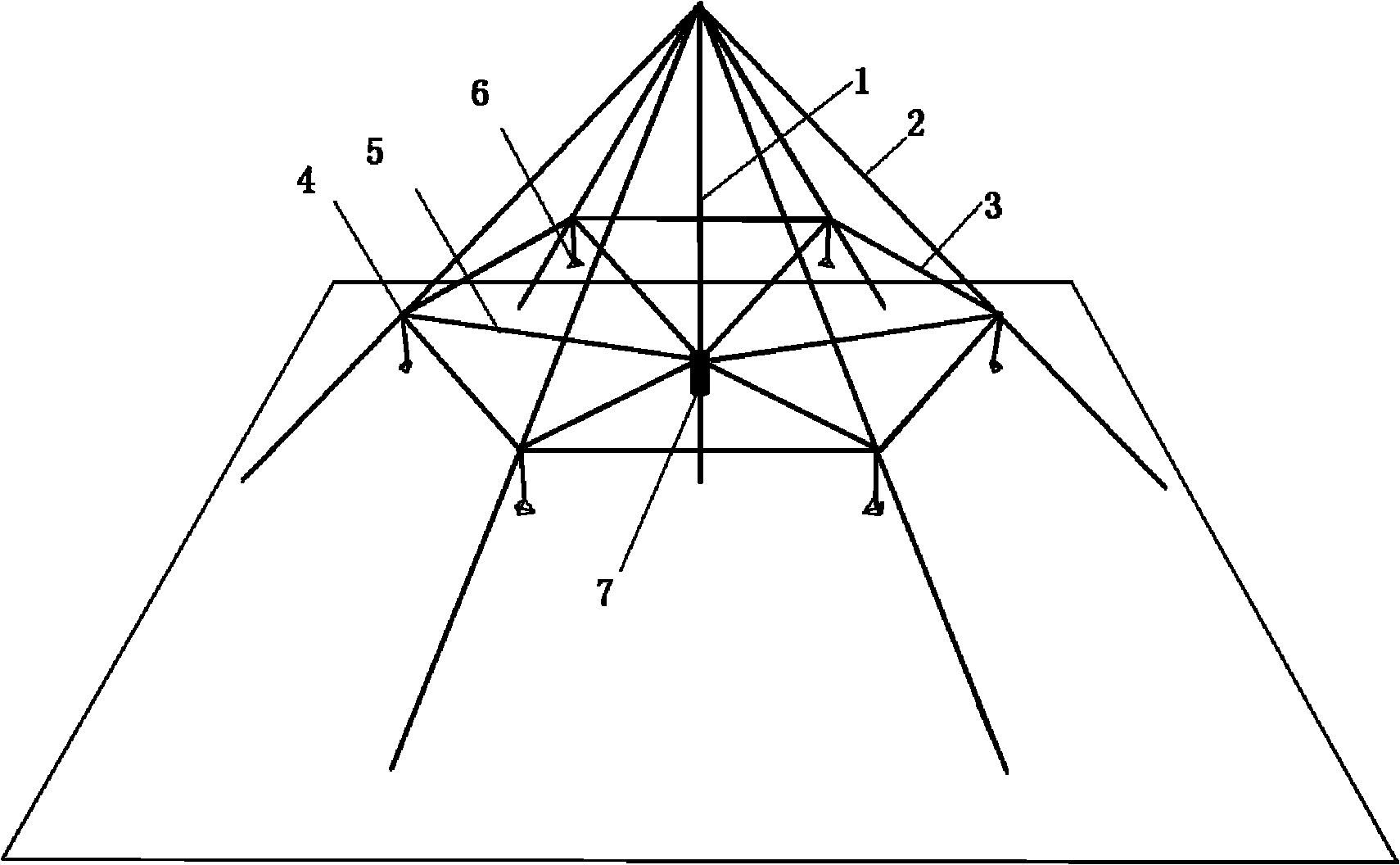

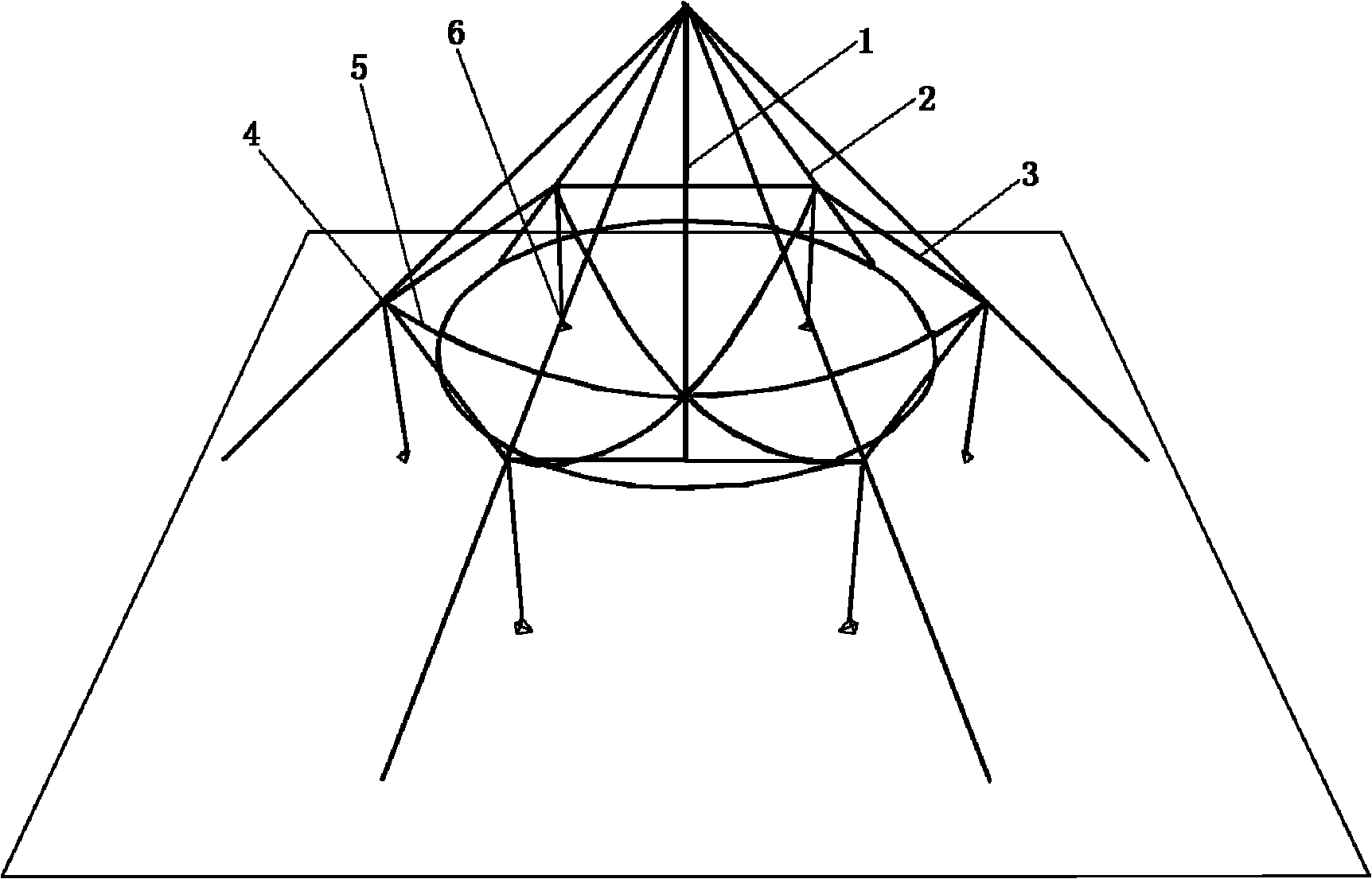

[0032] Example 1, the deployment of a deployable antenna with a diameter of 10 m under the device of the present invention.

[0033] The collapsed state of the device is as figure 1 As shown, the expanded state is as figure 2 shown.

[0034] The central column adopts a movable lifting rod, and the height after stretching is 12 meters; the test uses 6 positioning cables, each of which is 17 meters long, and is 45 degrees away from the lifting rod; a Kevlar support cable with a length of 42.43m; 6 6 suspension rings; 6 Kevlar traction cables; after deployment, the apex of the antenna is 1 meter from the bottom of the lifting rod; the weight of the antenna is 24 kg, and each counterweight is 4.5 kg; 0.5.

[0035] The simulation analysis of the reflective surface under the device shows that the maximum deformation occurs on the ring, the maximum deformation is 15mm, and the surface root mean square error RMS is 6mm. It can be seen that the unloading effect is still very ideal. ...

example 2

[0036] Example 2, the deployment of a deployable antenna with a diameter of 20m under the device of the present invention.

[0037] The folded state of the device is as Figure 4 As shown, the expanded state with cablenet installed is as follows Figure 5 shown.

[0038] The central column adopts a fixed lifting rod, and the height after stretching is 20m; due to the large diameter of the antenna, in order to ensure the accuracy of the unfolded antenna profile, more unloading points are used here. A total of 12 positioning cables are used for unloading, and steel strands are also used. After being unfolded, they are tightened with a winch. A traction cable, also made of Kevlar fiber material; 12 suspension rings; 12 counterweights; the antenna diameter is 20m, the focal diameter ratio is 0.5, the top base of the apex is 3m, the total weight is 84kg, and each counterweight is 9kg.

[0039] The simulation analysis of the reflective surface under the device shows that the maxi...

example 3

[0040] Example 3, an expandable flexible awning with a diameter of 30m.

[0041] The folded state of the device is as Figure 6 As shown, the expanded state is as Figure 7 shown.

[0042] The central column 201 adopts a fixed pillar and is 20 meters high; the positioning cable 202 has 6 sections in total, using steel strands, and the winch is tightened after pulling, and each section is 40 meters long; correspondingly, 6 lifting rings 203 are used; 6 counterweights 205 , each counterweight is 10 kg; the total weight of the awning is 102 kg, and the hoisting height is 18 meters. Due to the limit of the boundary size of the awning itself, the counterweight will stop sliding when it is pulled to a certain position. This device can provide an idea for quickly building a temporary sunshade.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com