Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2022results about "Fertiliser and seeding apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

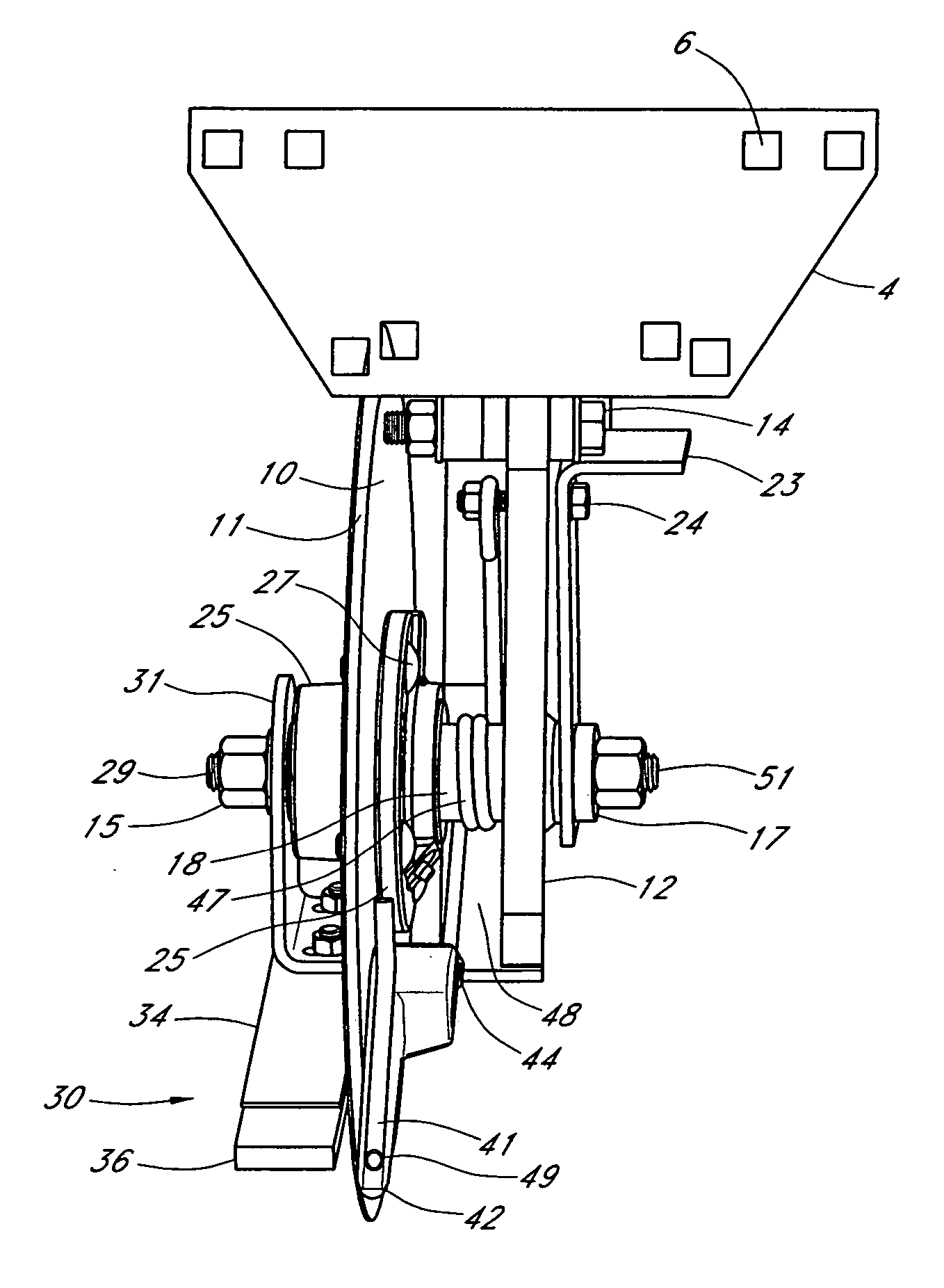

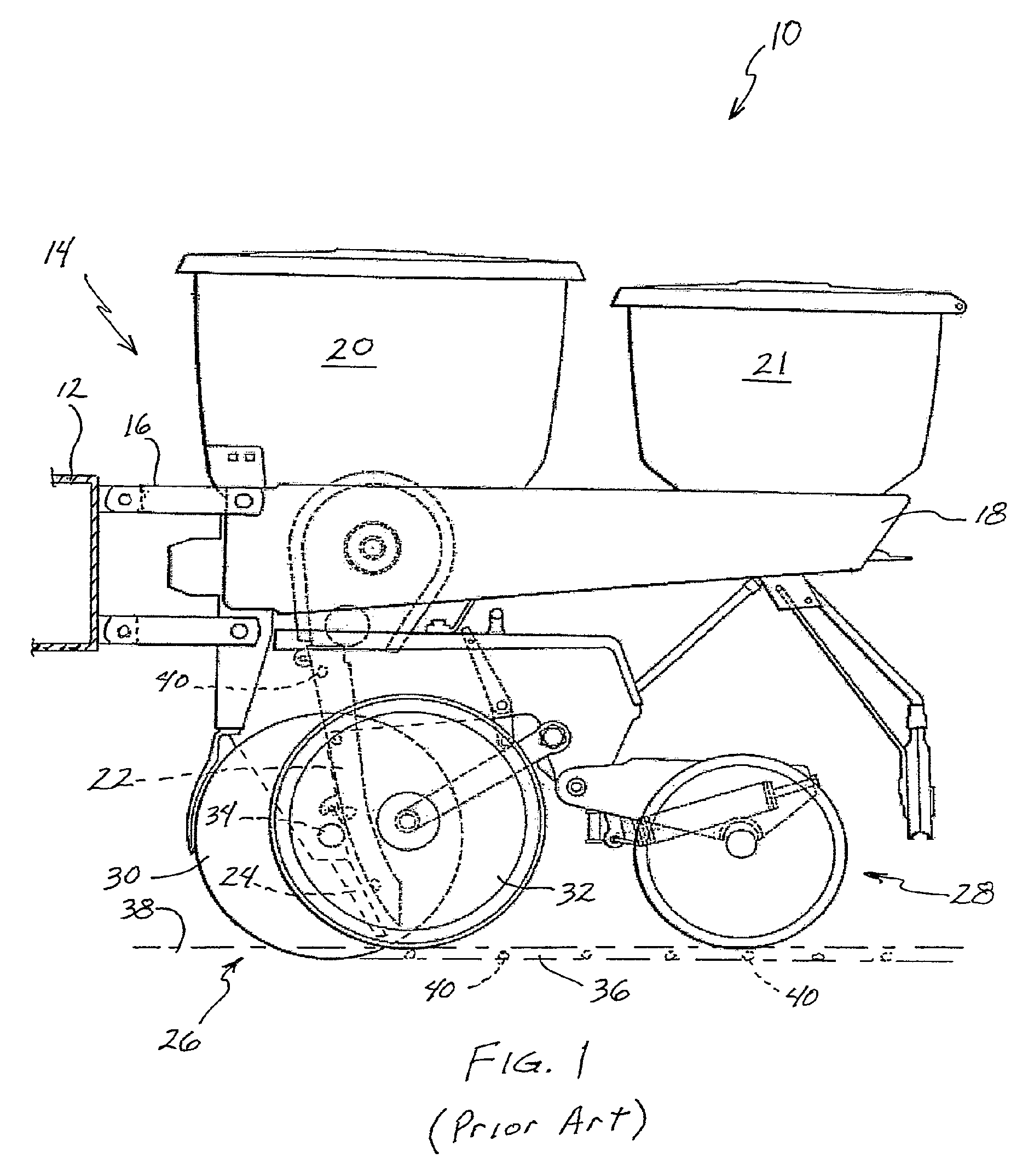

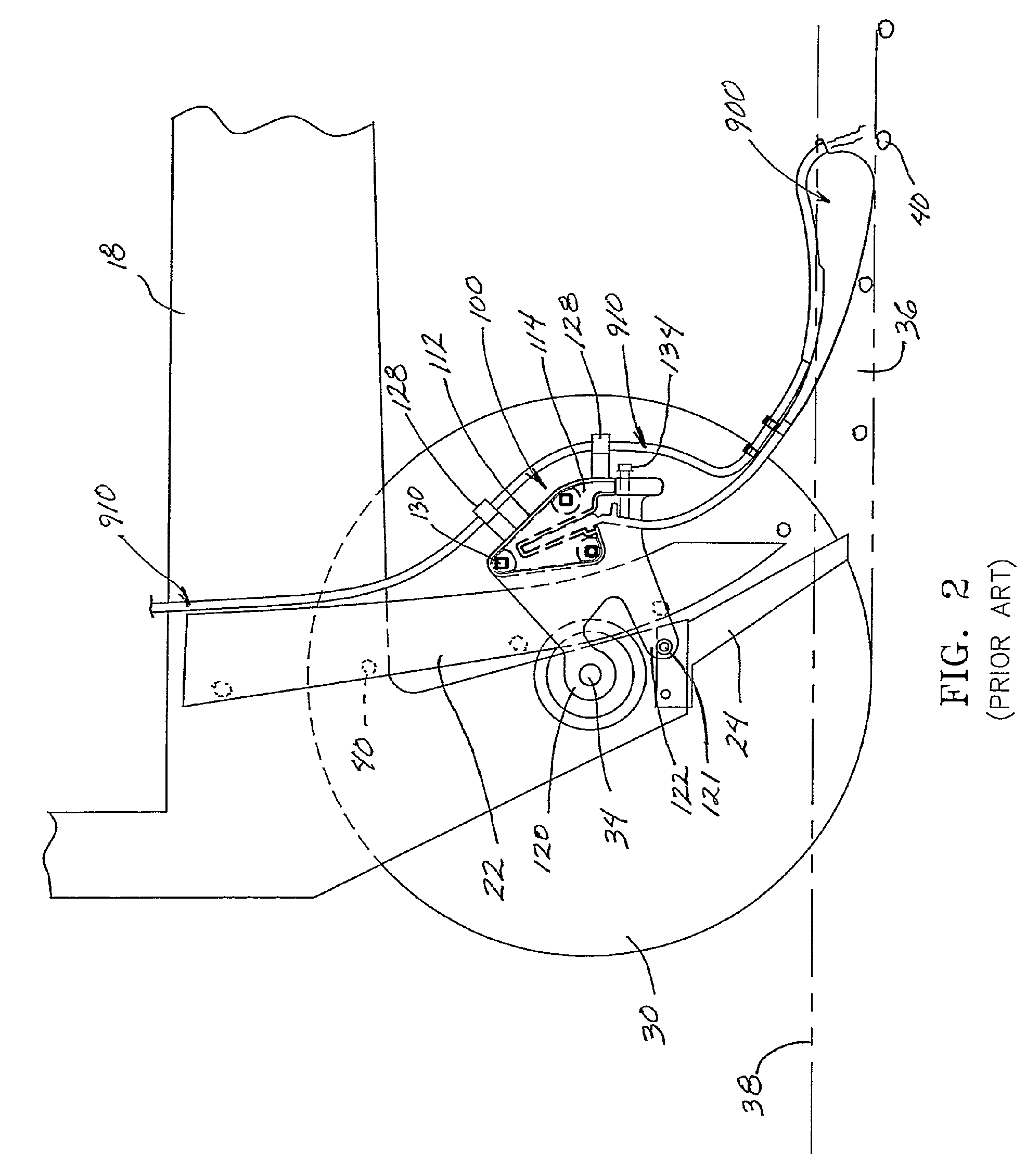

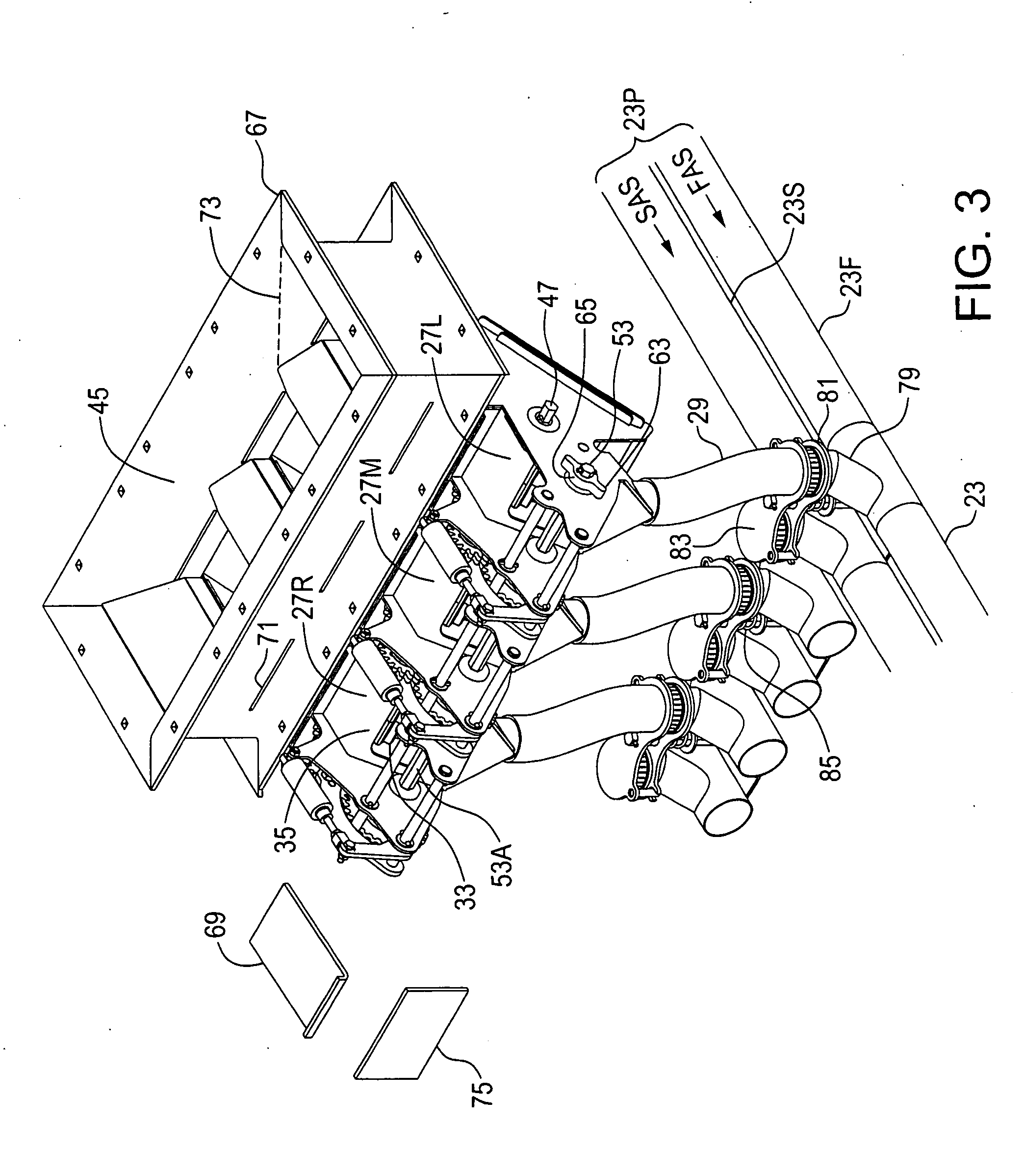

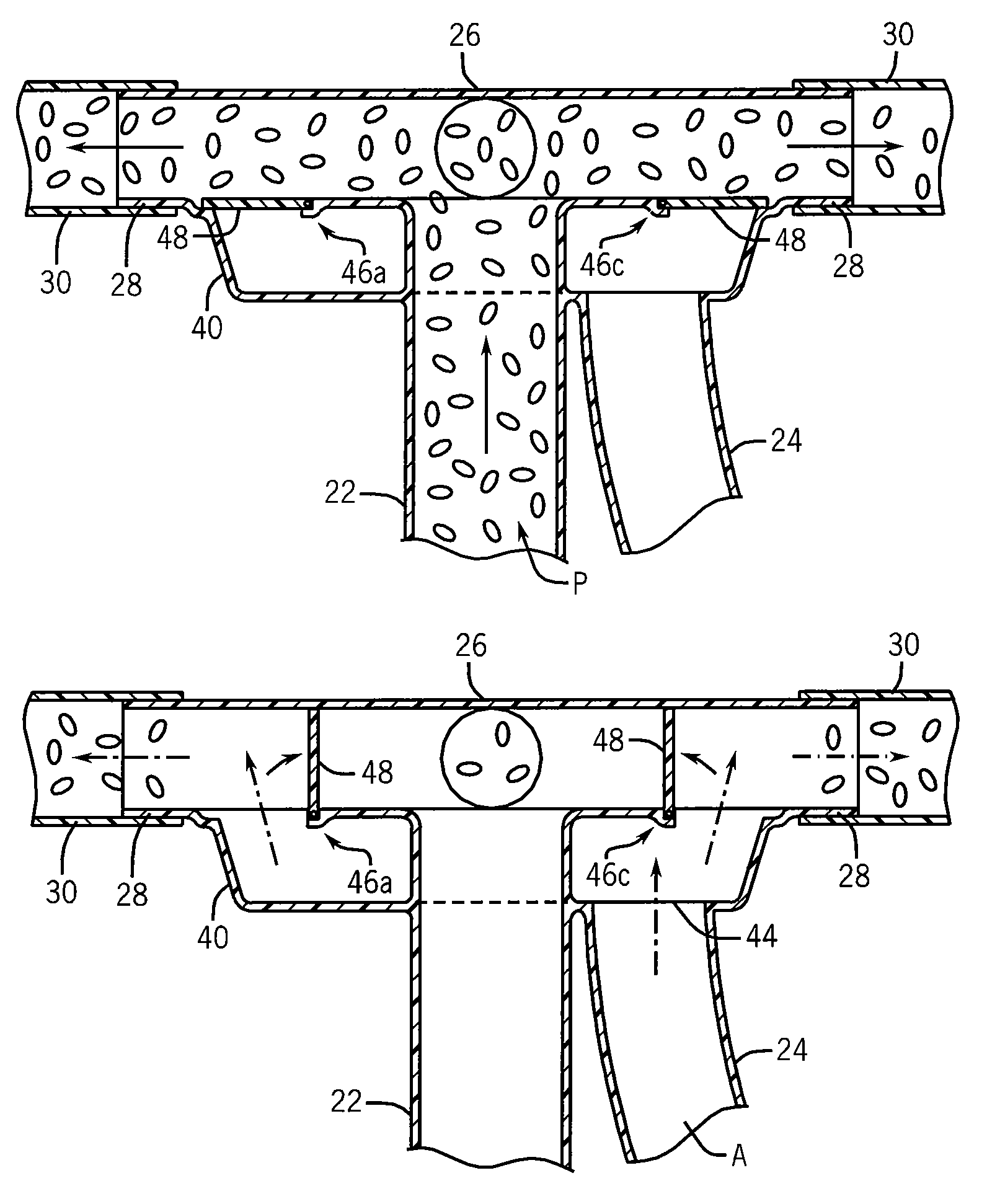

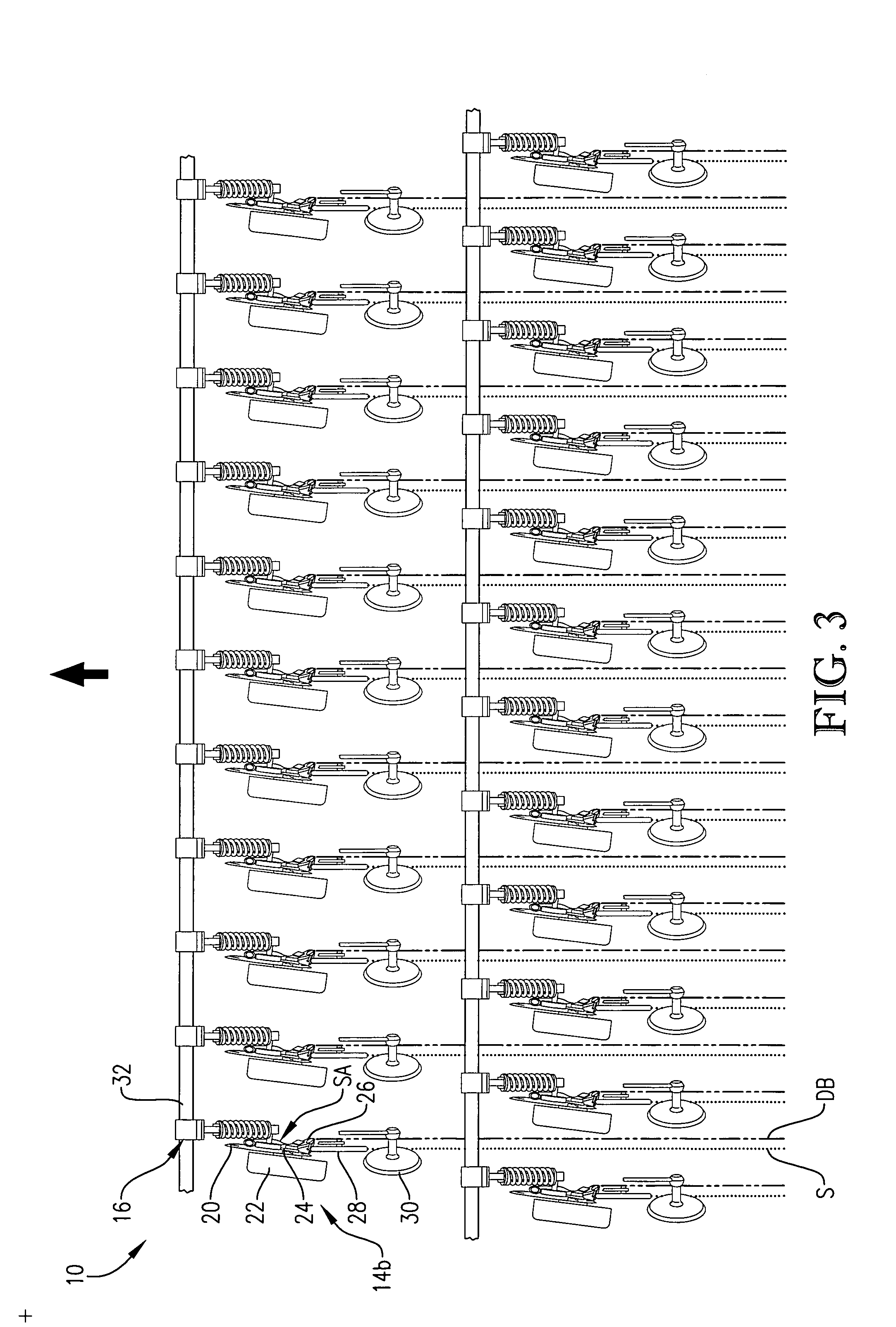

Fertilizer injector wing for disc openers

InactiveUS7004090B2High speed useReduce distractionsTill seedingDirect liquid fertiliser deliverySeederAgricultural engineering

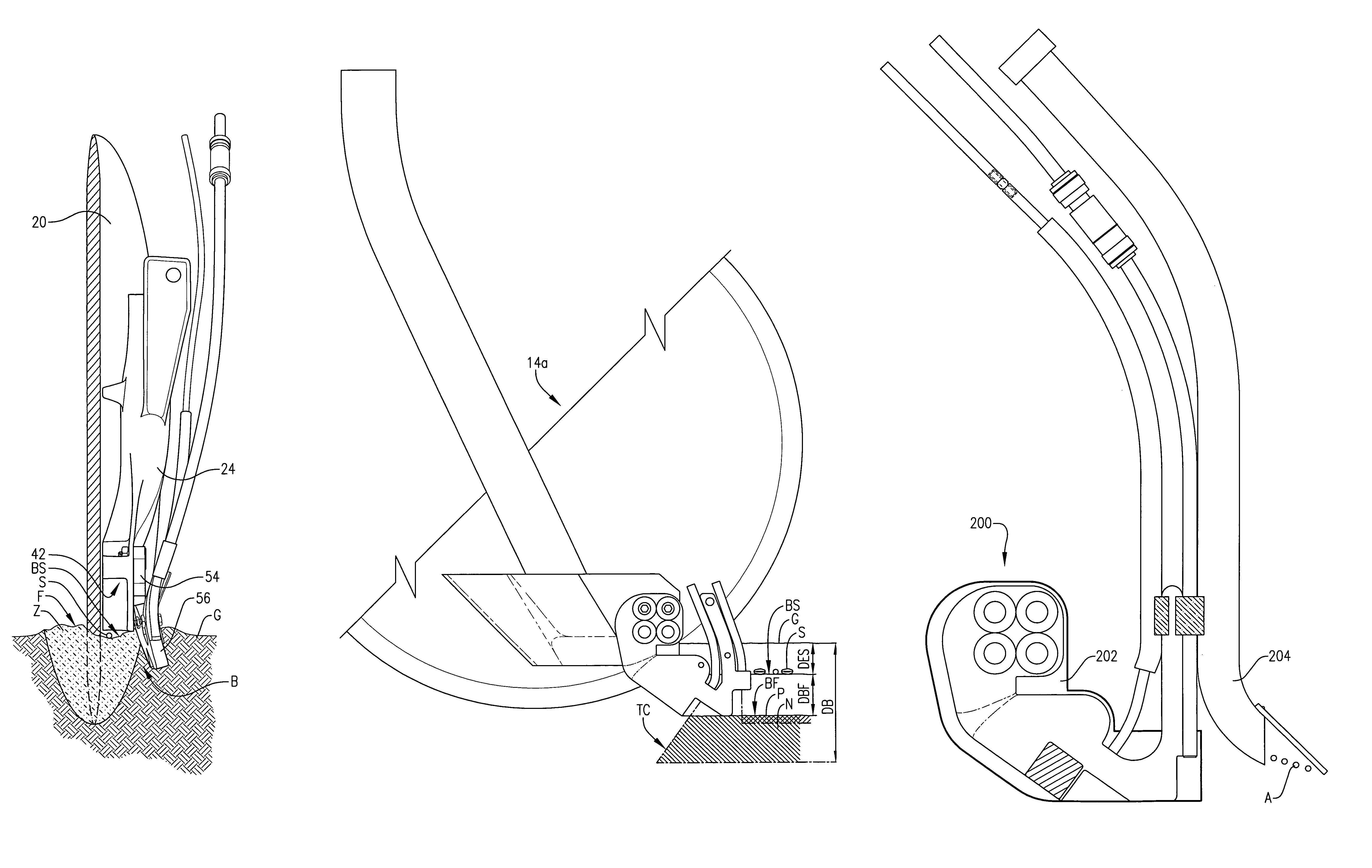

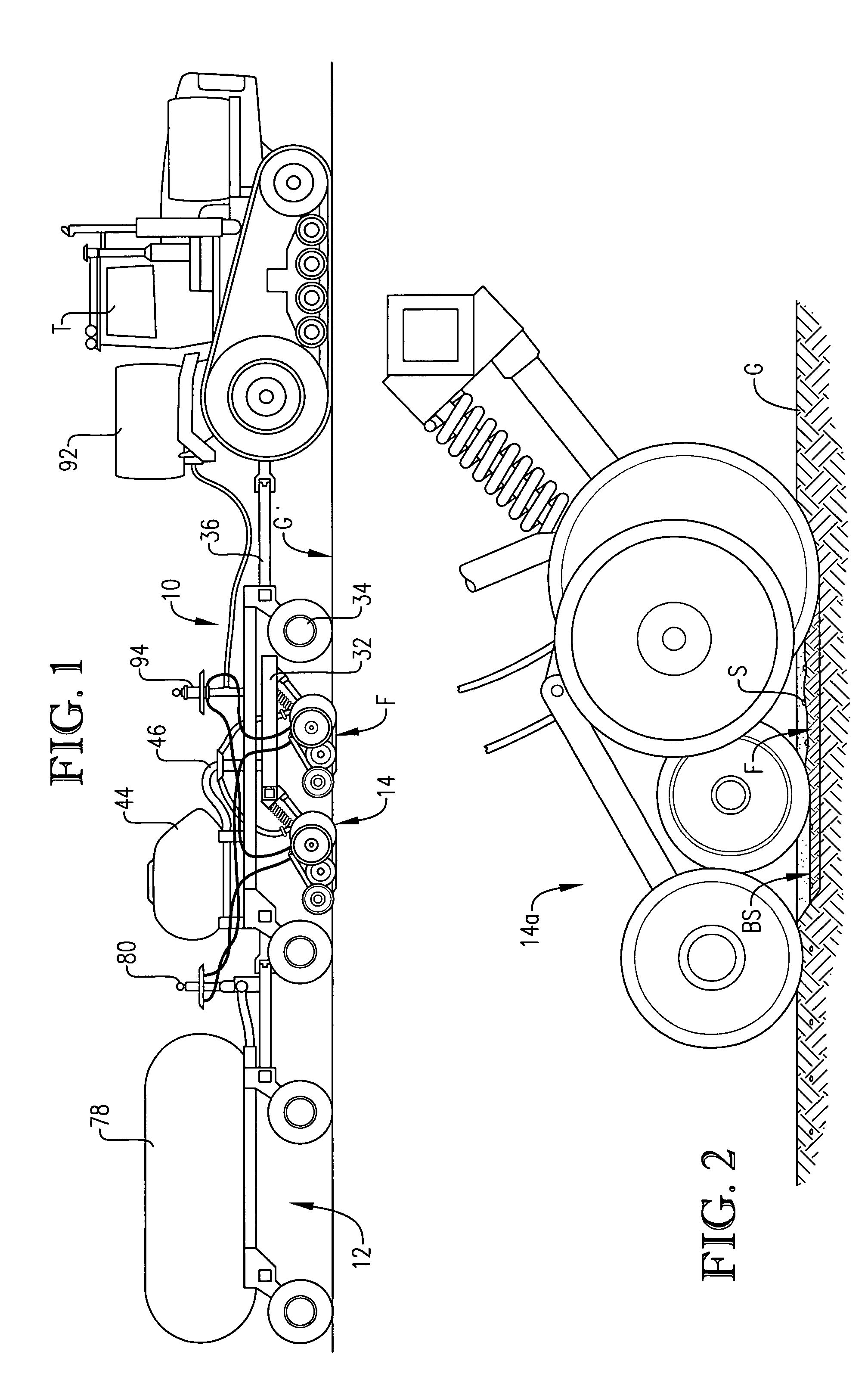

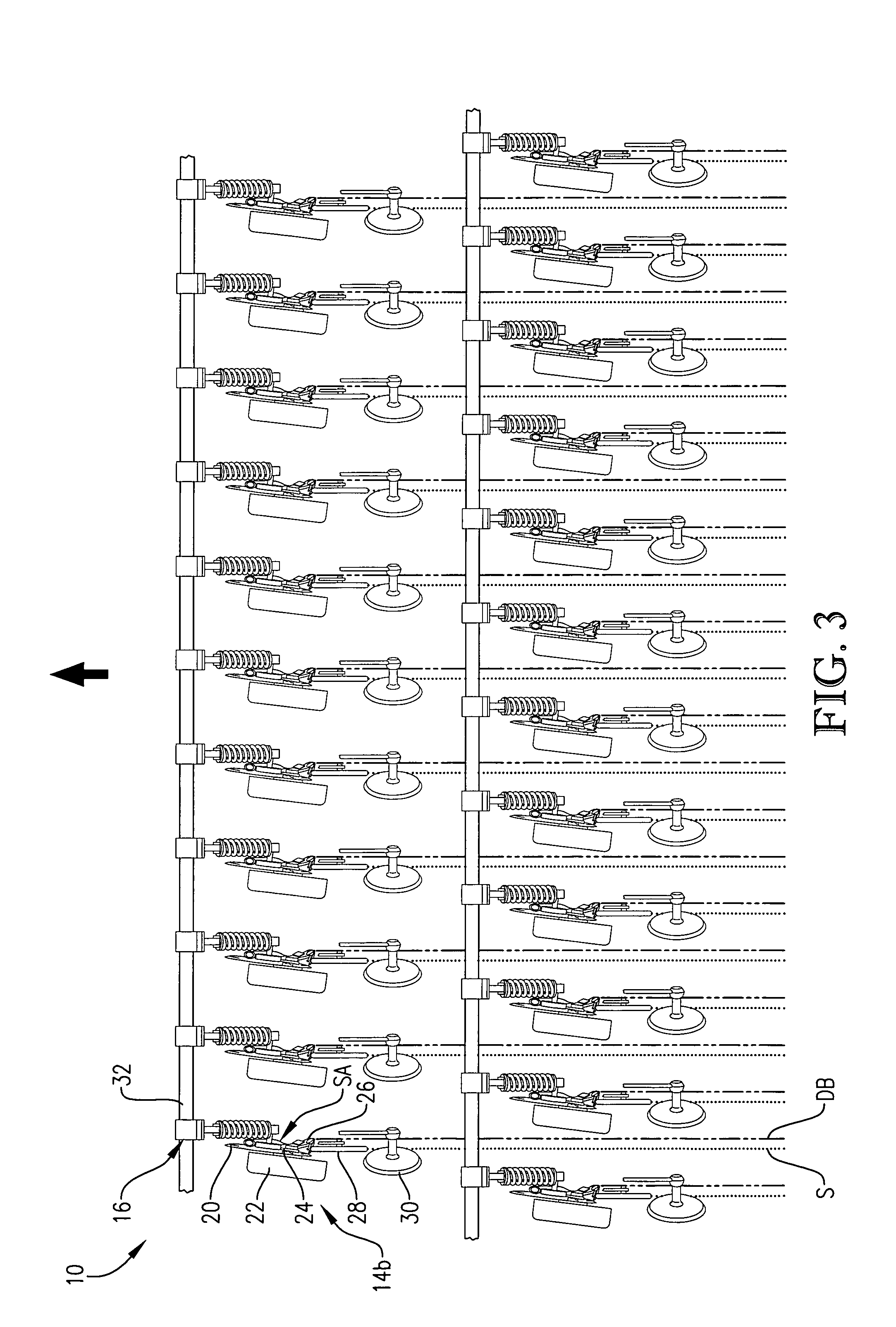

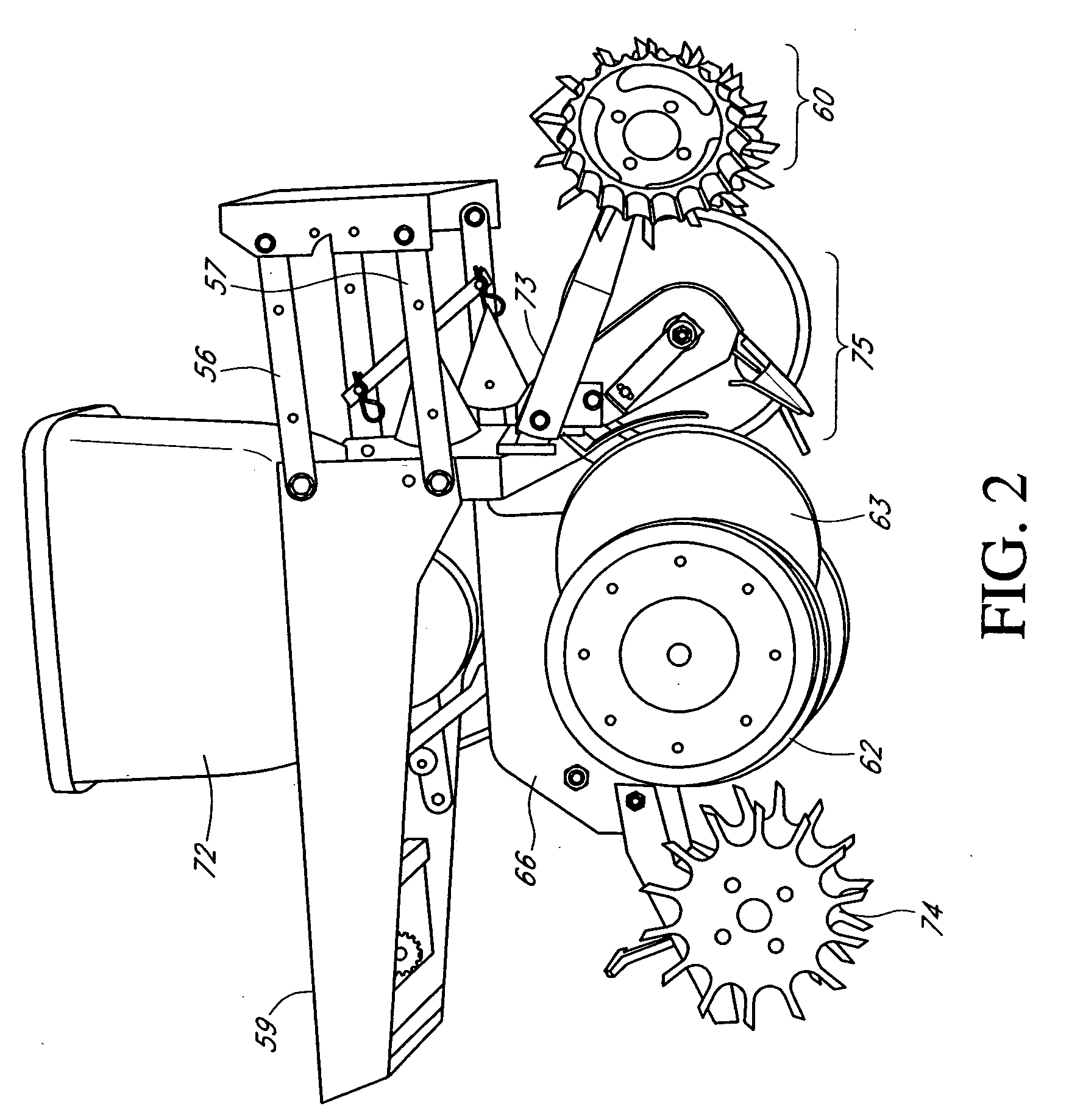

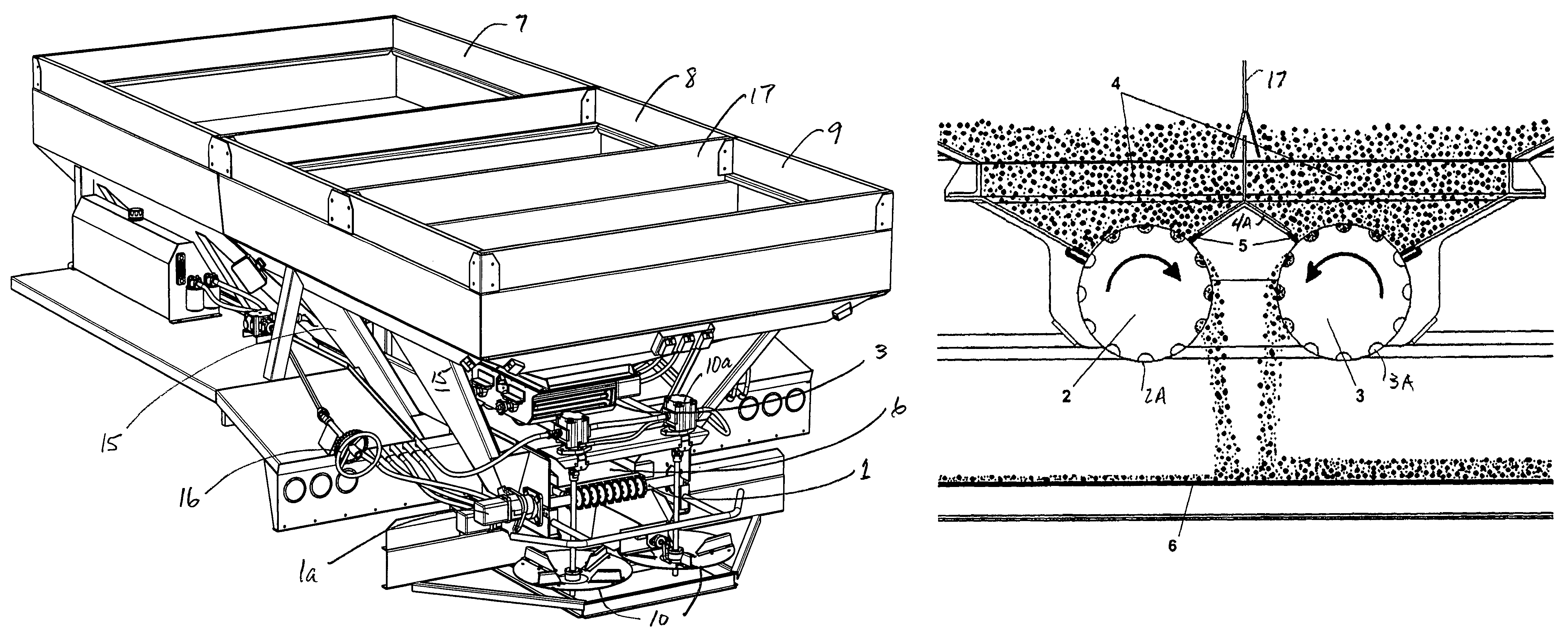

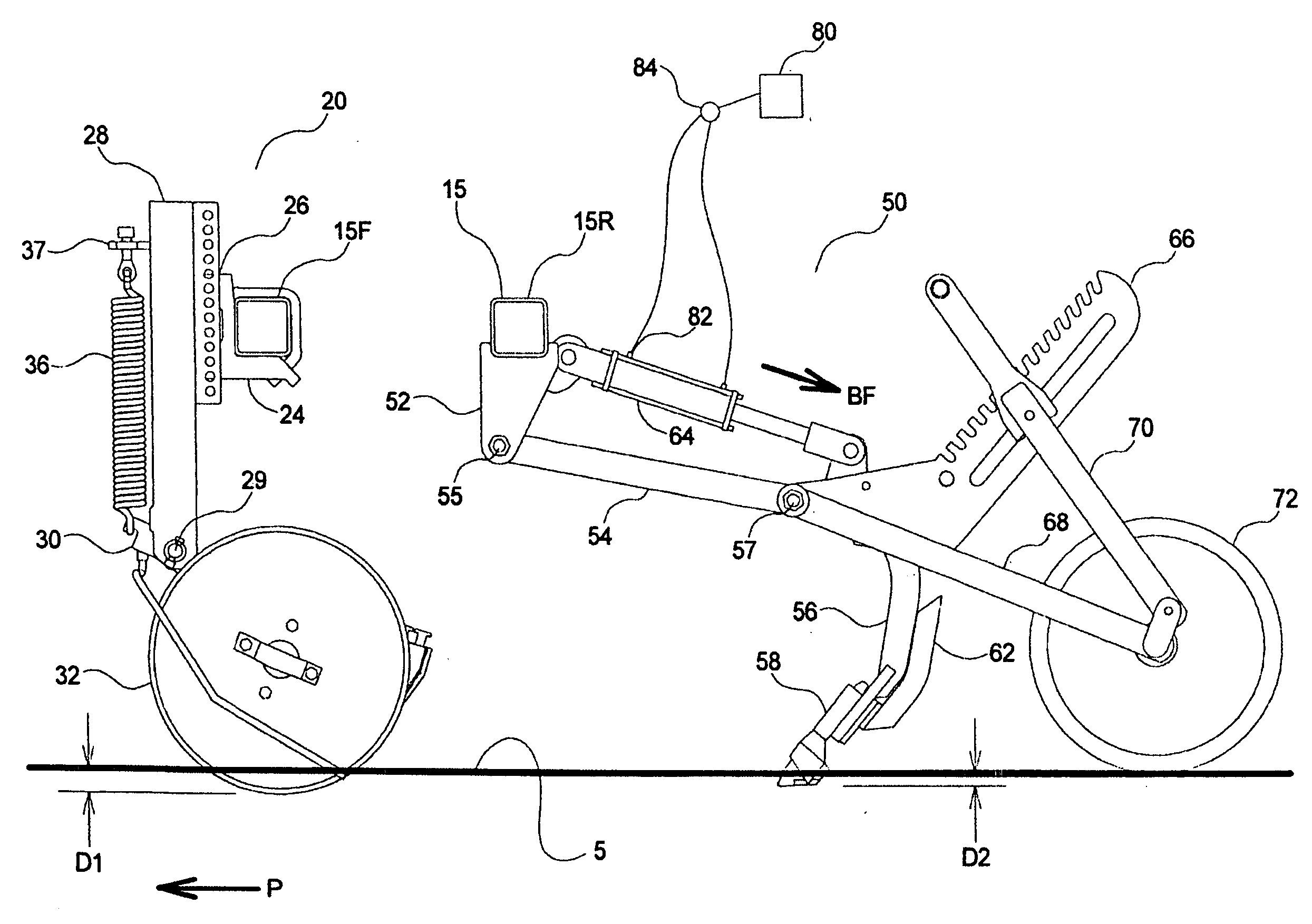

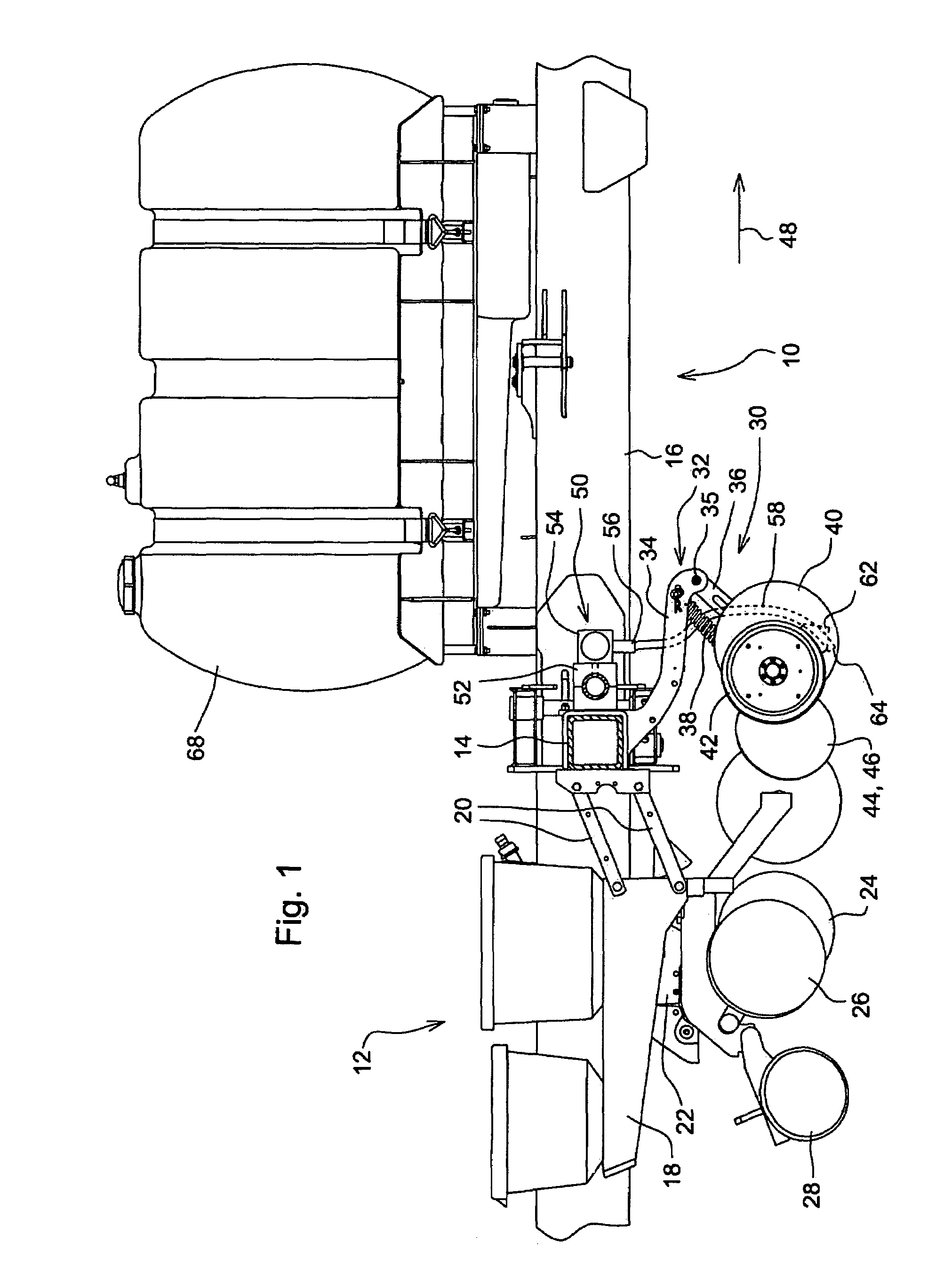

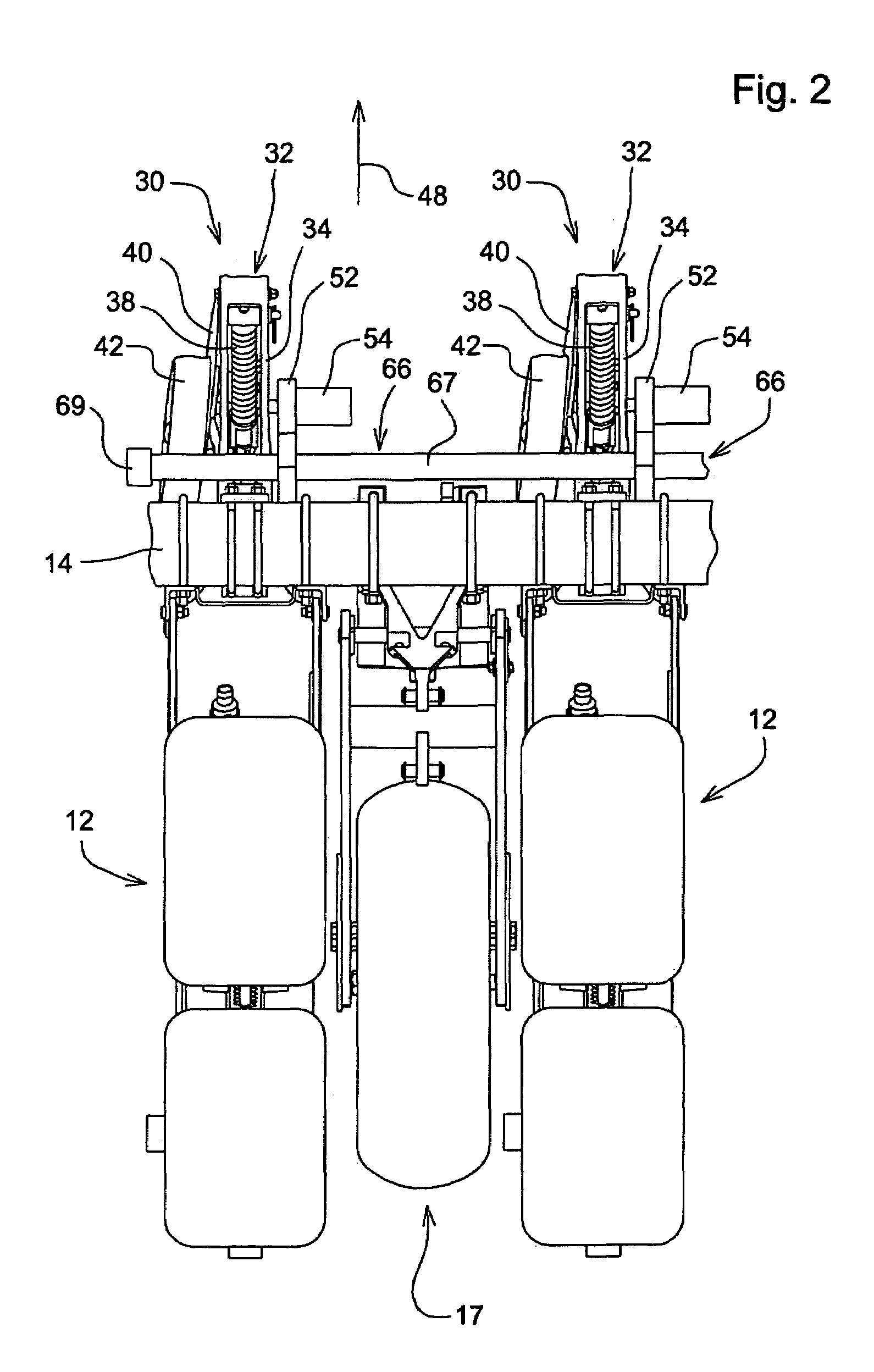

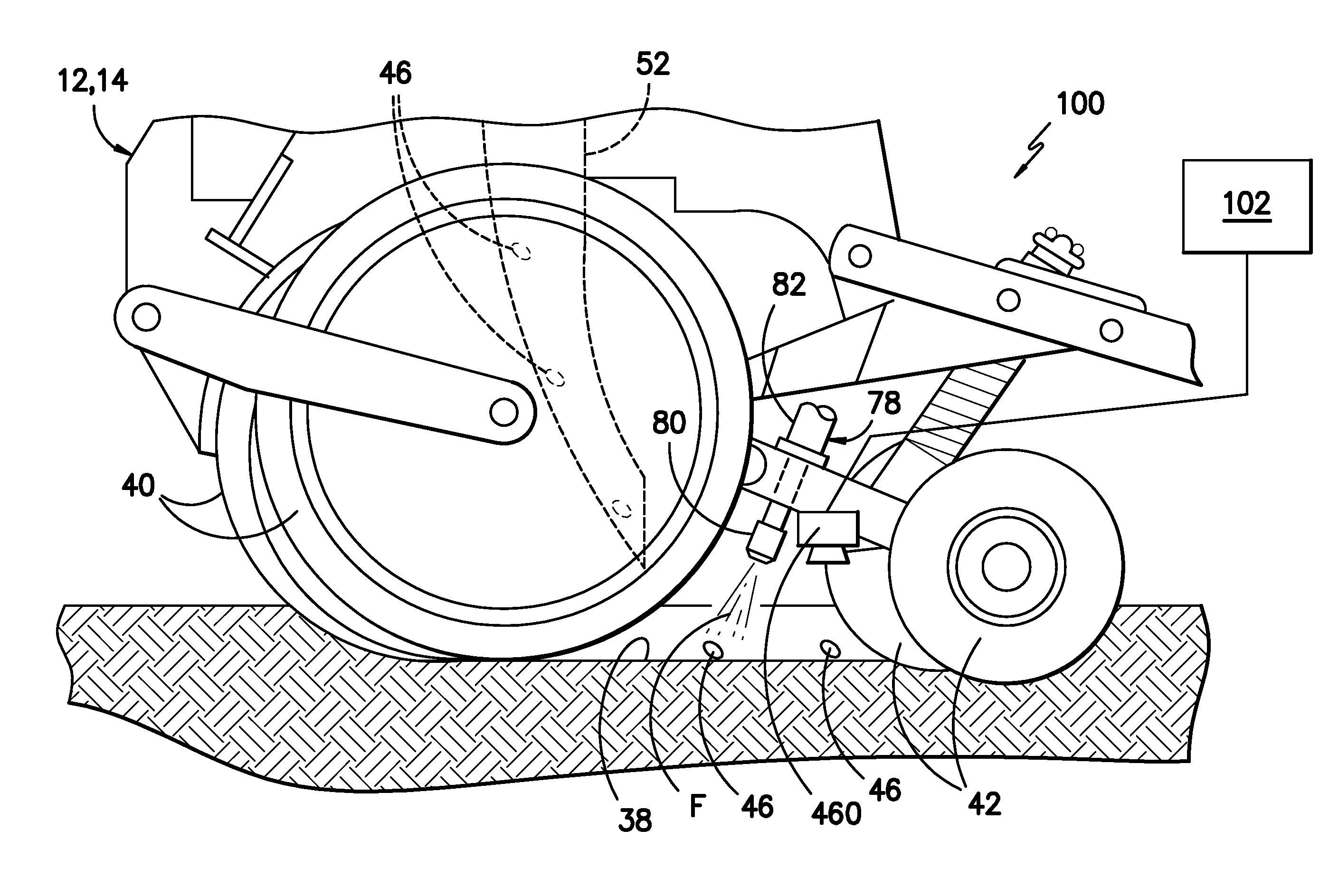

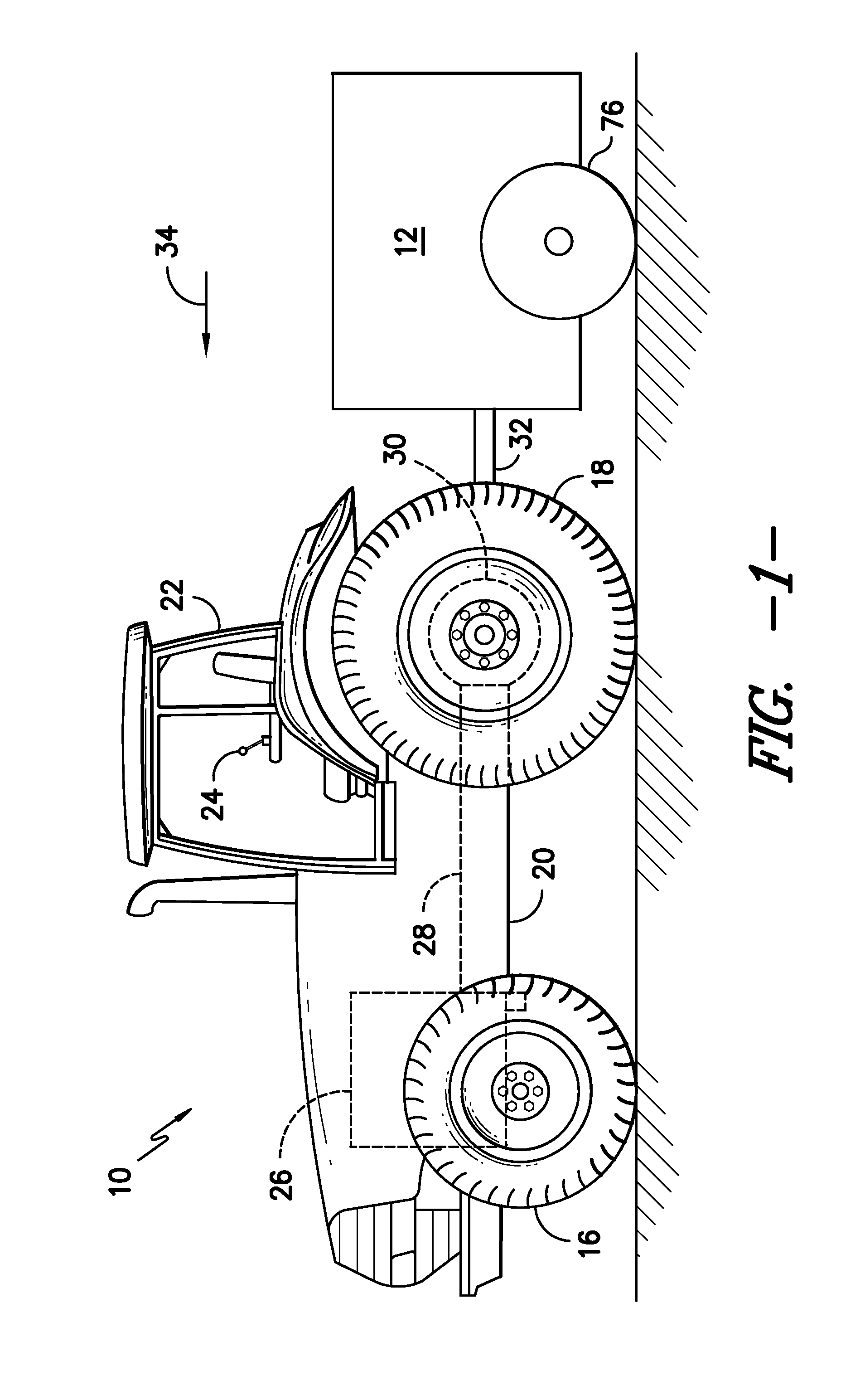

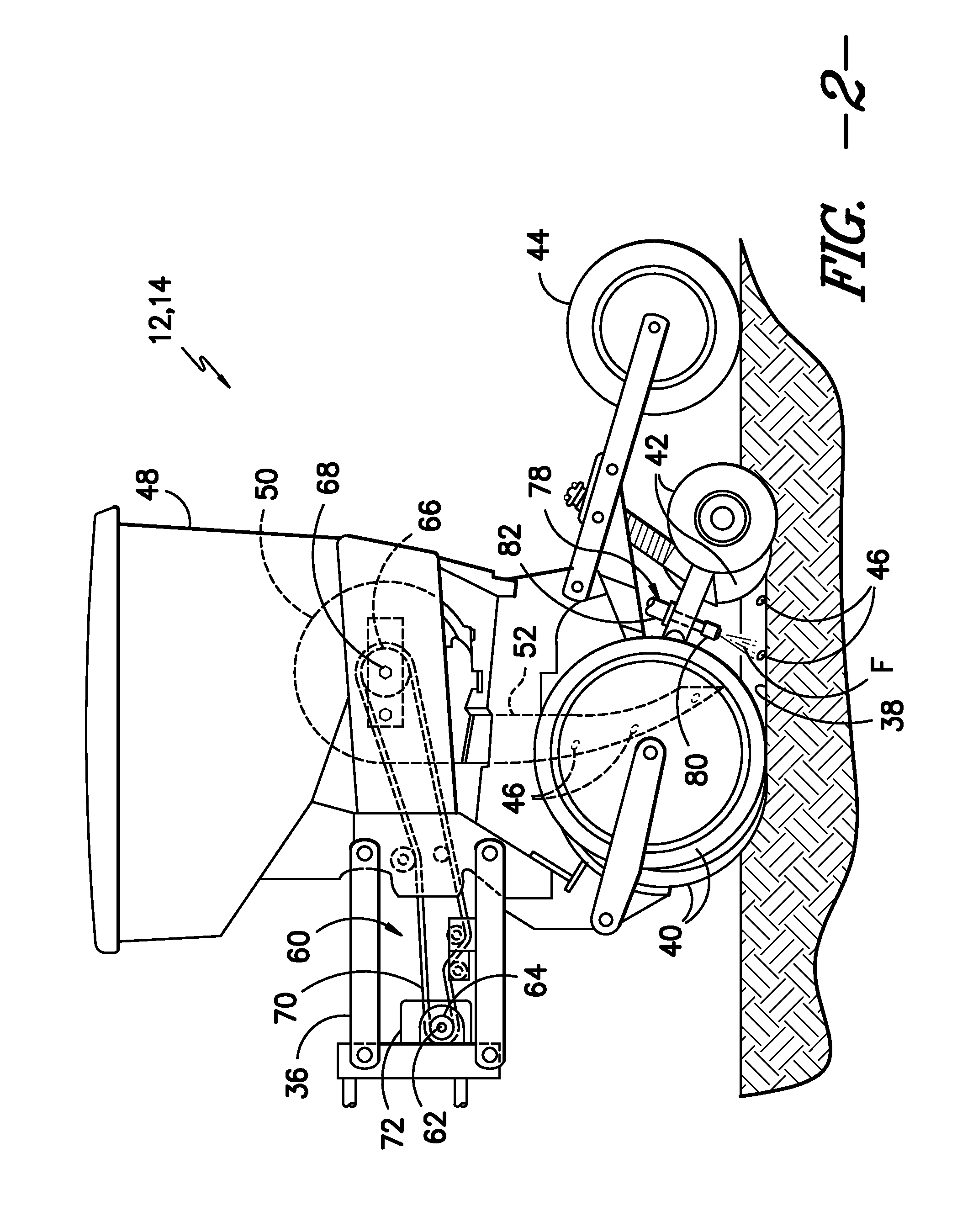

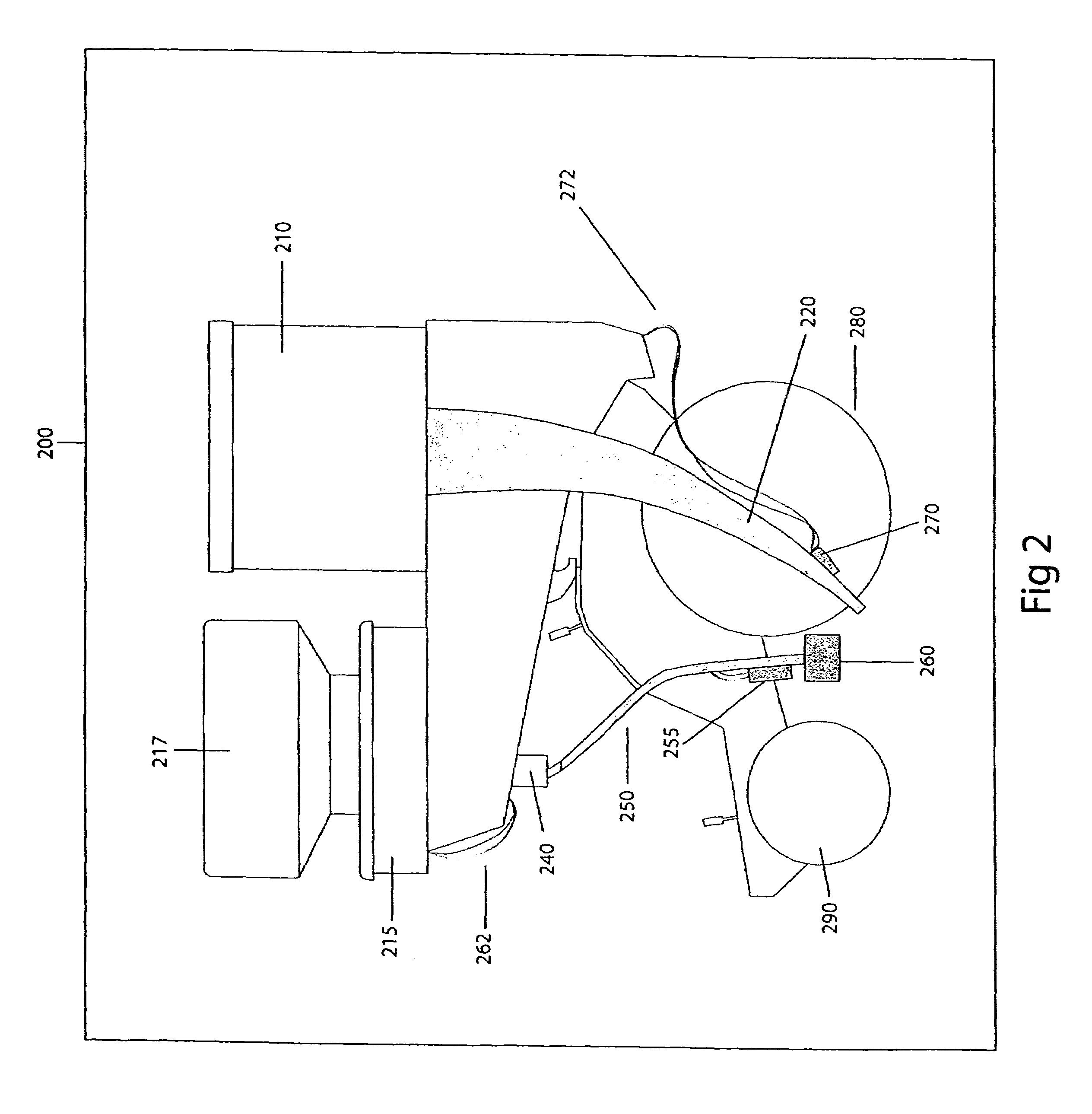

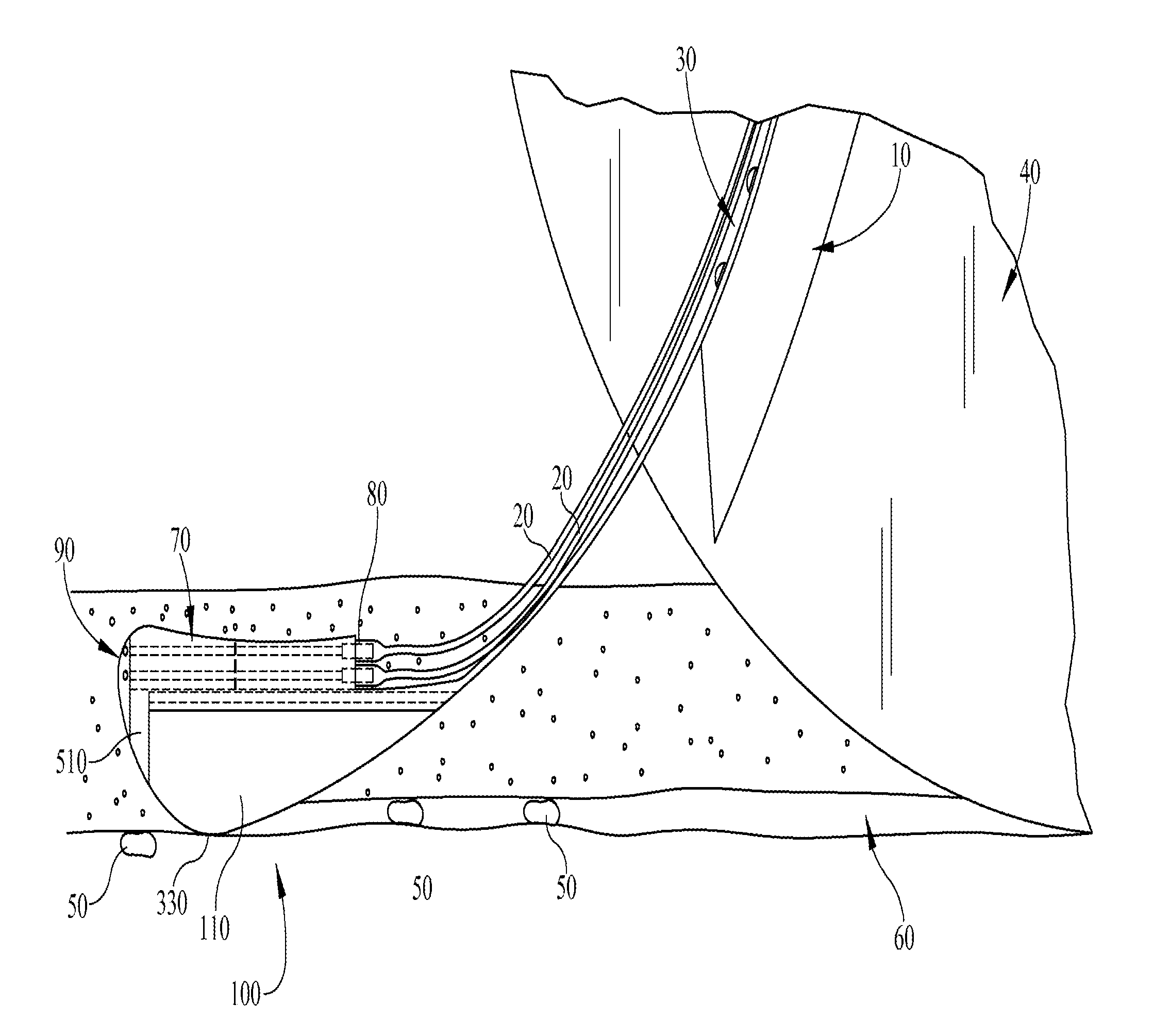

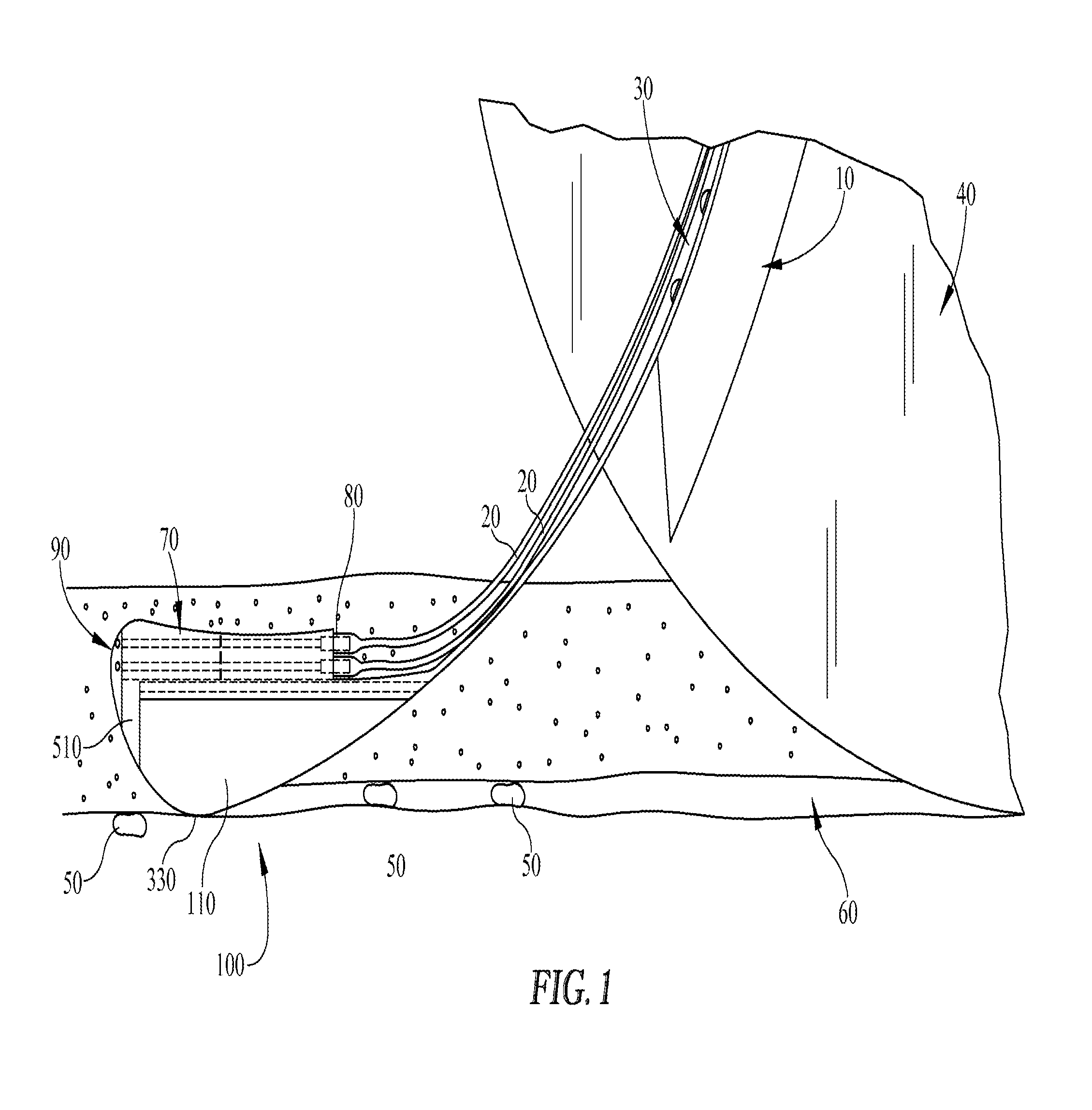

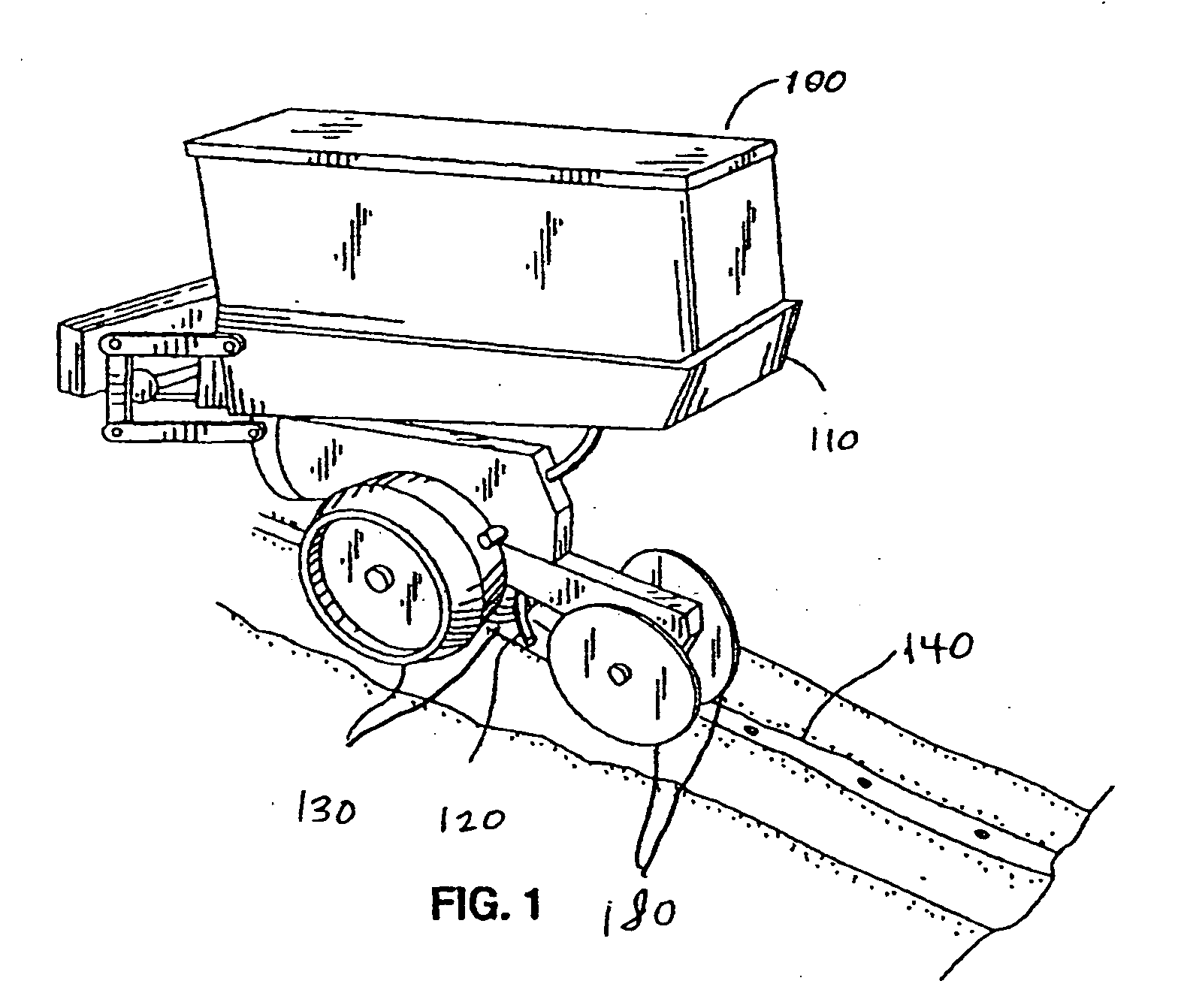

Disc openers (14) for use with an air seeder (10), are configured for seeding and fertilizing a field (G). The opener (14b) broadly includes a drawbar assembly (16), a disc assembly (18) including a coulter disc (20) and a gauge wheel (22), a seed boot (24), a fertilizer injector wing (26), a firming wheel assembly (28), and a closing wheel assembly (30). The fertilizer injector wing (26) is configured for fixed attachment to the seed boot (24) and broadly includes a body (48), including an angled outboard portion (56), a toxic fertilizer injector (50), and a non-toxic fertilizer injector (52). The opener (14b) with the fertilizer injector wing (26) is configured to place the seed row (S) and the dedicated fertilizer band (DB) at an optimum geometric positional alignment relative to the seed row (S), in a single, low soil disturbing planting pass without disrupting the seed bed (BS).

Owner:EXACTRIX

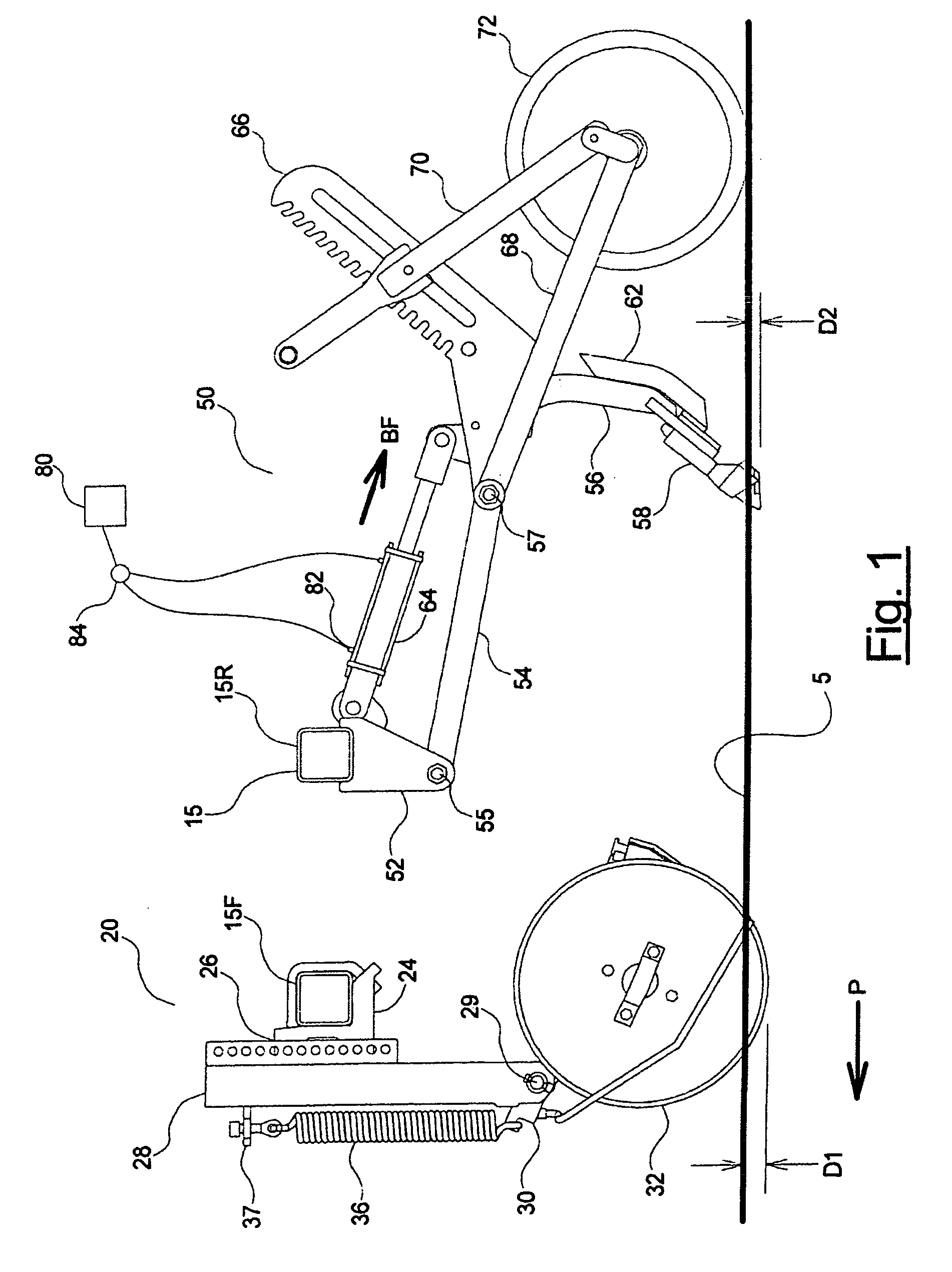

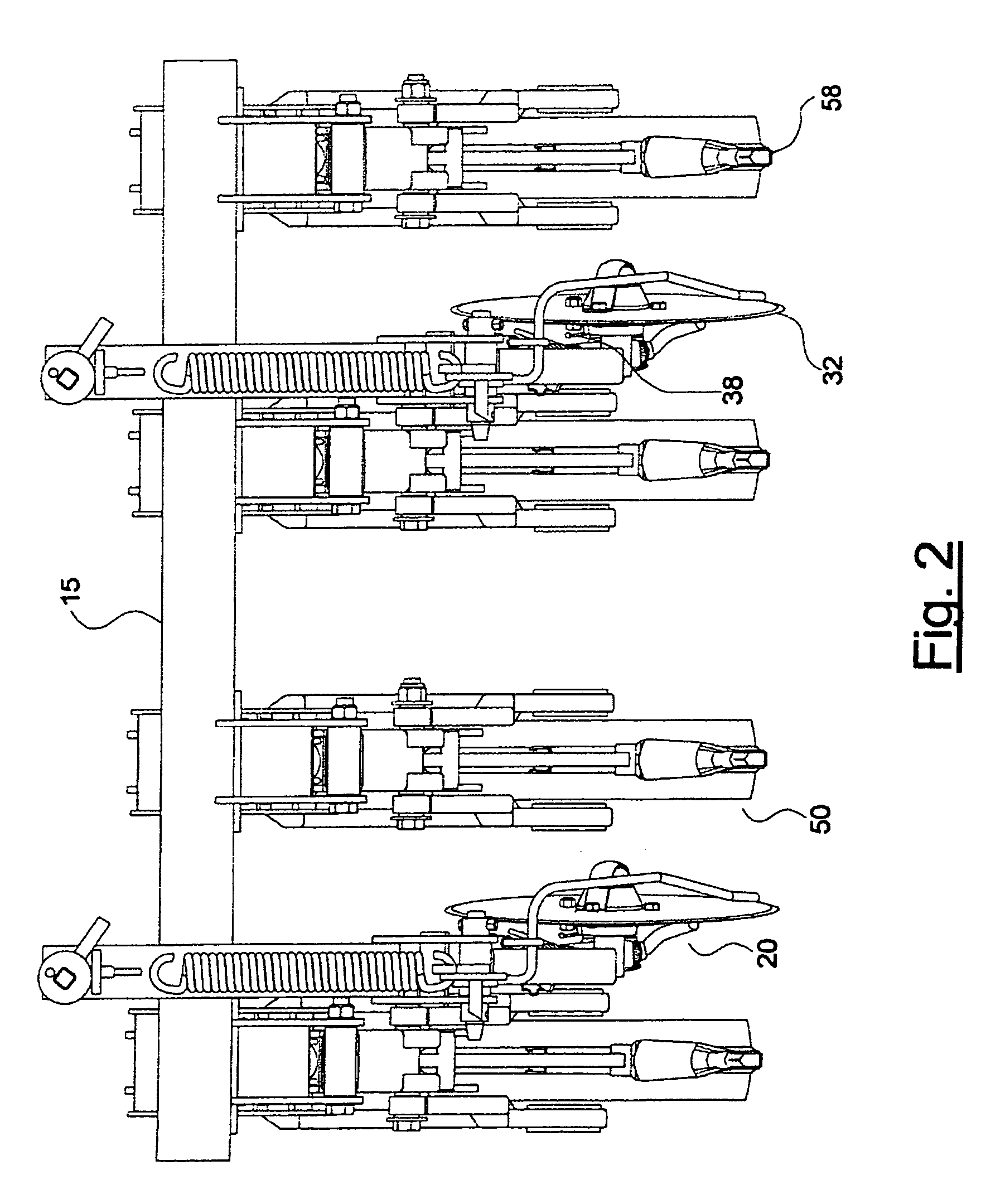

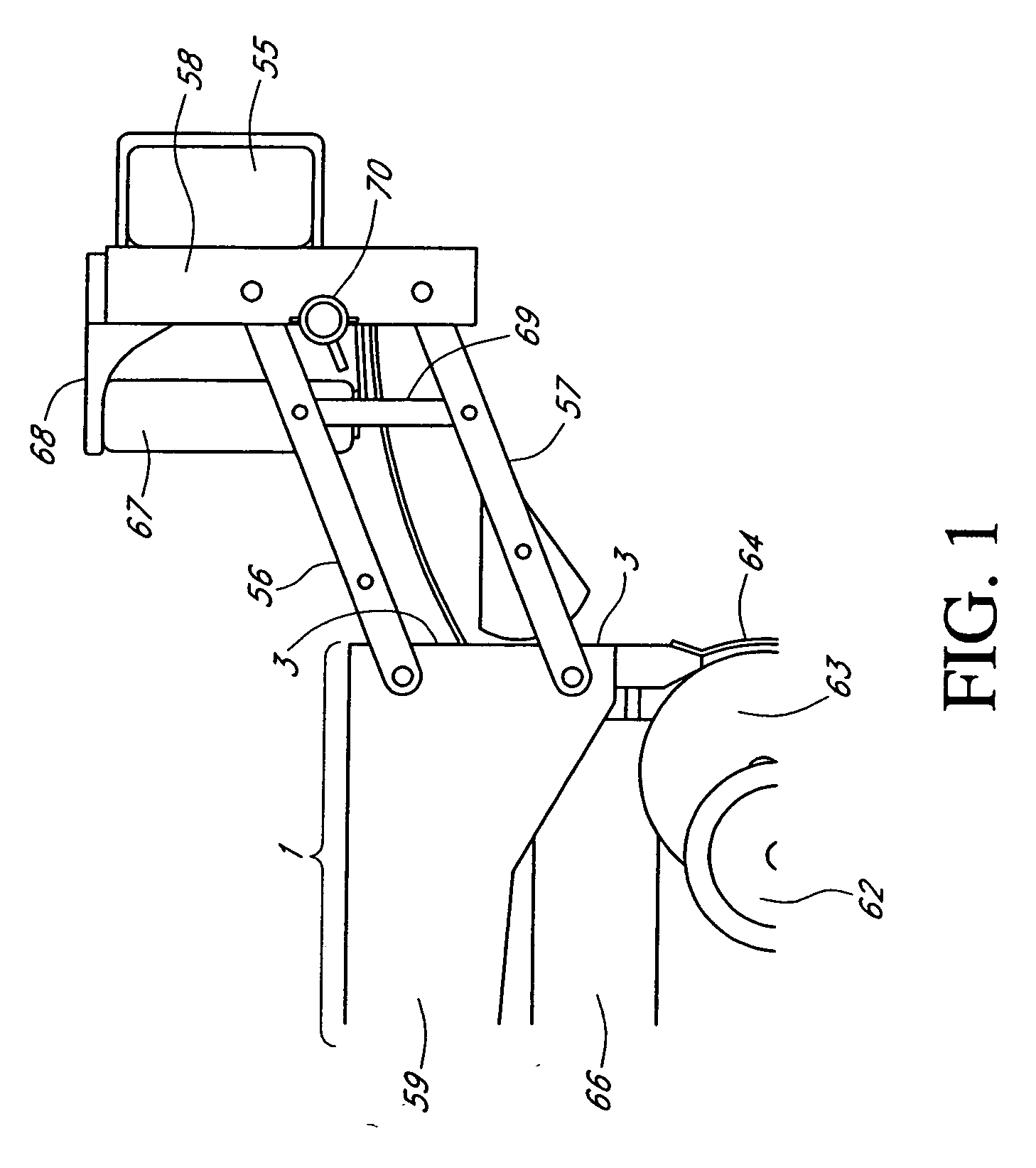

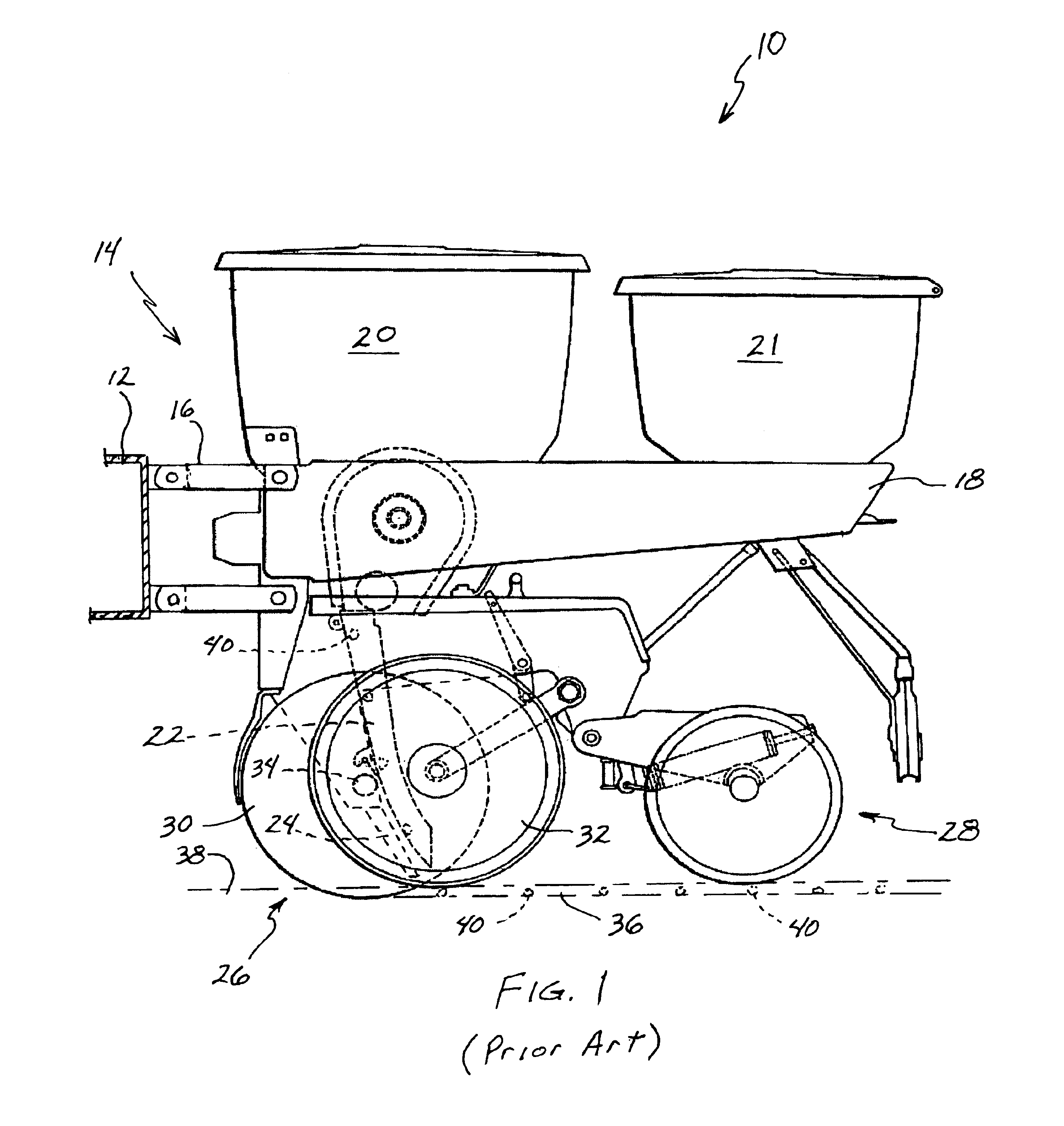

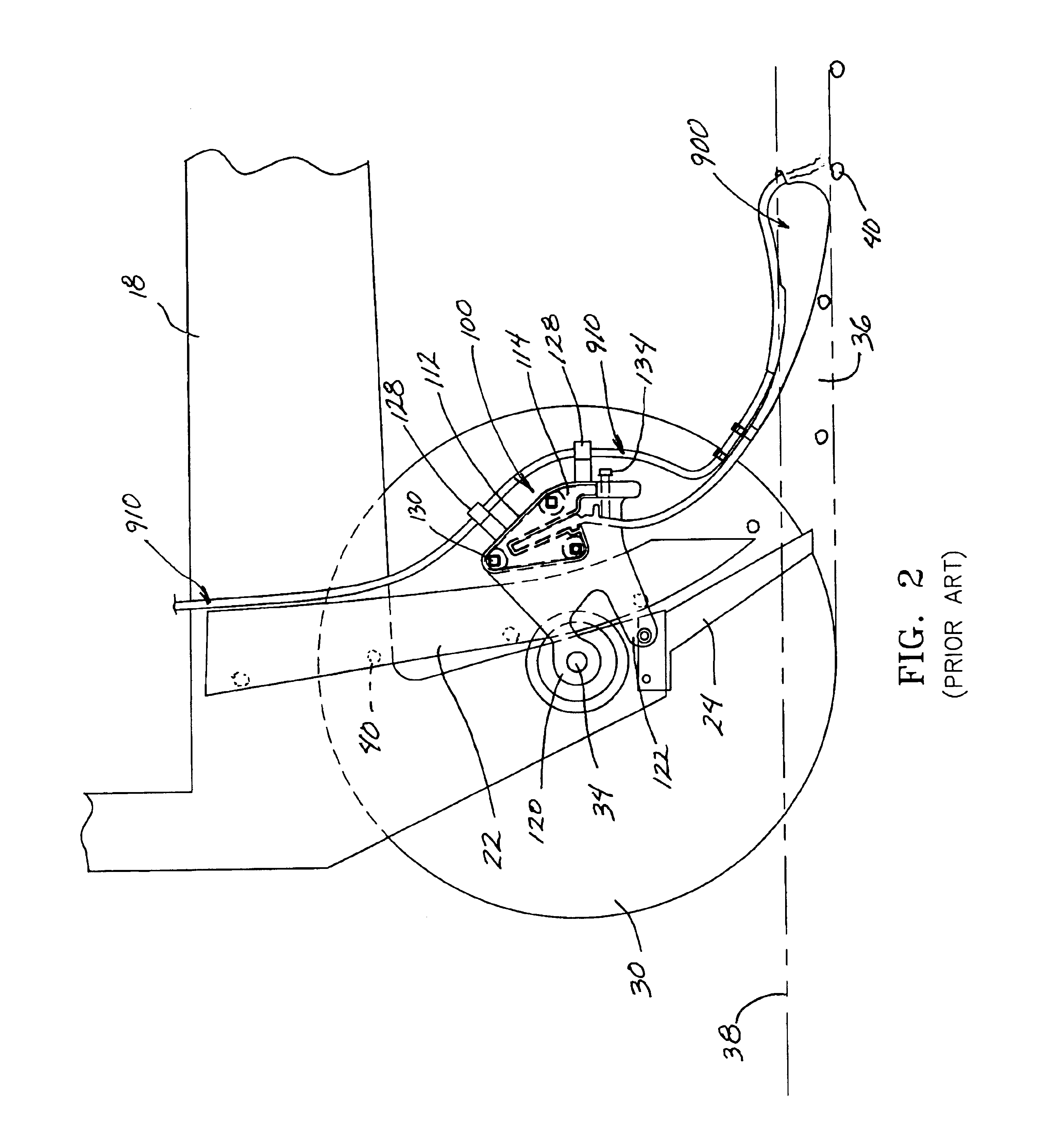

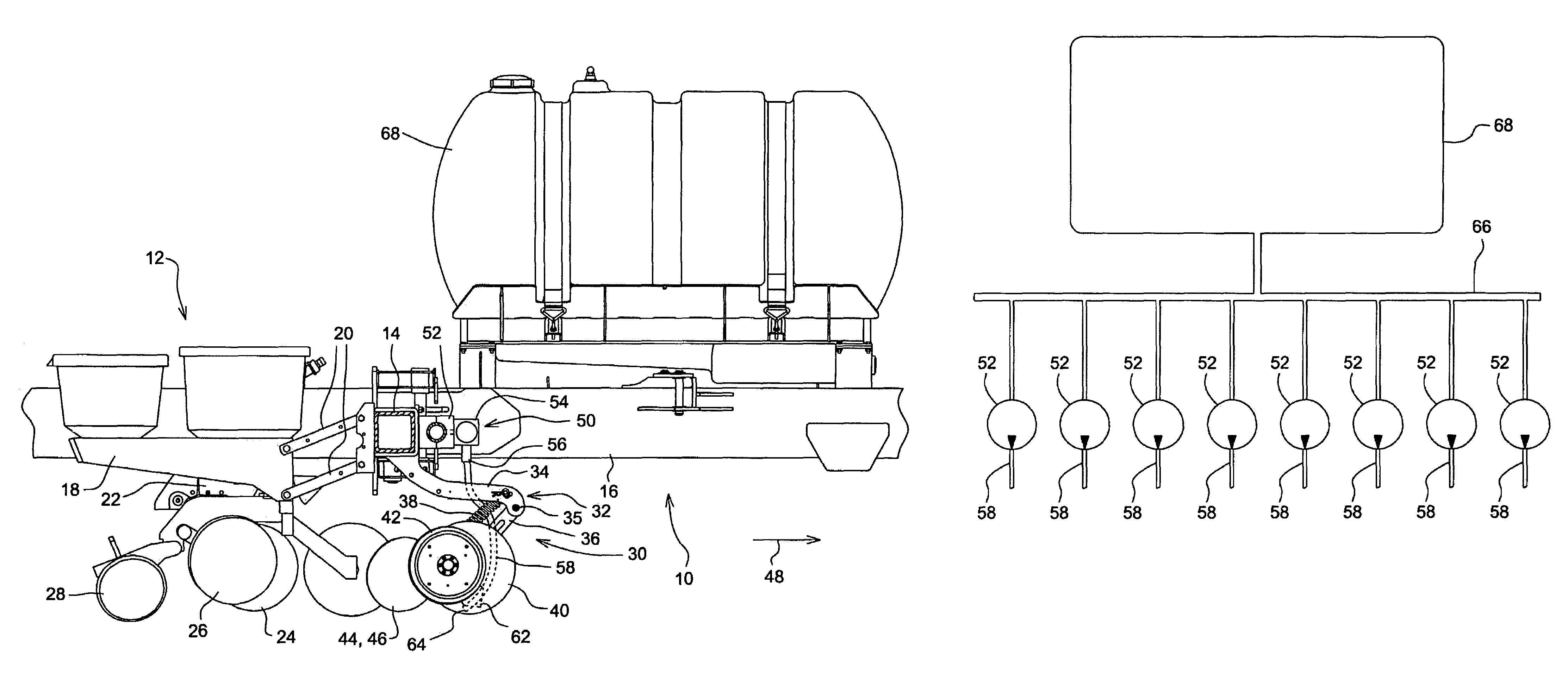

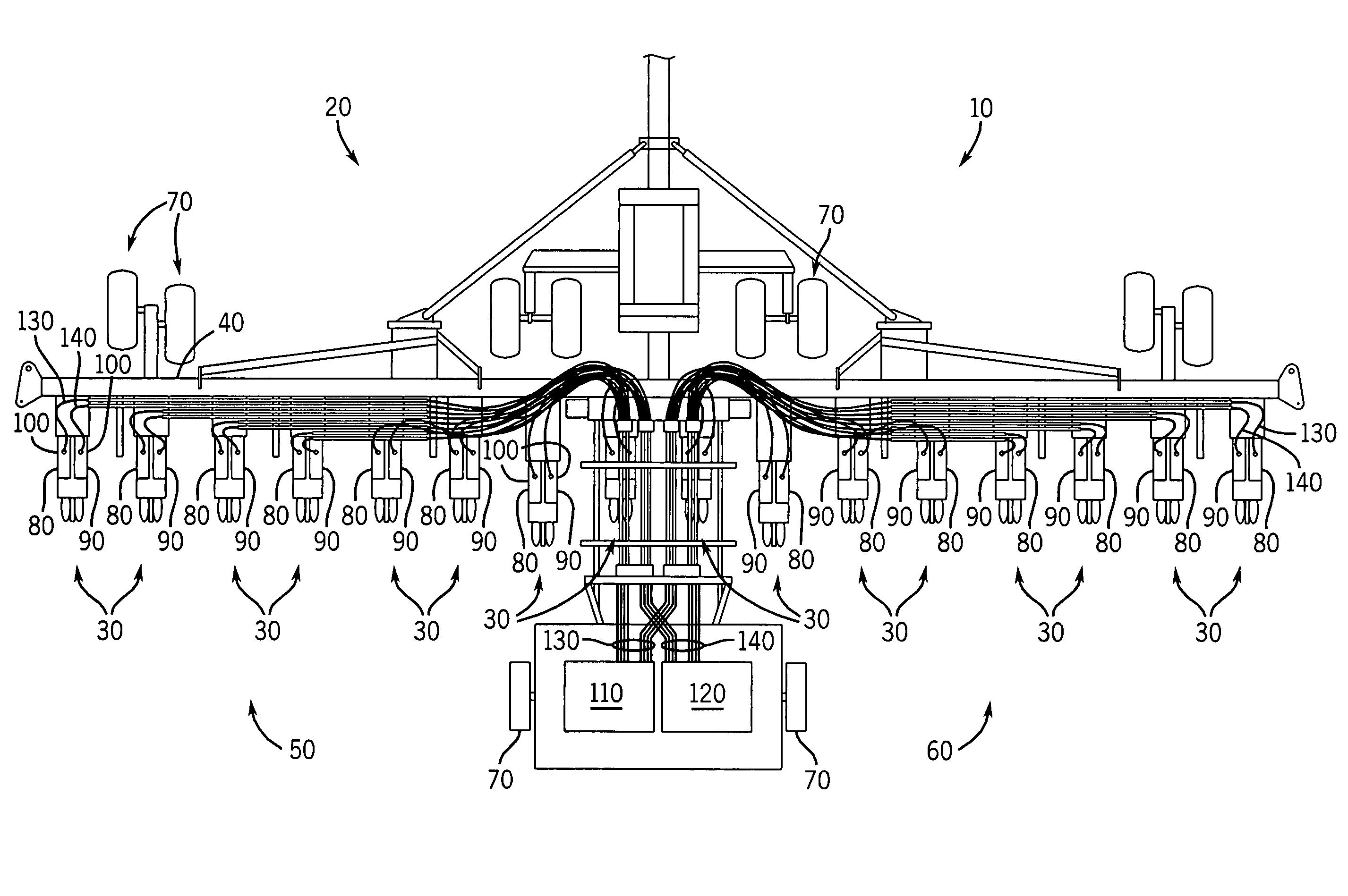

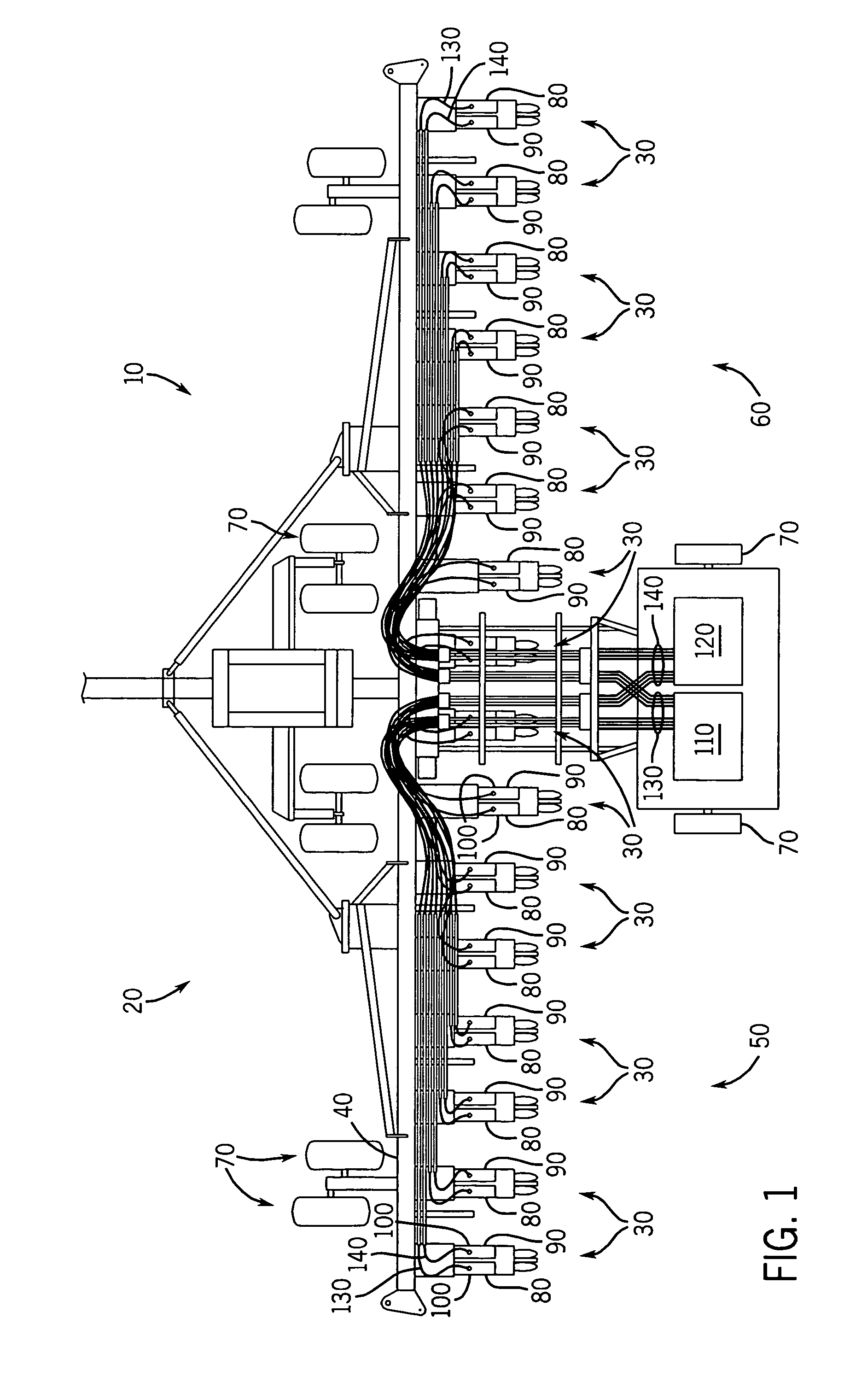

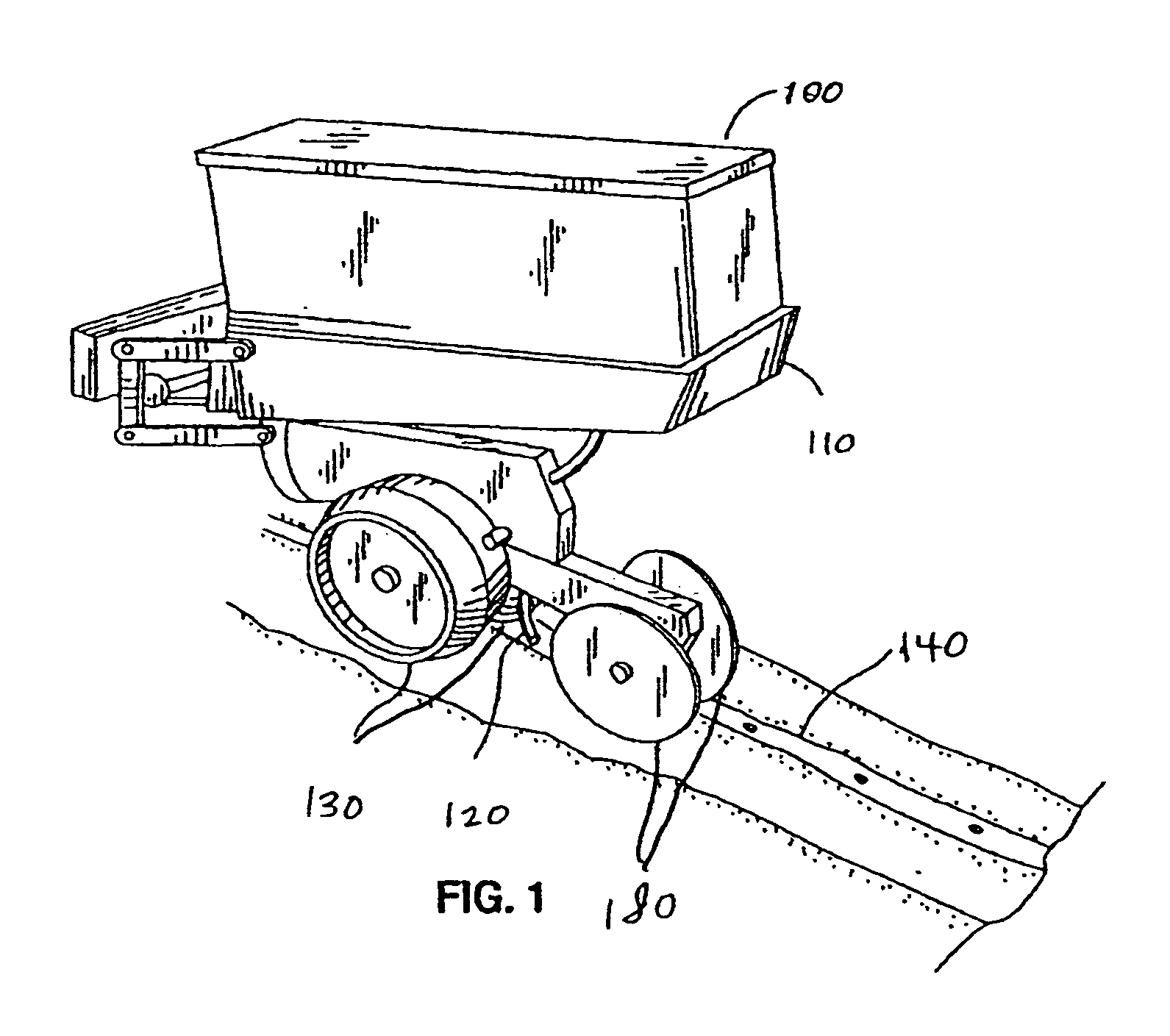

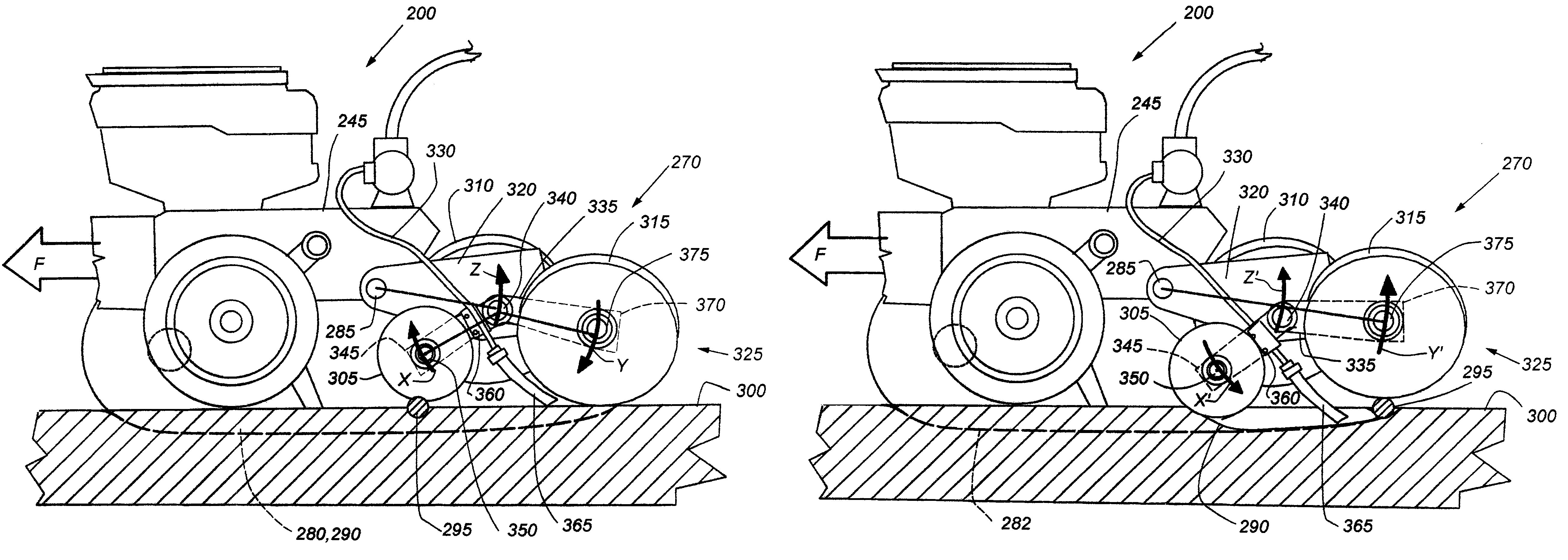

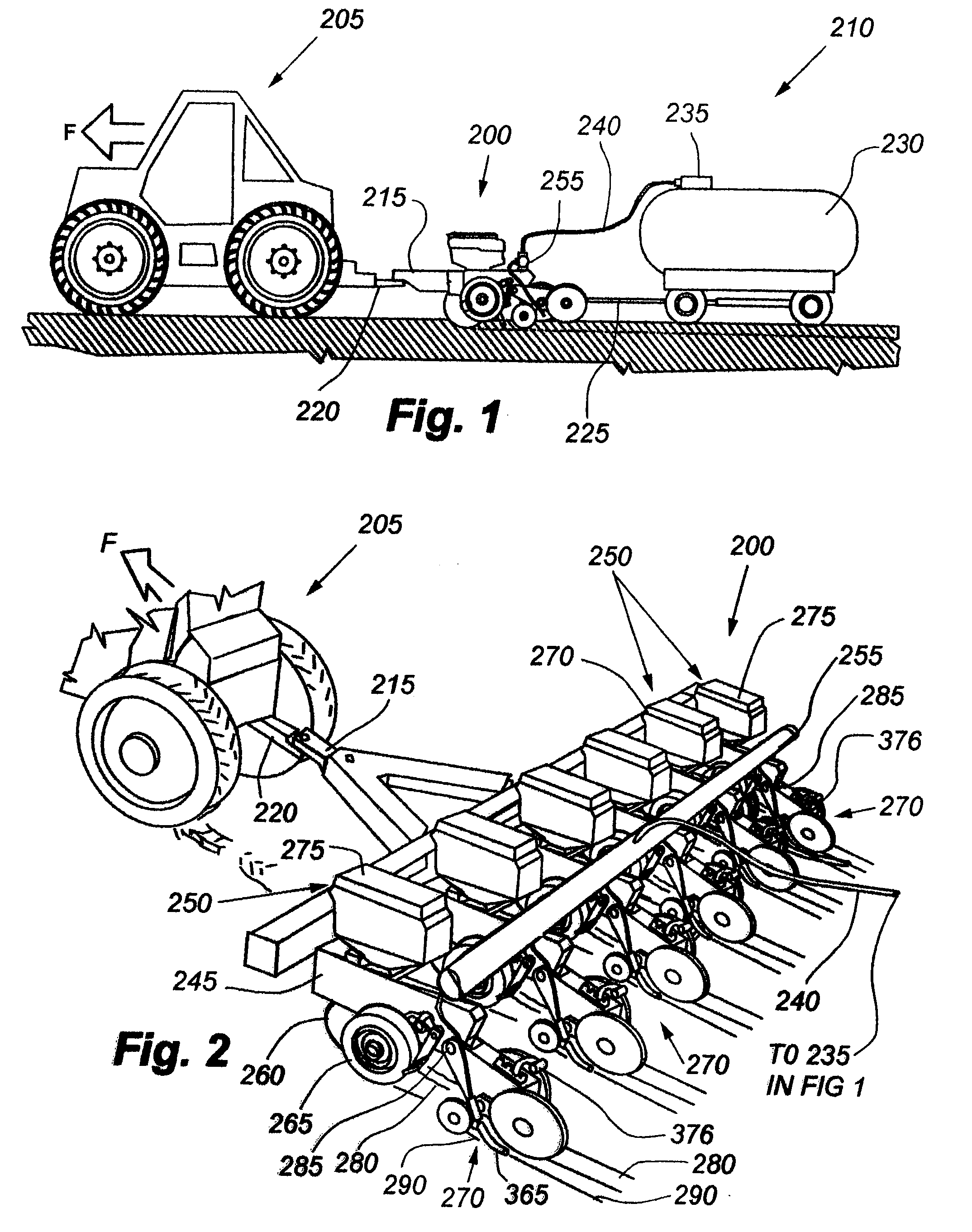

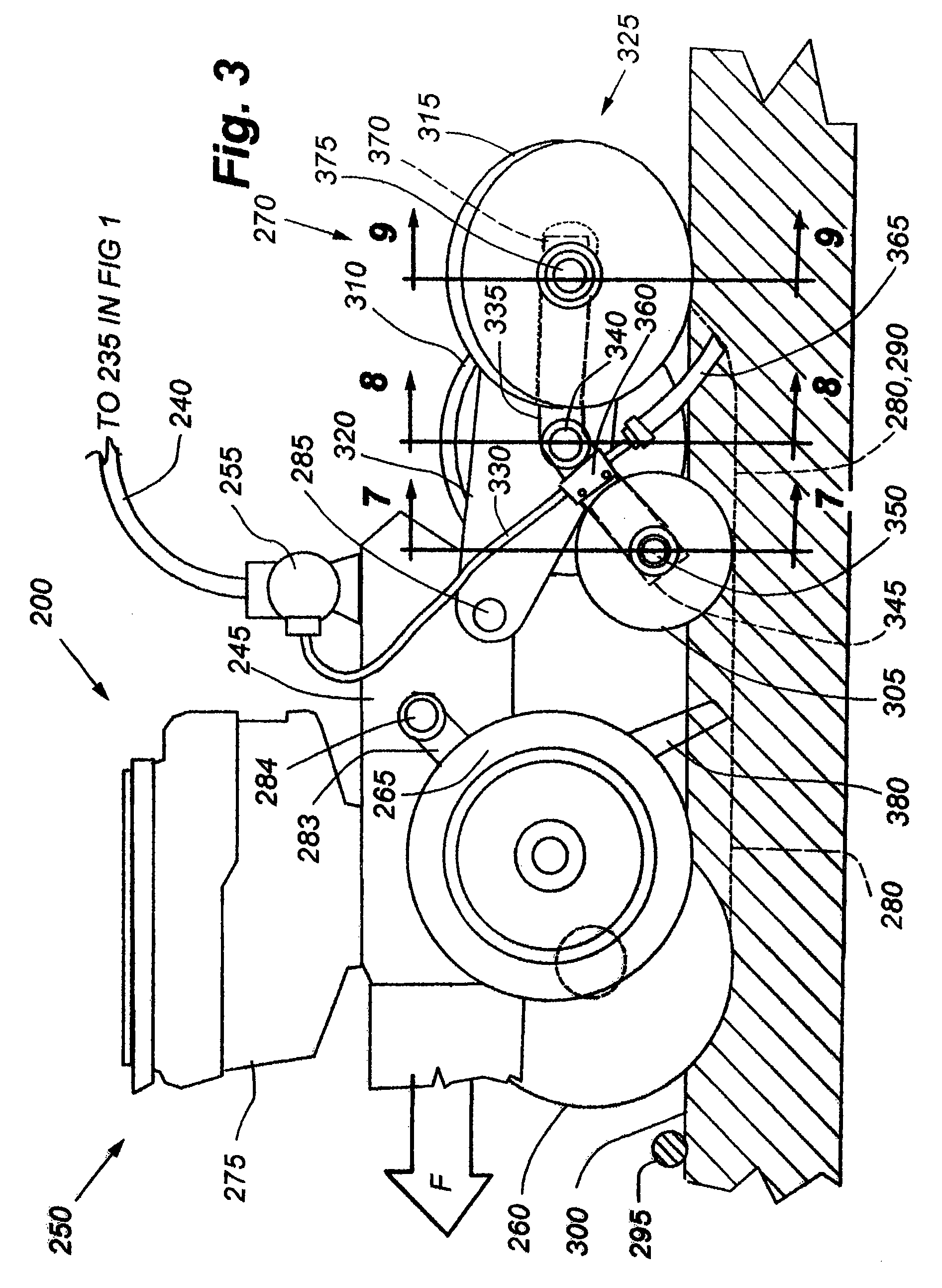

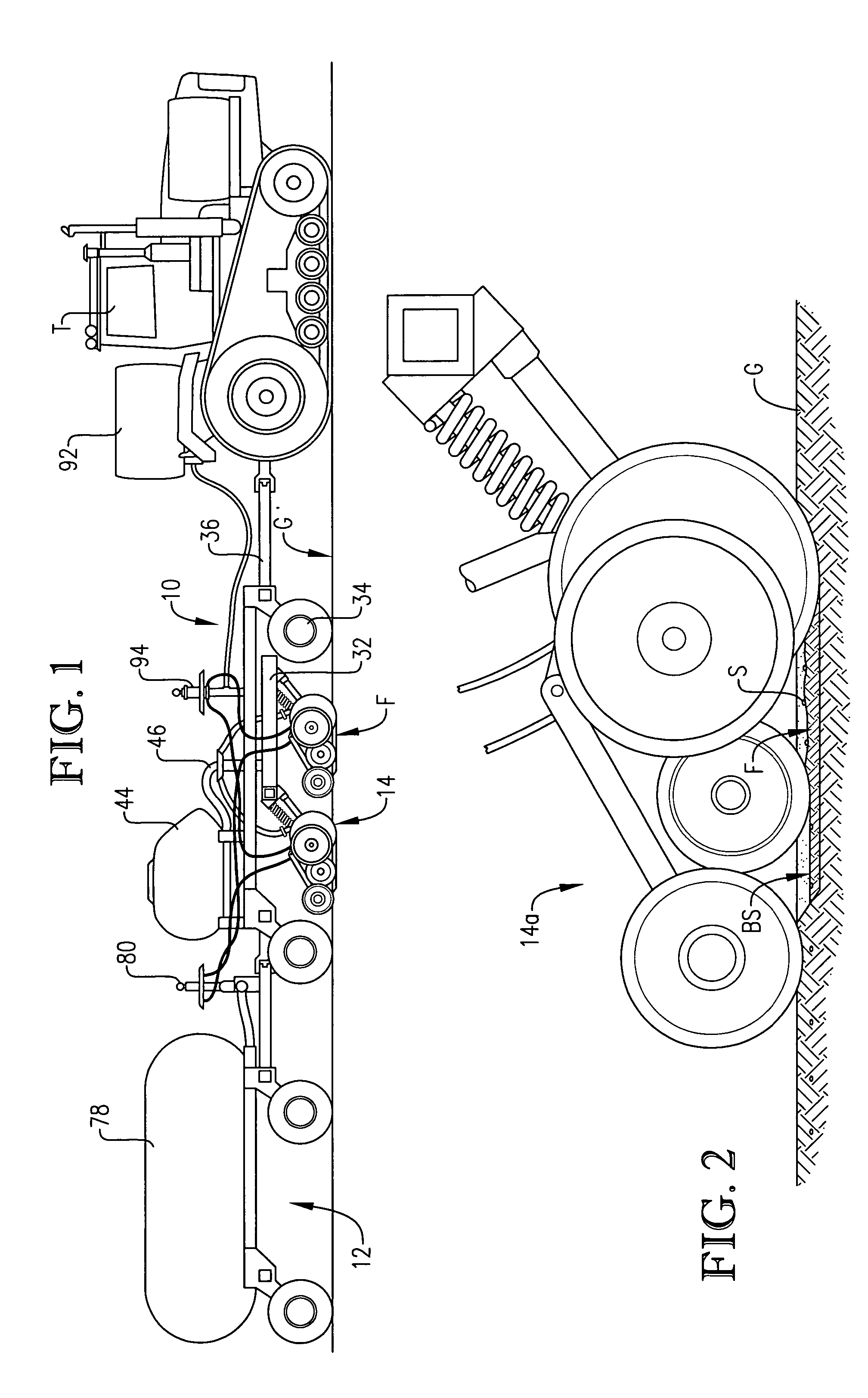

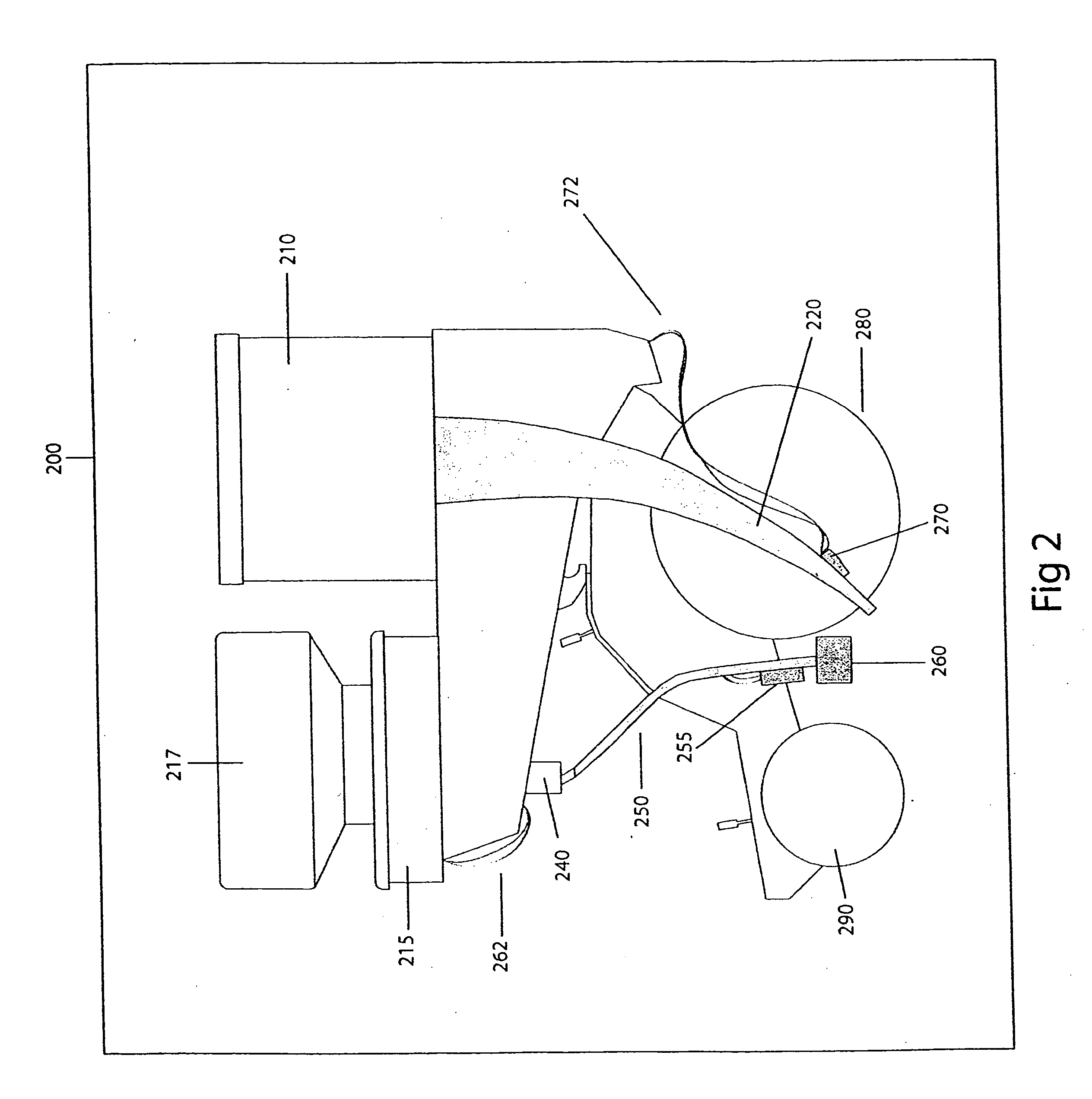

Method and apparatus of agricultural field seeding

ActiveUS7159523B2Accurate conditionImprove consistencyFertiliser distributersPotato plantersTrailing armEngineering

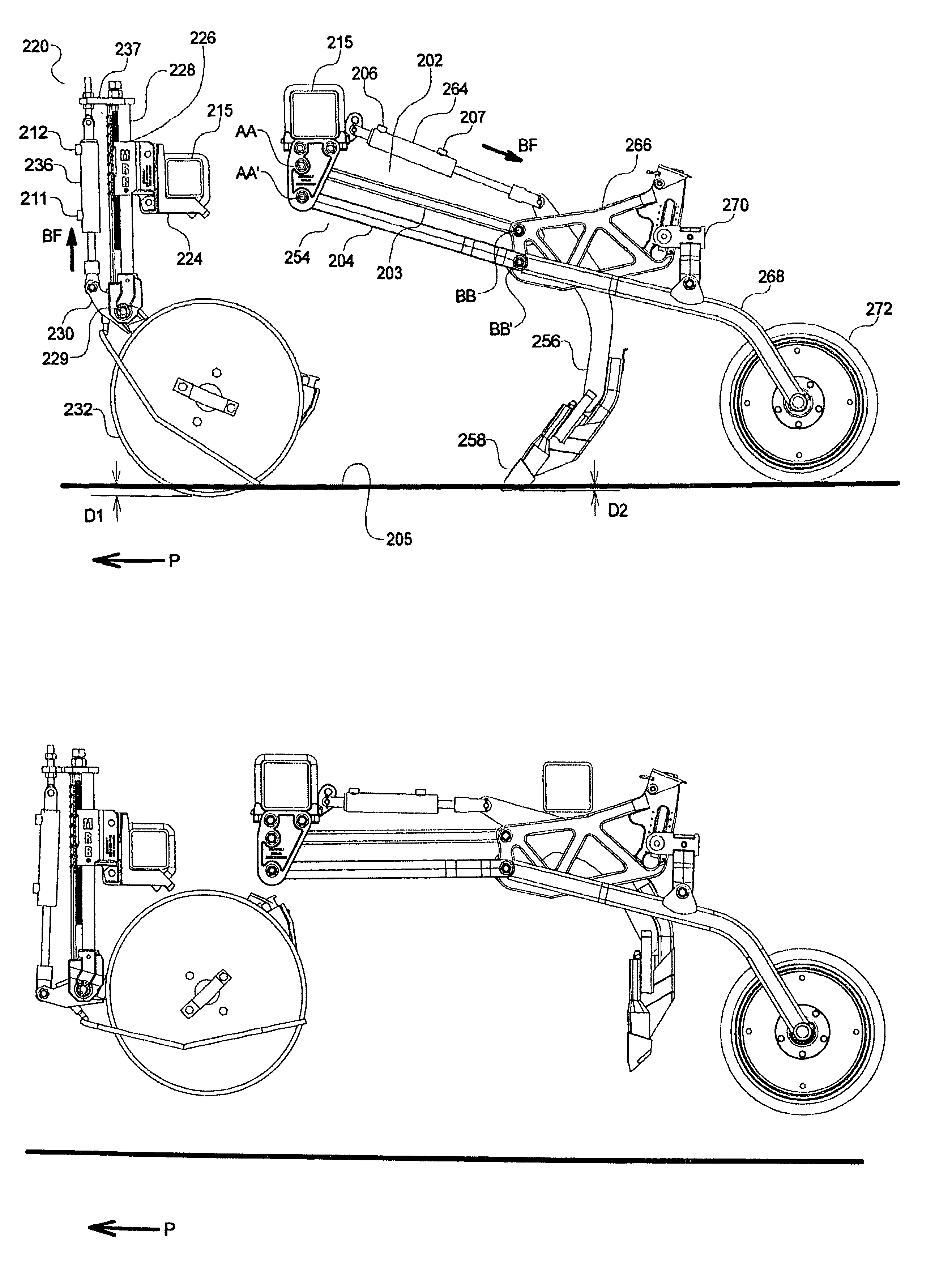

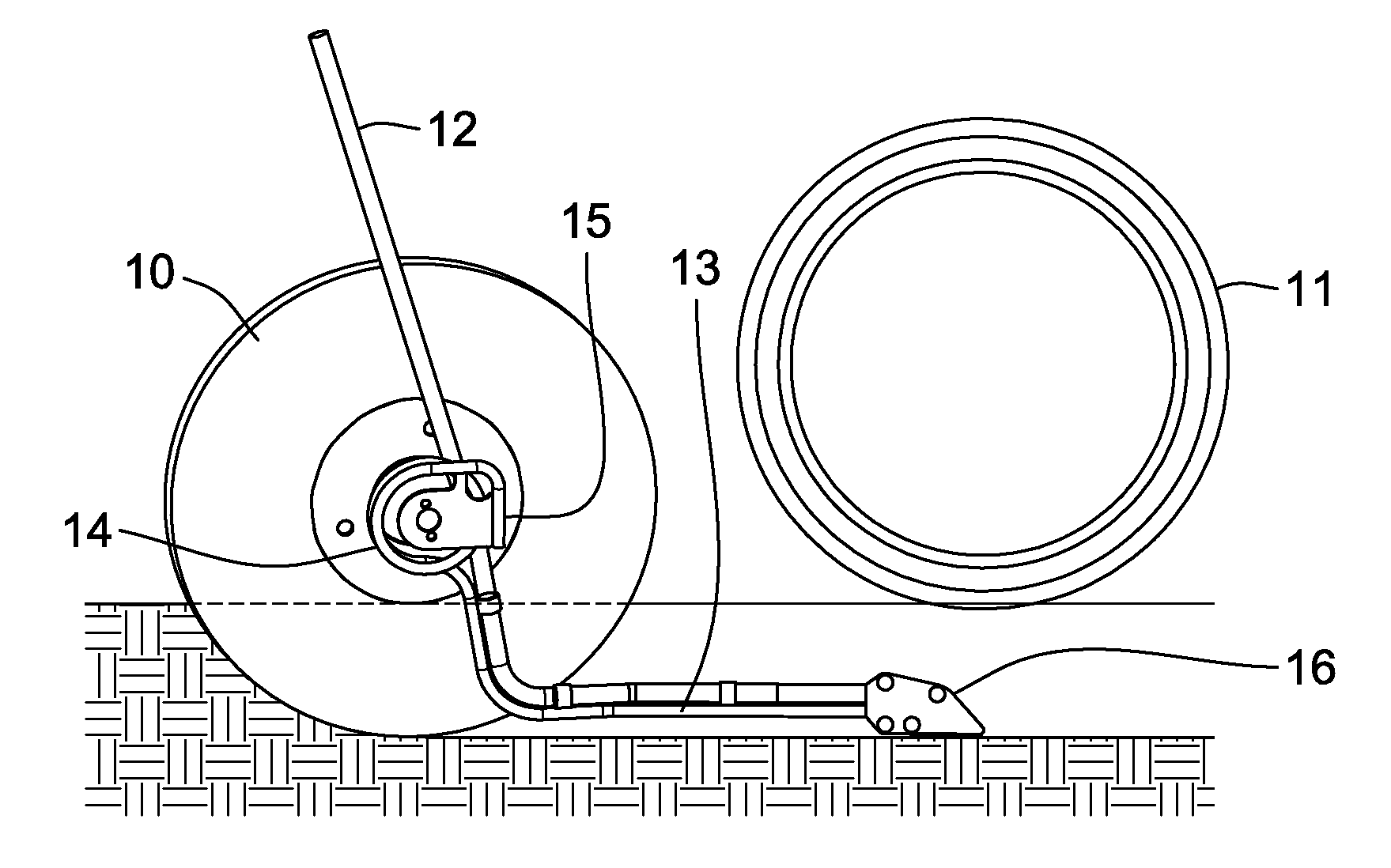

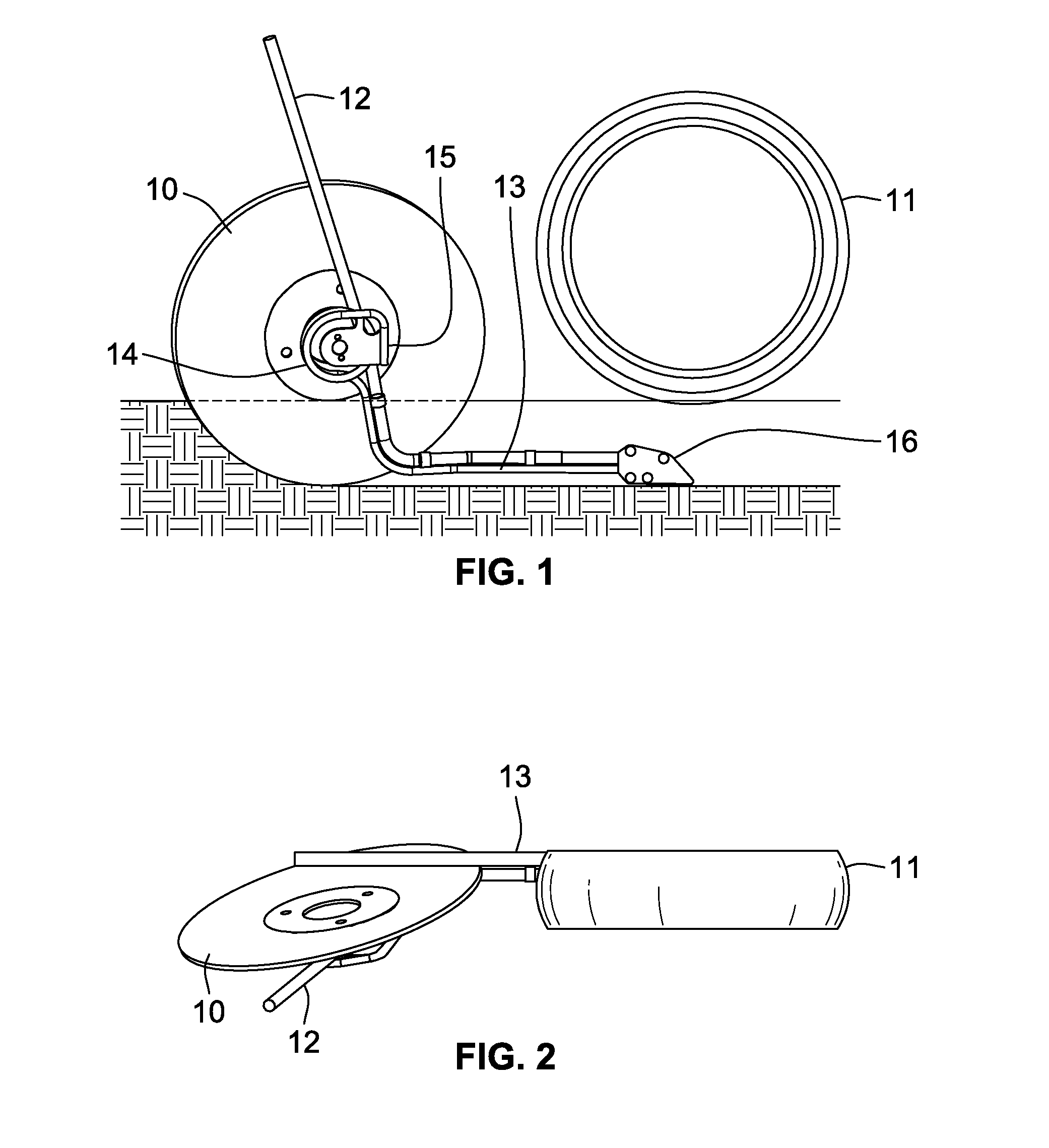

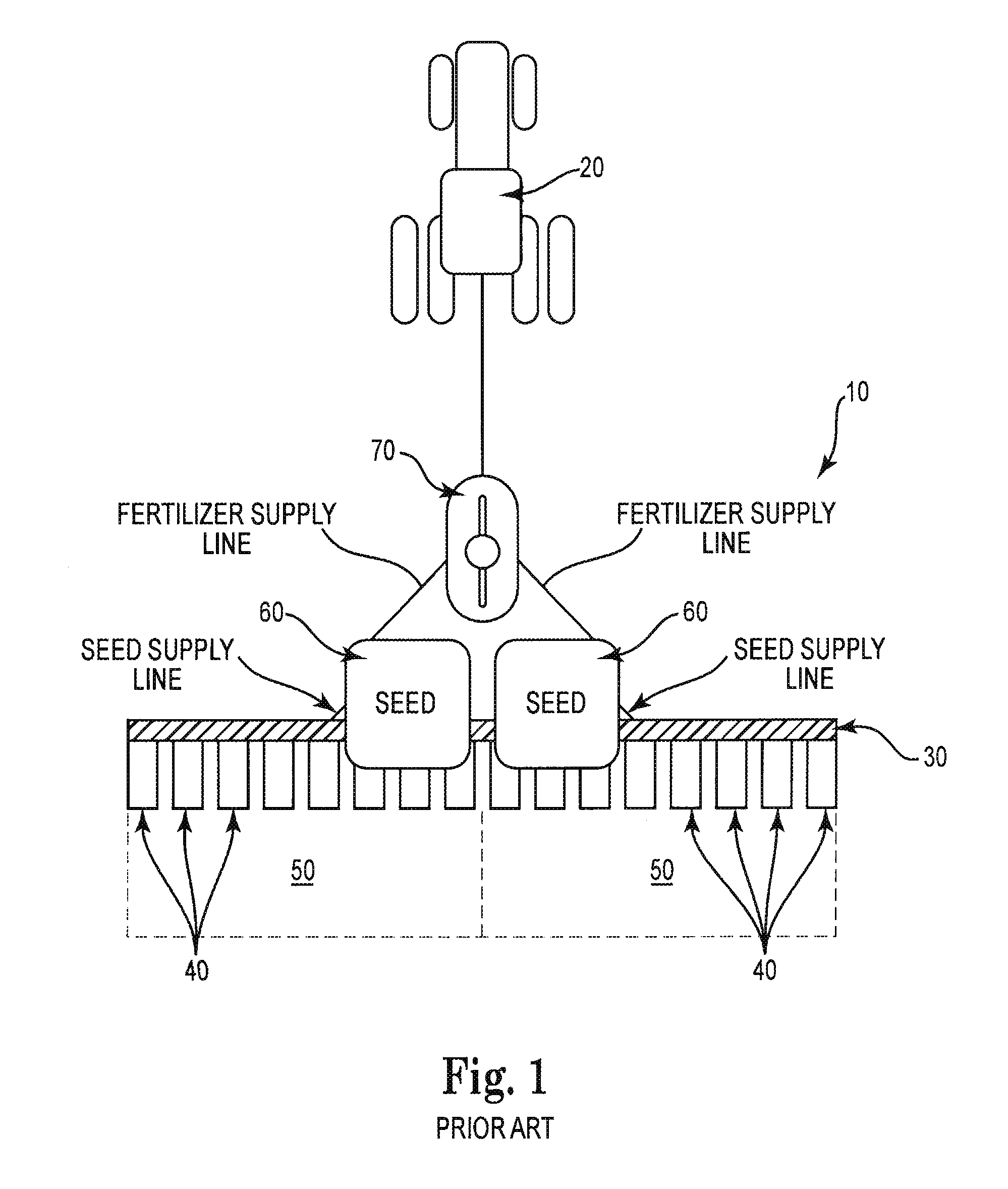

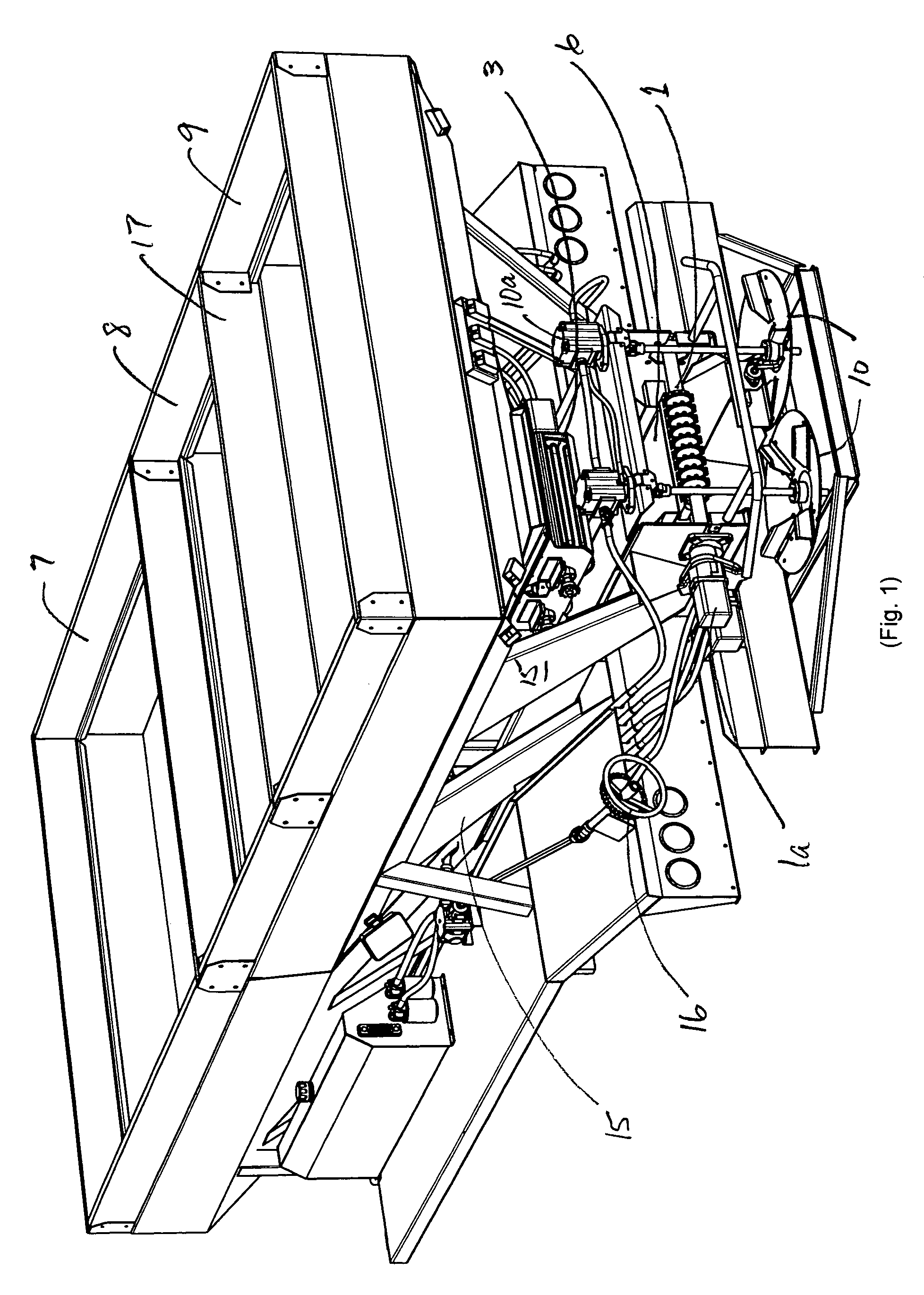

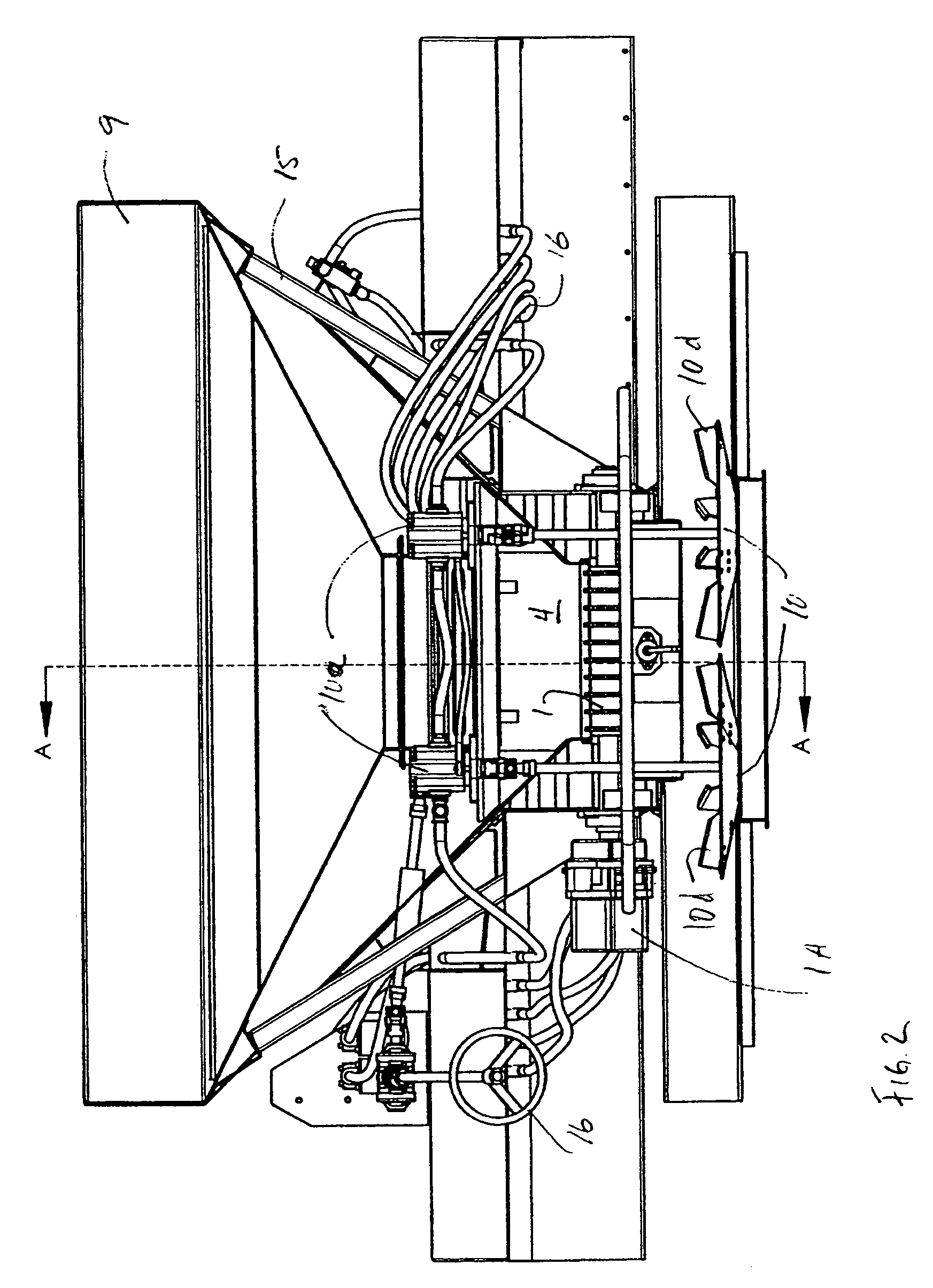

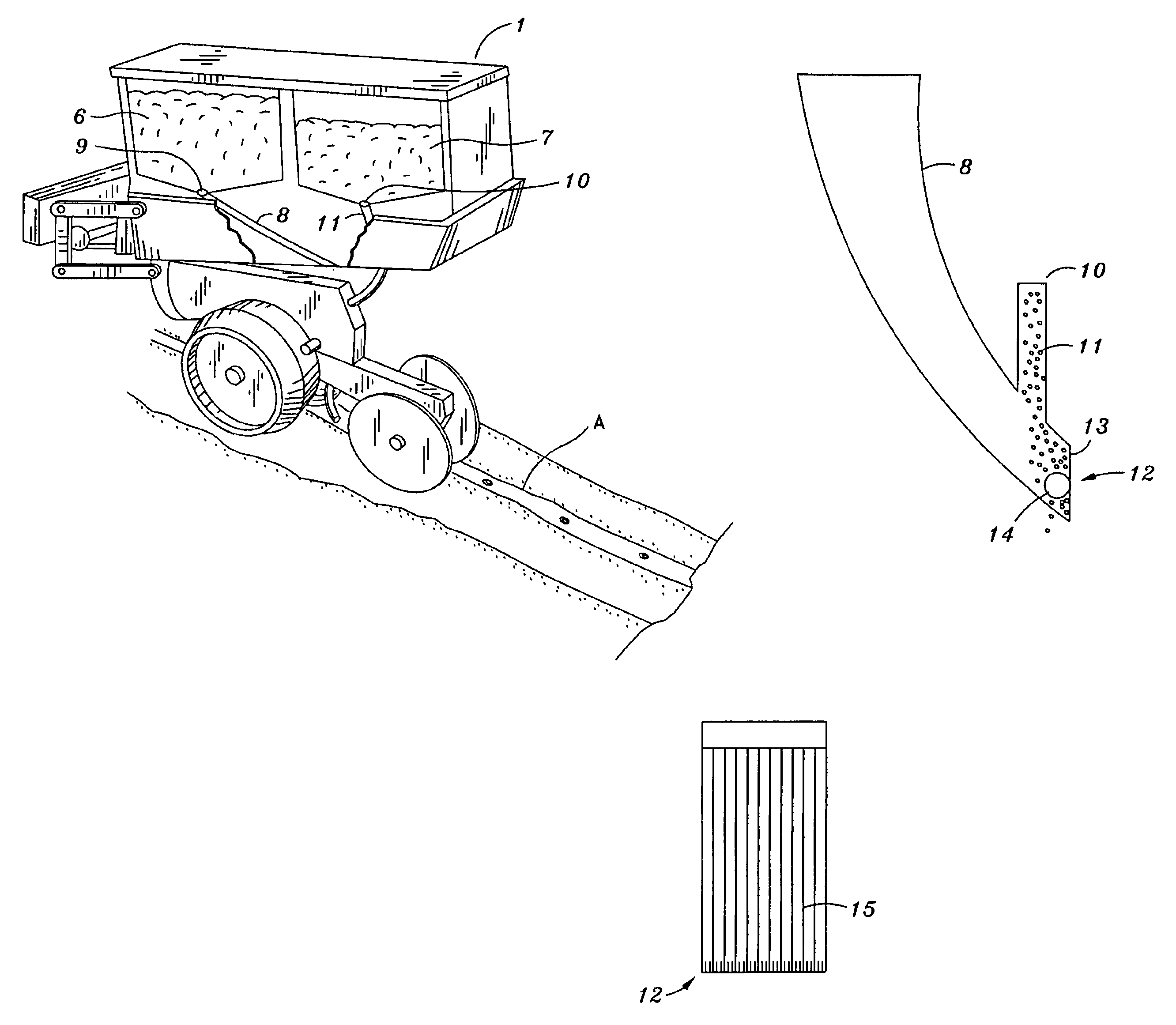

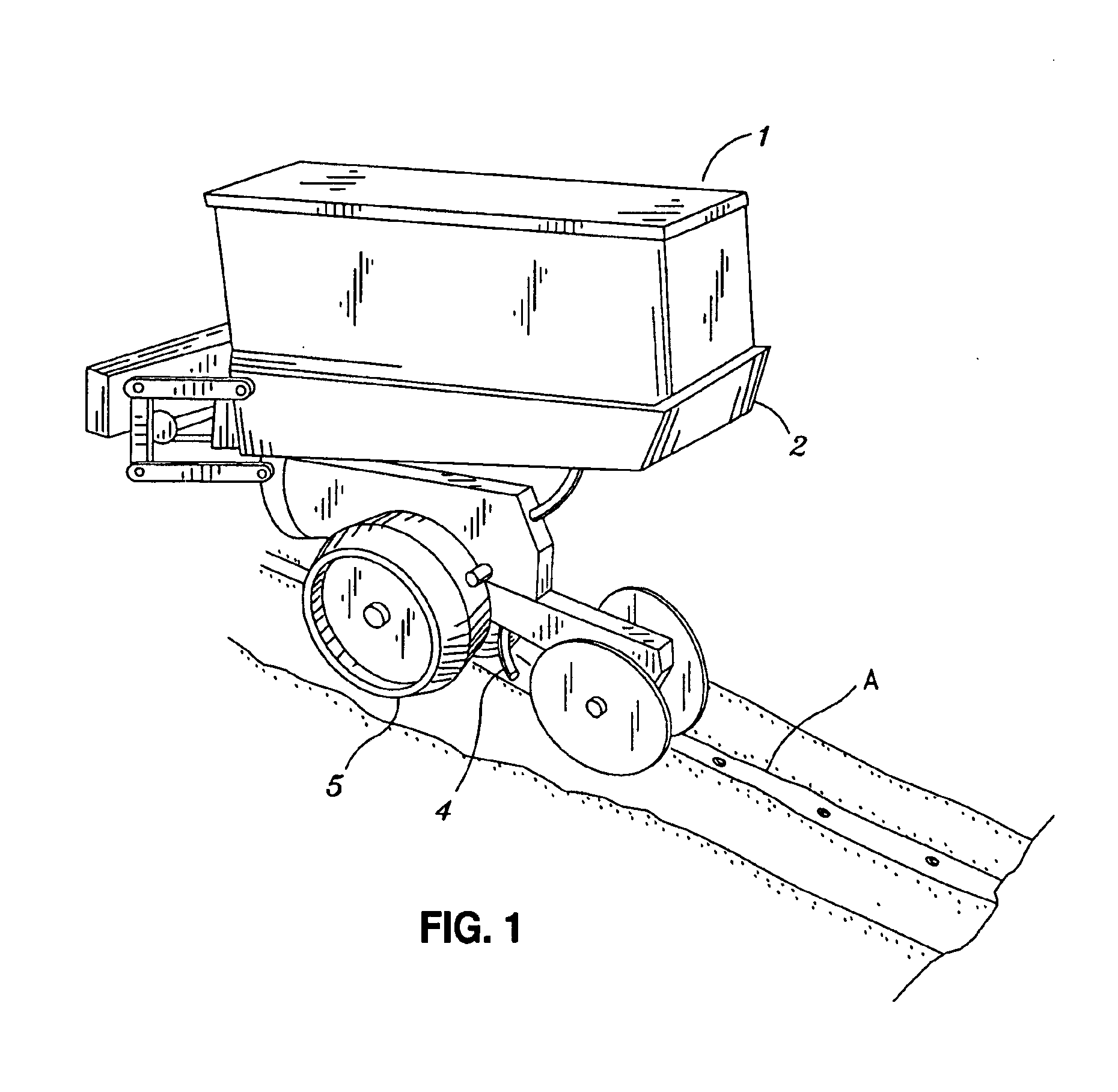

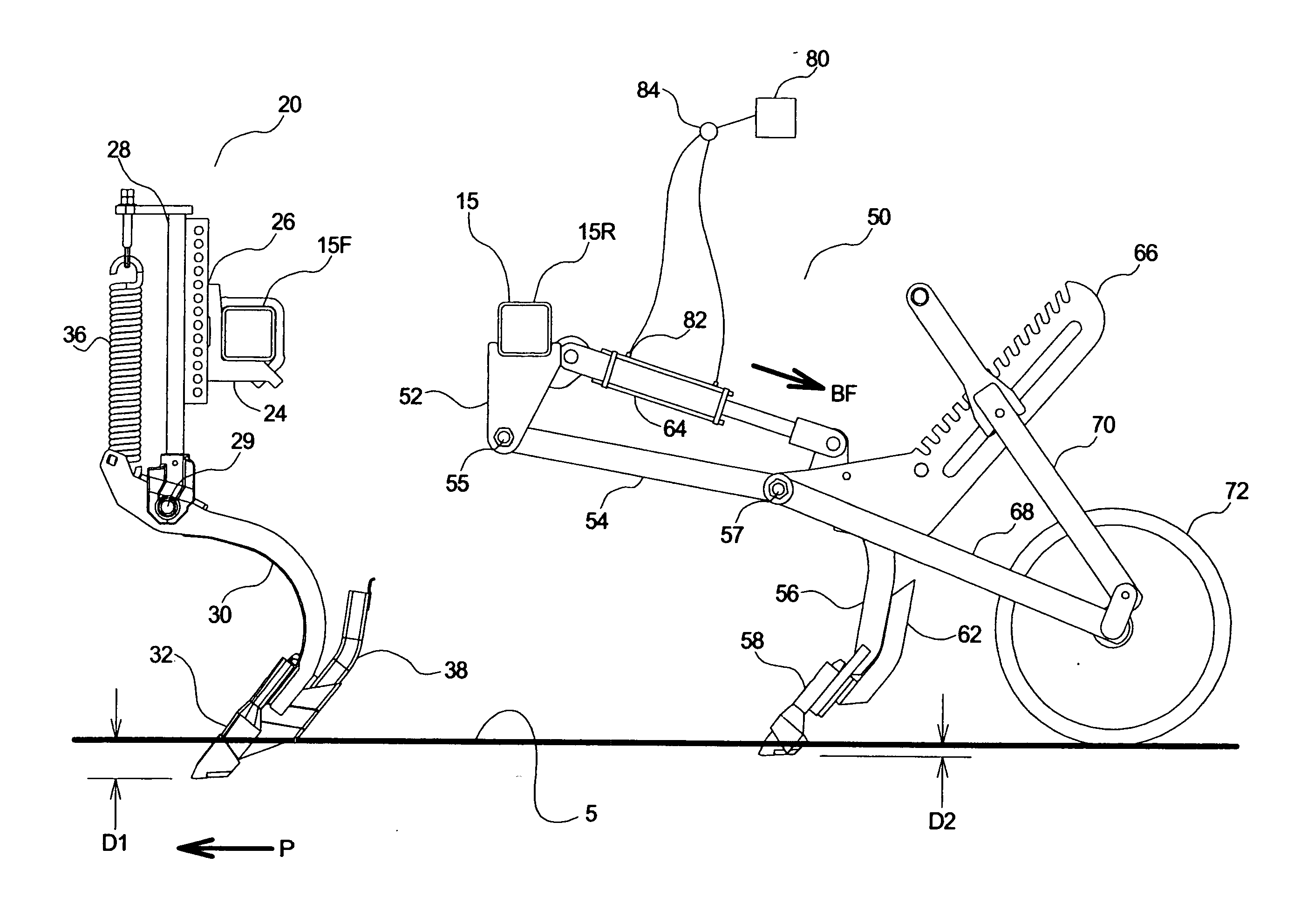

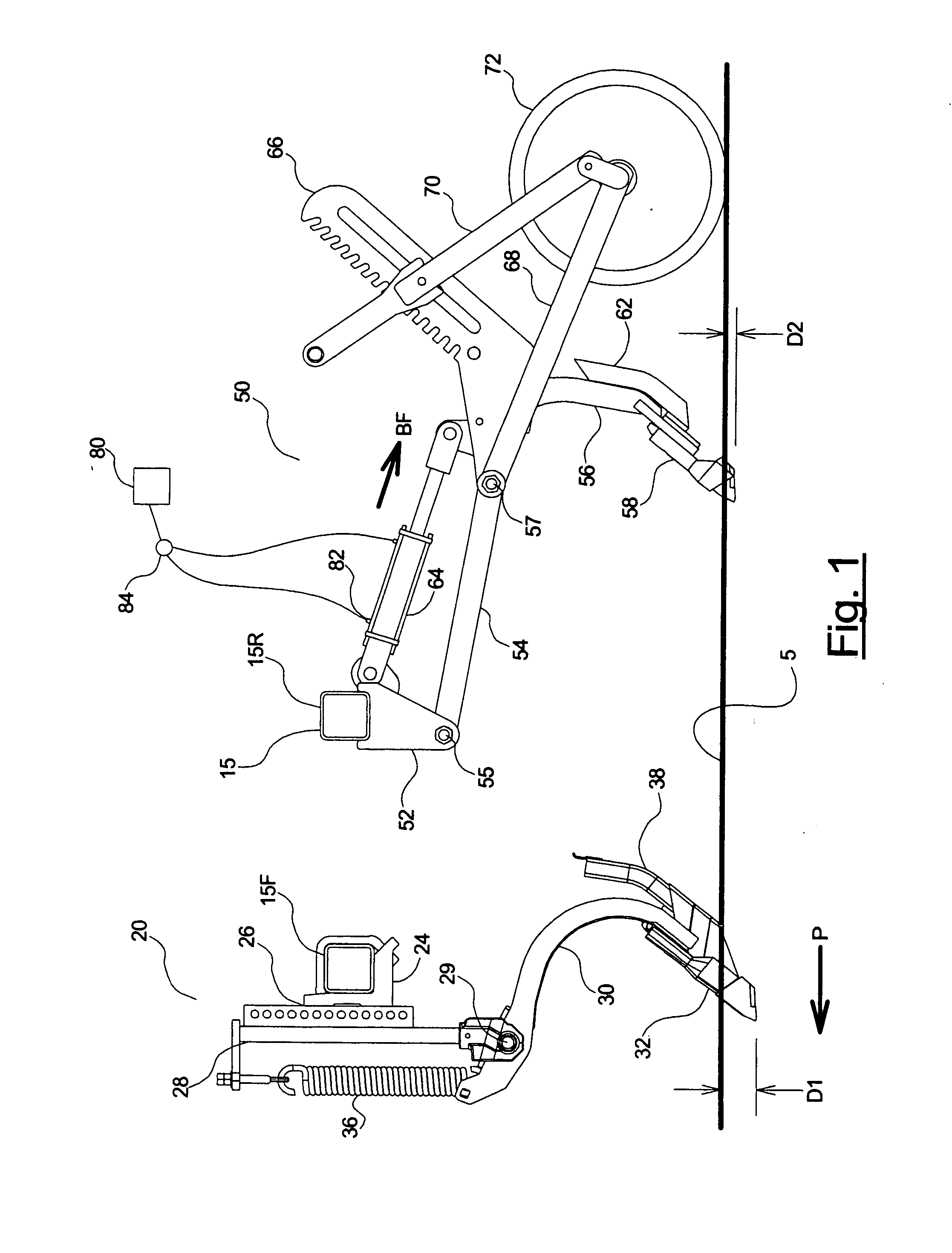

A seeding and fertilizing apparatus comprises a plurality of seed assemblies each comprising a trailing arm pivotally connected at a front end thereof to the frame and a packer wheel rotatably attached to rear end thereof. A seed knife is attached to the trailing arm ahead of the packer wheel which rolls along the seed furrow created by the knife. A vertical position of the knife with respect to the packer wheel is adjustable, and a bias device is operative to exert a downward bias force on the trailing arm. A plurality of fertilizer assemblies each comprises a fertilizer disc rotatably mounted to the frame such that a vertical position of the disc with respect to the implement frame is adjustable. The seed assemblies and fertilizer assemblies are oriented laterally such that each fertilizer furrow is located between adjacent seed furrows.

Owner:BOURGAULT INDS

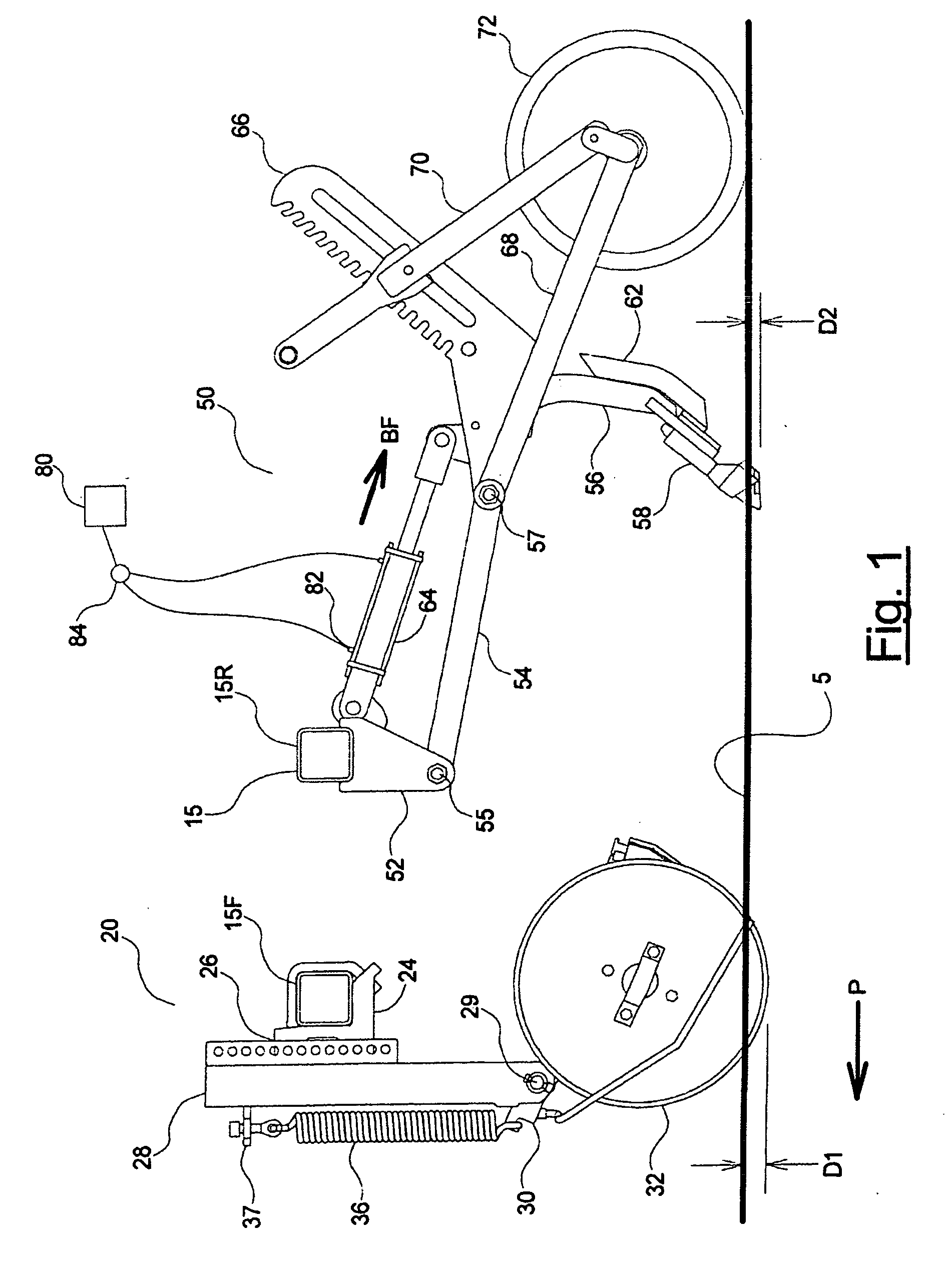

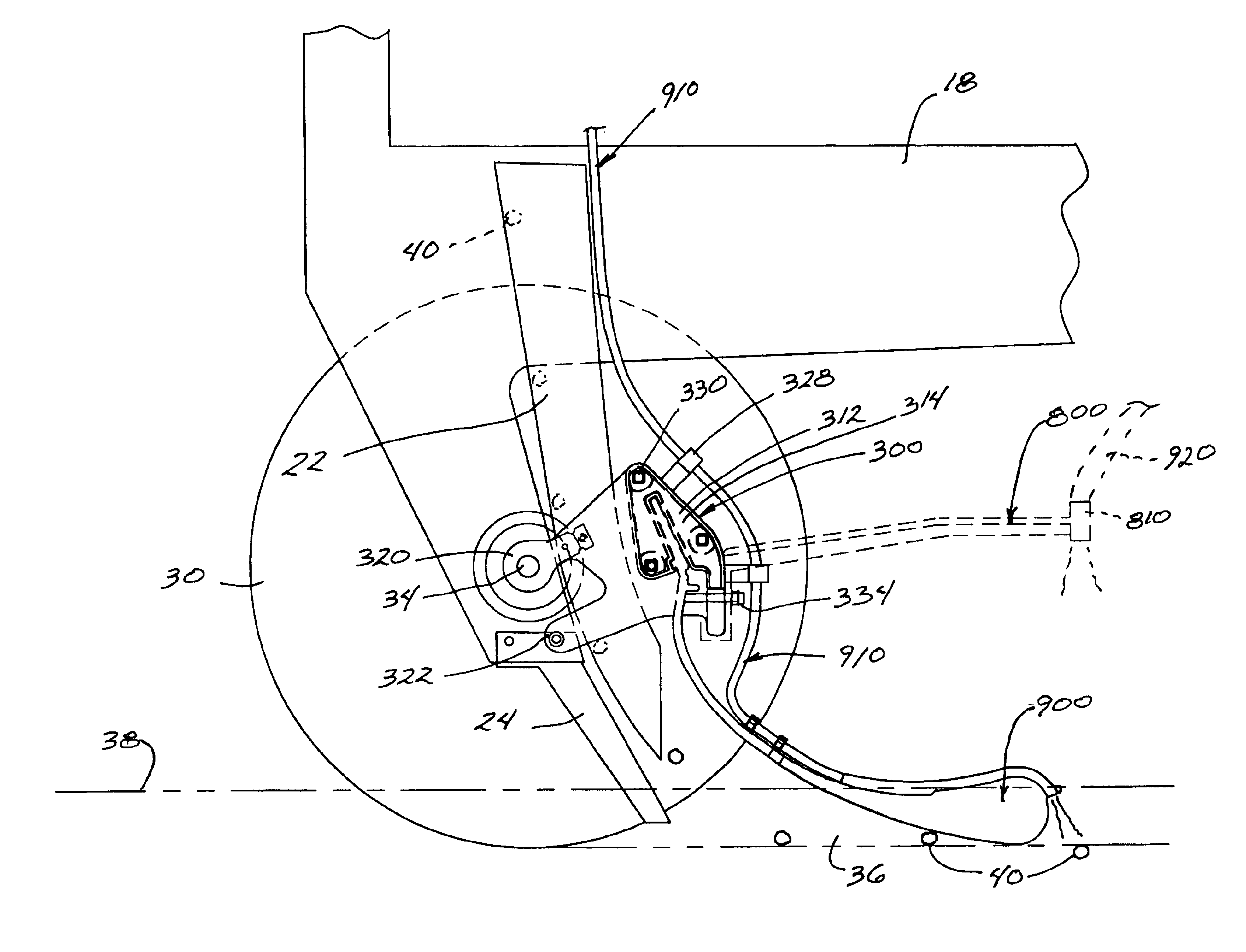

Single disc liquid fertilizer opener

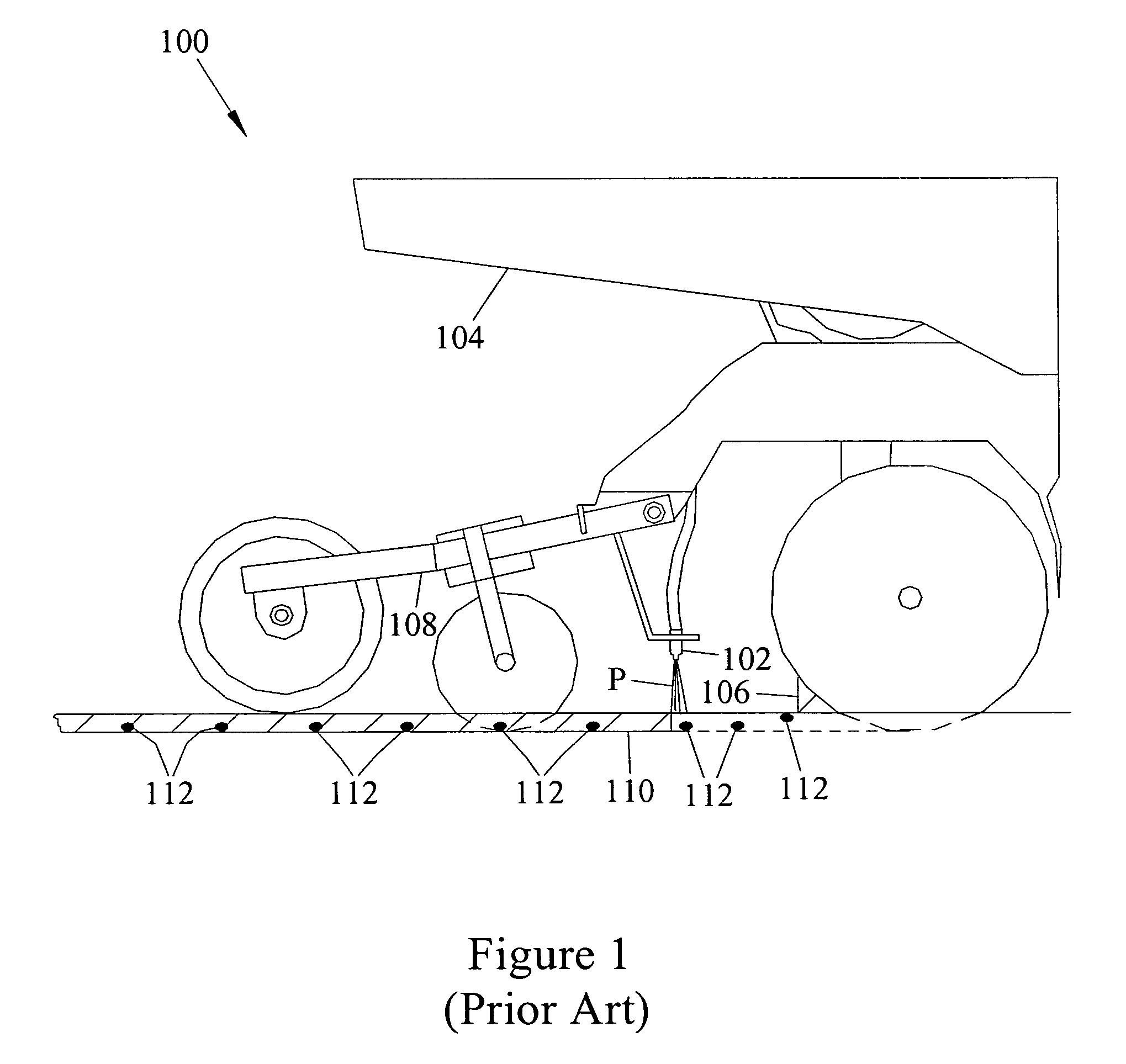

ActiveUS20070044694A1Minimize opportunityEliminate premature mechanical failureTill seedingPlantingForce structureCircular disc

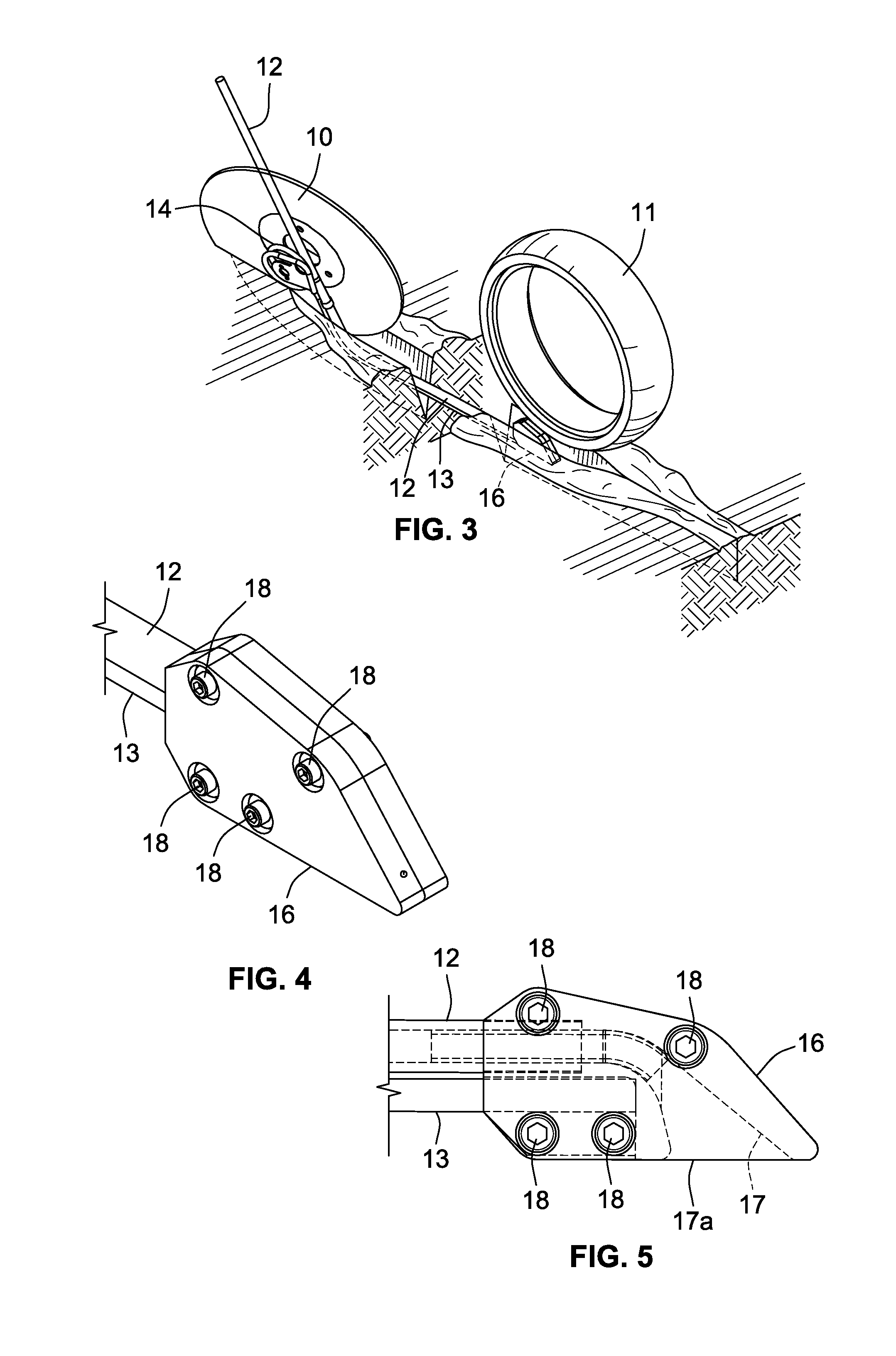

A method and apparatus to be mounted upon a planter row unit for delivering liquid fertilizer to the bottom of a trench without contacting the seed to be planted is disclosed and claimed. The system as claimed and described is adapted for mounting to substantially all modern row units employing floating row units. The method and apparatus as described does not interfere with existing down pressure or seed placement systems as found on modern row crop planters. As described and implemented, the method and apparatus is more compact and lighter in weight than the prior art. The attached assembly for a seed planting unit works in combination with a seed trench opener to form a trench for the deposit of liquid fertilizer offset from and parallel to the later formed seed trench. The apparatus allows directed liquid fertilizer delivery in close proximity to the seed trench with minimal disruption of said seed trench. The attachment includes a single disk blade disposed forward of the seed trench forming unit. The single disk blade is disposed at an angle of four degrees or less from the line defining the direction of travel of the seed planting implement in combination with a furrow strap. The attachment includes a selectively adjustable down force structure and a selectively adjustable depth control mechanism.

Owner:MARTIN HOWARD D

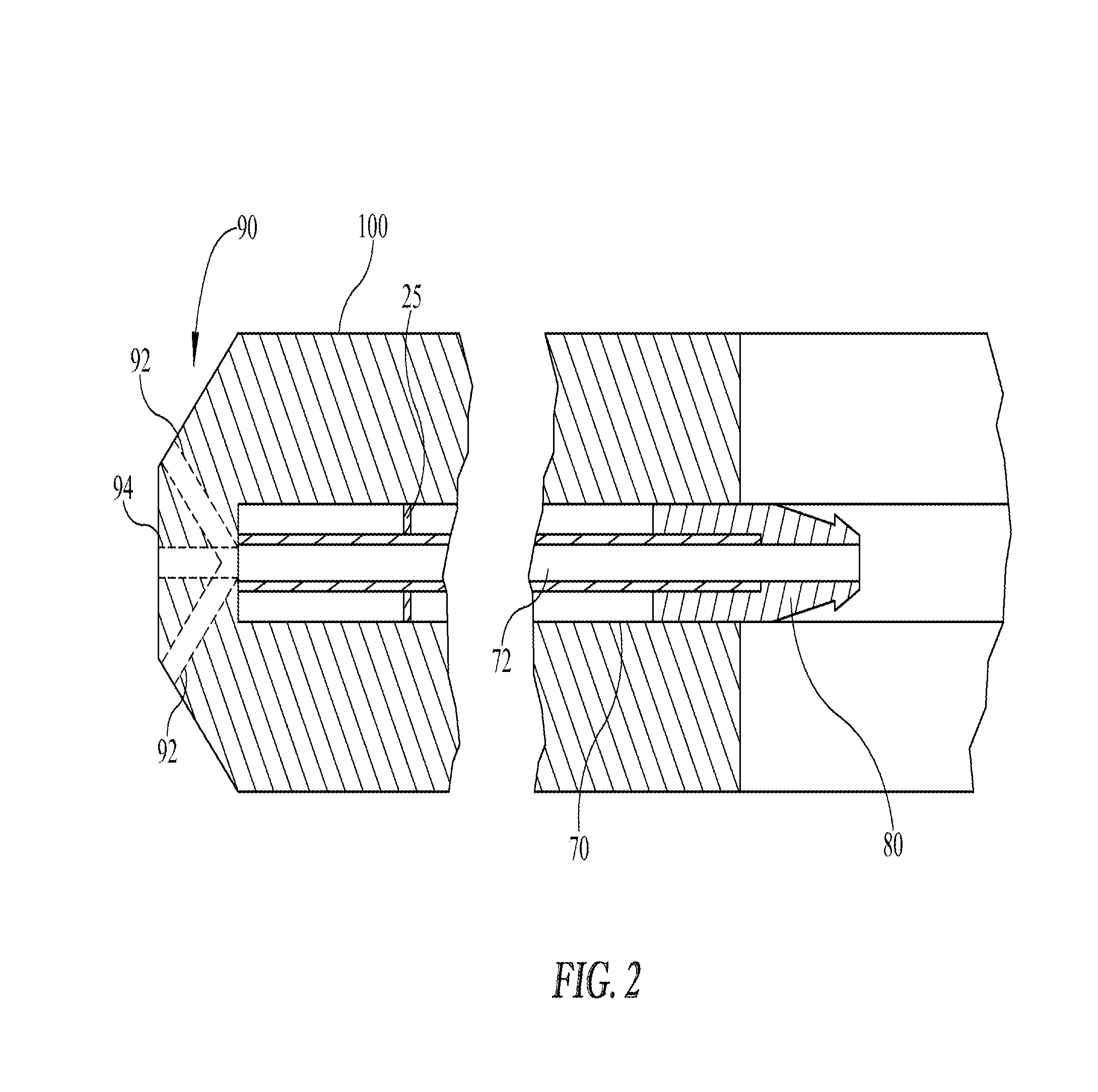

Agricultural implement having fluid delivery features

An agricultural implement for delivering fluid fertilizer into a furrow in the soil of an agricultural field includes a main frame, an opener device attached to the main frame for forming a furrow in the soil, a closing device having an axis of rotation and trailing the opener device for closing the furrow, and a dispensing device for delivering a fluid into the furrow. The injection device has a bottom end extending downwardly into the furrow between the opener device and the axis of rotation of the closing device, an inlet port for receiving the fluid, at least two outlet ports for discharging the fluid into different regions of the furrow, and a bifurcated passageway for conducting the fluid from the inlet port to the outlet ports. The outlet ports may be located to discharge the fluid onto or adjacent to both of the side walls of the furrow.

Owner:DAWN EQUIPMENT COMPANY

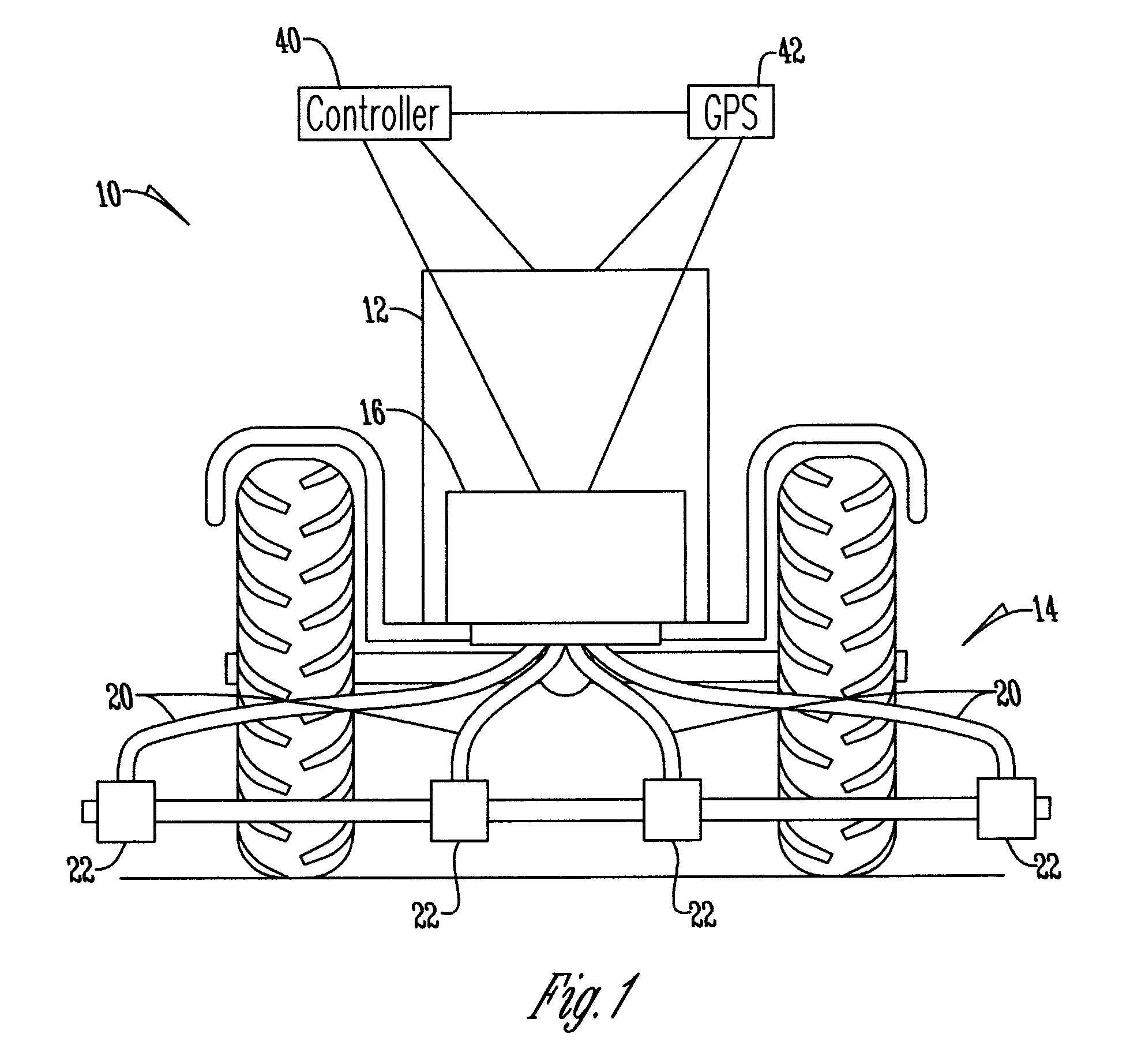

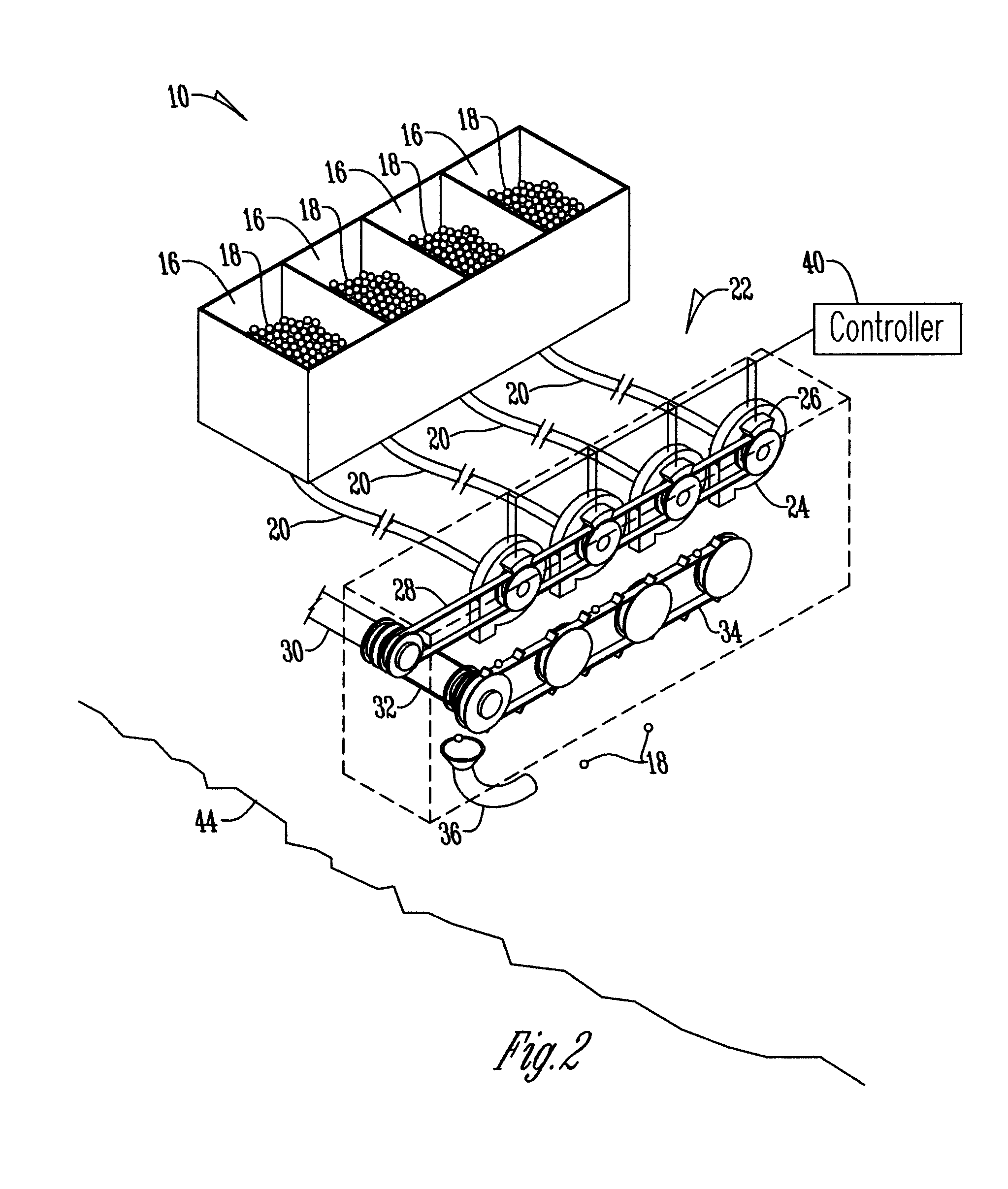

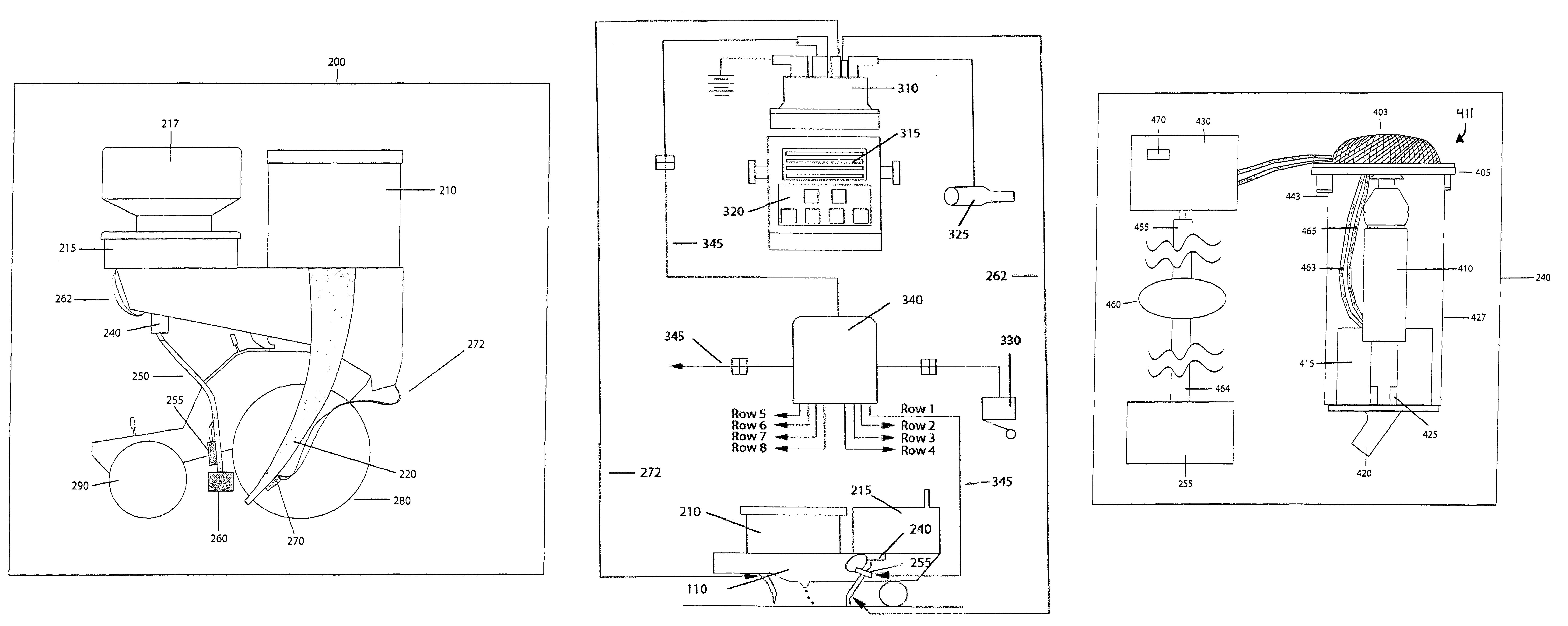

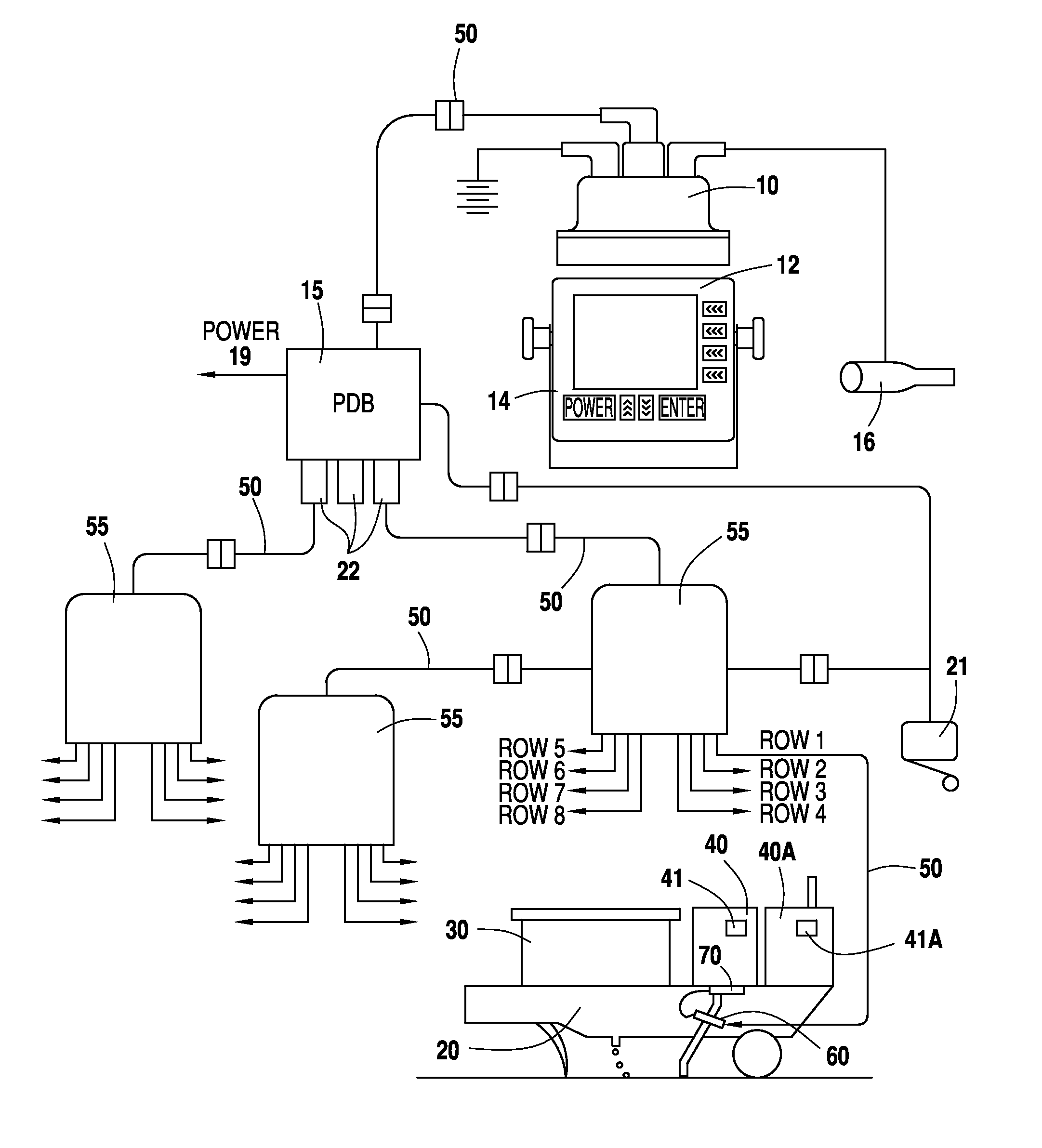

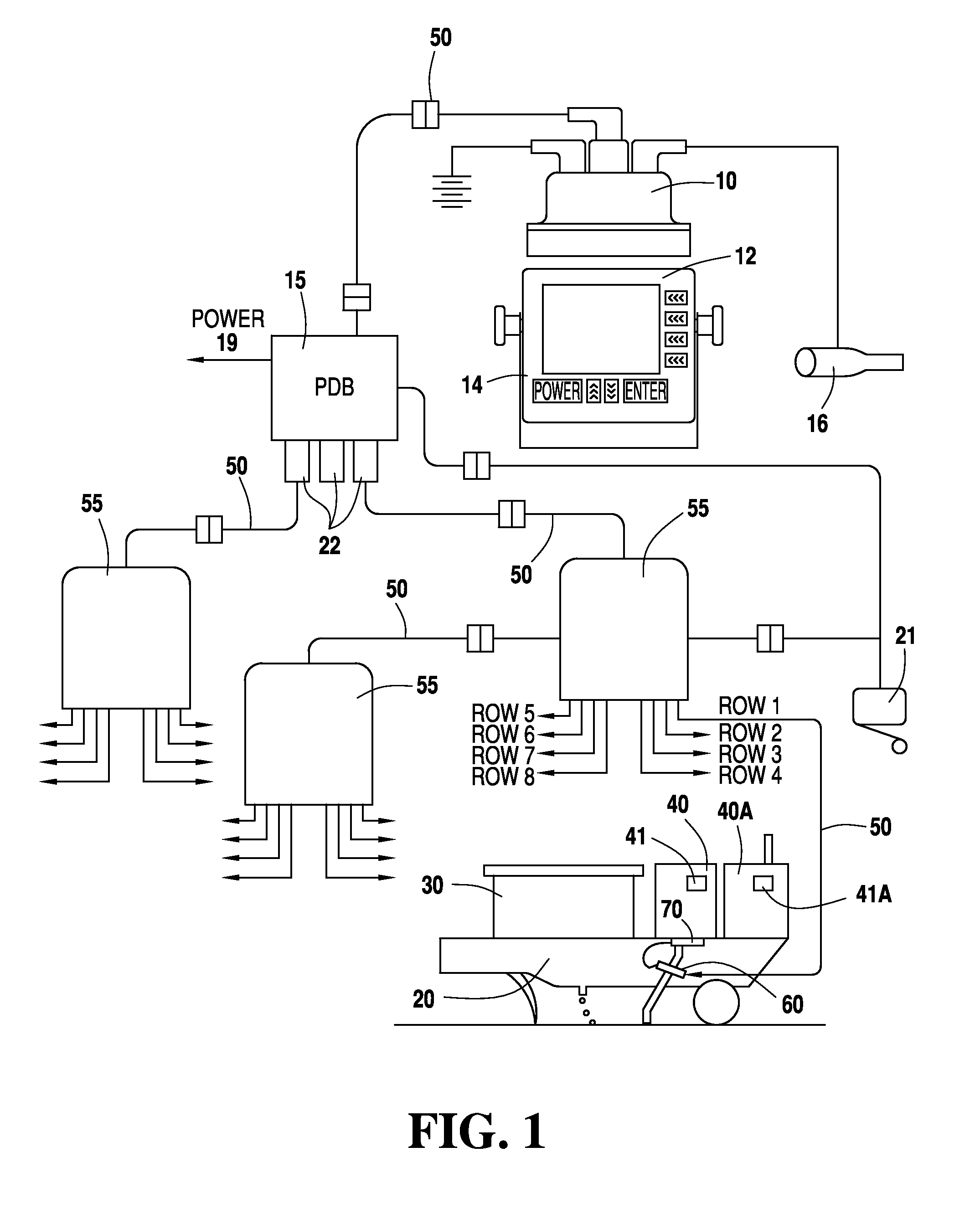

Multi-variable rate agricultural product application system, device and method

ActiveUS20110054743A1Fine rotational controlEasy to controlPlantingAnalogue computers for trafficHydraulic motorDrive shaft

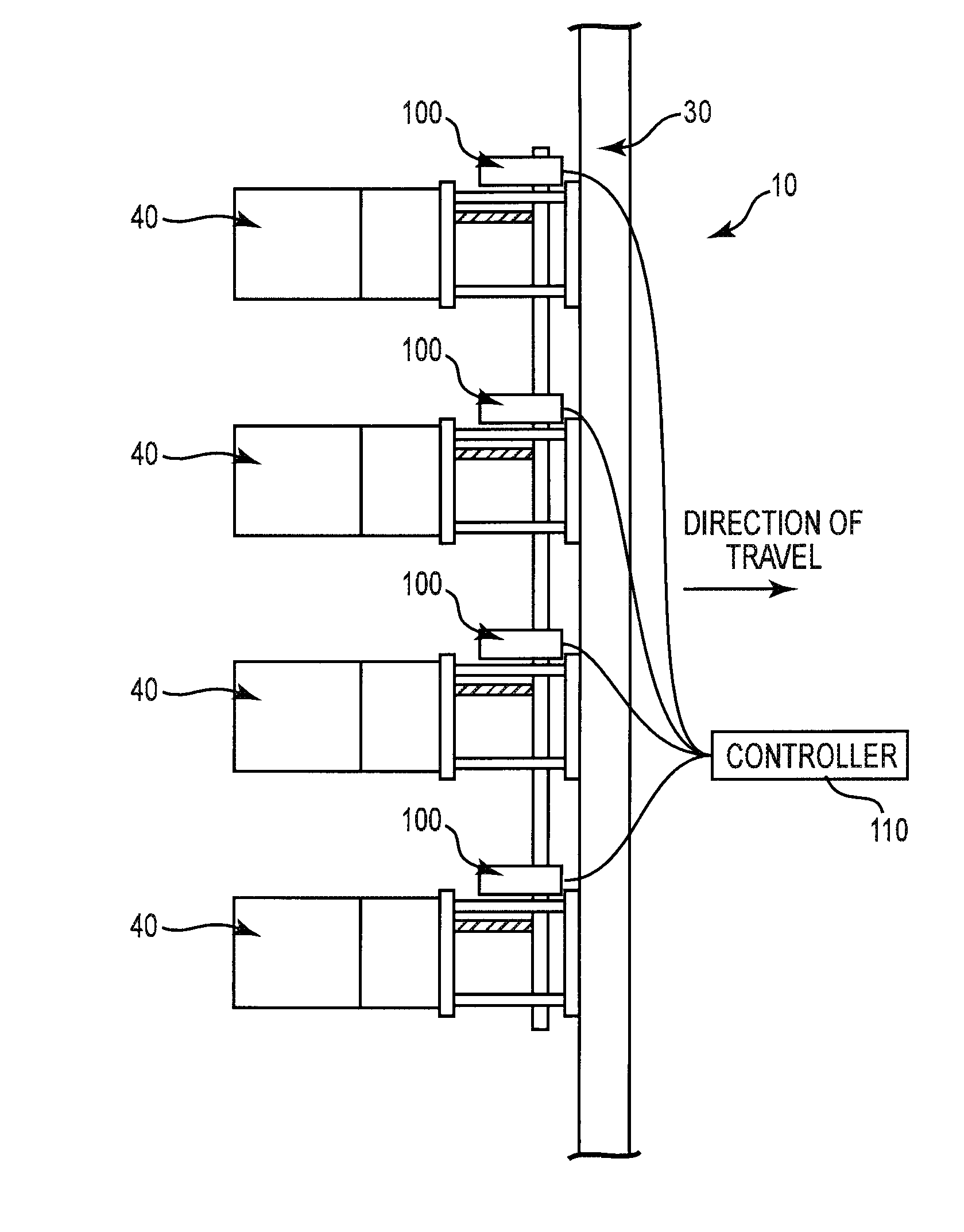

The invention provides a system, device and method that can control the rates of seed dispensation and fertilizer application as a function of forward speed as well as across all rows. Thus, the system and control device allow control of each individual row unit, whereby dispensation and application are effected, by a central controller which controls a plurality of pulse width modulation valves, each of which controls a hydraulic motor with an integrated rpm reduction and which drives a stub drive shaft which rotates at the proper speed in order to provide the desired seed and fertilizer metering. Each of the stub drive shafts may rotate at completely different speeds and / or may be shut down while the remaining stub drive shafts rotate at the desired speed. The integrated rpm reduction within each hydraulic motor allows very fine rotational control of the dispensation and application rates.

Owner:RAVEN INDUSTRIES INC

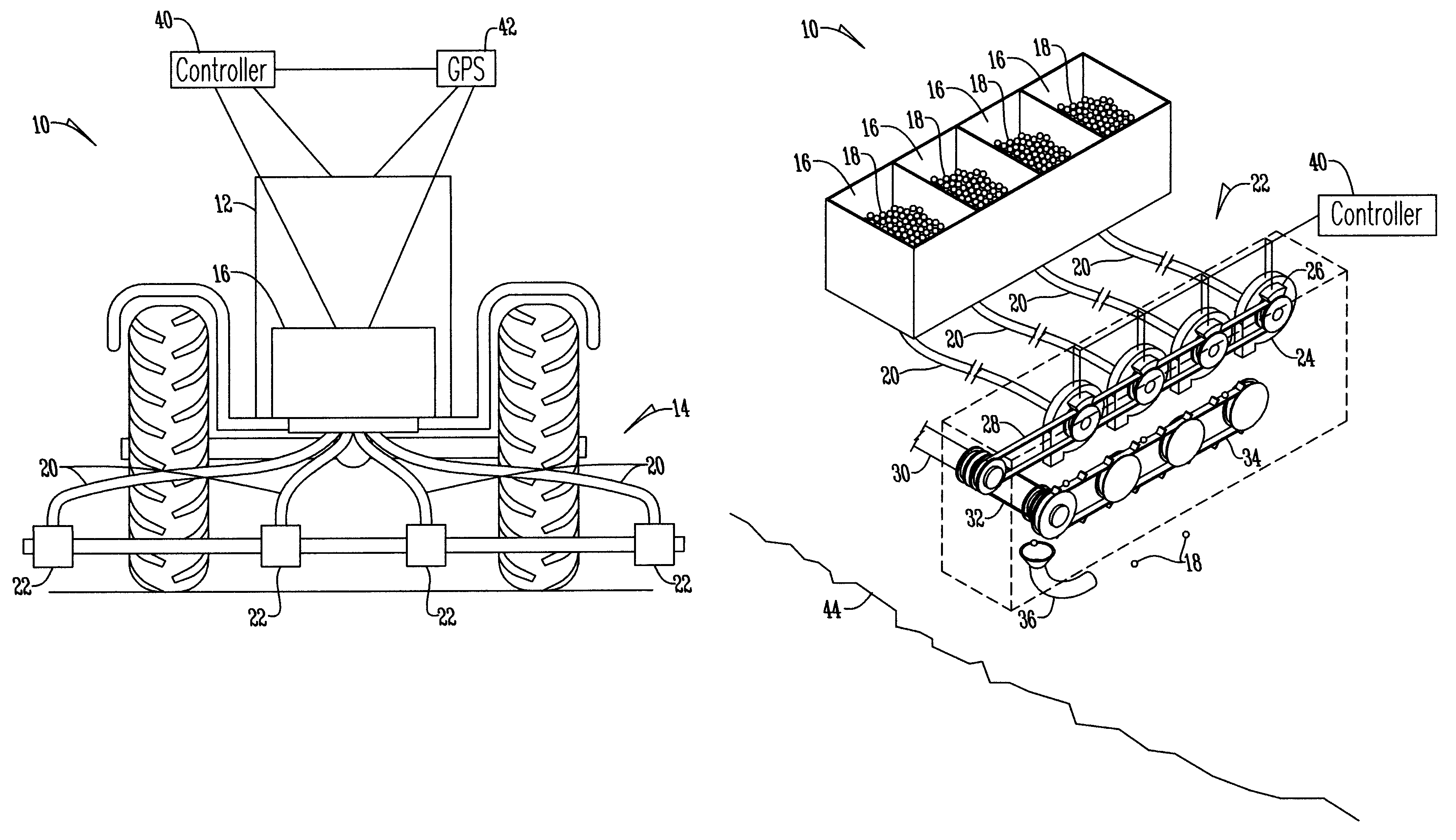

Plural bin metering system

ActiveUS7380733B2Low costLess-expensive to maintainFertiliser distributersCentrifugal wheel fertilisersOne passEngineering

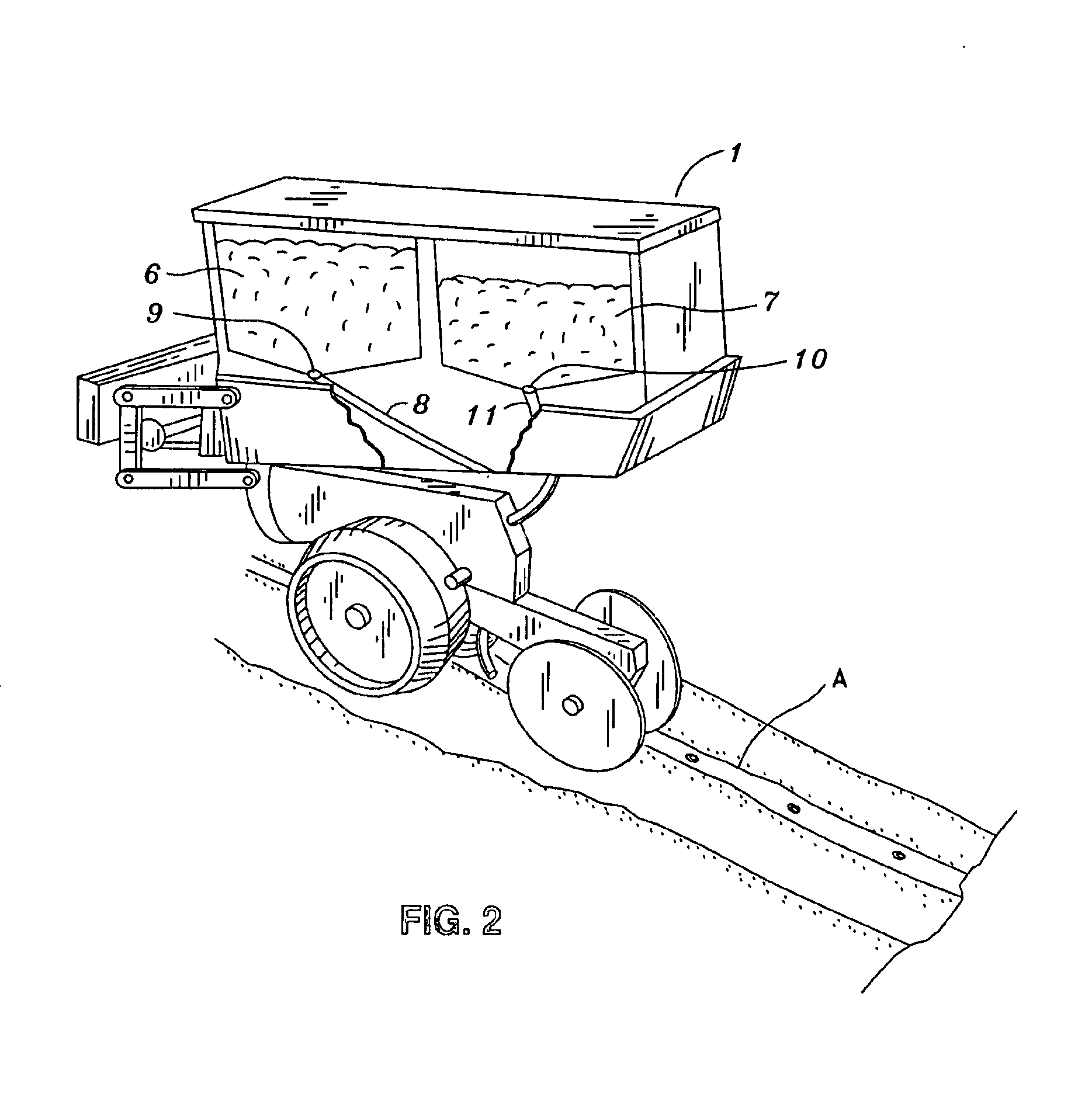

A plural bin metering system for broadcasting material ingredients contained therein over a ground surface. The system includes at least two material ingredient hoppers, each of the hoppers having a material ingredient discharge port. At least one of the material ingredient hoppers includes a variably controllable metering unit associated therewith for variably controlling the discharge of material ingredients therefrom independently from the rate of discharge of material ingredients from the other material ingredient hopper. A conveyor is disposed below the hoppers for receiving material ingredients discharged from the hoppers, and a material ingredient broadcasting device disposed off of one end of the conveyor for receiving material ingredients conveyed thereon, received from the hoppers, for broadcasting the material ingredients over a ground surface. The metering unit is capable of metering material ingredients from its associated hopper at ultra low rates. In a preferred embodiment the system has three hoppers for broadcasting, for example fertilizer across a field in one pass.

Owner:SALFORD BBI

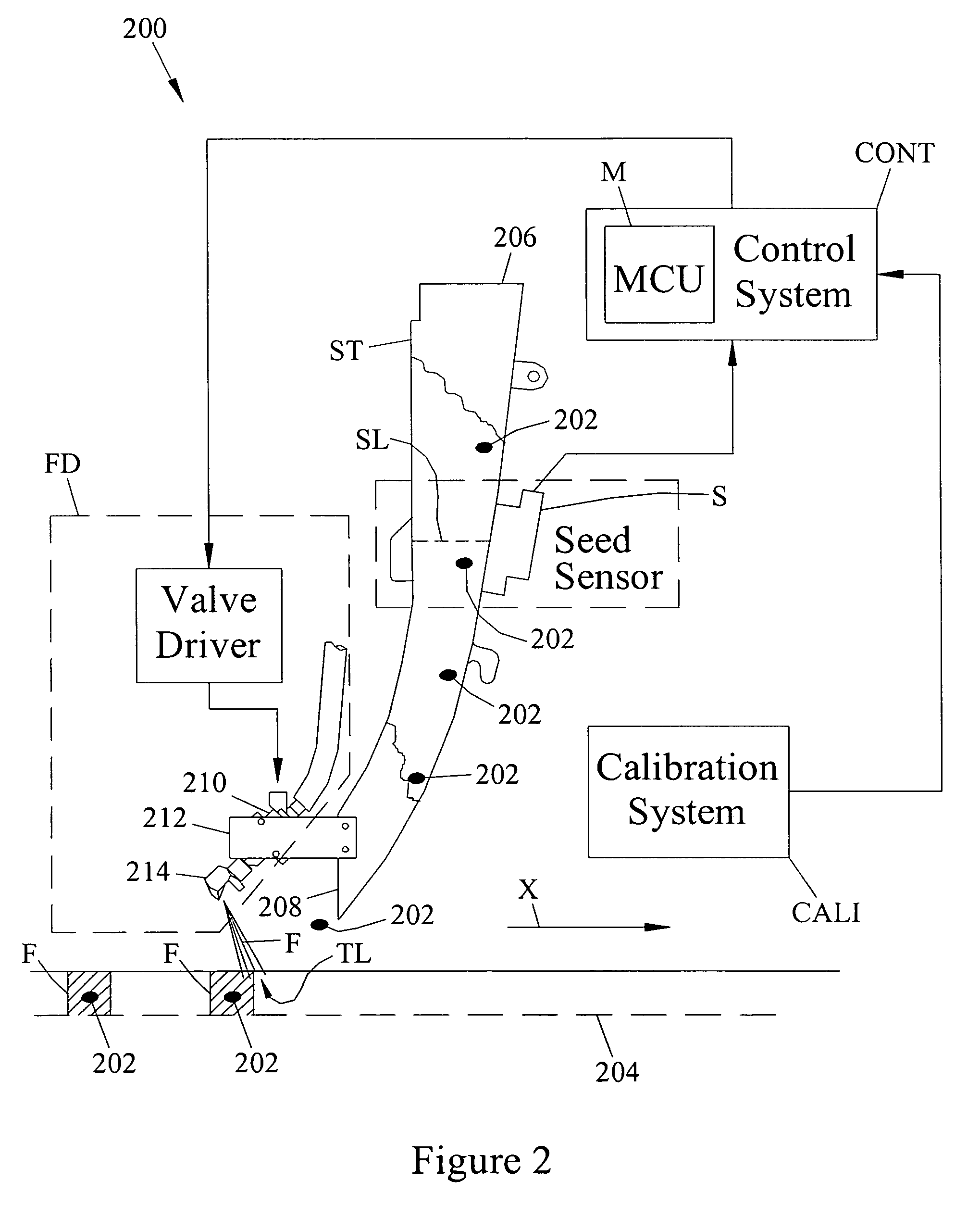

Systems and methods for fluid dispensing

Systems and methods are disclosed for dispensing fluids. The systems can include a sensor operable to detect when an object passes a first location as the object moves to a second location. The systems can also include a fluid dispenser operable to dispense fluid at the second location. In addition, the systems can include a control unit in communication with the sensor and the fluid dispenser. The control unit can receive information from the sensor that the object has passed the first location and to control the fluid dispenser to dispense fluid at the second location at a predetermined time after the object passes the first location.

Owner:UNIV OF TENNESSEE RES FOUND

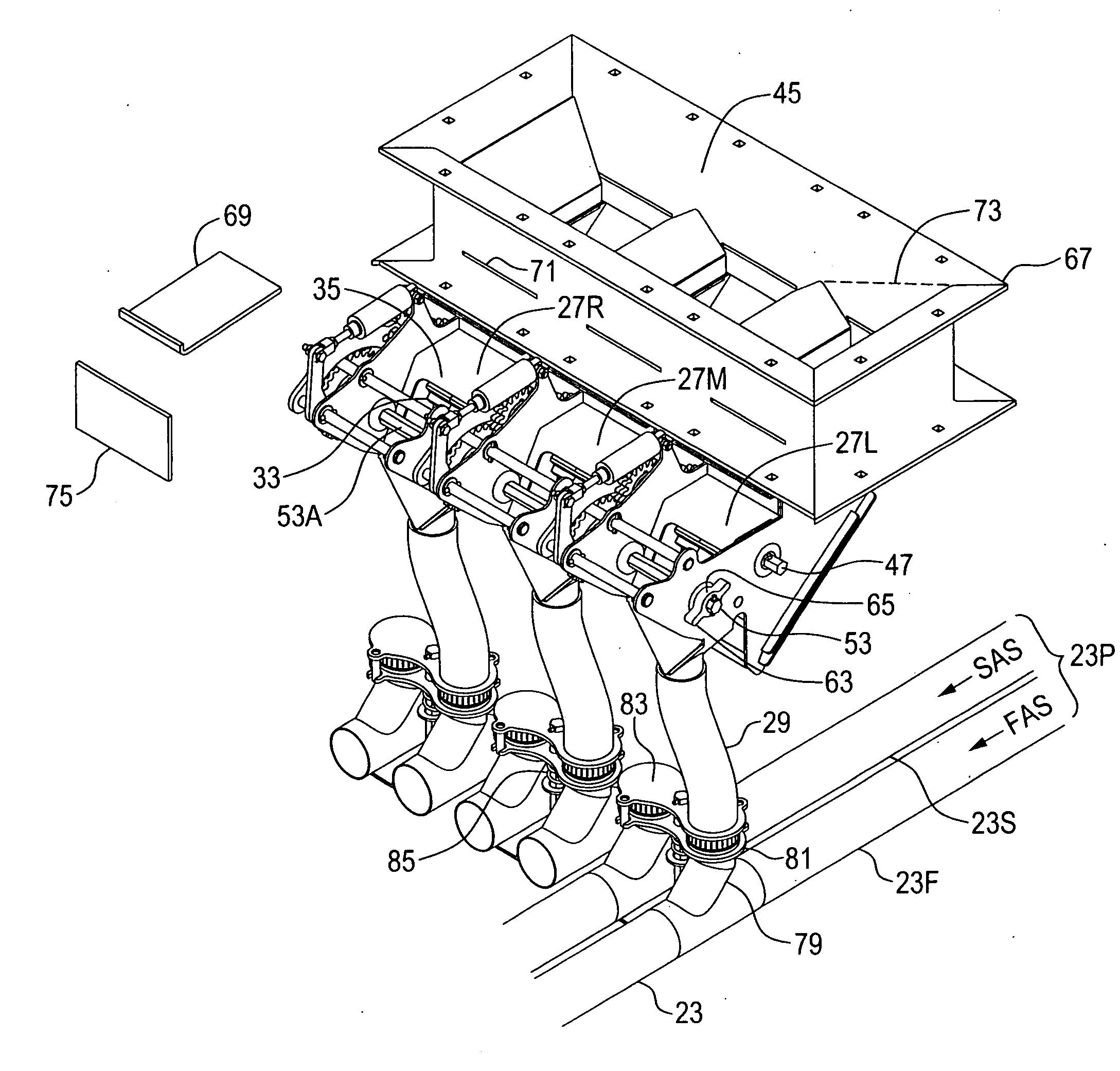

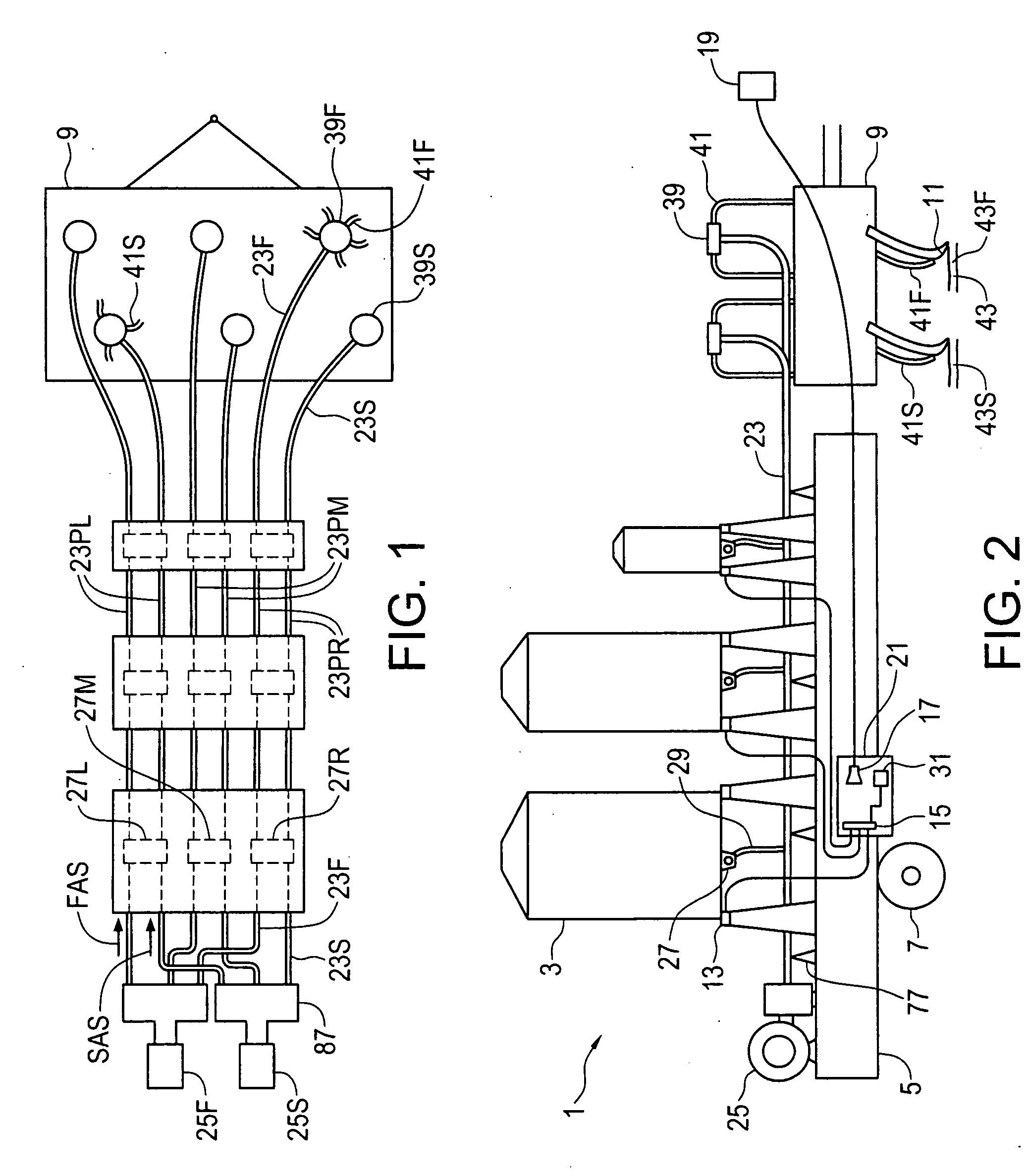

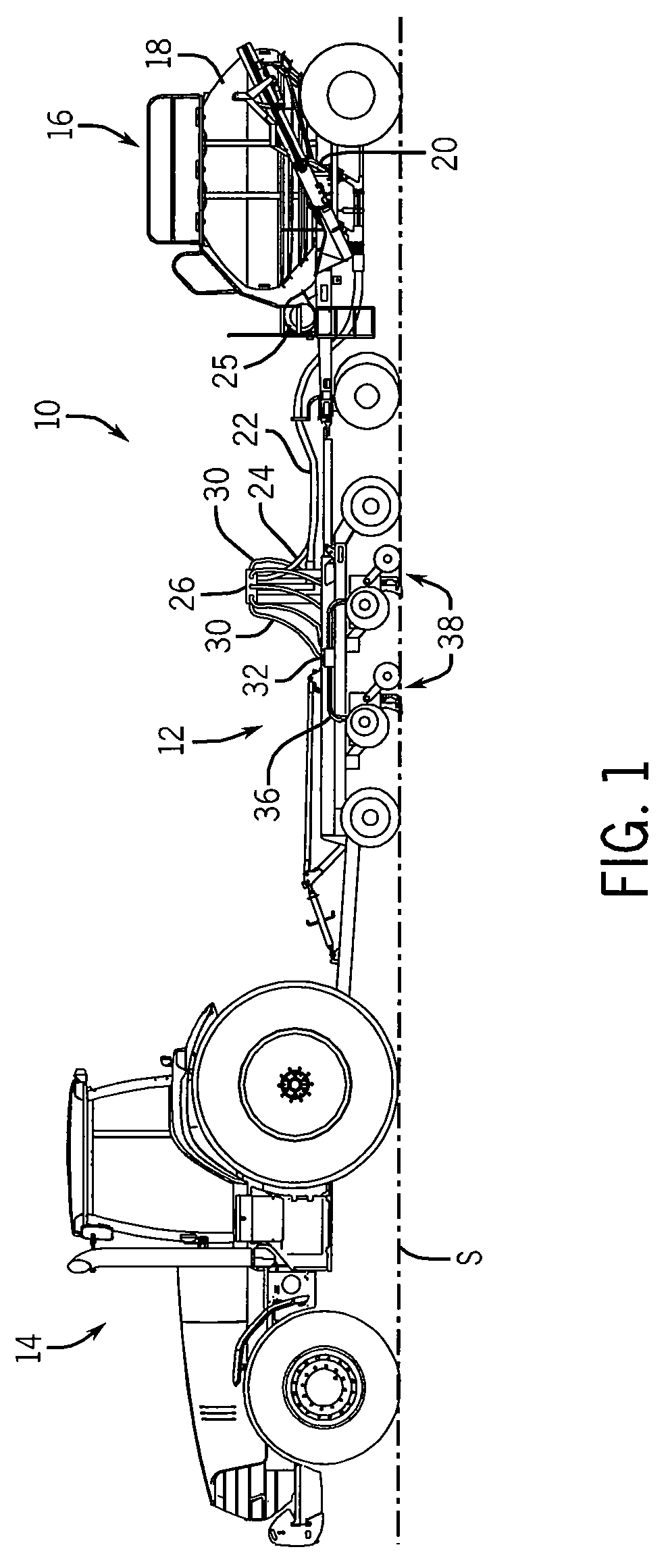

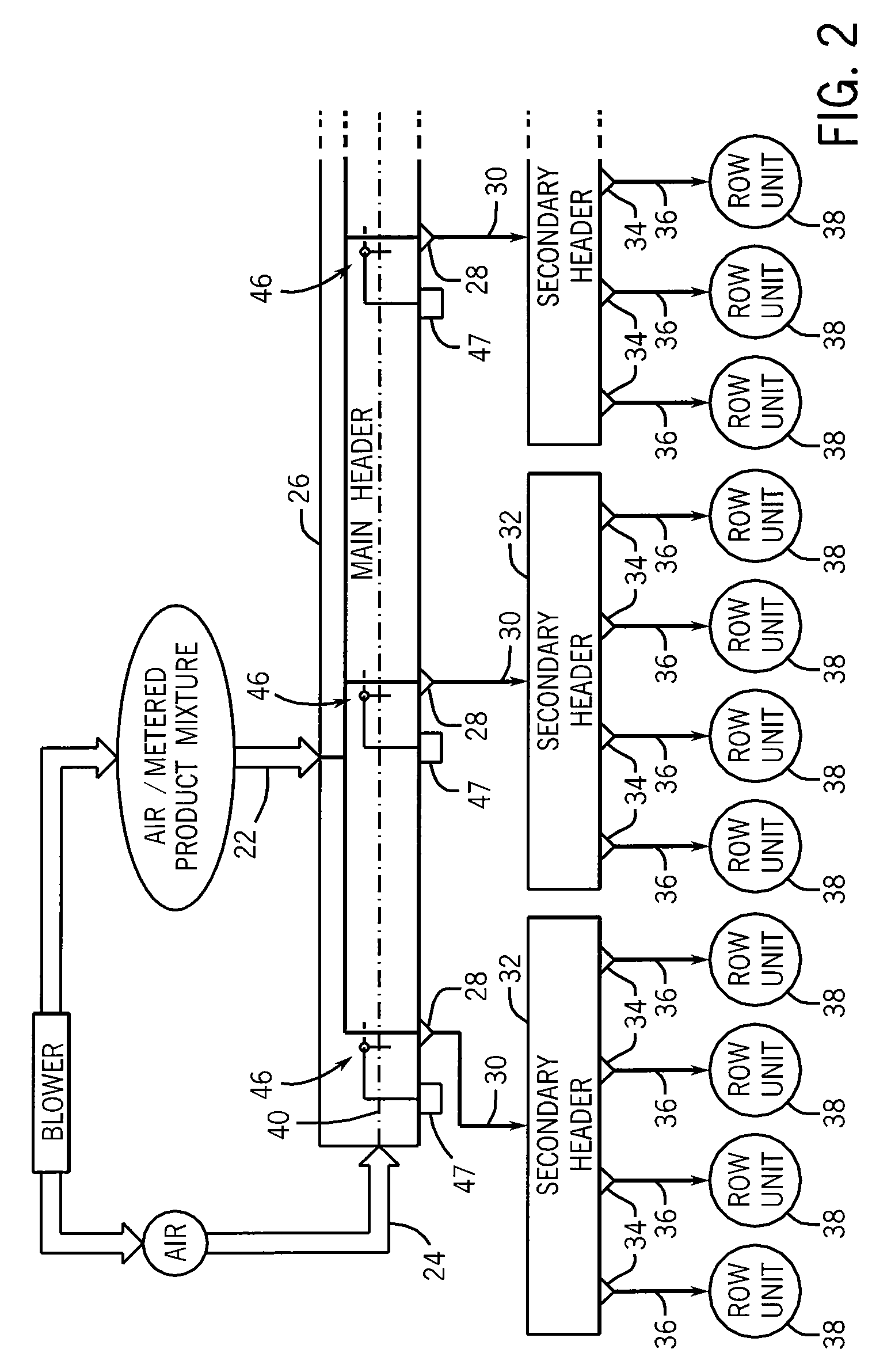

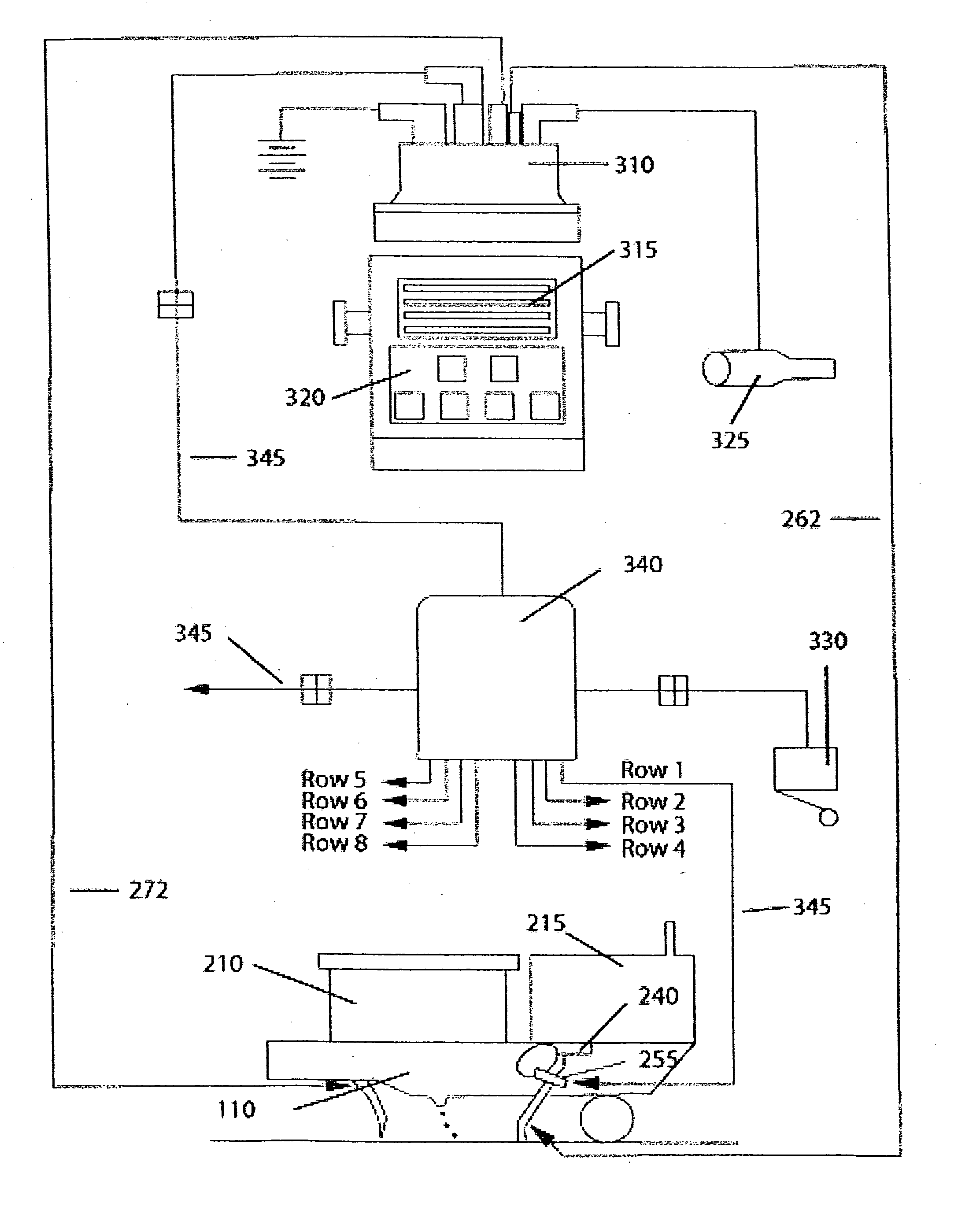

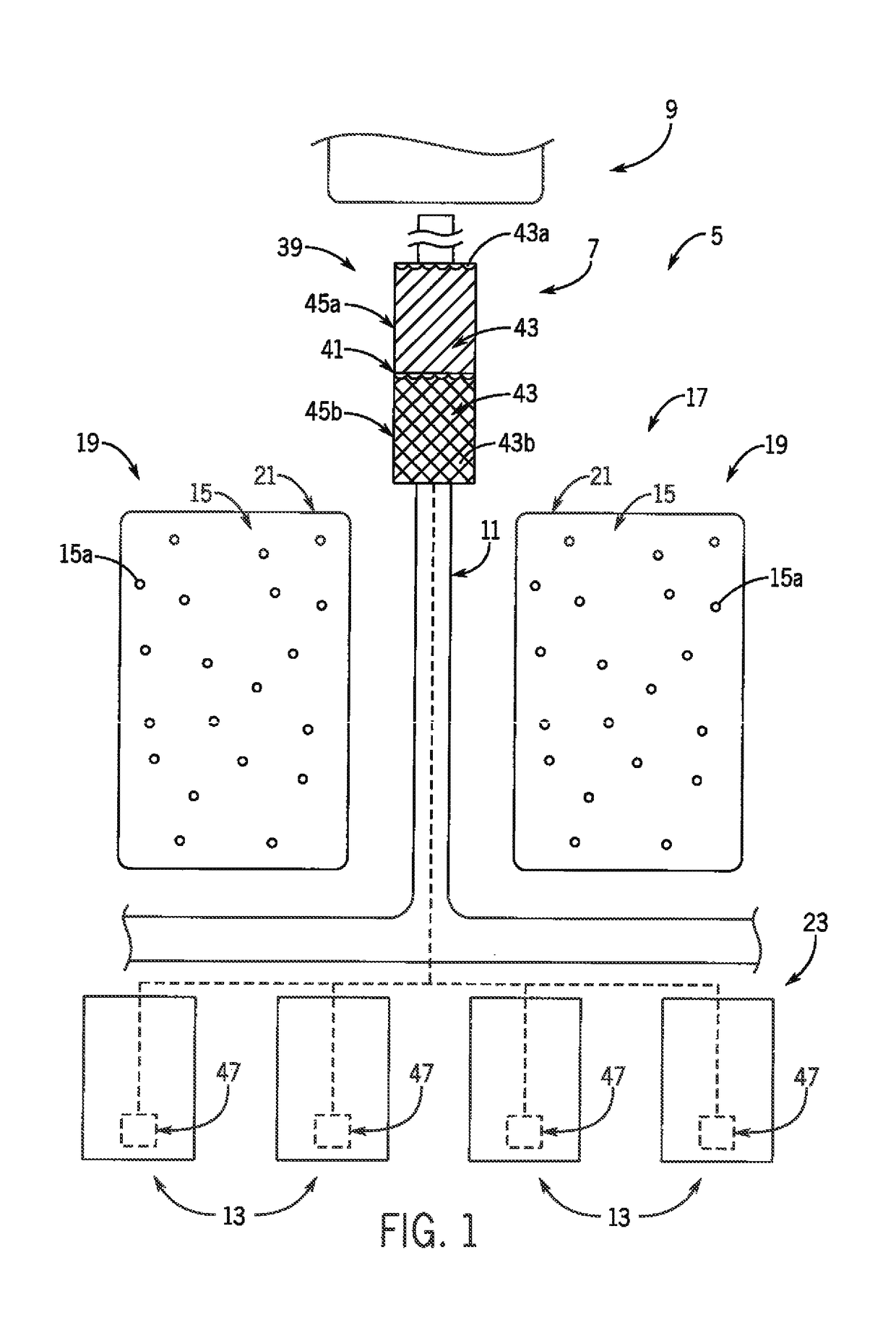

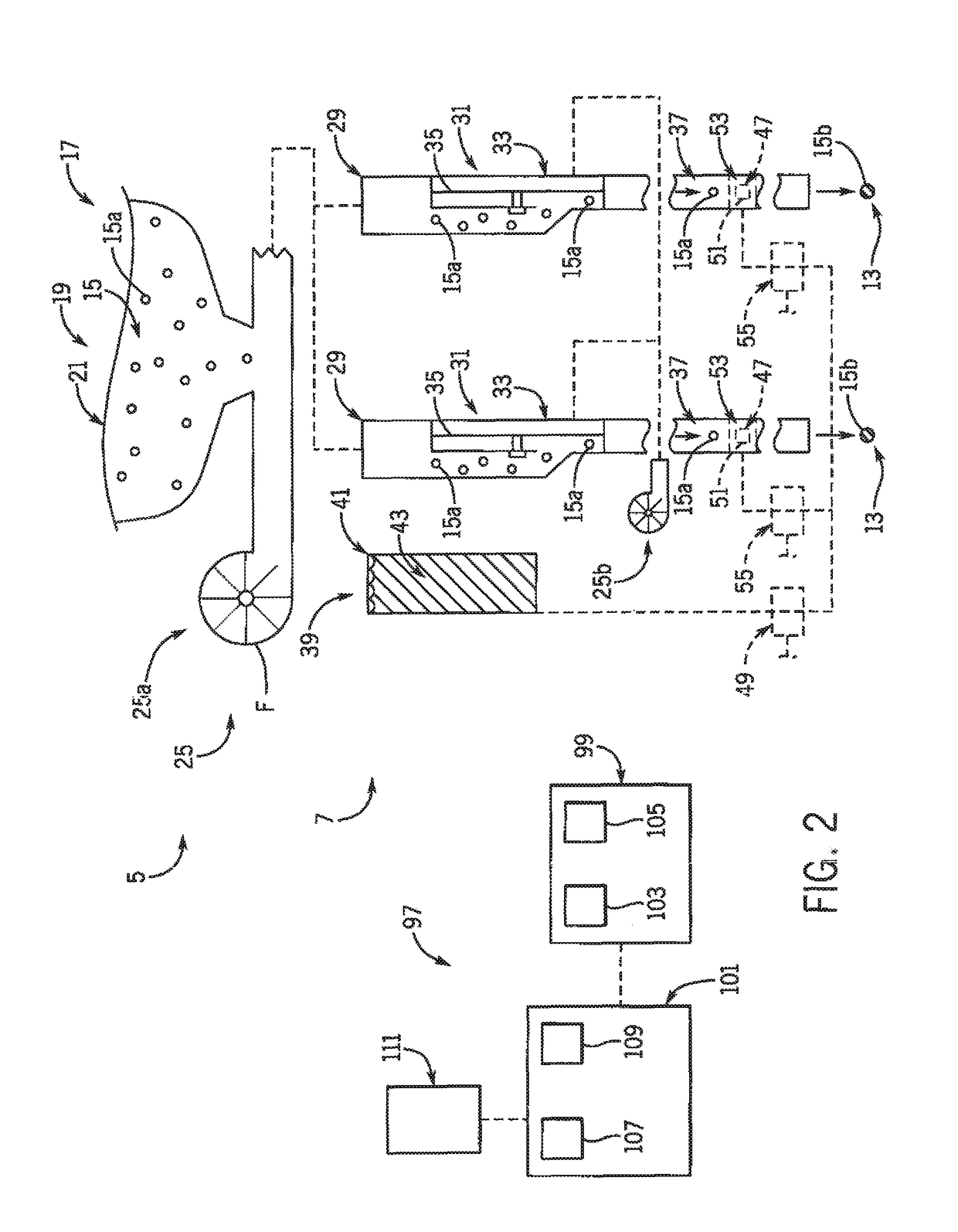

Method And Apparatus For Sectional Control Of Air Seeder Distribution System For A Farm Implement

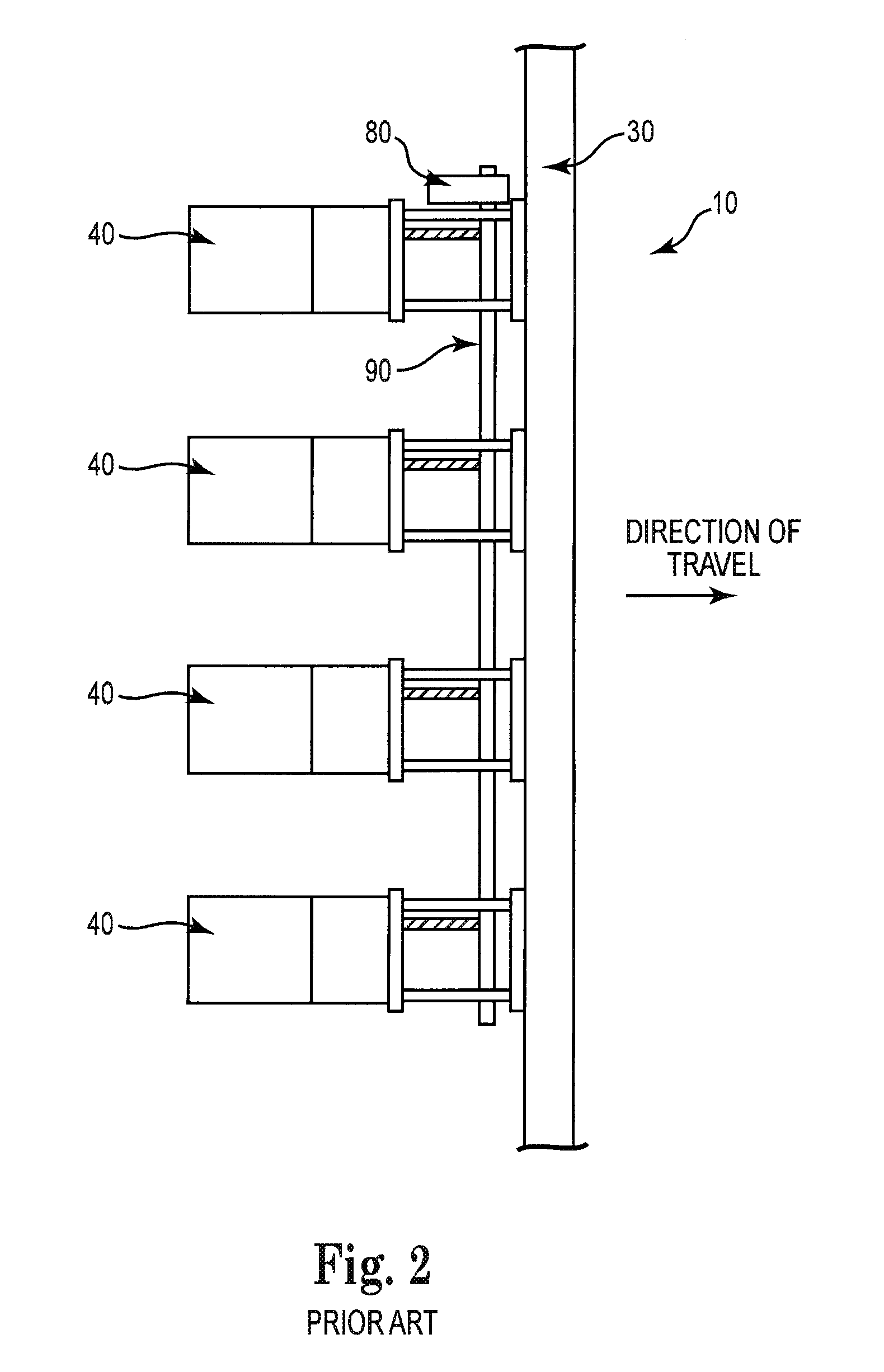

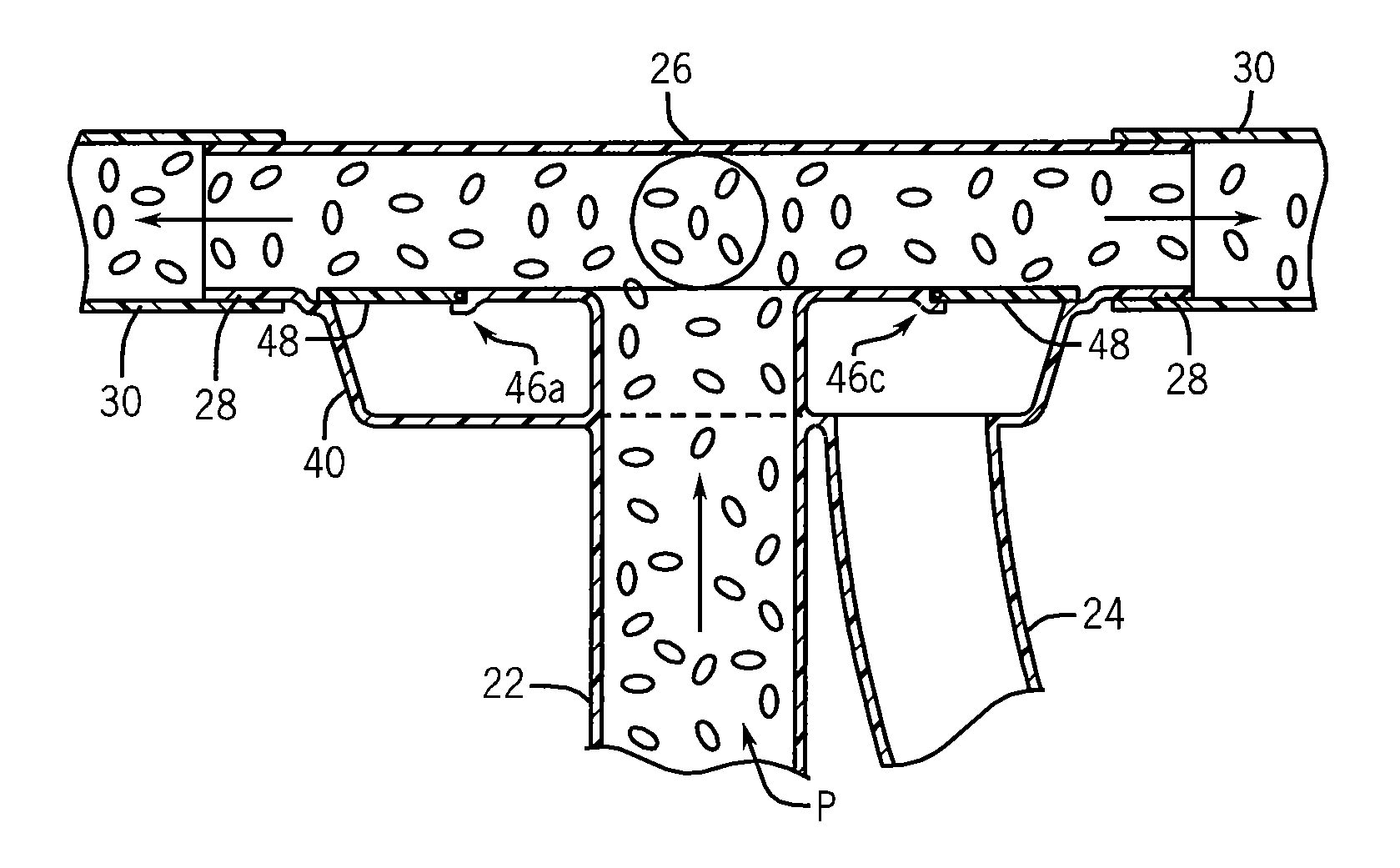

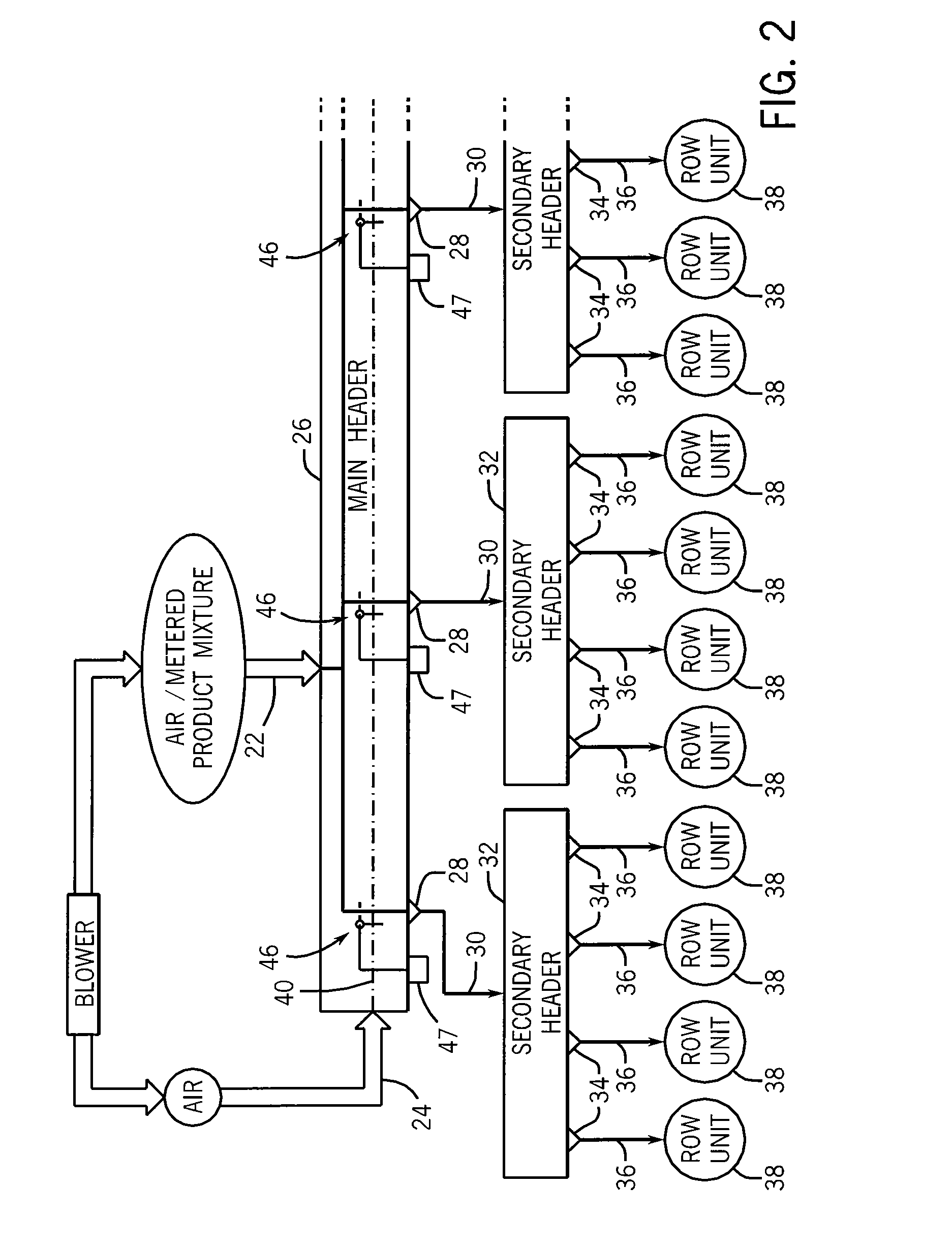

A method and system enables sectional control for an air seeding system of a farm implement by exposing a main header, or selected ports of the main header, to a purging air flow when product flow through the selected ports is stopped. A plenum of air is fluidly coupled to the main header and provides a purging air flow to any exit port of the main header that has been shut off from product flow. Valves are used to selectively flow couple the exit ports of the main header to the product flow and to the purging air flow.

Owner:CNH IND CANADA

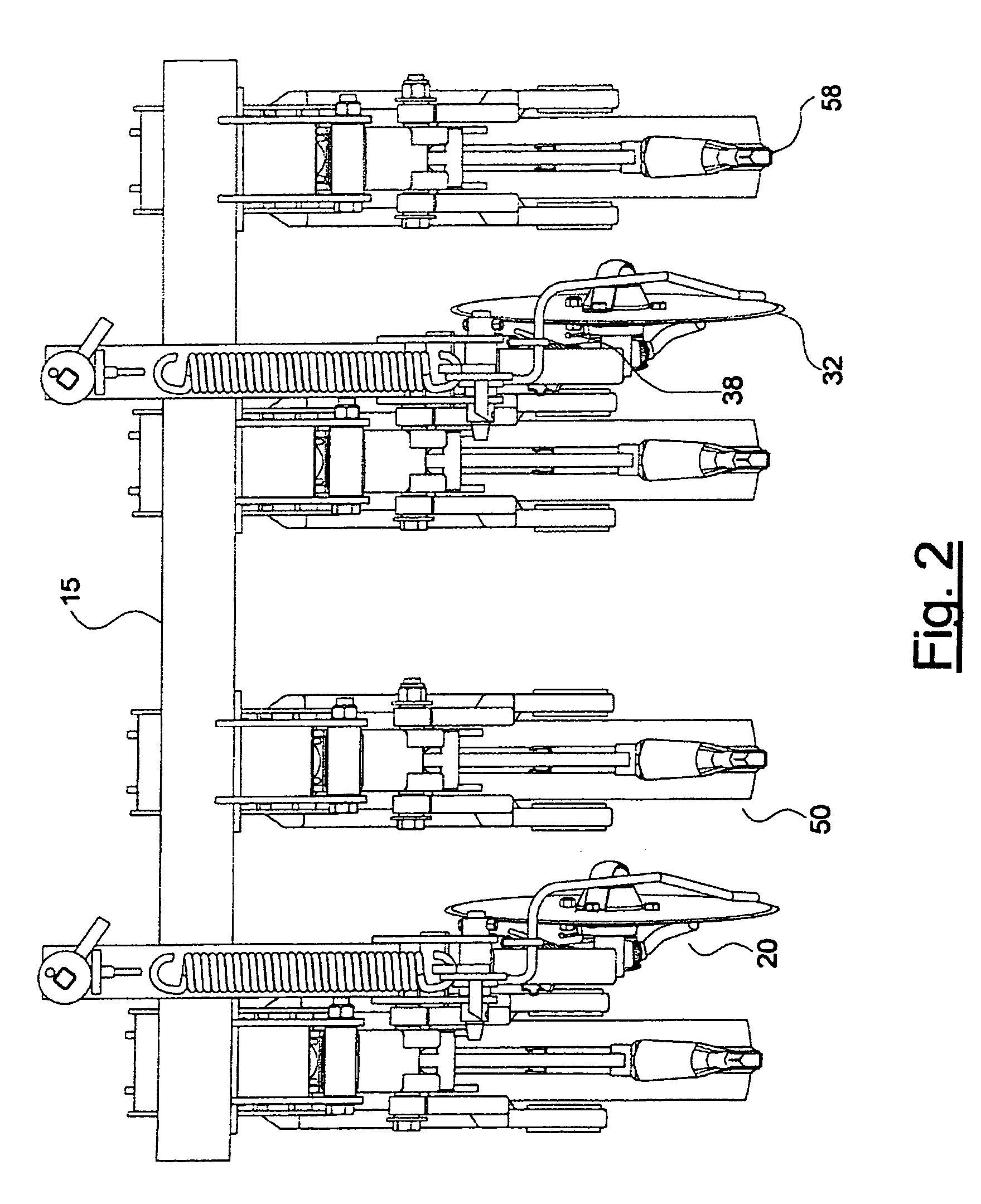

Method and apparatus of agricultural field seeding

ActiveUS20060162632A1Accurate conditionImprove consistencyFertiliser distributersPotato plantersTrailing armEngineering

A seeding and fertilizing apparatus comprises a plurality of seed assemblies each comprising a trailing arm pivotally connected at a front end thereof to the frame and a packer wheel rotatably attached to rear end thereof. A seed knife is attached to the trailing arm ahead of the packer wheel which rolls along the seed furrow created by the knife. A vertical position of the knife with respect to the packer wheel is adjustable, and a bias device is operative to exert a downward bias force on the trailing arm. A plurality of fertilizer assemblies each comprises a fertilizer disc rotatably mounted to the frame such that a vertical position of the disc with respect to the implement frame is adjustable. The seed assemblies and fertilizer assemblies are oriented laterally such that each fertilizer furrow is located between adjacent seed furrows.

Owner:BOURGAULT INDS

Method and apparatus for changing seed varieties at the row unit of a planter

A planting system for planting multiple seed varieties. The planting system includes a planter having a plurality of tanks and a plurality of row units. A plurality of seed meters are included in of the plurality of the row units. A seed transport belt is disposed below the plurality of seed meters to transport seed from each of the plurality of seed meters into a seed tube. Each of the plurality of seed meters is engaged and disengaged by a clutch, and the seed transport belt is disposed below the plurality of seed meters in an angled orientation.

Owner:KINZE MFG INC

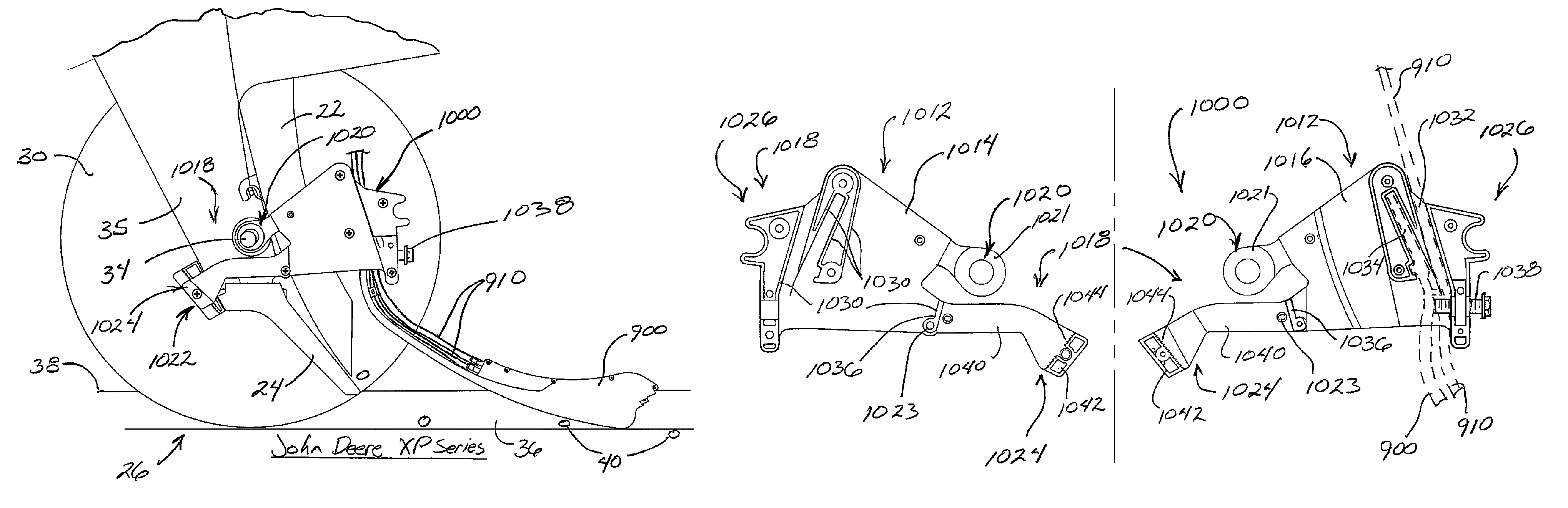

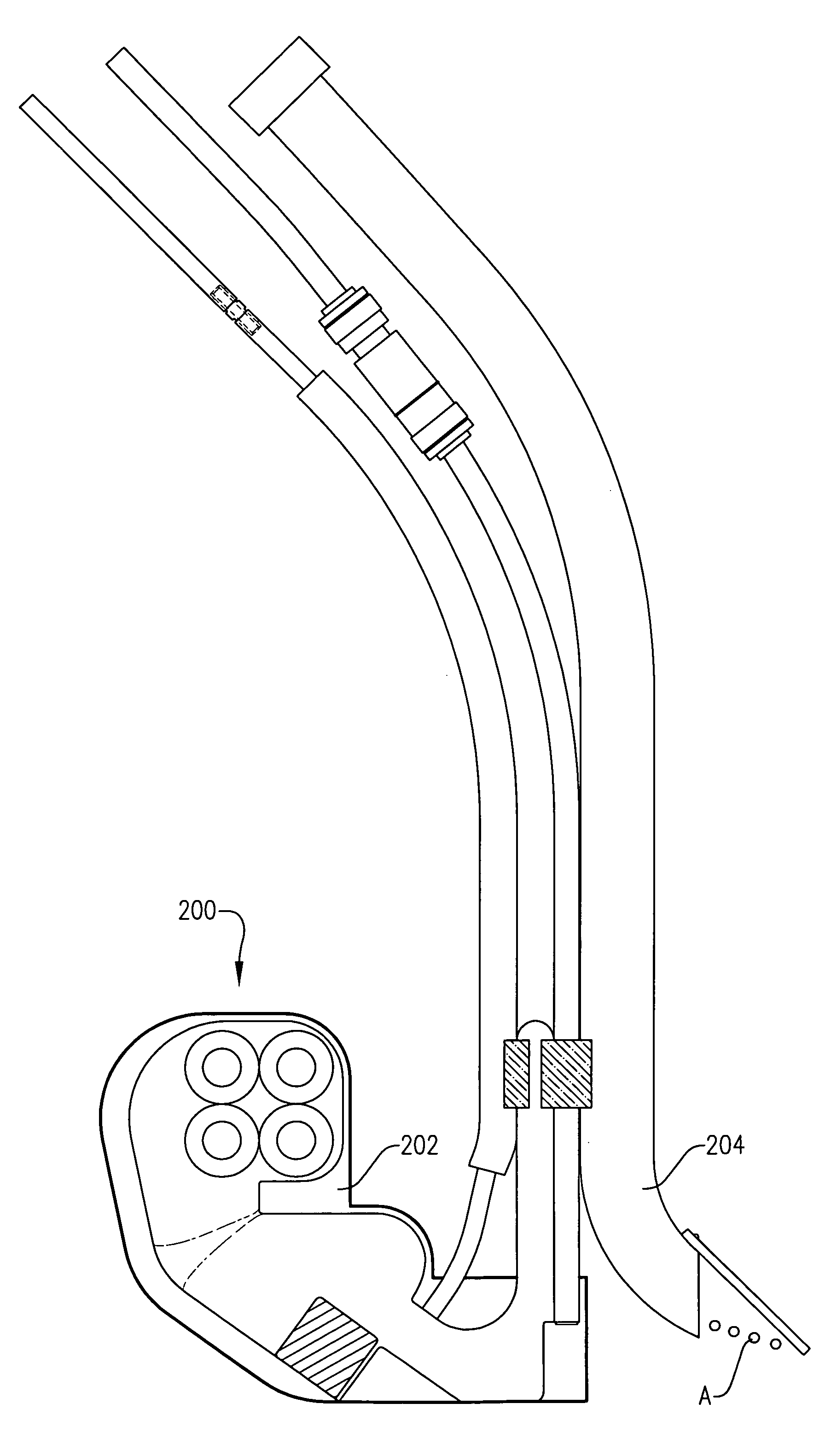

Planter bracket assembly for supporting appurtenances in substantial alignment with the seed tube

An improved bracket assembly for supporting seed planting appurtenances in substantial alignment with respect to a seed tube of an agricultural planter. The bracket assembly comprises a housing having opposing first and second sides. The housing includes mounting structure for rigidly securing the housing operably with respect to the planter frame. The sides of the housing further include interior walls for maintaining the sides of the housing in spaced apart relation. The housing may support various appurtenances alone or in combination, including a resilient tool, a liquid conduit, and a support arm for supporting any number of desired conduits all in substantial alignment with the seed tube.

Owner:PRECISION PLANTING LLC

Planter bracket assembly for supporting appurtenances in substantial alignment with the seed tube

ActiveUS7497174B2Soil-working equipmentsLiquid fertiliser distributionEngineeringMechanical engineering

Owner:PRECISION PLANTING LLC

Modular liquid metering system for an agricultural implement

ActiveUS7694638B1Precise applicationOvercome difficultiesPlantingWatering devicesElectricityEngineering

A liquid metering system for an agricultural implement is modular, having individual metering pumps for each crop row. The pumps are individually controlled for precise application of the liquid input and are preferable electrically driven. A common pump is used, making the system modular in that varying sizes of implements can be produced by varying the number of pumps. A common supply line is used to supply a liquid input from a reservoir to the pumps. Each pump is connected to the common supply line. By connecting each pump to the common supply line, the difficulty of routing individual hoses from a central pump to each row unit are overcome.

Owner:DEERE & CO

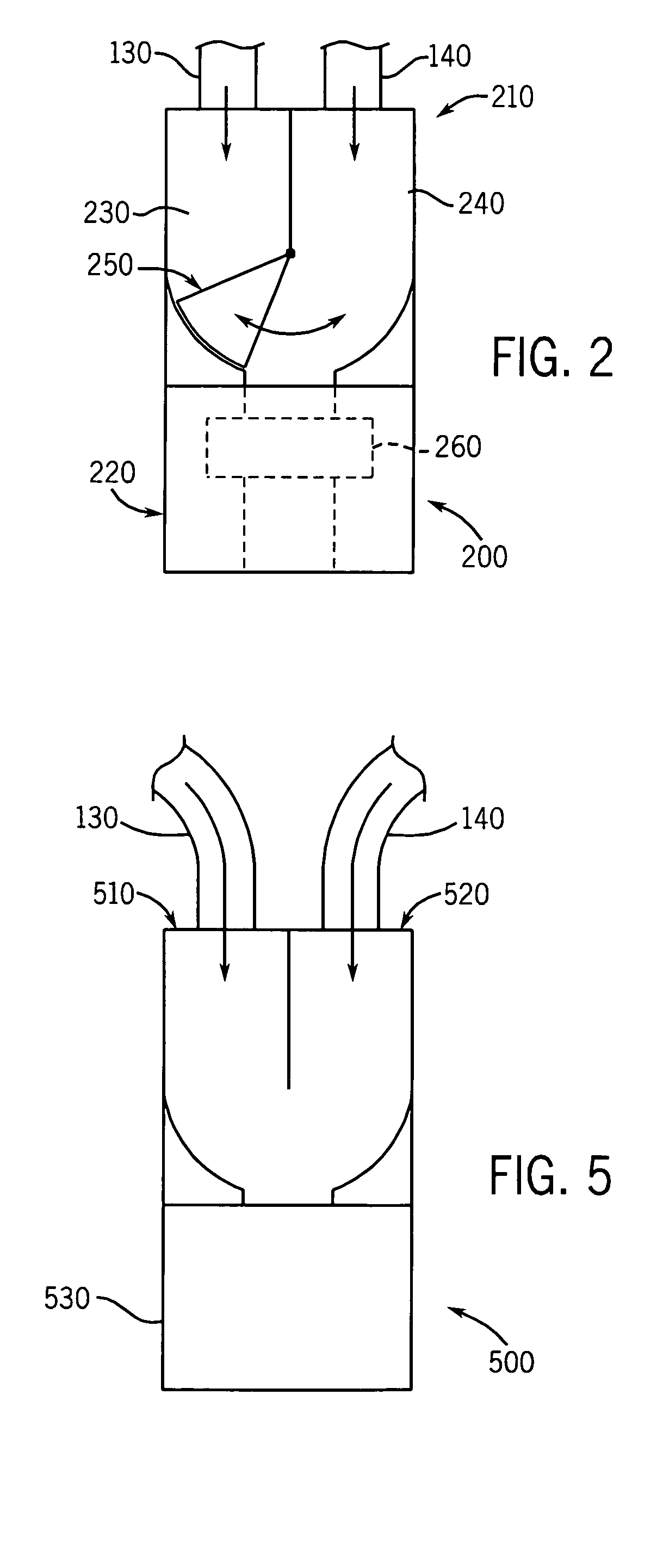

Method and system for concentrating chemical granules around a planted seed

ActiveUS6938564B2Easy to placeReduce the amount requiredPotato plantersSeed depositing seeder partsBiomedical engineering

A system or method for dispensing seeds and chemical granules, in which chemical granules are dispensed through a granule tube into a seed dispensing tube, where the granule tube is connected to the seed dispensing tube at a location above a lower opening of the seed dispensing tube, and where the lower opening of the seed dispensing tube is covered with a brush. A seed is dispensed through the seed dispensing tube. The brush holds chemical granules within the seed dispensing tube such that chemical granules accumulate within the seed dispensing tube, and the brush allows a seed and accumulated chemical granules to pass through the lower opening when the seed is dispensed via the seed dispensing tube.

Owner:AMERICAN CHEM CORP

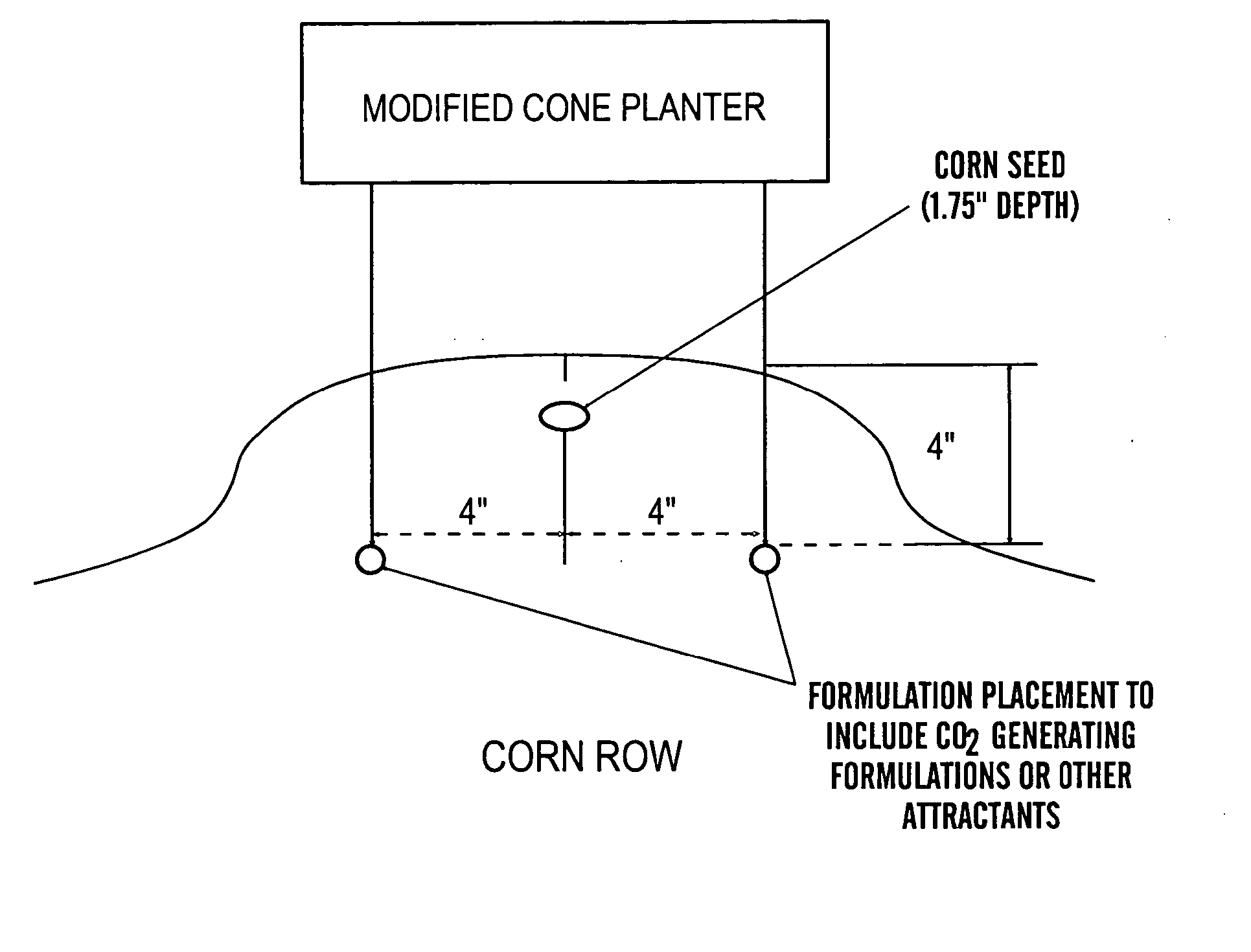

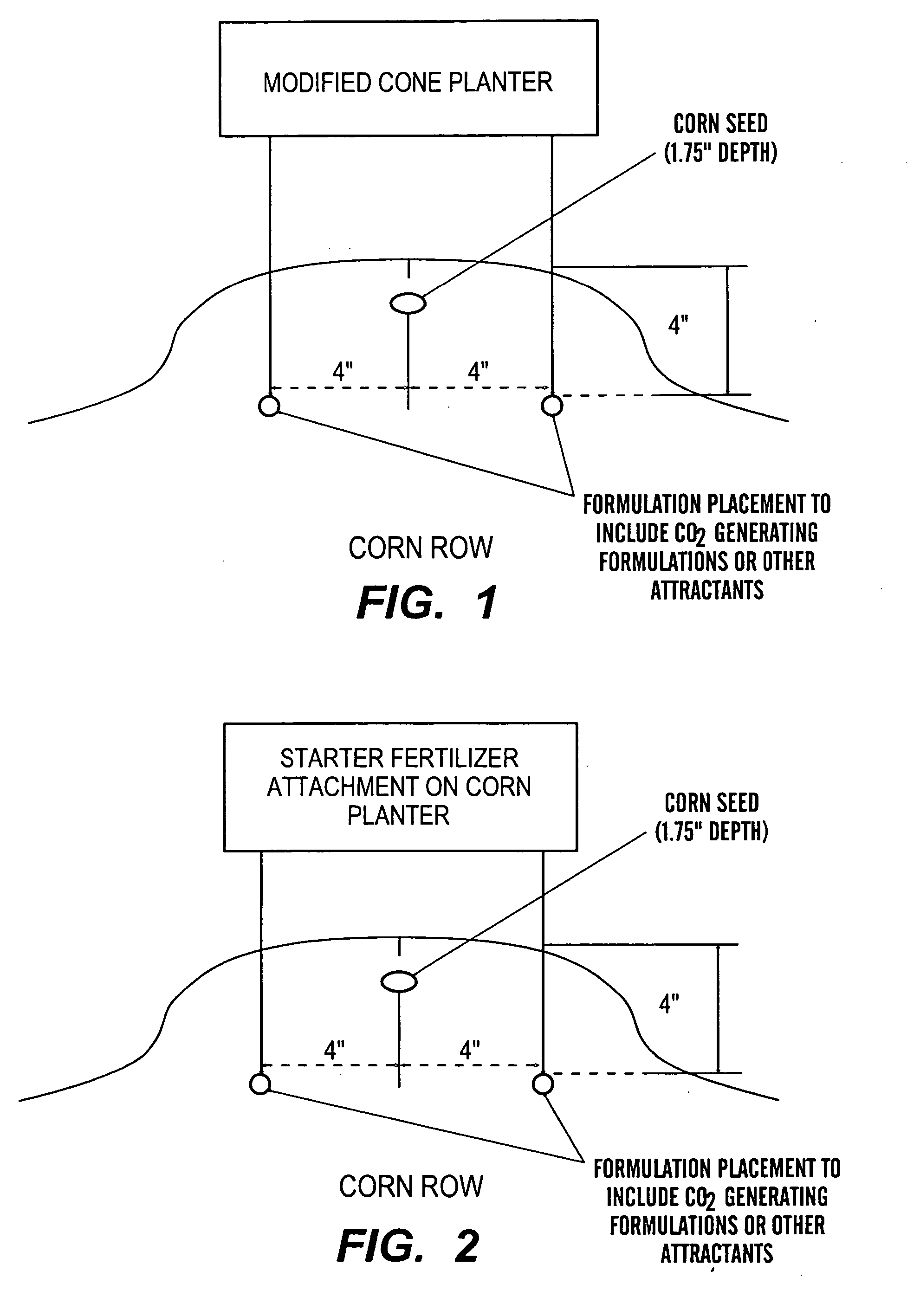

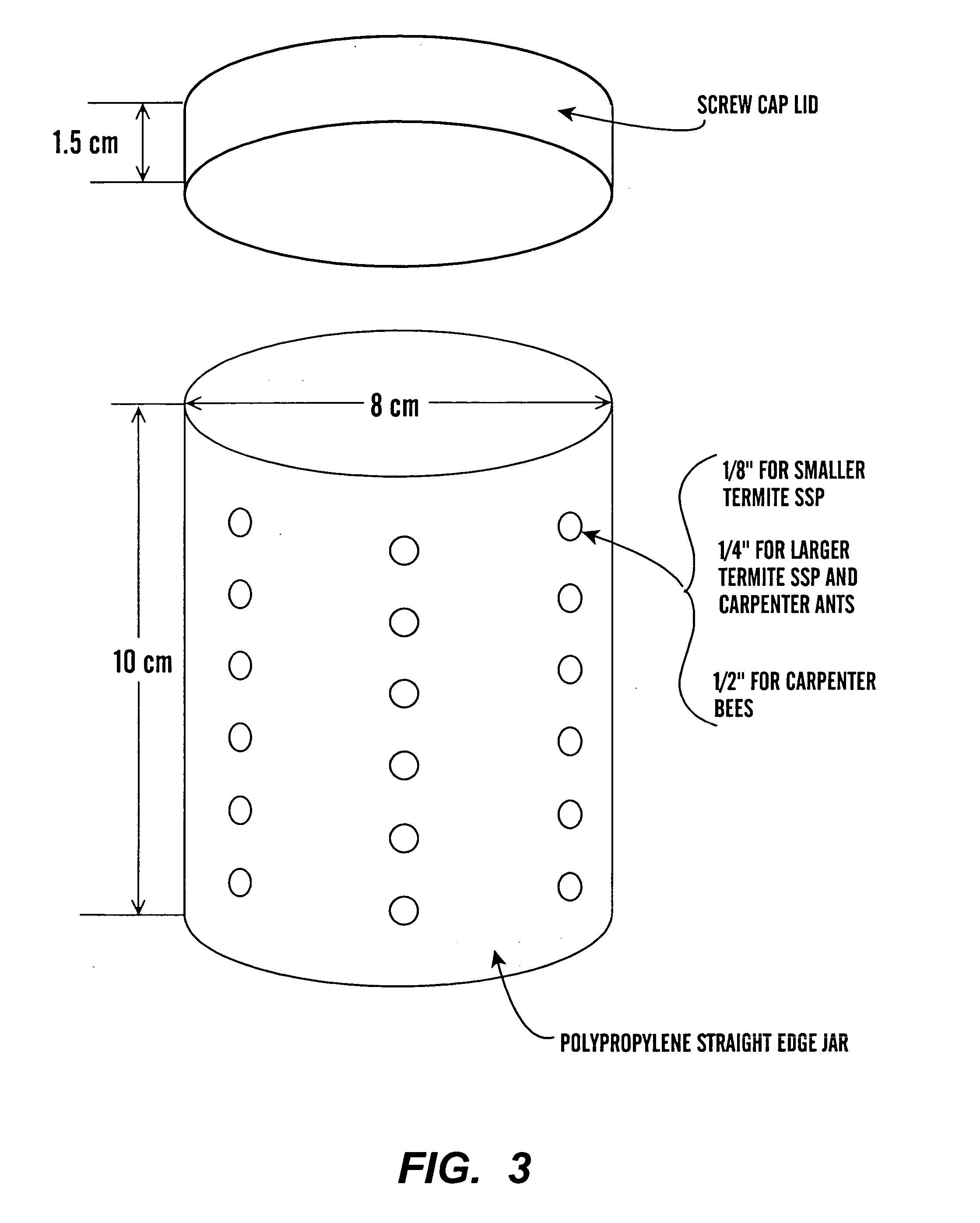

Method and device for attracting insects

A method and device for attracting insects involving the generation and / or release of particular amounts of carbon dioxide, in combination with an insecticide that does not repel such insects. Particular formulations as well as devices which incorporate such formulations for trapping, attracting and destruction of particular insects, including boring insects, such as termites and corn root worm insects, is set forth. Particular methods of administration of formulations and devices to enhance insect control and to prevent crop damage are disclosed.

Owner:COLORADO STATE UNIVERSITY

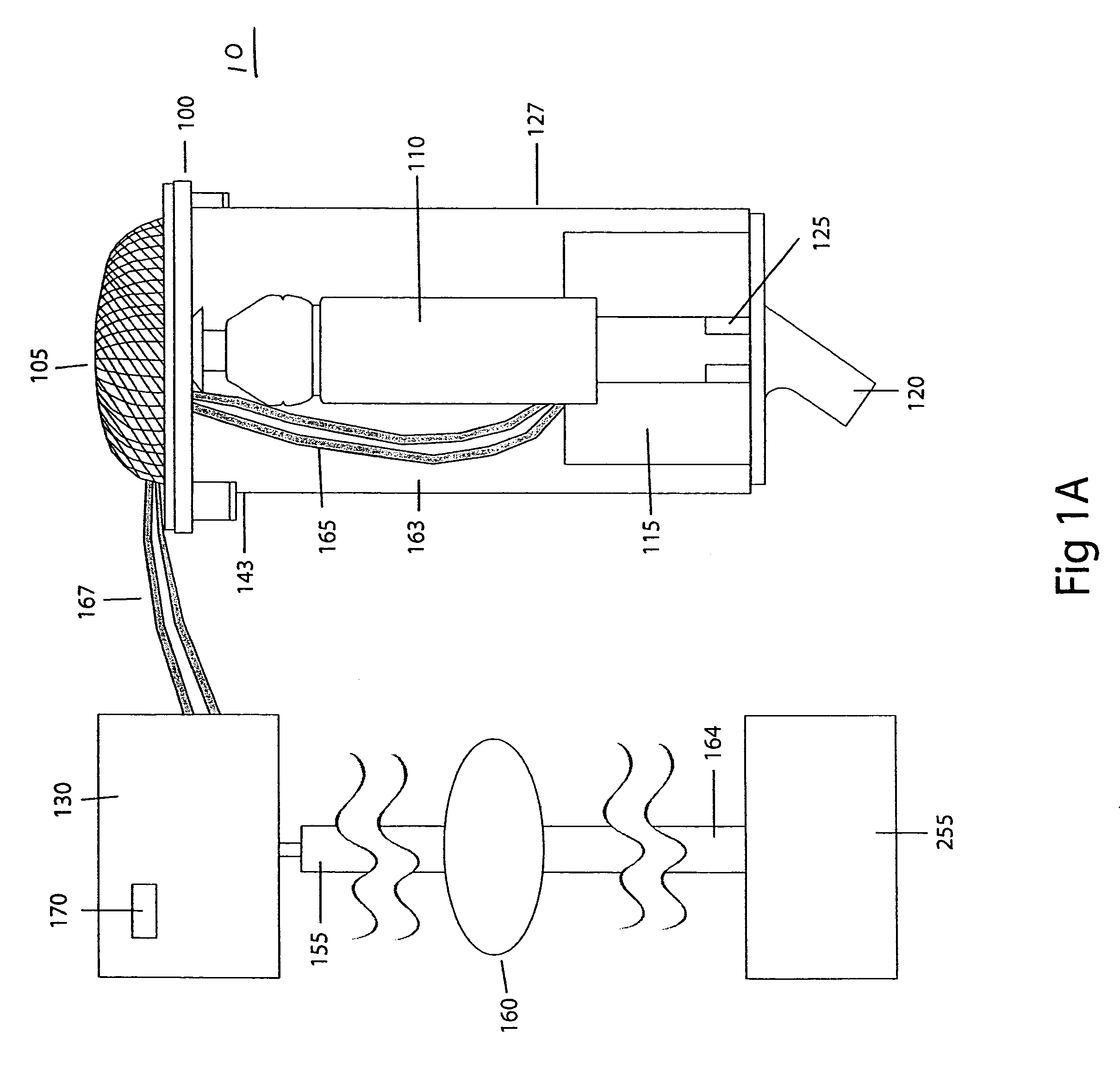

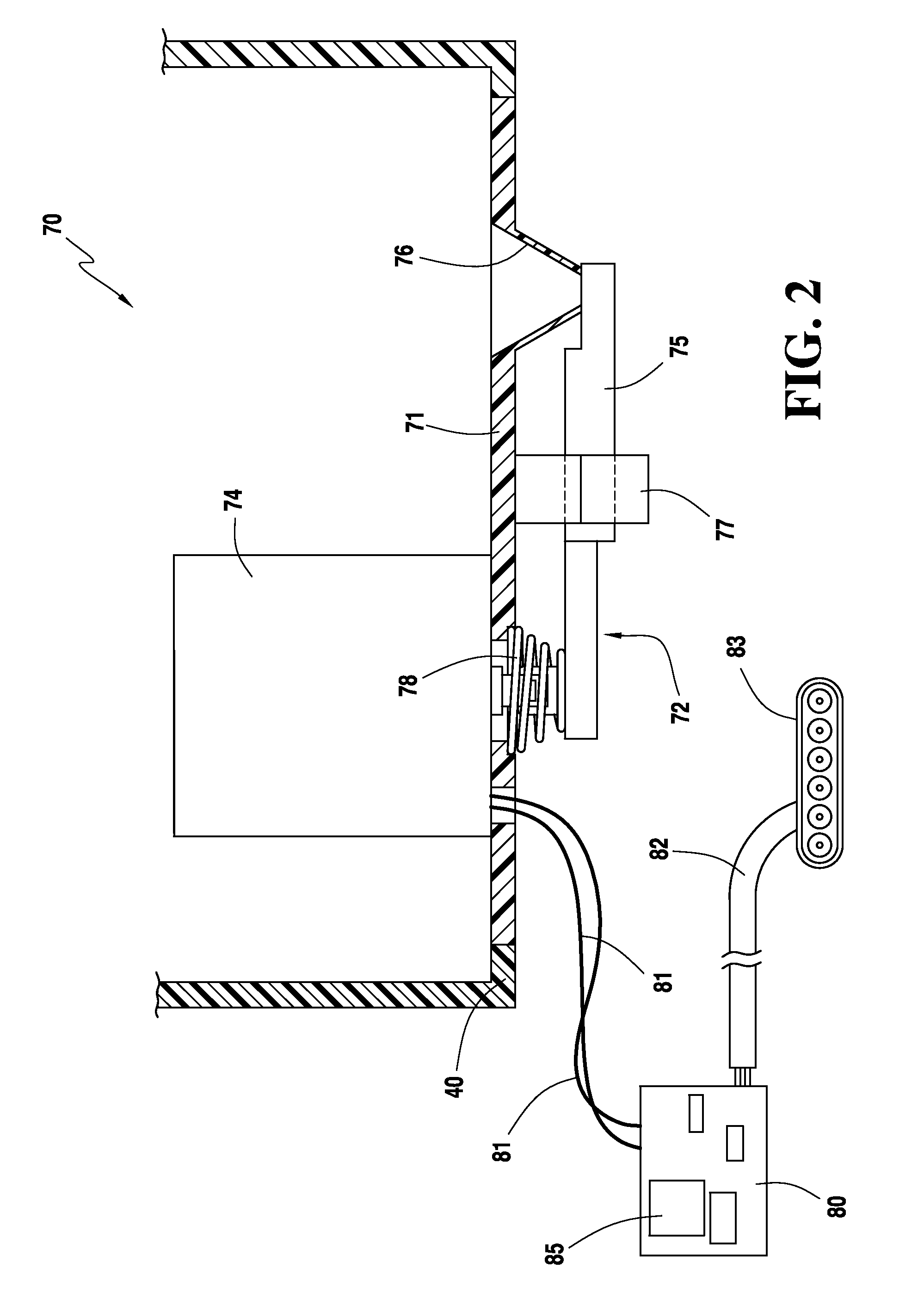

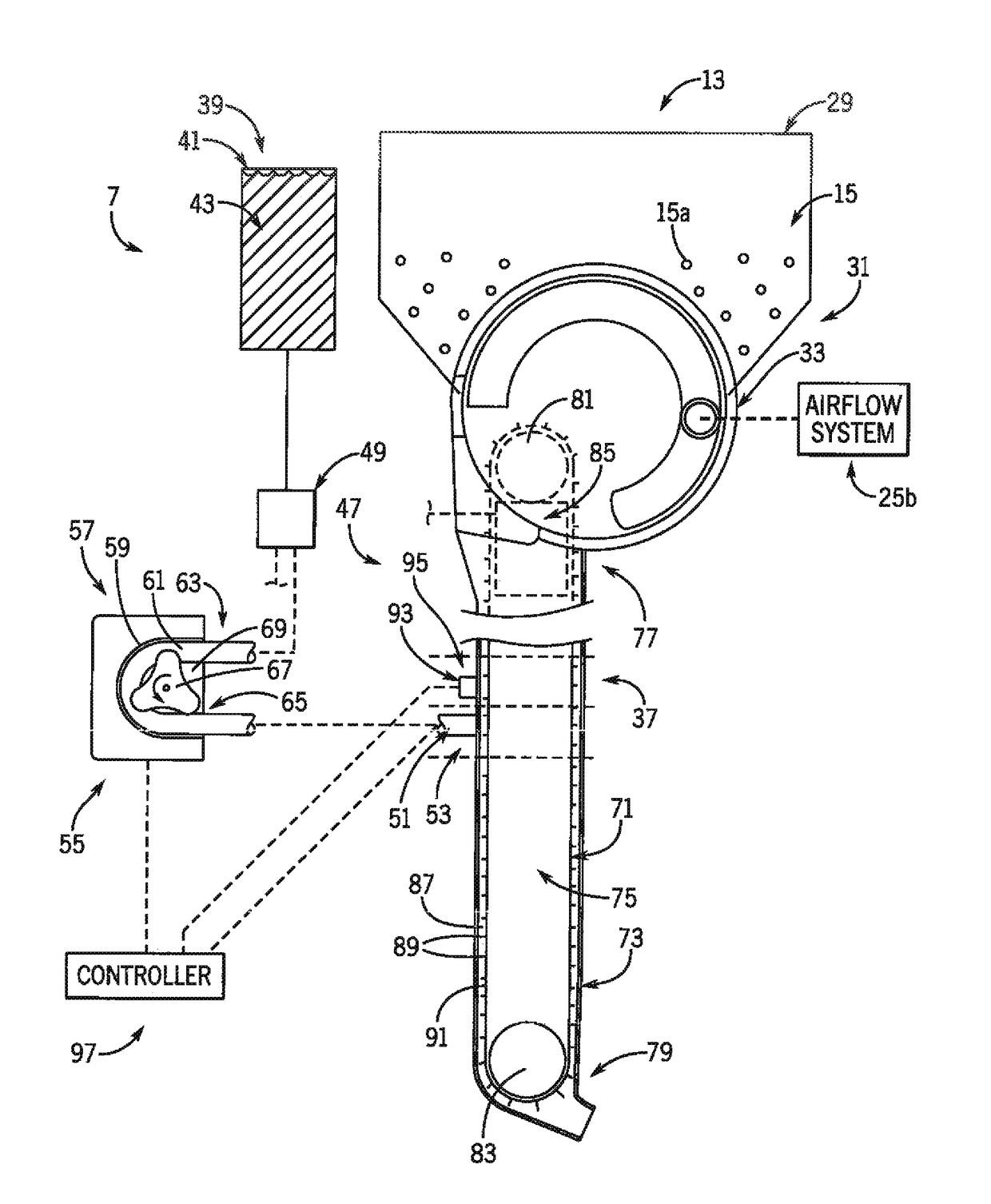

System and Method for Spraying Seeds Dispensed from a Planter

ActiveUS20140048002A1Liquid fertiliser regulation systemsFertilising methodsEngineeringControl valves

In one aspect, a system for providing seed-specific placement of fluid as seeds are planted by a planter is disclosed. The system may generally include a seed meter configured to dispense seeds into a furrow at a seed frequency and a nozzle assembly configured to spray the seeds dispensed into the furrow. The nozzle assembly may include a valve. In addition, the system may include a controller communicatively coupled to the valve. The controller may be configured to determine the seed frequency of the seed meter based on a speed-related parameter of the planter. The controller may also be configured to control the operation of the valve based on the seed frequency such that a metered amount of fluid is sprayed at least one of on or adjacent to each seed.

Owner:CAPSTAN

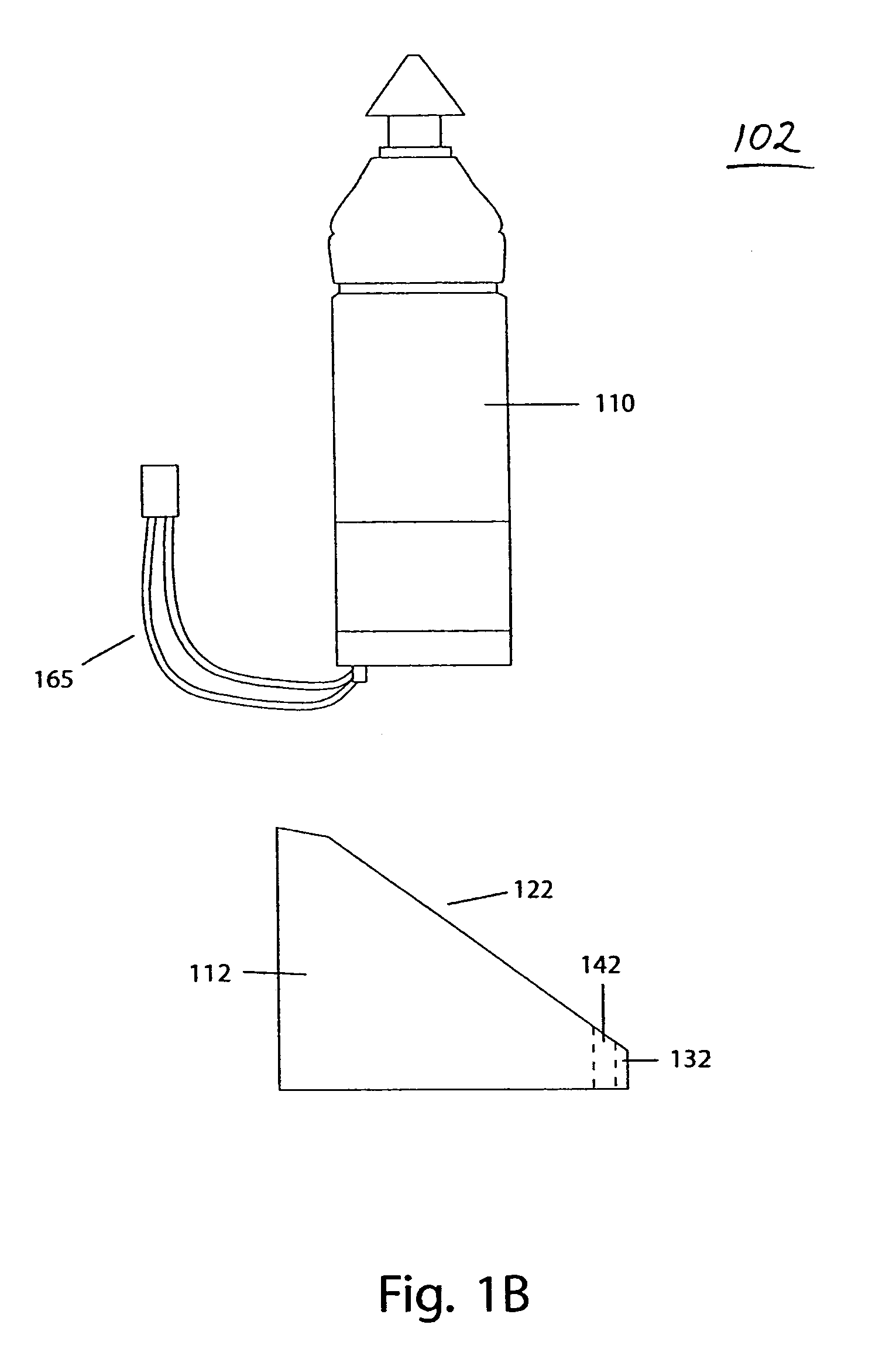

Self-calibrating meter with in-meter diffuser

A self-calibrating metering system for dispensing chemical granules. The system incorporates a flow sensor configured to sense a greater flow rate at the inlet aperture than at the outlet aperture. Further included is an adjustment mechanism configured to adjust the flow rate of the meter so as to calibrate the meter according to a known flow rate through a calibrated orifice within the meter. An electromechanical solenoid may be energized by a subcontroller operably coupled to the metering apparatus to allow chemical granules to flow by gravity from the pesticide container that may be disposed above the metering apparatus. The metering apparatus may be disposed on a planter unit designed to deposit granular materials with seed during the planting process. The metering system further includes an in-meter diffuser that receives foreign material and lumps in order to prevent the metering apparatus from becoming clogged.

Owner:AMERICAN CHEM CORP

Air seeder tank and distribution apparatus

ActiveUS20120103238A1Different air speedDifferent pressureFertiliser distributersAgriculture and animal husbandary industryInternal pressureMechanical engineering

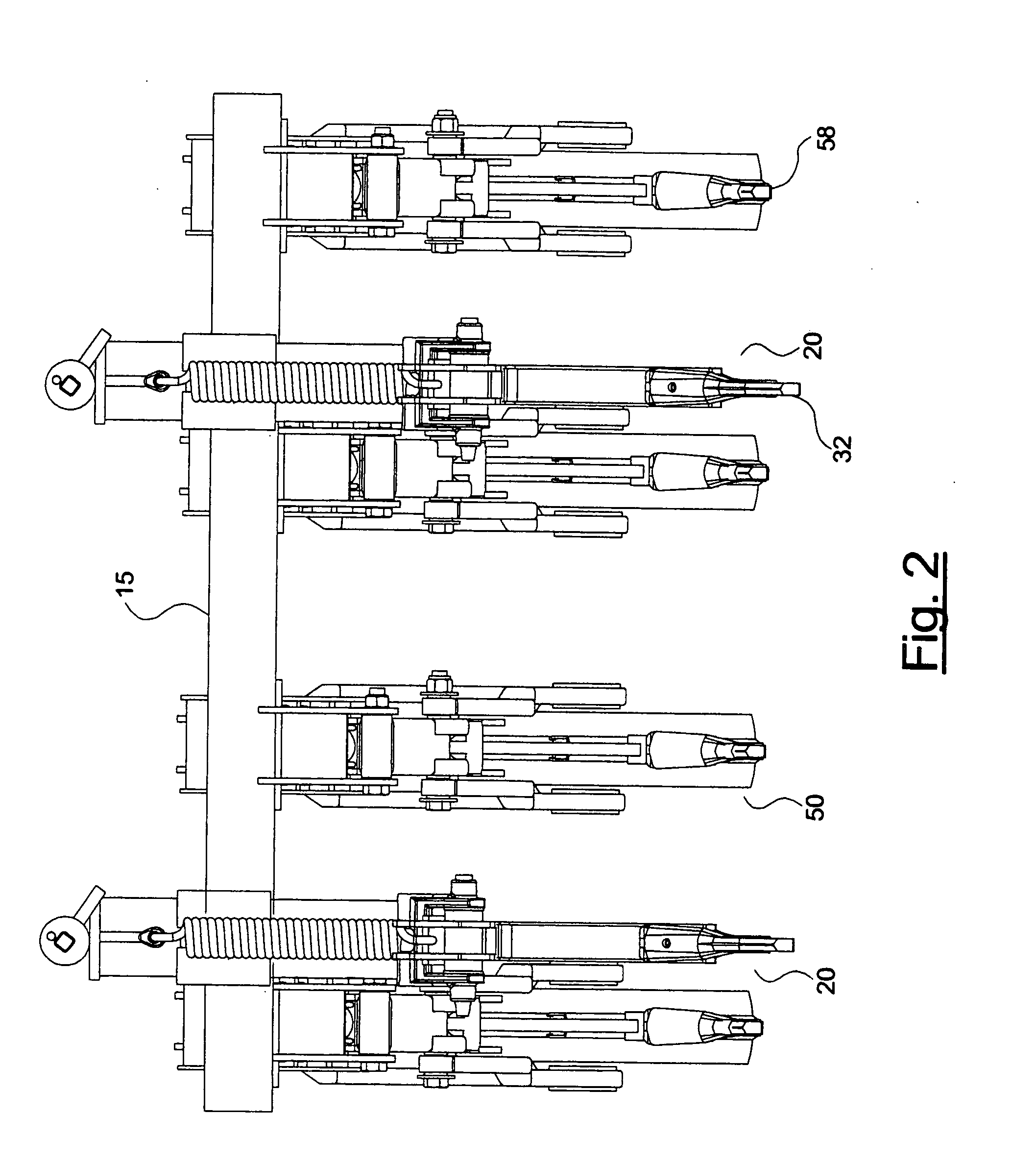

An air seeder distribution apparatus has seed and fertilizer tanks, and a like plurality of metering devices mounted on each product tank. A manifold set comprises a like plurality of product manifolds and each manifold is separately fed from one metering device on each of the seed and fertilizer tanks. A control selectively starts and stops rotation of the feed roller of each metering device to feed product from either tank, or both tanks to the connected manifold. The weight of each tank can be displayed on a weight indicator. Balancing of the pressure in each supply conduit can be provided. A remote opener exerts downward force on the tank lid to maintain interior pressure.

Owner:SEEDMASTER MFG

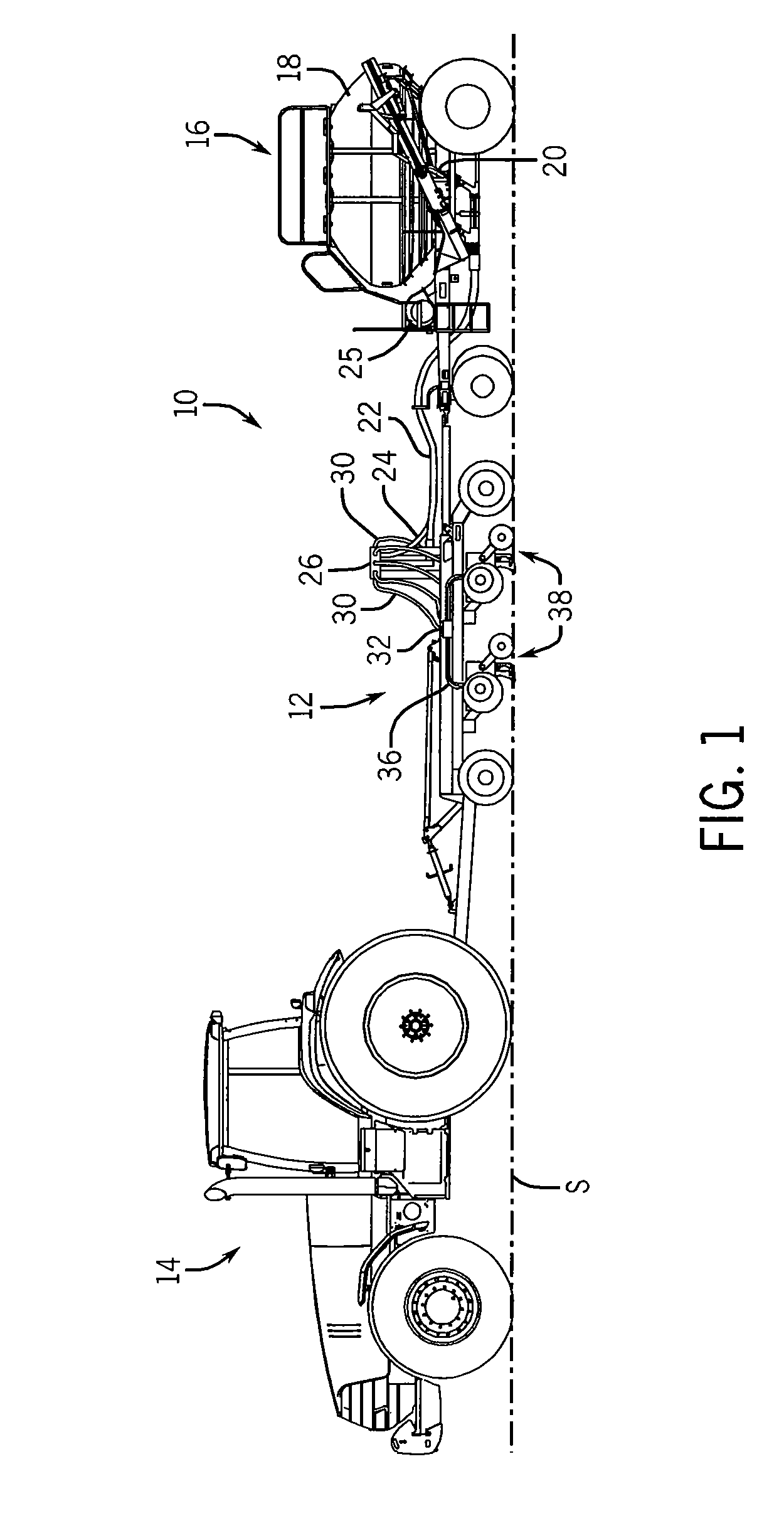

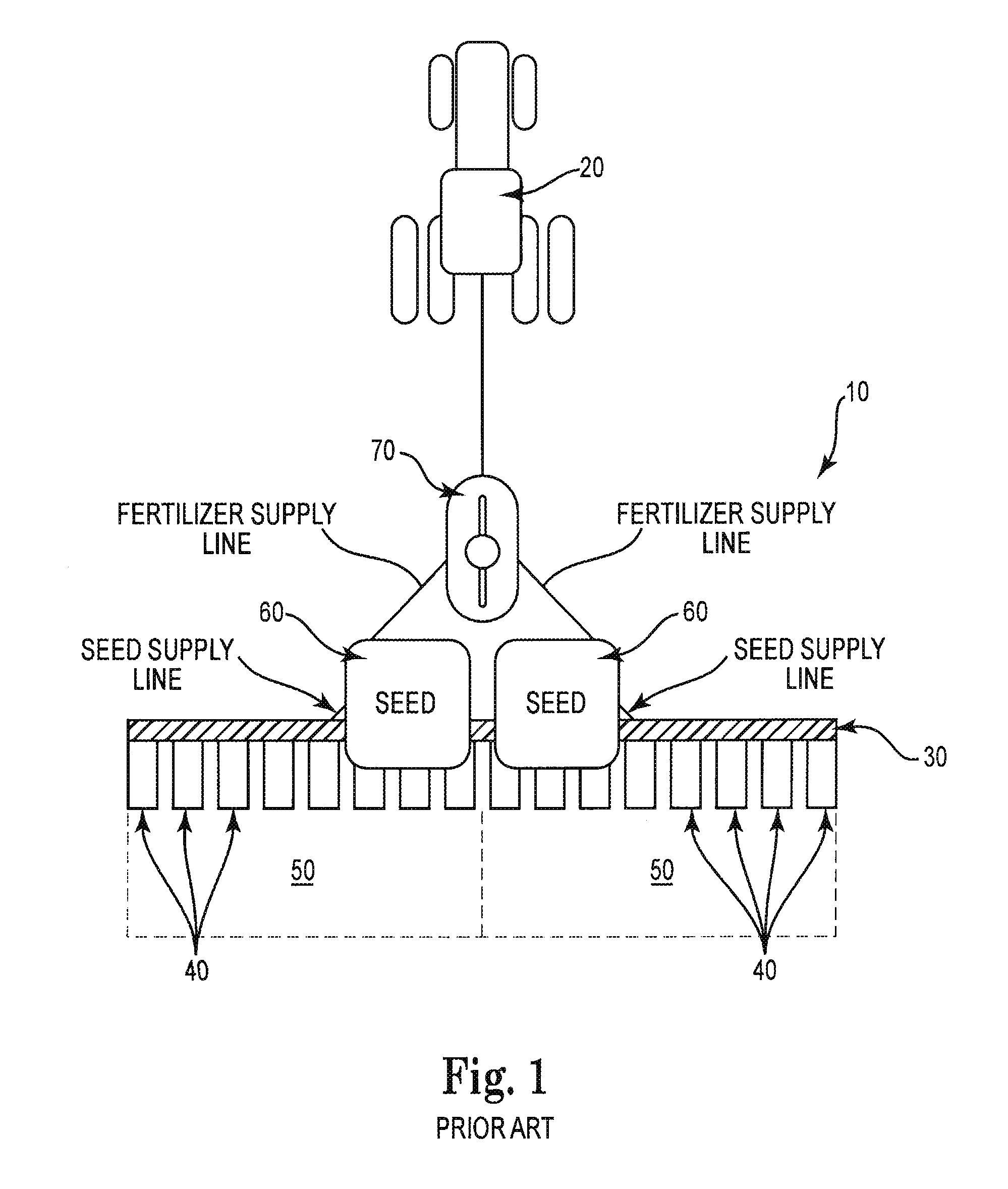

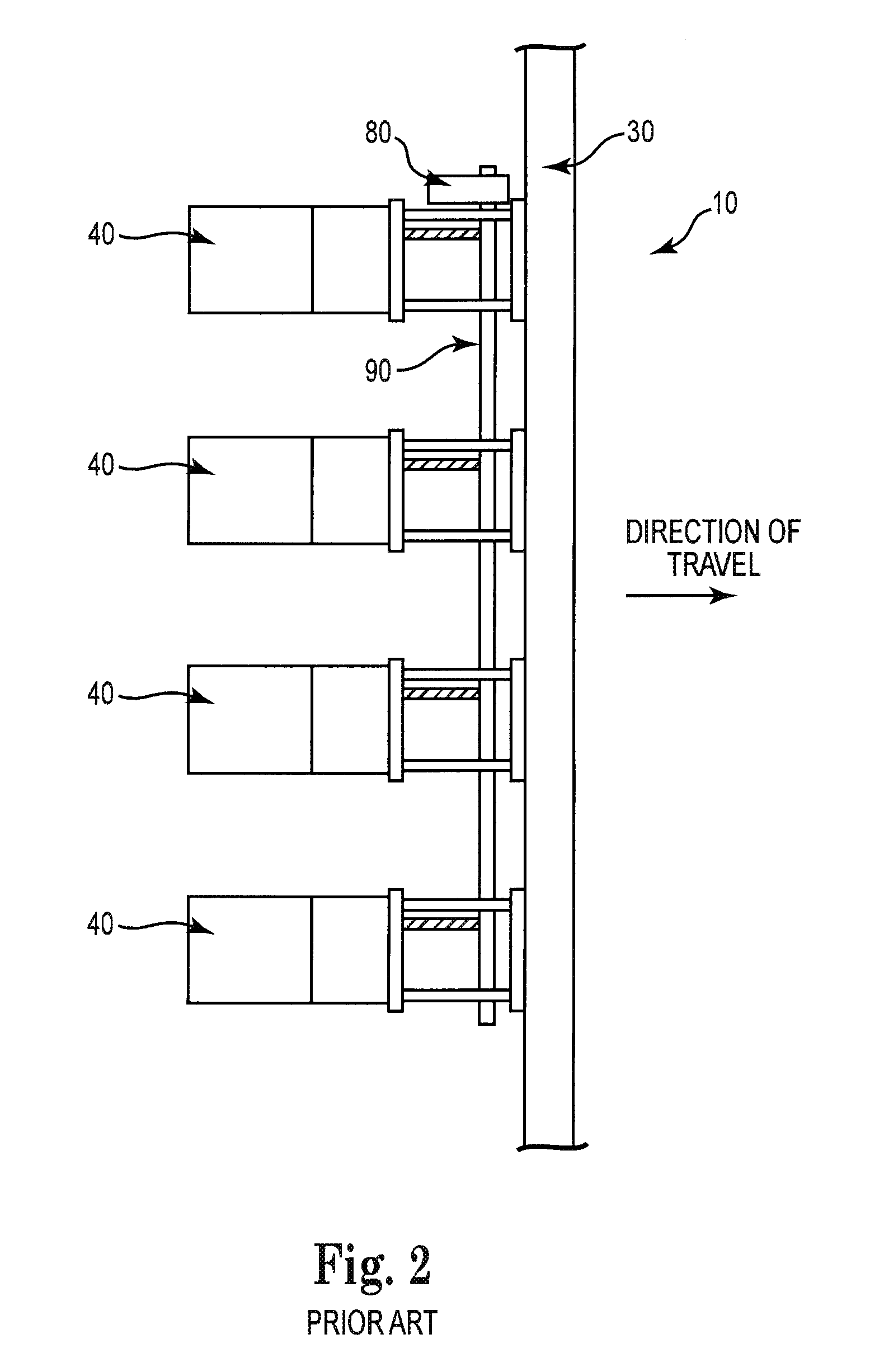

System and method for distributing multiple materials from an agricultural vehicle

InactiveUS7140310B2Coin-freed apparatus detailsFertilising methodsIndustrial engineeringSecond source

Owner:CNH IND CANADA

Multi-variable rate agricultural product application system, device and method

ActiveUS8868300B2Easy to controlAccurate ratingAnalogue computers for trafficLiquid fertiliser distributionHydraulic motorDrive shaft

Owner:RAVEN INDUSTRIES INC

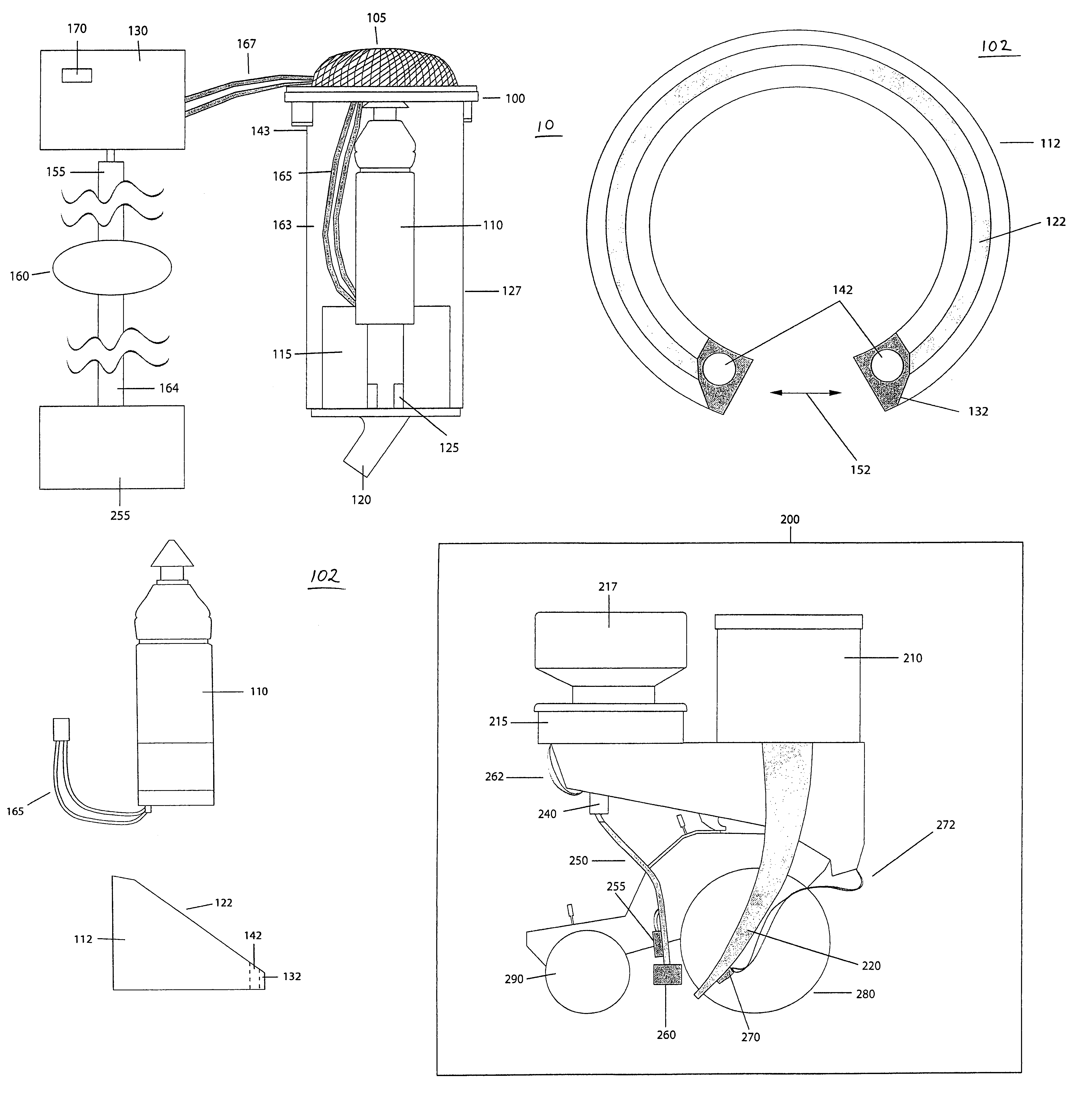

Electronic pulsing of chemical with seed

A system and method for electronically pulsing chemical with seed. The system and method incorporate a seed dispensing tube configured to dispense seeds, a granule tube configured to dispense chemical, an electrical valve configured to open so that chemical granules may be dispensed from the chemical granule tube, and a proximity sensor operably coupled to the electrical valve, the sensor being configured to sense a seed dispensed from the seed dispensing tube. The system may also include a metering mechanism for metering the quantity of chemical that is dispensed with the seed. The metering mechanism may be controlled by a radar unit on a tractor associated with the system, and the metering mechanism may be programmed to dispense a predetermined quantity of chemical with the seed.

Owner:AMERICAN CHEM CORP

Seeder with trailing arm and hoe-type mid row bander

A seeding and fertilizing apparatus comprises a plurality of seed assemblies each comprising a trailing arm pivotally connected at a front end thereof to the frame and a packer wheel rotatably attached to rear end thereof. A seed furrow opener is attached to the trailing arm ahead of the packer wheel which rolls along the seed furrow created by the opener. A vertical position of the seed furrow opener with respect to the packer wheel is adjustable, and a bias device is operative to exert a downward bias force on the trailing arm. A plurality of fertilizer assemblies each comprises a fertilizer knife mounted to the frame such that a vertical position of the fertilizer knife with respect to the implement frame is adjustable. The seed assemblies and fertilizer assemblies are oriented laterally such that each fertilizer furrow is located between adjacent seed furrows.

Owner:BOURGAULT INDS

Method and Arrangement For Growing Plants

ActiveUS20130104453A1Large specific surface areaClimate change adaptationHarvestersSprouted SeedsFlowerpot

A method for cultivating plants is described. The method comprises the steps of sowing seeds in the growing medium in sterilised pots (17) using a sowing device (7), allowing the seeds to germinate in a germination device (8), automatically moving the pots through a greenhouse (2) to allow the germinated seeds to grow into plants (43), harvesting the grown plants using a harvester (5), and sterilising the pots with the growing medium in a sterilisation device (6) after harvest in order to provide sterilised pots (17) with a growing medium. An arrangement for performing the method is also described.

Owner:PLANTAGON INT

System and process for dispensing multiple and low rate agricultural products

ActiveUS20150059626A1Low application rateEffective activityOpening closed containersBottle/container closureEngineeringMaster controller

A system for dispensing agricultural products includes: a master controller, sets of agricultural product containers, meter devices, and secondary controllers. The meter devices are operatively connected to the product containers and configured to dispense products from the containers to rows in a field wherein each of the sets of containers is associated with a respective row in the field. The secondary controllers actuate the meter devices. Each secondary controller receives command data from the master controller and controls the meter devices for dispensing in response to the command data. Agricultural product from each product container is dispensed in accordance with operator defined instructions to the master controller. The instructions are capable of being provided to the master controller during the planting allowing the dispensing of individual containers to be controlled. In one embodiment the invention is a process for dispensing agricultural products at low application rates utilizing precision placement equipment.

Owner:AMERICAN CHEM CORP

Seed planter with equalizer assembly

Disclosed herein is an agriculture planter. The planter may include a planter frame, a seed hopper and a trailing arm assembly. The planter frame may include a hitch tongue extending forwardly from the planter frame. The planter frame supports the seed hopper. The a trailing arm assembly is vertically pivotally coupled to a rear portion of the planter frame, extends rearward from the planter frame and includes a trailing arm frame and a lever arm vertically pivotally coupled to the trailing arm frame by a pivot point. The lever arm includes a leading end, a trailing end, a middle portion, a furrow opener disc and a first furrow closer wheel. The disc is rotatably mounted to the lever arm near the leading end. The first wheel is rotatably mounted to the lever arm near the trailing end. The middle portion is pivotably coupled to the pivot point.

Owner:SCHAFFERT MFG

Method and apparatus for sectional control of air seeder distribution system for a farm implement

A method and system enables sectional control for an air seeding system of a farm implement by exposing a main header, or selected ports of the main header, to a purging air flow when product flow through the selected ports is stopped. A plenum of air is fluidly coupled to the main header and provides a purging air flow to any exit port of the main header that has been shut off from product flow. Valves are used to selectively flow couple the exit ports of the main header to the product flow and to the purging air flow.

Owner:CNH IND CANADA

Seed firmer life extender

Owner:FLO RITE

Fertilizer injector wing for disc openers

InactiveUS20050051068A1Eliminate needHigh speed useTill seedingDirect liquid fertiliser deliverySeederCircular disc

Disc openers (14) for use with an air seeder (10), or other no-till drill and the like, configured for seeding and fertilizing a field (G) for crop production are disclosed. The representative opener (14b) broadly includes a drawbar assembly (16), a disc assembly (18) including a coulter disc (20) and a gauge wheel (22), a seed boot (24), a fertilizer injector wing (26), a firming wheel assembly (28), and a closing wheel assembly (30). The inventive fertilizer injector wing (26) is configured for fixed attachment to the seed boot (24) and broadly includes a body (48), including an angled outboard portion (56), a toxic fertilizer injector (50), and a non-toxic fertilizer injector (52). The opener (14b) with the unique fertilizer injector wing (26) is configured to place the seed row (S) and the dedicated fertilizer band (DB) at an optimum geometric positional alignment relative to the seed row (S), in a single, low soil disturbing planting pass without disrupting the seed bed (BS). The inventive wing (26) enables a toxic charge (TC) of the fertilizer (N,P)—a charge containing the optimum nutrient package to sustain season long growth of the crop—to be placed sufficiently close to the seed (S) while minimizing soil disturbance so that weed growth and moisture loss are minimized and crop yield is maximized.

Owner:EXACTRIX

Electronic pulsing of chemical with seed

A system and method for electronically pulsing chemical with seed. The system and method incorporate a seed dispensing tube configured to dispense seeds, a granule tube configured to dispense chemical, an electrical valve configured to open so that chemical granules may be dispensed from the chemical granule tube, and a proximity sensor operably coupled to the electrical valve, the sensor being configured to sense a seed dispensed from the seed dispensing tube. The system may also include a metering mechanism for metering the quantity of chemical that is dispensed with the seed. The metering mechanism may be controlled by a radar unit on a tractor associated with the system, and the metering mechanism may be programmed to dispense a predetermined quantity of chemical with the seed.

Owner:AMERICAN CHEM CORP

Planter with on-board seed treatment

ActiveUS9730377B2Reduce exposureGood choiceFertilising methodsSeed depositing seeder partsOn boardSpray nozzle

A planter is provided with onboard seed treatment for treating seeds on the go during row-crop planting of an agricultural field. The seed treatment system of the planter allows for selective planting of specific zones of a field with treated seed, which may include planting different zones of the field with seeds having different treatments. The planter may store untreated seed in bulk and include a seed treatment system that selectively and precisely treat the untreated seeds during treatment events by way of an injection or spray nozzle system that applies liquid treatment to the seeds traveling along a tightly defined travel path, such as within pockets of a belt that carries the seeds through a seed tube.

Owner:CNH IND CANADA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com