Extrusion feeding mechanism of pasty fluid filling machine

A technology of feeding mechanism and filling machine, which is applied in the directions of liquid materials, packaging, transportation and packaging, can solve the problems of affecting the efficiency of filling, clogging of feeding devices, increasing labor costs, etc., to improve feeding efficiency, The effect of ensuring continuity and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

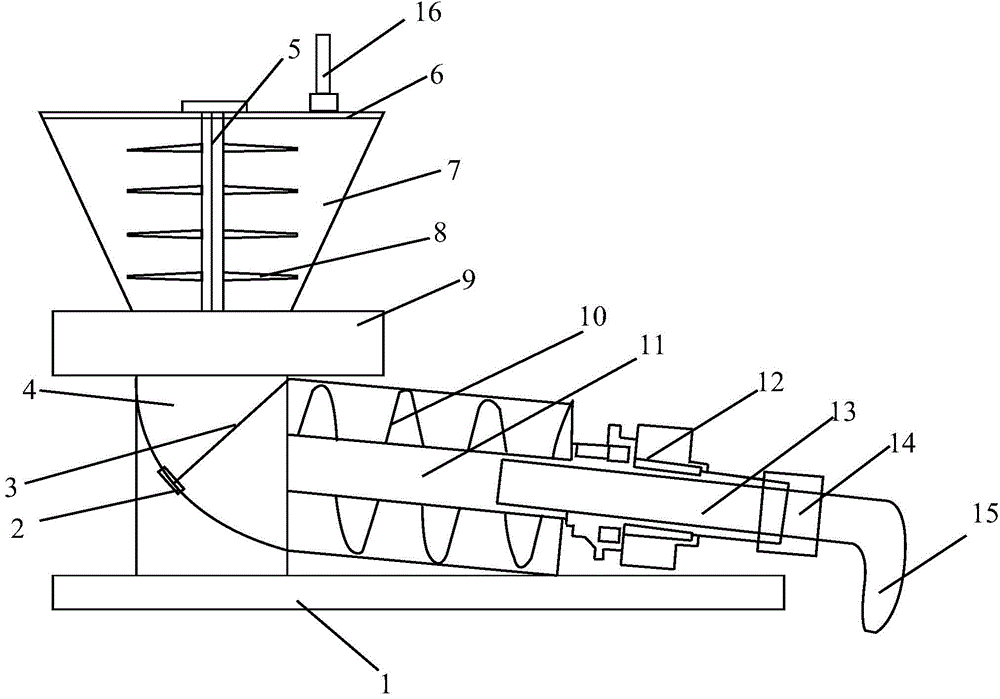

[0020] Such as figure 1 As shown, the present invention provides an extrusion feeding mechanism for a paste filling machine, which includes a base 1, an arc-shaped feeding chute 4 is arranged above the base 1, and a fixing frame 9 is arranged above the feeding chute 4 , the feed hopper 7 is installed on the fixed frame 9, the feed hopper 7 is connected with the feed tank 4, the filter screen 3 is arranged in the feed tank 4, and the feed tank 4 side is provided with a horizontal direction inclined 10-15 ° The filter cartridge, the main rotating shaft 11 is installed in the filter cartridge and one end extends out of the filter cartridge, the main rotating shaft 11 is provided with an extruding screw 10, and the main rotating shaft 11 protrudes from the end to the axis center in the filter cartridge A feeding chamber 13 is formed in the hollow, and the main rotating shaft 11 is provided with a feeding port, and the feeding port communicates with the feeding chamber 13, and a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com