Feeding device of battery cooling pipe

A feeding device and cooling pipe technology, applied in the direction of transportation and packaging, vibrating conveyors, conveyor objects, etc., can solve problems such as pauses, inability to ensure that materials are conveyed one by one, and materials are stuck, so as to achieve the effect of ensuring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Attached below Figure 1-13 The embodiments of the present invention are described in detail.

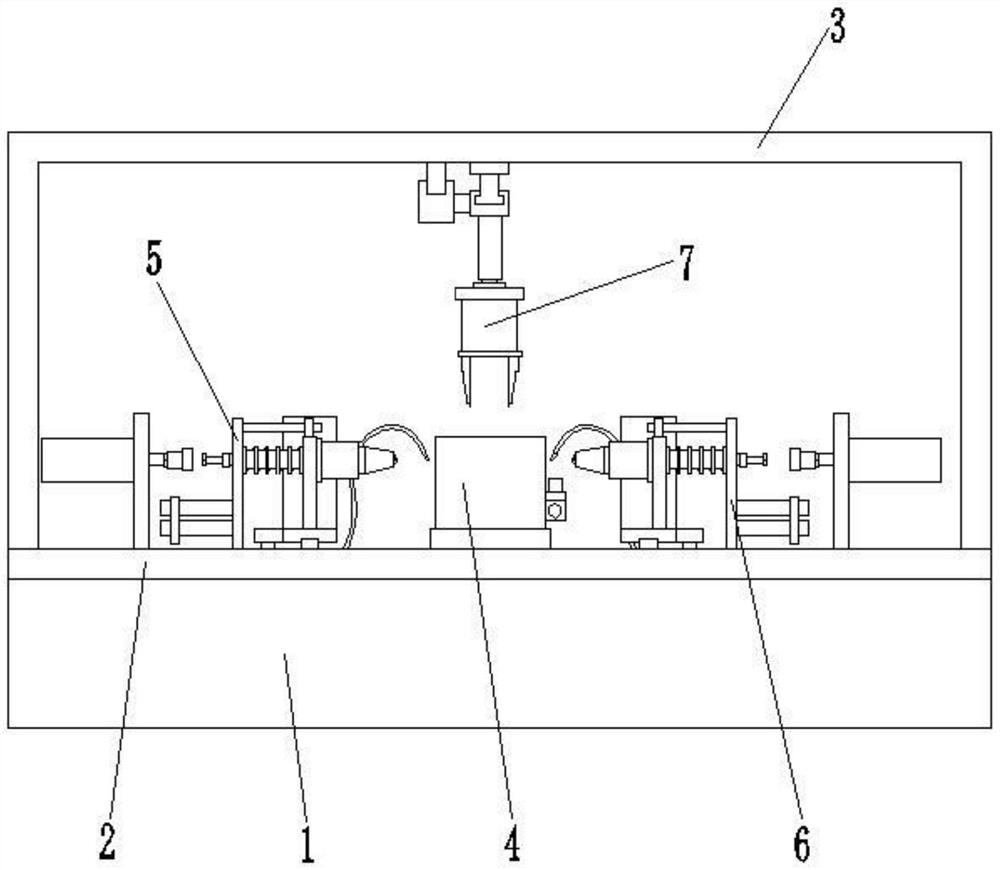

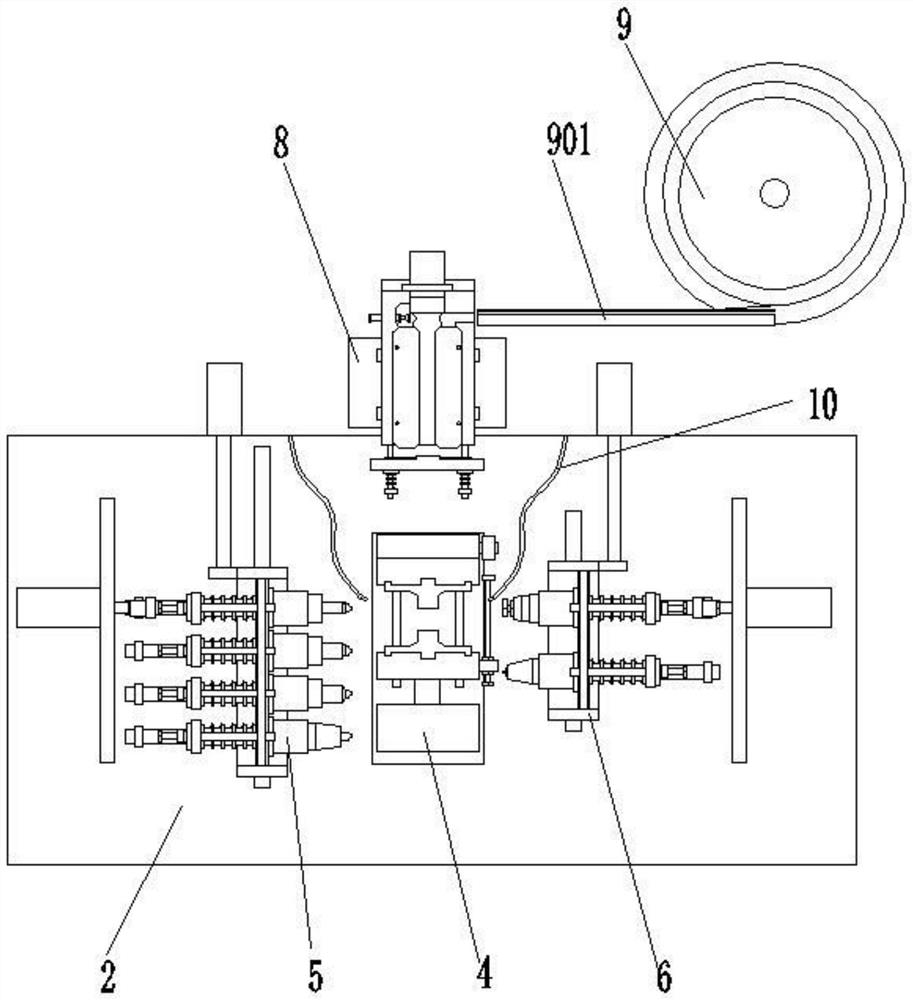

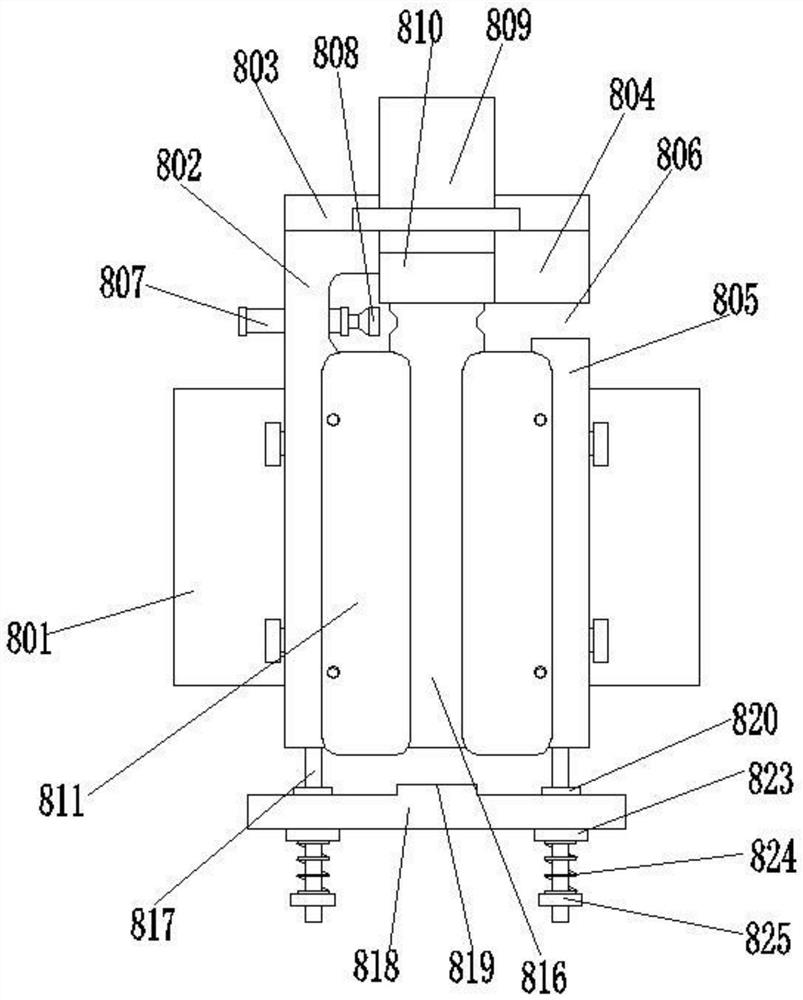

[0028] A feeding device for a battery cooling pipe, comprising a base 1, a platform 2 is arranged on the upper part of the base 1, a frame 3 is arranged on the outer periphery of the upper part of the platform 2, a fixing mechanism 4 is arranged in the middle of the upper part of the platform 2, and the fixing mechanism 4 is arranged on the left and right sides. The first processing mechanism 5 and the second processing mechanism 6 are respectively arranged on the side, and the first processing mechanism 5 includes the first flaring die 519, the second flaring die 520, the third flaring die 521, the pier head die 522, the second The processing mechanism 6 includes a block 614 and a shrinking die 615. The lower part of the frame 3 is provided with a feeding mechanism 7 at a position above the fixed mechanism 4. The rear side of the fixed mechanism 4 is provided with a feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com