Heat dissipating rack for solid-sealed polar pole

A technology of solid-sealed poles and heat sinks, which is applied in the field of heat sinks, can solve the problems of affecting the service life of vacuum interrupters and circuit breakers, the small area of arc spot melting zone, and the rise of contact temperature, and achieves simple structure and metal vapor The effect of low concentration and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

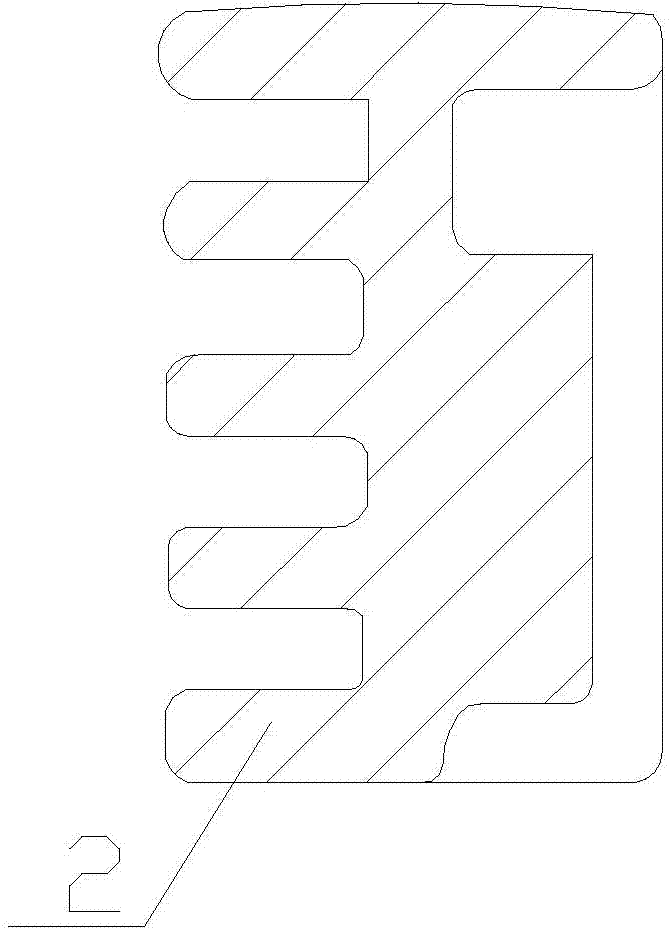

[0015] Such as Figure 1~3 As shown, a heat sink for solid sealing on poles includes a heat sink body. The heat sink body includes a door-shaped bottom plate 1 and a heat sink 2 located on the bottom plate 1. The heat sink 2 includes a strip-shaped structure. Radiating fins 21 and radiating fins 22 with a wave-shaped structure, the back of the base plate 1 is provided with a connecting seat 3 connected to the solid-sealed pole, the connecting seat 3 is provided with threaded holes 4, and the four corners of the base plate 1 are also provided with Seal 5.

[0016] Further, there are five cooling fins 2, one of which is a cooling fin 22 with a wave-shaped structure. The heat sinks 2 of the prior art are all strip-shaped heat sinks 21, and one of the heat s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com