Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "There will be no material jams" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

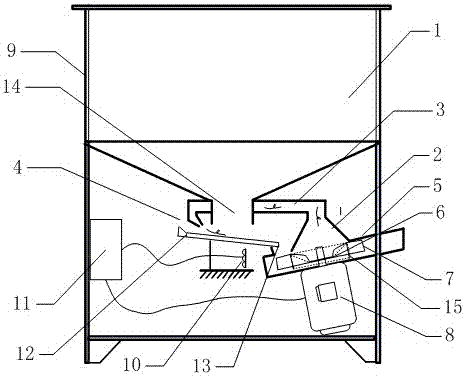

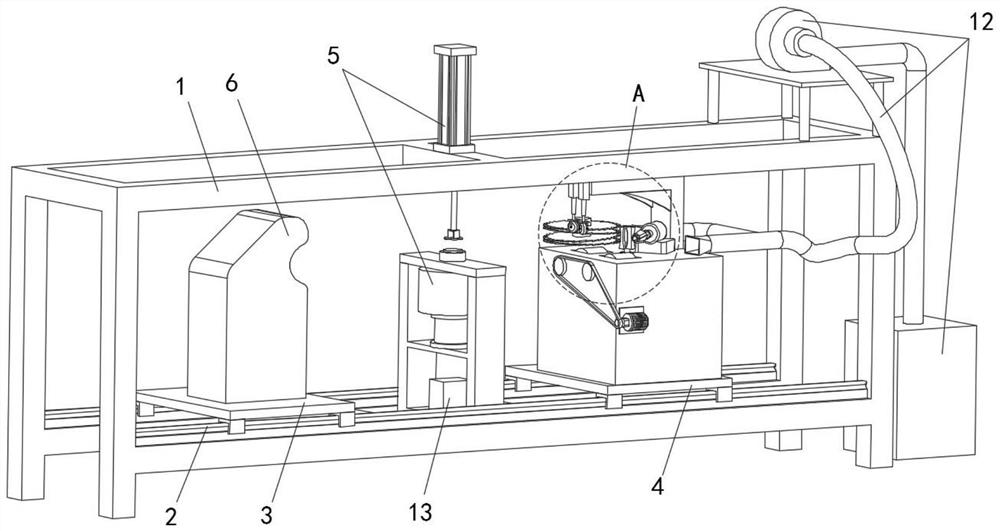

Automatic IC testing and sorting device

The invention discloses an automatic IC testing and sorting device. The device comprises a feeding device, a testing device and a sorting and storing device which are arranged on a machine frame; andthe machine frame comprises a first mounting plate and a second mounting plate, wherein the first mounting plate is vertically arranged, and the second mounting plate is connected with the bottom of the first mounting plate and is obliquely arranged. An IC material tube is clamped on the feeding device, IC chips which are not tested in the IC material tube are supplied to the testing device for testing through the feeding device, after the testing is finished, the chips are classified through the sorting and storing device and are stored in a plurality of empty material tubes. According to thedevice, a clamping mechanism with the IC material tube clamped is turned over, so that the IC material tube is changed into a vertical state, and the IC chips in the IC material tube slide out and get to a vertical material channel; the IC chips can be controlled by a blocking and pressing mechanism to be fed to the testing device one by one, testing chucks clamp the IC chips and push the IC chips to a testing PCB for testing, the IC chips are received through a material receiving table after the test is completed and are classified and placed to a first material storing mechanism or a second material storing mechanism, so that the speed of sorting and storing is increased, and the labor cost is saved.

Owner:昆山宇辰光通自动化科技有限公司

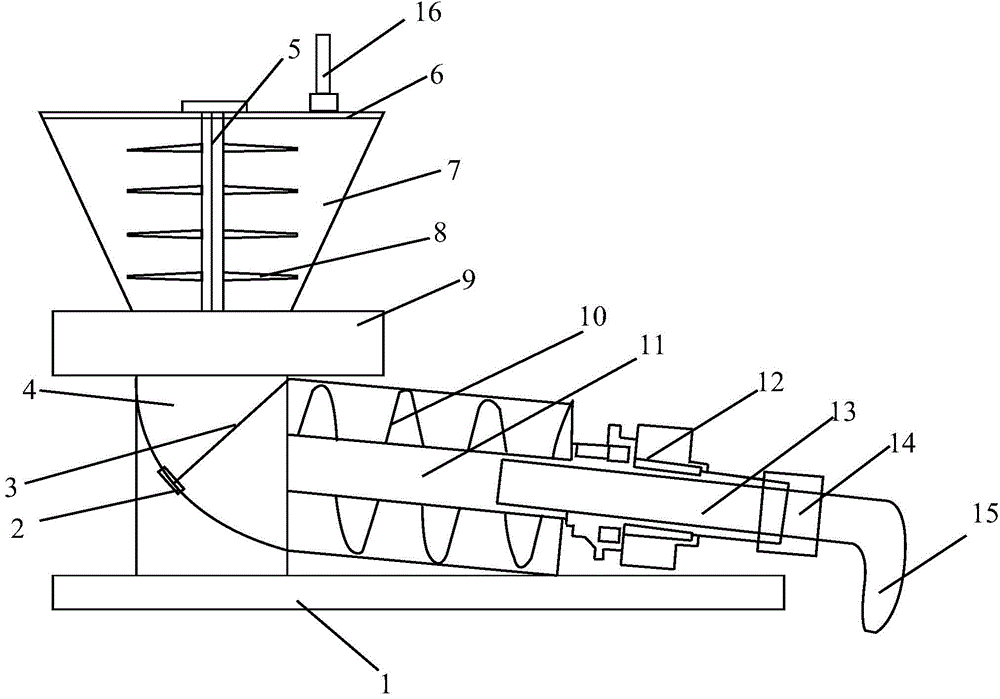

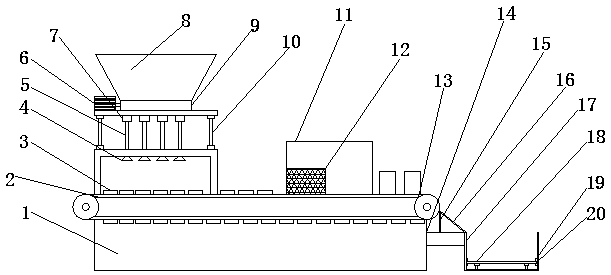

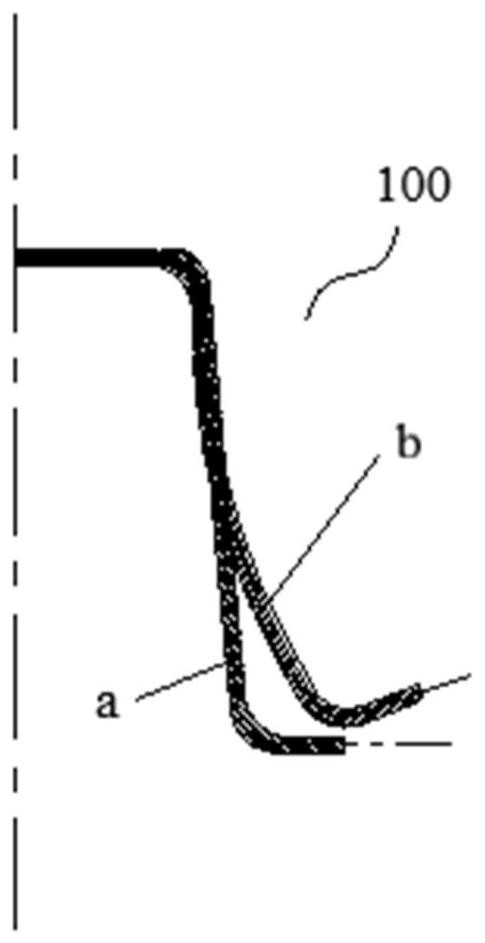

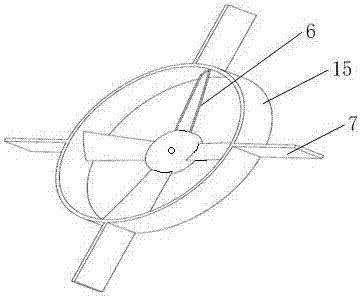

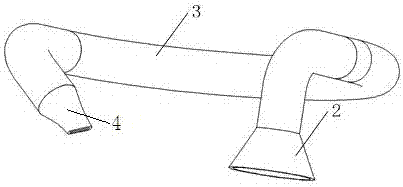

Feeding mechanism of stamping equipment for motor rotor piece

InactiveCN103949558AReduce size requirementsReduced precision requirementsMetal-working feeding devicesPositioning devicesElectric machineryEngineering

The invention particularly relates to a feeding mechanism of stamping equipment for a motor rotor piece, and belongs to the technical field of stamping equipment. The feeding mechanism comprises a frame, wherein a material storage bucket and a material distribution device are arranged on the frame; the material distribution device is arranged above the material storage bucket through a support frame, and comprises a material suction disk and a power component for driving the material suction disk to perform reciprocating straight line movement; a magnetic device is arranged at the discharge end of the material storage bucket; a push device is arranged on one side of the material suction disk; a material guide groove is formed in the other side, opposite to the push device, of the material suction disk. The feeding mechanism has low requirements on the size and the precision or the cleanliness of blank and has a wide application range, is simple in structure, low in manufacturing cost, simple and convenient to maintain, and long in service life; materials are distributed accurately, and one piece is distributed for each time; the phenomena of piece clamping and material blocking are avoided; the production efficiency is high; 90-95 pieces of blank can be machined per minute averagely when the feeding mechanism is matched with a stamping mechanism; manpower is saved; one person can control a plurality of machines.

Owner:池海平

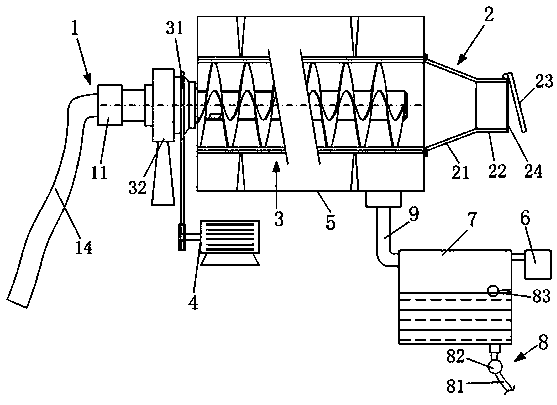

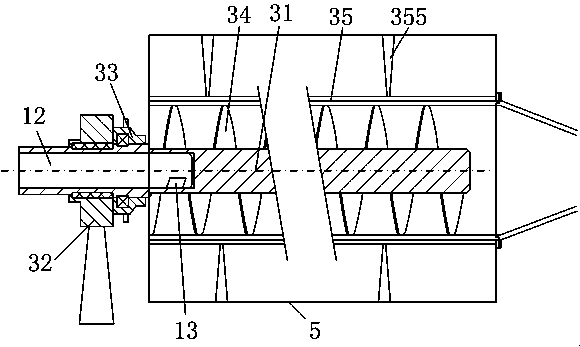

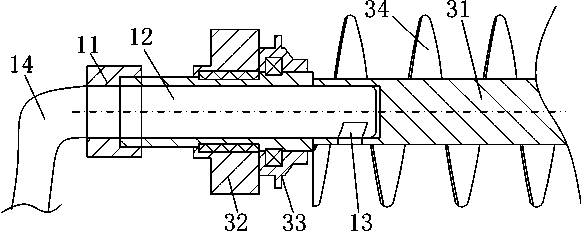

Vacuum suction-type screw-extrusion solid-liquid separation system

ActiveCN103641289AReduce processing timeSave time and costSludge treatment by de-watering/drying/thickeningSuction forceSlag

The invention discloses a vacuum suction-type screw-extrusion solid-liquid separation system. The vacuum suction-type screw-extrusion solid-liquid separation system comprises a screw extruding mechanism, a driving mechanism, a sealing box body, a vacuumizing machine, an airtight water tank and a continuous liquid discharging mechanism, wherein the screw extruding mechanism is connected with a continuous feeding mechanism and a continuous solid discharging mechanism, the driving mechanism is used for providing the rotation power, the screw extruding mechanism is sealed inside the sealing box body, the vacuumizing machine is communicated with the sealing box body through a pipeline and used for providing vacuum suction force to the vacuum suction-type screw-extrusion solid-liquid separation system, the airtight water tank is connected onto a pipeline between the sealing box body and the vacuumizing machine and used for collecting the liquid discharged from the screw extruding mechanism, and the continuous liquid discharging mechanism is arranged on the airtight water tank. By utilizing the integral vacuum suction principle, the vacuumizing machine which is arranged at the rear end is used for providing the vacuum suction force to the entire internal space, the reliability is high, the flow is optimized, the continuous suction function, the continuous solid / slag discharging function and the continuous liquid discharging function can be realized, the sewage waste treatment time is effectively saved, and the time cost and the labor cost can be greatly saved.

Owner:CHENGDU XINCHAOSHUN ENVIRONMENTAL TECH

Extrusion feeding mechanism of pasty fluid filling machine

InactiveCN104085549AGuaranteed continuityAvoid the gapLiquid materialEngineeringUltimate tensile strength

The invention provides an extrusion feeding mechanism of a pasty fluid filling machine. The extrusion feeding mechanism comprises a base, an arc-shaped feeding groove is formed in the base, a fixed support is arranged above the feeding groove, a feeding hopper is installed on the fixed support and communicated with the feeding groove, a filtering screen is arranged in the feeding groove, a filtering barrel is arranged on one side of the feeding groove, a main rotating shaft is installed in the filtering barrel, one end of the main rotating shaft extends out of the filtering barrel, and an extrusion screw is arranged on the main rotating shaft. By means of the extrusion feeding mechanism, axial feeding is carried out to enable a feeding opening to be located in the main rotating shaft, a gap between the screw and the lateral wall of the filtering barrel is effectively avoided, material blocking is avoided, the feeding continuity is guaranteed, and the feeding efficiency is accordingly improved. By means of the extrusion feeding mechanism, the filtering screen can be conveniently disassembled and washed through the arrangement of a detachable fixed plate, the working strength of an operator is reduced, the packaging efficiency is improved, the extrusion feeding mechanism has the advantages of being ingenious in design, safe and reliable, and the wide market application prospect is achieved.

Owner:天津尚永科技有限公司

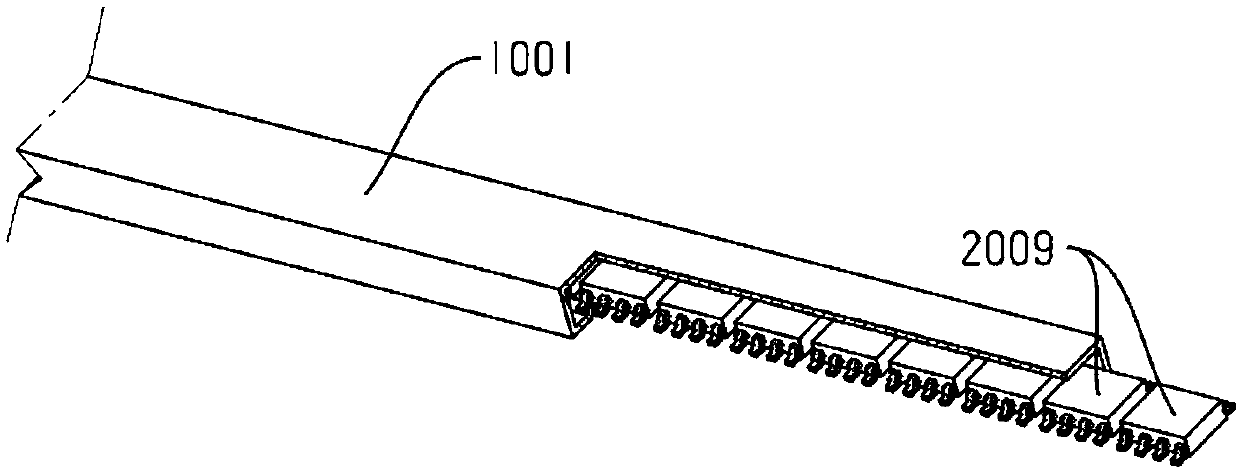

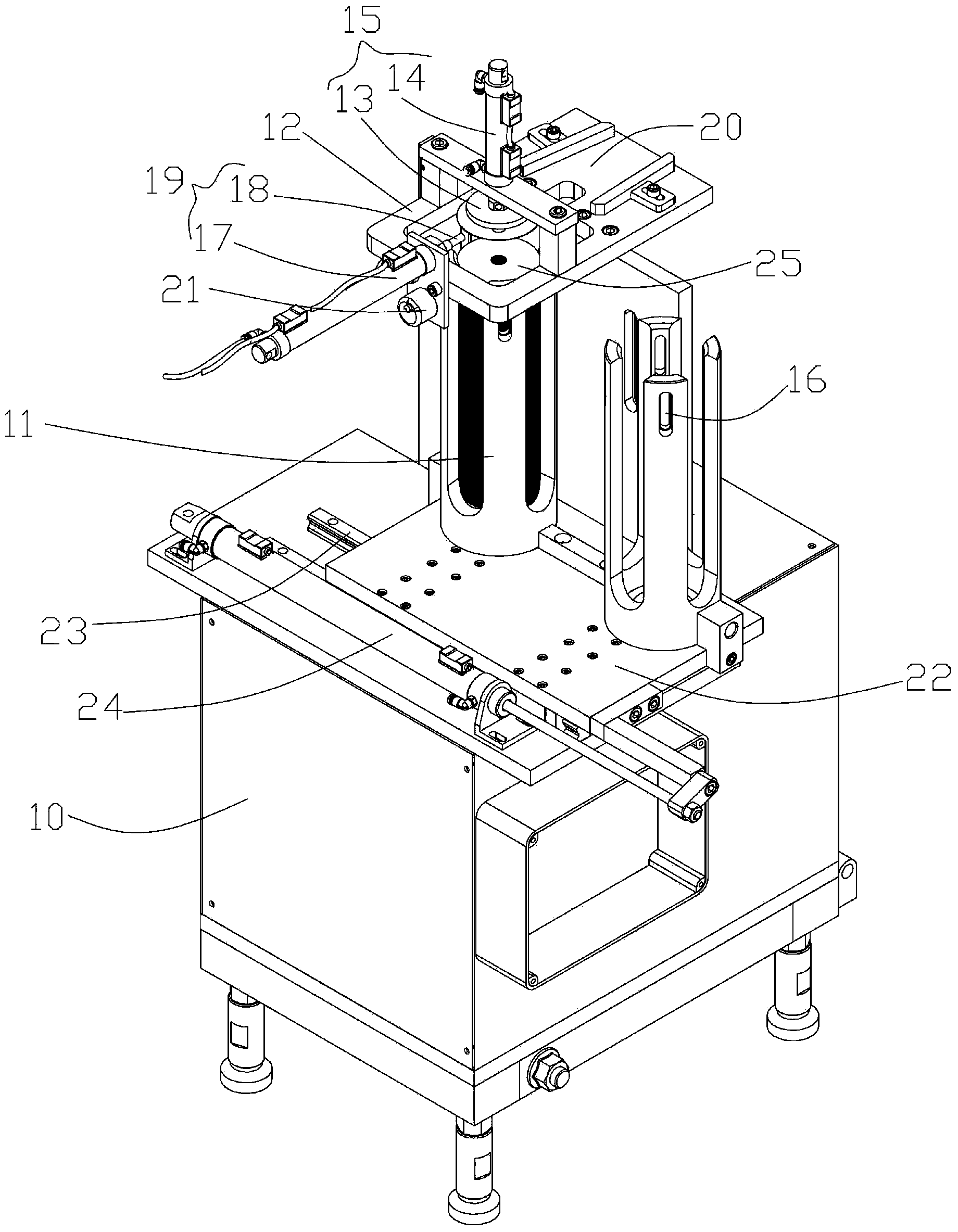

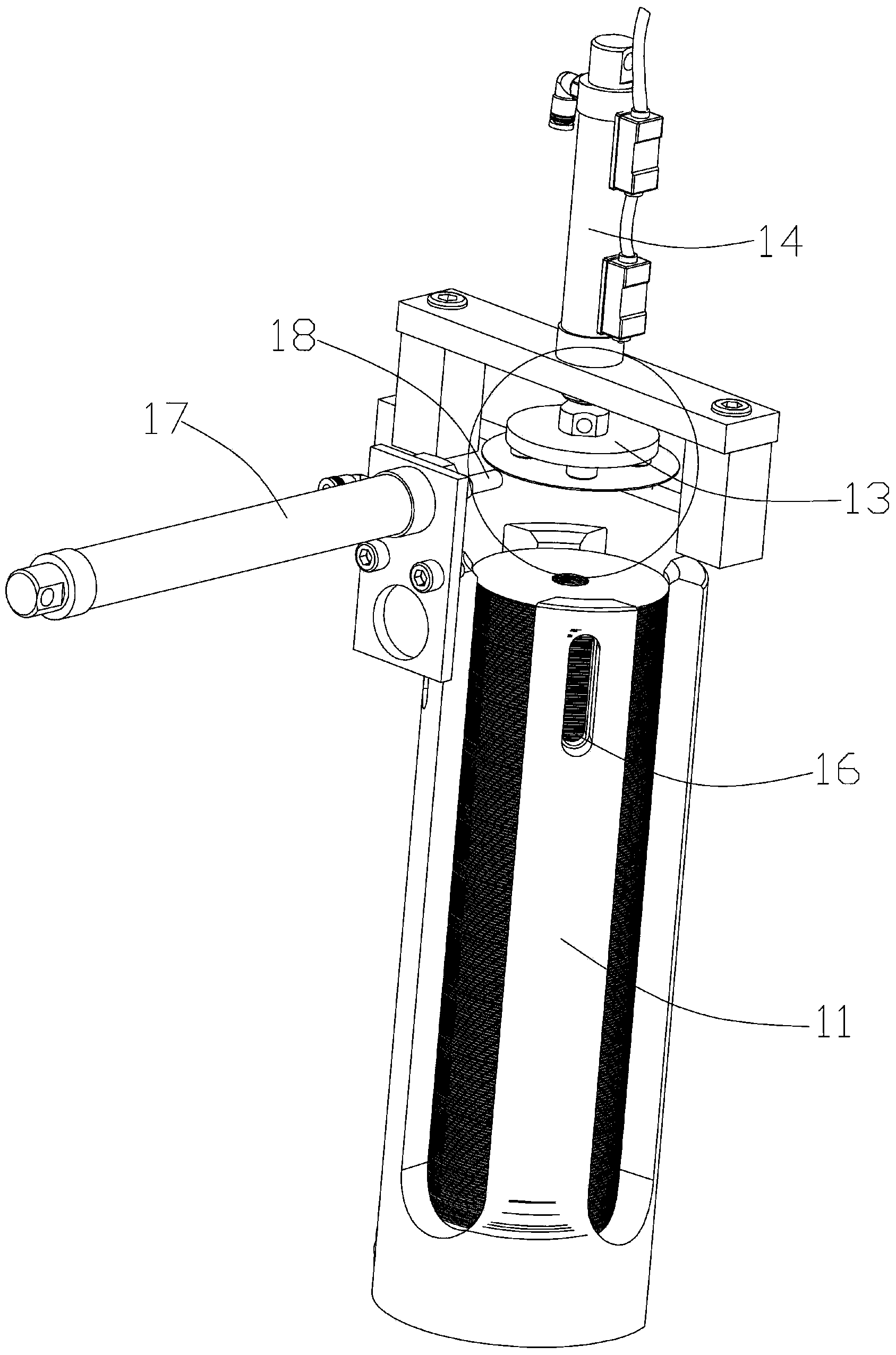

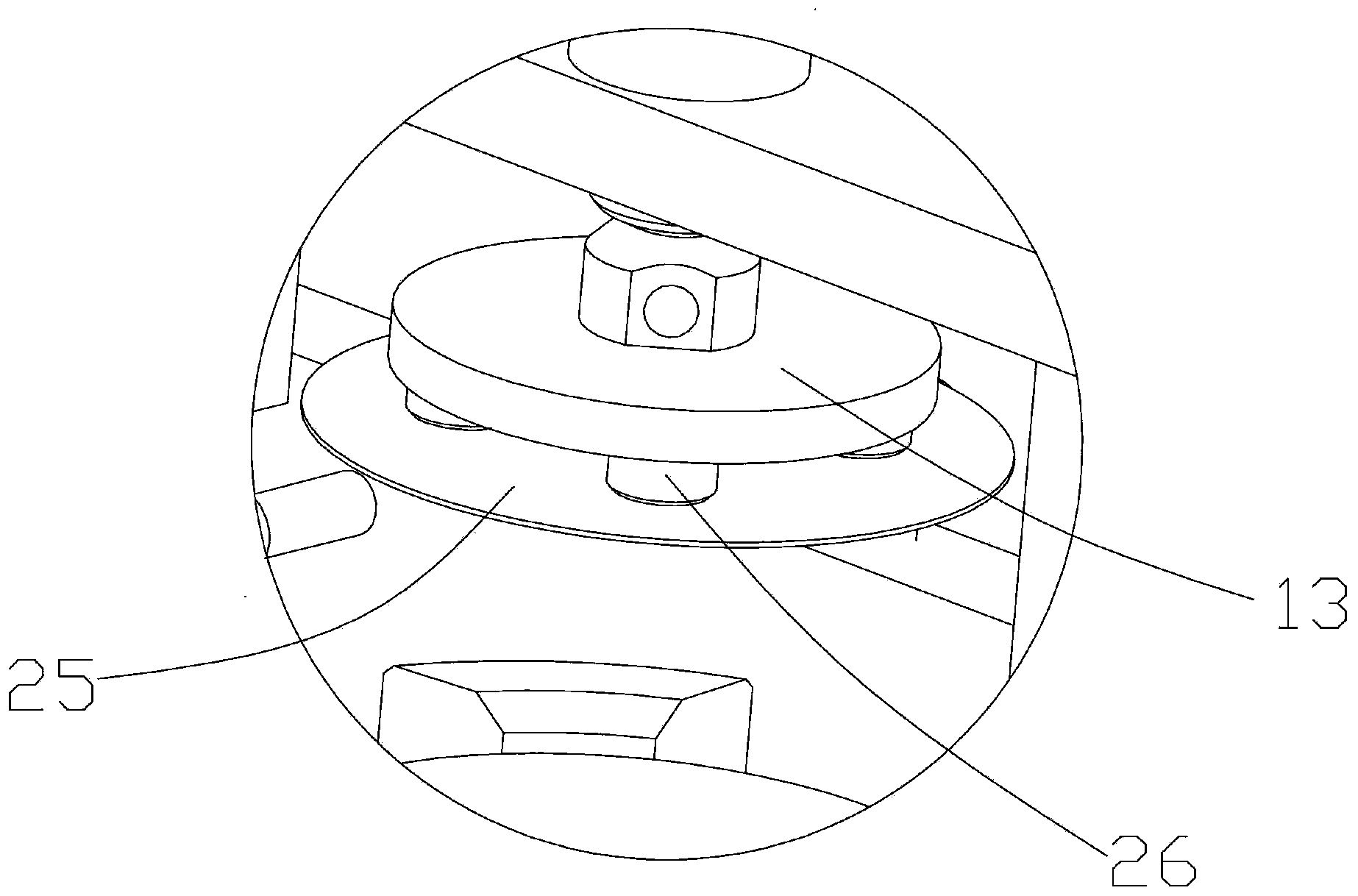

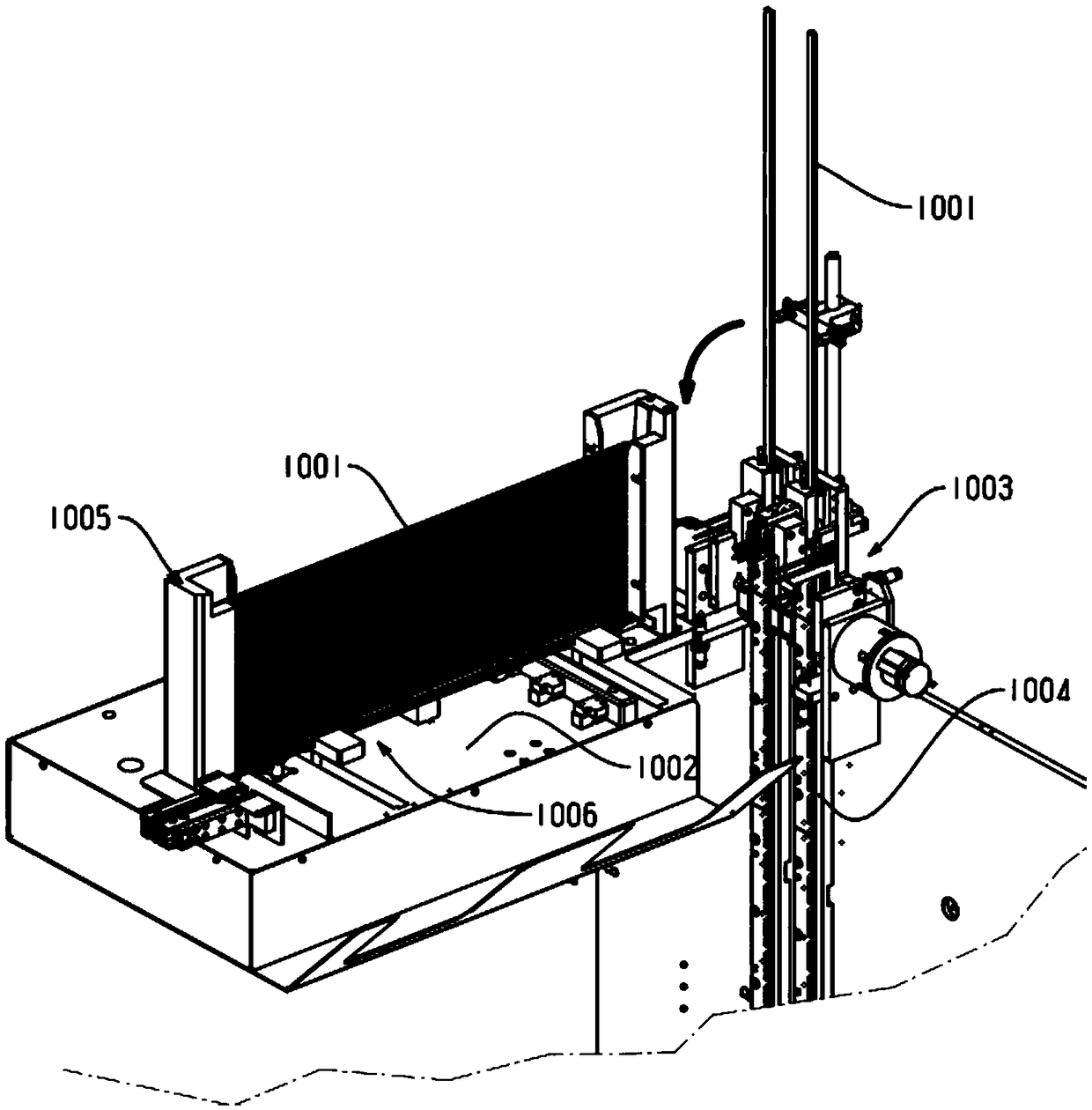

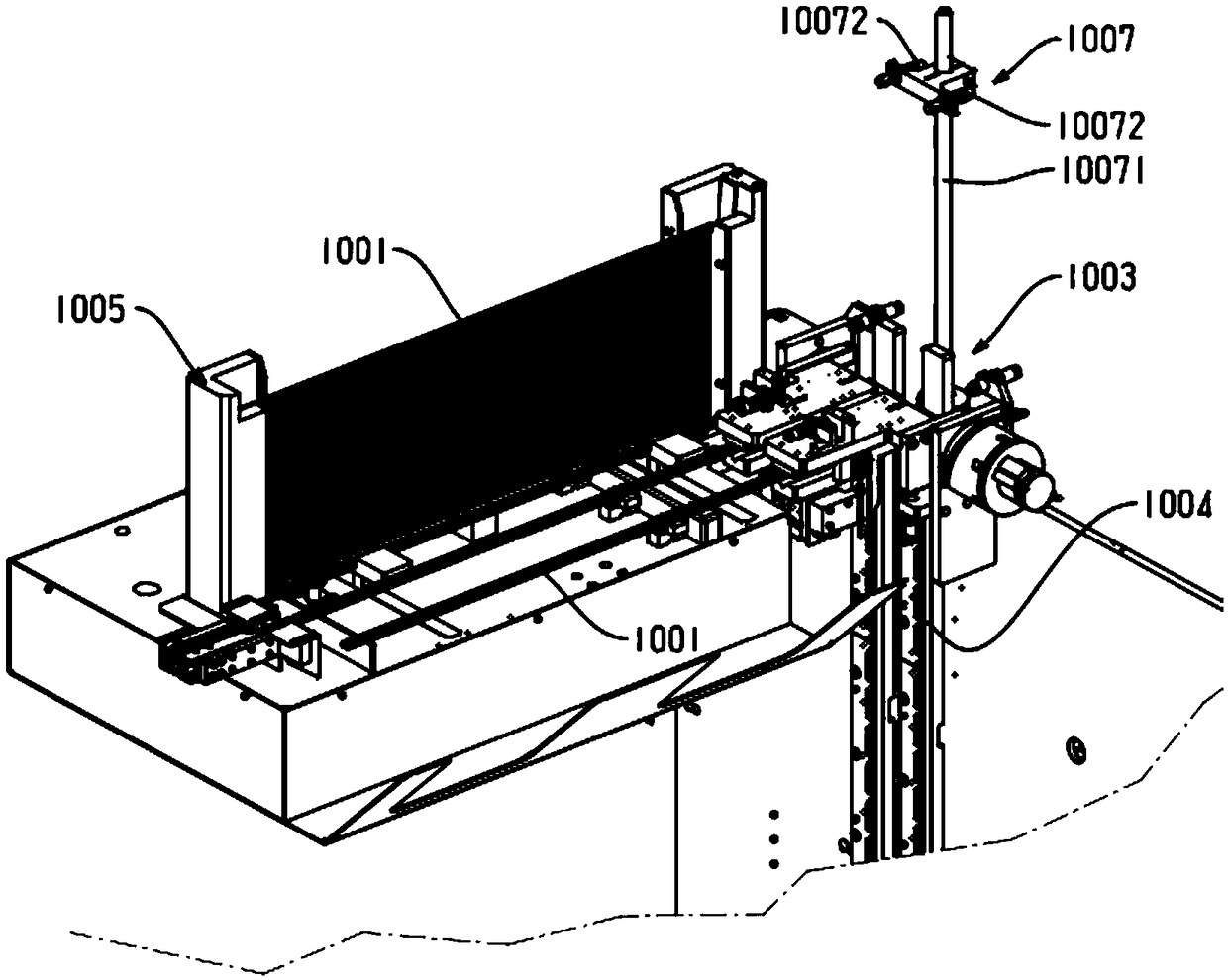

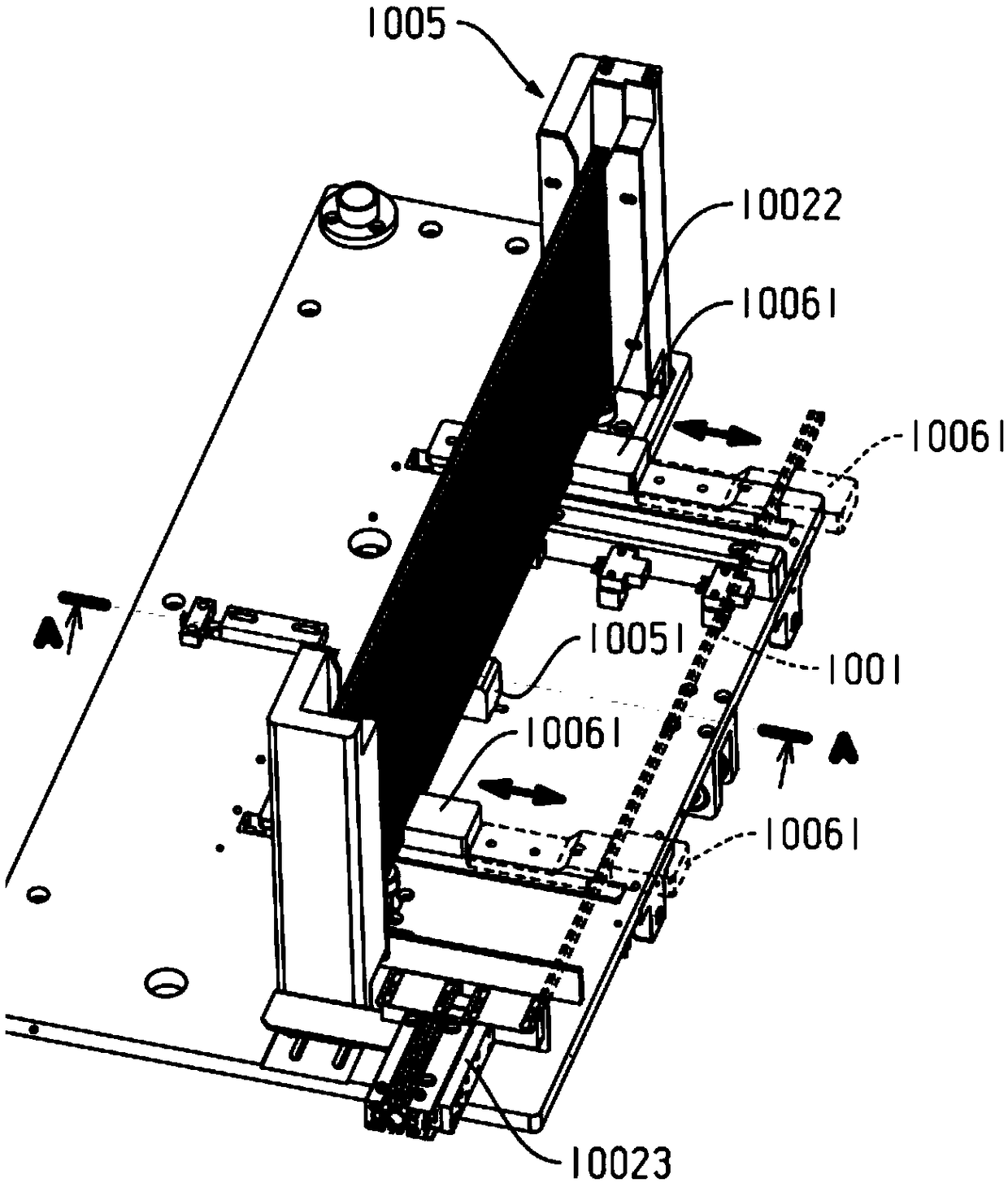

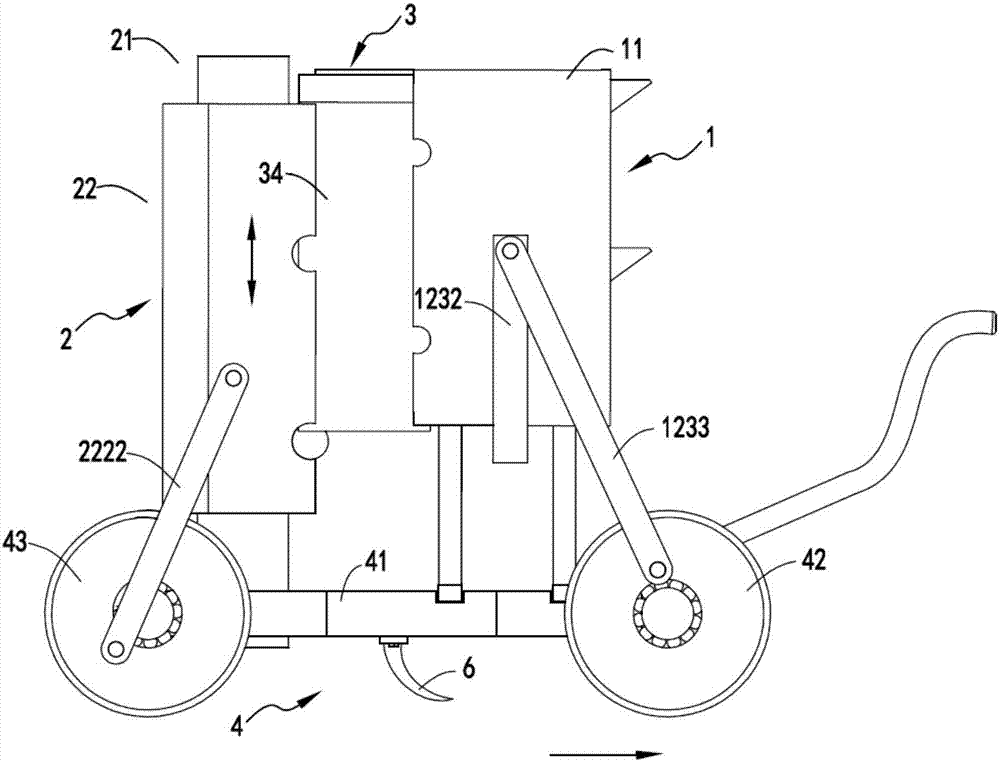

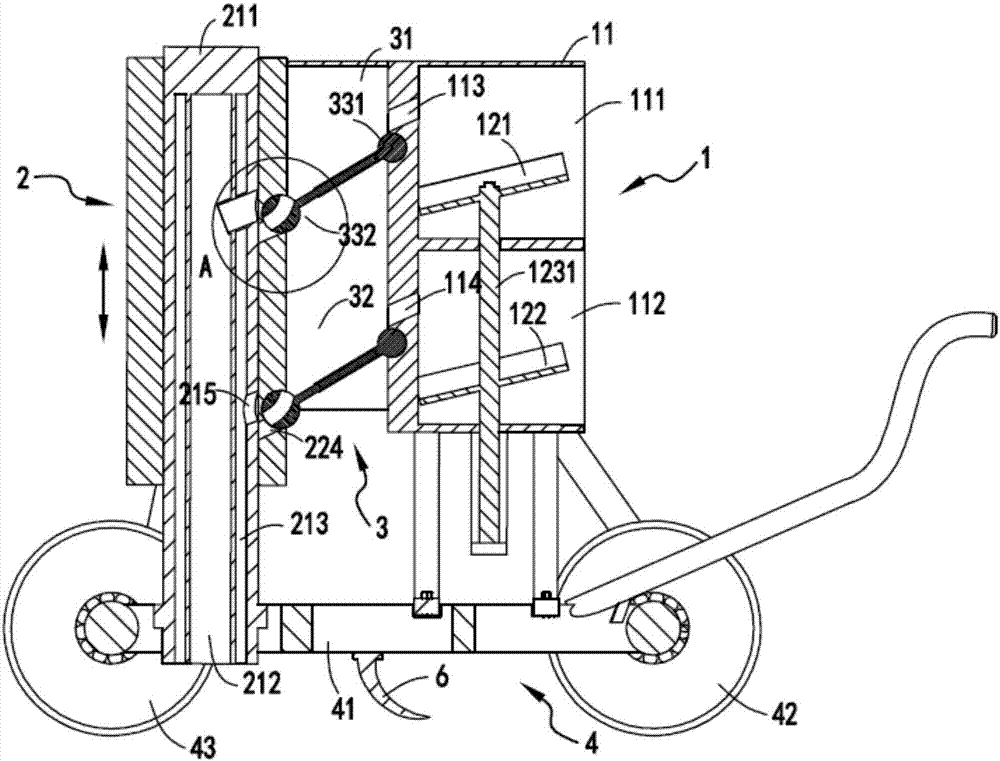

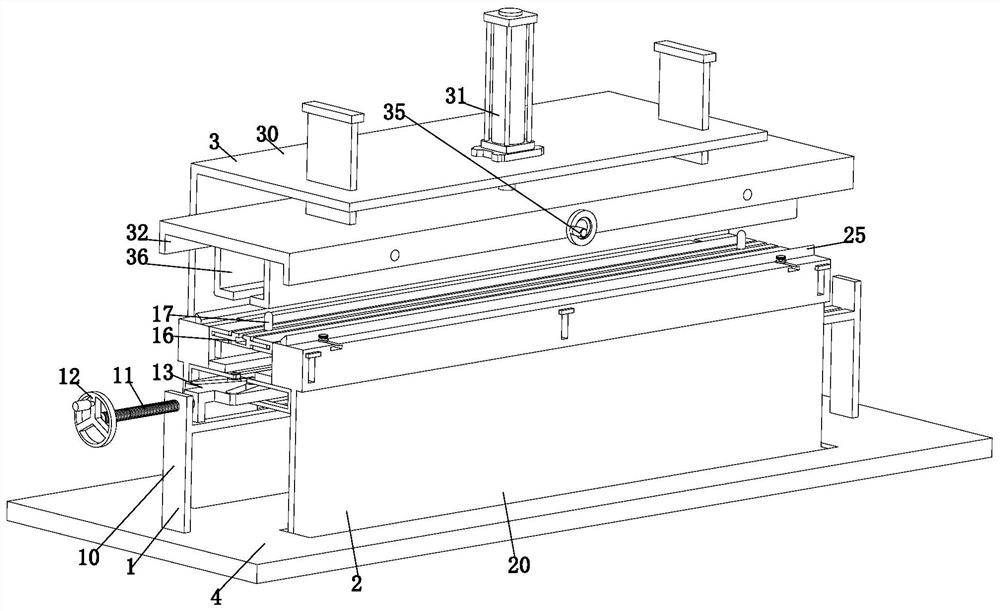

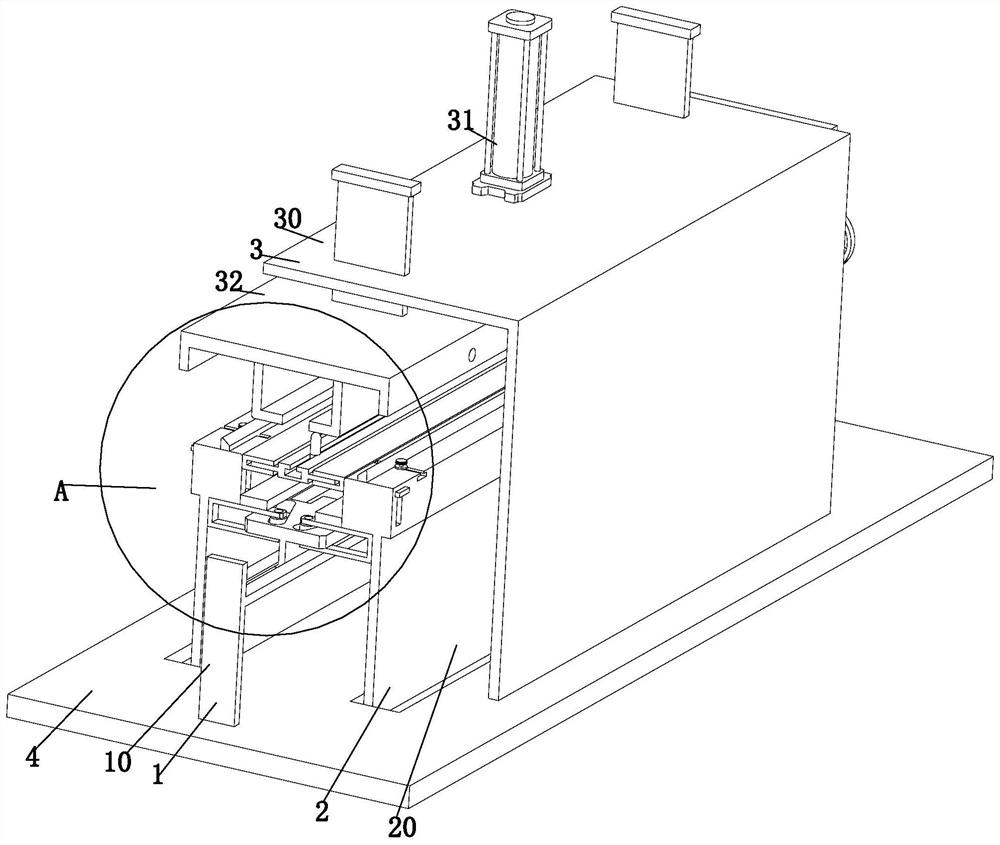

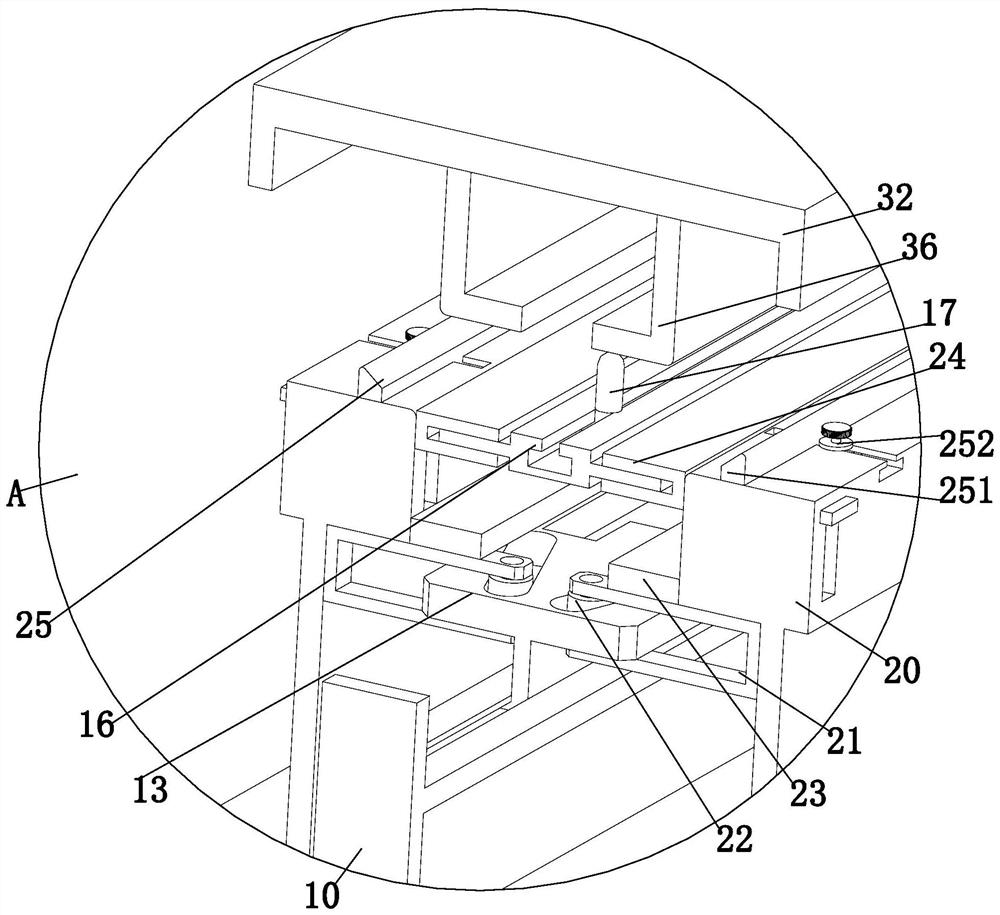

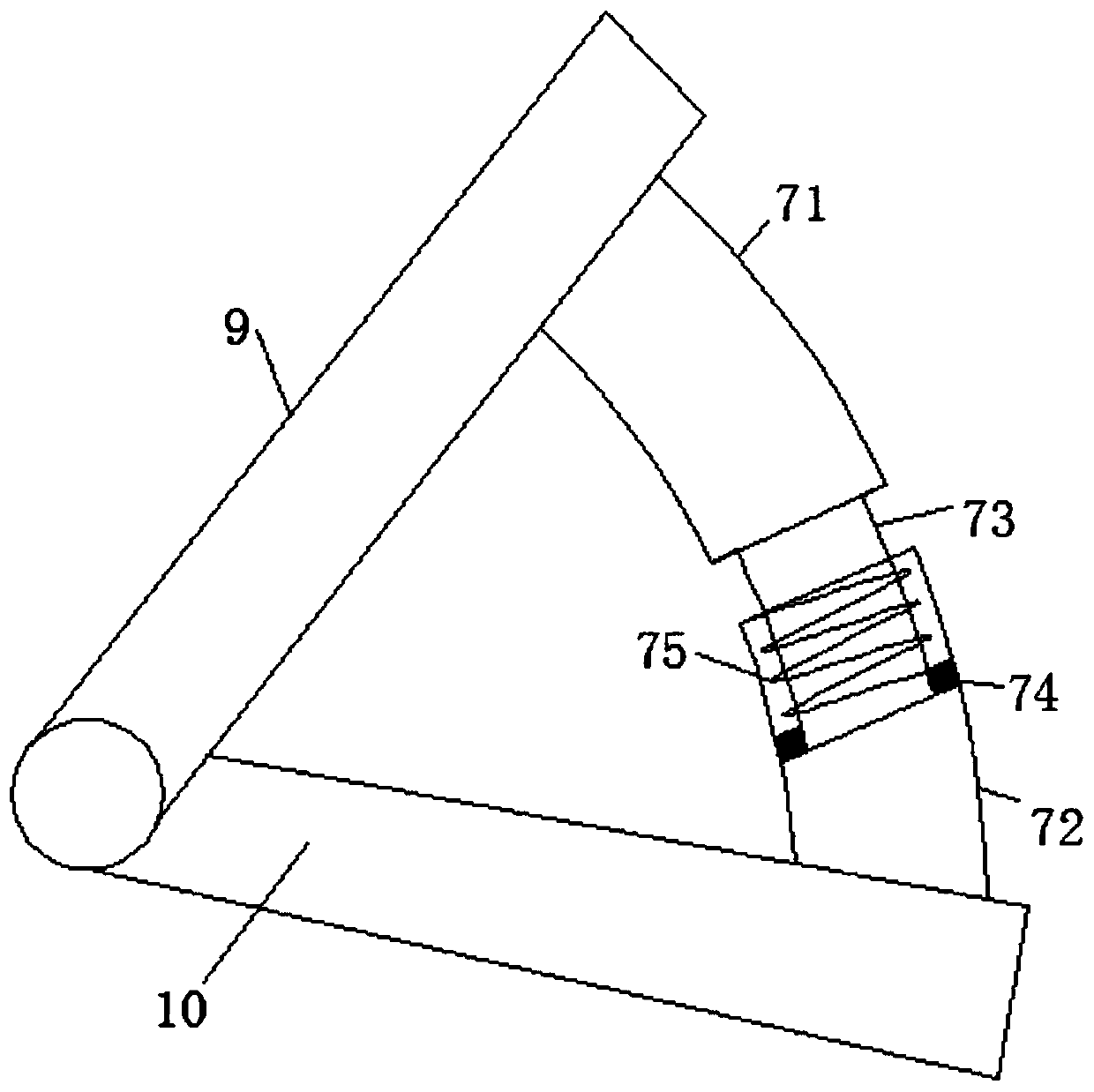

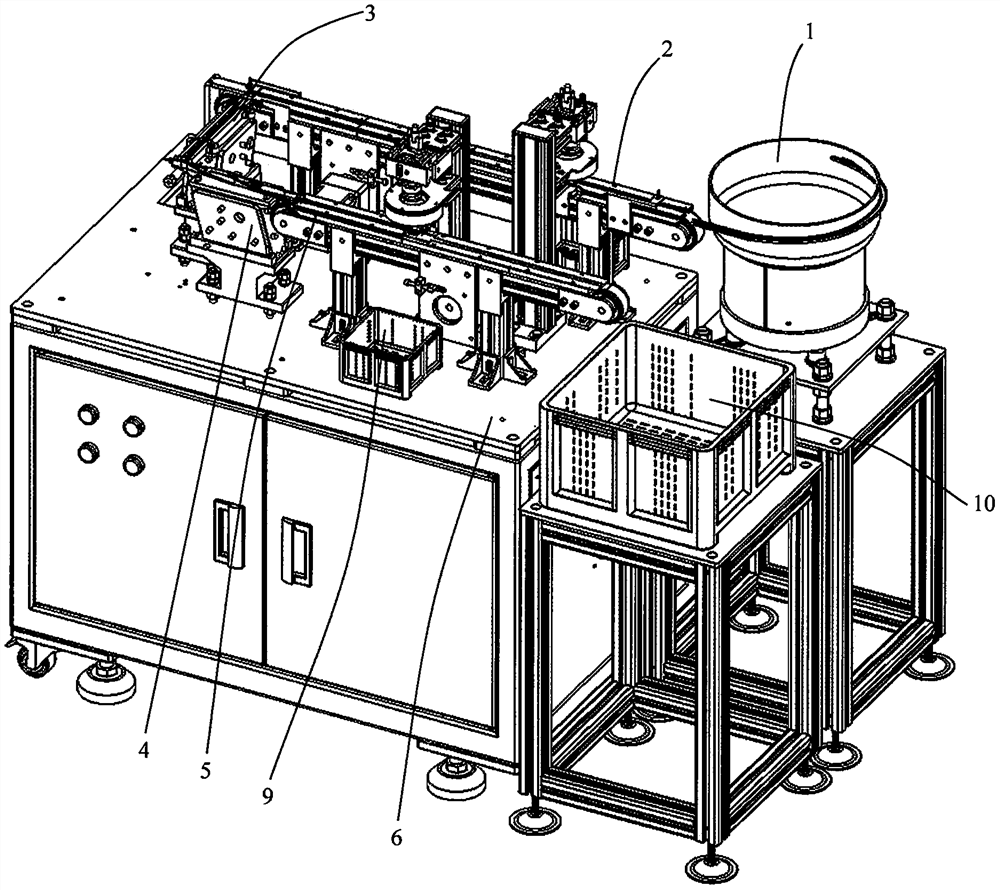

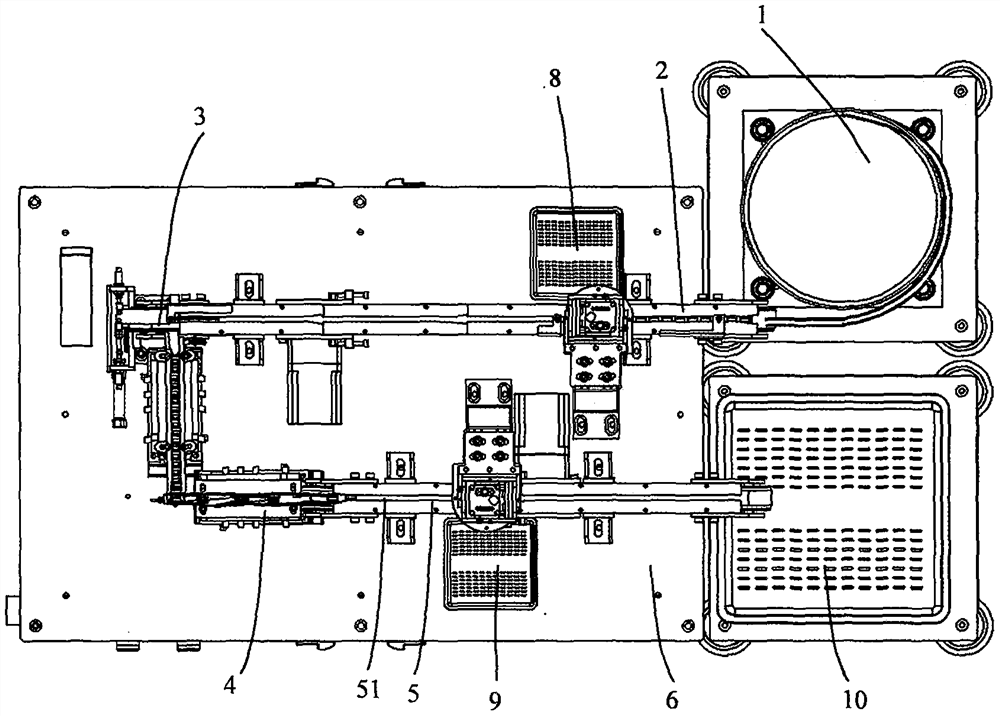

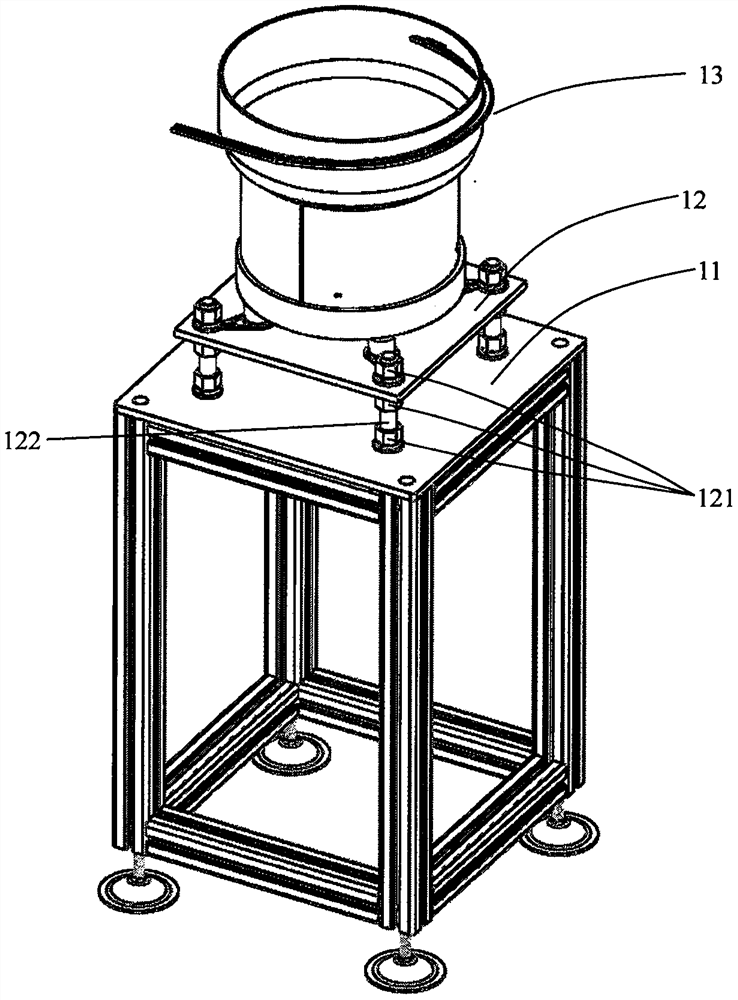

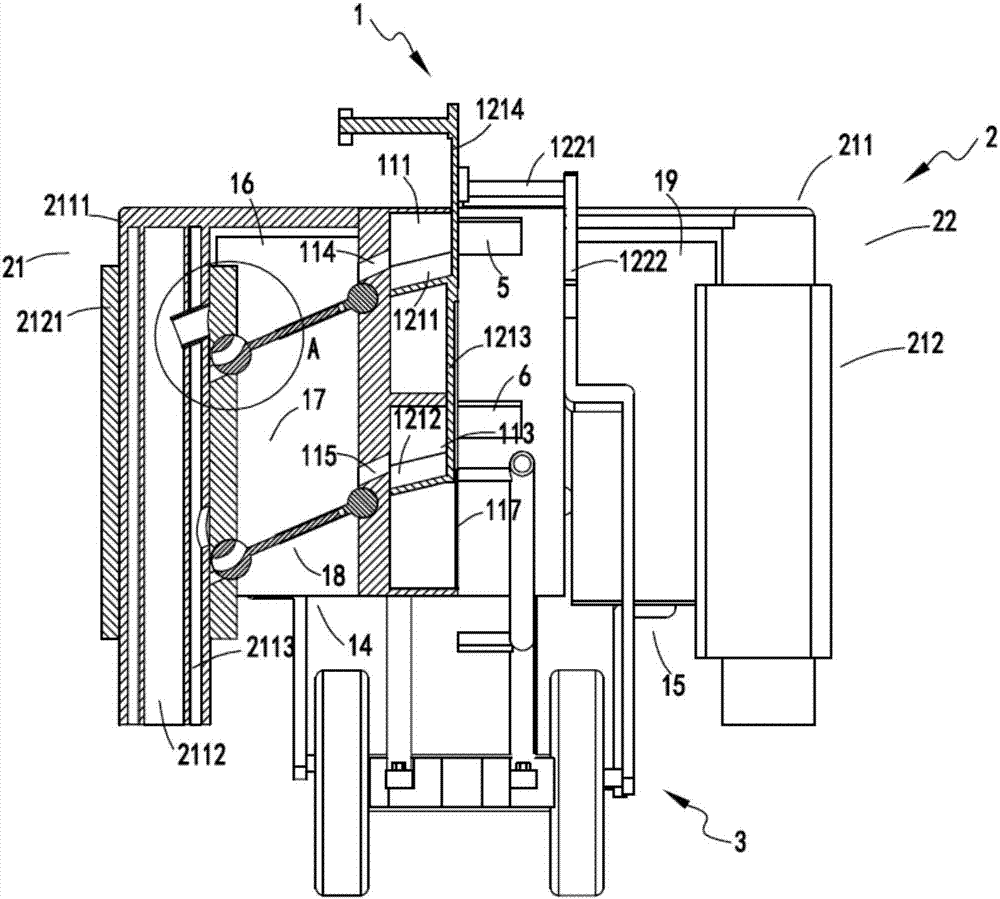

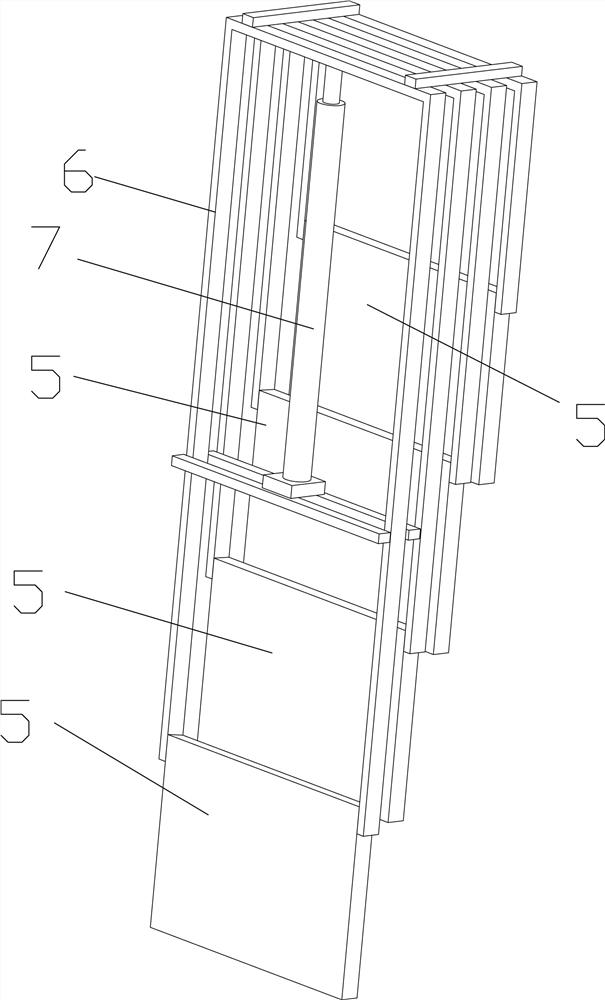

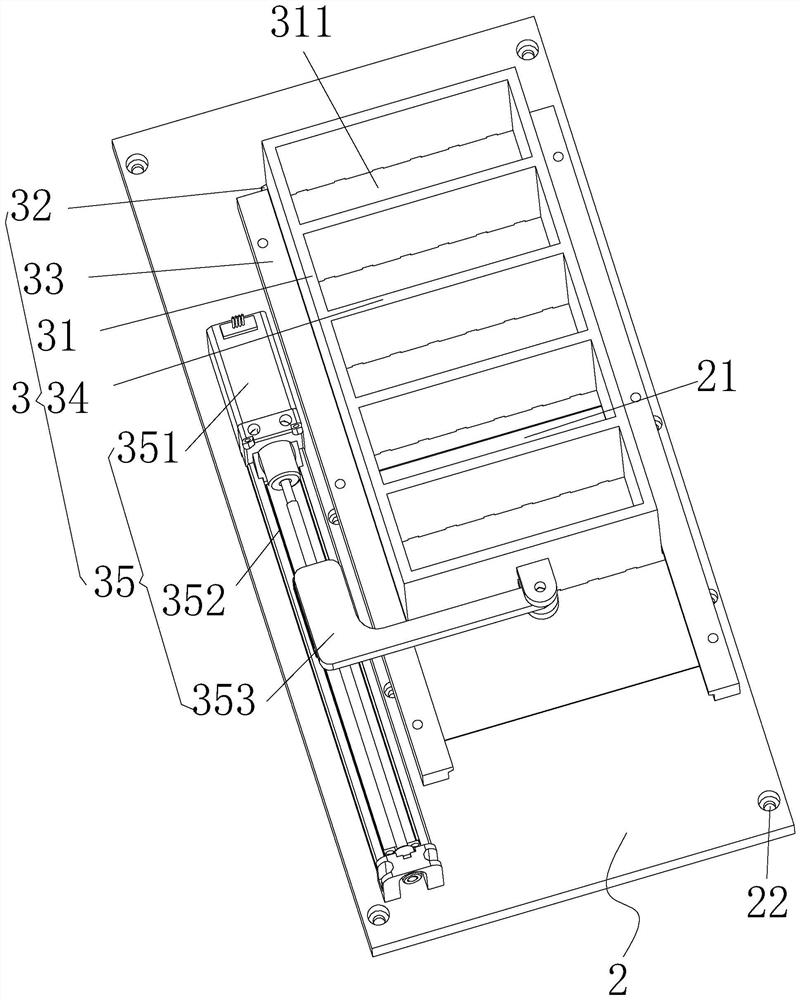

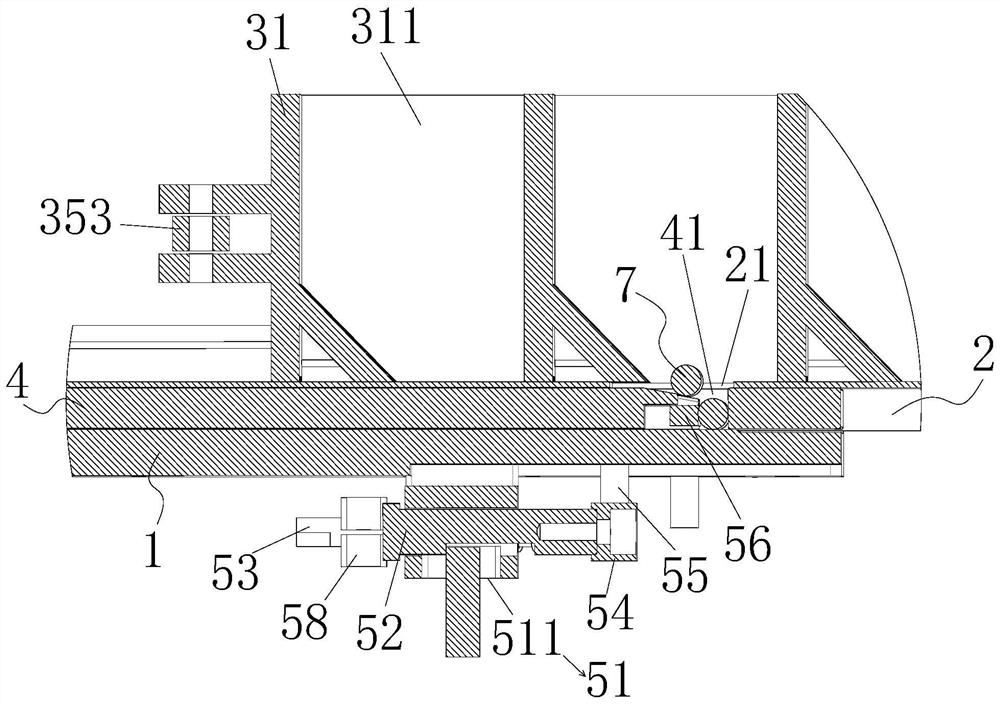

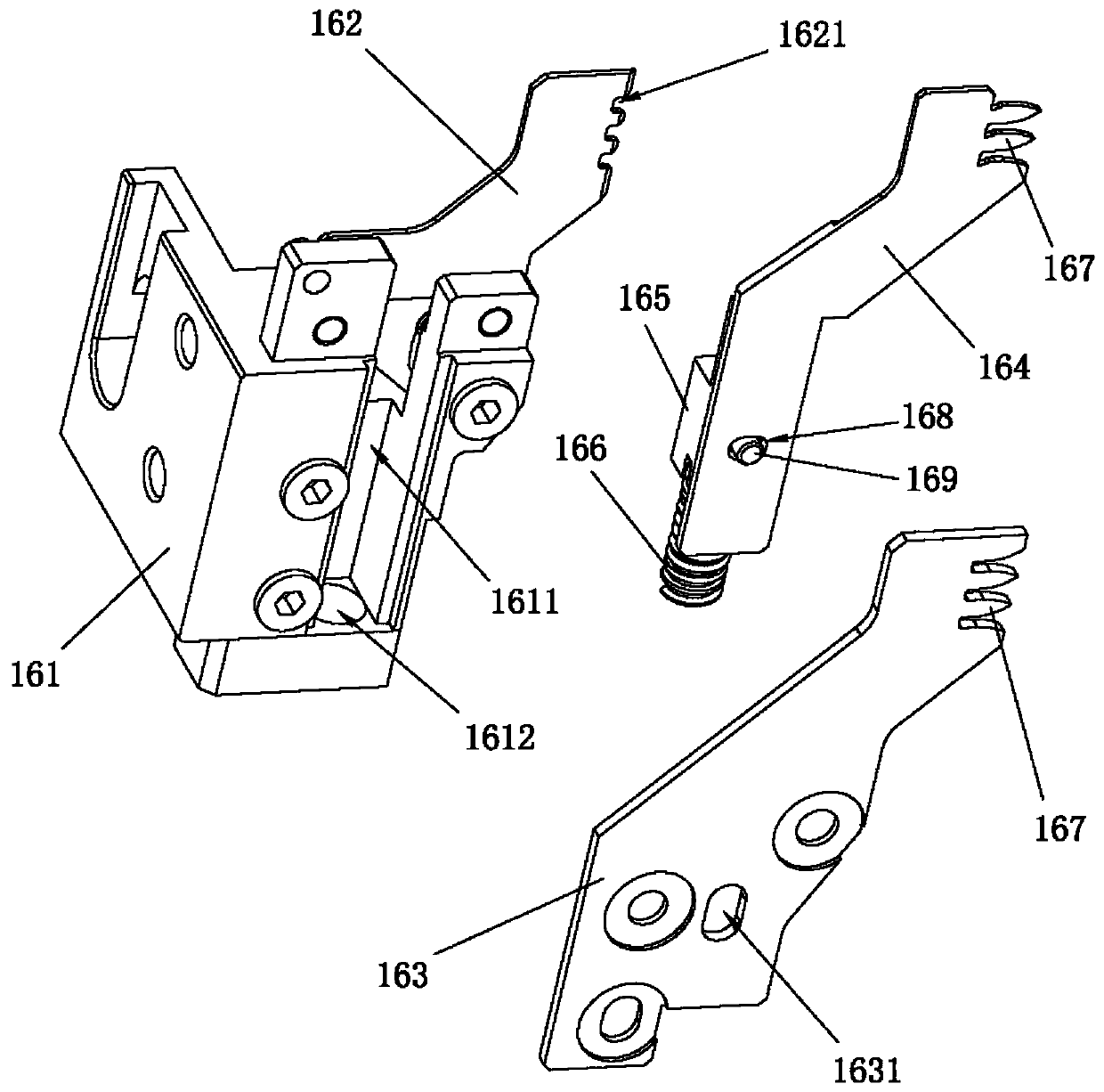

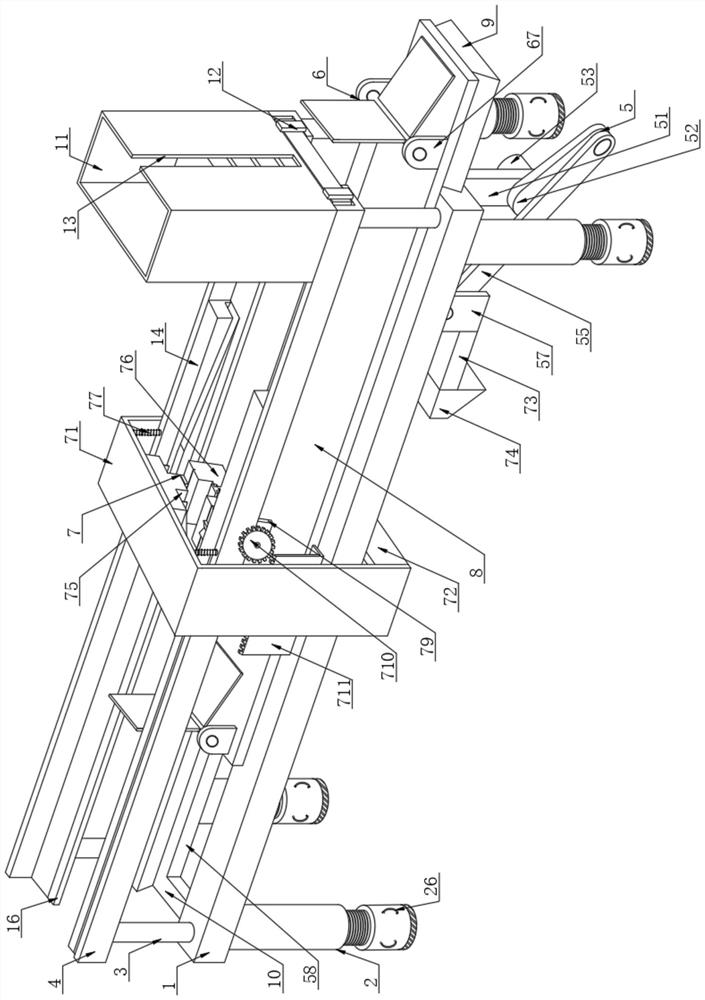

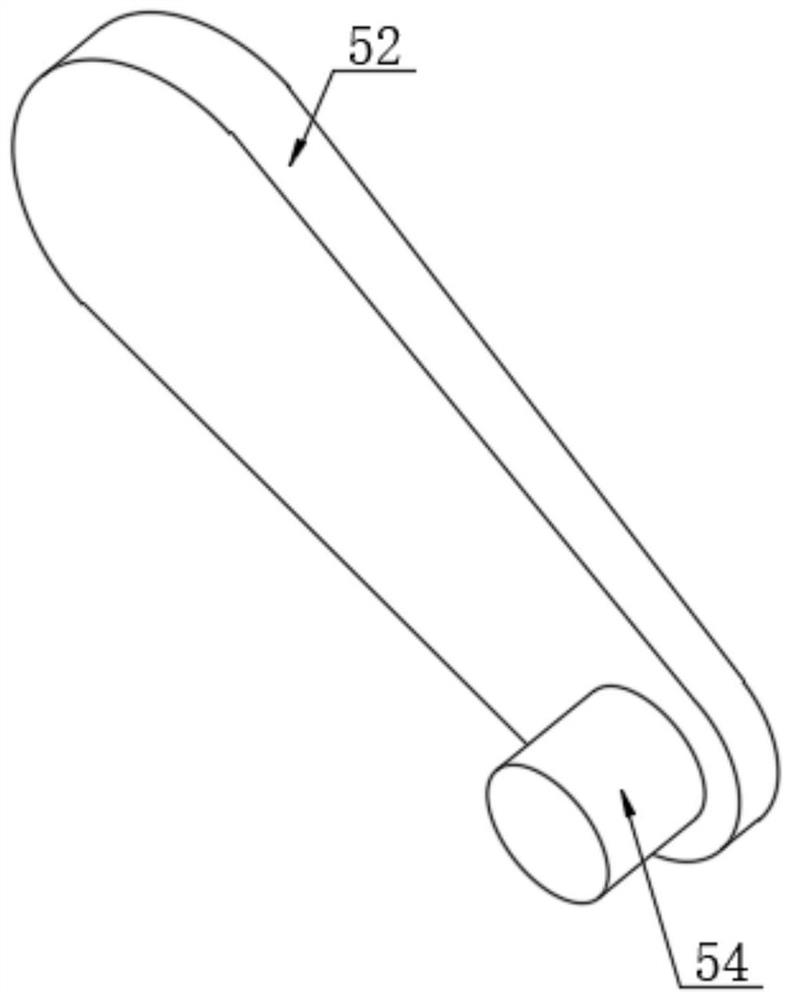

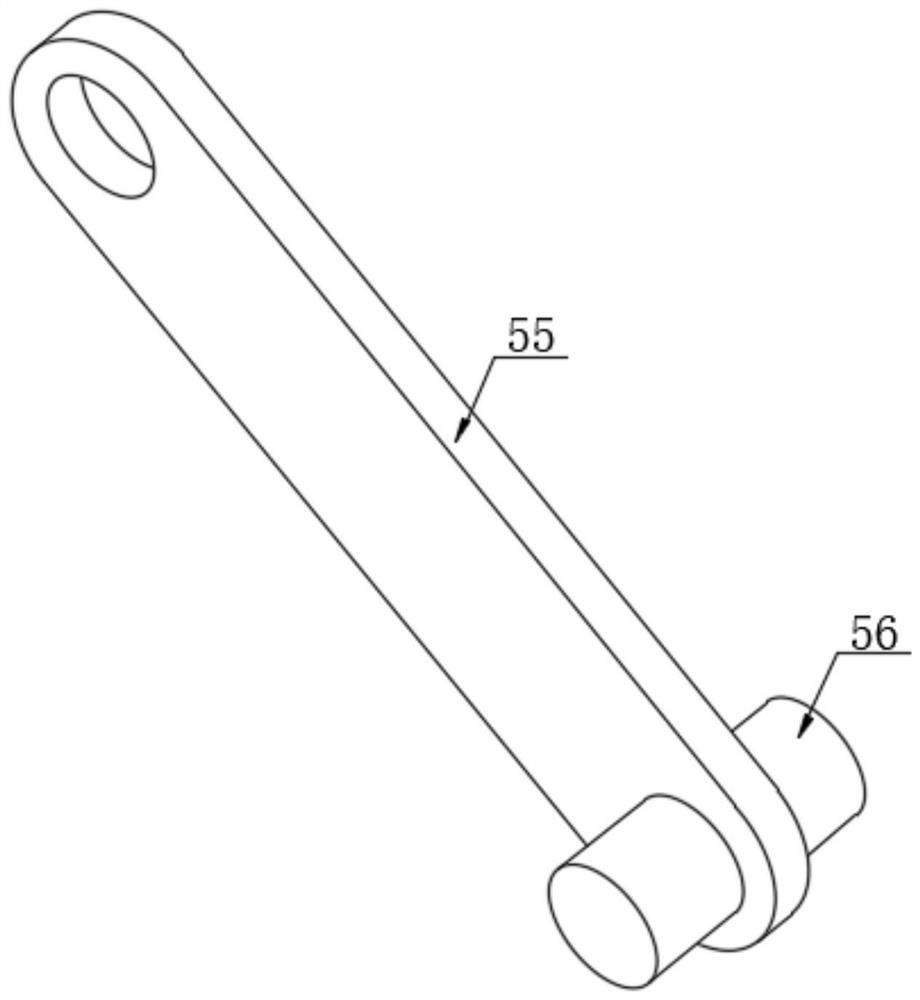

Overturning feeding device of IC chip testing machine

PendingCN109502296AAvoid stuck situationsImprove reliabilityConveyorsControl devices for conveyorsElectrical and Electronics engineering

The invention discloses an overturning feeding device of an IC chip testing machine. The overturning feeding device comprises a material carrying table used for placing an IC material pipe, a feedingmechanism used for taking an IC chip out, and a material channel used for conveying the IC chip. The material carrying table is provided with a material cabin and a push mechanism. The push mechanismcan clamp the IC material pipe in the material cabin and push the IC material pipe out to a preset position of the material carrying table. The feeding mechanism comprises a clamping mechanism used for clamping the IC material pipe on the material carrying table, and an overturning mechanism. The clamping mechanism can clamp the IC material pipe. The overturning mechanism drives the clamping mechanism to overturn, and therefore the clamped IC material pipe is perpendicular to the material carrying table and communicates with the material channel, and the IC chip in the IC material pipe can slide into the material channel from the IC material pipe. The overturning mechanism overturns the clamping mechanism clamping the IC material pipe, and therefore the clamping mechanism is changed from ahorizontal state to a vertical state, so that the IC chip in the IC material pipe slides into the material channel communicating with the IC material pipe.

Owner:昆山宇辰光通自动化科技有限公司

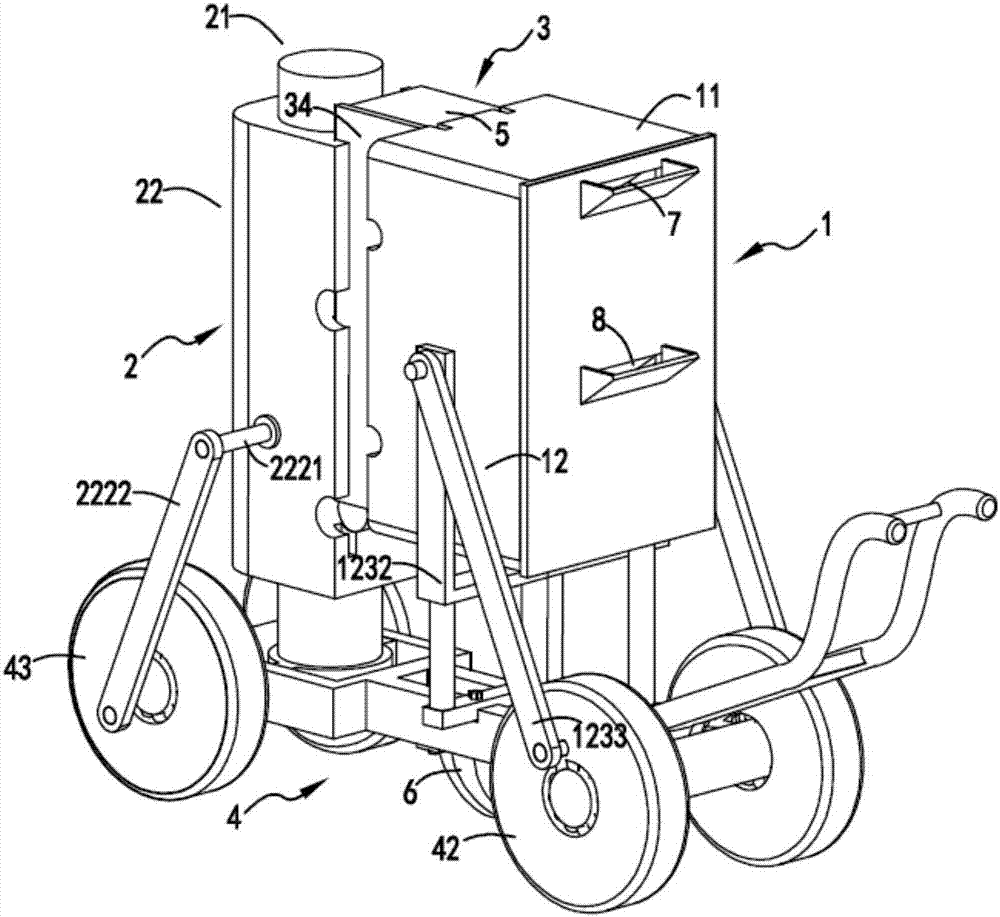

Small sowing and fertilizing integrated machine

InactiveCN106937540ASimple structureSimple structure but more flexibleSpadesFertiliser distributersEngineeringSowing

The invention relates to a small integrated planting and fertilizing machine, comprising a feeding part, the feeding part includes a feeding box and a feeding mechanism, the feeding box is provided with a seed supply bin and a fertilizer supply bin, and the feeding mechanism is used to separate the seeds and fertilizer Backward intermittent output; the sowing and fertilizing part, the sowing and fertilizing part includes a discharge mechanism and a control mechanism, the control mechanism is used to control the fertilizer and seeds entering the discharge mechanism; the buffer part, the buffer part is set between the feeding part and the sowing and fertilizing part , the buffer part includes a seed buffer space for accepting the seeds delivered by the feeding part and transporting the seeds into the sowing and fertilizing part, and a fertilizer buffer space for receiving the fertilizer delivered by the feeding part and transporting the fertilizer into the sowing and fertilizing part ; It also includes a walking carrier; it overcomes the problems of uneven fertilizer and seed ratio during fertilization and seeding, easy blockage during fertilizer and seed output, and poor working stability of the equipment.

Owner:奥林精密机械科技(长兴)有限公司

Special steel bar feeding machine used during electric pole reinforcement cage preparing

The invention discloses a special steel bar feeder used in the preparation of steel bar cages for electric poles. One end of the material rack is fixedly connected to the second feed rack, and supports are fixedly connected to both sides of the top of the base, and the top of the base is fixedly connected to a material distribution motor at the position on the left side of the support through a fixed seat, and the output of the material distribution motor is One end of the shaft is fixedly connected with a connecting shaft. The end of the connecting shaft away from the material distribution motor runs through the bracket and extends to the inside of the bracket. The end of the connecting shaft extending to the inside of the bracket is rotatably connected with the bracket. The invention relates to steel cage manufacturing technology field. It solves the problems that the existing steel bar feeder has large volume, low feeding speed, easy material jam, low efficiency of steel cage preparation, waste of manpower and the like.

Owner:泰州市春为强通用机械有限公司

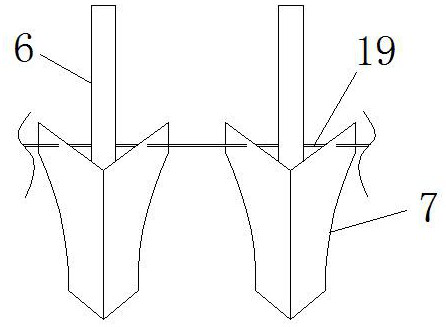

Round bar runway of guide pin sequencing-feeding device

The invention discloses a round bar runway of a guide pin sequencing-feeding device, wherein the round bar runway is used for preventing a guide pin from entering a flat vibrating runway and can convey the guide pin stably. The round bar runway comprises two round bars (3) with same diameter, a V-shaped block (2) is arranged on a feeding platform of a vibration disk (7), one ends of the two roundbars (3) are horizontally installed on the V-shaped block (2) in parallel, a material channel (8) is formed between the round bars (3), the width of the material channel (8) is larger than the diameter of a leading wire part (13) of a guide pin (1) and smaller than the diameter of an aluminum stem part (12) of the guide pin (1), and the round bar runway is characterized in that the diameter of each round bar (3) is 1.3-1.8mm. According to the round bar runway, the structure is simple, the waste can not be caused as the guide pin can not fall on a machine or the ground, the guide pin can be conveyed stably on the round bar runway, the crossing of the adjacent guide pins due to the large swinging radian of the guide pins can be avoided, the guide pin can enter the flat vibrating runway smoothly and can not be blocked.

Owner:HUNAN AIHUA GRP

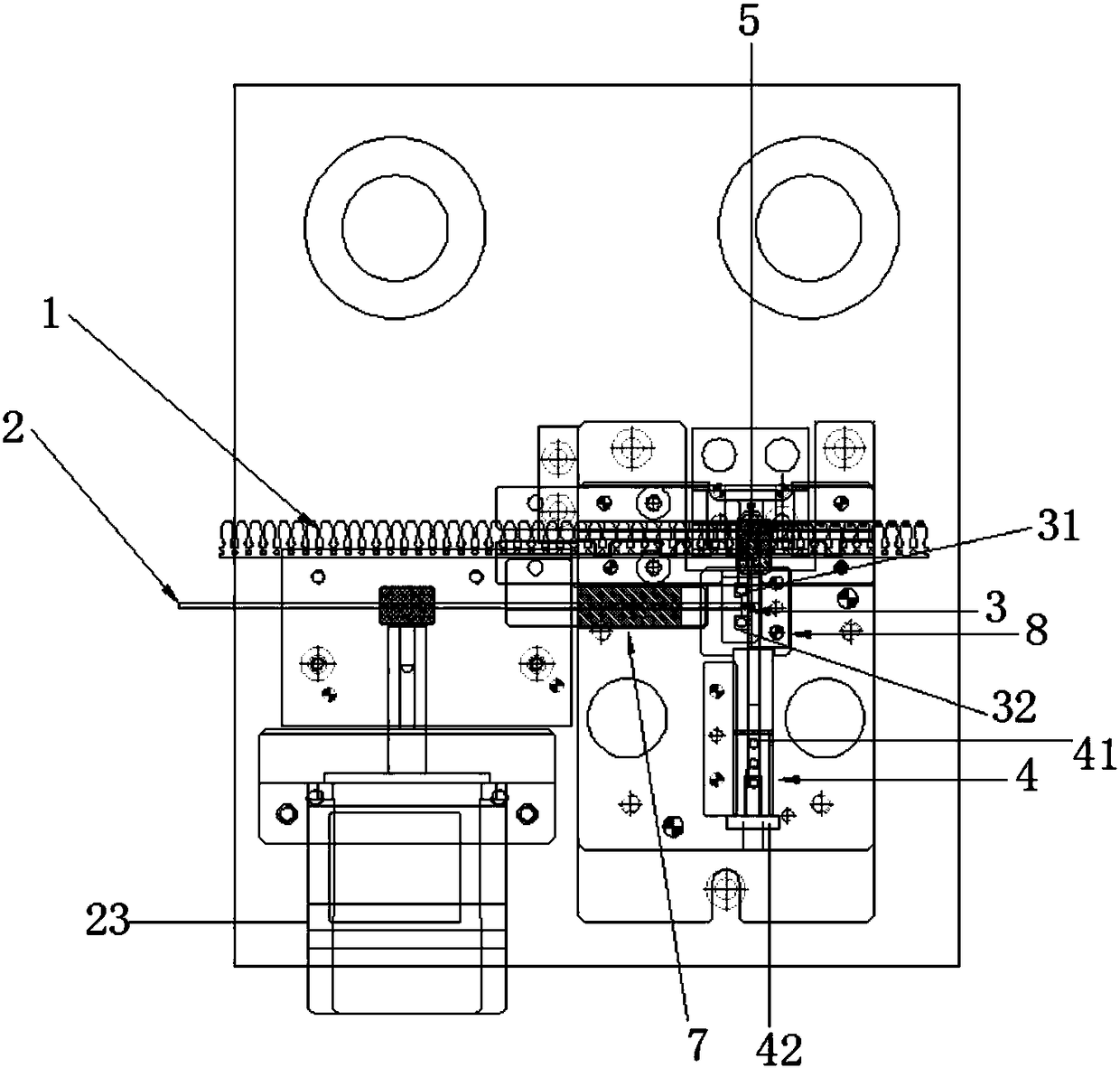

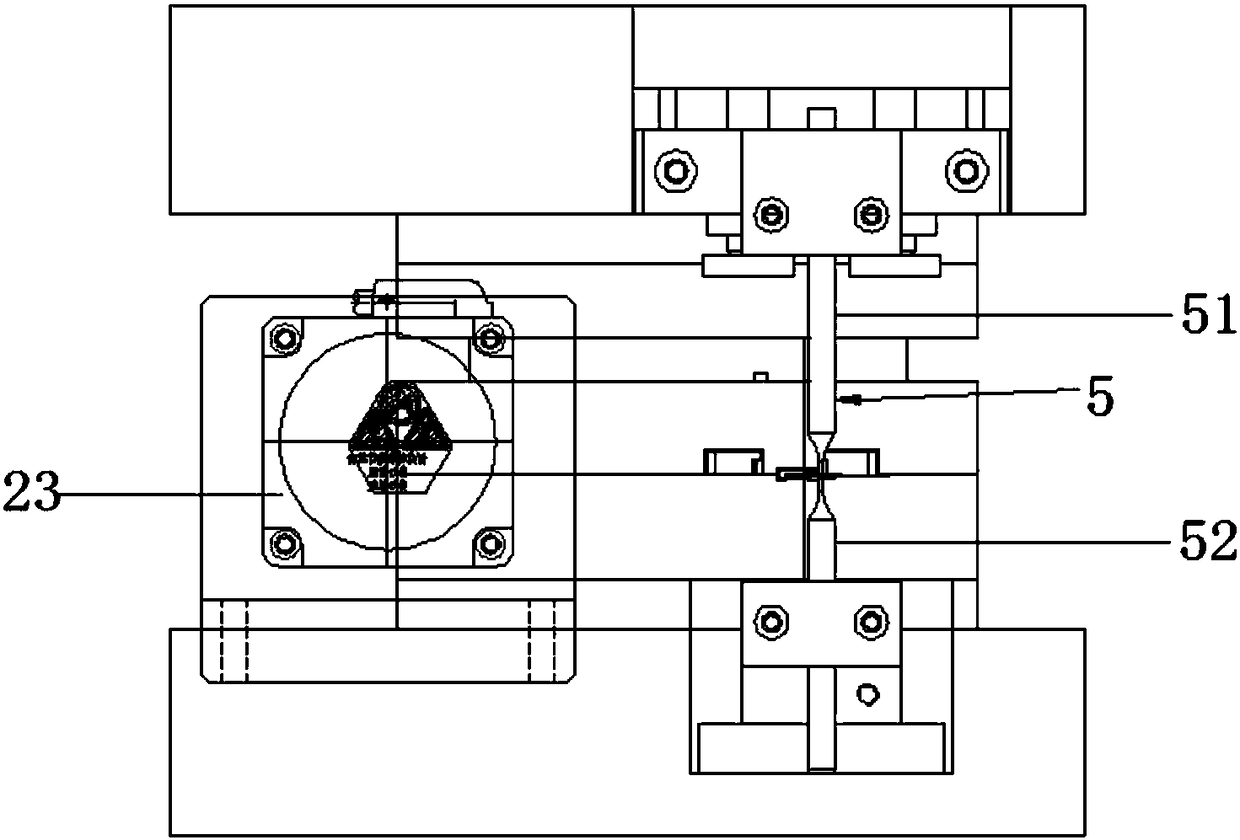

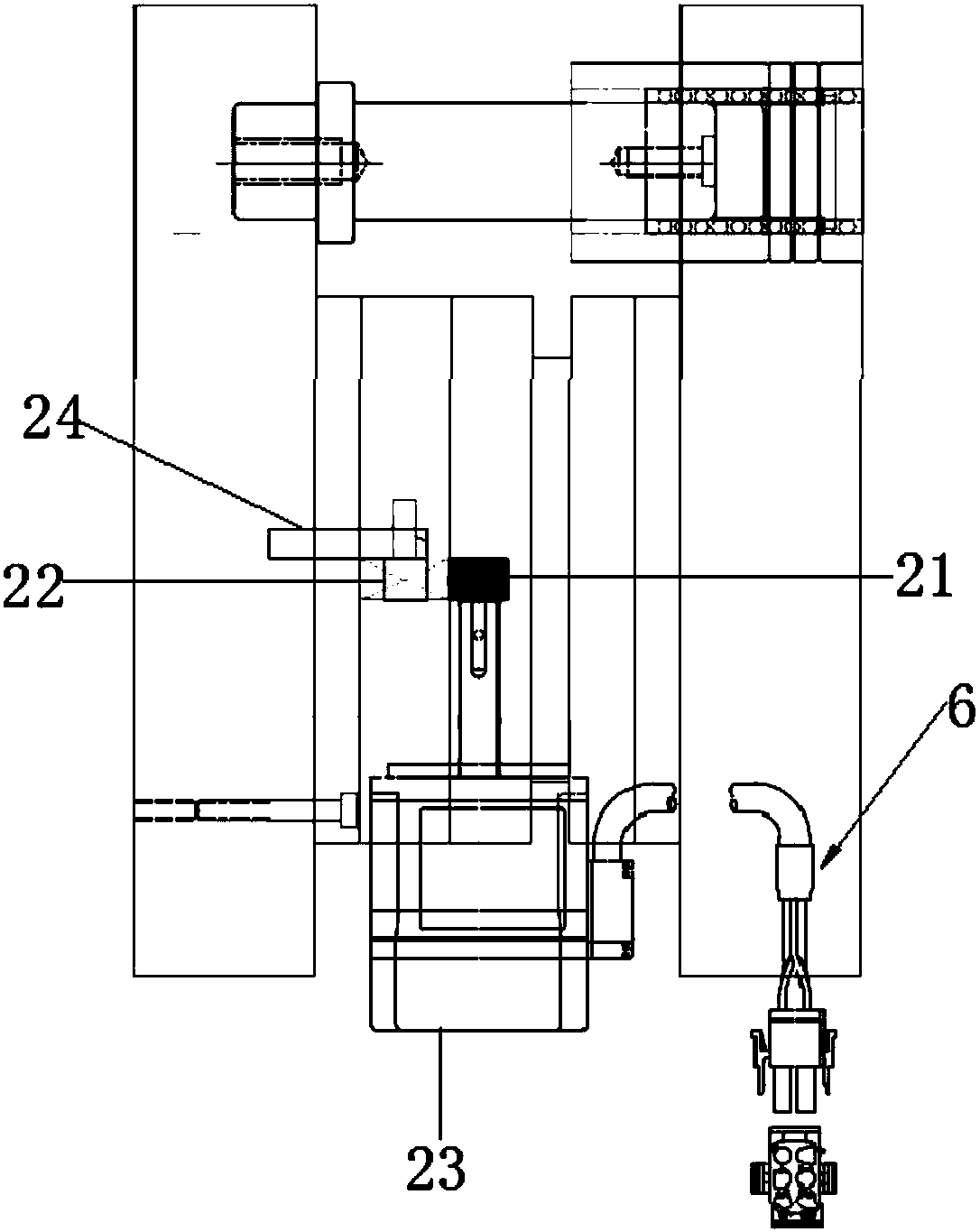

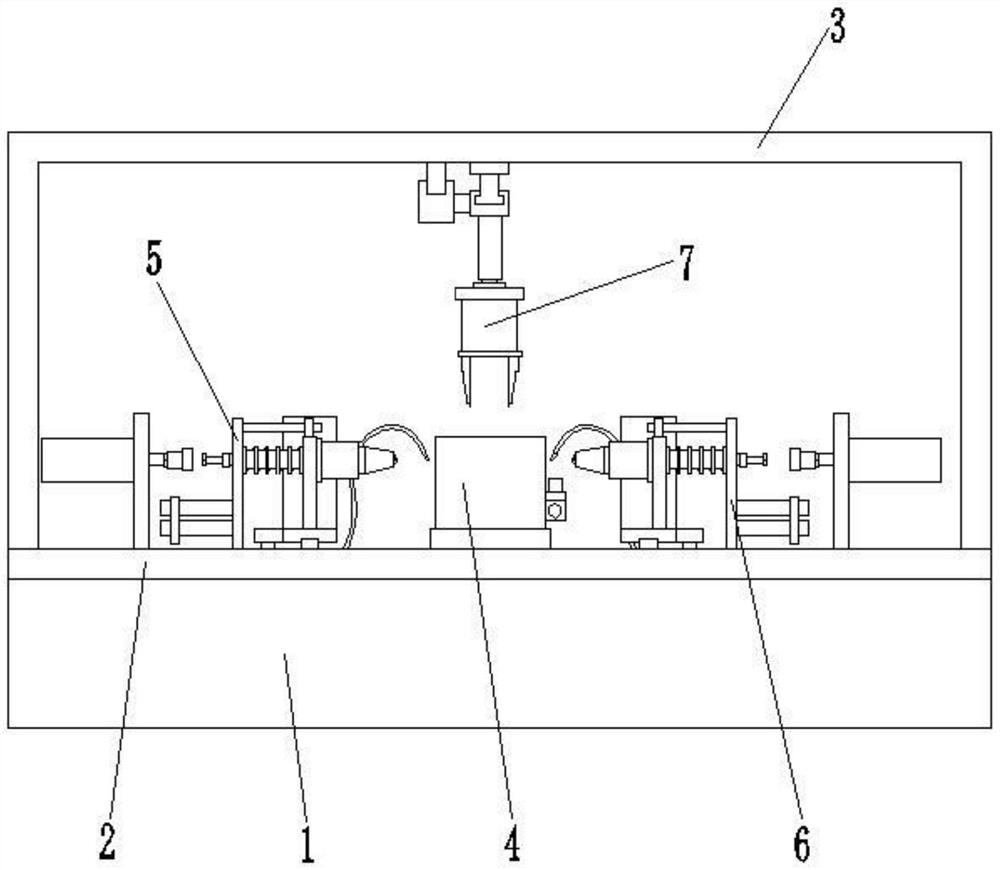

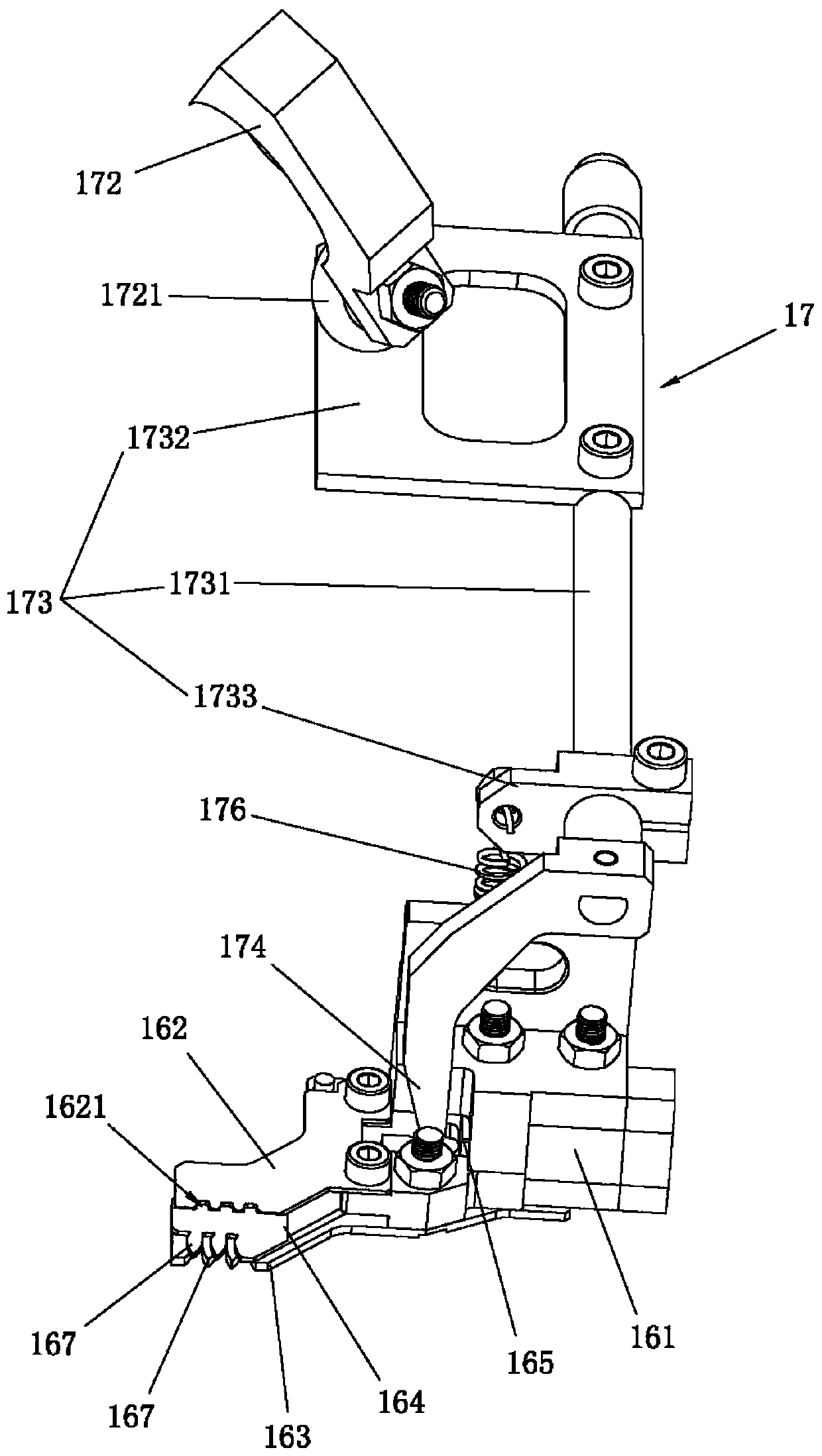

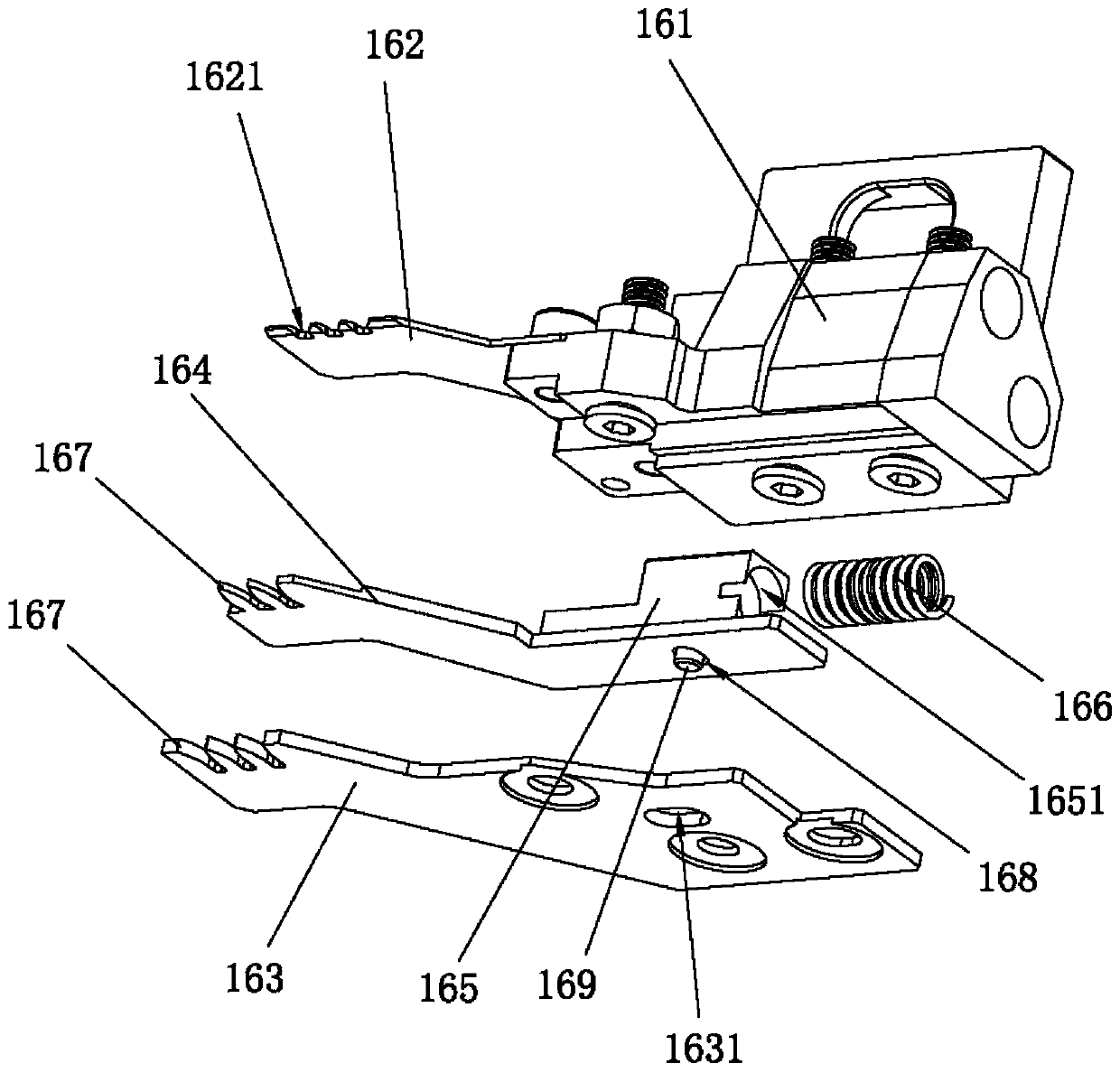

Automatic silver point welding equipment for bimetal sheet of thermal protector

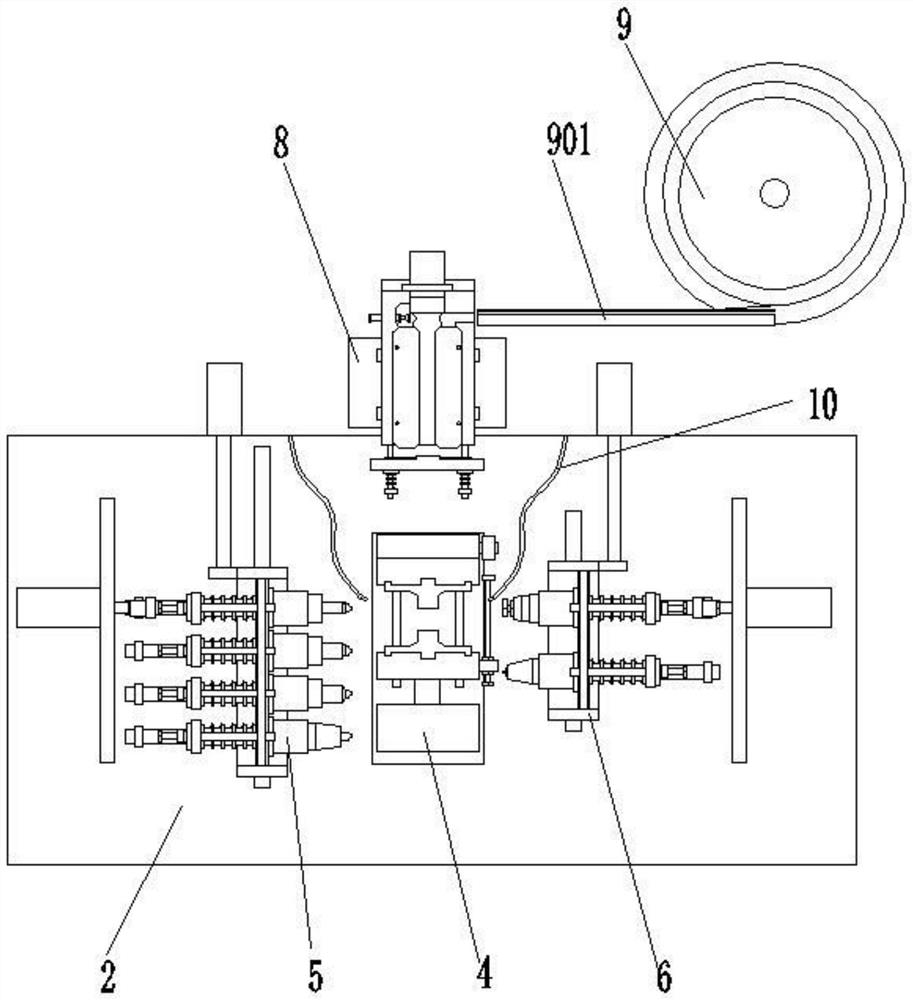

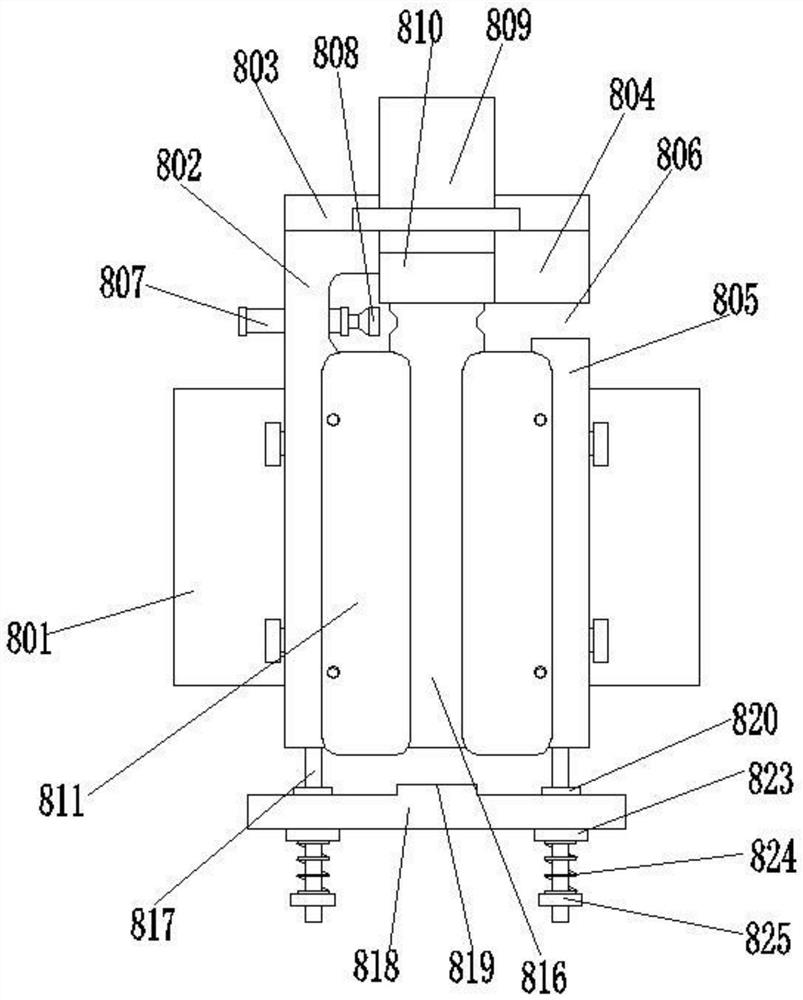

PendingCN108067718ARunning speed is stableThere will be no material jamsWelding/soldering/cutting articlesMetal working apparatusFailure rateDrive wheel

The invention discloses automatic silver point welding equipment for a bimetal sheet of a thermal protector. The automatic silver point welding equipment comprises a bimetal sheet feeding mechanism, asilver belt feeding mechanism, a material cutting mechanism, a material pushing mechanism and a welding mechanism. The bimetal sheet feeding mechanism, the silver belt feeding mechanism, the materialcutting mechanism, the material pushing mechanism and the welding mechanism are respectively fixed on a worktable. The silver belt feeding mechanism includes a conveyor belt, a driving wheel, a driven wheel and a first motor for driving the driving wheel to rotate. The material cutting mechanism includes an upper blade and a lower blade disposed opposite to the upper blade and arranged in dislocation with upper blade. The material pushing mechanism includes a push rod and a cylinder for driving the push rod to move. The welding mechanism includes a positive electrode welding pin and a negative electrode welding pin which are arranged oppositely. According to the equipment, the silver belt feeding mechanism can smoothly convey silver belts to the material cutting mechanism for cutting intosquare silver points to be welded on bimetal sheets, the overall operation speed of the equipment is stable, the phenomenon of material blocking is reduced, the failure rate of equipment operation isreduced, and production efficiency is improved.

Owner:苏州聚生精密冲件有限公司

Groove type cable bridge cover plate punch forming die and punching method thereof

ActiveCN113560401AMeet the needs of stamping and formingReduce frictional resistanceShaping toolsMetal-working feeding devicesPunchingCable tray

The invention provides a groove type cable bridge cover plate punch forming die and a punching method thereof. The groove type cable bridge cover plate punch forming die comprises a material supporting mechanism, a bending mechanism, an executing mechanism and a bottom plate. The problems that due to the fact that the two side edges of a cover plate formed and machined at present are bent, internal stress is generated, outward expansion and springback are caused, the material clamping condition can be caused, the cover plate is difficult to take, and the labor intensity of workers is increased are solved; the forming die can only conduct extrusion forming treatment on raw material plates of one type and size, when extrusion forming is conducted on the raw material plates of different widths, lengths or thicknesses, the corresponding forming die needs to be replaced, the production efficiency of a factory is reduced, and the production cost of the cover plate is increased; the raw material plates cannot be accurately positioned in the extrusion forming process, position deviation is caused, size deviation of the formed cable bridge cover plate can be caused, and the actual use requirement cannot be met; and the problems that the surfaces of the raw material plates are prone to being scratched in the extrusion forming process, and the forming quality of the cover plate is reduced are solved.

Owner:广东联标线管桥架有限公司

An Efficient Bread Packing Machine

ActiveCN105883046BIncrease productivityImprove securityPackaging protectionPackaging bakeryButt jointPackaging machine

The invention discloses an efficient bread packing machine. The efficient bread packing machine comprises a body. A supporting frame and a bread packing device are movably installed at the top of the body respectively, a first supporting plate is fixedly installed on one side of the body, an inner cavity of the body is movably connected with conveying wheels through a rotating shaft, the end of one conveying wheel is connected with the end of the other conveying wheel through a conveying belt, material troughs are fixedly installed at the top and the bottom of the conveying belt, the top of the supporting frame is movably connected with a discharging cabin, a motor is movably connected to one side of the discharging cabin, a storage cabin and an electric stretchable rod are arranged at the top and the bottom of the discharging cabin respectively, discharging tubes are movably connected to an inner cavity of the electric stretchable rod, and discharging openings are movably formed in the bottoms of the discharging tubes. According to the efficient bread packing machine, the discharging openings are in butt joint with the material troughs through the electric stretchable rod, the storage cabin is opened, bread in the storage cabin can be slid to the discharging tubes through the discharging cabin, and then is slid to the material troughs from the discharging openings, and packing efficiency is improved.

Owner:WUXI KING MO MACHINERY

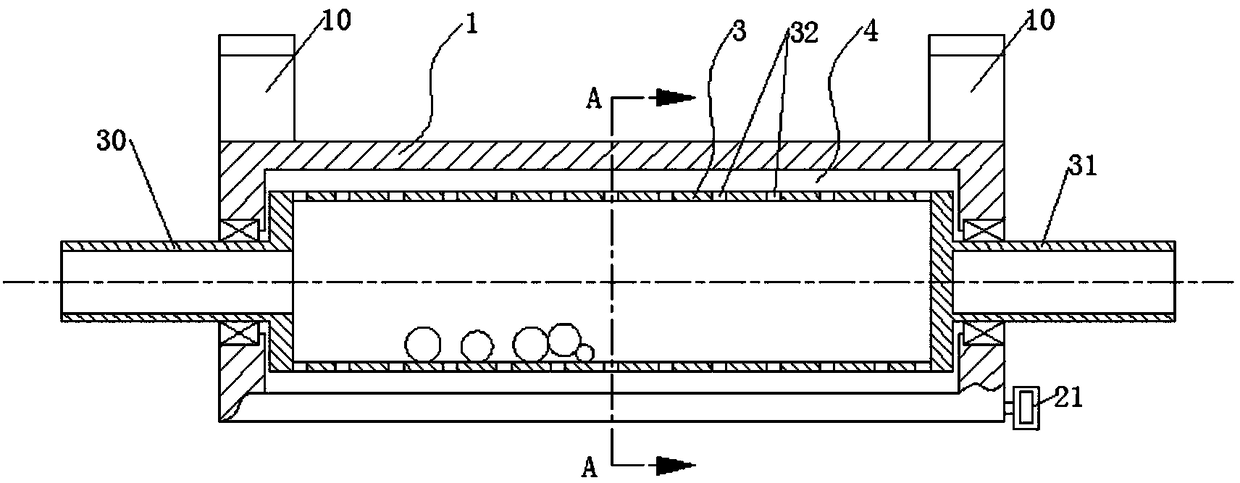

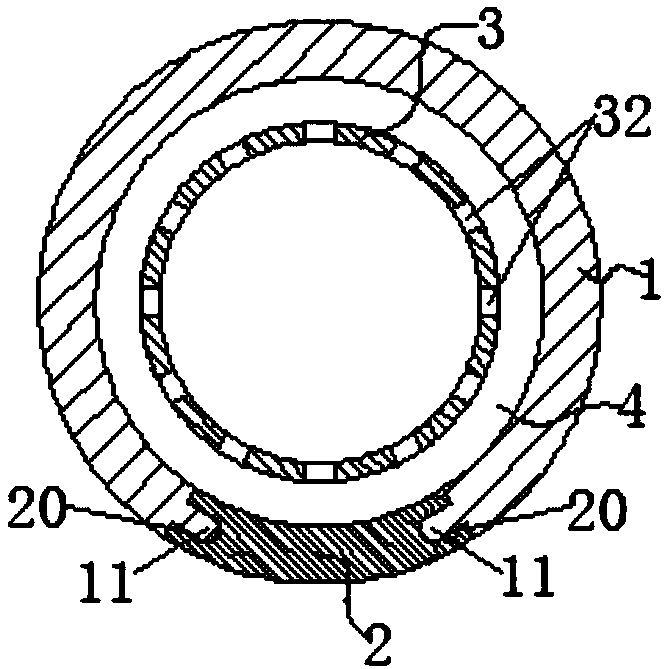

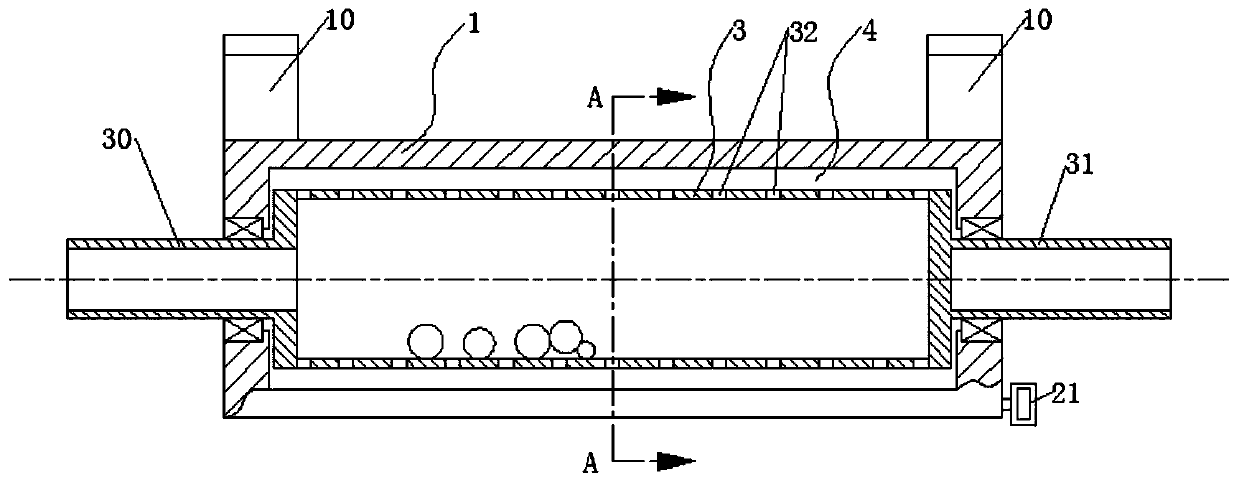

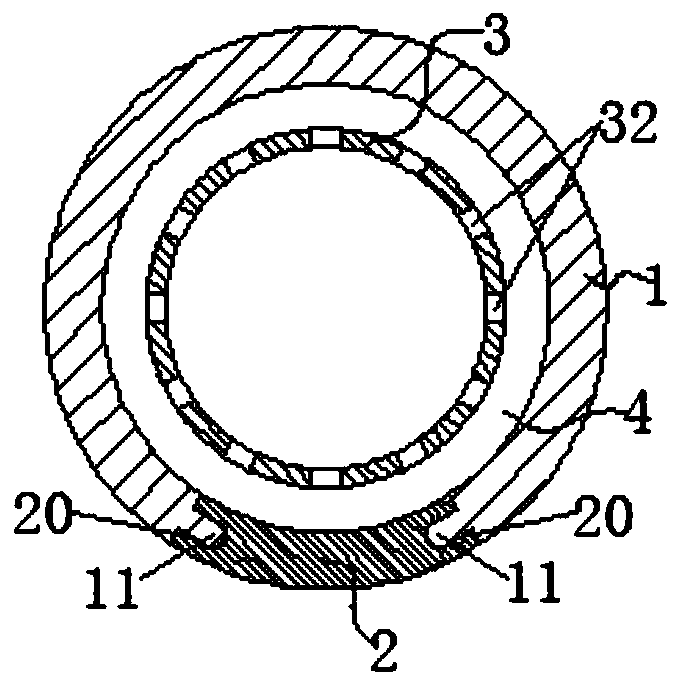

Ball grinding mill facilitating discharge

The invention discloses a ball grinding mill facilitating discharge. The ball grinding mill comprises an outer cylinder base, an arc buckle plate and an inner rotation barrel. The upper end of the outer cylinder base is provided with installation feet, convex edges are symmetrically arranged on the outer cylinder base, inserting slots are symmetrically arranged in the arc buckle plate, the inserting slots in the arc buckle plate are connected with the convex edges, one end of the inner rotation barrel is provided with a cut-through shaft, the other end of the inner rotation barrel is providedwith a closing shaft, the outer wall of the inner rotation barrel is evenly provided with discharge holes, and the cut-through shaft at one end of the inner rotation barrel and the closing shaft at the other end of the inner rotation barrel are rotationally connected with the outer barrel base through rolling bearings. Dual cylinder type inner rotation cylinder grinding is achieved, materials aredischarged from the outer cylinder base after being stored, and discharge is thorough.

Owner:安徽红旗弹簧有限公司

A packaging cardboard slotting machine

ActiveCN108790276BReduce labor efficiencyImprove delivery efficiencyBox making operationsPaper-makingCardboardEngineering

The invention discloses a packing paperboard slotting machine. The packing paperboard slotting machine comprises a working platform. A feeding device comprises a push device and a material containingbox. The push device comprises a cylinder. The end of the cylinder is provided with a telescopic rod. The end of the telescopic rod is provided with a push plate. The material containing box is internally provided with overlapped paperboards. One side of the material containing box is provided with a push plate inlet. The other side of the material containing box is provided with a paperboard outlet. A conveyor belt is arranged on one side of the paperboard outlet. A conveyor belt I is arranged on one side of the feeding device. A limiting device is ad on the conveyor belt I. An indentation roller set is arranged on one side of the conveyor belt I. A slotting roller set is arranged on one side of the indentation roller set. A conveyor belt II is arranged on one side of the slotting rollerset. The limiting device comprises a supporting frame. A fixed rod is fixed to the supporting frame. The end of the fixed rod is provided with a movable rod. A limiting roller is arranged at the end of the movable rod. An extension device is arranged between the movable rod and the fixed rod. The packing paperboard slotting machine facilitates feeding through arrangement of the feeding device andprevents the paperboards from being deviated through arrangement of the limiting device.

Owner:怀宁县隆昌包装有限公司

A front and back appearance detection and screening system for micro switches

ActiveCN110479637BThe operation process is fully automatedNo human intervention requiredSortingControl engineeringControl theory

Owner:浙江名瑞智能装备科技股份有限公司

A multifunctional sowing and fertilizing machine

InactiveCN106941828ARealize double-row parallel sowing and fertilizationImprove the efficiency of sowing and fertilizingFertiliser and seeding apparatusEngineeringFeed tank

The invention relates to a multifunctional seeding and fertilizing machine, comprising a supply part, the supply part includes a material box, a feeding mechanism a, a material feeding mechanism b, a buffer mechanism a and a buffer mechanism b, and the material box is fixedly arranged on a trolley. A seed bin a, a seed bin b and a fertilizer bin are provided, and the feeding mechanism a sends the seed a and fertilizer in the seed bin a and the fertilizer bin to the buffer mechanism a, and the feeding mechanism b sends the seed b and the seed b in the seed bin a and the fertilizer bin and The fertilizer is sent into the buffer mechanism b; the output part, the output part includes the output mechanism a and the output mechanism b, the output mechanism a and the output mechanism b both include a lead-out device and a control device, and the control device controls the buffer mechanism a and the fertilizer in the buffer mechanism b and The seed b enters the export device; it overcomes the problems that the existing equipment does not satisfy the synchronous staggered interplanting of two plants and can ensure equal spacing during the interplanting process, and the problems of material blockage and poor working stability are easy to occur in the process of sowing and fertilizing.

Owner:奥林精密机械科技(长兴)有限公司

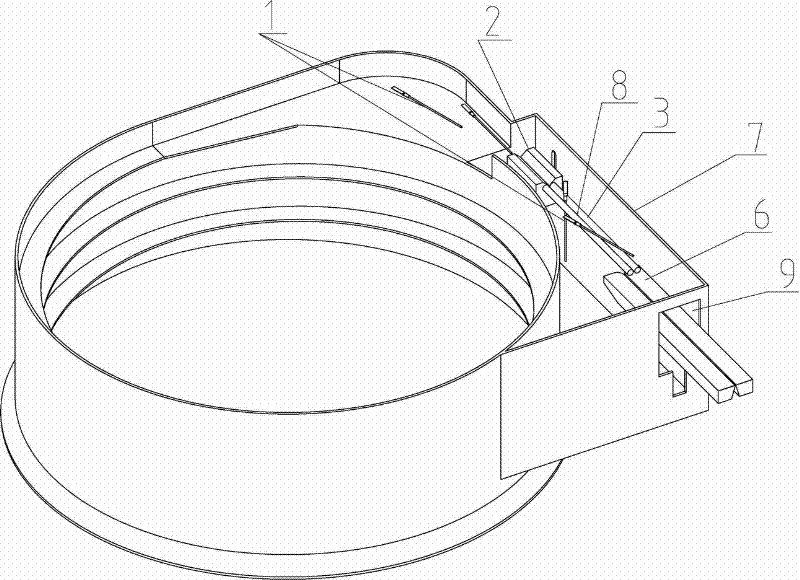

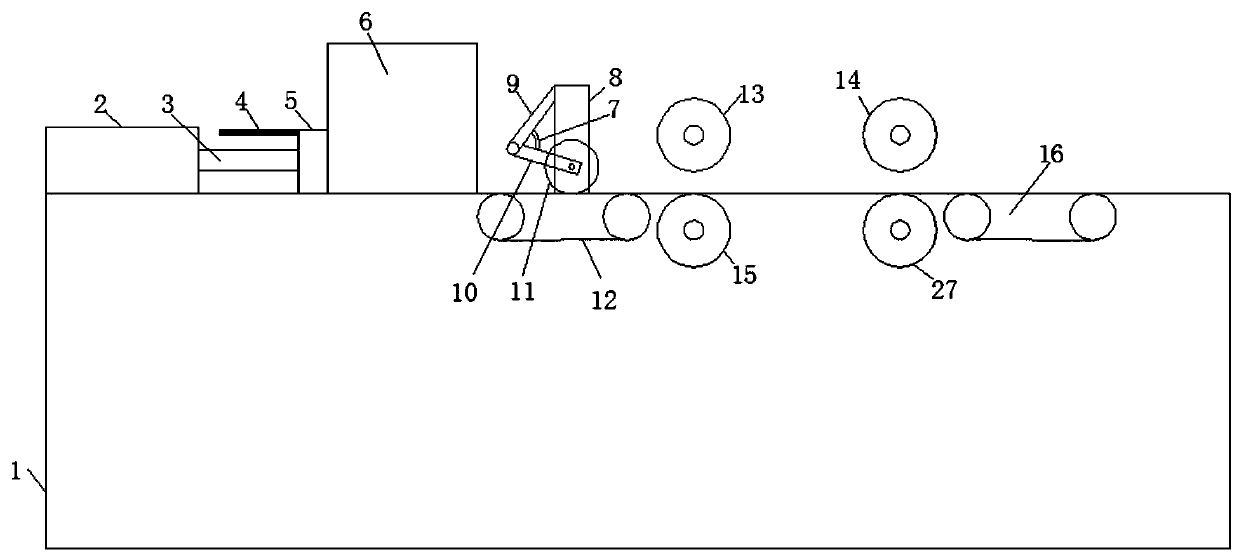

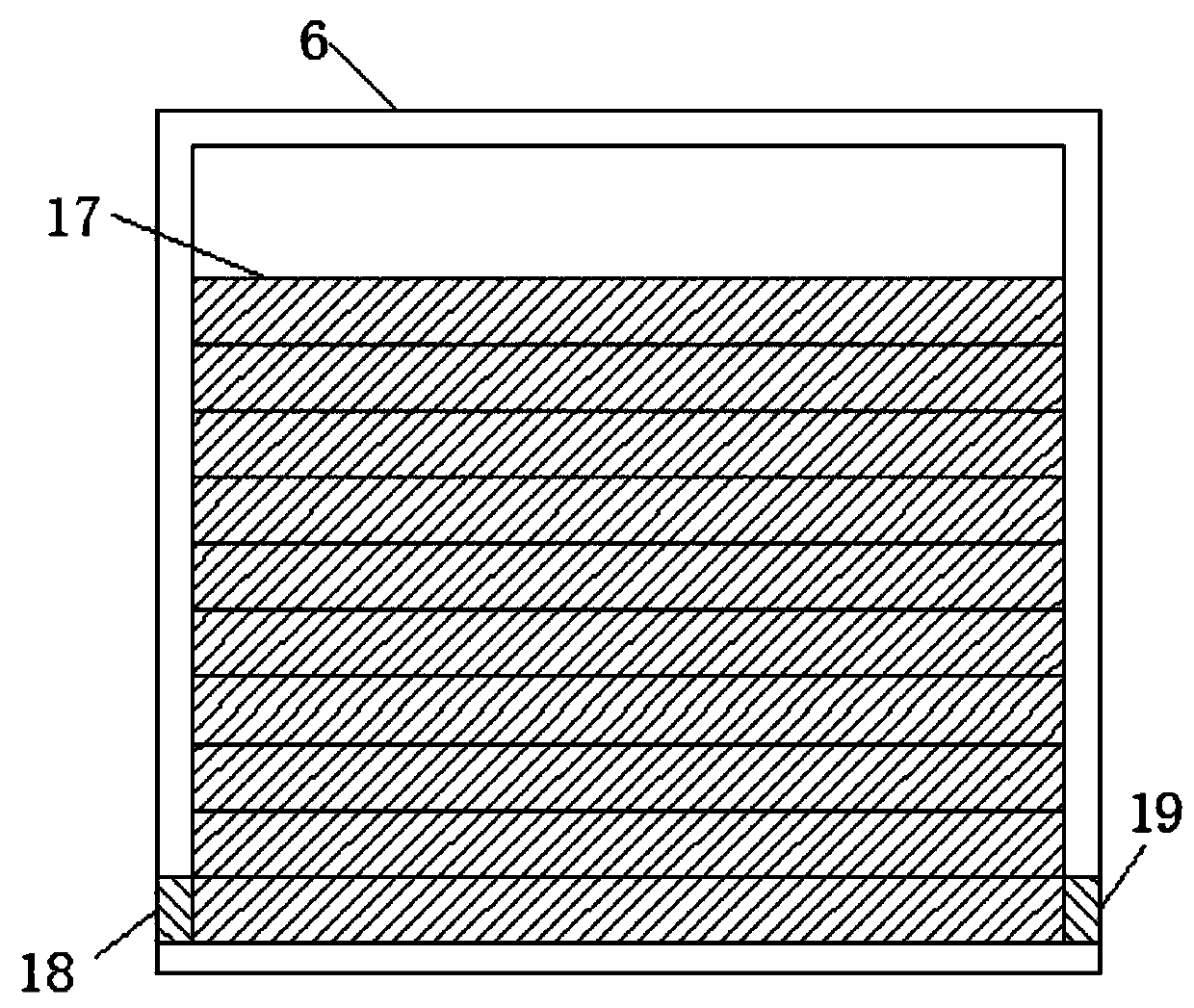

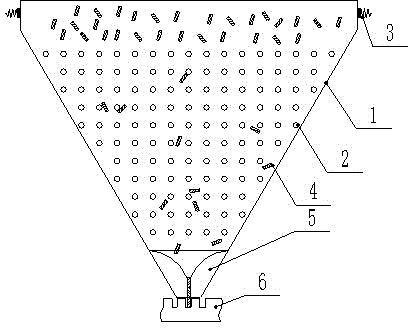

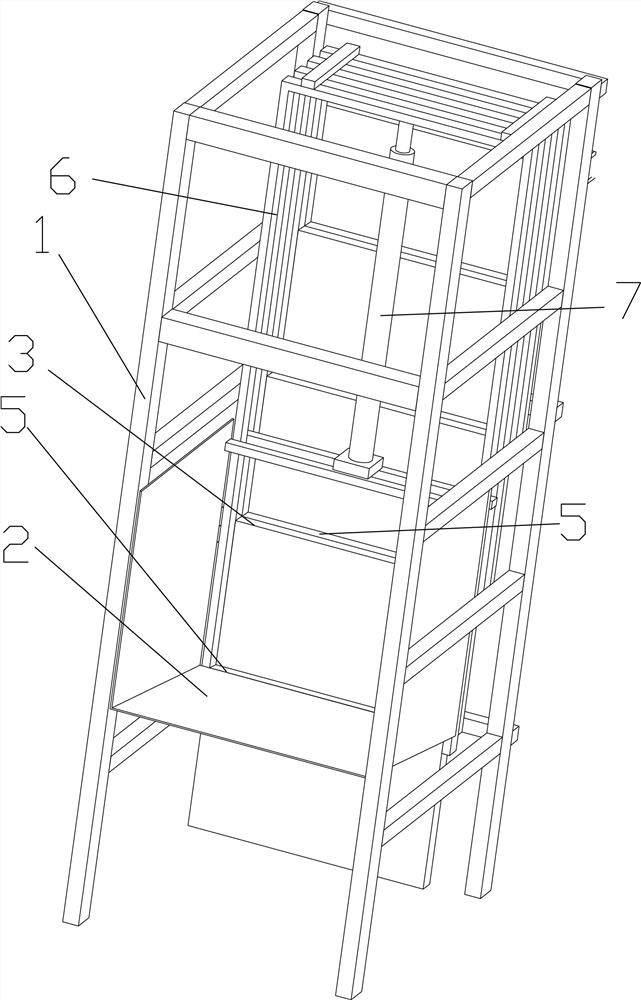

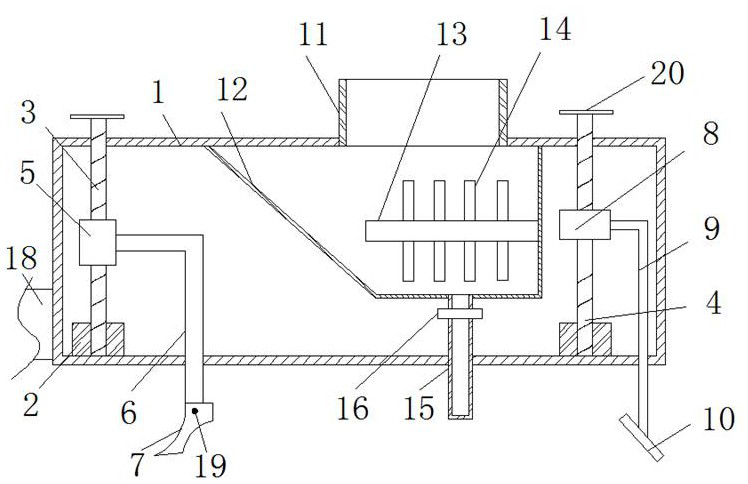

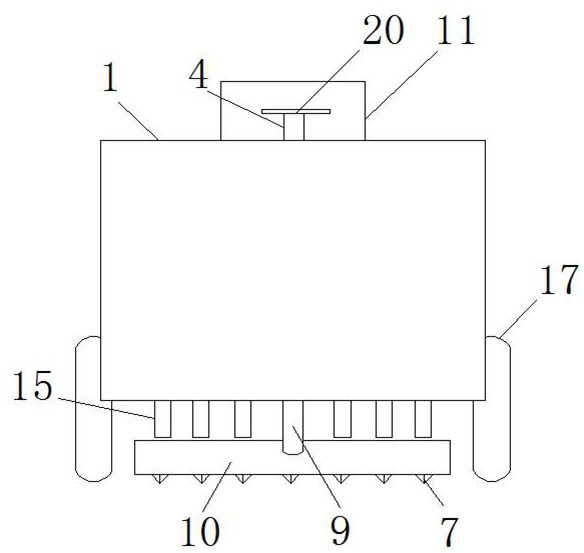

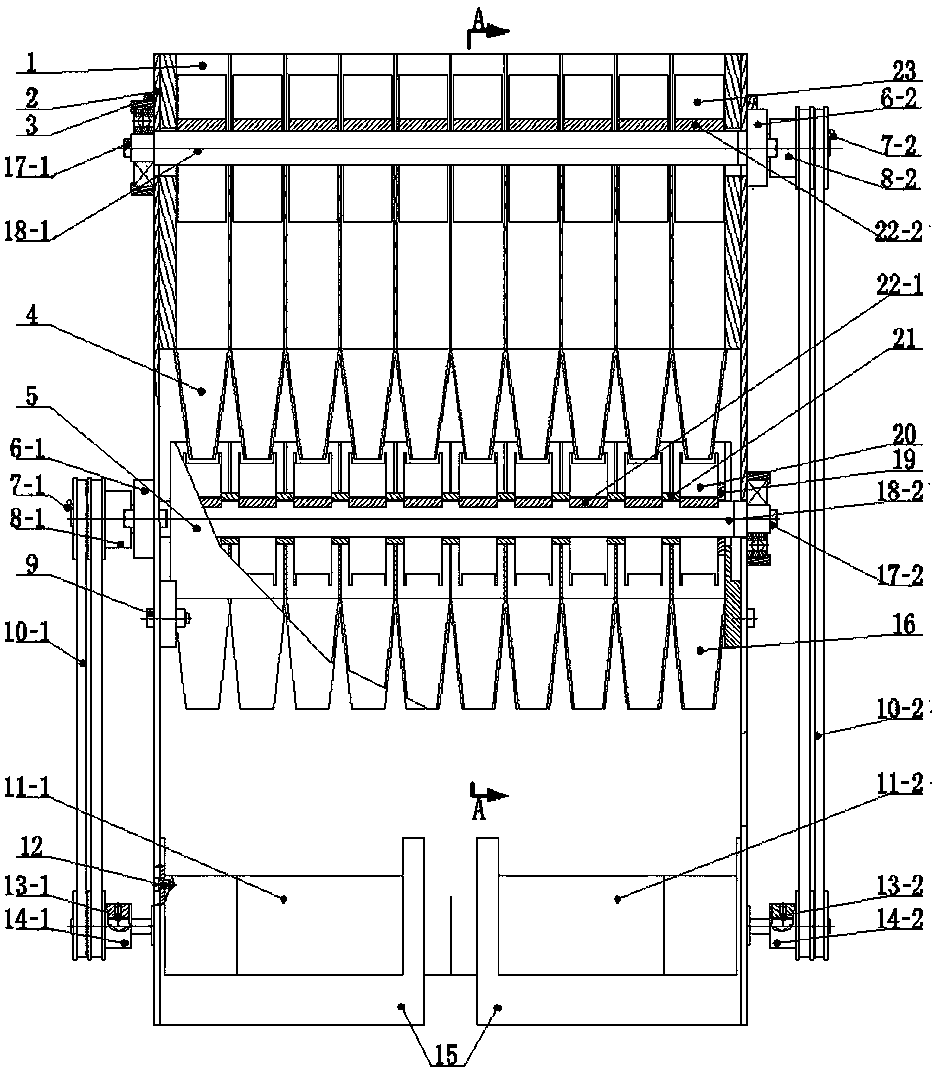

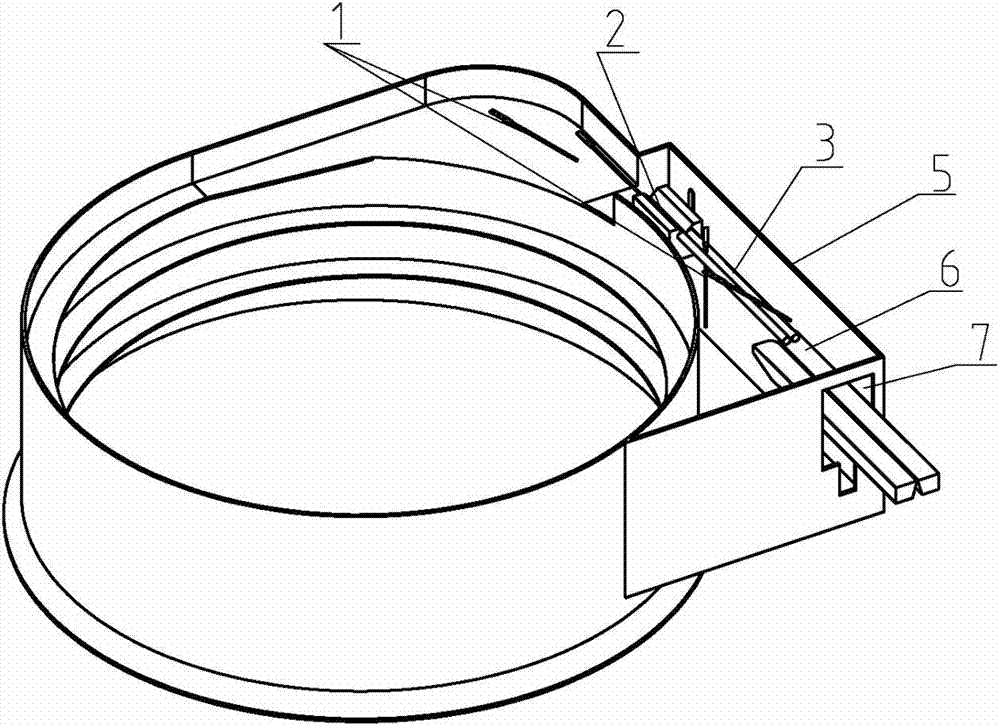

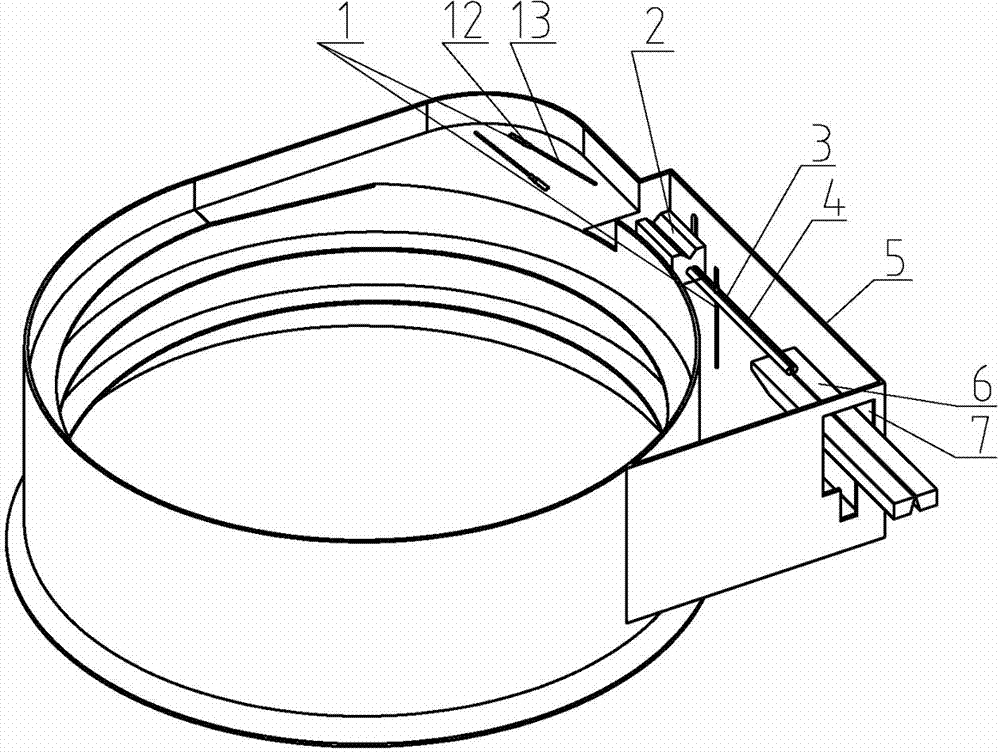

Arranging and conveying device for ventilating slot tooth pressing strips of motor

ActiveCN104860041ANeat and orderly deliveryThere will be no material jamsConveyorsLarge containersEngineeringAutomation

The invention discloses an arranging and conveying device for ventilating slot tooth pressing strips of a motor. The arranging and conveying device comprises a material tank, wherein the upper end and the lower end of the material tank are open; at least one column of guiding circular tubes are vertically arranged on the inner wall of the material tank and used for dividing tooth pressing strips; a discharging opening is formed in the lower end of the material tank; the diameter of the most narrow part of the discharging opening is matched with those of the tooth pressing strips; a conveyor belt is correspondingly arranged at a position below the discharging opening; positioning grooves are formed in the conveyor belt. Compared with the prior art, the arranging and conveying device has the benefits as follows: the scattered motor ventilating slot tooth pressing strips can be arranged regularly and then conveyed to the position of the next work station one by one, the automation efficiency for production of motor ventilating slot end plates is greatly improved, discharging openings with different bore diameters can be replaced to meet the arranging and conveying requirements of tooth pressing strips of different models; vibrating devices can ensure that the tooth pressing strips cannot be stuck in the material tank and can be regularly arranged and orderly conveyed, and the conveying error is avoided.

Owner:NANTONG TONGDA SILICON STEEL STAMPING TECH CO LTD

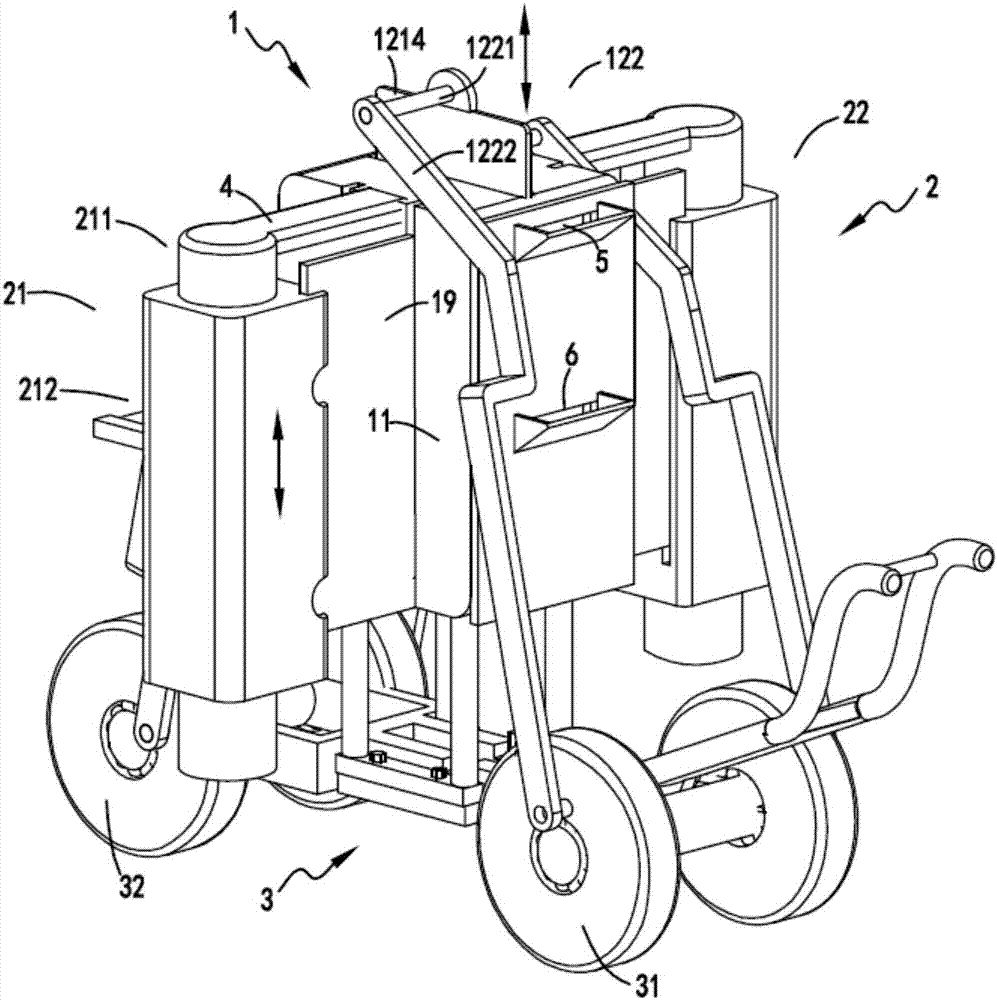

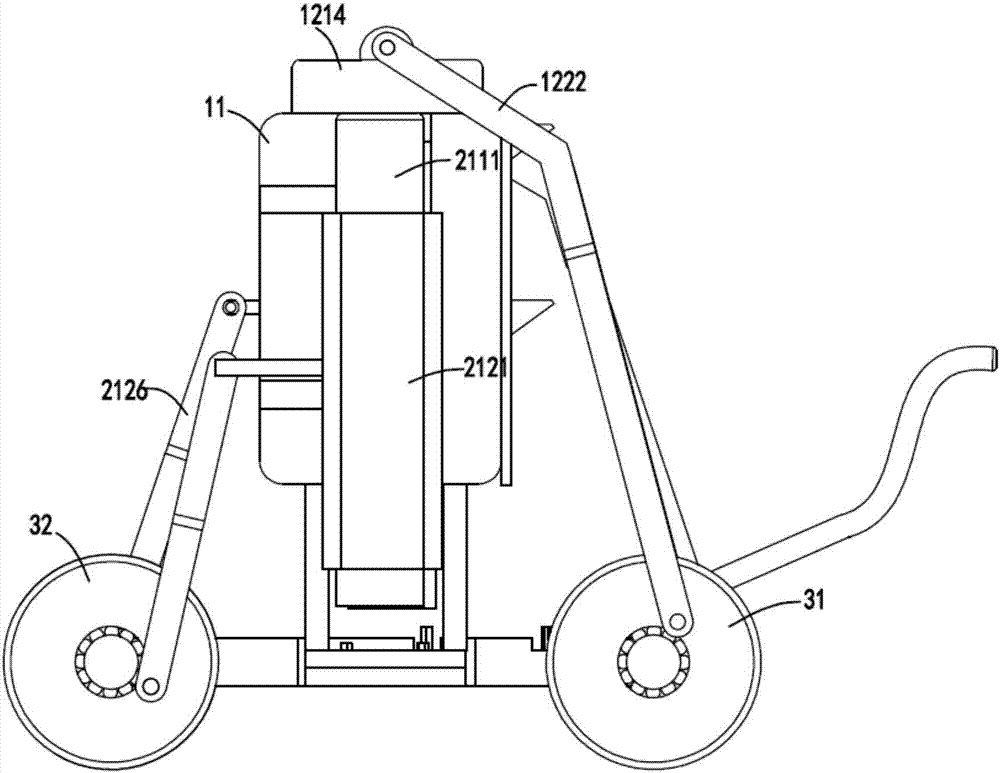

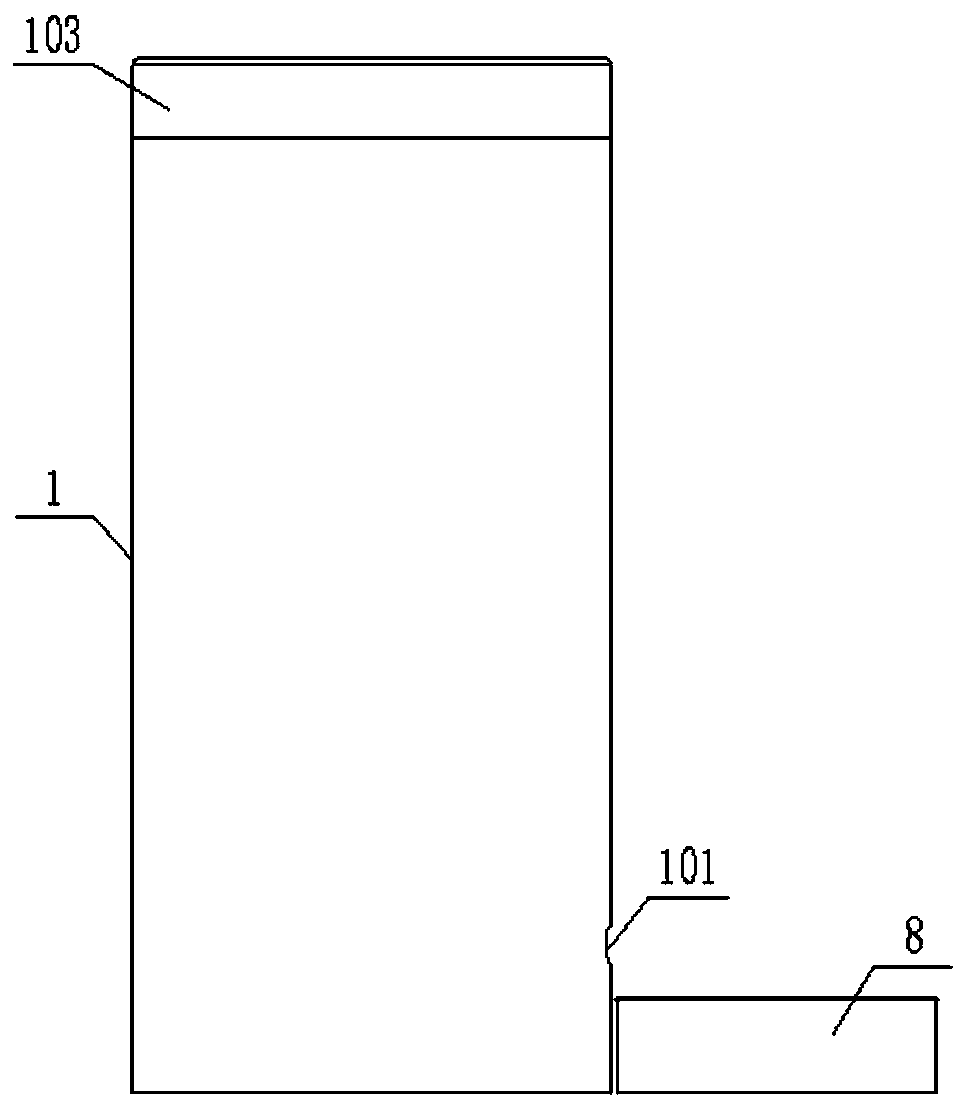

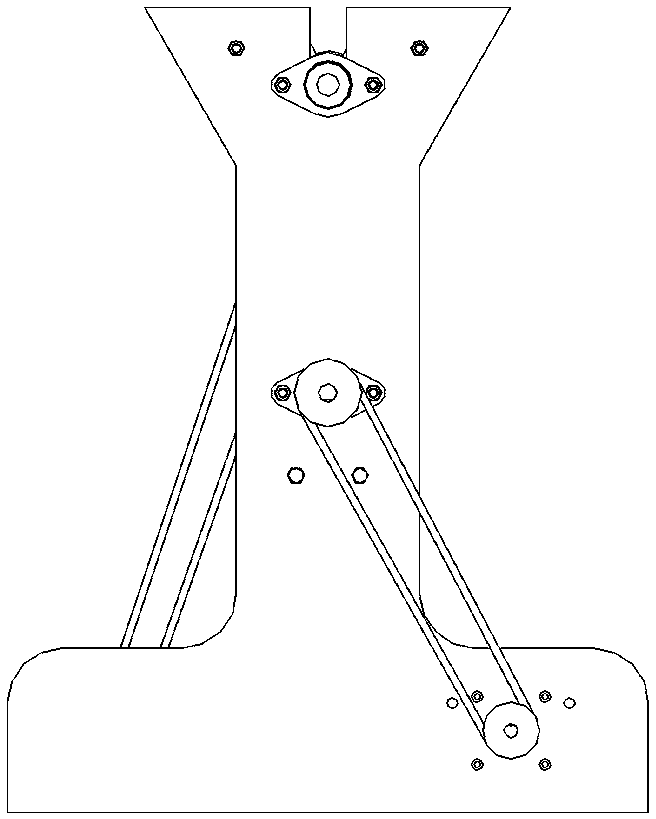

Stepped lifting, conveying and feeding device for automobile sleeve polishing and method

PendingCN112757067AEasy for automatic loadingThere will be no material jamsRevolution surface grinding machinesStructural engineeringMachine

The invention discloses a stepped lifting, conveying and feeding device for automobile sleeve polishing and a method. The device mainly comprises a device body, a storage chamber is installed at the front end of a rack of the device body, fixed stepped plates which are lifted step by step are arranged at the rear end of the rack, intervals are formed between the storage chamber and the fixed stepped plates and between the adjacent fixed stepped plates, and movable stepped plates are arranged in the intervals; and the movable stepped plates are lifted step by step, all the movable stepped plates are connected with a support, and the support is lifted or descended through the telescopic action of a heavy-load air cylinder. When the support descends, the movable stepped plates are flush with the corresponding fixed stepped plates at the front sides or the storage chamber. After the support is lifted, the movable stepped plates are flush with the corresponding fixed stepped plates at the rear sides. According to the stepped lifting, conveying and feeding device for automobile sleeve polishing and the method, feeding can be automatically conducted on a grinding machine, and the automation level is improved.

Owner:宜昌华益工具制造股份有限公司

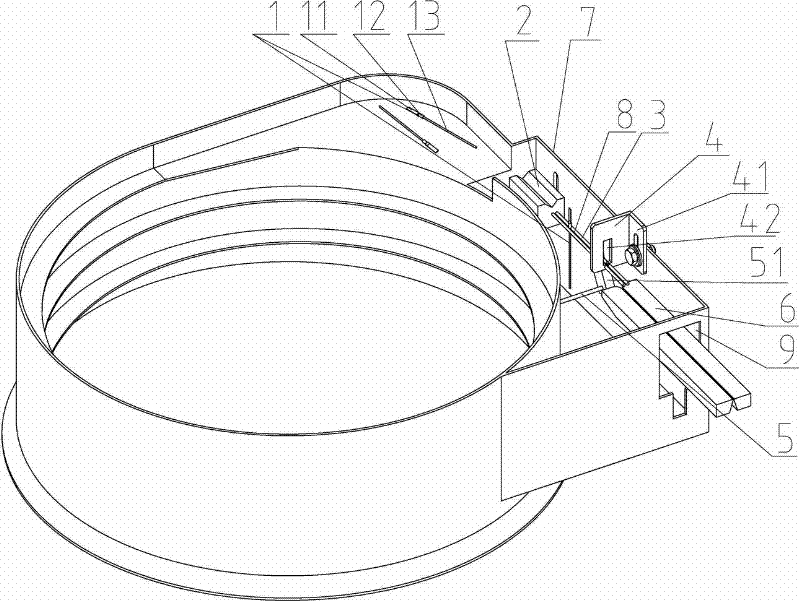

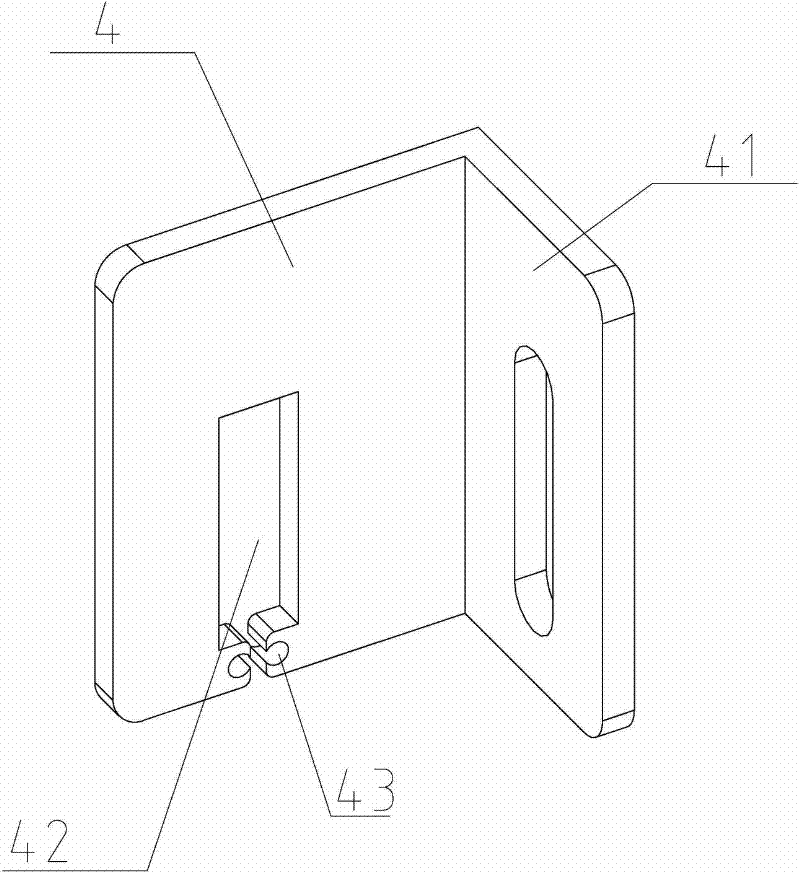

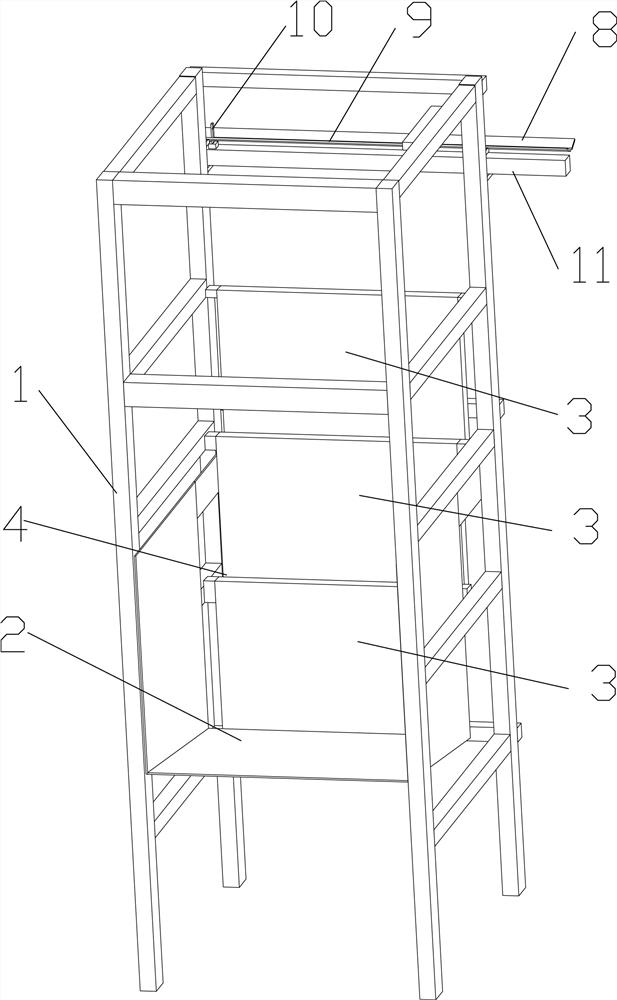

Feeding device of battery cooling pipe

ActiveCN114426178AThere will be no material jamsThere will be no material leakageJigging conveyorsConveyor partsEngineeringCooling pipe

The invention provides a battery cooling pipe feeding device which comprises a base, a platform is arranged on the upper portion of the base, a rack is arranged on the periphery of the upper portion of the platform, a fixing mechanism is arranged in the middle of the upper portion of the platform, a feeding mechanism is arranged at the position, located above the fixing mechanism, of the lower portion of the rack, and a feeding mechanism and a vibration disc are arranged on the rear side of the fixing mechanism. The vibration disc is connected with a feeding rail, a feeding notch is formed in the feeding mechanism, the end, away from the vibration disc, of the feeding rail right faces the feeding notch, and the feeding mechanism is used for conveying materials on the feeding mechanism into the fixing mechanism to be machined and taking out the machined materials in the fixing mechanism.

Owner:ZHEJIANG XINLONG IND

A convenient ball mill

ActiveCN108160226BEasy dischargeComplete dischargeGrain treatmentsRolling-element bearingStructural engineering

The invention discloses a ball grinding mill facilitating discharge. The ball grinding mill comprises an outer cylinder base, an arc buckle plate and an inner rotation barrel. The upper end of the outer cylinder base is provided with installation feet, convex edges are symmetrically arranged on the outer cylinder base, inserting slots are symmetrically arranged in the arc buckle plate, the inserting slots in the arc buckle plate are connected with the convex edges, one end of the inner rotation barrel is provided with a cut-through shaft, the other end of the inner rotation barrel is providedwith a closing shaft, the outer wall of the inner rotation barrel is evenly provided with discharge holes, and the cut-through shaft at one end of the inner rotation barrel and the closing shaft at the other end of the inner rotation barrel are rotationally connected with the outer barrel base through rolling bearings. Dual cylinder type inner rotation cylinder grinding is achieved, materials aredischarged from the outer cylinder base after being stored, and discharge is thorough.

Owner:安徽红旗弹簧有限公司

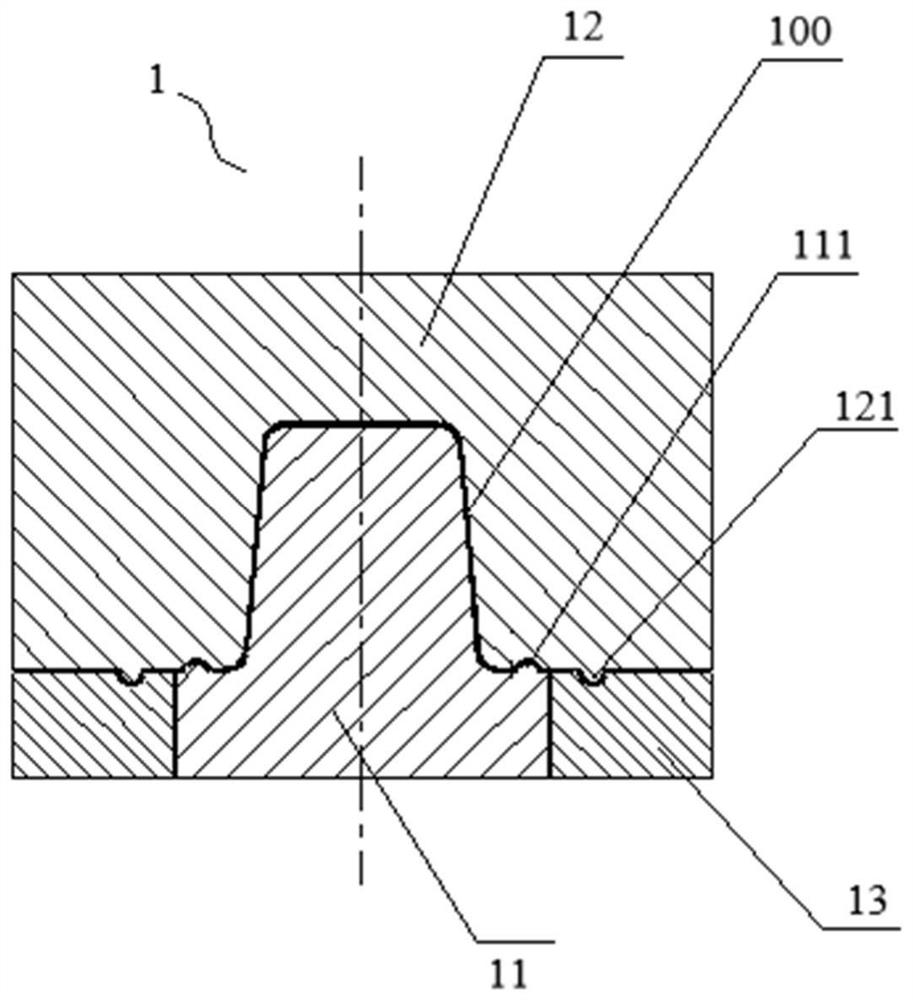

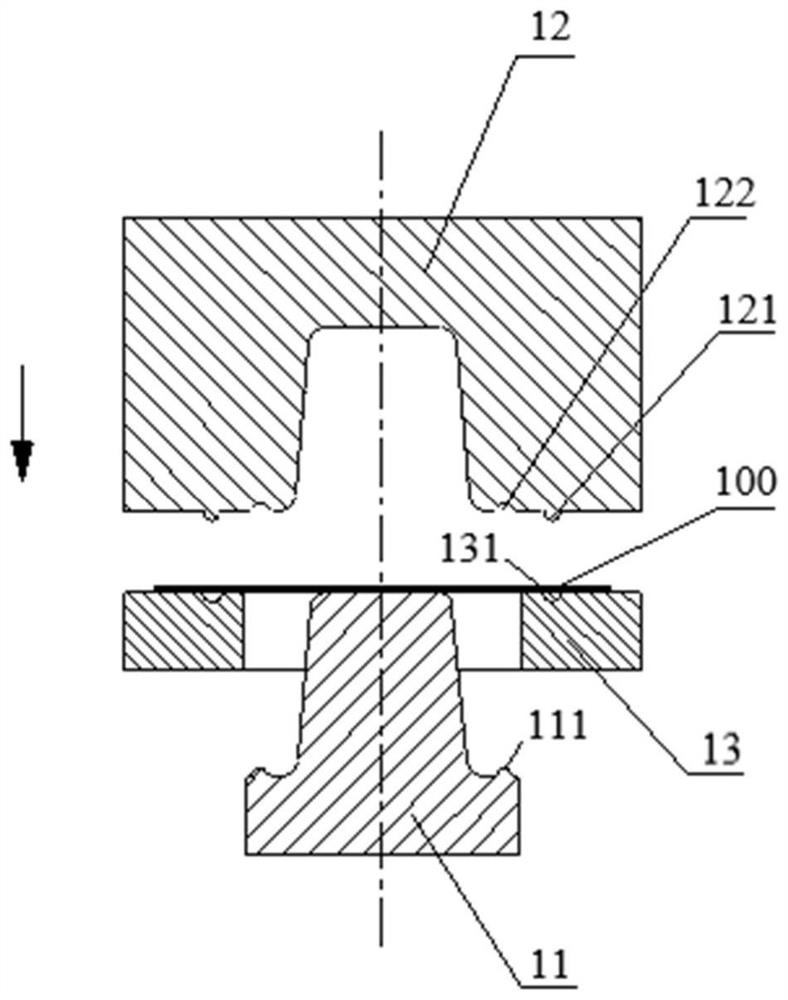

Die

PendingCN112536375ASufficient plastic deformation of the side wallIncrease resistanceShaping toolsMechanical engineeringEngineering

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

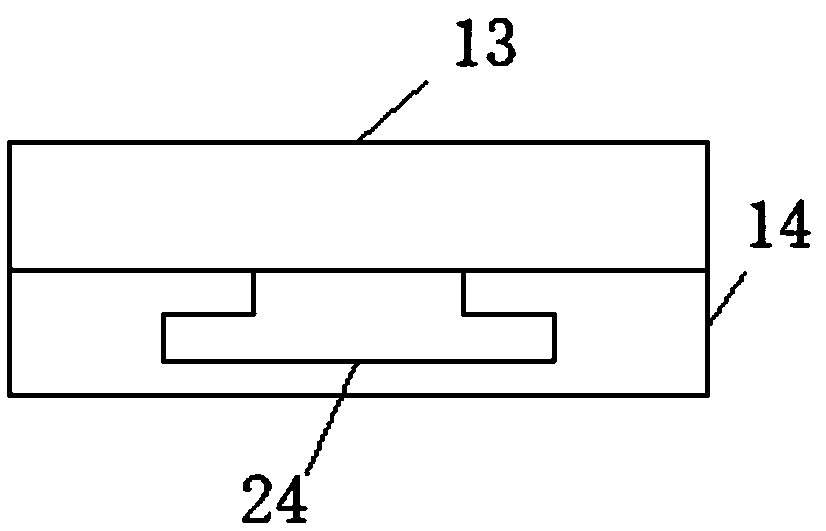

Feeding structure and feeder

PendingCN110395593AThere will be no material jamsSolve the leakLarge containersLoading/unloadingEngineeringMechanical engineering

The invention relates to the technical field of feeding devices, in particular to a feeding structure and a feeder. The feeding structure comprises a first cylinder body, a second cylinder body, a lifting disc and a driving mechanism, one end of the first cylinder body is provided with an opening, and the lower portion of the first cylinder body is provided with a discharge opening; the two ends of the second cylinder body are opened, the second cylinder body is fixed in the first cylinder body, and a material passage is formed between the second cylinder body and the first cylinder body; thelifting disc is arranged in the second cylinder body; and the driving mechanism drives the lifting disc to move vertically in the second cylinder body. The feeder includes the feeding structure and adischarging plate, the discharging plate is inclined downwards, the upper end of the discharging plate is fixed to the inner wall of the first cylinder body and below the second cylinder body, and thelower end of the discharging plate is fixed to the inner wall of the first cylinder body and below the discharge port. The feeding structure is provided with the lifting disc, the lifting disc can bemoved up and down along the second cylinder body through a screw, and the problems of material leakage and material clamping can be effectively solved.

Owner:MANGO IOT CHANGZHOU CO LTD

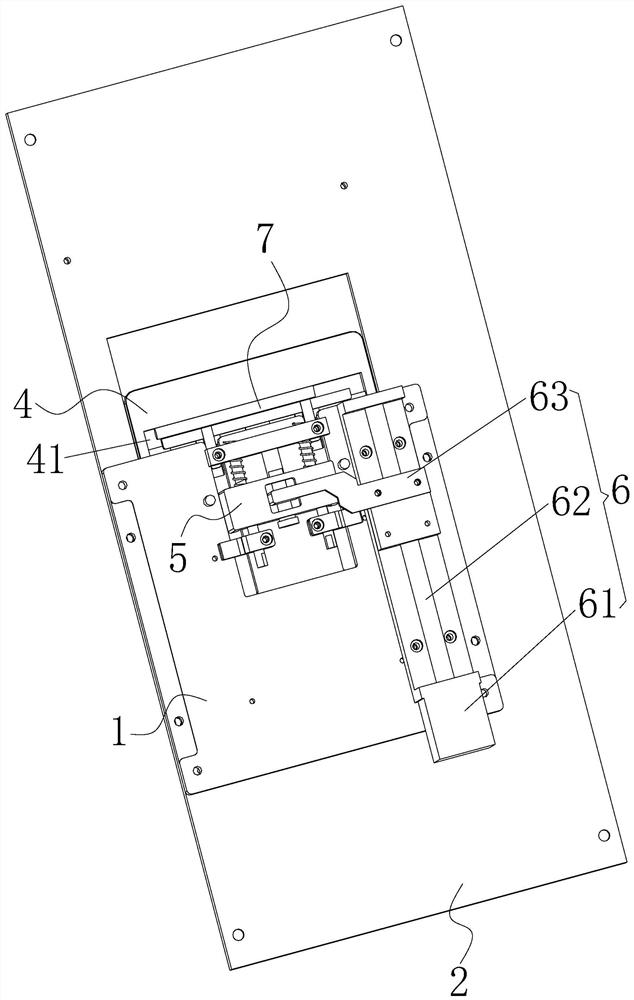

Horizontal automatic sampling device

PendingCN112595855ASimple device structureStrong applicabilityMaterial analysisElectrical and Electronics engineeringControl theory

The invention discloses a horizontal automatic sample injection device which comprises a bottom plate, a fixed plate, a stock bin mechanism, a push-pull plate, a clamping mechanism and a main push mechanism, the fixed plate is fixed to the top surface of the bottom plate, a discharge port is formed in the fixed plate at the top of the bottom plate, and the stock bin mechanism is arranged on the top surface of the fixed plate; a push-pull plate is arranged between the bottom plate and the fixed plate, a clamping groove is formed in the push-pull plate, the clamping mechanism is fixed to the bottom face of the push-pull plate, the clamping end of the clamping mechanism is arranged in the clamping groove, the main pushing mechanism is fixed to the bottom plate, and the stock bin mechanism comprises a stock bin, a partition plate and a driving device. The horizontal automatic sample injection device has the advantages that the structure is simple, materials cannot be clamped, different types of cigarettes can be placed in different bins, the driving device is driven to move the different bins to the top of the discharging port, and therefore the different types of cigarettes can be output from the discharging port, automatic feeding of various sample cigarettes is achieved, and the applicability is higher.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Automatic fertilizing equipment with fertilization depth adjusting and soil covering functions

InactiveCN112806136AFunctionalAdjust Fertilization DepthPlantingFertiliser distributersEdaphicAgricultural engineering

The invention relates to the technical field of automatic fertilizing of odorless charcoal-based organic fertilizers, and discloses automatic fertilizing equipment with fertilizing depth adjusting and soil covering functions. The automatic fertilizing equipment comprises a case, the interior of the case is rotatably connected with a first screw rod and a second screw rod through limiting blocks separately, and the outer side of the first screw rod is sleeved with a first fixing block. The right side of the first fixing block is fixedly connected with a plow column, the lower end of the plow column is fixedly connected with a plow share, and the outer side of a rotating shaft is fixedly connected with overturning teeth. According to the automatic environment-friendly fertilizing equipment with the fertilization depth adjusting function, through cooperative use of the limiting blocks, the first screw rod, the first fixing block, the plow column and the plow share, the effect that the plow share can adjust the depth of a soil furrow is achieved, and the purpose that the fertilizing depth can be adjusted according to the soil texture condition of soil and different types of selected odorless carbon-based organic fertilizers is achieved.

Owner:HUNAN UNIV OF TECH

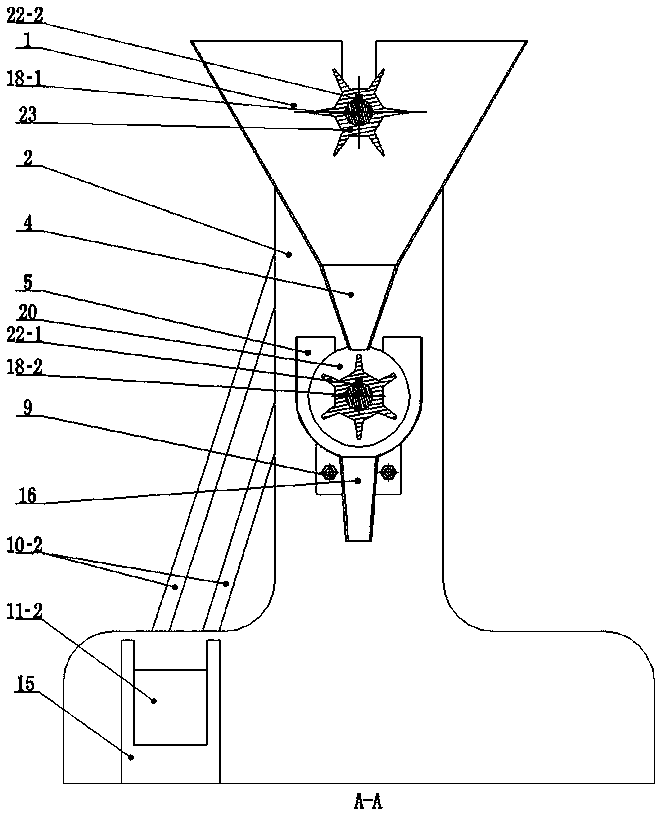

Tubular reactor catalyst stirring and distributing device

PendingCN108160007AImprove efficiencyAccurate cutting amountChemical/physical processesEngineeringMaterial storage

The invention discloses a tubular reactor catalyst stirring and distributing device which comprises a material distributing box, wherein a stirring wheel, main driving shafts and keys are arranged inthe material distributing box; the main driving shaft is fixed to the main driving shaft through the keys, and the two ends of the main driving shaft are fixed to a deep groove ball bearing on a supporting plate on one side; the material distributing box is divided into a plurality of material storage tanks; long conical hoppers, material separating boxes and short conical hoppers are sequentiallyconnected under the plurality of the material storage tanks; the material separating boxes are fixed to the supporting plates on the two sides through cuboid bases and fastening bolts; material stirring wheels, main driving shafts, material stirring wheel interval sleeve, shaft end sleeves and keys are arranged in the material separating boxes; discharging openings of the long conical hoppers areembedded into inner grooves of the material stirring wheels. The tubular reactor catalyst stirring and distributing device disclosed by the invention can replace workers to add catalysts and can wellavoid the problems of material clamping, uneven distribution and the like of the catalysts in an adding process; the catalysts can be accurately and evenly distributed in the reactor; a producing process has the advantages of safety and environmental friendliness.

Owner:JIEHUA HLDG +1

A single-motor circulating water culture floating bait uniform bait feeding machine and method

ActiveCN105048710BReduce energy consumptionReduce power consumptionClimate change adaptationPisciculture and aquariaEngineering

The invention discloses a single-motor recirculating-aquaculture floating-bait uniform bait casting machine and a method. A side of a feeding box is provided with a discharge part which is connected with a material receiving port and is inclined downwards. A part, which is close to the material receiving port, below the feeding box is provided with an electromagnetic switch which is connected with a controller. A housing of the upper part of a main motor is fixedly provided with a material throwing disc, and an output shaft of the main shaft is fixedly provided with an internal blade. An outer end of the internal blade is fixedly connected with an inner wall of a partitioning plate, and an outer wall of the partitioning plate is fixedly connected with an external blade. An air outlet above the internal blade is provided with an air collection port which is connected and communicated with one end of an air pipe, and the other end of the air pipe is provided with an air collection mouth which faces the feeding box. The electromagnetic switch absorbs the feeding box, thereby enabling a lower material port to be opened. When the main motor works, the internal blade generates upward air which enters into the air collection port. Air is sprayed to bait in the feeding box, and the external blade rotates and drives the bait to be thrown out from the material throwing disc. The machine employs one motor, provides power for material throwing, also can prompt feeding, and achieves the uniform distribution of bait in a bait region through employing the controller to control the main motor.

Owner:JIANGSU UNIV

Material taking head

PendingCN110167328AAvoid leaningAvoid deflectionElectrical componentsEngineeringMechanical engineering

The invention relates to the technical field of component inserters, and particularly relates to a material taking head. The material taking head comprises a material taking seat, a material taking assembly and a material strengthening member, wherein the material taking assembly and the material strengthening member are respectively arranged on the material taking seat, the material strengtheningmember is arranged in a mode of being spaced from the material taking assembly and located above the material taking assembly, the material strengthening member is provided with material strengthening grooves, the material taking assembly includes a fixed clamping member fixedly connected to the material taking seat, a movable clamping member slidably arranged on the fixed clamping member or / andmaterial taking seat, a sliding block slidably arranged on the fixed clamping member or / and the material taking seat and an elastic member arranged between the sliding block and the material taking seat, the sliding block is connected with the movable clamping member, and the fixed clamping member is matched with the movable clamping member so as to clamp a component. The material taking head is simple and compact in structure, stable in component picking-up and releasing and not easy to have a phenomenon of material clamping. In addition, the component is strengthened by the material strengthening member, thereby avoiding inclination or deflection of the component, and further improving the stability of the component.

Owner:广东岩田智慧机电有限公司

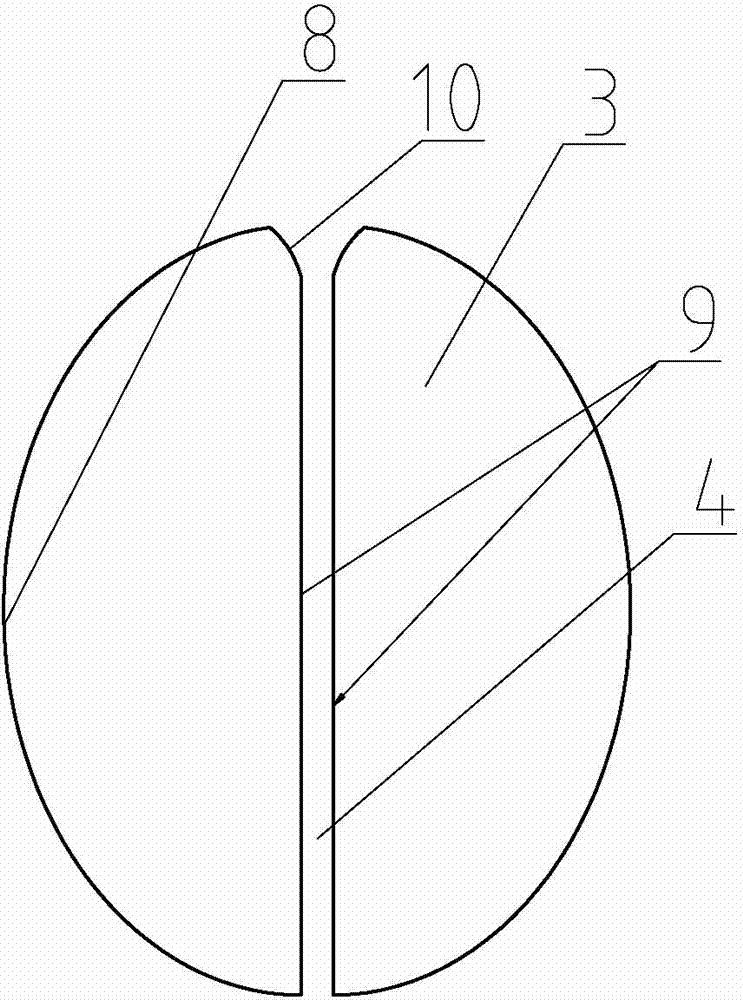

Rod-like track of guide pin feeding and sorting device

The invention discloses a rod-like track of a guide pin feeding and sorting device which can prevent guide pins from moving to a horizontal vibration track and steadily convey the guide pins. The rod-like track of the guide pin feeding and sorting device comprises two rods (3) with the same shape and size, a V-shaped block (2) is arranged on a feeding platform of a vibration plate (5), one end of each of the two rods (3) is arranged on the V-shaped block (2) horizontally in parallel, and a feeding track (4) is formed between the rods (3). The rod-like track of the guide pin feeding and sorting device is characterized in that the rods (3) have arched cross sections at a section of the feeding track (4), and the feeding track (4) is formed from arched strings (9). The rod-like track of the guide pin feeding and sorting device has the advantages of simple structure and low cost, the guide pins can be prevented from being dropped out to a machine or the ground to cause waste, and can be steadily conveyed on the rod-like track, two adjacent guide pins can be prevented from being crossed due to a relatively large swinging radian of the guide pins, and the guide pins can be smoothly conveyed to the horizontal vibration track, and a material blockage phenomenon can be prevented.

Owner:YIYANG AIHUA FUXIAN ELECTRONICS

Bending equipment for processing craft product raw materials and using method thereof

InactiveCN114850259AEasy to moveRealize continuous processingPortable framesMetal-working feeding devicesStructural engineeringProduct processing

The invention discloses bending equipment for craft product raw material processing and a using method of the bending equipment, and particularly relates to the technical field of craft product processing.The bending equipment comprises a rack composed of a base plate and supporting legs fixedly arranged at the four corners of the bottom of the base plate, and a movable plate is slidably connected to the middle of the top of the base plate; stand columns are fixedly arranged at the four corners of the top of the base plate, an L-shaped bracket is fixedly arranged between the top ends of every two stand columns arranged on the same side, a driving assembly is arranged at one end of the bottom of the base plate, a bending and discharging assembly is arranged in the middle of the position between the two L-shaped brackets, and shifting assemblies are arranged at the two ends of the top of the movable plate. The driving assembly is used for pushing the material shifting assembly to conduct intermittent feeding and pushing the bending and discharging assembly to conduct bending forming and automatic discharging on to-be-bent plate-shaped raw materials at the same time, the production efficiency is improved, and the problem that in the prior art, special-shaped craft products cannot be machined in place at a time is solved.

Owner:司立壮

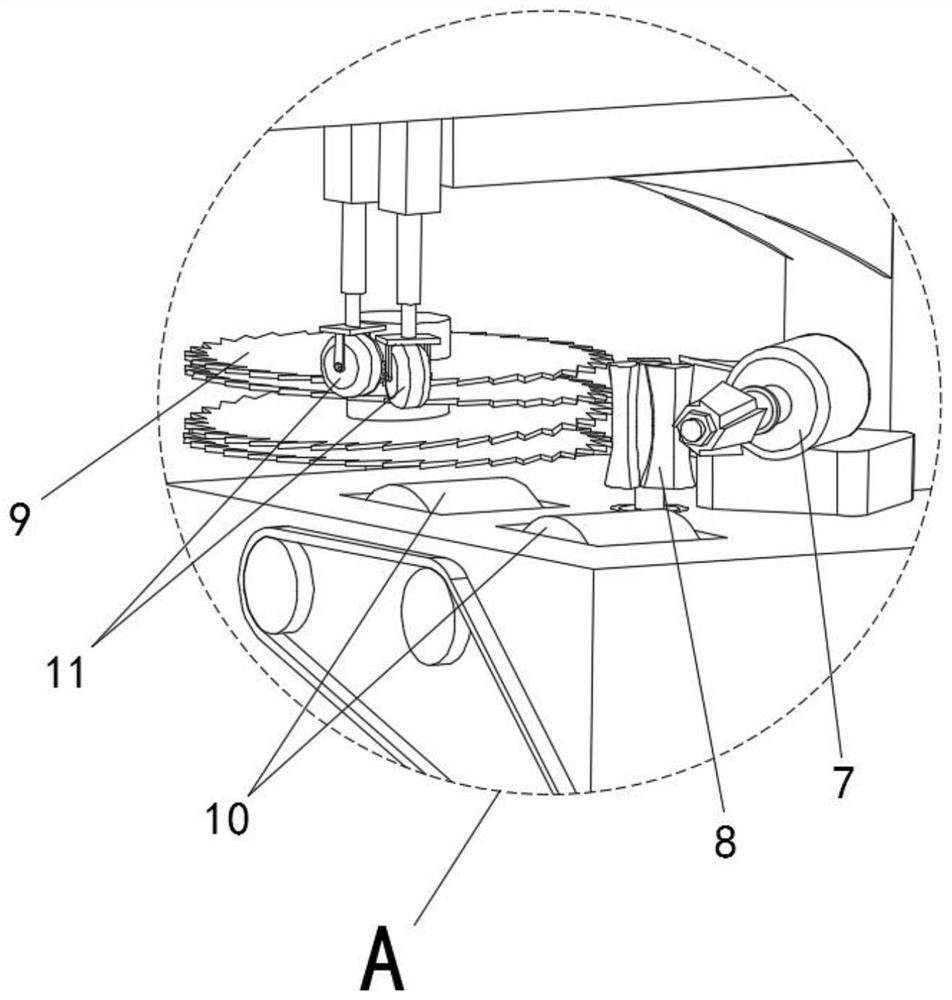

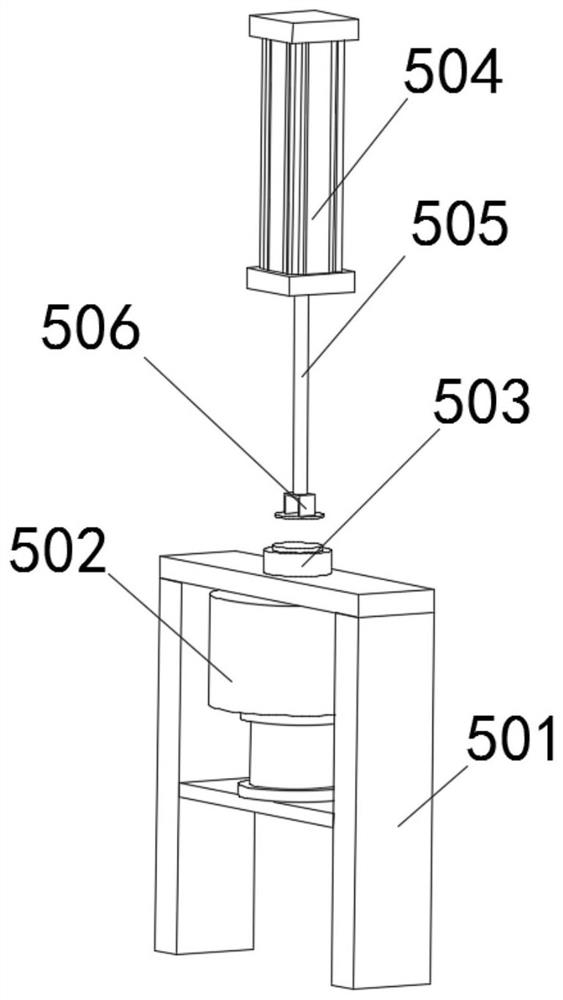

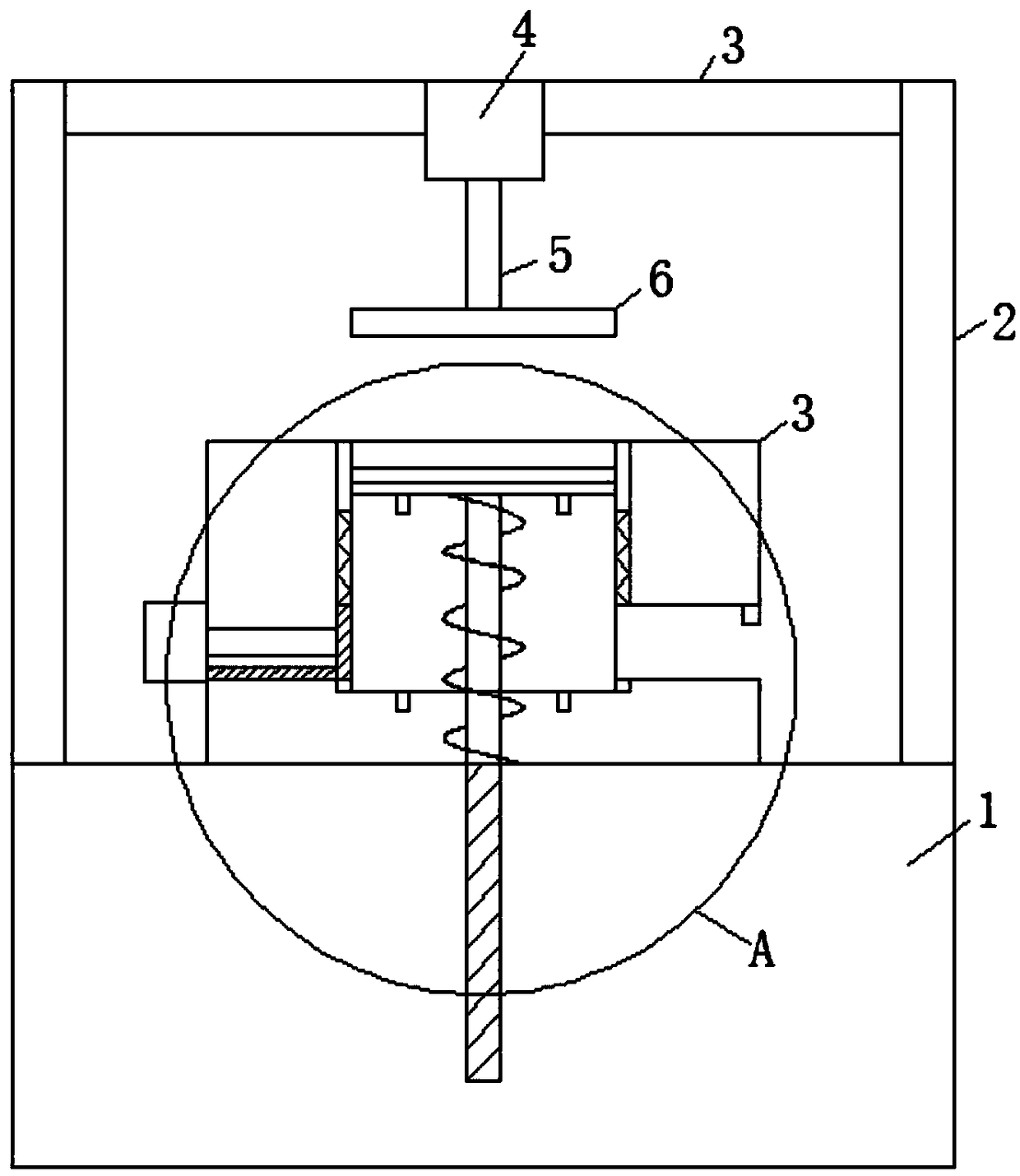

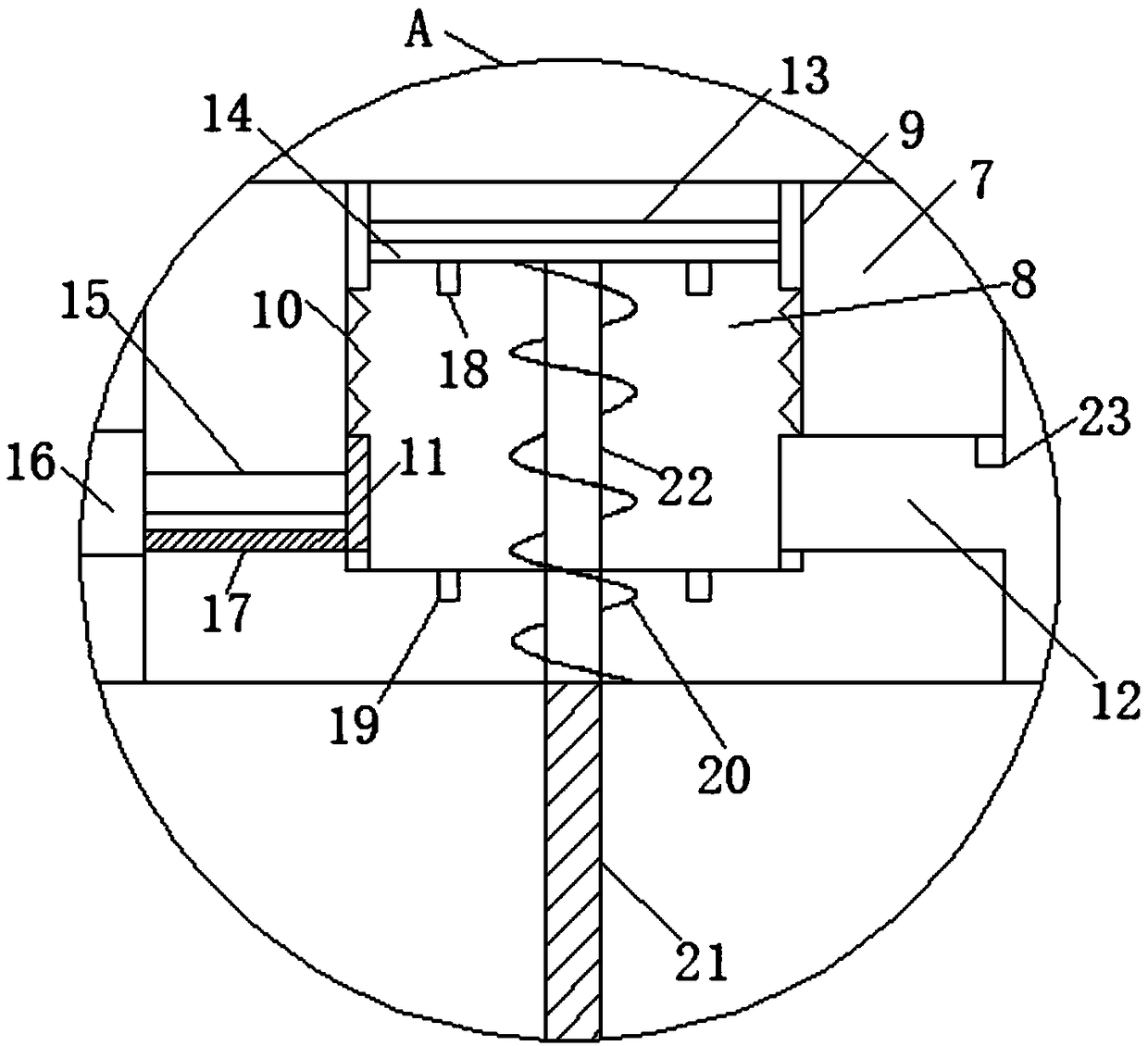

Wood round table machining device

PendingCN114131723AIncrease productivityProcess stability and precisionPolishing machinesMulti-purpose machinesCircular sawIdler-wheel

The invention provides a wood round table machining device. The wood round table machining device comprises a rack, a guide rail, a first workbench, a second workbench, a machining fixing mechanism, a polishing machine, a horizontal cutting mechanism, a vertical cutting mechanism, a circular saw, a supporting wheel mechanism, a pressing wheel mechanism and a dust collection mechanism. The guide rail is installed at the bottom of the rack, the first workbench and the second workbench are installed on the guide rail, the machining fixing mechanism is installed between the first workbench and the second workbench, the polishing machine is installed on the first workbench, and the circular saw, the vertical cutting mechanism and the horizontal cutting mechanism are sequentially arranged and installed on the second workbench in the rotating direction of a round table. The supporting wheel mechanism is installed on the second workbench and located on the sides, close to the machining fixing mechanism, of the horizontal cutting mechanism, the vertical cutting mechanism and the circular saw, a main body of the pressing wheel mechanism is a pair of idler wheels located above the supporting wheel mechanism, and the dust collection mechanism is installed behind the second workbench and away from the machining fixing mechanism; the method has the characteristic of high production efficiency.

Owner:LIUZHOU LIUCHENG HONGSEN FURNITURE MFG

Stamping trimming mold convenient for converting materials

ActiveCN108580649AEasy to transfer materialsEasy to take outEdge grinding machinesEjection devicesEngineeringMechanical engineering

The invention discloses a stamping trimming mold convenient for converting materials. The mold comprises a worktable, an upper mold seat and a lower mold seat, wherein the lower mold seat is arrangedon the worktable, and the upper mold seat is arranged on the lower mold seat; the lower mold seat comprises a substrate, a groove, a pushing device, a supporting plate, a guide bar, a spring and a guide hole; the substrate is arranged on the worktable, the groove is formed in the substrate, the supporting plate is arranged in the groove, the bottom of the supporting plate is connected to the guidebar, the guide bar is inserted into the guide hole, the guide hole is formed in the worktable, a spring I is arranged on the guide bar in a sleeved manner, the pushing device is arranged on one sideof the groove, a discharge groove is formed in the outer side of the groove, an inductor is arranged on the top of the discharge groove, a snap joint is arranged at the lower end of the supporting plate, and a slot matched with the snap joint is formed in the bottom of the groove. The mold disclosed by the invention can trim a workpiece as the lower mold seat is matched with the upper mold seat, and can convert materials for the workpiece by means of the supporting plate matched with the pushing device.

Owner:CHUZHOU MODERN MOLD MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com