Overturning feeding device of IC chip testing machine

A chip testing and chip technology, which is applied in conveyor control devices, conveyors, and unstacking of objects, can solve problems such as material jams and IC chips cannot be slipped out, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

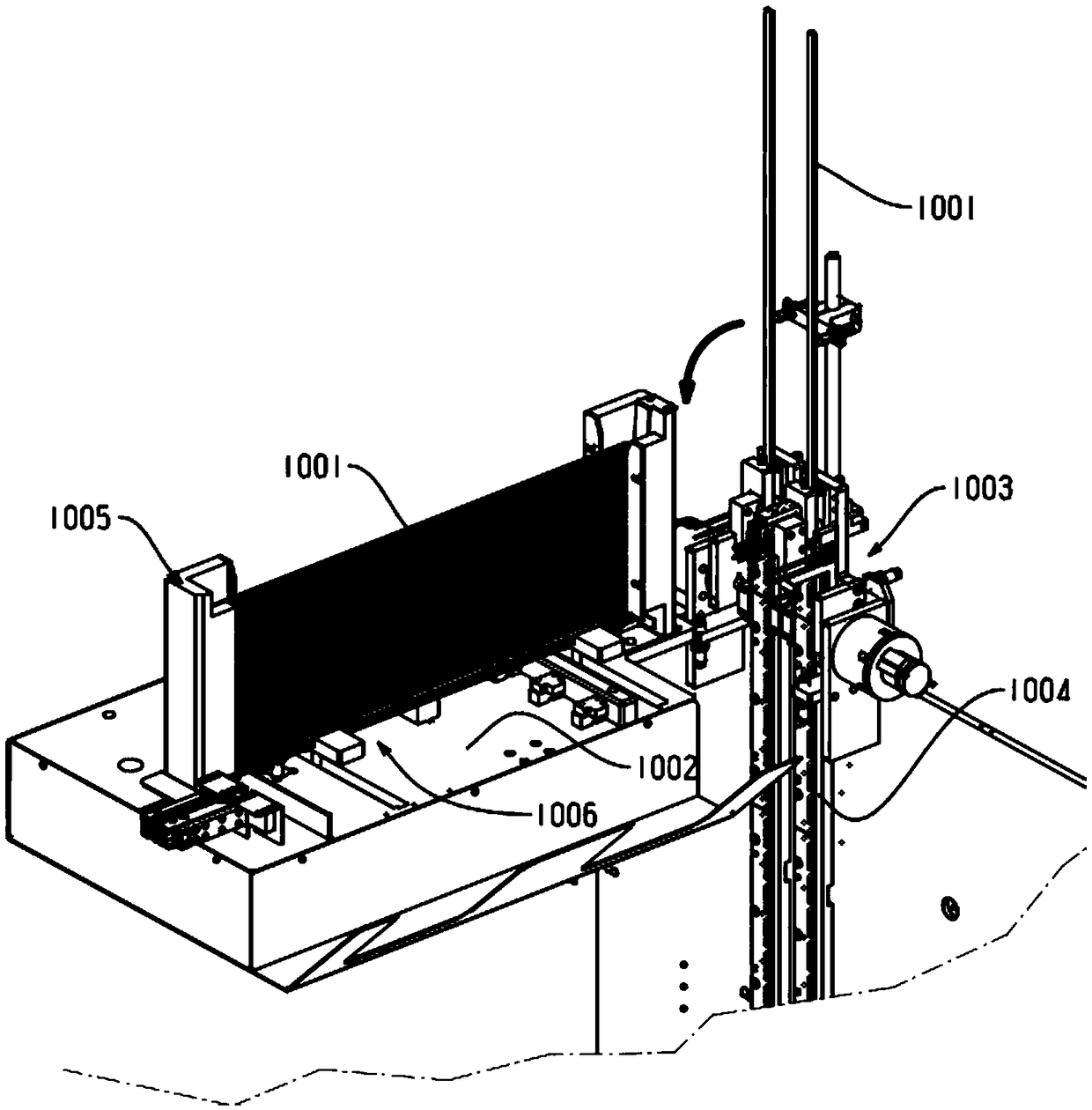

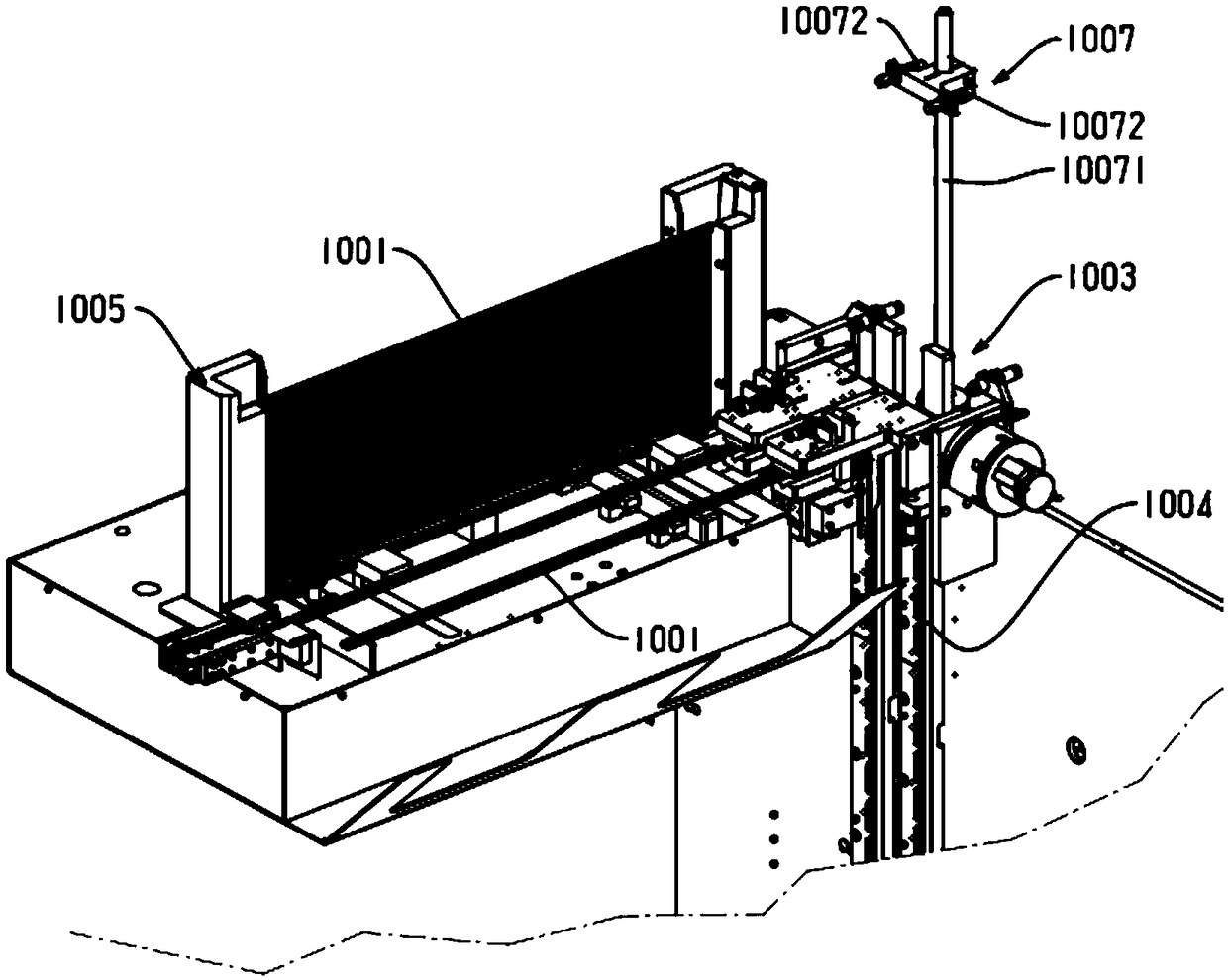

[0044] Embodiment: a kind of flip feeding device of IC chip testing machine, as Figure 1 to Figure 7 As shown: it includes a loading platform 1002 for placing an IC material tube 1001, a feeding mechanism 1003 for taking out the IC chips in the IC material tube, and a material channel 1004 for transporting the IC chips. It is set horizontally, and the forehearth is perpendicular to the loading platform;

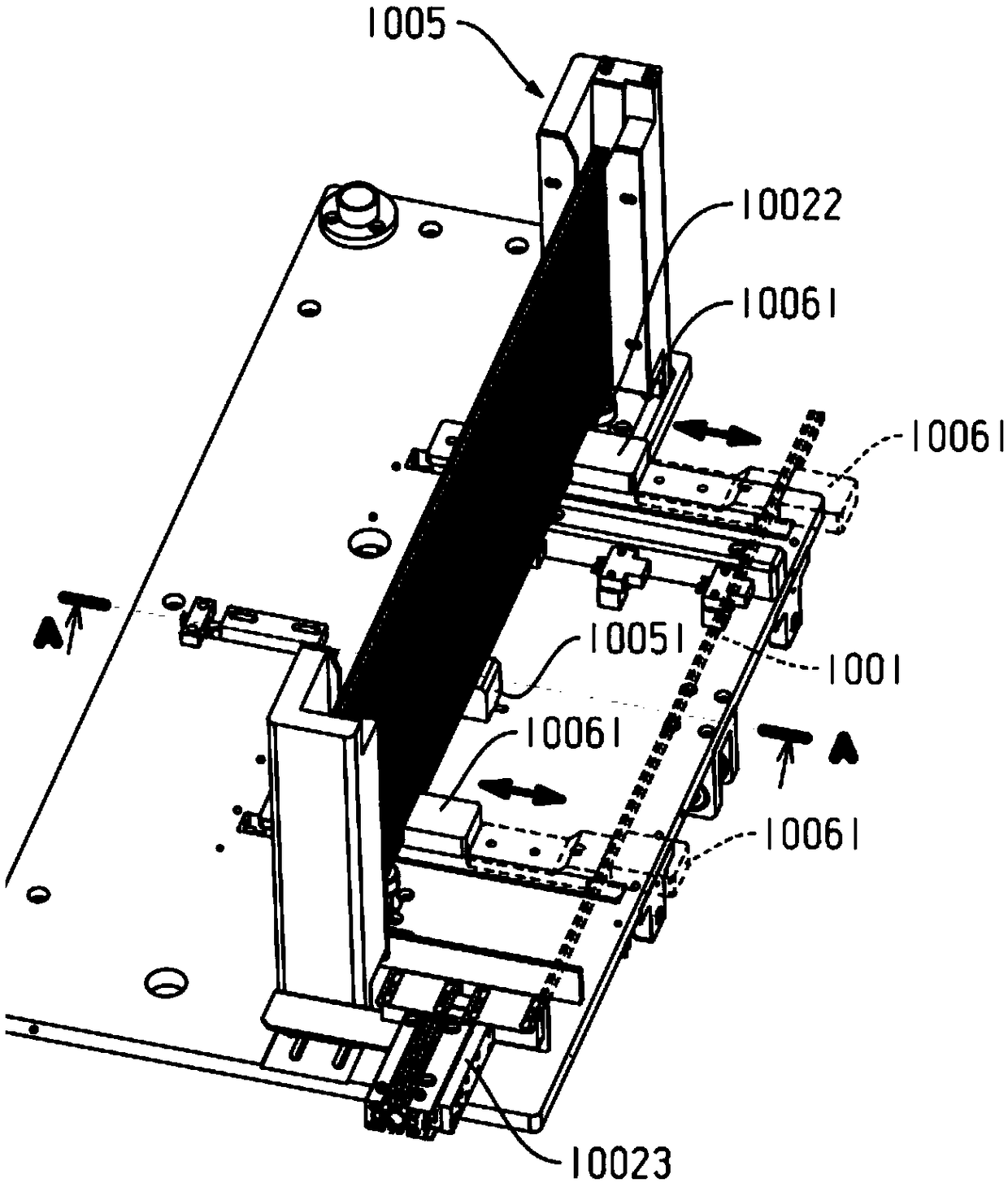

[0045] The loading platform is provided with a material bin 1005 and a push mechanism 1006, the IC material tubes are horizontally stacked in the material bin, the push mechanism is located at the bottom of the material bin, and the push mechanism includes a material tube slide block 10061 and a drive unit 10062 for driving the tube slider capable of holding one of the IC tubes in the bin and pushing it out to the loading unit through the drive unit the intended location of the station;

[0046] In this embodiment, the drive unit includes a servo motor, a synchronous belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com