Full-automatic metal plate punching and shearing production line and using method thereof

A technology for stamping and shearing and sheet metal, which is applied in the field of automatic sheet metal stamping and shearing production lines, which can solve the problem that feeding equipment, punching machines and shearing machines cannot be effectively used together, affect the stress on the lower stamping die, and occupy labor resources, etc. problems, to achieve the effect of improving shear quality and production efficiency, improving production efficiency, and good striking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention can be explained in detail through the following embodiments, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

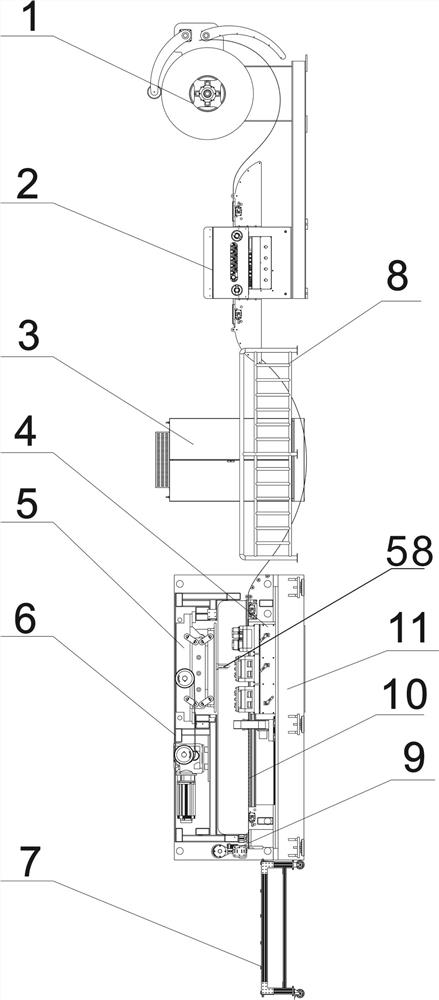

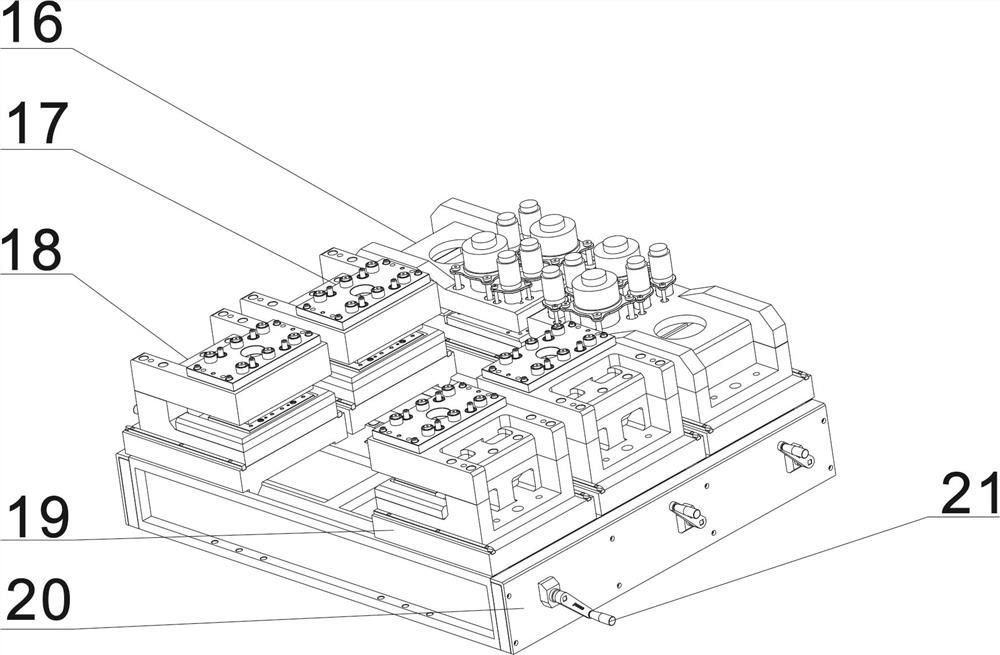

[0044] Attached Figure 1-10 Said sheet metal stamping and shearing automatic production line includes a feeding frame 1, a leveling machine 2, a punch 6 and a feeding cart 7. A feeding frame 1 is provided on one side of the leveling machine 2, and a feeding frame 1 is provided on the other side. Punch 6, the two sides between the punch 6 and the leveling machine 2 are provided with corresponding guardrails 8, and a feed cart 7 is provided on the outside of the discharge end of the punch 6. The punch 6 includes the bed, the upper part of the bed and the frame on both sides , Gantry pulling device 10, workbench 4, percussion device 5 and shearing device 9. A workbench 4 is provided on the upper part of the gantry pull device 10 and on the side close to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com