Contacts with cathode spot trap structure contact pieces, DC vacuum arc extinguisher and DC vacuum contactor

A vacuum interrupter and cathode spot technology, which is applied to high-voltage air circuit breakers, high-voltage/high-current switches, electrical components, etc., can solve the problems of not realizing direct current breaking of vacuum circuit breakers, so as to promote wide application, Increase the vacuum arc voltage and promote the effect of extinguishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

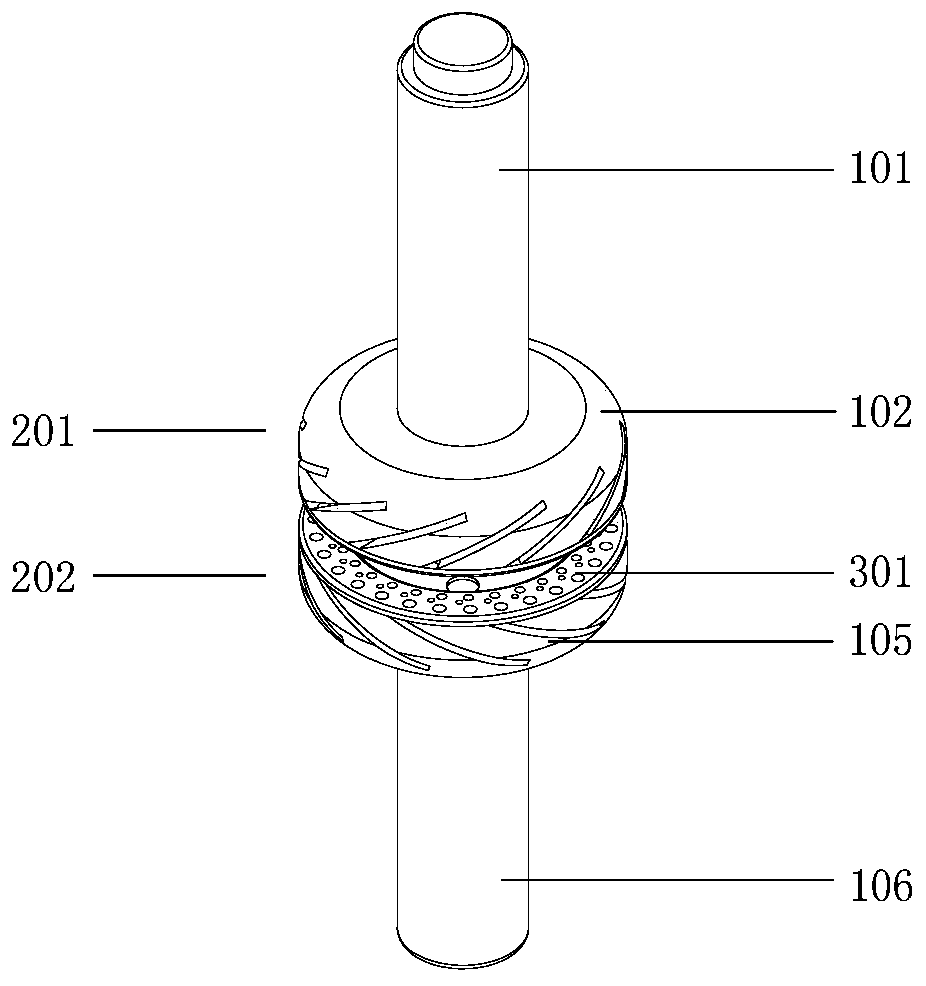

[0037] figure 1 with figure 2 They are respectively a schematic diagram and an axial sectional view of a contact sheet with a cathode spot trap structure of the present invention. Such as figure 1 with figure 2As shown, the present invention has a contact sheet with a cathode spot trap structure, including a static side contact combination structure 201 and a moving side contact combination structure 202; the static side contact combination structure 201 includes a static side conductive rod (101), the static side contact structure (102) welded on one end of the static side conductive rod (101), and the static side contact piece with the cathode spot trap structure welded on the end of the static side contact structure (102) (103); the moving side contact combination structure 202 includes a moving side conductive rod (106), a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com