A multifunctional sowing and fertilizing machine

A fertilizer applicator and multi-functional technology, which is applied to fertilizers and planting equipment, etc., can solve the problems of synchronous interplanting that are prone to blockage and poor working stability, and achieve the effect of ensuring stability and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

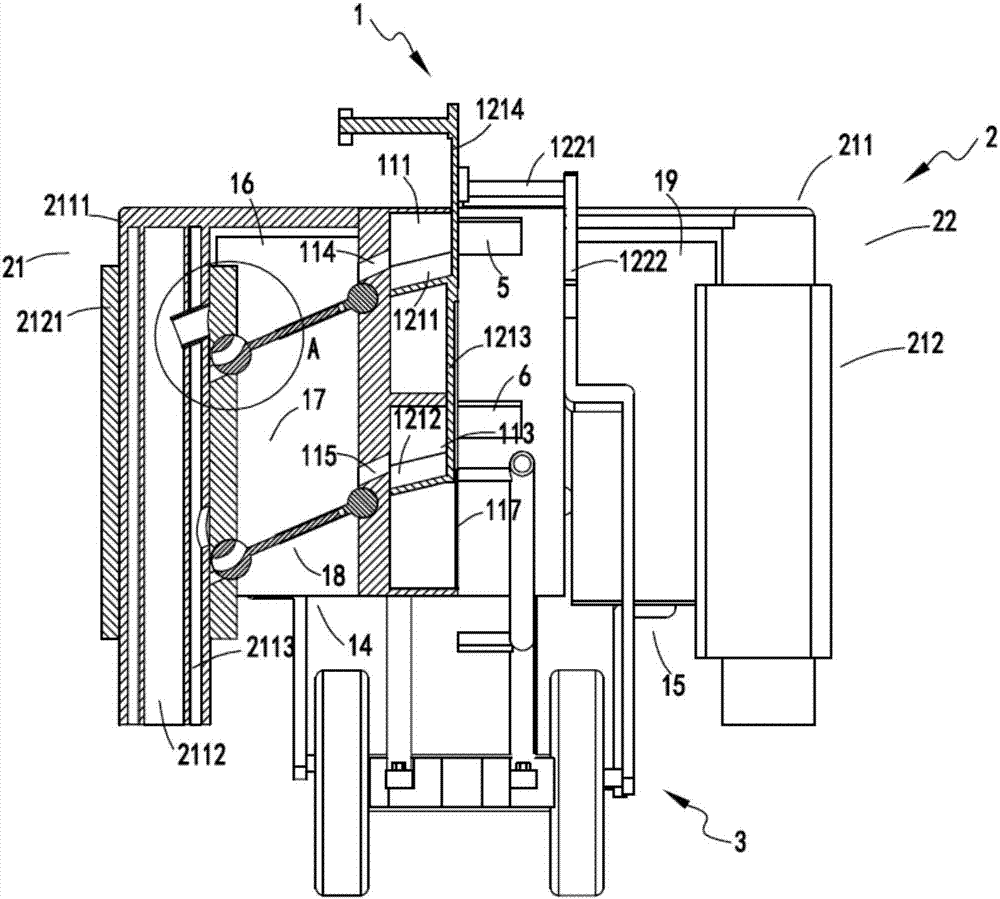

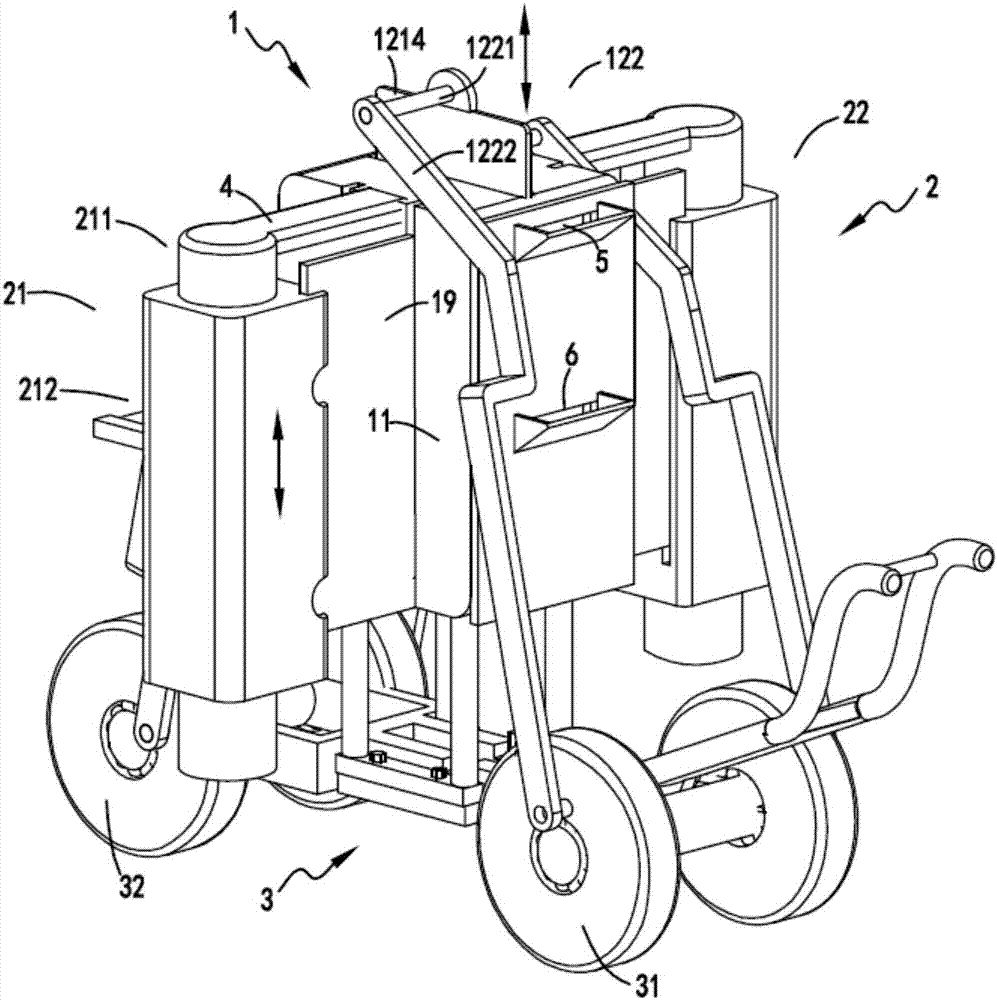

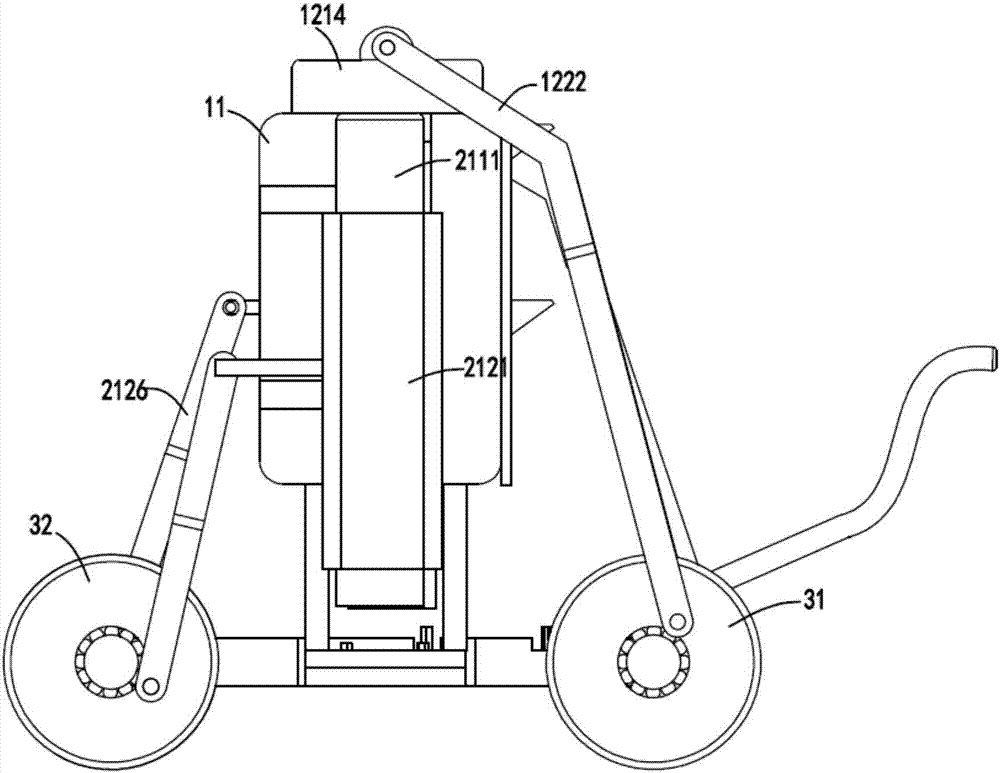

[0041] figure 1 It is a partial cut-away schematic diagram of a multifunctional seeding and fertilizing machine, figure 2 It is a schematic diagram of the structure of the multifunctional seeding and fertilizing machine, image 3 It is a schematic diagram of the side view of the multifunctional seeding and fertilizing machine, Figure 4 It is a cut-away schematic diagram of a multifunctional seeding and fertilizing machine, Figure 5 It is an enlarged schematic diagram of part of the structure of the multifunctional seeding and fertilizing machine, Image 6 It is a partial structural diagram of the multifunctional seeding and fertilizing machine, Figure 7 It is a schematic diagram of the enlarged structure of the rotating discharge device, Figure 8is a structural schematic diagram of output mechanism a or output mechanism b, Figure 9 It is a structural schematic diagram of the feeding mechanism a and the feeding mechanism b, Figure 10 is the schematic diagram of the...

Embodiment 2

[0055] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 with Figure 11 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that the power device 122 includes a fixed shaft 1221 arranged on the upper end of the lifting plate 1214, one end is rotatably arranged on the end of the fixed shaft 1221 and the other end is eccentrically and rotatably arranged The transmission rod a1222 on the front wheel 31 of the cart 3; the transmission unit 2122 includes a support shaft 2125 fixed on the side of the sliding sleeve 2121 and one end is rotatably arranged on the end of the support shaft 2125 and the other end is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com