Rod-like track of guide pin feeding and sorting device

A sorting device and rod-shaped technology, which is applied in the manufacture of capacitors, electrical components, capacitors, etc., can solve problems affecting the normal operation of equipment, waste, and material jams in nail coilers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

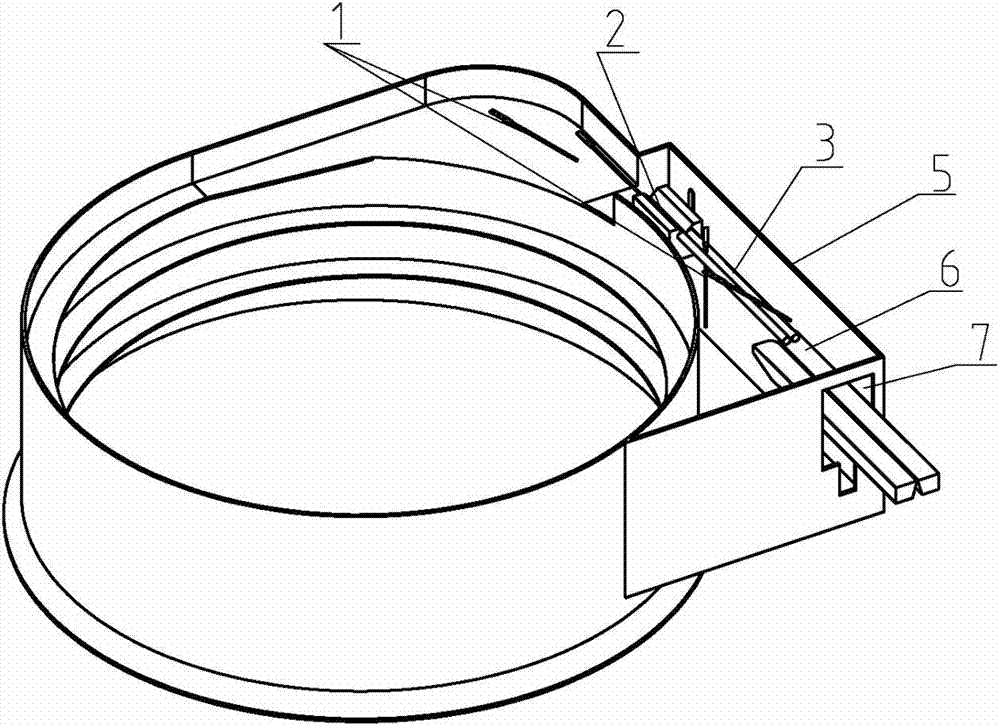

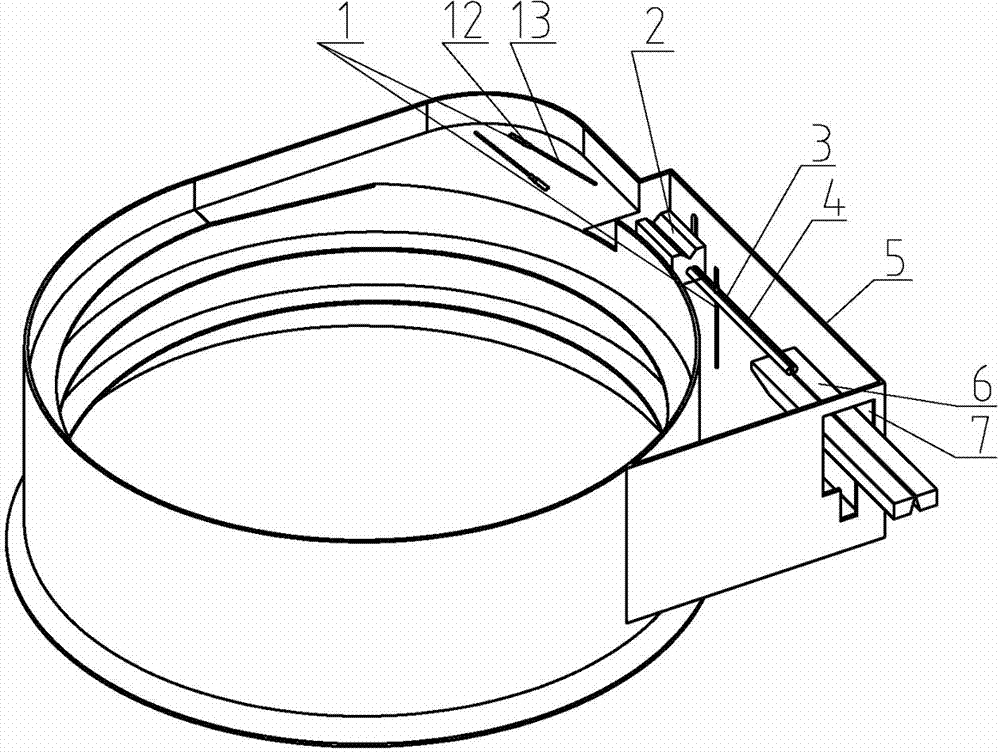

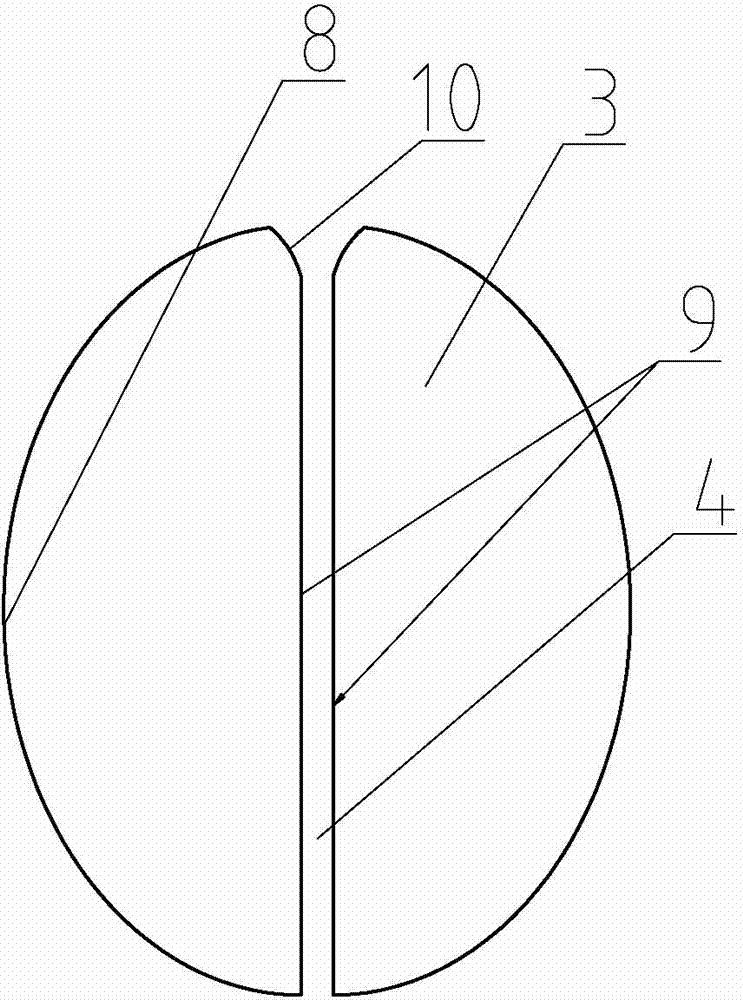

[0016] Depend on figure 2 , image 3 It can be seen that a rod-shaped runway of a guide needle feeding sorting device includes two rods 3 of the same shape and size, a V-shaped block 2 is arranged on the feeding platform of the vibrating plate 5, and one end of the two rods 3 is horizontally installed on the V On the block 2, a feedway 4 is formed between the rods 3, the width of the feedway 4 is greater than the diameter of the lead part 13 of the guide pin 1, and smaller than the diameter of the aluminum stem part 12 of the guide pin 1, the rod 3 is in the feeder 4 The sections are arcuate in cross-section, the forehearth 4 being formed by the bow-shaped chords 9 .

[0017] In order to facilitate the guide needle 1 to enter the feedway 4, the bow-shaped chord 9 in the present invention forms a transition arc 10 smoothly connected with the bow-shaped arc 8 at the upper part of the feedway 4.

[0018] For the convenience of processing, the bow-shaped arc 8 in the present in...

Embodiment 2

[0022] The arc 8 of the arc in the present invention is a circular arc. The rest are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com