Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Cathode spots" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

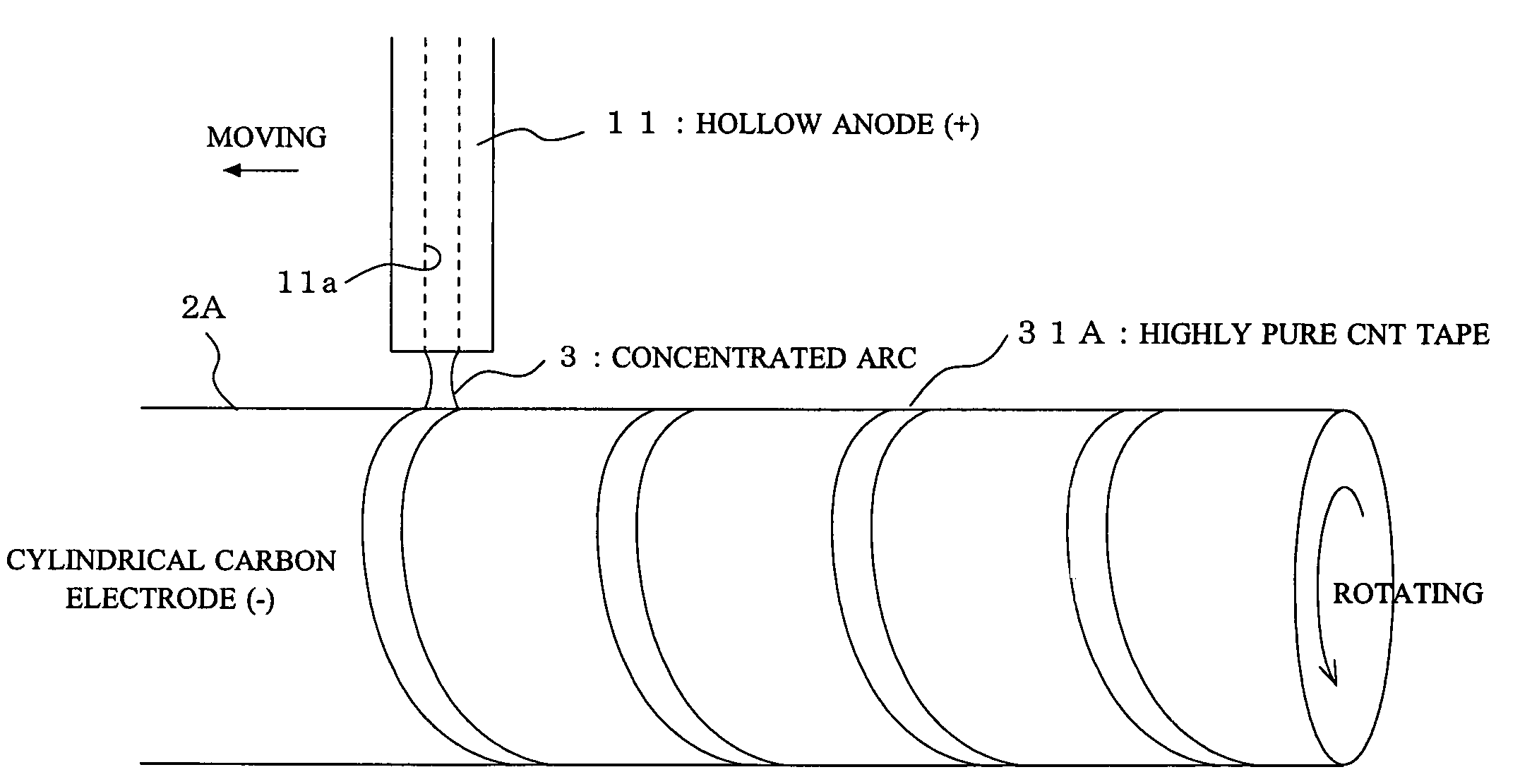

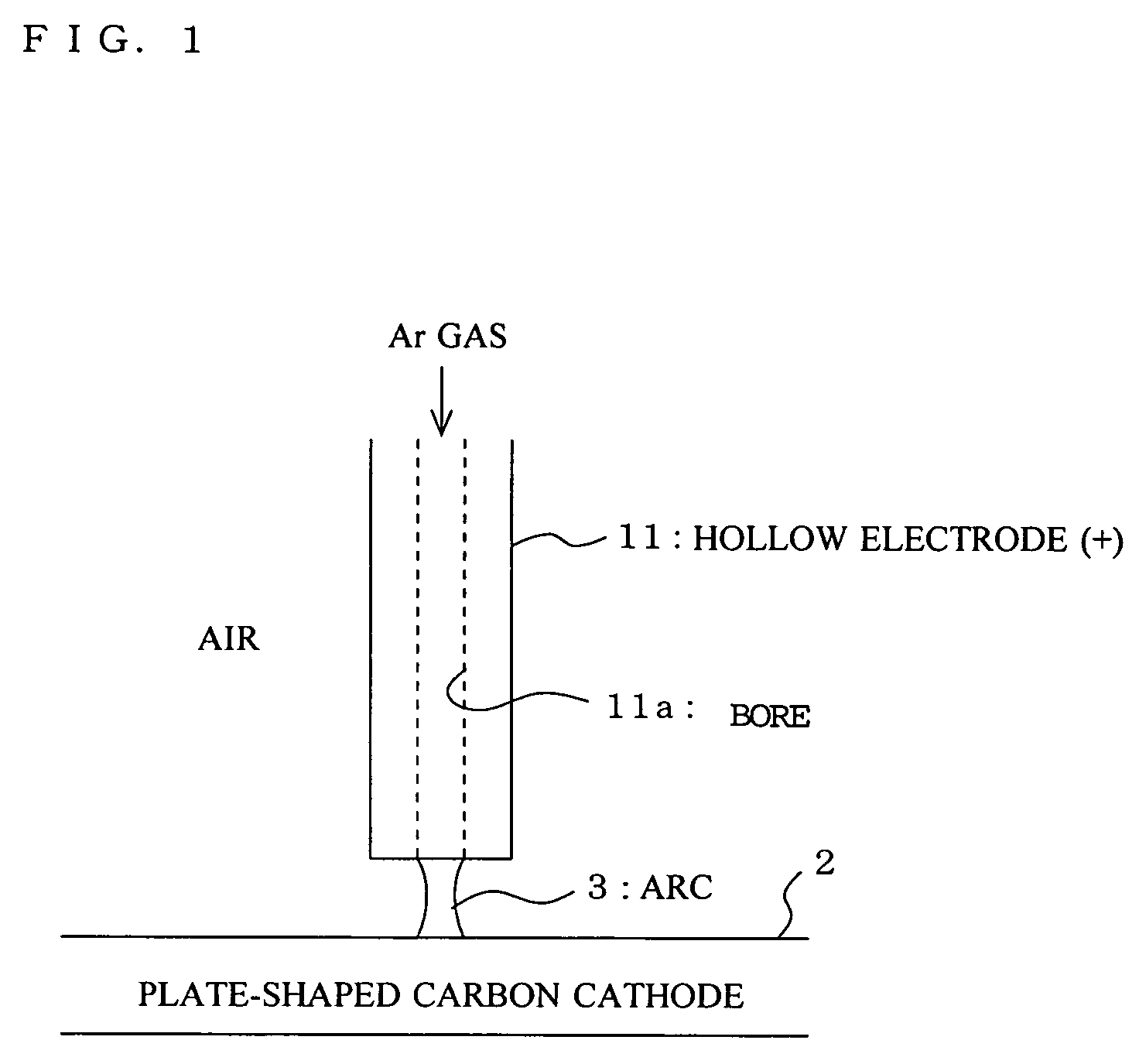

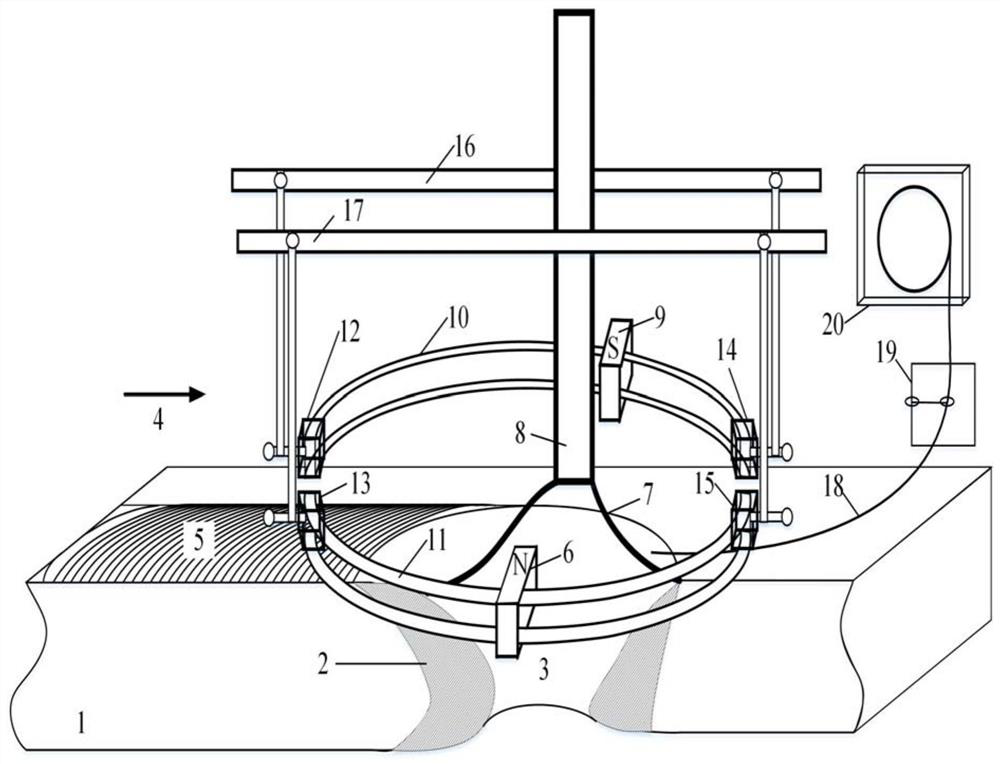

Tapelike material containing carbon nanotube and production method for cabon nanotube and electric field emission type electrode containing the tapelike material and production method therefor

InactiveUS20060005381A1Facilitate strippingReduce the temperatureMaterial nanotechnologyLamination ancillary operationsHigh densityNanotube

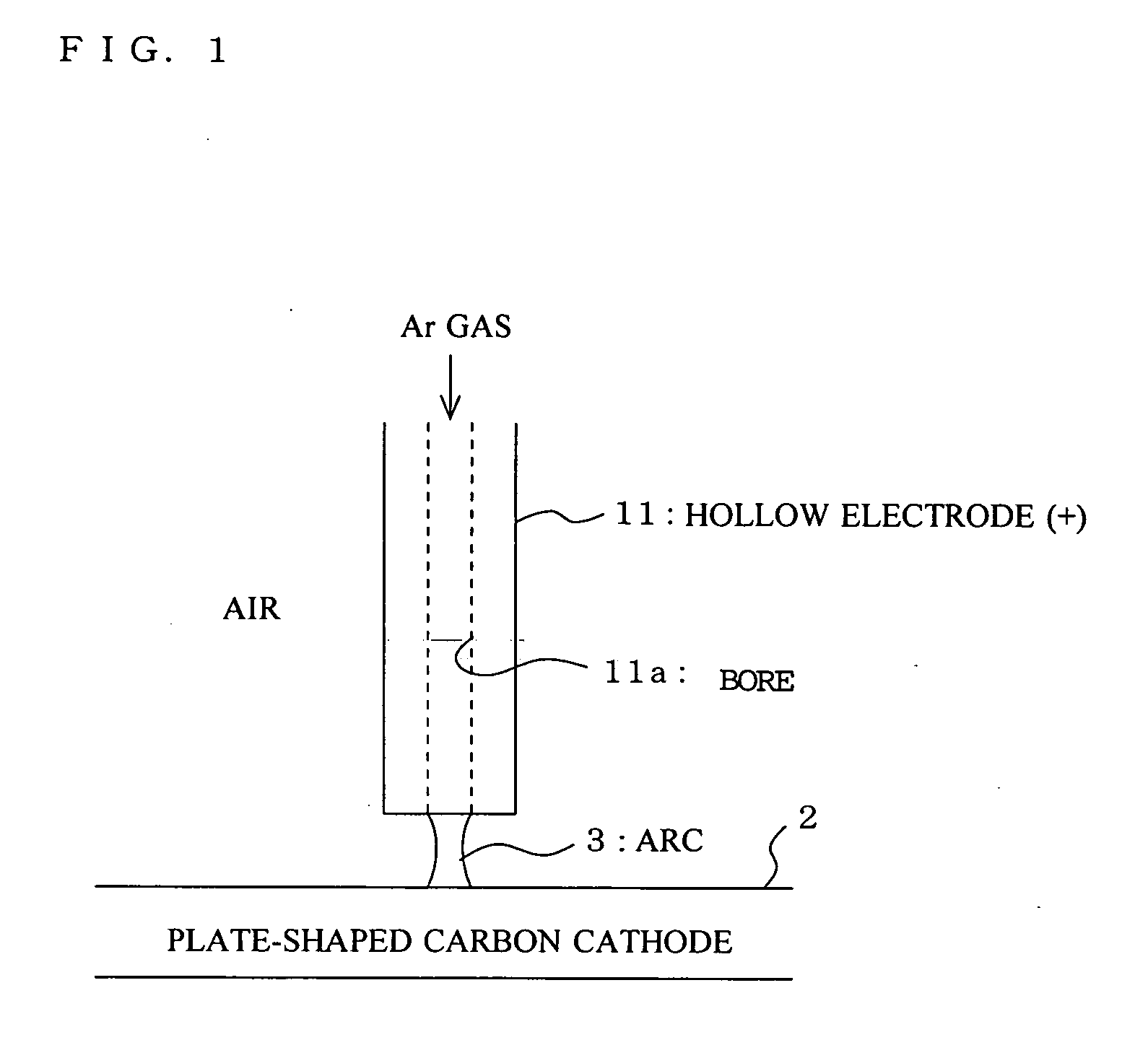

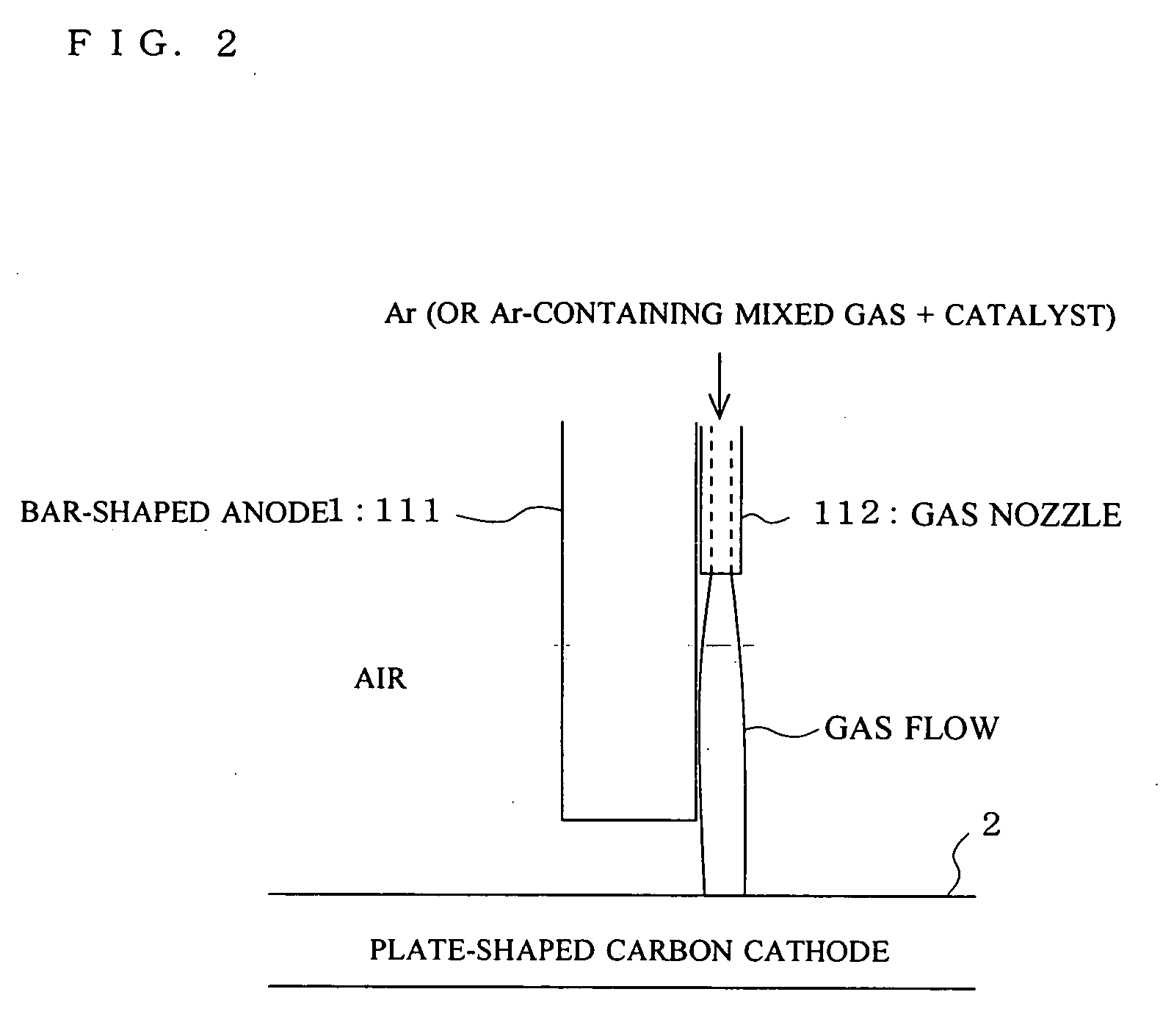

A process for producing a tape-like material uniformly containing highly pure single-walled or multi-walled carbon nanotubes with a high density highly pure single-walled or multi-walled carbon nanotubes; a high-performance field emission electrode including the tape-like material; and a process for producing the field emission electrode. For synthesis of carbon nanotubes by arc discharge, an inert gas or inert gas-containing mixed gas is jetted onto a cathode (2) comprising a carbon material from the inside (11a) of a hollow electrode (11) used as an anode, and simultaneously an arc is generated to form a path of arc discharge along the stream of the gas. Consequently, the cathode spot is prevented from irregularly moving, and thus highly pure carbon nanotubes can be produced. At the same time, by relatively moving both electrodes so as to move the cathode spot of the arc (3) on cathode, the synthesized carbon nanotubes are formed into a tape.

Owner:JFEENG CORP

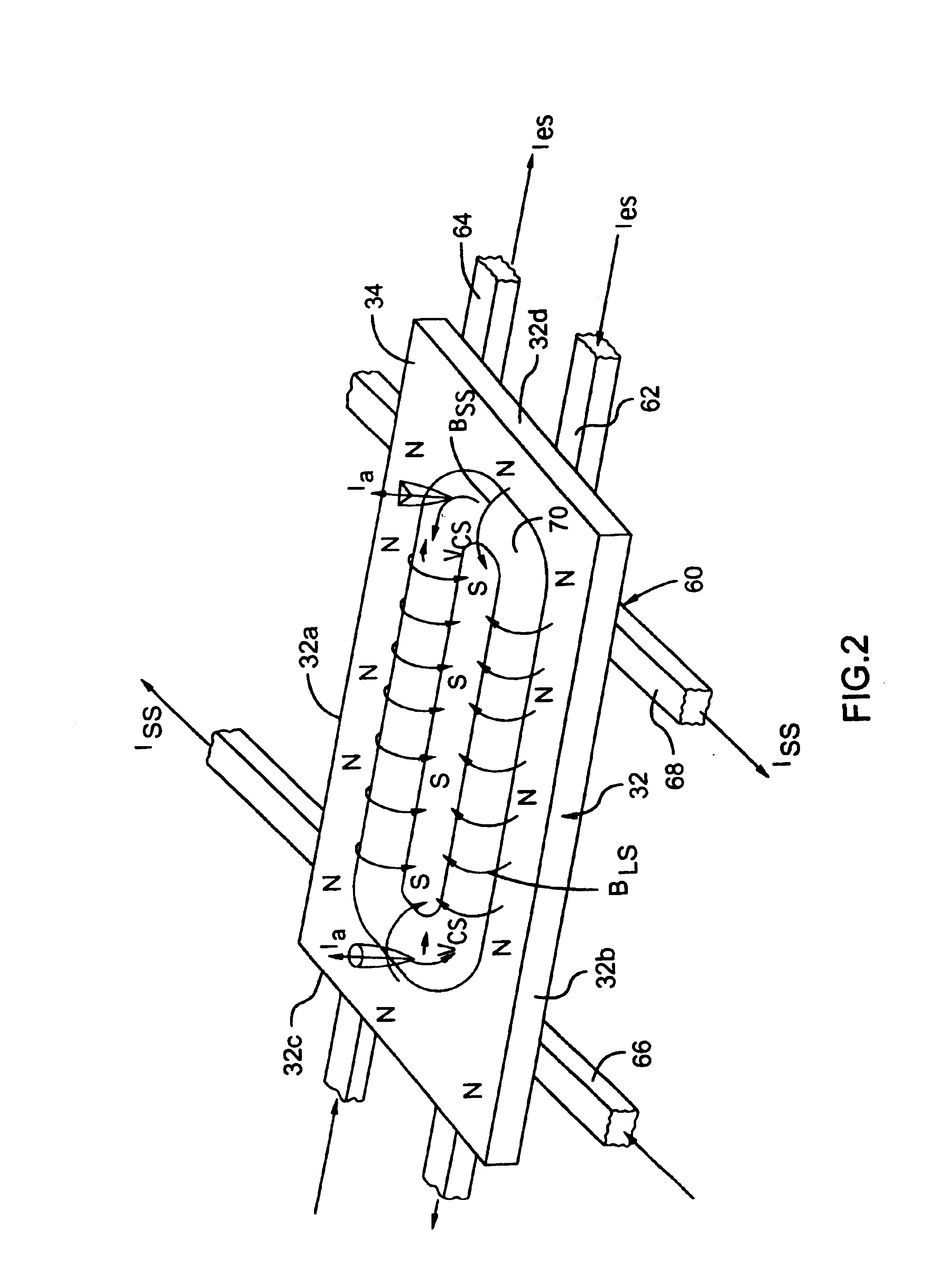

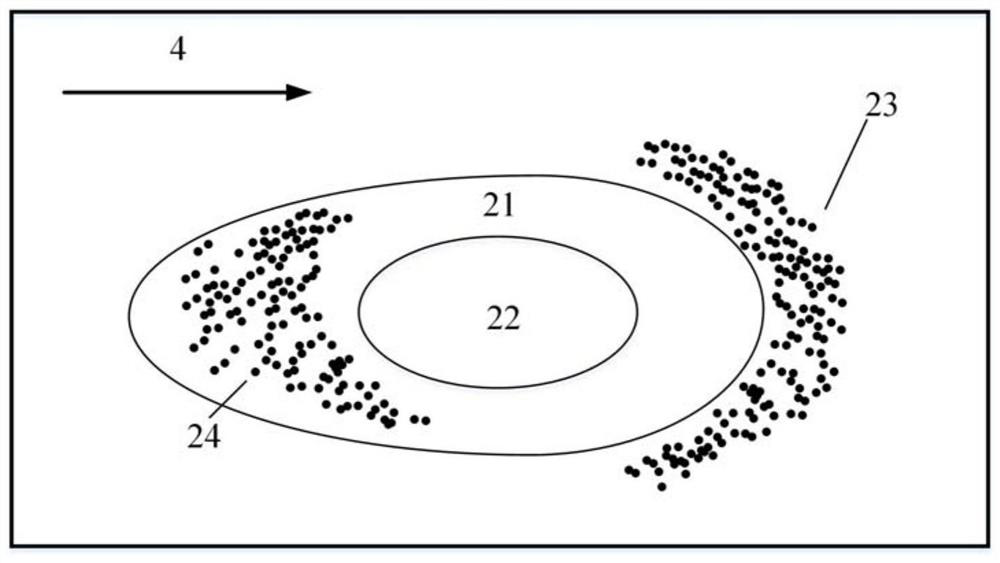

Rectangular cathodic arc source and method of steering an arc spot

InactiveUS6929727B2Improve distributionUniform coatingCellsLiquid surface applicatorsElectrical conductorEvaporation

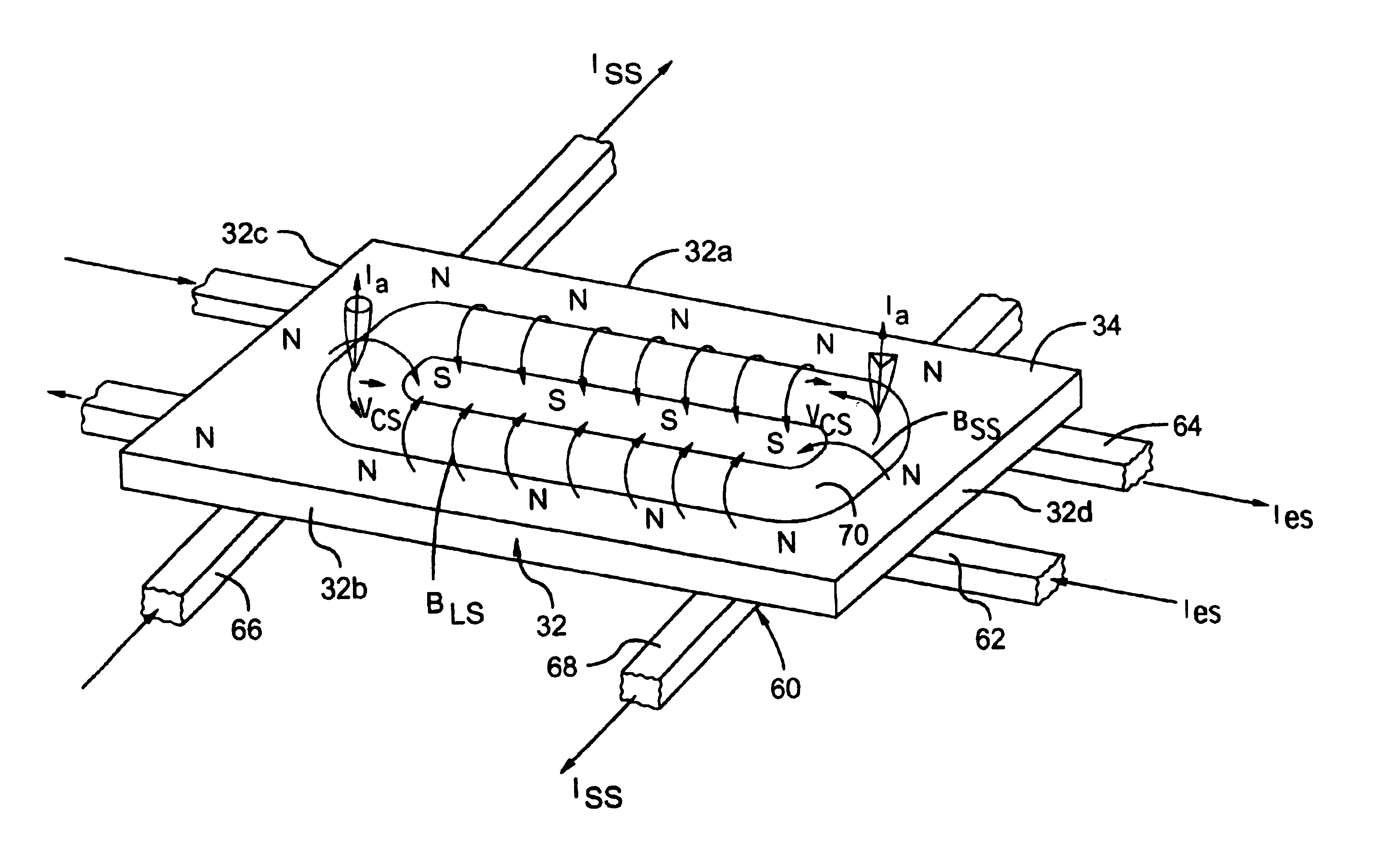

The invention provides an arc coating apparatus having a steering magnetic field source comprising steering conductors disposed along the short sides of a rectangular target behind the target, and a magnetic focusing system disposed along the long sides of the target in front of the target which confines the flow of plasma between magnetic fields generated on opposite long sides of the target. The plasma focusing system can be used to deflect the plasma flow off of the working axis of the cathode. Each steering conductor can be controlled independently. In a further embodiment, electrically independent steering conductors are disposed along opposite long sides of the cathode plate, and by selectively varying a current through one conductor, the path of the arc spot shifts to widen an erosion corridor. The invention also provides a plurality of internal anodes, and optionally a surrounding anode for deflecting the plasma flow and preserving a high ionization level of the plasma. The invention also provides a shield at floating potential, restricting the cathode spot from migrating into selected regions of the target evaporation surface outside of the desired erosion zone. The shield may be positioned immediately above the region of the target surface in the vicinity of the anode, protecting the anode from deposition of cathodic evaporate and providing better distribution of cathodic evaporate over the substrates to be coated. The invention further provides correcting magnets adjacent to the short sides of the target, to move the arc spot between the long sides.

Owner:G&H TECH LLC

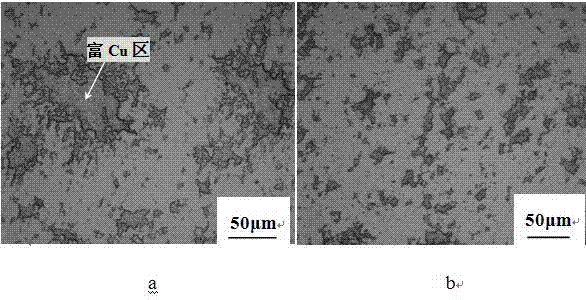

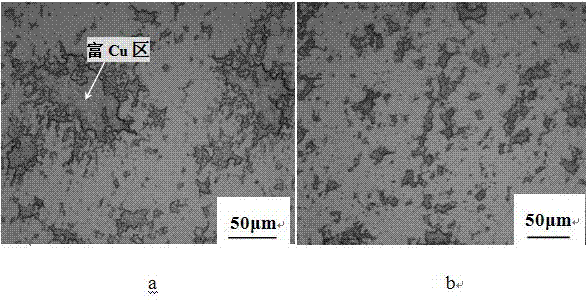

Preparation method of CuW70 contact material

The invention discloses a preparation method of a CuW70 contact material, comprising the steps of: adding inducing copper powder into tungsten powder in certain proportion and mixing them well, putting the mixed powder into a rubber sheath which is then placed in the high pressure cylinder of a cold isostatic pressing machine so as to be pressed into a skeleton green body, and then preparing the CuW70 contact material through copper infiltration of the sintered skeleton. Due to disappeared copper-rich area and uniform two-phase distribution of the prepared CuW70 contact material by the methodof the invention, the material has rapidly moving cathode spot on the surface, effectively dispersed electric arc, less copper phase splashing, and improved ablation resistance.

Owner:XIAN UNIV OF TECH

Pretreatment liquid and pretreatment method before rare earth conversion

InactiveCN102011115AFast film formationHigh film forming efficiencyMetallic material coating processesPretreatment methodSorbent

Owner:SOUTH CHINA UNIV OF TECH

Method for forming a superhard amorphous carbon coating in vacuum

InactiveUS20070134436A1Increase compressive stressVacuum evaporation coatingSputtering coatingPulse streamCarbon plasma

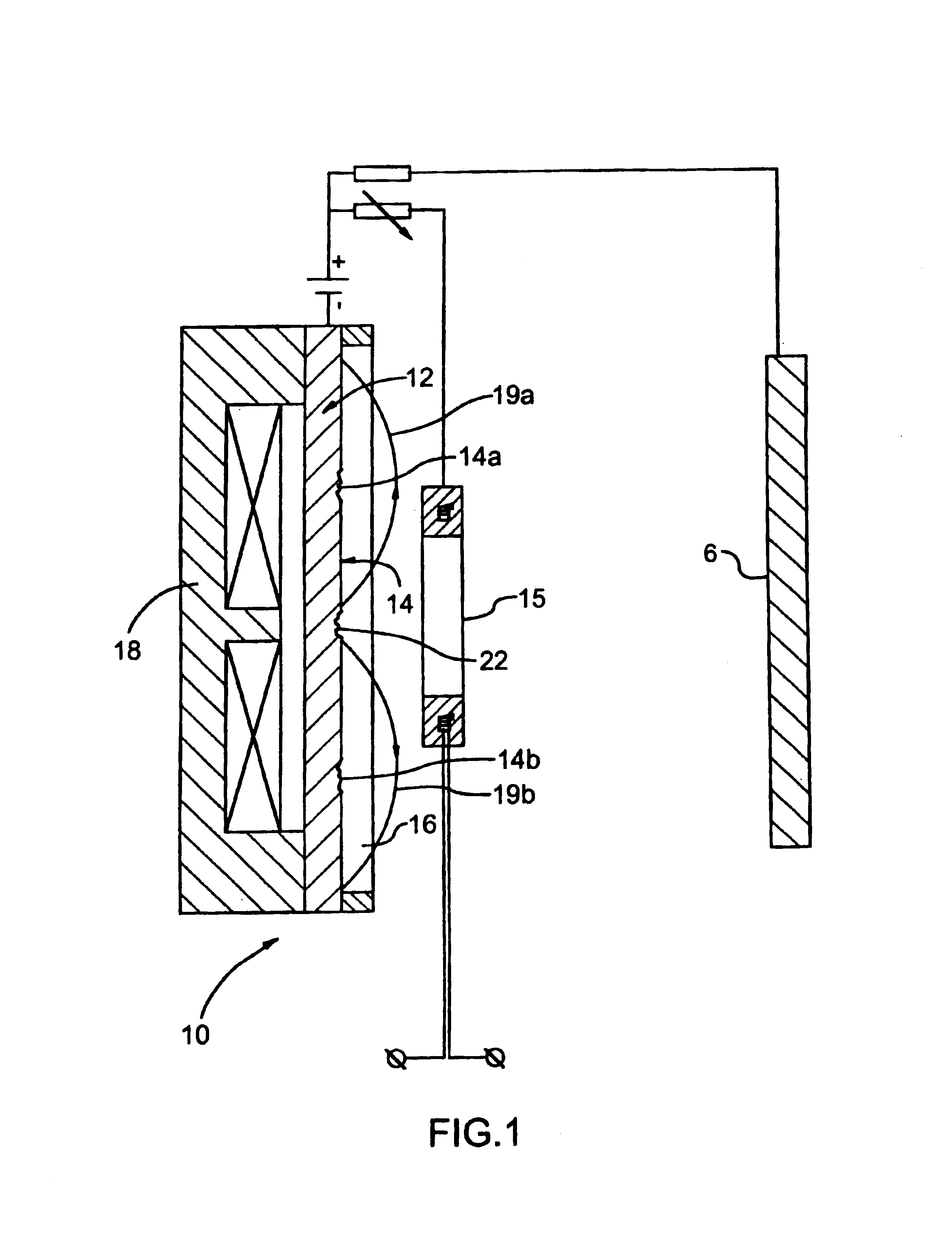

A method for forming a superhard amorphous carbon coating in vacuum, comprising the steps of: placing an article in a vacuum chamber, evacuating the chamber, treating a surface for the article with accelerated ions; applying, on the treated surface, a layer of a material that provides adhesion for subsequent layers, initiating pulsed electric-arc discharge on a graphite cathode, and obtaining a pulsed carbon plasma stream from a plurality of cathode spots that move along the cathode surface. After that, the carbon plasma is condensed in a predetermined area on the article surface to produce a superhard amorphous carbon coating, the article temperature being maintained within the range of 200 to 450 K through controlling a repetition frequency of the electric-arc discharge pulses. According to the invention, the carbon plasma pulsed stream has average ion energy of 25-35 eV and ion concentration of 1012, 1013 cm−3; axis of the carbon plasma stream being set at angle of 15-45° to a predetermined surface of an article. During application of the coating, the article temperature change Δt is maintained within the range of 50-100 K.

Owner:ARGOR ALJBA

Test apparatus for breakdown strength of material

InactiveCN101059549AImprove accuracyHigh degree of automationTesting dielectric strengthBreakdown strengthLaser ranging

The invention discloses a tester of material breakage field strength, comprising a XYZ three-coordinate support (1) and a laser ranging device (5), wherein a vacuum room (2) is arranged with the a XYZ three-coordinate support (1) and a fixed anode device (8) fixed with an anode (4), the XYZ three-coordinate support (1) is used to fix the object sample (3) as cathode, the vacuum room (2) is arranged with the laser ranging device (5) outside and vertical to the XYZ three-coordinate support (1), the laser ranging device (5) is communicated with the vacuum room (2). The invention can process accurate adjustment on three-dimension, and accurately measure the breakage distance, with wide application for the accurate tests of breakage field strength and current of metal materials or metal base compound materials, and the generation of cathode spot, and the cathode spot shape real-time watch.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method of Deposition of a Wear Resistant DLC Layer

ActiveUS20190040518A1Reduce generationReduce roughnessElectric discharge tubesVacuum evaporation coatingWear resistantLow voltage

A method of deposition of a wear resistant DLC layer onto substrates in a vacuum chamber from a graphite cathode by means of a low-voltage pulsed arc. Current pulses alternate with a holding current and a cathode spot moves on a surface of a graphite cathode. The motion of the cathode spot on the surface of the graphite cathode being steered by a magnetic field generated by a magnetic field source arranged under the surface of the graphite cathode. The value of the current pulses is 250 to 1000 A, the value of the holding current is 40 to 200 A, the frequency of the pulses is 100 to 5000 Hz and the pulse duty cycle is 1 to 90%, the intensity of the magnetic field in the place of the cathode spot being 5 to 40 mT.

Owner:PLATIT

Shielding for cathodic arc metal ion sources

ActiveCN102296274AAvoid damageAvoid pollutionVacuum evaporation coatingSputtering coatingMetalAtomic physics

The invention provides a shielding device for a cathode arc metal ion source. The cathode arc metal ion source comprises a target material, a magnetic field assembly located below the target material and producing a magnetic field above the target material, and an ion source hermetically connected with the target material to enclose the magnetic field assembly; the shielding device comprises marginal shielding pieces arranged around but spaced from the margin of the target material and a central shielding piece located above the center of the target material and positioned at the center relative to the marginal shielding pieces. Application of the central shielding piece and the marginal shielding pieces provided in the invention and an arc closed magnetic field constructed on the surface of a cathode target material by using a magnetic circuit makes cathode spots only do unilateral zigzag movement along a rectangular annular runway, and therefore, nonuniformity of deposition caused by random reciprocation of arc spots at halfway can be avoided.

Owner:北京镨玛瑞驰科技有限公司

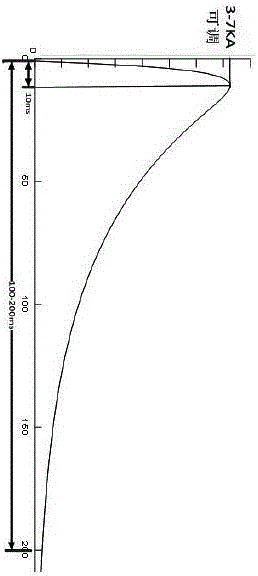

Vacuum switch tube direct-current steep-wave bipolar large-current impact aging device and process

InactiveCN105742095AImprove cleanlinessHigh dielectric strengthElectric switchesCurrent ageEngineering

The invention discloses a vacuum switch tube direct-current steep-wave bipolar large-current impact aging device and process. The device comprises a direct-current arc-striking power supply circuit, a direct-current steep-wave large-current bipolar impact loop and a main charging circuit. The direct-current arc-striking power supply circuit is connected with the direct-current steep-wave large-current bipolar impact loop. The direct-current steep-wave large-current bipolar impact loop is connected with the main charging circuit. According to the invention, an alternating current cathode spot is adopted to perform current aging on a vacuum switch tube contact, and the cathode spot covers the whole surface of the contact in the aging process, so that neither the phenomenon of insufficient aging nor the phenomenon of excessive aging will happen. The insulating property and the reliability of productions are improved. According to the invention, the cleanliness and the insulating strength of a vacuum switch arc extinguishing chamber are improved, and the breaking success rate at the time when the production encounters a rated short-circuit breaking current for the first time is increased greatly.

Owner:XIAN BONENG ELECTRIC TECH

Process for producing carbon nanotubes by arc discharge

InactiveUS7625545B2Easy to produceEasily produce the field emission electrodeMaterial nanotechnologyLamination ancillary operationsCarbon nanotubeField electron emission

A process for producing a tape-like material uniformly containing highly pure single-walled or multi-walled carbon nanotubes and a tape-like material produced thereby; a high-performance field emission electrode including the tape-like material; and a process for producing the field emission electrode. The carbon nanotubes are synthesized by arc discharge, wherein an inert gas or inert gas-containing mixed gas is jetted onto a cathode having a carbon material from the inside of a hollow electrode (11) used as an anode, and simultaneously an arc is generated to form a path of arc discharge along a stream of the gas. At the same time, by relative movement of the electrodes, the cathode spot of the arc is moved on the cathode, and the synthesized carbon nanotubes are formed into a tape.

Owner:JFEENG CORP

Stainless steel tube welding method

InactiveCN108015394AIncrease productivityImprove welding qualityArc welding apparatusTubular articlesSS - Stainless steelMixed gas

The invention discloses a stainless steel tube welding method. According to the method, a stainless steel tube is welded through a welding mode formed by TIG welding in combination with MAG welding, wherein TIG welding is used as backing welding, and MAG welding is used as filling welding and cosmetic welding. According to TIG welding, soluble paper or a combination of the soluble paper and a block board is adopted to block ventilation, and coating welding wires are adopted for backing. Active mixed gas is adopted to protect MAG welding, and all-position filling and cosmetic layer welding areconducted; stability of globular transfer can be improved; cathode spots can be stabilized; and the thermal power of electric arcs can be increased.

Owner:无锡市迪索数控焊接设备有限公司

A method for forming a superhard amorphous carbon coating in vacuum

InactiveCN1795285AExtended service lifeGood biocompatibilityVacuum evaporation coatingSputtering coatingCarbon plasmaGraphite

A method for forming a superhard amorphous carbon coating in vacuum, comprising the steps of: placing an article in a vacuum chamber, evacuating the chamber, treating a surface for the article with accelerated ions; applying, on the treated surface, a layer of a material that provides adhesion for subsequent layers, initiating pulsed electric-arc discharge on a graphite cathode, and obtaining a pulsed carbon plasma stream from a plurality of cathode spots that move along the cathode surface. After that, the carbon plasma is condensed in a predetermined area on the article surface to produce a superhard amorphous carbon coating, the article temperature being maintained within the range of 200 to 450 K through controlling a repetition frequency of the electric-arc discharge pulses. According to the invention, the carbon plasma pulsed stream has average ion energy of 25-35 eV and ion concentration of 1012, 1013 cm-3; axis of the carbon plasma stream being set at angle of 15-45° to a predetermined surface of an article. During application of the coating, the article temperature change Deltat is maintained within the range of 50-100 K.

Owner:ARGOR ALJBA

Spot welding device for computer hardware development and good in heat radiation effect

InactiveCN111266720ASimple structureReduce manufacturing costResistance welding apparatusEngineeringAnode spot

The invention discloses a spot welding device for computer hardware development and good in heat radiation effect. The spot welding device comprises a spot welding machine, a fixed plate, a fixed seat, a base, a cooling water tank, a supporting seat, a first cooling fan, a circulating pump, a fixed arm, an S-shaped water path, a spiral water path, a cathode spot welding head, an anode spot weldinghead, heat radiation holes, a connecting sleeve, a second cooling fan, a connecting arm, a hoop, a moving seat, a guide slot, a screw, a motor and the like. The spot welding device is reasonable andsimple in structure, low in production cost and convenient to mount, and complete functions are achieved; through the arranged S-shaped water path and spiral water path, the connecting arm and the cathode spot welding head can be cooled through cyclically-flowing cooling water, and therefore it is guaranteed that the connecting arm can directly absorb heat generated during workpiece welding duringwelding, and cooling time is reduced; and the arranged first cooling fan can directly cool cooling water in the cooling water tank, and therefore the effect of long-time cooling and heat radiation isimproved.

Owner:JIANGSU VOCATIONAL COLLEGE OF BUSINESS

Heat dissipating rack for solid-sealed polar pole

InactiveCN104752094AReduce concentrationGuaranteed normal breakingHigh-tension/heavy-dress switchesAir-break switchesElectric power systemWave shape

The invention relates to switch equipment parts in power systems, particularly to a heat dissipating rack for a solid-sealed polar pole. The heat dissipating rack for the solid-sealed polar pole comprises a heat dissipating rack body. The heat dissipating rack body comprises a bottom plate in a door-shaped structure and heat dissipating fins arranged on the bottom plate, wherein the heat dissipating fins are composed of bar-shape-structured heat dissipating fins and wave-shape-structured heat dissipating fins; the back surface of the bottom plate is provided with a connecting seat connected with the solid-sealed polar pole; the connecting seat is provided with a threaded hole; the four corners of the bottom plate are provided with sealing members. The heat dissipating rack for the solid-sealed polar pole is simple in structure and reasonable in design, obtains good thermal conductivity and can cool cathode spots and reduce metal vapor concentration, thereby ensuring normal on and off of a vacuum arc-extinguishing chamber.

Owner:施周平

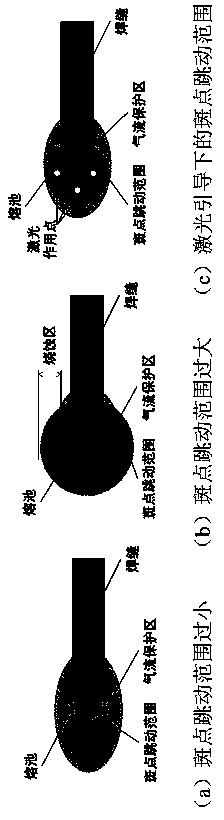

Method for controlling cathode cleaning area in aluminum alloy welding process

ActiveCN108356394AAvoid damageFree Width ControlArc welding apparatusWelding/soldering/cutting articlesMelting tankLaser power density

The invention discloses a method for controlling a cathode cleaning area in the aluminum alloy welding process. The method is characterized in that during aluminum alloy electric arc welding, when a to-be-welded workpiece is connected with a cathode, three beams of lasers acting on the front face and the two sides of a molten pool correspondingly are adopted for adjusting the range of the cathodecleaning area. According to the method, the width and the cleaning range of the cleaning area can be freely controlled, and damage of too large or too small cathode spot dancing to welding quality isavoided; during corner joint, the cleaning area can be prevented from deviating to a certain side through laser guide; and the requirement for the laser power density is low, and the effect of guidingcathode spots can be achieved through the low-power lasers being about 300 W.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

Preparation method of CuW70 contact material

InactiveCN102312146BUniform network structureImprove conductivityElectric switchesCopperHigh pressure

The invention discloses a preparation method of a CuW70 contact material, comprising the steps of: adding inducing copper powder into tungsten powder in certain proportion and mixing them well, putting the mixed powder into a rubber sheath which is then placed in the high pressure cylinder of a cold isostatic pressing machine so as to be pressed into a skeleton green body, and then preparing the CuW70 contact material through copper infiltration of the sintered skeleton. Due to disappeared copper-rich area and uniform two-phase distribution of the prepared CuW70 contact material by the methodof the invention, the material has rapidly moving cathode spot on the surface, effectively dispersed electric arc, less copper phase splashing, and improved ablation resistance.

Owner:XIAN UNIV OF TECH

Variable polarity plasma arc welding pore suppression method based on spot cluster directional movement control and quality compensation

ActiveCN113953634AEasy to cleanClean up thoroughlyPlasma welding apparatusEnergy absorptionWeld seam

The invention discloses a variable polarity plasma arc welding pore suppression method based on spot cluster directional movement control, and belongs to the field of forming and manufacturing. A device is composed of a variable polarity plasma arc perforation welding system and a pulsed magnetic field generating device, a pulsed magnetic field controls the position of cathode spots on the surface of a workpiece in the positive polarity plasma arc welding stage, the cathode spots are gathered at the front end of a small hole for perforation welding, and a compact oxide film on the surface of the workpiece is cleaned before the small hole reaches the position; and because the current density of the cathode spots is large, according to the electromagnetic force action principle, the cathode spots are concentrated at one position under the action of the magnetic field to remove the oxide film, the direction of the magnetic field is adjusted to enable a cathode spot cluster to move on the surface of a perforated molten pool, and bubbles are evaporated and released by utilizing the thermal action of the spots. The action mode not only can quickly and effectively clean the oxide film and reduce the defect of pores in a welding seam, but also can increase energy absorption of the workpiece to an electric arc and improve the energy utilization rate, and can be applied to welding of a large complex structure or a high-alloy material.

Owner:BEIJING UNIV OF TECH

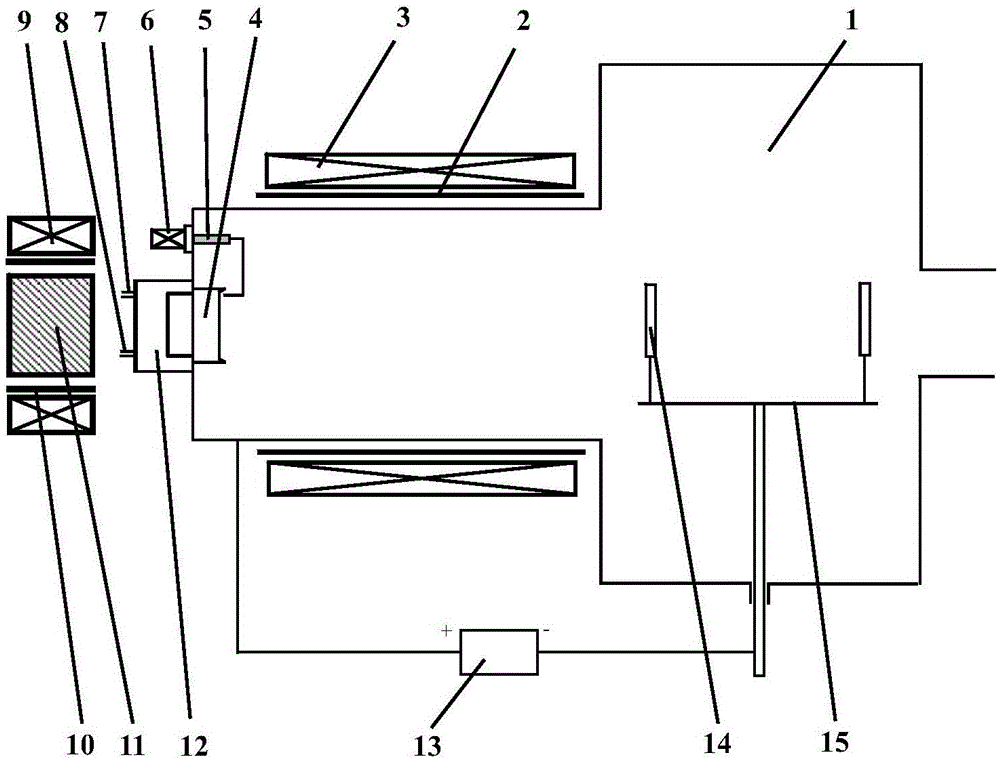

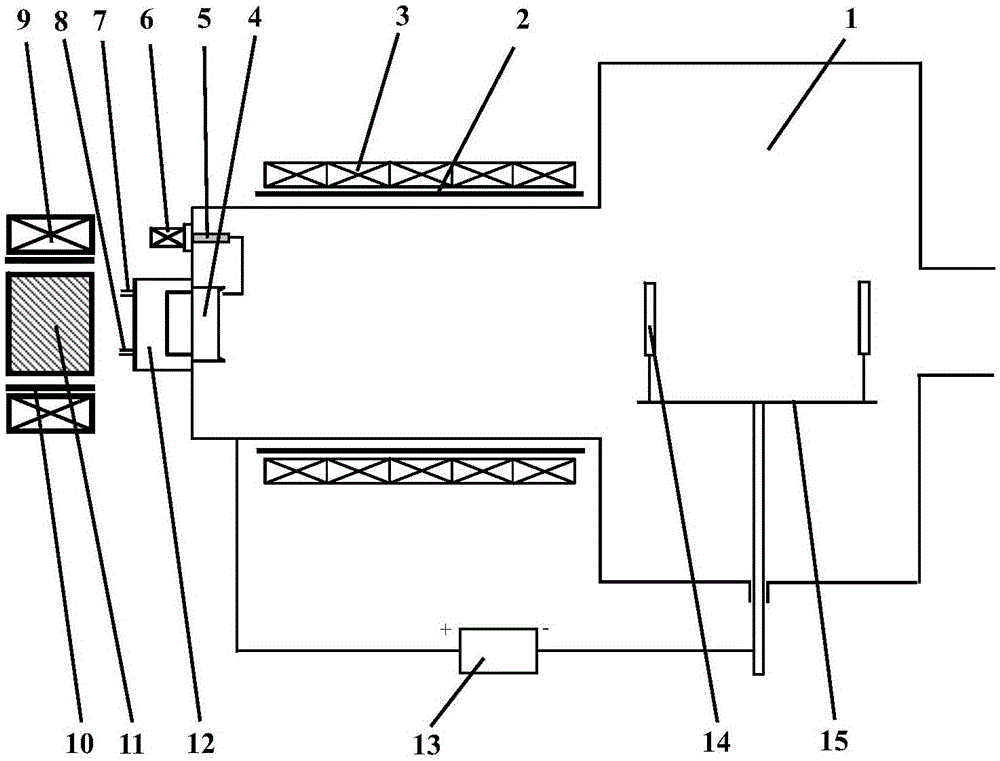

Strong light simulation light source lighting device

ActiveCN111828878AEasy to adjustLight source combinationsLighting support devicesEngineeringMaterials science

The invention belongs to the field of optics, and discloses a strong light simulation light source lighting device, which comprises a light source, a reflection optical system, a light source focusingassembly, a light source heat dissipation mechanism, a wind speed acquisition module, a xenon lamp main control system, a xenon lamp electronic ballast, a direct-current stabilized power supply, a light source moving platform and a supporting mechanism. When the device works, the light source heat dissipation mechanism, the wind speed acquisition module, the xenon lamp main control system, the xenon lamp electronic ballast and the direct-current stabilized power supply are sequentially turned on; the output of the xenon lamp electronic ballast is adjusted, a xenon lamp in the light source isslowly ignited, a three-axis adjusting mechanism in the light source focusing assembly is adjusted to enable a xenon lamp cathode spot in the light source to coincide with the focus of a parabolic reflector in the reflection optical system, and parallel illumination is output. By adjusting the output power of the xenon lamp electronic ballast and the direct-current stabilized power supply, ambientlight with different color temperatures and different illuminance is obtained, and the photoelectric parameter measurement requirement of the liquid crystal display in the daytime light environment is met.

Owner:西安应用光学研究所 +1

A composite deposition process and deposition device of magnetron arc ion plating

ActiveCN103540900BEmission reductionReduce in quantityVacuum evaporation coatingSputtering coatingIon depositionTransmission channel

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

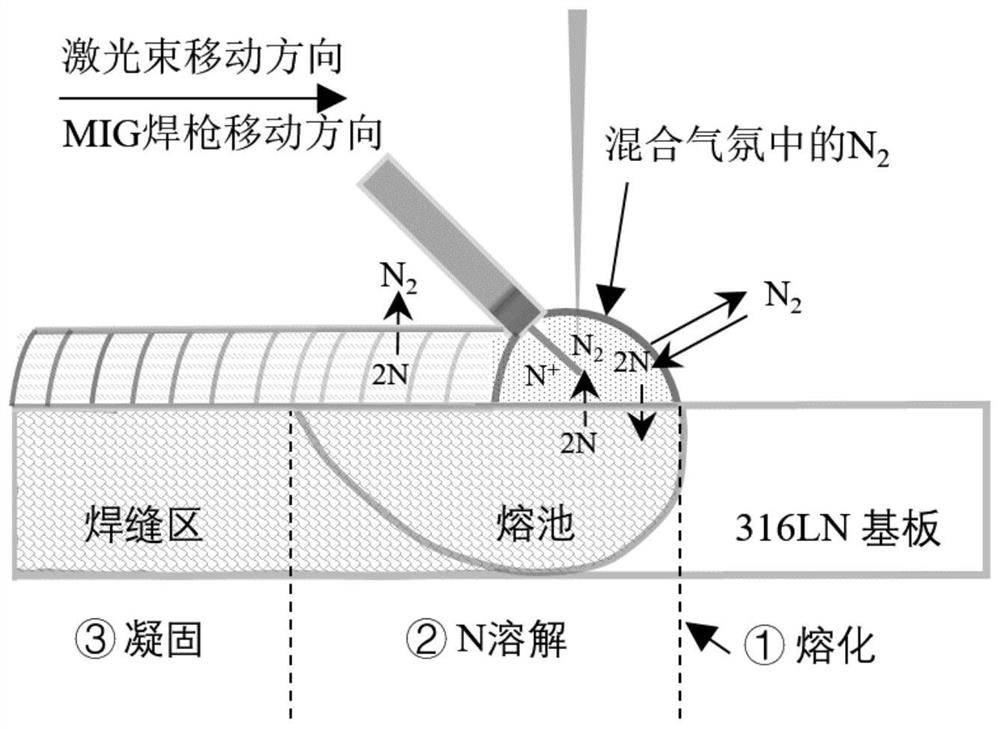

Method and device for improving corrosion resistance of MIG welding Cr-Ni series stainless steel

ActiveCN113814563AGuaranteed arc stabilityHigh nitrogen contentLaser beam welding apparatusSS - Stainless steelNitrogen gas

The invention belongs to the related technical field of Cr-Ni series stainless steel welding, and discloses a method and device for improving corrosion resistance of MIG welding Cr-Ni series stainless steel. The method comprises the steps that in the protective gas atmosphere, a to-be-welded piece is welded through laser beam assisted MIG electric arcs during MIG welding, wherein the protective gas is mixed gas of inert gas and nitrogen, the gas flow ratio of the inert gas to the nitrogen is 22.5:2.5-17.5:7.5, and the energy of the laser beam is 0.6-1.5 KW, so that the laser irradiates the surface of the to-be-welded piece to generate metal steam to provide stable cathode spots for MIG electric arcs to promote MIG electric arc ionization; and meanwhile, the nitrogen is subjected to ionization reaction, so that the nitrogen content of a molten pool is increased, then the solidification temperature interval of an austenite phase is expanded, transformation from ferrite to austenite is accelerated, and the corrosion resistance is improved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

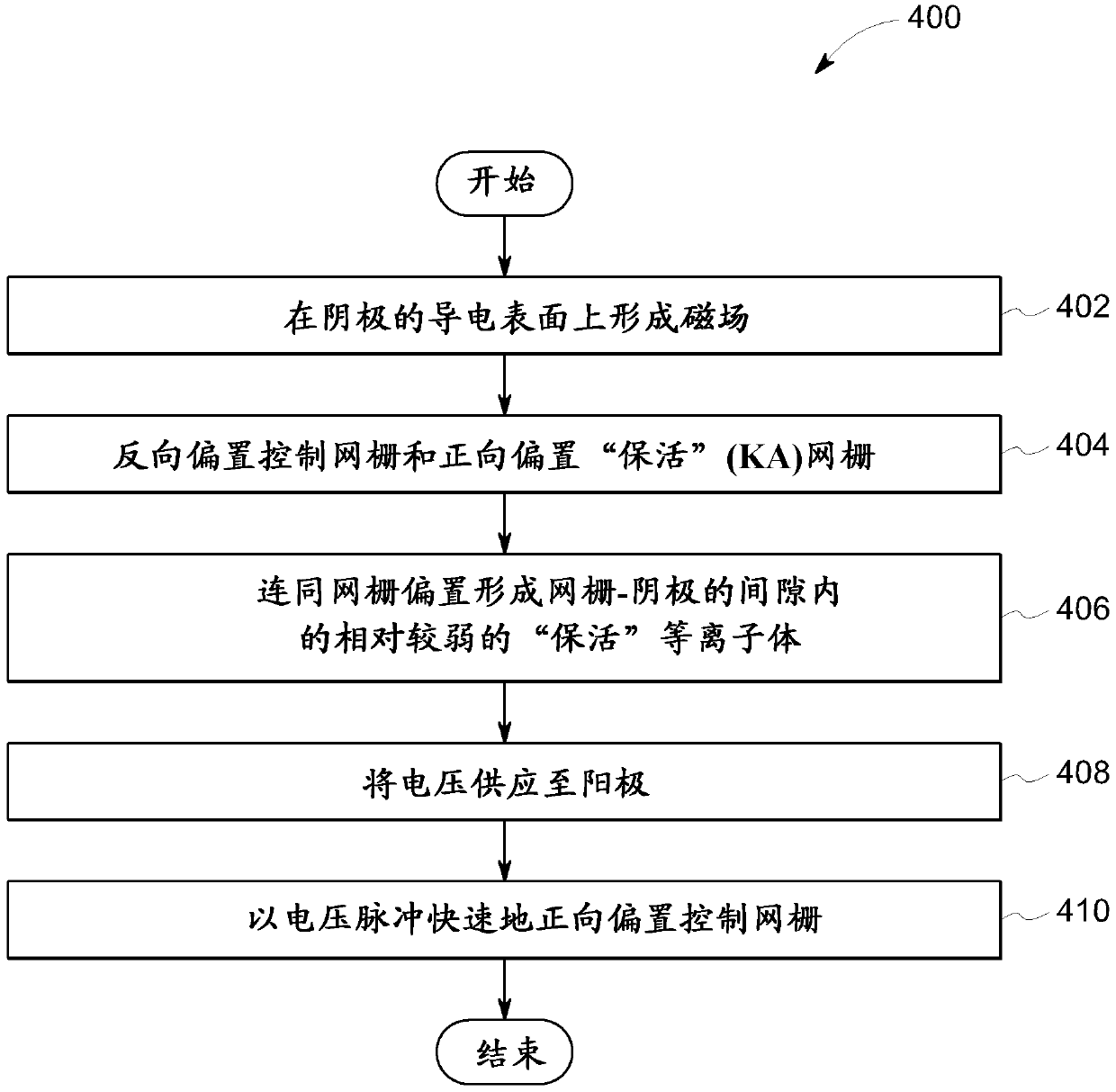

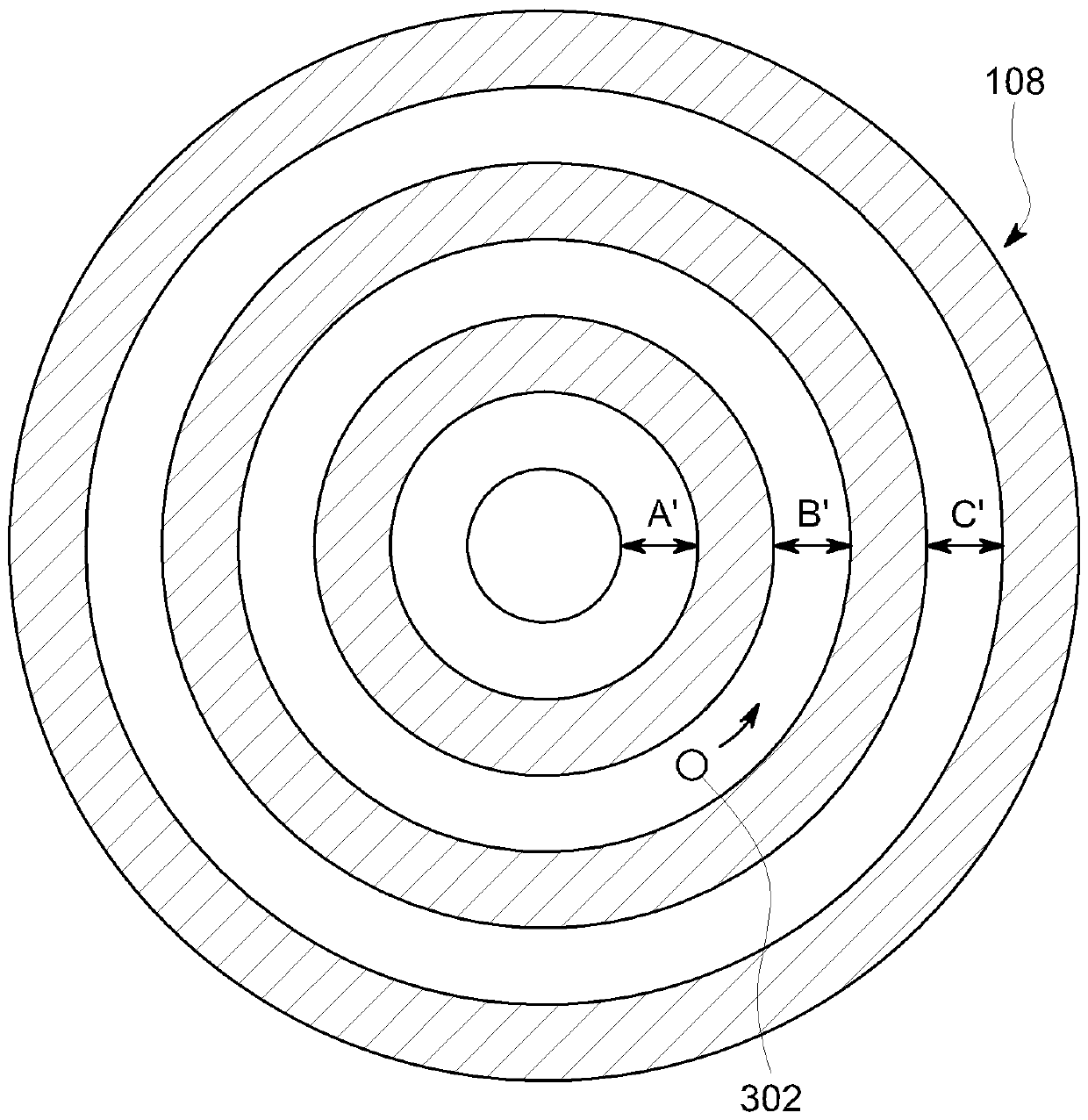

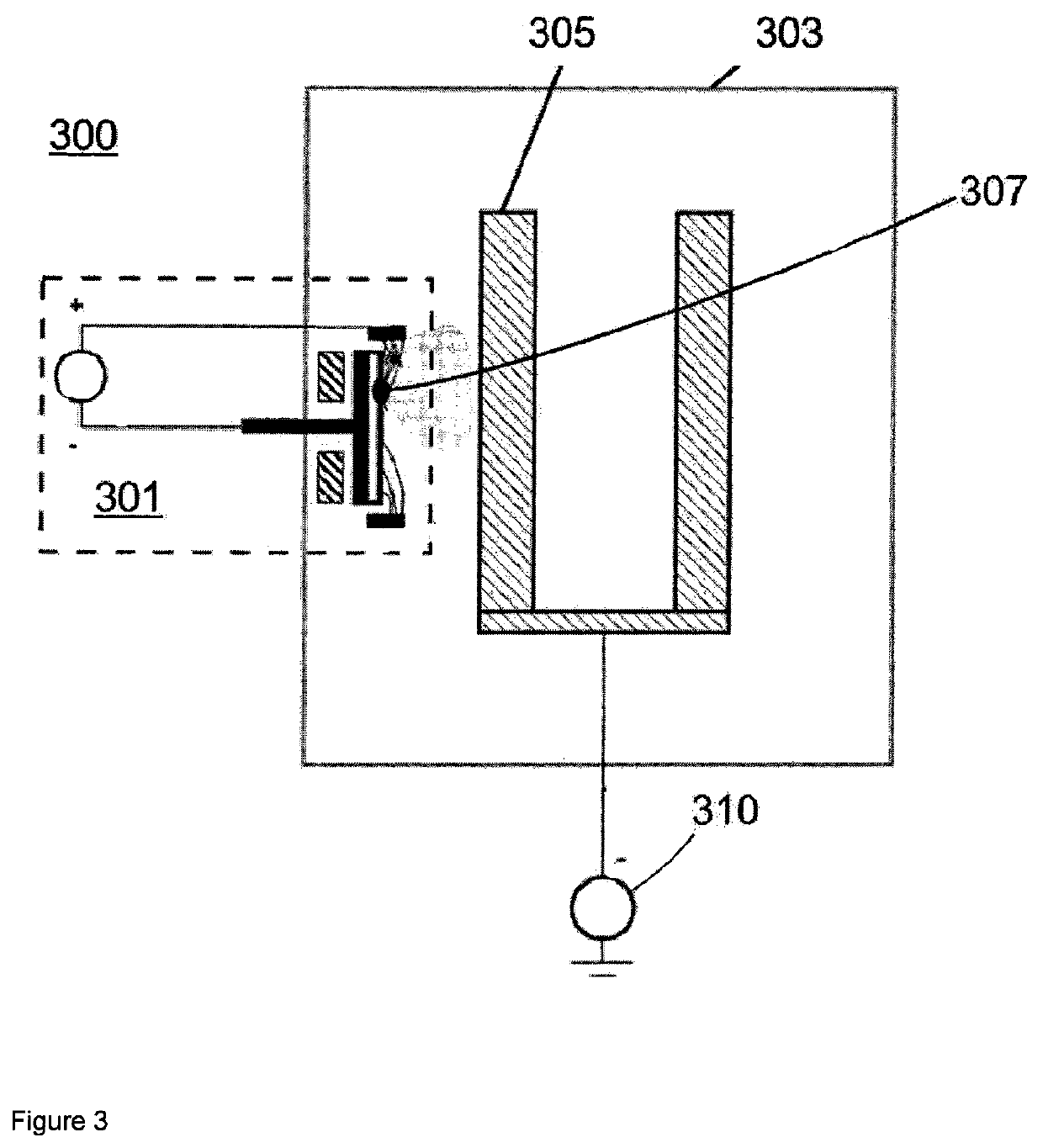

Low voltage drop, cross-field, gas switch and method of operation

A gas switch includes an anode and a cathode spaced apart from the anode, wherein the cathode includes a conduction surface. The gas switch also includes a plurality of magnets arranged to generate amagnetic field that defines an annular path over a portion of the conduction surface at a radial distance from a switch axis, and a control grid positioned between the anode and the cathode. In operation, the control grid is arranged to establish a conducting plasma between the anode and the cathode, wherein, in the presence of the conducting plasma, a voltage drop between the anode and the cathode is less than 150 volts, and wherein the conducting plasma forms a cathode spot that circles the annular path.

Owner:GENERAL ELECTRIC CO +1

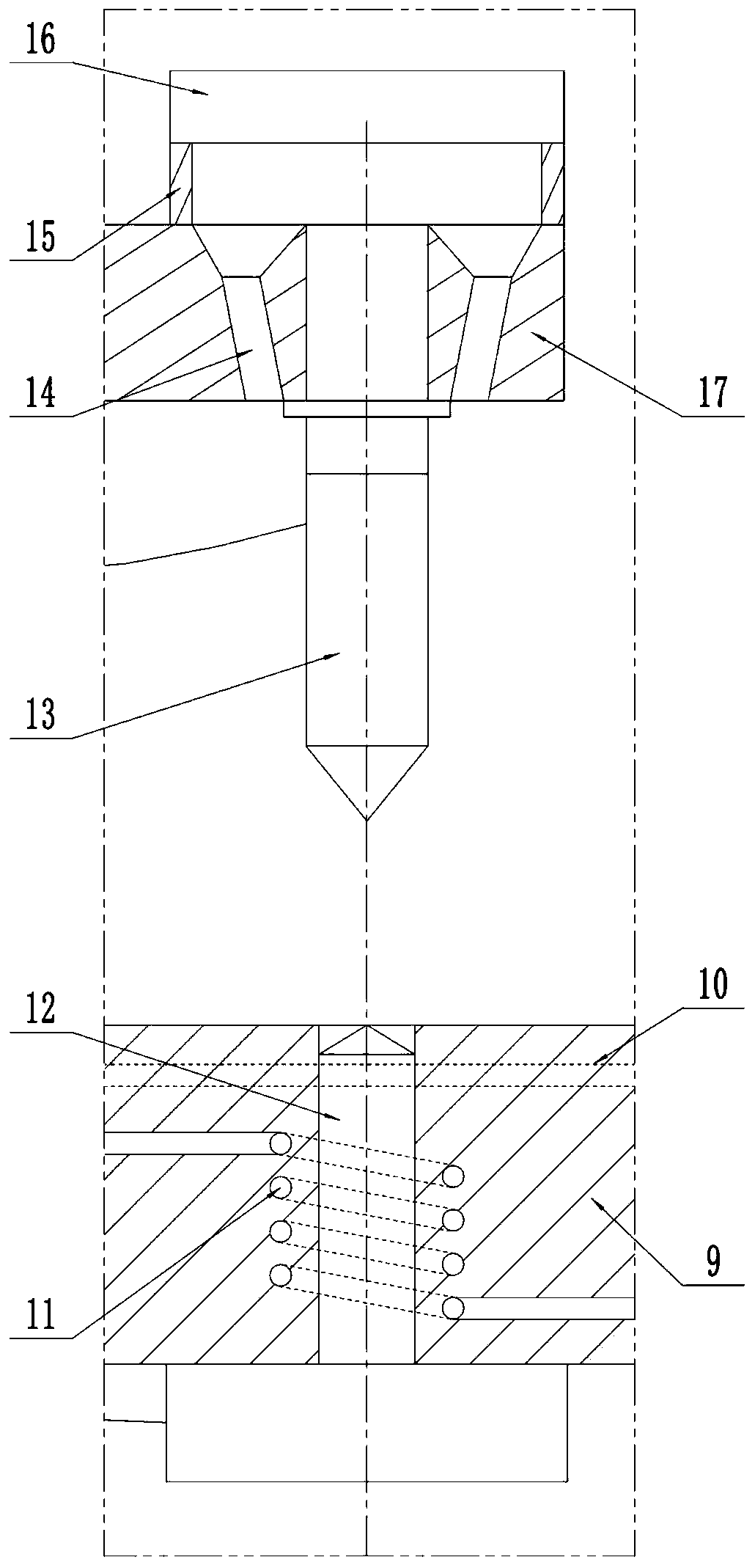

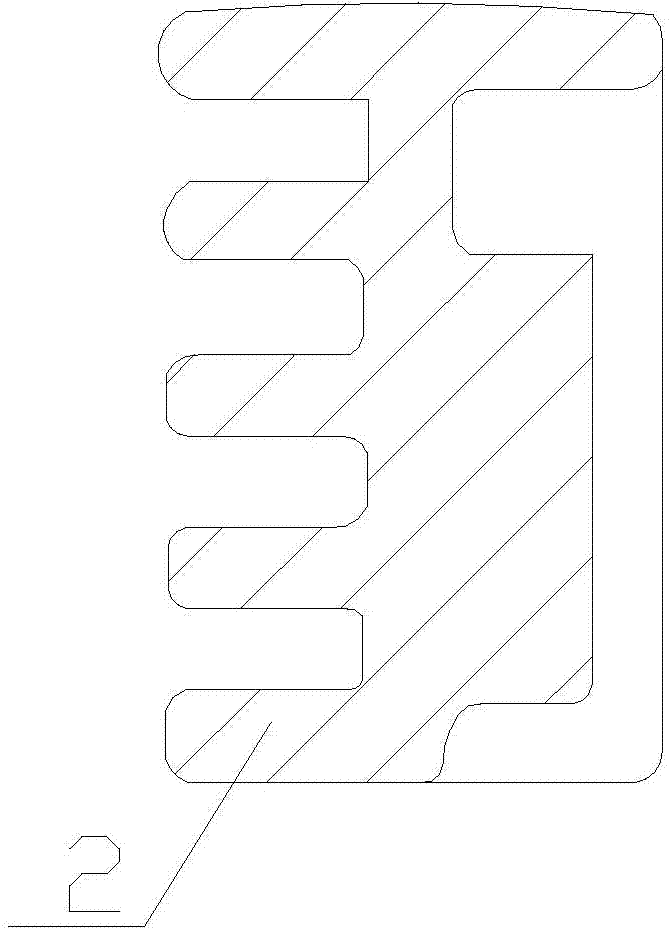

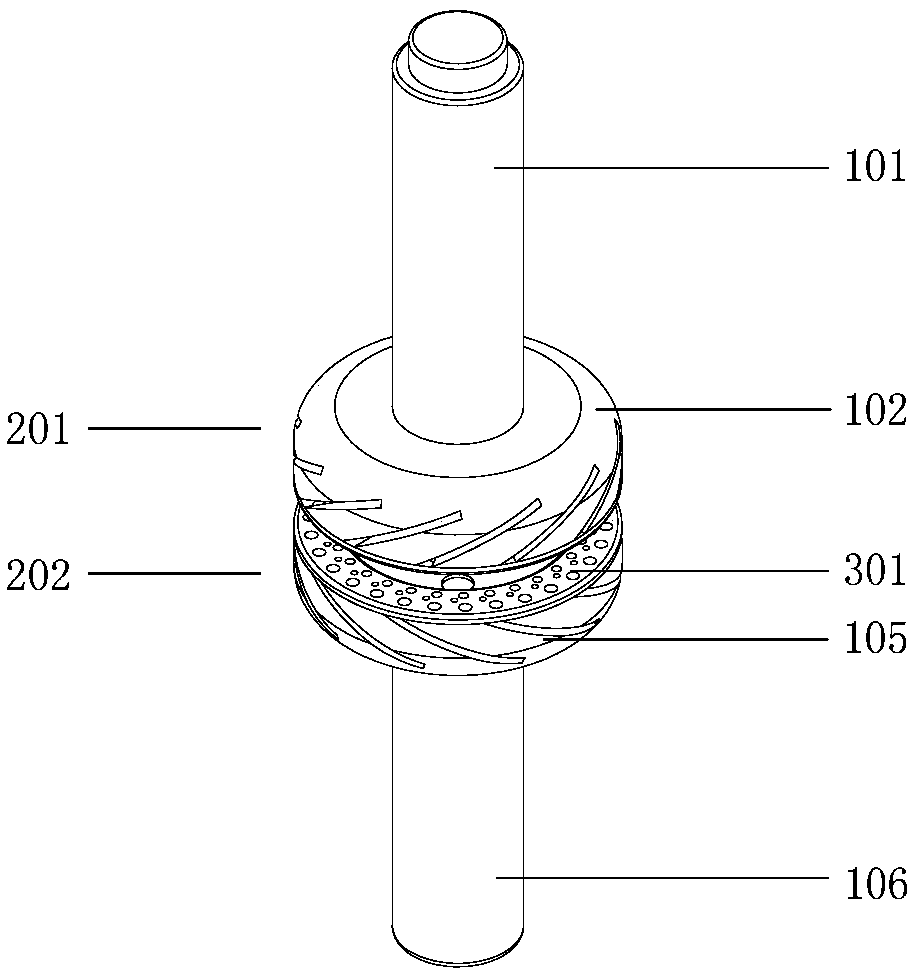

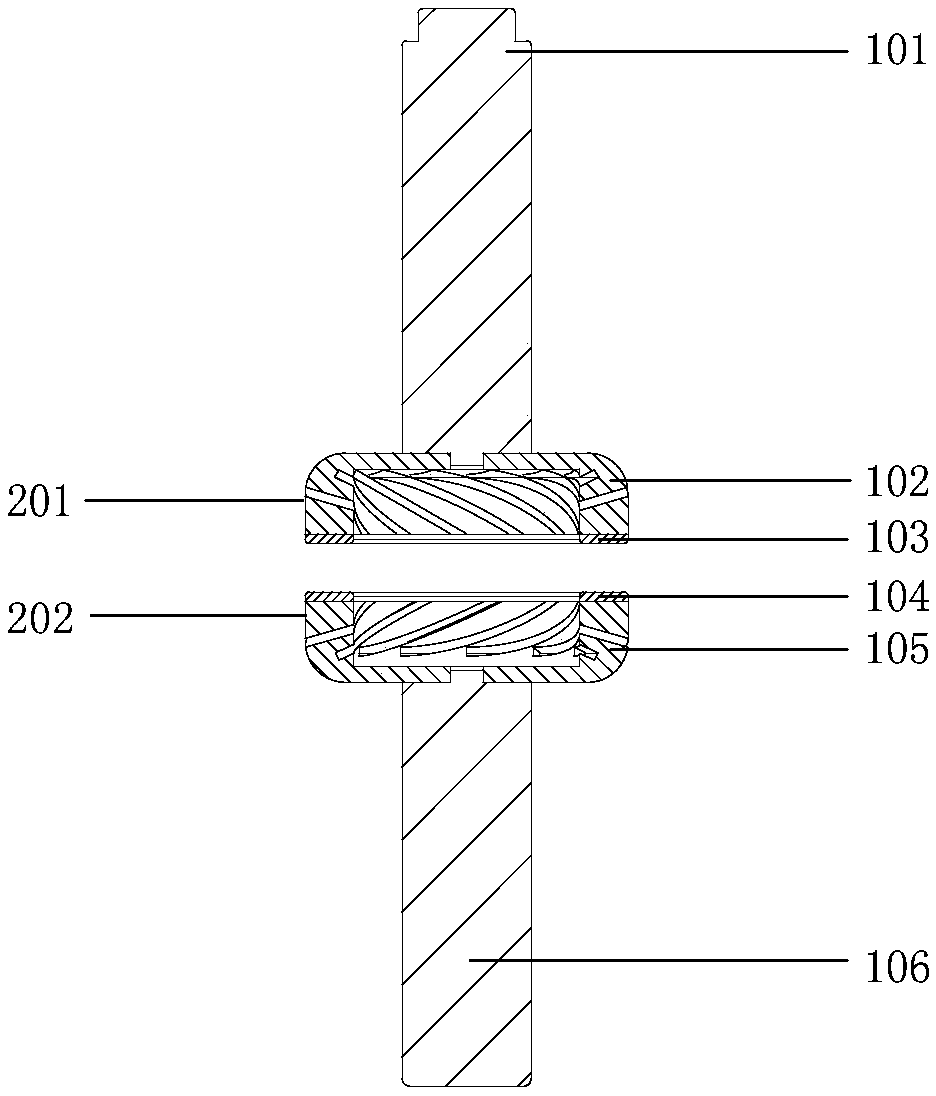

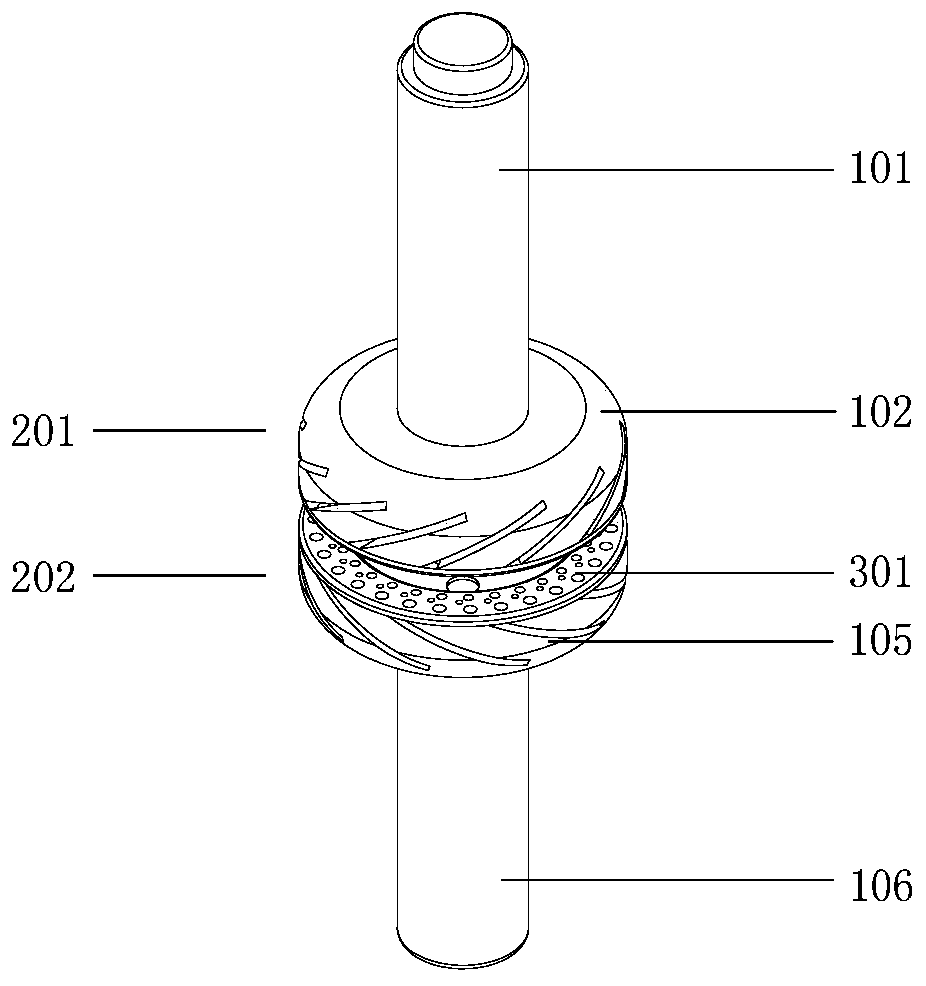

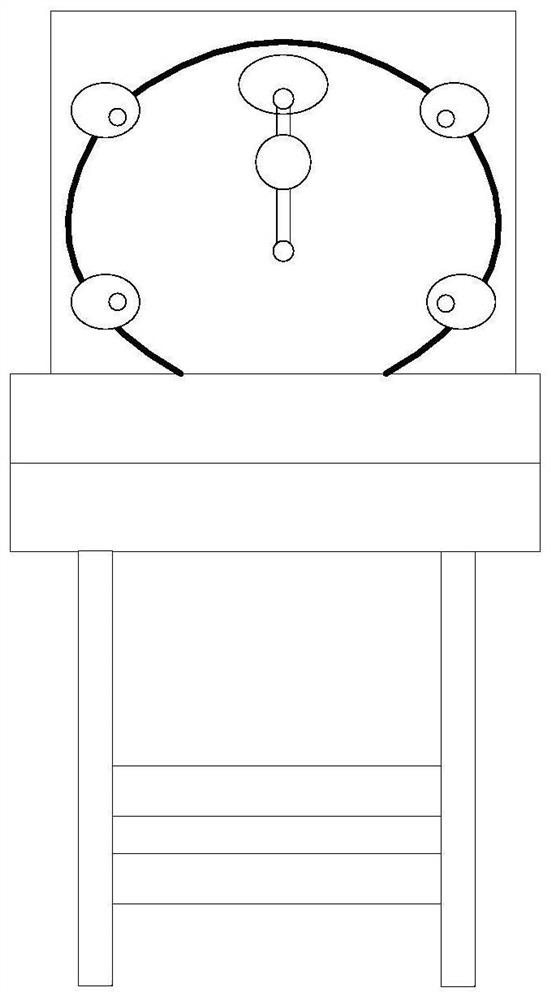

Contact with contact piece of cathode spot trap structure, direct-current vacuum arc-extinguishing chamber and direct-current vacuum contactor

ActiveCN109671590AIncrease relative volatilityAccelerate offHigh-tension/heavy-dress switchesAir-break switchesEngineeringDirect current

The invention discloses a contact with a contact piece of a cathode spot trap structure, a direct-current vacuum arc-extinguishing chamber and a direct-current vacuum contactor. The contact comprisesa moving-side contact combination structure and a static-side contact combination structure. The moving-side contact combination structure is welded at one end of a moving-side conducting rod. A moving-side contact piece is welded at the end part of the moving-side contact structure. The static-side contact combination structure comprises a static-side contact structure welded at one end of a static side conducting rod and a static-side contact piece welded at the end part of the static-side contact structure. Cathode spot trap structures are respectively arranged on the moving-side contact piece and the static-side contact piece. Each cathode spot trap structure is provided with a plurality of open pores in an annular contact piece. Through the arrangement of the cathode spot trap structures, the fluctuation of cathode spots on the surface of the contact piece is facilitated. The extinguishing of cathode spots is accelerated, and the vacuum arc voltage is effectively improved. The invention also provides the direct-current vacuum arc-extinguishing chamber and the direct-current vacuum contactor provided with the contact piece of the cathode spot trap structure.

Owner:XI AN JIAOTONG UNIV

Contacts with cathode spot trap structure contact pieces, DC vacuum arc extinguisher and DC vacuum contactor

ActiveCN109671590BIncrease relative volatilityAccelerate offHigh-tension/heavy-dress switchesAir-break switchesMaterials scienceVacuum interrupter

The invention discloses a contact with a contact piece of a cathode spot trap structure, a direct-current vacuum arc-extinguishing chamber and a direct-current vacuum contactor. The contact comprisesa moving-side contact combination structure and a static-side contact combination structure. The moving-side contact combination structure is welded at one end of a moving-side conducting rod. A moving-side contact piece is welded at the end part of the moving-side contact structure. The static-side contact combination structure comprises a static-side contact structure welded at one end of a static side conducting rod and a static-side contact piece welded at the end part of the static-side contact structure. Cathode spot trap structures are respectively arranged on the moving-side contact piece and the static-side contact piece. Each cathode spot trap structure is provided with a plurality of open pores in an annular contact piece. Through the arrangement of the cathode spot trap structures, the fluctuation of cathode spots on the surface of the contact piece is facilitated. The extinguishing of cathode spots is accelerated, and the vacuum arc voltage is effectively improved. The invention also provides the direct-current vacuum arc-extinguishing chamber and the direct-current vacuum contactor provided with the contact piece of the cathode spot trap structure.

Owner:XI AN JIAOTONG UNIV

Test apparatus for breakdown strength of material

InactiveCN100523846CImprove accuracyHigh degree of automationTesting dielectric strengthBreakdown strengthMetallic materials

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A method of controlling the cathodic cleaning area in the aluminum alloy welding process

ActiveCN108356394BAvoid damageInhibition biasArc welding apparatusWelding/soldering/cutting articlesLaser power densityWelding process

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

Super-high pressure mercury lamp for projector with high light utilization rate

InactiveCN101847561AHigh strengthRequires minimizationProjectorsGas discharge lamp detailsLuminous intensityOptoelectronics

The invention relates to a super-high pressure mercury lamp for a projector with high light utilization rate, which comprises an electric arc tube (1) and two electrodes (2) which are arranged in a discharge space (3) of the electric arc tube (1) oppositely; the mercury lamp is characterized in that the distance between the two electrodes (2) is the distance which makes an electric arc center (5) is crossed or overlapped with a cathode spot (4) when in discharge and light emitting. The super-high pressure mercury lamp for the projector has high light utilization rate, and can greatly improve the intensity of the light emitted by an LCD panel of the projector under the circumstance of not improving the overall light emitting intensity of the lamp.

Owner:王国华

Radiating frame mounted on solid-sealed polar pole

InactiveCN104752093AReduce concentrationGuaranteed normal breakingHigh-tension/heavy-dress switchesAir-break switchesElectric power systemMetal

The invention relates to spare parts of switching equipment in a power system, and in particular relates to a radiating frame mounted on a solid-sealed polar pole. The radiating frame comprises an integrally formed base; an arch door is formed one side surface of the base; inwards vertical radiating fins are arranged on the rest three side surfaces of the base; a groove is formed in the middle part of the upper surface of the base; a connecting seat connected with the solid-sealed polar pole is arranged on the rear surface of the base; a bolt hole is formed in the connecting seat. The radiating frame is high in heat transfer performance; cathode spots can be cooled; metal steam concentration can be reduced; a vacuum arc-extinguishing chamber can be disconnected normally; the radiating frame is simple in structure, reasonable in design, nice, and firm.

Owner:施周平

A strong light simulated light source lighting device

ActiveCN111828878BEasy to adjustLight source combinationsLighting support devicesEngineeringDaylight

The invention belongs to the field of optics, and discloses a strong light analog light source lighting device, comprising: a light source, a reflective optical system, a light source focusing assembly, a light source heat dissipation mechanism, a wind speed acquisition module, a xenon lamp main control system, a xenon lamp electronic ballast, a direct current Stabilized power supply, light source mobile platform and supporting mechanism. When the device of the present invention is working, turn on the heat dissipation mechanism of the light source, the wind speed acquisition module, the main control system of the xenon lamp, the electronic ballast of the xenon lamp, and the DC power supply in sequence, adjust the output of the electronic ballast of the xenon lamp, slowly light the xenon lamp in the light source, and adjust the light source The three-axis adjustment mechanism in the focusing assembly makes the xenon lamp cathode spot in the light source coincide with the focus of the parabolic mirror in the reflection optical system, and outputs parallel light. By adjusting the output power of the xenon lamp electronic ballast and the DC stabilized power supply, different color temperatures and ambient light with different illuminance can be obtained, which meets the photoelectric parameter measurement requirements of the liquid crystal display in the daylight environment.

Owner:西安应用光学研究所 +1

Pretreatment liquid and pretreatment method before rare earth conversion

InactiveCN102011115BFast film formationHigh film forming efficiencyMetallic material coating processesPretreatment methodSorbent

The invention discloses pretreatment liquid and a pretreatment method before rare earth conversion. The pretreatment liquid consists of acid, a buffering agent, a complexing agent, a surfactant and a surface adsorbent. The pretreatment method comprises the following steps of: immersing an aluminum alloy in the pretreatment liquid, impregnating for 1 to 5 minutes, taking out and washing by using running water; and immersing in alkaline solution for 2 to 60 seconds, taking out and washing by using the running water. Uniform and dense cathode spots can be generated on the surface of the aluminumalloy after the treatment of the method, and good film forming conditions can be provided for the generation of a subsequent rare earth conversion coating. In the pretreatment method, the pretreatment liquid does not need to be heated in the treatment process, and the defects of non-uniform film formation and high aluminum loss in the traditional strong alkali pretreatment can be well overcome. The method is simple, and easy and convenient to operate, and low in cost, and industrialization is easy to realize.

Owner:SOUTH CHINA UNIV OF TECH

Low temperature arc ion plating coating

ActiveUS10865472B2Improve mechanical propertiesOvercome disadvantagesElectric discharge tubesVacuum evaporation coatingVacuum chamberChemistry

Coating method for arc coating or arc ion plating coating of substrates in a vacuum chamber in which using an arc evaporator solid material that functions as cathode is evaporated, during arc evaporation the motion of the cathode spot on the solid material surface is accelerated using a magnetic field for avoiding ejection of a large amount of macro-particles or droplets from the solid material surface, negative charged particles resulted from the arc evaporation flow from the cathode to an anode, characterized by the motion of the negative charged particles from the cathode to the anode fundamentally doesn't cause an additional increase of the absolute value of the potential difference between cathode and anode allowing a lower increment of the substrate temperature during coating.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com