A single-motor circulating water culture floating bait uniform bait feeding machine and method

A circulating aquaculture, single-motor technology, applied in fish farming, electrical components, electromechanical devices, etc., to achieve the effects of reduced energy consumption, long service life, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

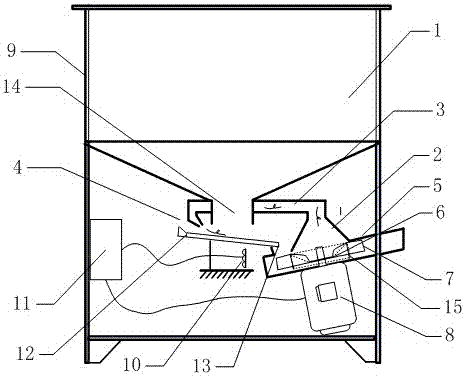

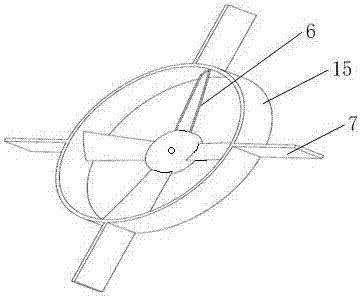

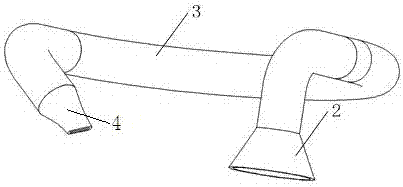

[0022] see figure 1 As shown in the structure of the bait-throwing machine of the present invention, the outside of the whole bait-throwing machine is a box body 9 , which is supported by the box body 9 . The upper part in the casing 9 is a storage bin 1, and the lower part in the casing 9 is equipped with parts such as feeding box 12, throwing material tray 5, main motor 8, electromagnetic switch 10, controller 11. The bottom of the storage bin 1 is a feeding port 14, and a feeding box 12 is installed directly below the feeding port 14, and one side of the feeding box 12 is a discharge place, and the discharge place is connected to the feeding port 13. An electromagnetic switch 10 is installed near the material receiving port 13 below the feeding box 12. The electromagnetic switch 10 has an electromagnet of attraction, and the electromagnetic switch 10 is connected to the controller 11 through a control line. When the bait throwing machine is not working, the controller 11 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com