Small sowing and fertilizing integrated machine

An all-in-one, small-scale technology, which is applied to fertilization devices, fertilizer and seeding equipment, fertilizer distributors, etc., can solve problems such as blockage, poor stability of equipment work, uneven ratio of fertilizer and seeds, etc., and achieve simple equipment structure and ensure stability The effect of sex and ratio stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

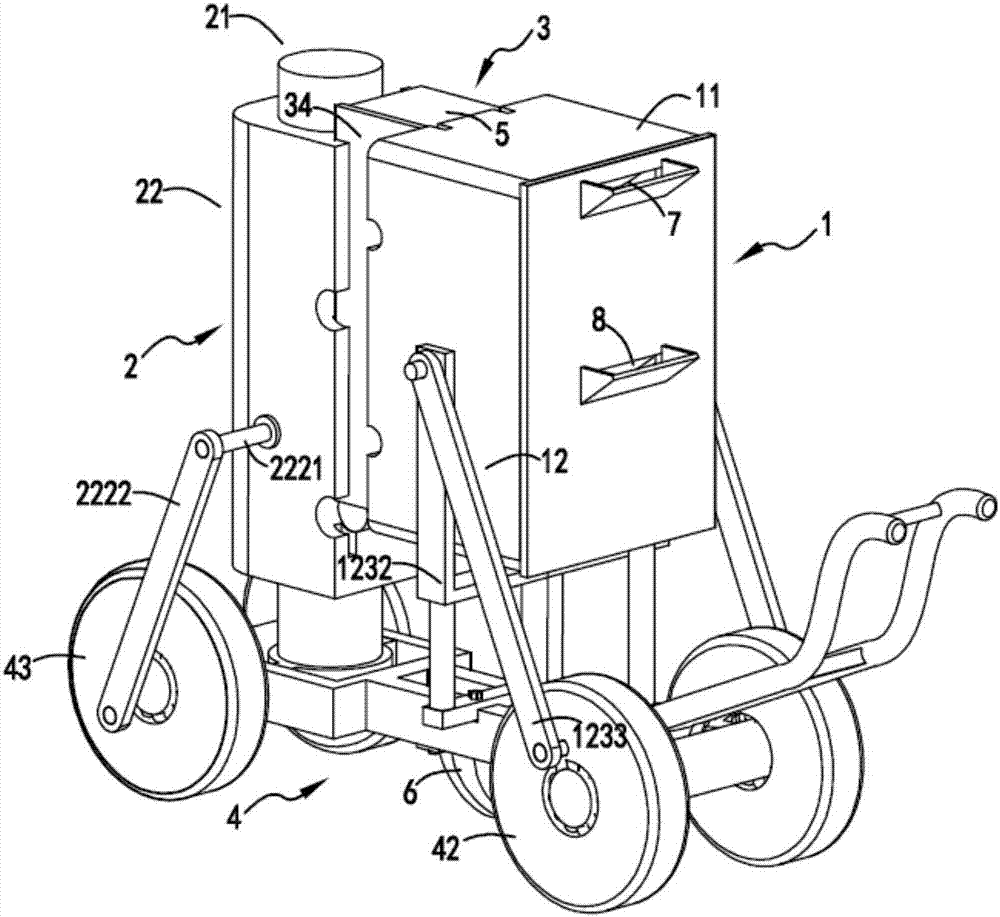

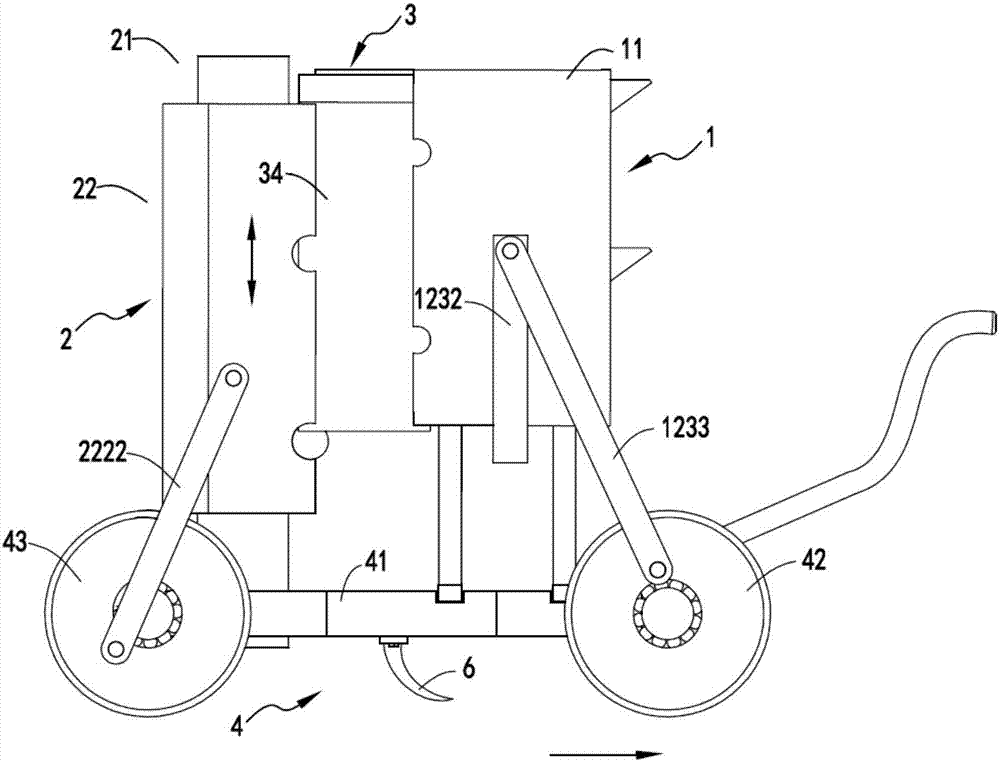

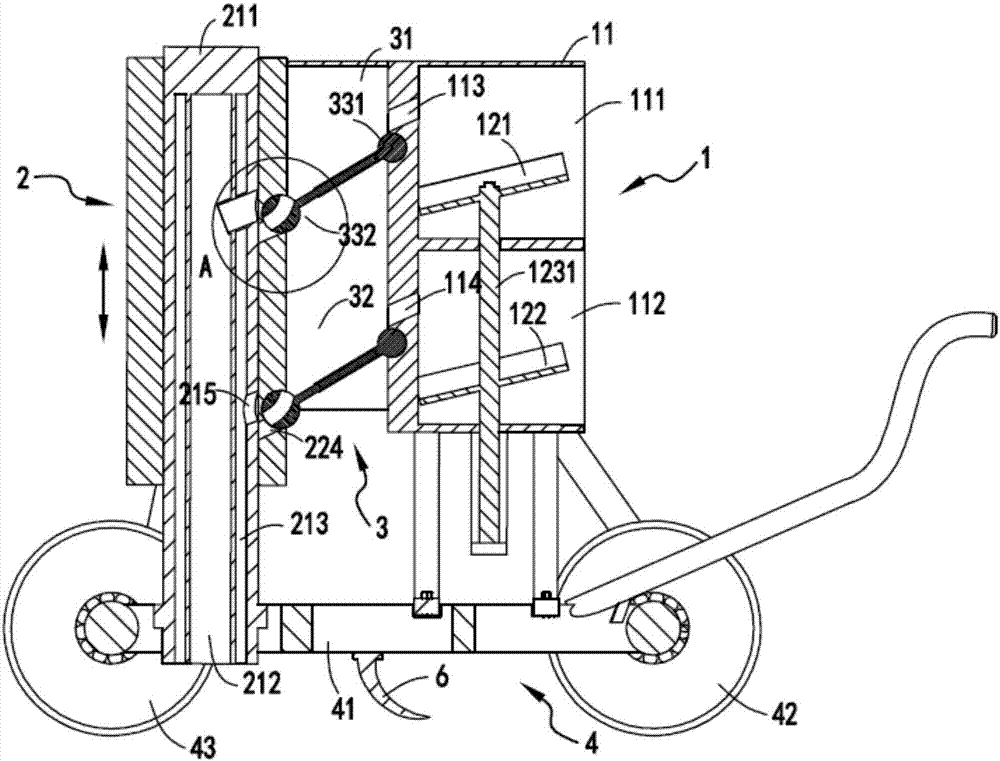

[0043] figure 1 It is a schematic diagram of the structure of a small sowing and fertilizing machine, figure 2 It is a schematic diagram of the front view of a small all-in-one planting and fertilizing machine, image 3 It is a cross-sectional schematic diagram of a small all-in-one planting and fertilizing machine, Figure 4 It is a schematic diagram of a partially enlarged structure of a small all-in-one planting and fertilizing machine, Figure 5 It is a partial structural diagram of a small sowing and fertilizing machine, Image 6 It is a partial structural diagram of a small sowing and fertilizing machine, Figure 7 is a schematic diagram of the structure of the feed box, Figure 8 It is a schematic diagram of the structure of the rotating discharge mechanism, Figure 9 It is a schematic diagram of the structure of the feeding mechanism. Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9As shown, ...

Embodiment 2

[0056] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that: the sliding sleeve 221 is also provided with guide grooves 225 on both sides of the rotating part b332, the baffle plate 34 slides with the guide grooves 225, and the guide grooves 225 On the one hand, the arrangement satisfies the up-and-down sliding of the sliding sleeve (221) relative to the baffle (34), and on the other hand, the disassembly and assembly of the equipment is relatively convenient, and the rotating part a331 and The rotating part b332 is drawn out from the side of the sliding sleeve 221 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com