Round bar runway of guide pin sequencing-feeding device

A technology of feeding device and round bar, which is applied in the manufacture of capacitors, electrical components, capacitors, etc., can solve the problems of jamming, difficult to align the material channel, and large swinging arc of the guide needle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

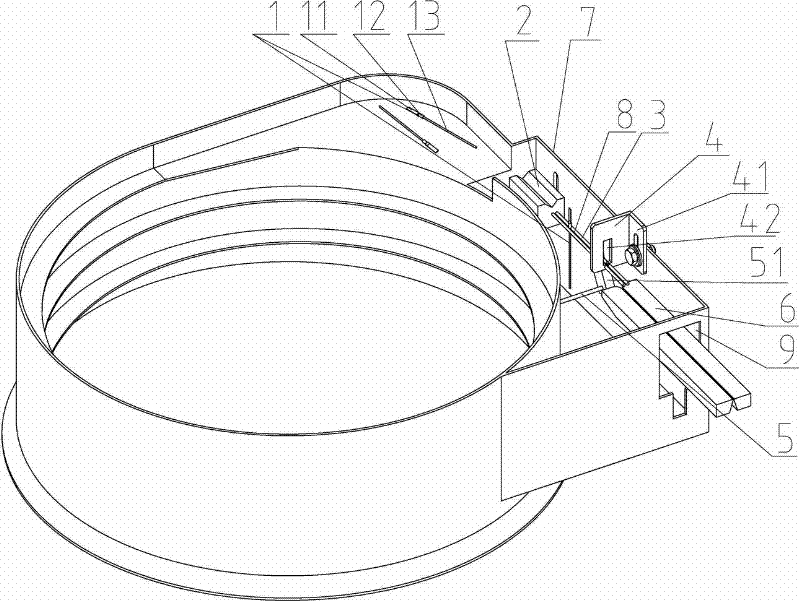

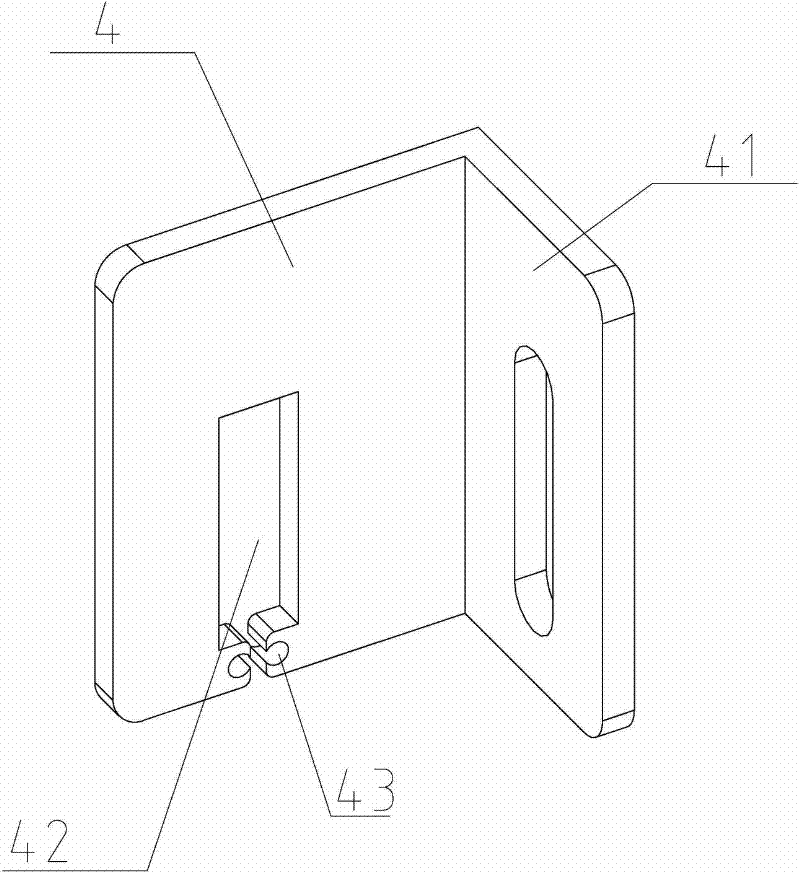

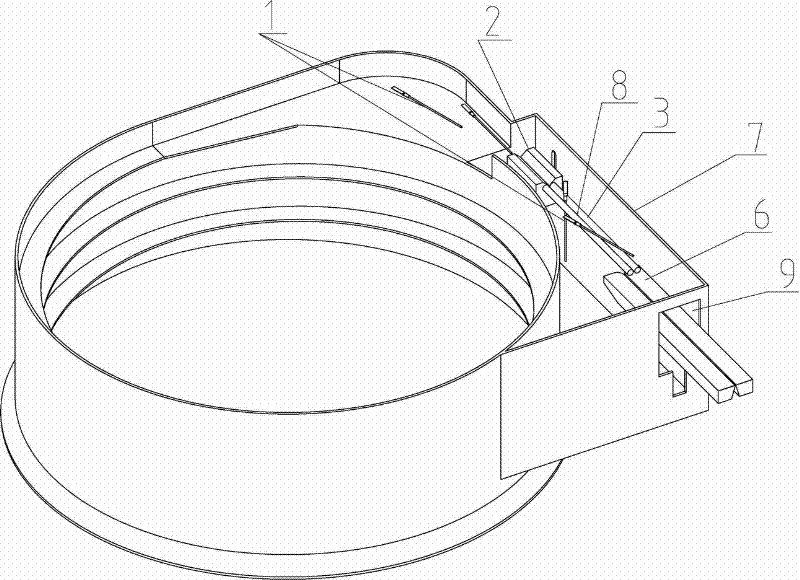

[0017] Depend on figure 1 It can be seen that the guide needle sorting and feeding device includes a V-shaped runway composed of V-shaped blocks 2 , a round bar runway composed of two round rods 3 , and a flattened runway 6 . Under the action of vibration force, the guide pin 1 passes through the vibrating plate 7 barrel wall track to the top feeding platform, and is oriented to the round bar track through the V-shaped track to be erected, and then sent to the flat vibrating track 6 to be grabbed by the manipulator of the nail coiler.

[0018] In order to ensure the rigidity of the round rods and ensure that the distance between the round rods is uniform, the diameter of the existing round rods 3 is generally above φ3.5mm, so that the area of the plane formed by the two round rods 3 is relatively large, and is subject to equipment Due to size limitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com