Bending equipment for processing craft product raw materials and using method thereof

A technology for raw materials and products, applied in the field of bending equipment for processing raw materials of craft products, can solve problems such as reducing production efficiency, manual loading and unloading, and inability to process special-shaped craft products in place at one time, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

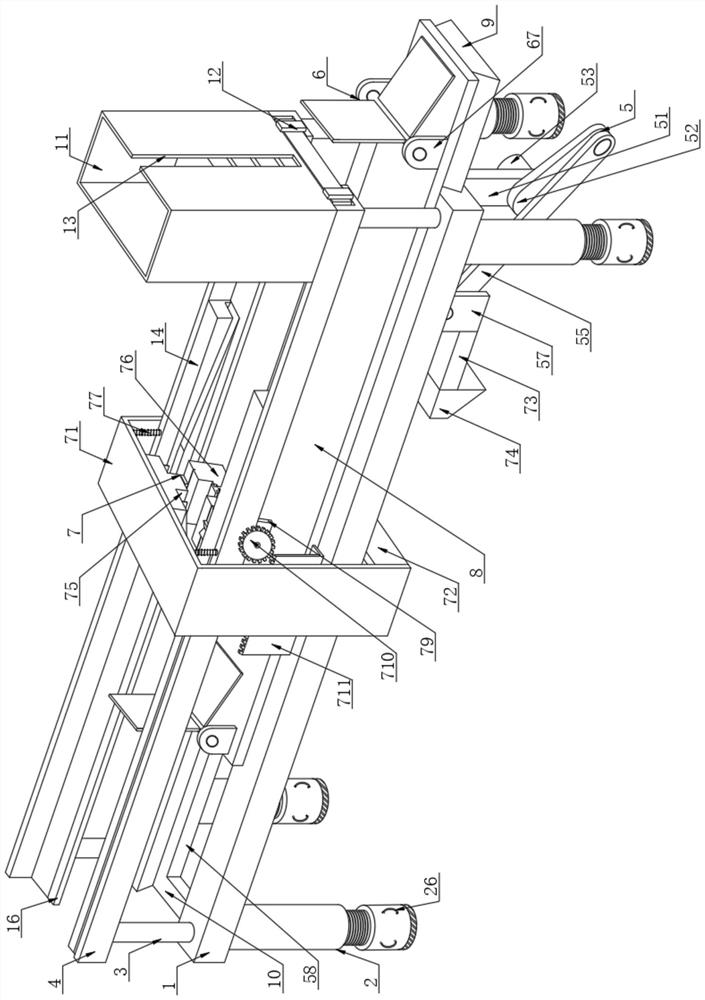

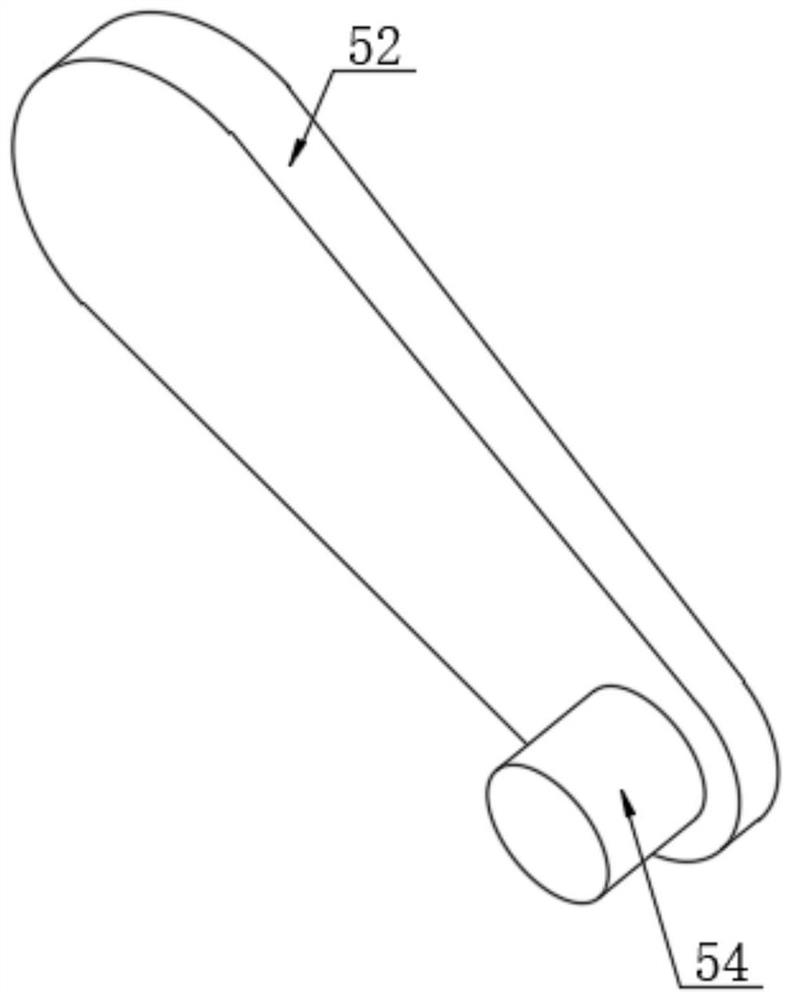

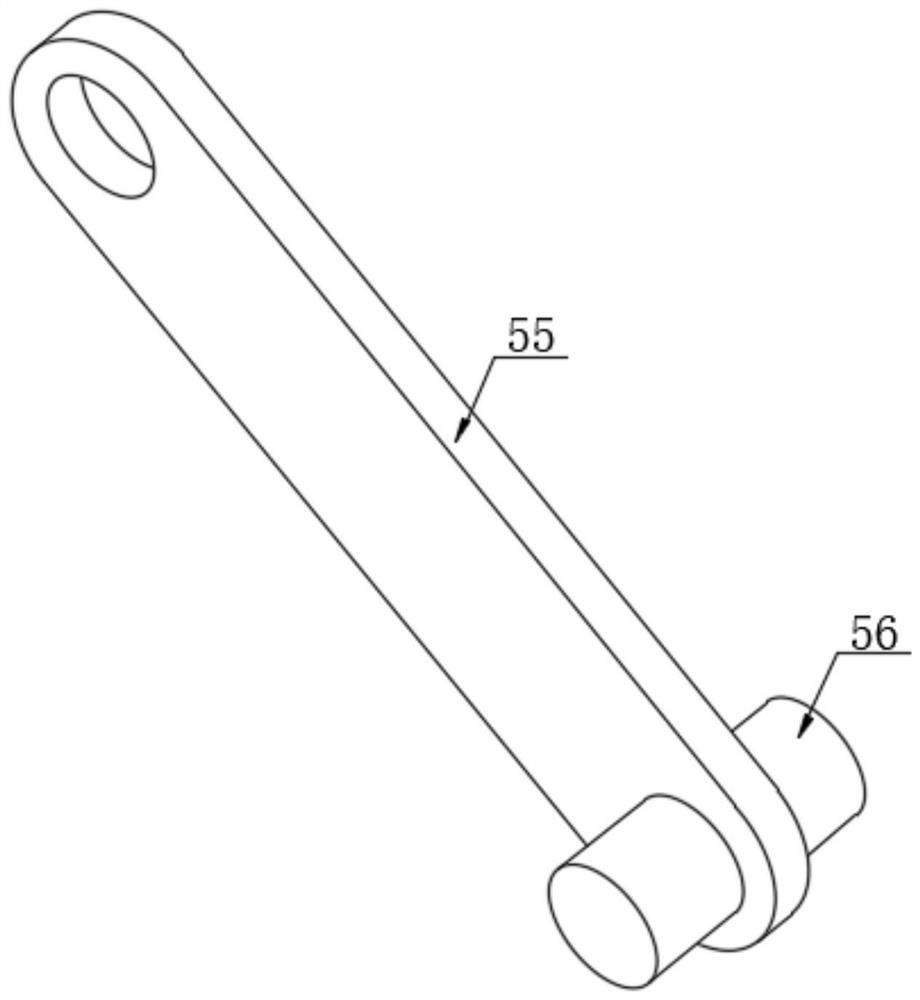

[0046] Refer to the manual attached Figure 1-8 , a bending equipment for processing raw materials of craft products according to an embodiment of the present invention includes a frame composed of a base plate 1 and legs 2 fixedly arranged at the bottom four corners of the base plate 1, and a movable plate is slidably connected to the top and middle of the base plate 1 8. A key block 9 is fixed in the middle of the bottom of the movable plate 8, a key slot 10 is provided at the position corresponding to the key block 9 on the top of the base plate 1, and the key block 9 is slidably connected to the inside of the key slot 10, and the top four corners of the base plate 1 are fixed with uprights 3, and an L-shaped bracket 4 is fixed between the tops of every two columns 3 arranged on the same side, a material box 11 is fixedly erected between the tops of one end of the two L-shaped brackets 4, and one end of the bottom of the base plate 1 is provided with a material box 11. In t...

Embodiment 2

[0061] Refer to the manual attached figure 1 and Figure 9 , a bending equipment for processing raw materials of craft products according to an embodiment of the present invention, its legs 2 include a column 21 that is fixedly connected with the base plate 1, and a stud 22 is fixed at the center of the bottom end of the column 21. The stud The bottom end of 22 is threadedly connected with a ring sleeve 23, the bottom end surface of the ring sleeve 23 is fixedly connected with a ring washer 24, the bottom end of the stud 22 is fixedly installed with a roller 25, and the outer peripheral surface of the ring sleeve 23 is fixedly provided with a plurality of circular evenly distributed arcs Rod 26.

[0062] It should be noted that (1) the ring washer 24 can be made of rubber material to enhance its wear resistance and contact friction with the ground; (2) in order to improve the holding comfort of the arc rod 26, it can be The grip area of the rod 26 is covered with a non-sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com