Material taking head

A technology of material head and material retrieving seat, which is applied in the field of material reclaimer, can solve the problems of low efficiency of reclaiming and unloading, unstable retrieving and unloading of components, complex structure, etc., and achieve stable picking and releasing of components, Avoid tilting or yaw, compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

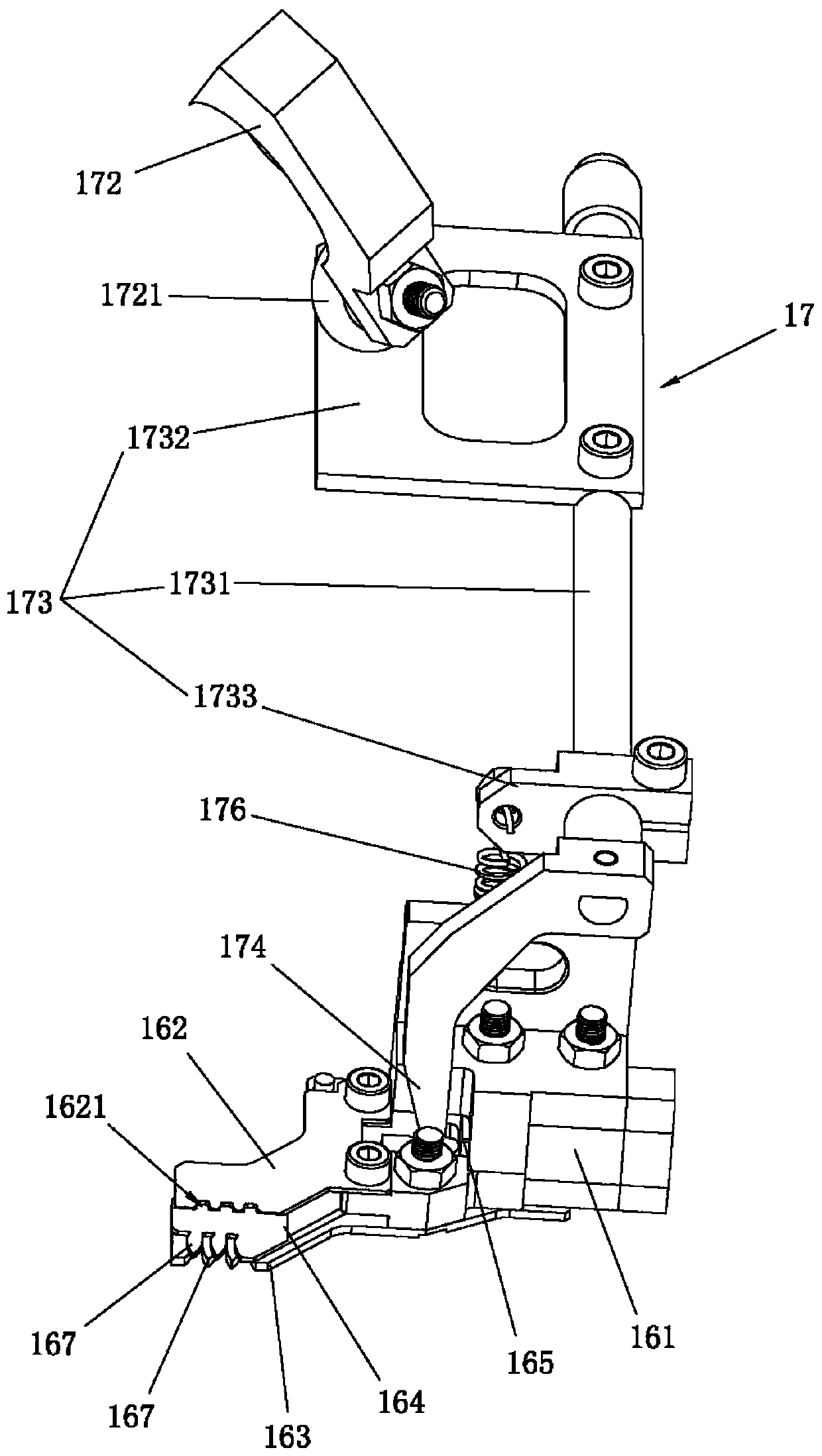

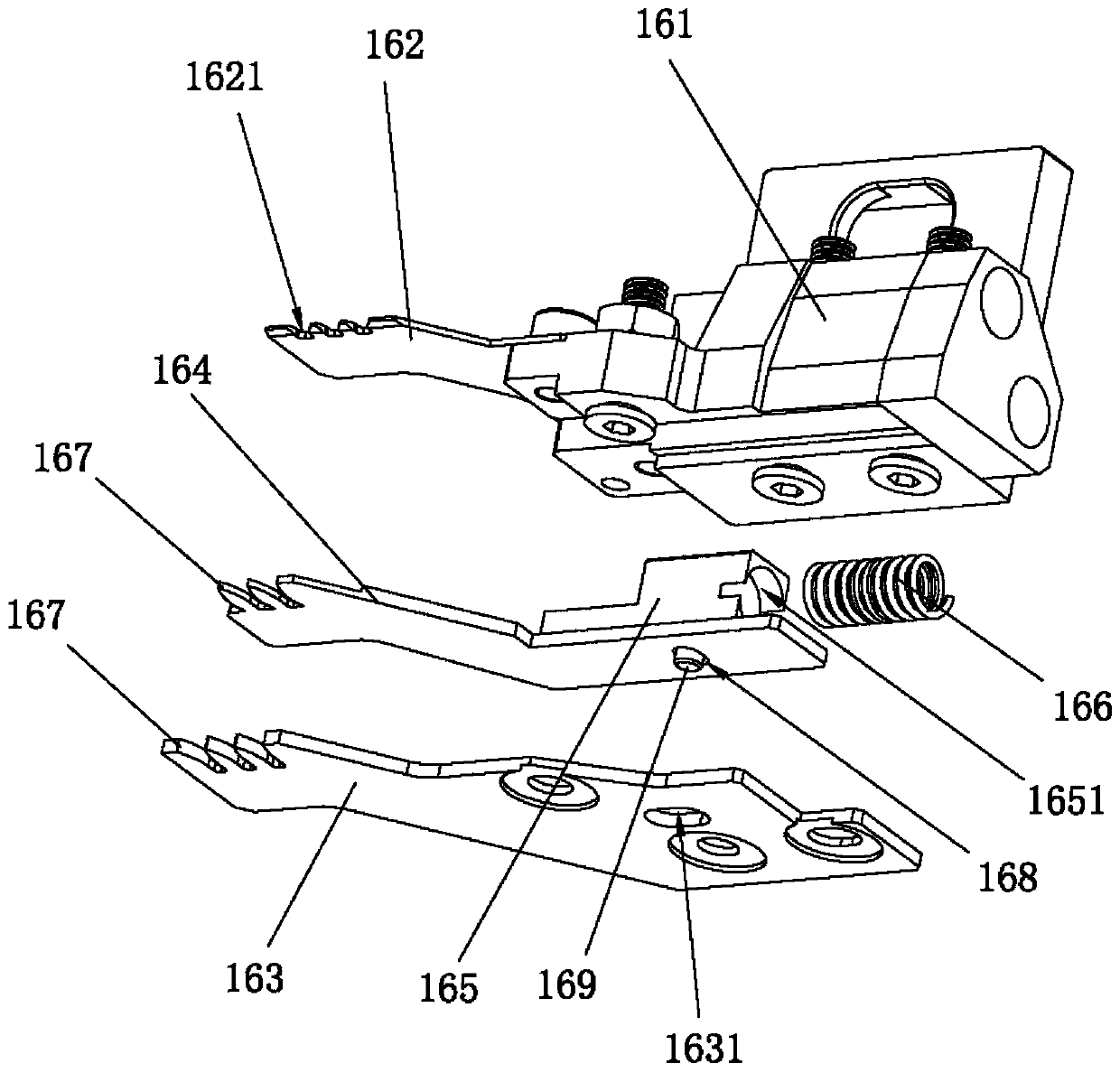

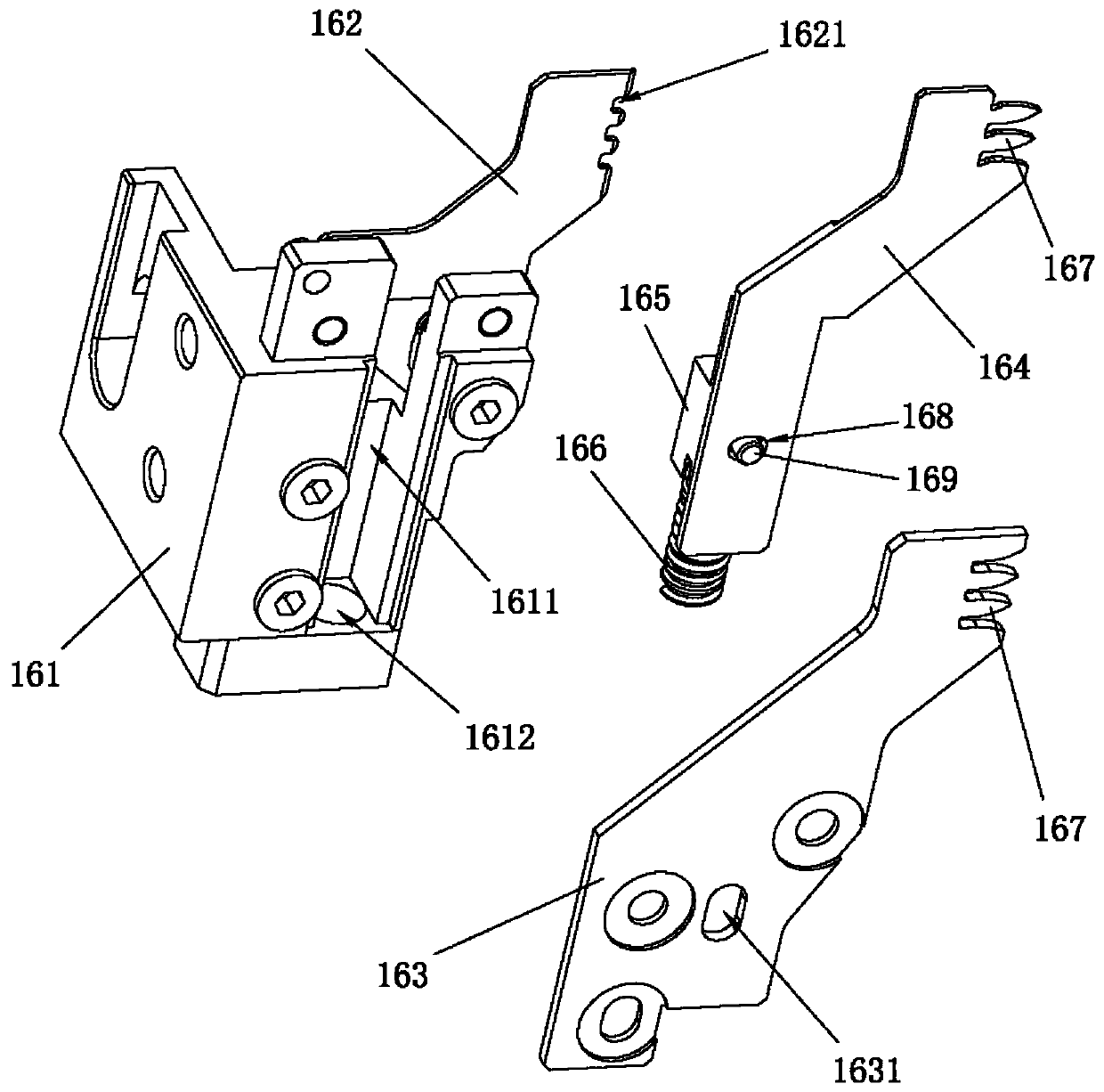

[0022] like Figure 1 to Figure 3 As shown, a kind of pick-up head provided by the present invention includes a pick-up seat 161, a pick-up assembly and a support member 162 respectively installed on the pick-up seat 161, and the support member 162 is spaced apart from the pick-up assembly. And be positioned at the top of material fetching assembly, described supporting material 162 is provided with supporting material groove 1621, and described material fetching assembly comprises the fixed clamping material 163 that is fixedly connected to taking material seat 161, is slidably arranged on fixed clamping material 163 or / and the movable clamping member 164 of the material retrieving seat 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com