Groove type cable bridge cover plate punch forming die and punching method thereof

A cable tray and stamping forming technology is applied to the stamping and forming die for a slotted cable tray cover plate and its stamping field. , the effect of reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific drawings. It should be noted that, in the case of no conflict, the embodiments and Features in the embodiments can be combined with each other.

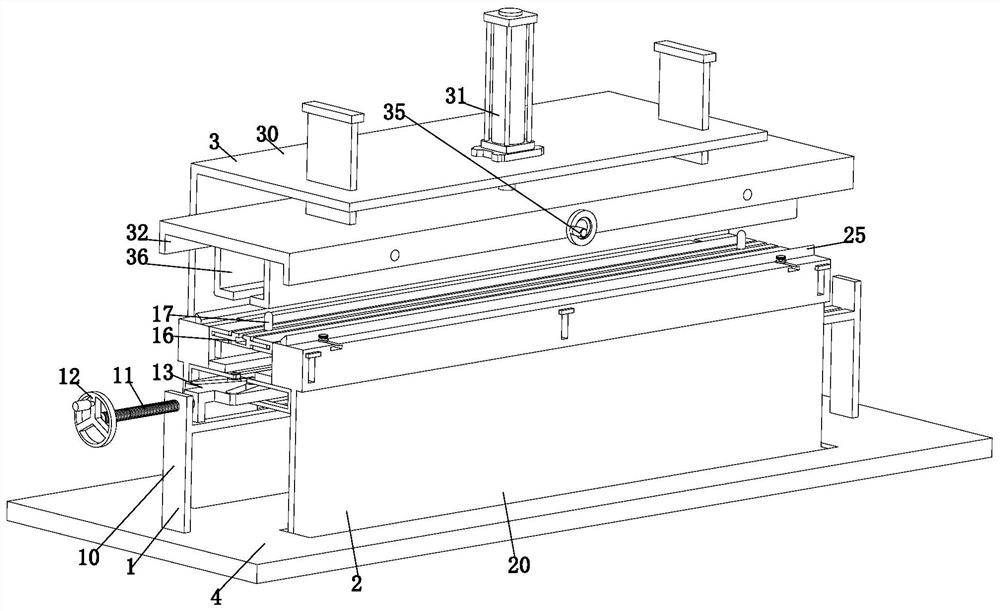

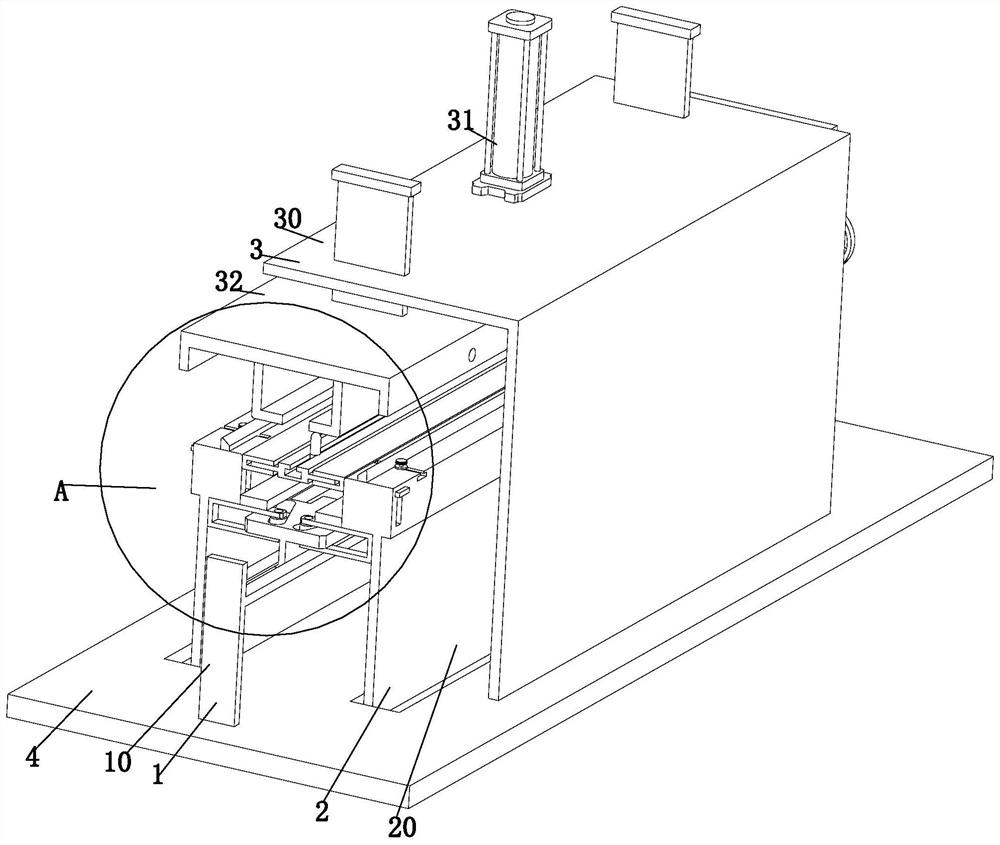

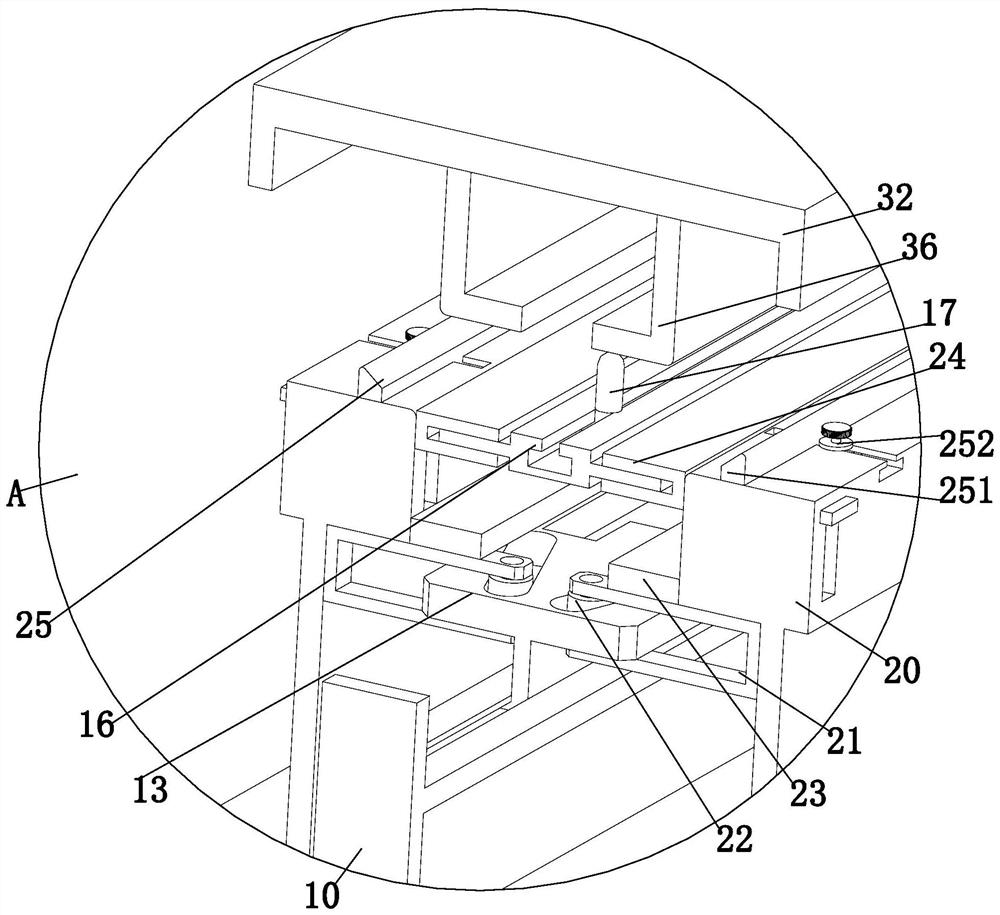

[0038] like Figure 1 to Figure 10 As shown, a trough type cable bridge cover plate stamping forming mold includes a material supporting mechanism 1, a bending mechanism 2, an actuator 3 and a bottom plate 4. The actuator 3 is installed on the bottom plate 4 and is located at the bottom of the actuator 3 There is a bending mechanism 2 directly below, and the bending mechanism 2 is symmetrically installed on the bottom plate 4 through a sliding fit. A supporting mechanism 1 is arranged between the bending mechanisms 2. The material mechanism 1 is connected to the bending mechanism 2 through a movable connection, where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com