Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Suitable for processing and production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and technique for producing selenium-rich germinated brown rice

The invention relates to a method for producing selenium-enriched germinated brown rice and a process thereof. The method is characterized in that fresh rough rice or brown rice used as a raw material is supplied with water in segments, namely the semi-dry and semi-humid germinated process (the water for germination is specially-prepared selenium containing water with selenium content between 0.1 and 250ppm.). The water supply quantity can ensure the minimum water quantity needed for the germination of the rough rice and the brown rice; the germinated temperature is between 15 and 40 DEG C; the germinated time is between 10 and 72 hours; when the germinated length of 80 percent of the rough rice and the brown rice is between 0.5 and 1mm(the rough rice is processed by the first drying into the brown rice), the rough rice and the brown rice are subjected to gelatinization and enzyme-killing treatments; the germinated brown rice is dried at normal temperature or at the temperature of below 50 DEG C; and the water content of the finished production is less than or equal to 14 percent. The organic selenium content of the selenium-enriched germinated brown rice is 0.9mg / kg; and compared with other brown rice, the r-propalanine content of the selenium-enriched germinated brown rice produced by the method is nearly 40 percent higher. The method has the advantages that the special mechanism of the germination of rough rice and brown rice seeds is utilized; and after the seeds absorb the selenium containing water and are subjected to enzymatical conversion, the contents of the organic selenium and other nutrient components in the rough rice and the brown rice are higher.

Owner:凌启瑞

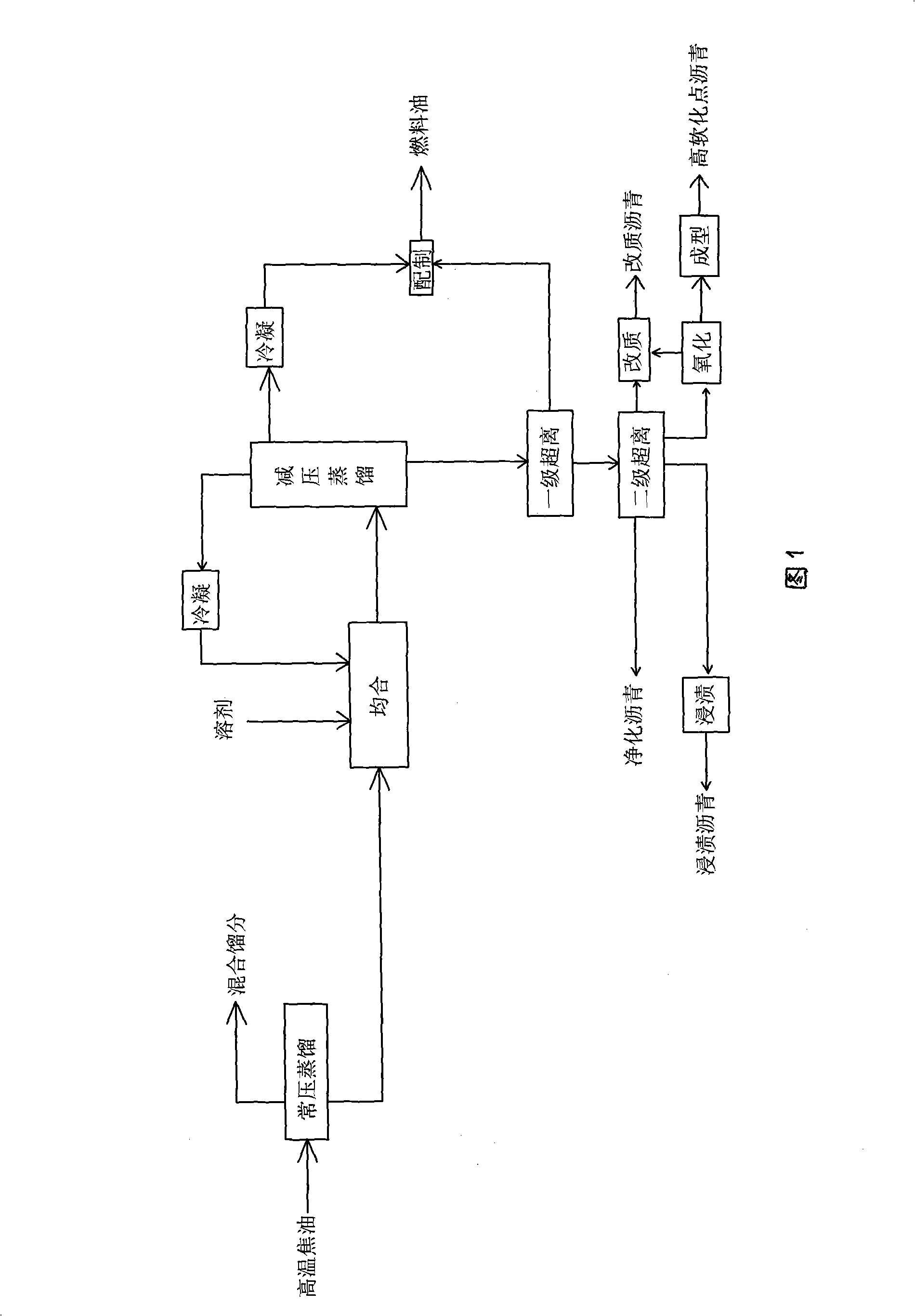

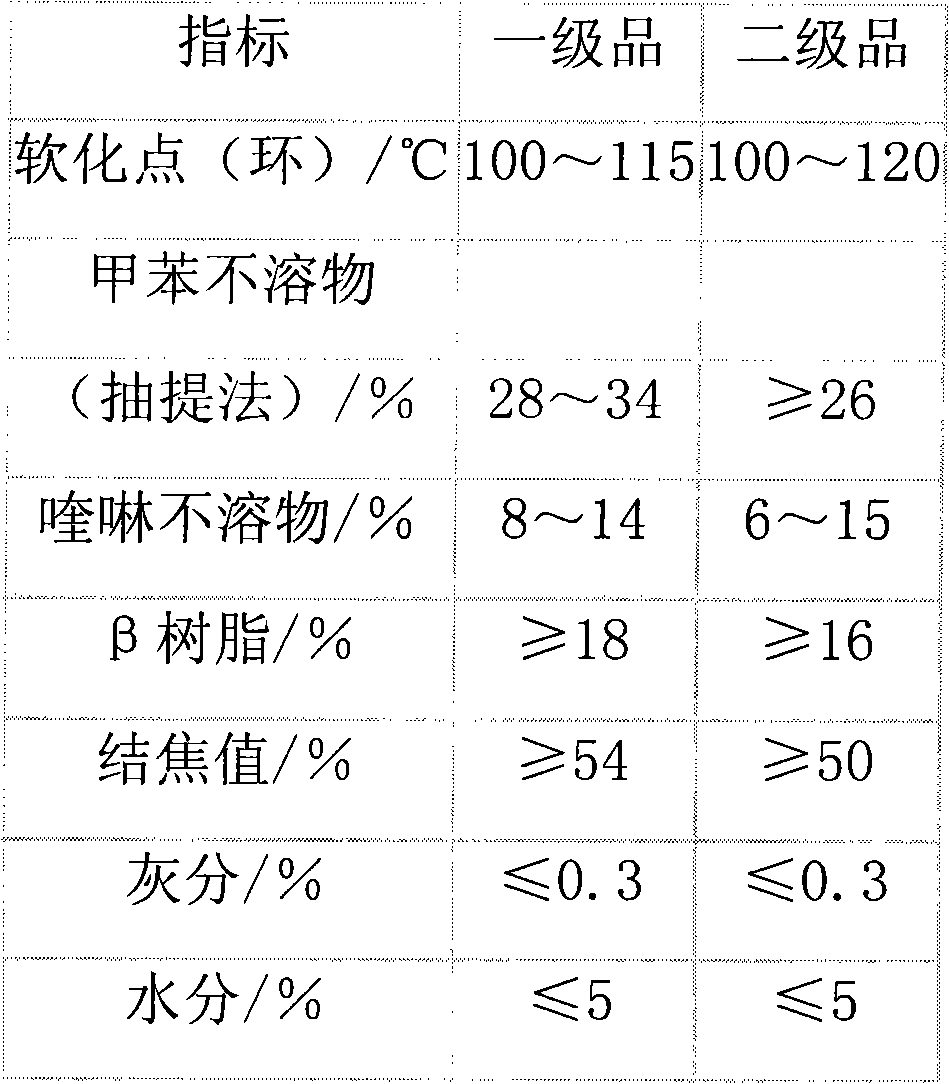

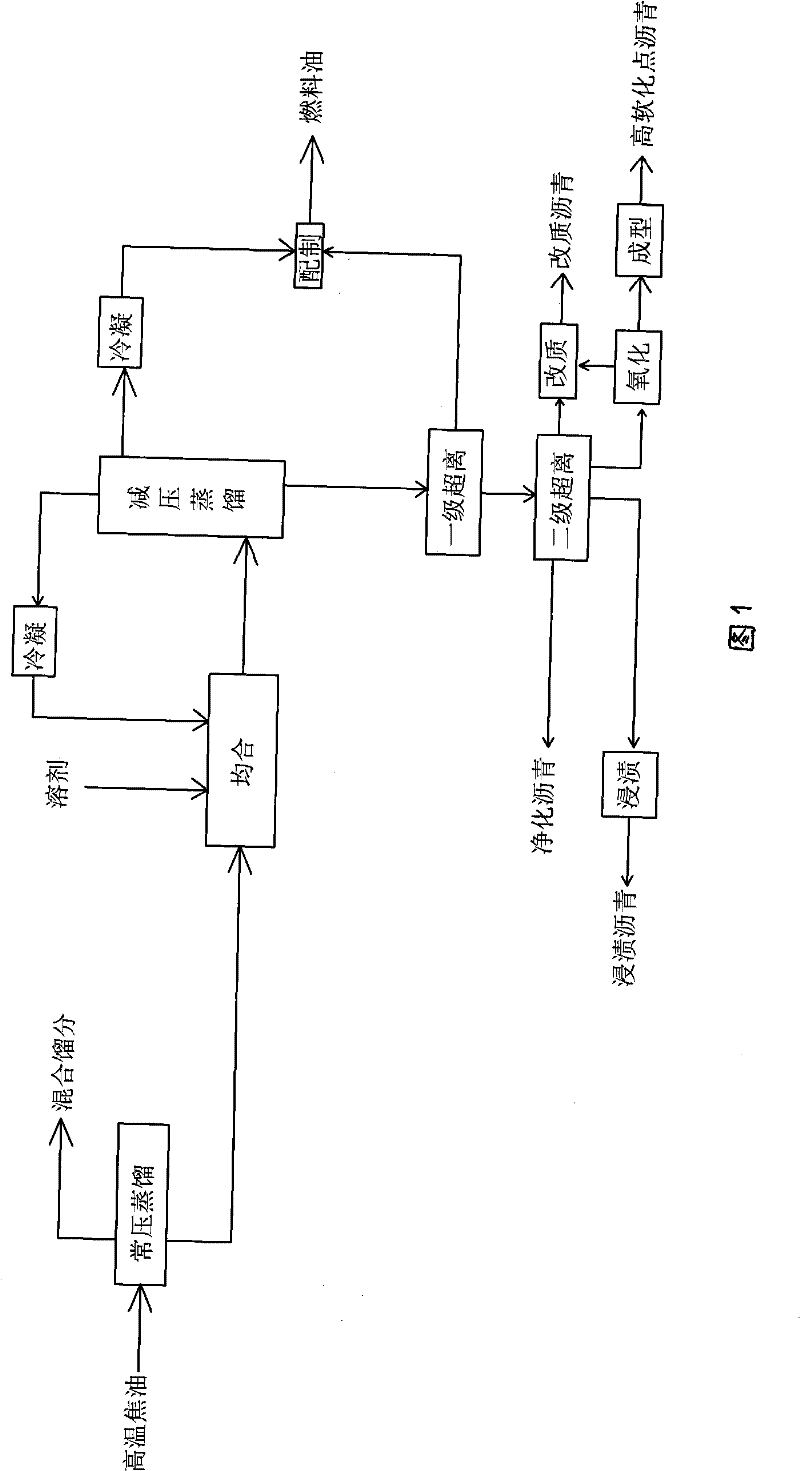

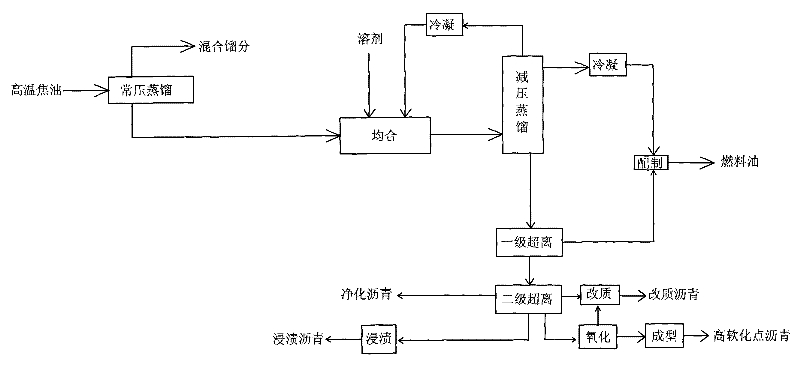

Processing process for preparing various asphalt and fuel oil with coal tar

ActiveCN101323788AImprove qualityIncrease added valueTar working-up by distillationCoal tar preparationFuel oil

The invention discloses a processing technology for preparing various pitches and fuel oils by coal tar which comprises the steps that: the coal tar is heated to 350 DEG C to 360 DEG C, rectified at ordinary pressure first and then at reduced pressure, primarily ultracentrifugated and secondarily ultracentrifugated to produce purified pitch, impregnating pitch, modified pitch, high softening point pitch and fuel oils. The invention has simple technology and convenient operation, can produce various high quality pitches and fuel oils and is characterized by less investment in devices and stable quality, thus better solving the problems of low general grade of pitches of China at present, unstable fraction of fuel oils and pitches and plenty of impurities and being quite applicable to the processing and producing of the fuel oils.

Owner:浙江美阳国际工程设计有限公司

Castanea mollissima shelling device

The present invention discloses a castanea mollissima shelling device and belongs to shelling devices. A structure comprises a conveying heating mechanism, an extruding mechanism and a separating mechanism. The extruding mechanism is arranged at a lower part of the conveying heating mechanism, the separating mechanism is arranged at a lower part of the extruding mechanism, the conveying heating mechanism comprises a motor, a coupling, a rotation shaft, screw blades and a shell body, the rotation shaft and screw blades are arranged in the shell body, a material inlet is arranged at a left side of an upper part of the shell body, a material outlet is arranged at a right side of a lower part of the shell body, a material outlet valve is arranged on the material outlet, a plurality of hot air inlets are arranged at the lower part of the shell body, a plurality of moisture extraction outlets are arranged at the upper part of the shell body, and the material outlet is connected with the extruding mechanism. The castanea mollissima shelling device has characteristics of saving time and effort, not causing harms to human body, being high in shelling efficiency and suitable for large-scale processing and production of the castanea mollissima, etc.

Owner:INST OF QUALITY STANDARDS & TESTING TECH FOR AGRO PROD OF SHANDONG ACADEMY OF AGRI SCI

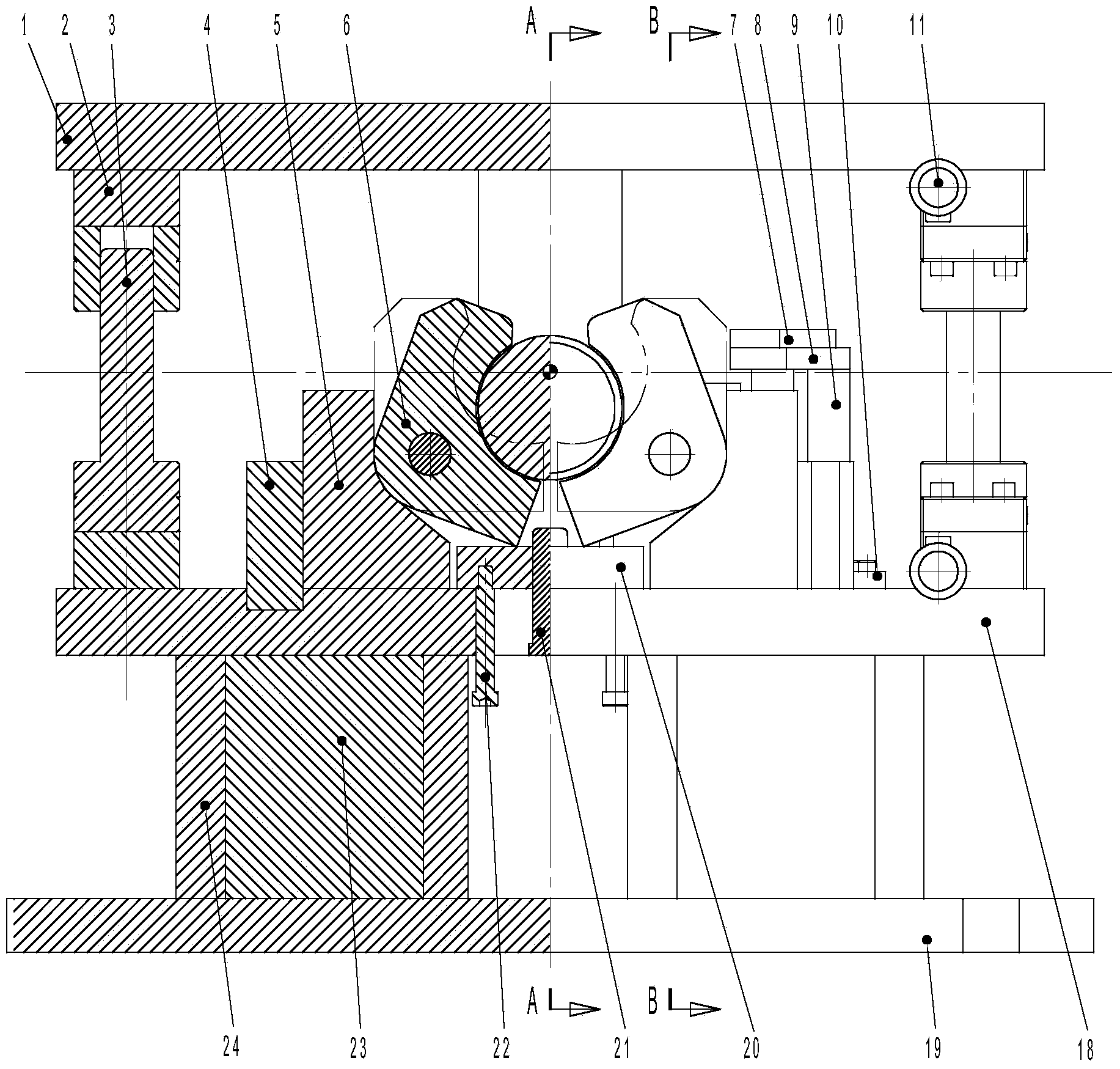

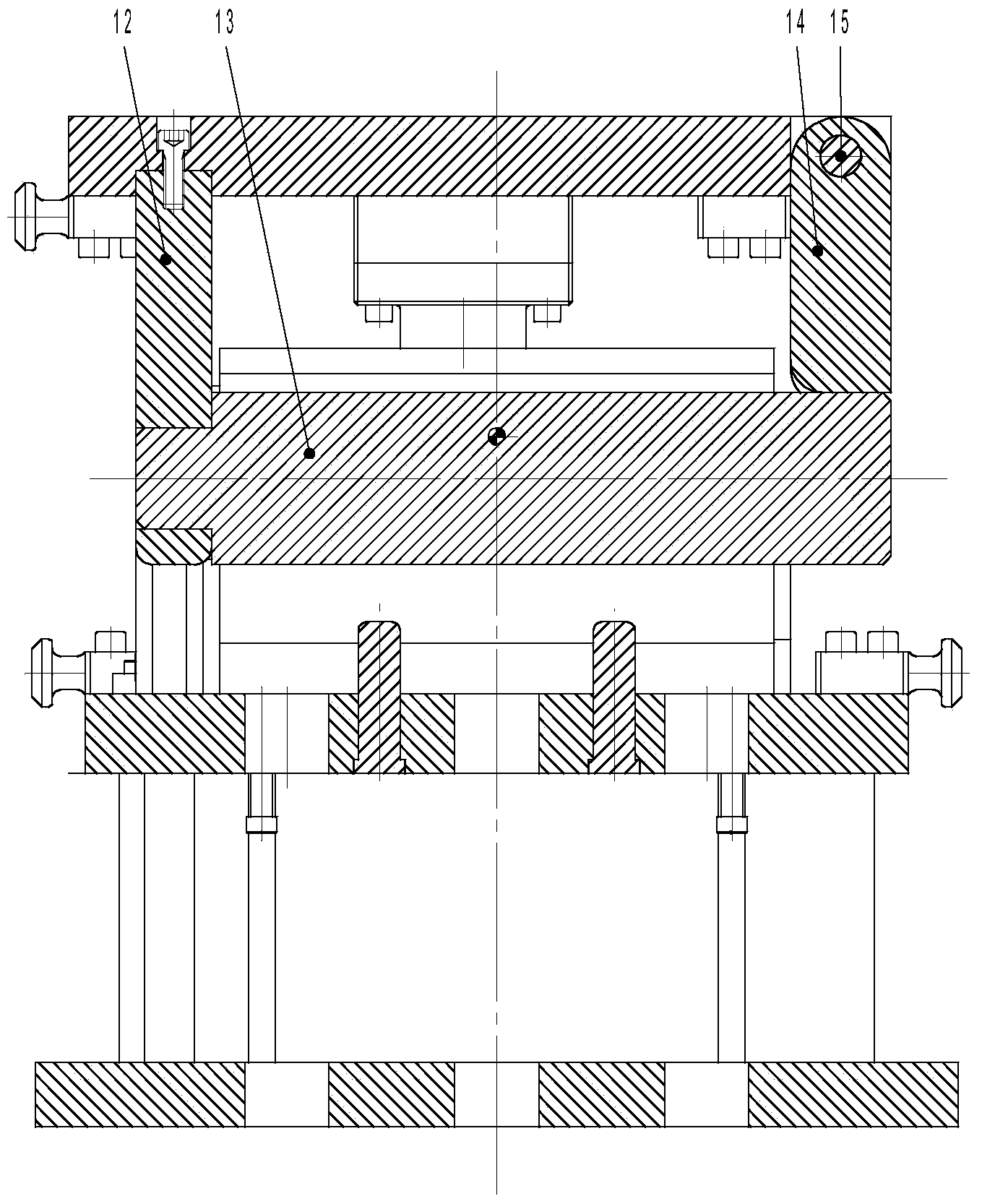

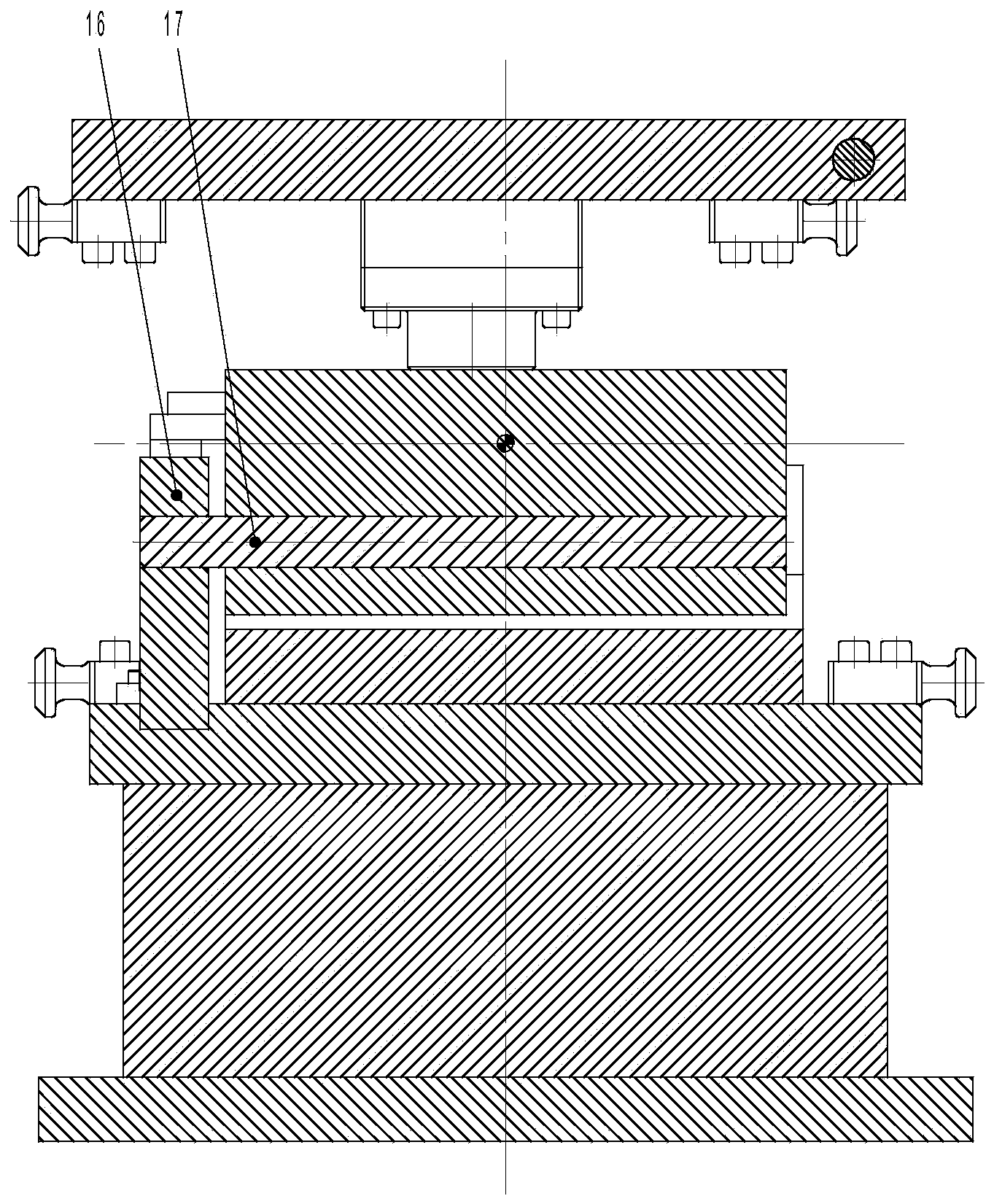

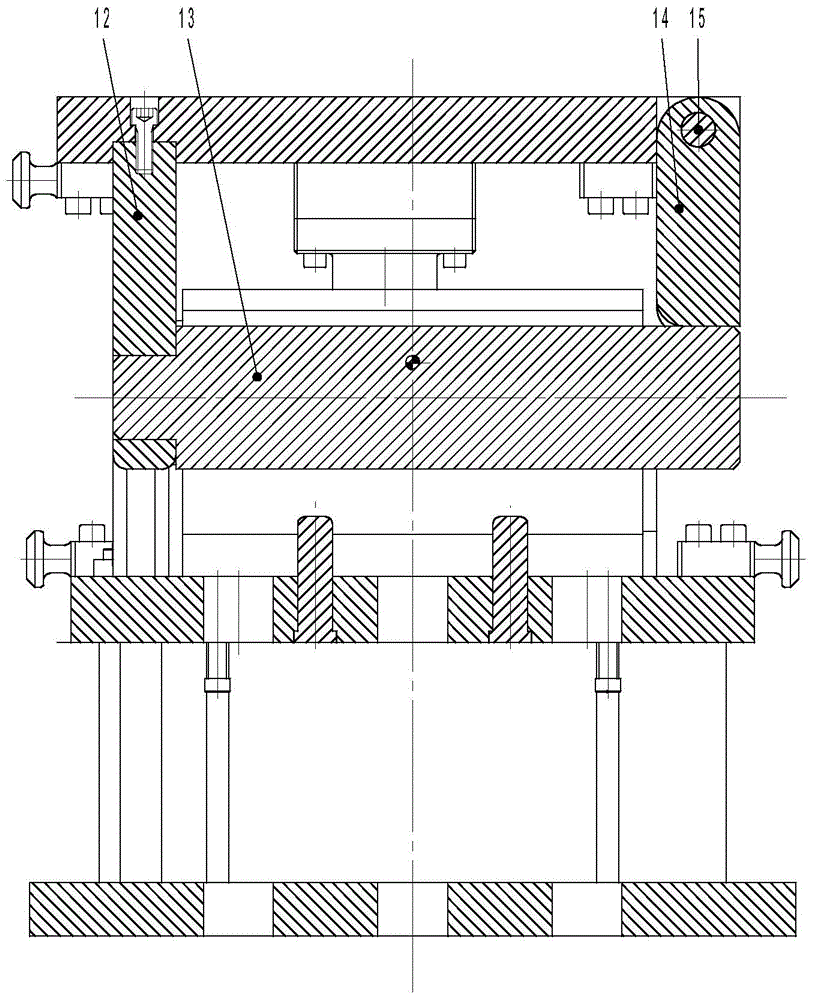

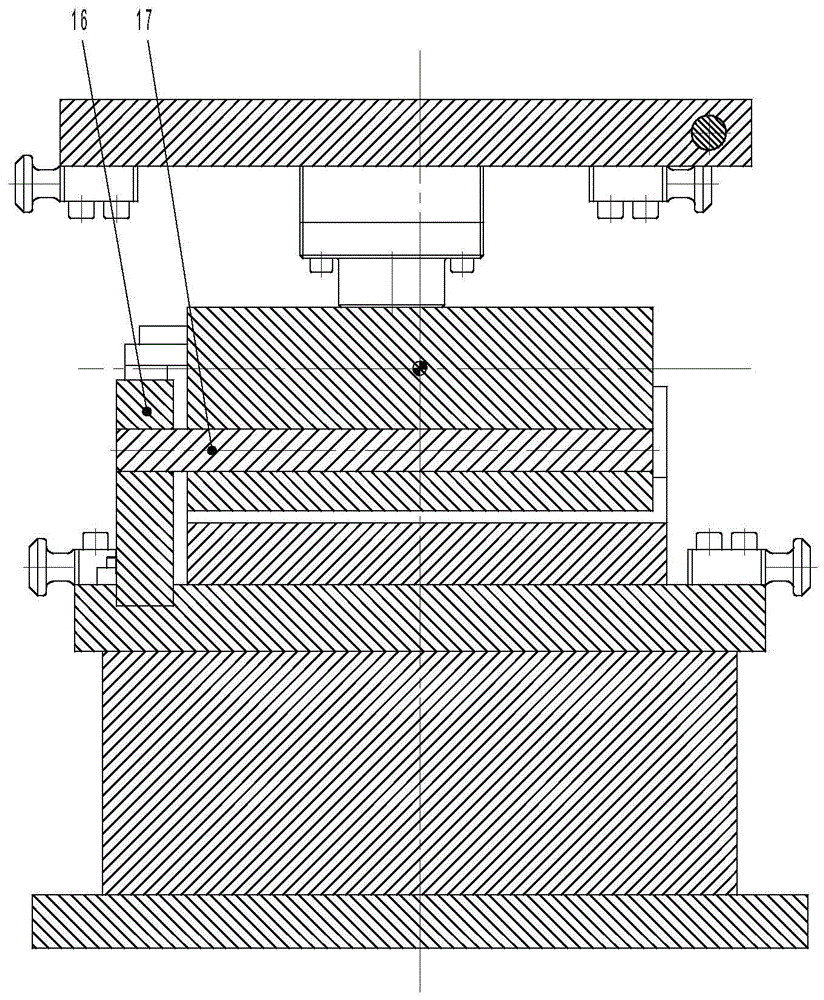

Automatic edge rolling die

The invention relates to a mechanical machining die, in particular to an automatic edge rolling die. The automatic edge rolling die comprises an upper die plate, a male die body, a female die body, a lower die fixing plate and a lower base plate. The male die body is connected with the upper die plate through a male die fixing plate and a male die supporting plate. The female die body is composed of a left L-shaped female die block and a right L-shaped female die block, wherein the left L-shaped female die block and the right L-shaped female die block are symmetrical. The inner sides of the two L-shaped female die blocks are provided with inner circular arcs which can surround the male die body. Each L-shaped female die block is installed on the lower die fixing plate through a lower die fixing pin and a lower die fixing pin fixing plate. Female die fixing bases are further arranged on the two sides of the female die body. Each female die fixing base is fixed to the lower die fixing plate. Female die pressing and supporting assemblies fixed to the lower die fixing plate are installed on the two sides of each female die fixing base. The bottom of the lower die fixing plate is connected with the lower base plate through lower plate supporting blocks. The top of the lower die fixing plate is connected with the upper die plate through guide post guide sleeves. A material returning plate is further installed on the lower die fixing plate. The automatic edge rolling die is simple in structure, low in cost, high in production efficiency and suitable for machining and producing small-sized sheet type cylinder parts.

Owner:LIUZHOU LIUHE FANGSHENG MACHINERY

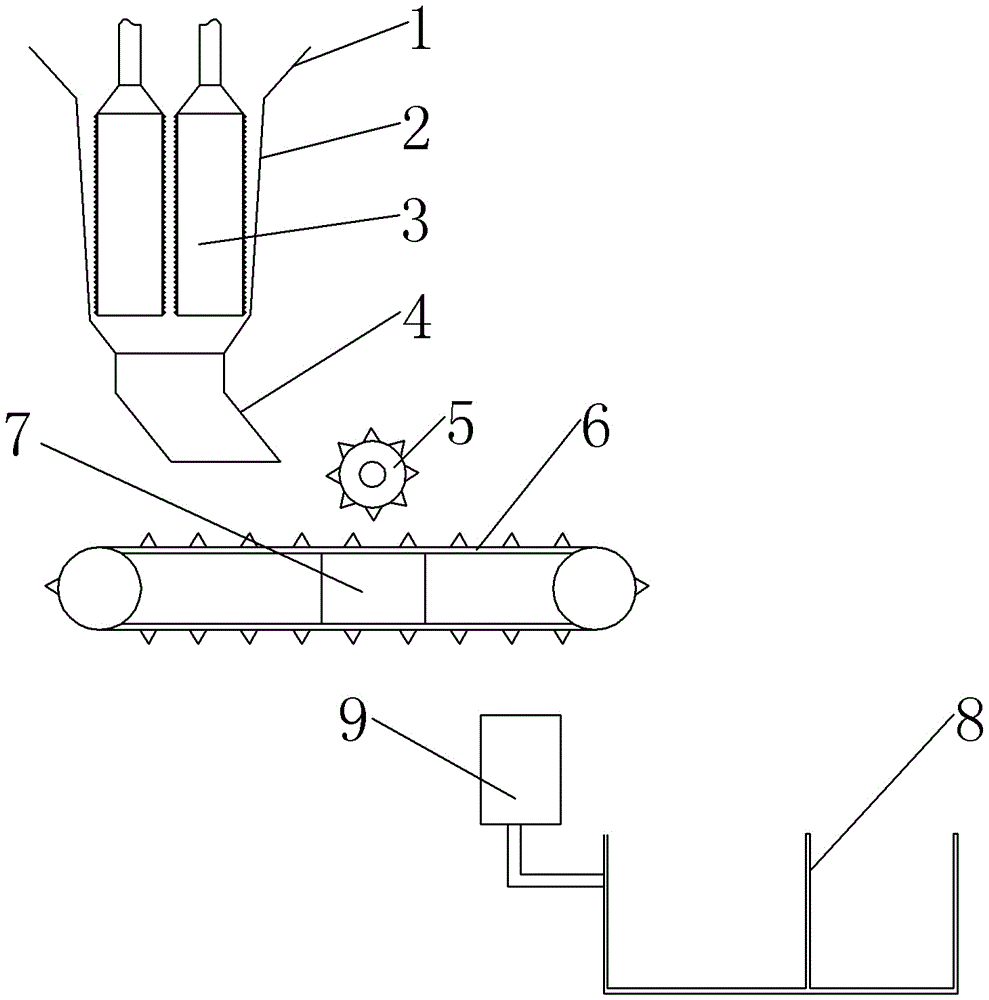

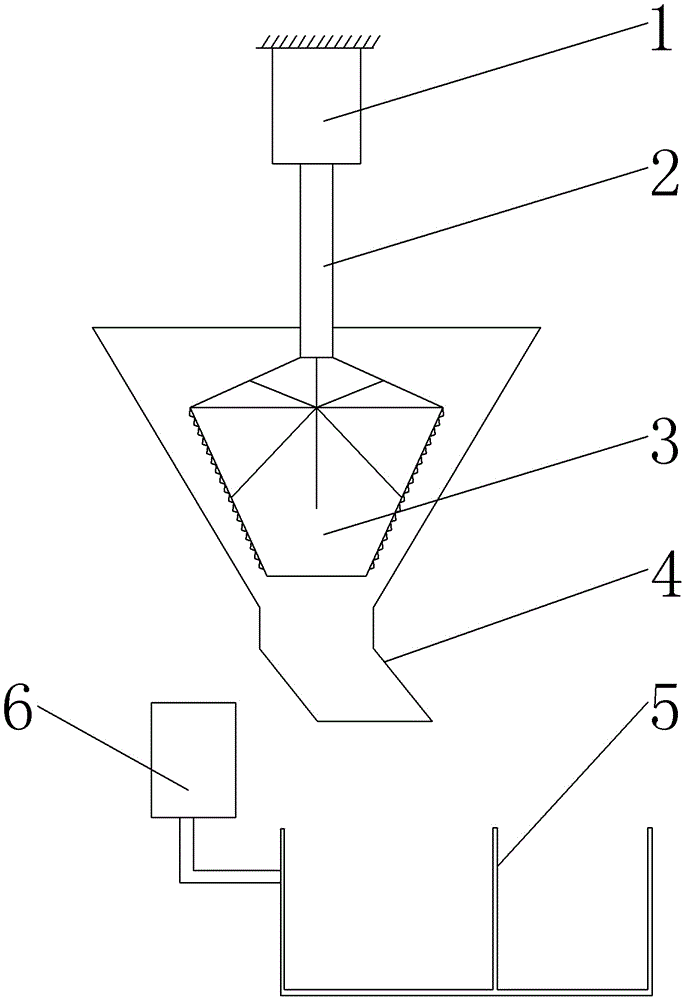

Mechanical equipment for processing walnut powder

The invention discloses mechanical equipment for processing walnut powder. The mechanical equipment for processing walnut powder comprises a frame, wherein an accumulating chamber is inverted-cone-shaped, the taper of the accommodating chamber is 1:7-8, shell breaking rolls which are connected with a motor and a driving shaft are suspended in the accommodating chamber, and are two rolls which are distributed at intervals, the bottom of the accommodating chamber communicates with a discharging channel, the discharging channel is inclined rightwards, spines are uniformly distributed on an additional roll, the additional roll is mounted between the discharging channel and a conveying belt, a supporting frame is arranged between two belt pulleys, a storage tank is arranged below the conveying belt and comprises a front tank for storing walnut kernels and a rear tank for storing walnut shells, the front tank and the rear tank are separated from each other by a partition, a fan is mounted on the outer wall of the left side of the front tank, and air blown out from the fan is horizontally rightward. By the mechanical equipment for processing the walnut powder, shells can be broken fully, time and labor are saved, efficiency is high, and walnut shell breaking costs are greatly reduced; and the mechanical equipment has great promotion effect on development of the industry.

Owner:贵州天和农业发展有限公司

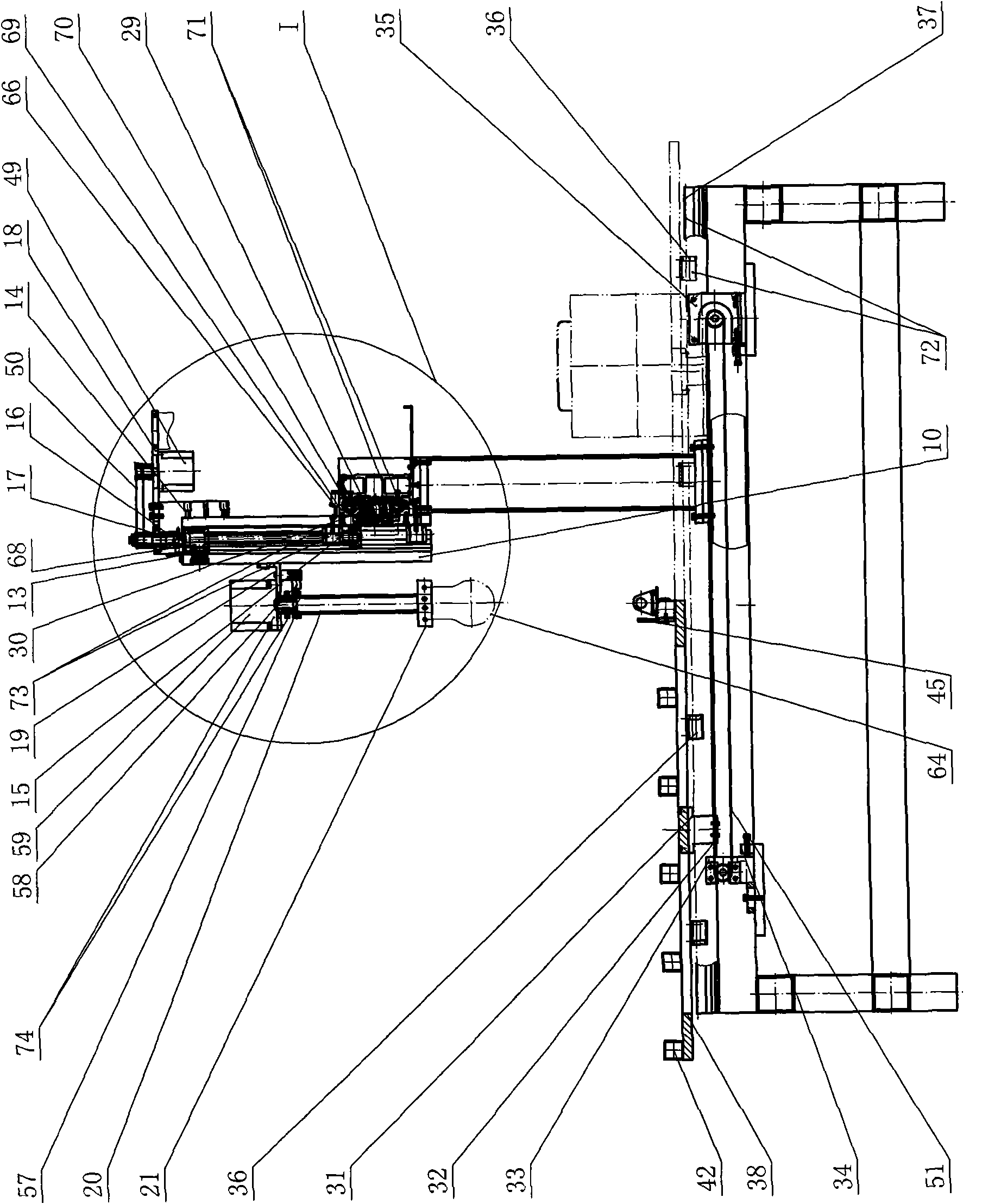

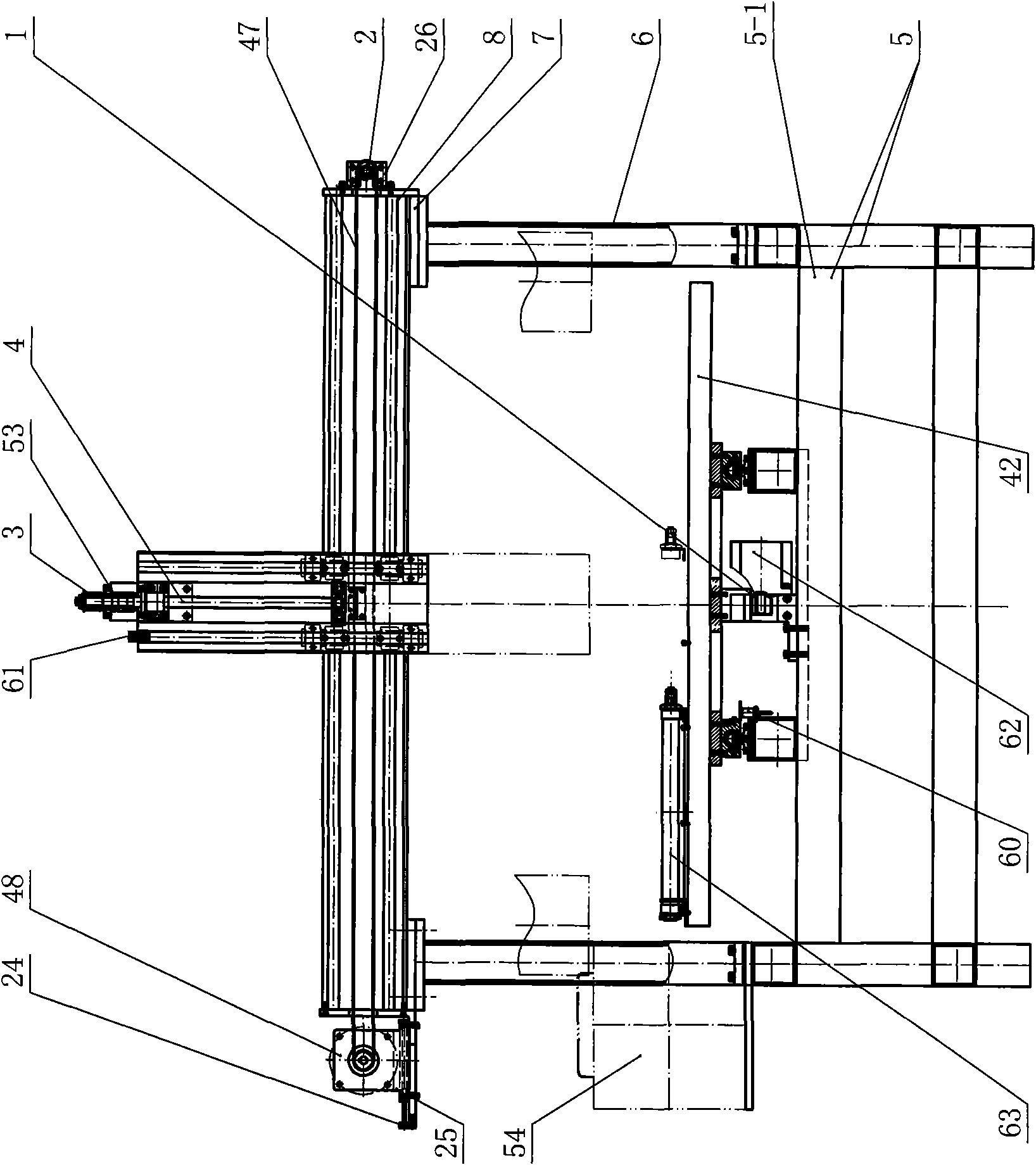

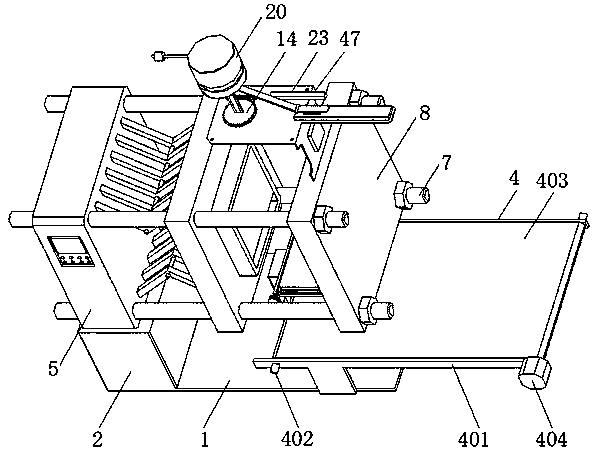

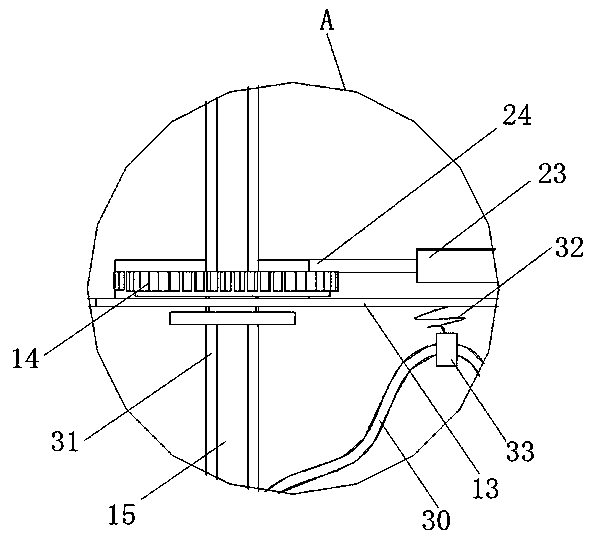

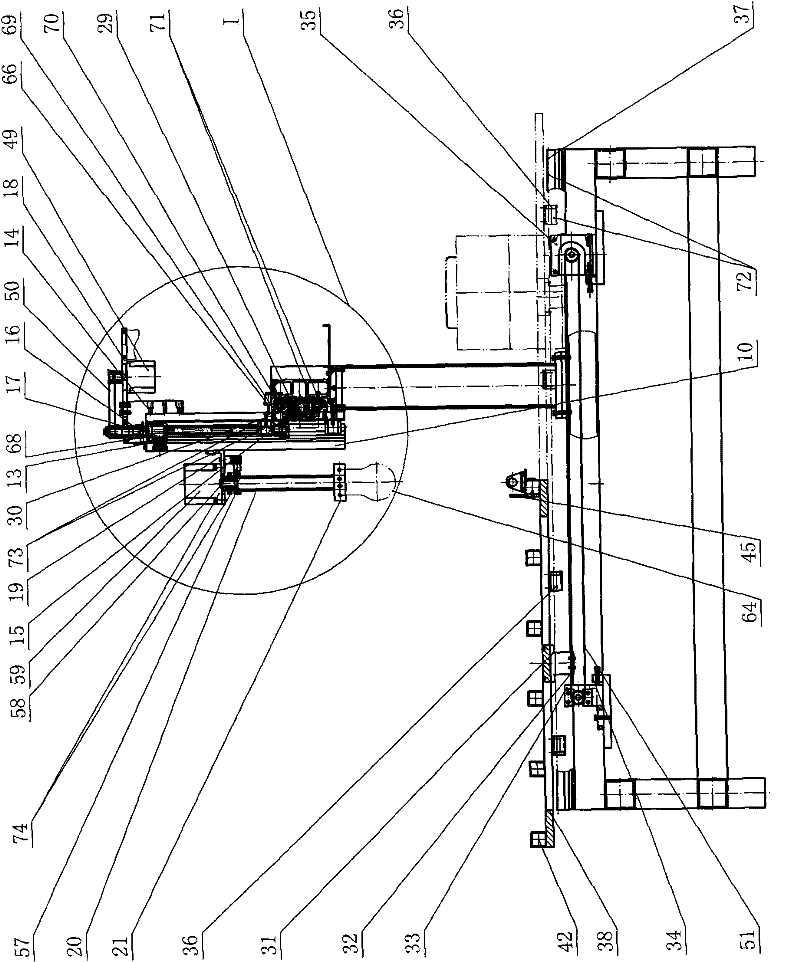

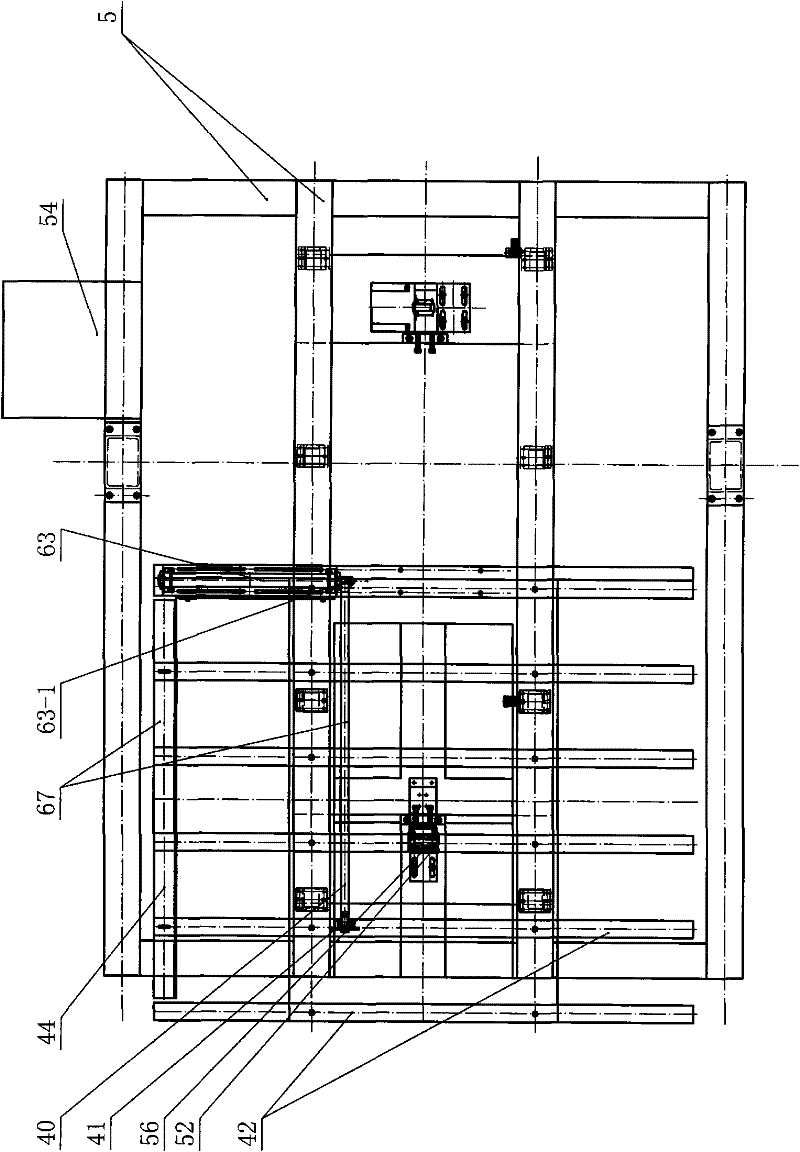

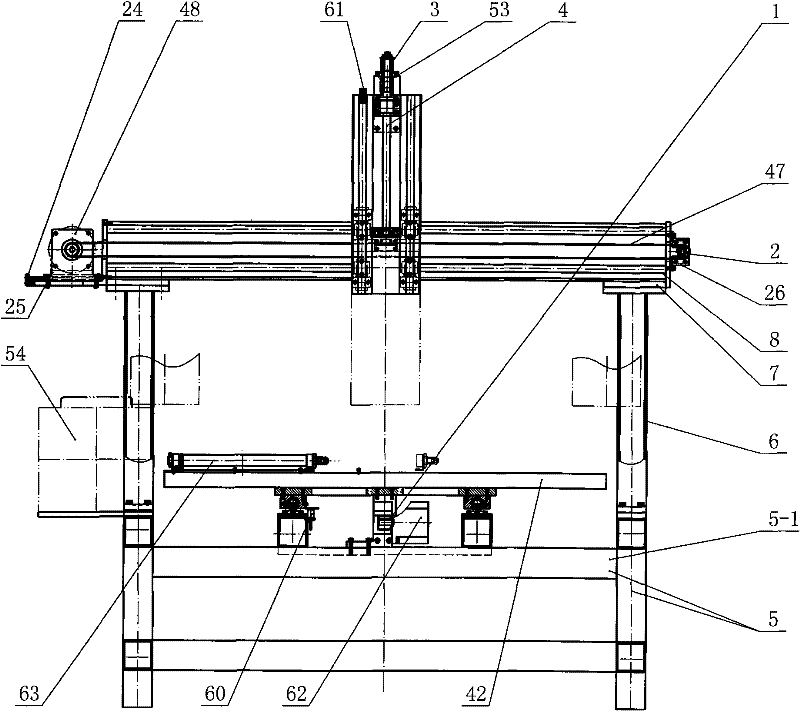

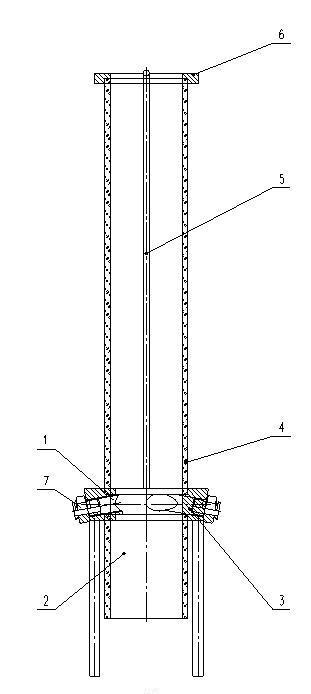

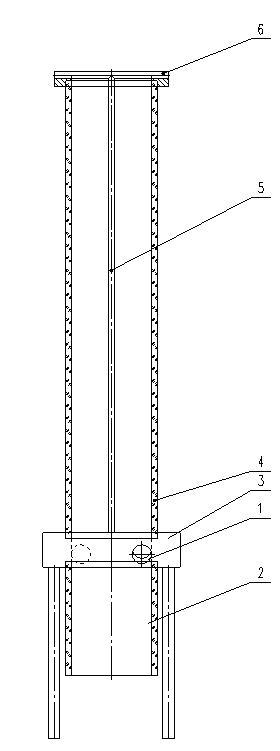

CNC (Computer Numerical Control) four-axis full-automatic foam die-free forming machine

ActiveCN102126231ARealize full circle rotationImprove processing qualityMetal working apparatusNumerical controlFree form

The invention relates to a foam forming machine, in particular to a CNC (Computer Numerical Control) four-axis full-automatic foam die-free forming machine which comprises a digital control computer, an electric heating wire transformer (54), an electric heating wire (64), a machine body (5), an operating platform (42), a stand column (6), a beam (8) and a Z-direction sliding device (73), wherein an X-direction sliding device (71) is arranged on the beam (8). The CNC four-axis full-automatic foam die-free forming machine also comprises a fixing device (67) for a workpiece to be processed on the operating platform (42). The workpiece to be processed moves linearly forth and back along the Y-axis direction, the electric heating wire (64) moves linearly left and right along the X-axis direction and moves linearly up and down along the Z-axis direction, and the electric heating wire (64) rotates. The invention has the advantages of simple structure, realization of processing various complicated shapes of foams, good processing quality, low cost and wide application range.

Owner:常州市新罗特数控机械有限公司

Anti-corrosion dipping liquid

InactiveCN104141232APrevent volatilizationImprove performanceFibre treatmentEmulsionButadiene-styrene rubber

The invention discloses anti-corrosion dipping liquid. The anti-corrosion dipping liquid is composed of, by weight, 9-11 parts of natural emulsion, 10-15 parts of butadiene-vinylpyridine copylymer latex, 11-13 parts of styrene-butadiene latex, 1-5 parts of resorcinol, 2-6 parts of methanal, 1-2 parts of penetrant, 1-2 parts of sodium hydroxide and 70-80 parts of pure water. The natural emulsion is added into the raw materials, so that a film is rapidly formed on the surface of the dipping liquid with which a piece of industrial cloth is dipped, the film can effectively prevent the raw materials from volatilizing, and the bonding performance between the dipping liquid and the surface of the industrial cloth is ensured; meanwhile, through the addition of the penetrant, the anti-corrosion dipping liquid has the advantages of resisting high temperature, acid and alkali and being high in abrasion resistance, and the performance of the dipping liquid is improved; in addition, a preparation method is easy to operate, no long working time is occupied, the labor cost is lowered, and the method is applicable to machining production of small-scale enterprises.

Owner:旌德县合力工业布厂

Die casting machine tool with automatic part taking and spraying function

The invention discloses a die casting machine tool with an automatic part taking and spraying function. The die casting machine tool comprises a bottom plate and is characterized in that a conveying mechanism is mounted on the upper surface of the bottom plate, a vertical first electric telescopic rod is mounted on the left side of the conveying mechanism, a transfer device is mounted at the upperend of the first electric telescopic rod, the transfer device is located above the conveying mechanism, a lateral seat is fixed at the left end of the upper surface of the bottom plate, a fixing seatis fixed to the upper surface of the lateral seat, a control switch is mounted on the front side of the fixing seat, and horizontal guide columns are arranged at four corners of the fixing seat. Thedie casting machine tool is simple in structure, convenient to use, capable of taking and transferring die casting parts through the coordination of the transfer device and the conveying mechanism, capable of avoiding manpower consumption and accidents, capable of lowering worker labor intensity, capable of drying the inner side of a die seat and performing release agent spraying through a spraying device, capable of automatically selecting spraying and drying positions and capable of adjusting spraying and drying angles.

Owner:瑞安市欧潮汽车部件有限公司

Sauting method for producing chafing dish fish bottom flavoring

InactiveCN1907119AThe taste is delicate and not greasyFull of nutritionFood preparationAlkanna tinctoriaSugar

The invention provides a process for making bottom flavoring of chafing fish dish, wherein the raw material includes salad oil, butter, bean cotyledon, pepper, fresh ginger, toasted garlic, onion, crystal sugar, fermented glutinous rice, star aniseed, rhizome of galange resurrectionlily, cassia bark, common fennel fruit, tsaoko cardamon, alkanna tinctoria, geranium, vanilla leaves and cloves.

Owner:刘玉祥

Walnut shell breaking equipment

The invention discloses walnut shell breaking equipment. The walnut shell breaking equipment comprises a rack, wherein a containing chamber is inverted conical; the conical degree of the containing chamber is 1:(7-8); a shell breaking roll is connected with a motor and a driving shaft and then is suspended in the containing chamber; the shell breaking roll comprises a conical upper roll, an inverted conical lower roll and an inner fixed frame for fixing the upper roll and the lower roll; the conical degree of the lower roll is 1:(11-15); the bottom of the containing chamber is communicated with a discharge channel which is disposed in a right-leaning manner; a storage tank is disposed below the discharge channel; the storage tank comprises a front tank for storing walnut kernels and a rear tank for storing walnut shells; the front tank and the rear tank are separated via a partition plate; a fan is mounted on the outer wall of the left side of the front tank. According to the walnut shell breaking equipment, the shells can be fully broken, time and labor are saved, the efficiency is high, the walnut shell breaking cost is greatly reduced, and the equipment greatly promotes industrial development.

Owner:贵州天和农业发展有限公司

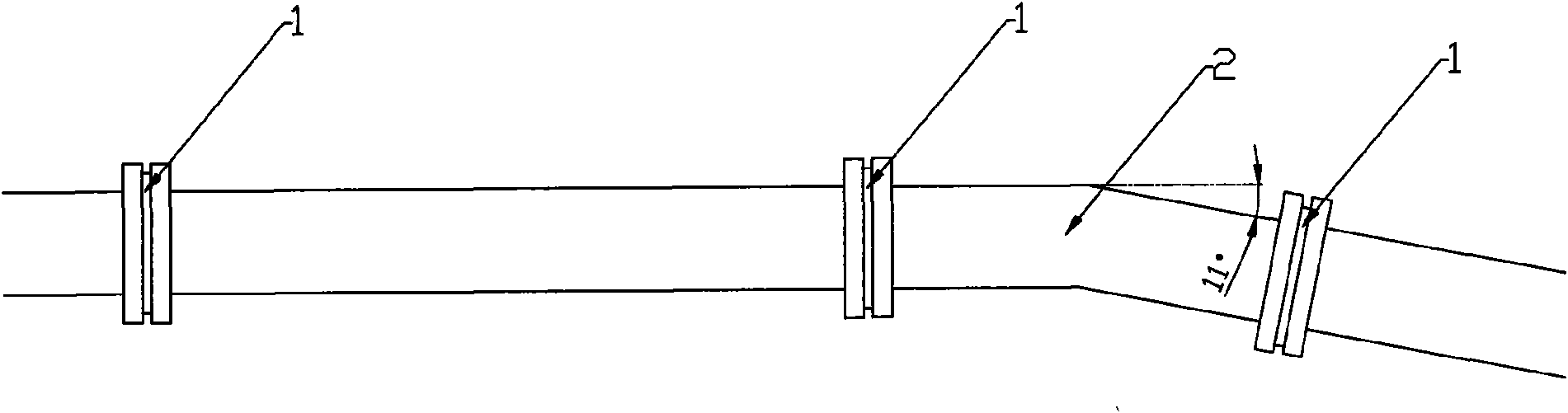

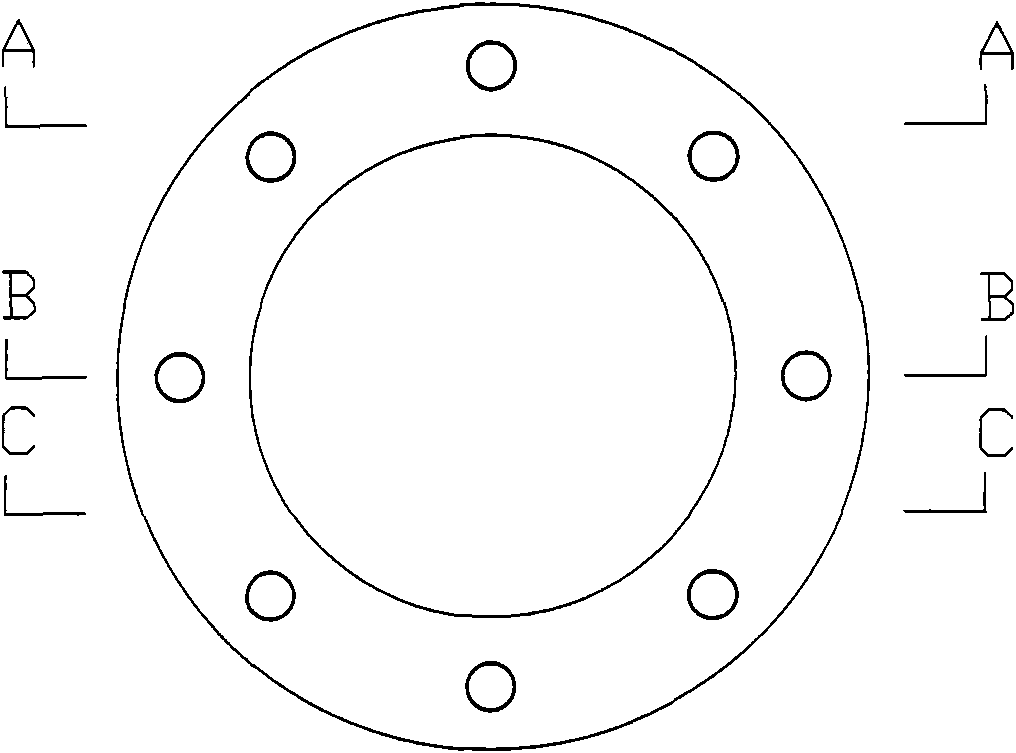

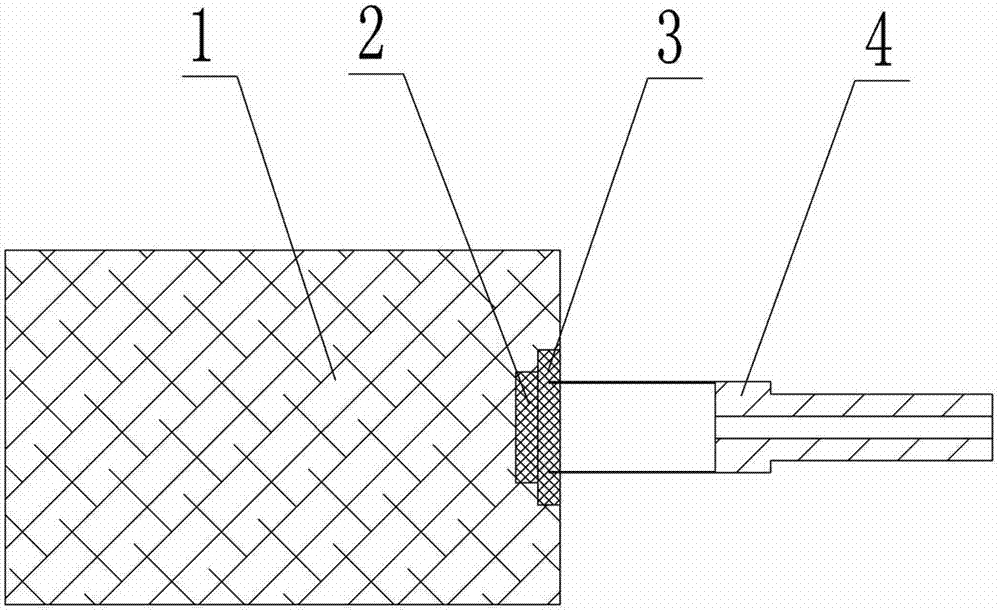

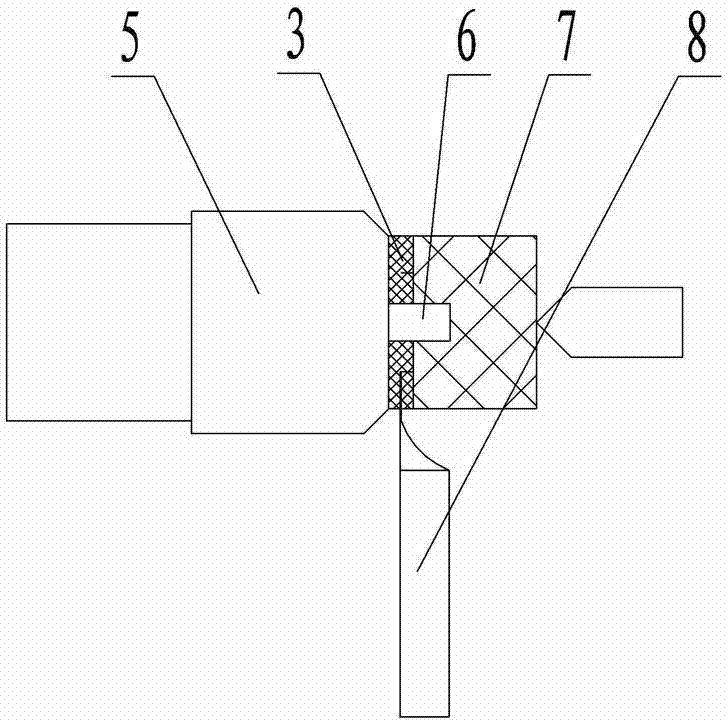

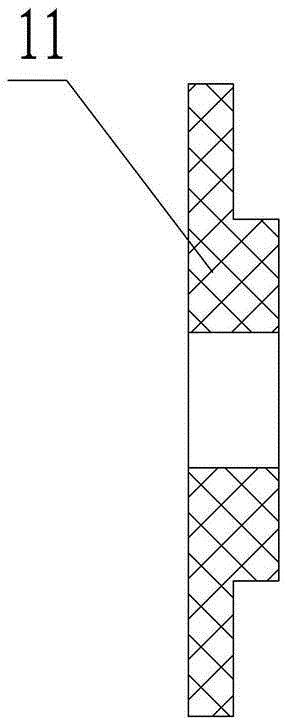

Turning gasket for connecting flanges

InactiveCN101598253AChange connection directionSimple structureFlanged jointsWashersState of artEngineering

The invention discloses a turning gasket for connecting flanges, which is used for solving the problem of higher cost when the direction of two connecting pipes are changed in the prior art. The turning gasket for connecting the flanges comprises a gasket body, wherein extension lines connecting the planes on both sides of the gasket body intersect to form an included angle less then 90 degrees. By using the turning gasket for connecting the flanges with the included angle to connect the two pipes, the connecting direction of the pipes can be changed conveniently. The turning gasket for connecting the flanges has simple structure and low production cost and is suitable for processing and production.

Owner:叶尔肯·拜山

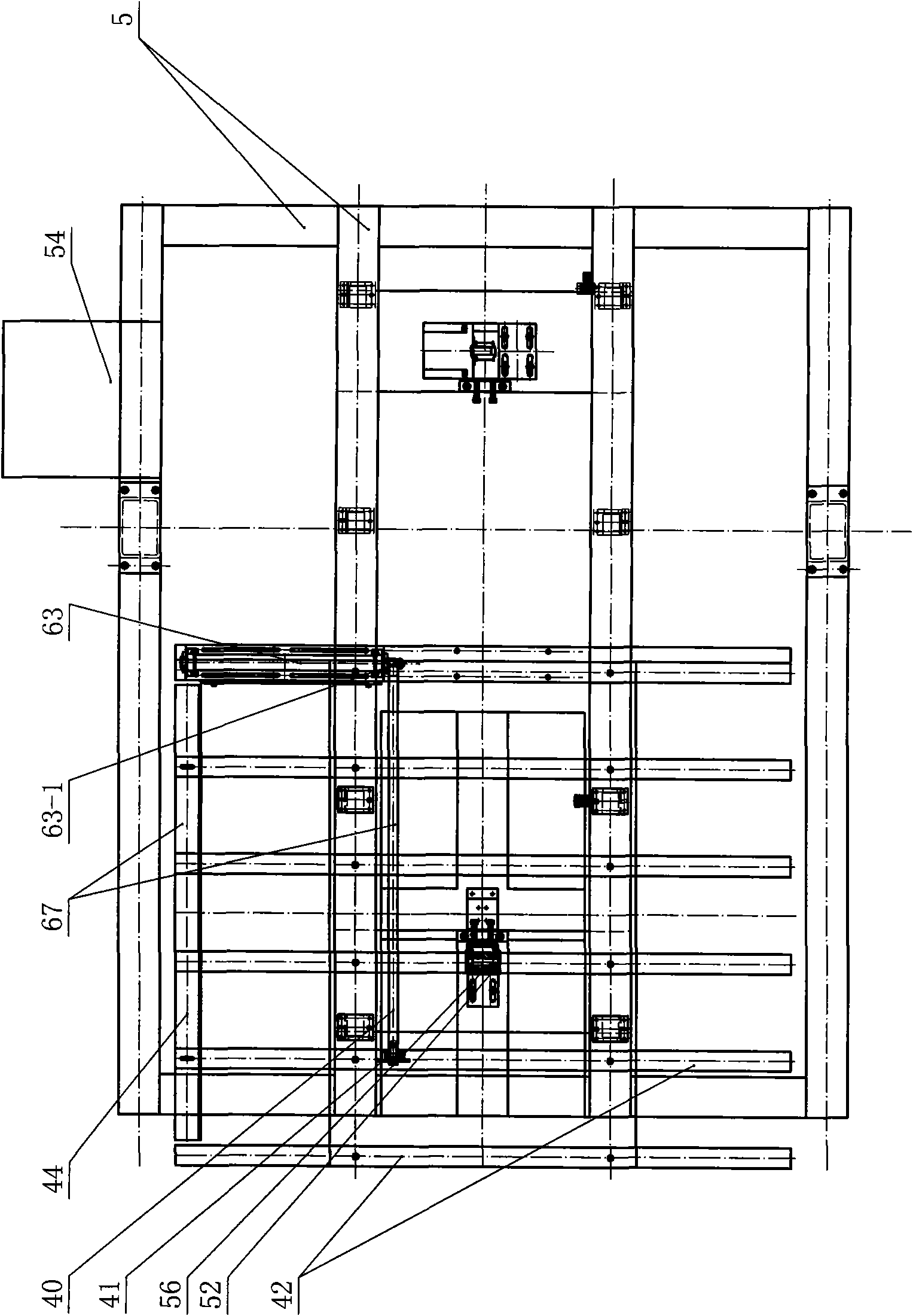

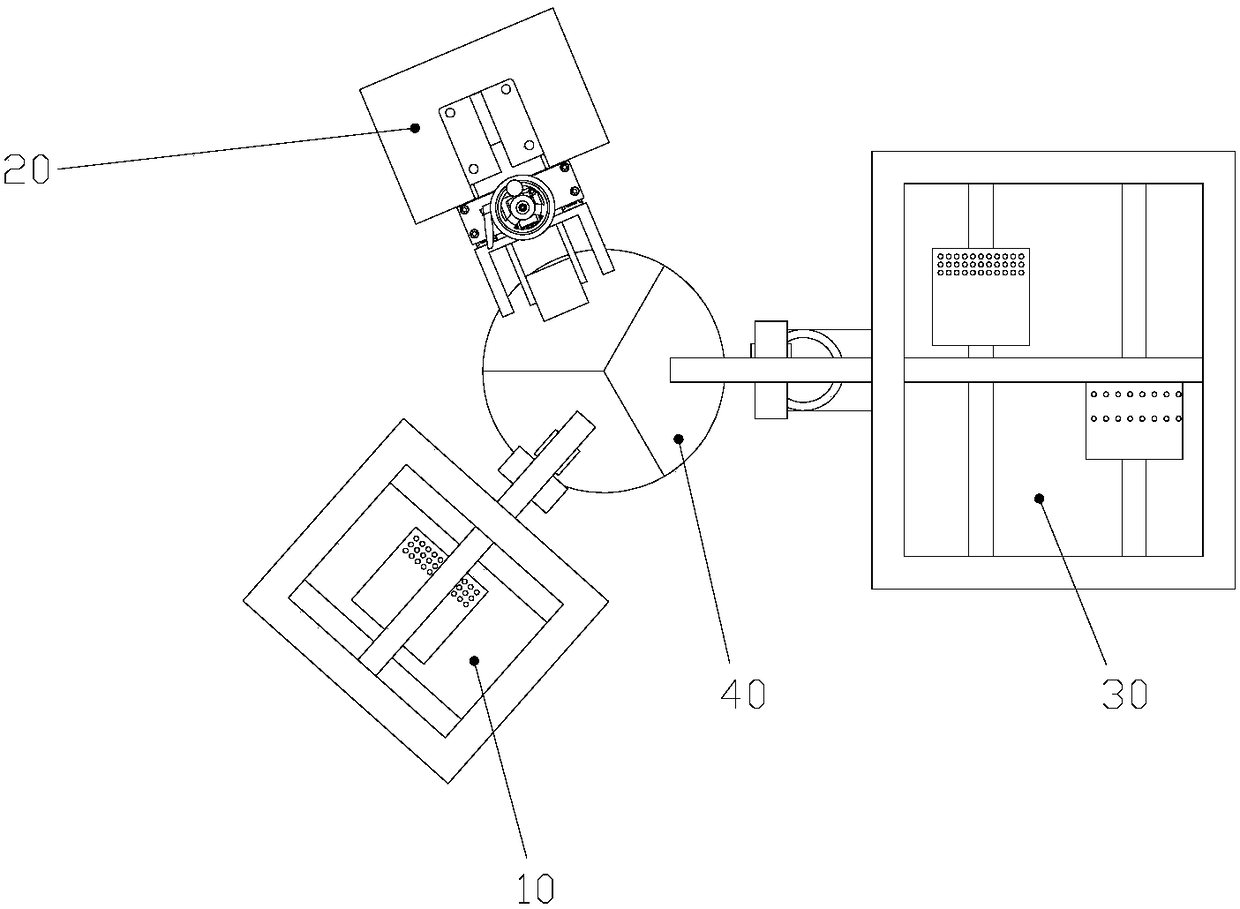

Membrane processing equipment

InactiveCN108237588AAvoid secondary pollutionFinished layout rulesSortingMetal working apparatusAutomatic processingMembrane configuration

The invention provides membrane processing equipment. The equipment comprises a cutting mechanism, a detection mechanism and a typesetting mechanism, wherein the cutting mechanism is used for cuttingthe membrane into the membrane of a finished product with a preset size; the detection mechanism is used for receiving the membrane of the finished product and detecting the membrane of the finishedproduct so as to obtain a detection result; and the typesetting mechanism is used for receiving the detected membrane of the finished product and classifying and typesetting the membrane of the finished product according to the detection result. According to the diaphragm processing equipment, automatic processing is adopted in each stage of cutting, detecting and typesetting of the membrane, andthe full-process automation of cutting, detecting and typesetting the membrane is achieved, production efficiency is improved, and a secondary pollution caused by manual participation is reduced.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

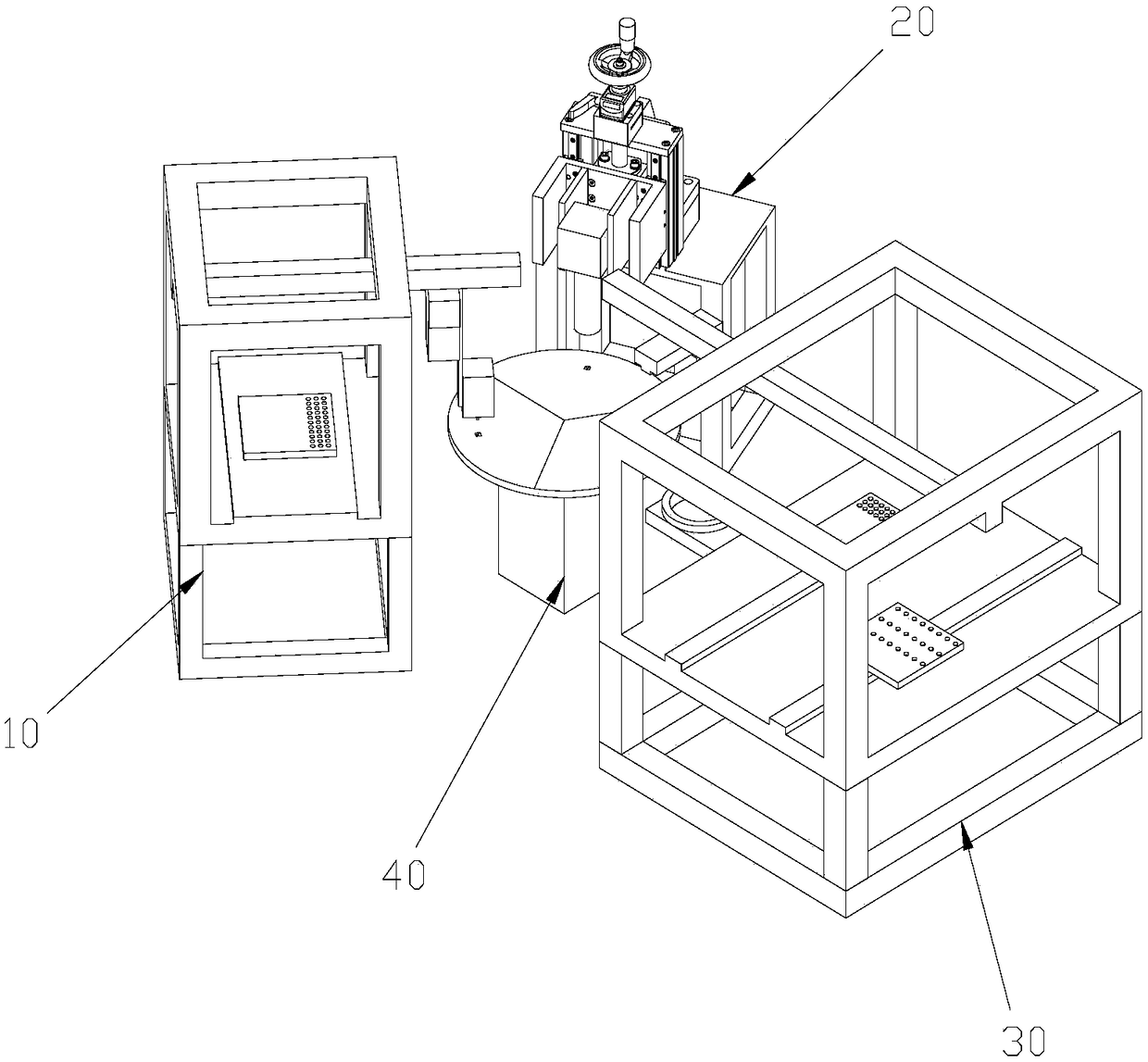

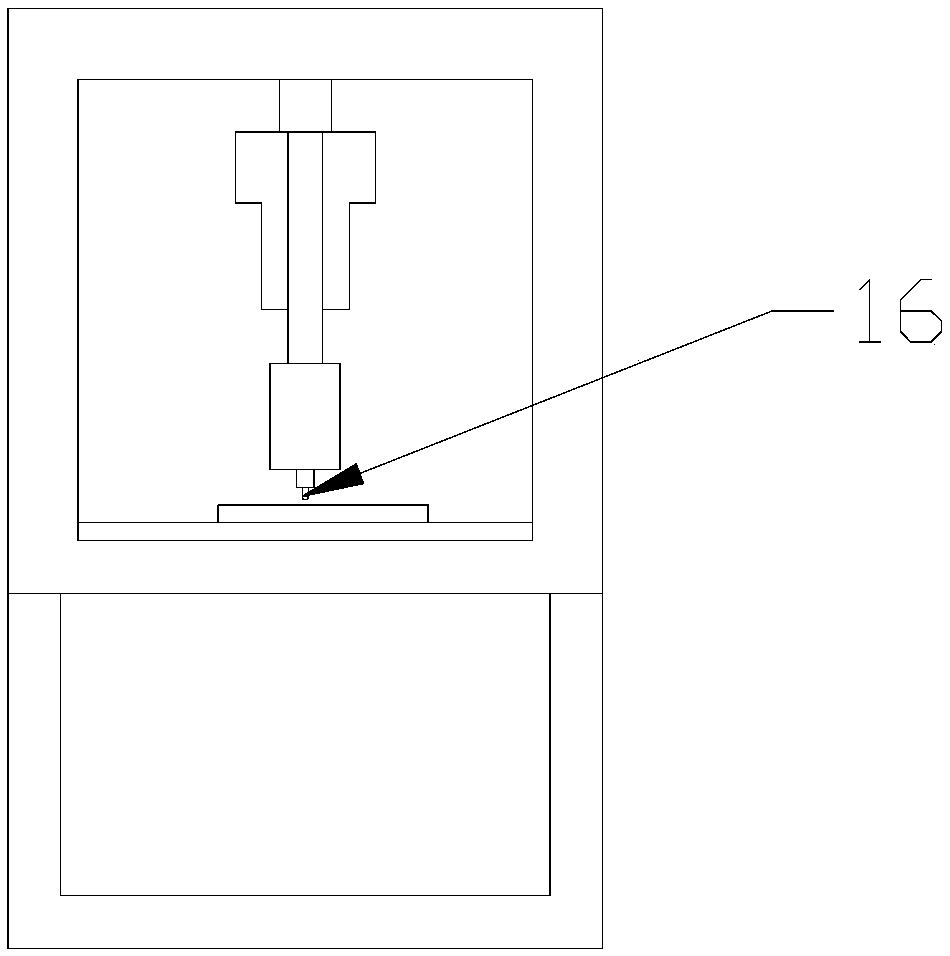

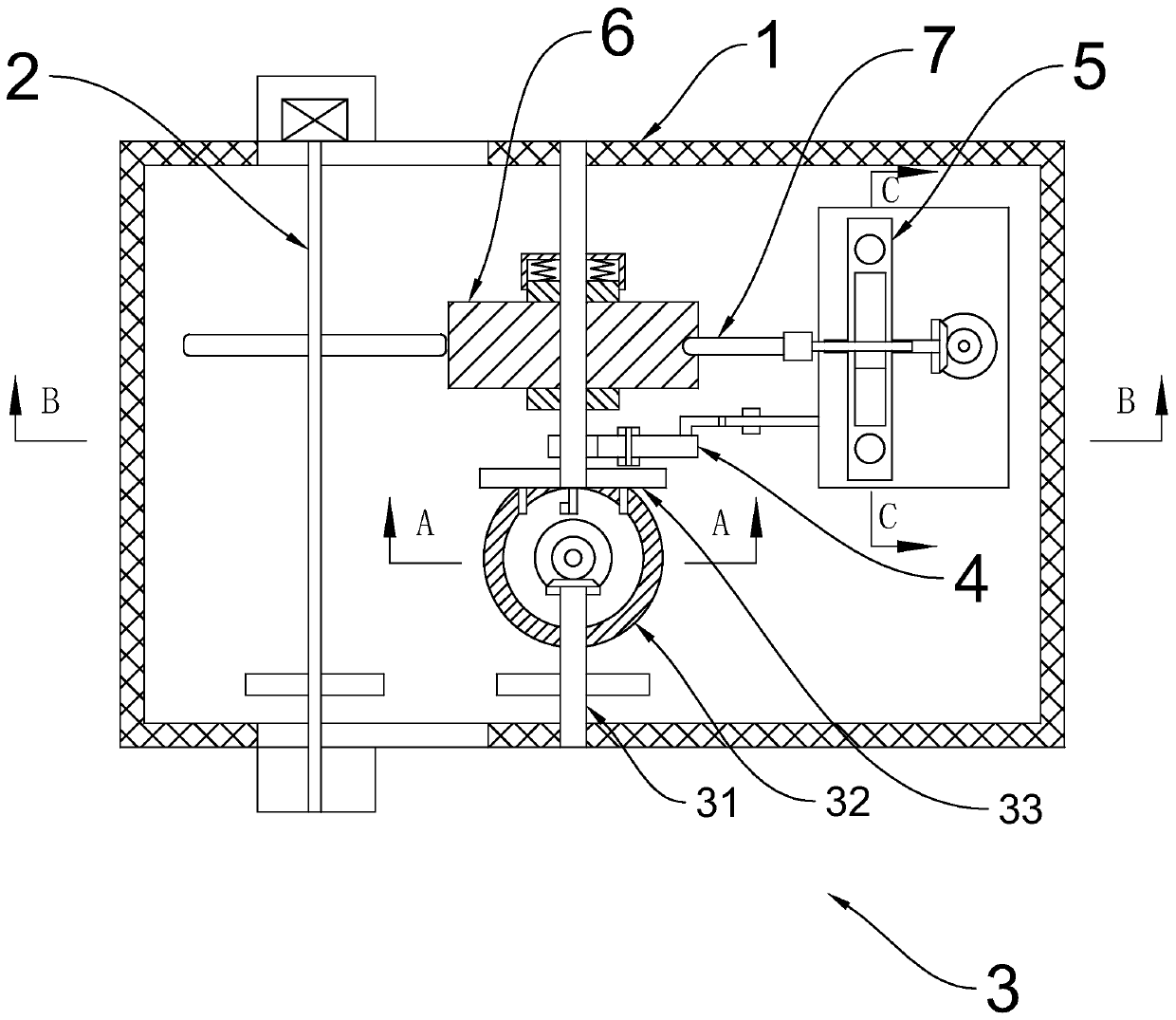

Integrated processing device of neodymium-iron-boron magnet

ActiveCN110509064AMeet cuttingSatisfy processabilityFeeding apparatusOther manufacturing equipments/toolsRotational axisSteering wheel

The invention discloses an integrated processing device of a neodymium-iron-boron magnet. The integrated processing device comprises a stand, a cutting assembly, a steering mechanism, a lifting mechanism, a traction mechanism and a grinding assembly, wherein the steering mechanism comprises a steering driving mechanism, a turning wheel and an abnormal-shaped steering wheel; the abnormal-shaped steering wheel and a processing piece are mounted on a seventh rotating shaft; the steering driving mechanism is in meshed transmission with a first gear which is arranged in the cutting assembly; the steering driving mechanism drives the abnormal-shaped steering wheel to be rotated through the turning wheel in a reversing manner; the cutting assembly and the grinding assembly are separately arrangedon the two sides of the processing piece; the cutting assembly is moved along sliding slots which are formed in the two sides of the stand in the horizontal direction; the grinding assembly is mounted on the lifting mechanism; the lifting mechanism is moved under an effect of the traction mechanism; and one end of the traction mechanism is connected with the lifting mechanism while the other endof the traction mechanism is connected with the seventh rotating shaft. The integrated processing device disclosed by the invention has the advantages of being high in integration degree, high in grinding efficiency and simple in operation; and moreover, cutting and grinding operations can be performed completely and sequentially, and meanwhile, double-sided grinding on the cut processing piece can be realized.

Owner:宁波可可磁业股份有限公司

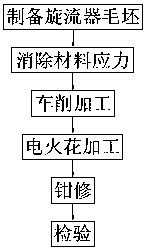

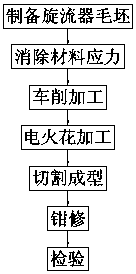

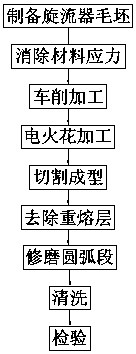

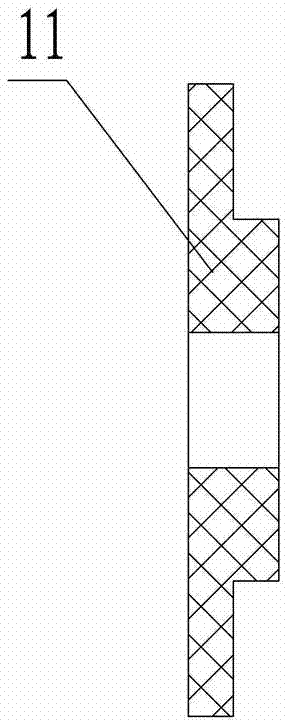

Technical method for manufacturing aero-engine cyclone through special processing technology

The invention relates to the field of aero-engines and gas turbines, and particularly relates to a technical method for manufacturing an aero-engine cyclone through a special processing technology. The method comprises the step of manufacturing a cyclone blank, wherein the cyclone bank is manufactured through a cylindrical forging piece. The method further comprises the step of manufacturing semi-finished cyclone and the step of finishing through pincers; the step of manufacturing the semi-finished cyclone is that the cyclone blank is sequentially subjected to turning processing and electric spark processing to obtain the semi-finished cyclone; the step of finishing through the pincers is that the semi-finished cyclone is finished based on the requirement on a finished cyclone so as to obtain the finished cyclone. According to the method, the forging piece is outstanding in mechanical property, and two processing modes are provided, so that the manufactured cyclone product is high in strength and toughness; the yield is increased; and the processing cost and the processing period are reduced; the manufactured cyclone product can stably run for a long time in an aero-engine combustion chamber; and the service life of the aero-engine combustion chamber cannot be influenced by the quality of the cyclone.

Owner:广汉天空动力机械有限责任公司

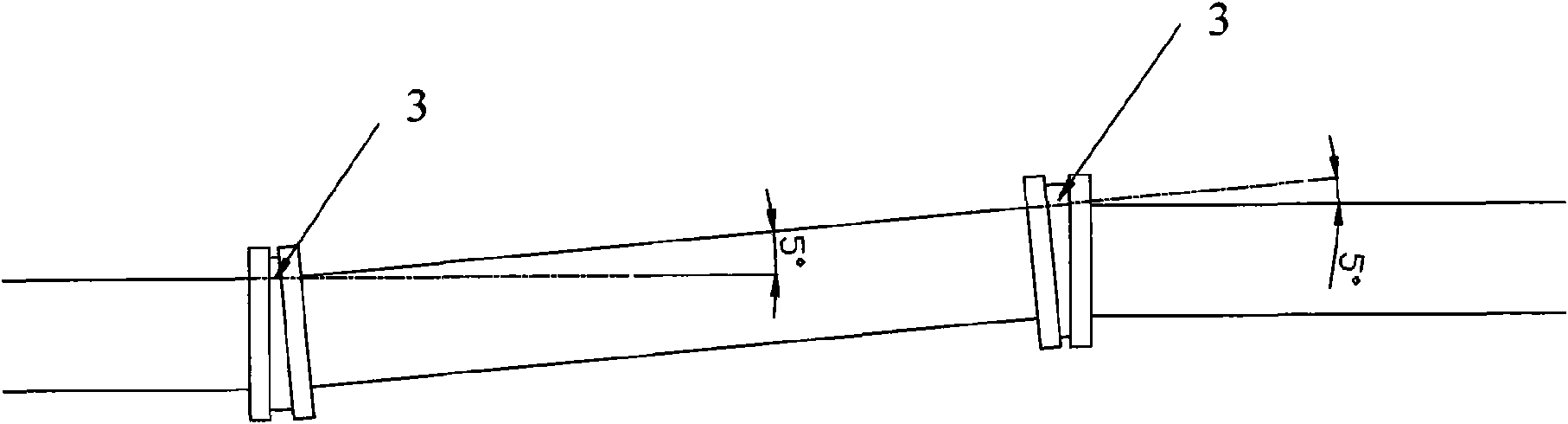

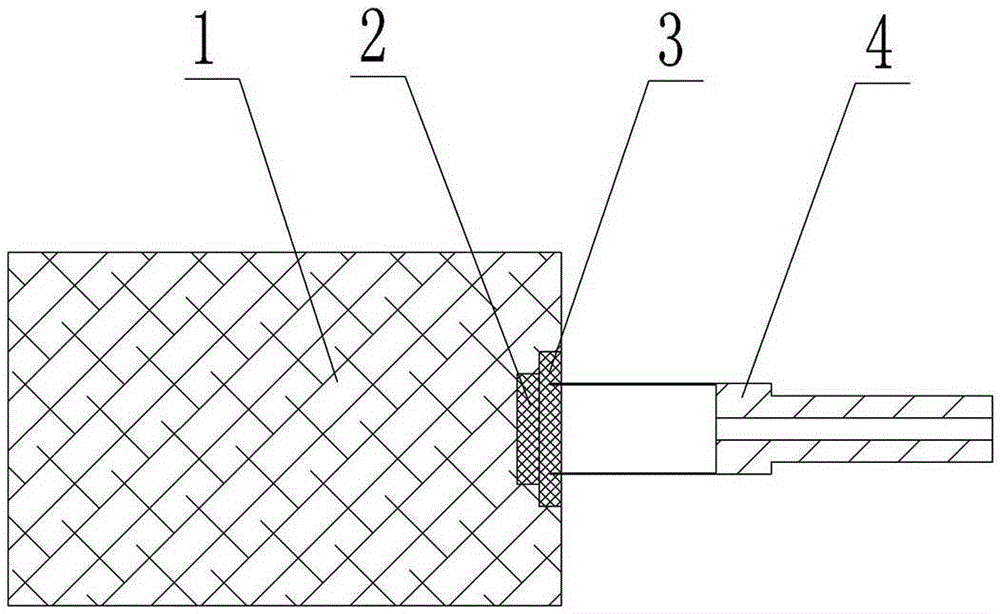

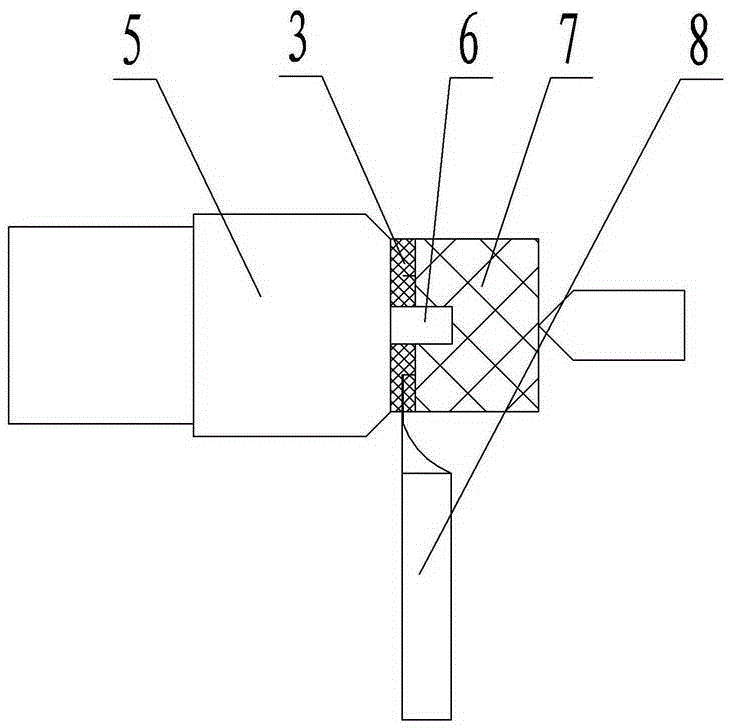

Machining process method of rubber workpiece step surface

ActiveCN104290127AFast processingSuitable for processing and productionMetal working apparatusRapid processingMachining process

The invention discloses a machining process method of a rubber workpiece step surface. The method includes the following steps of firstly, machining an annular end face shear mark on the outer end face of a circular platy rubber blank workpiece through a hollow drill bit, wherein the depth of the end face shear mark is equal to the height of a small-diameter section of the workpiece to be machined, and the diameter of the end face shear mark is equal to the diameter of the small-diameter section of the workpiece to be machined; secondly, machining an annular circumferential shear mark on the outer circumferential face of the blank workpiece through a tool which rotates relative to the blank piece, wherein the mark bottom of the circumferential shear mark and the mark bottom of the end face shear mark coincide; thirdly, removing an annular body, disengaged from the blank workpiece, between the end face shear mark and the circumferential shear mark. In the whole process, the whole unnecessary part of the blank workpiece can be smoothly cut off, and therefore the rubber workpiece step surface is rapidly machined, and the method has the advantages of being low in cost and short in cycle and is quite suitable for machining and producing small batches of workpieces.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

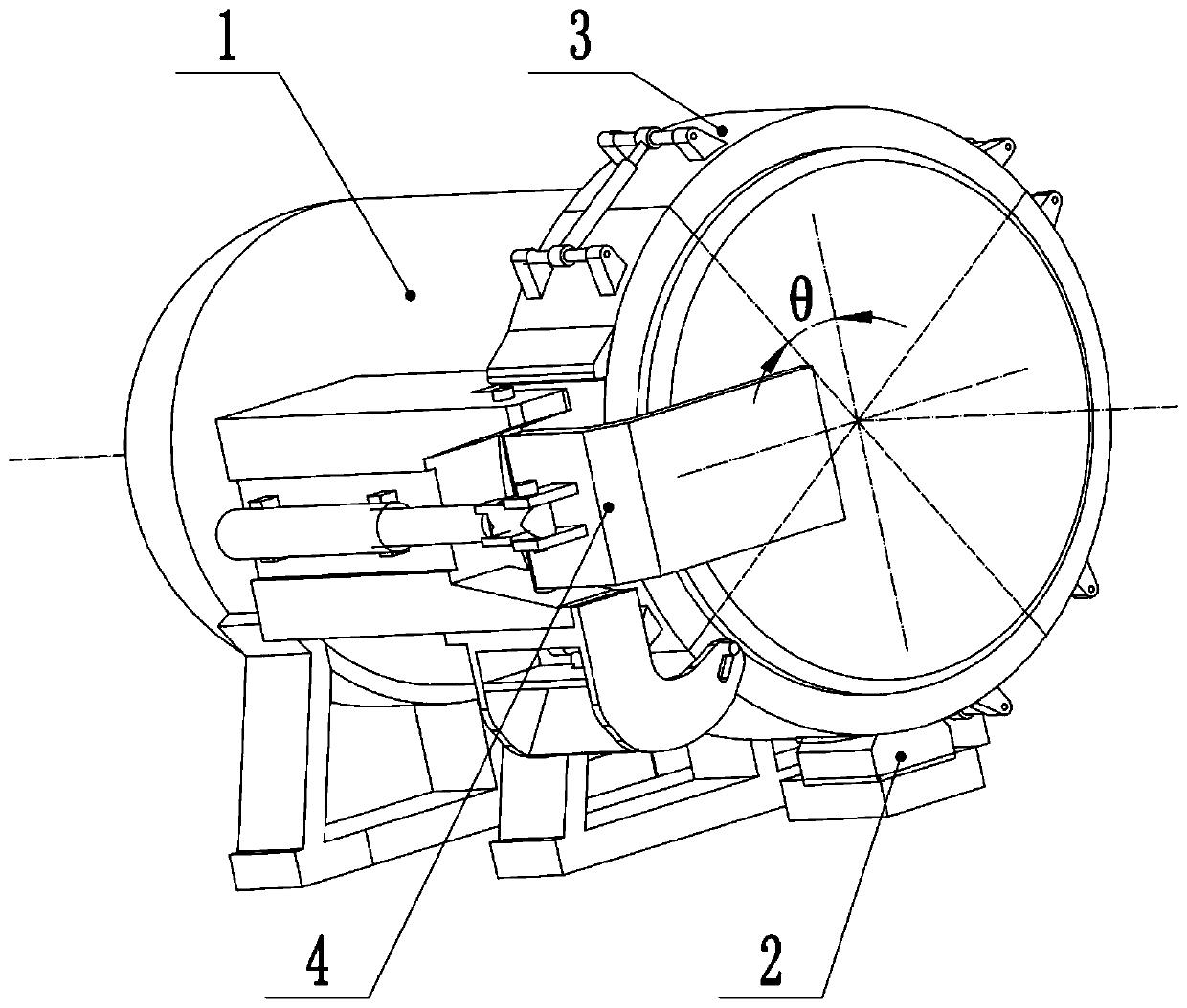

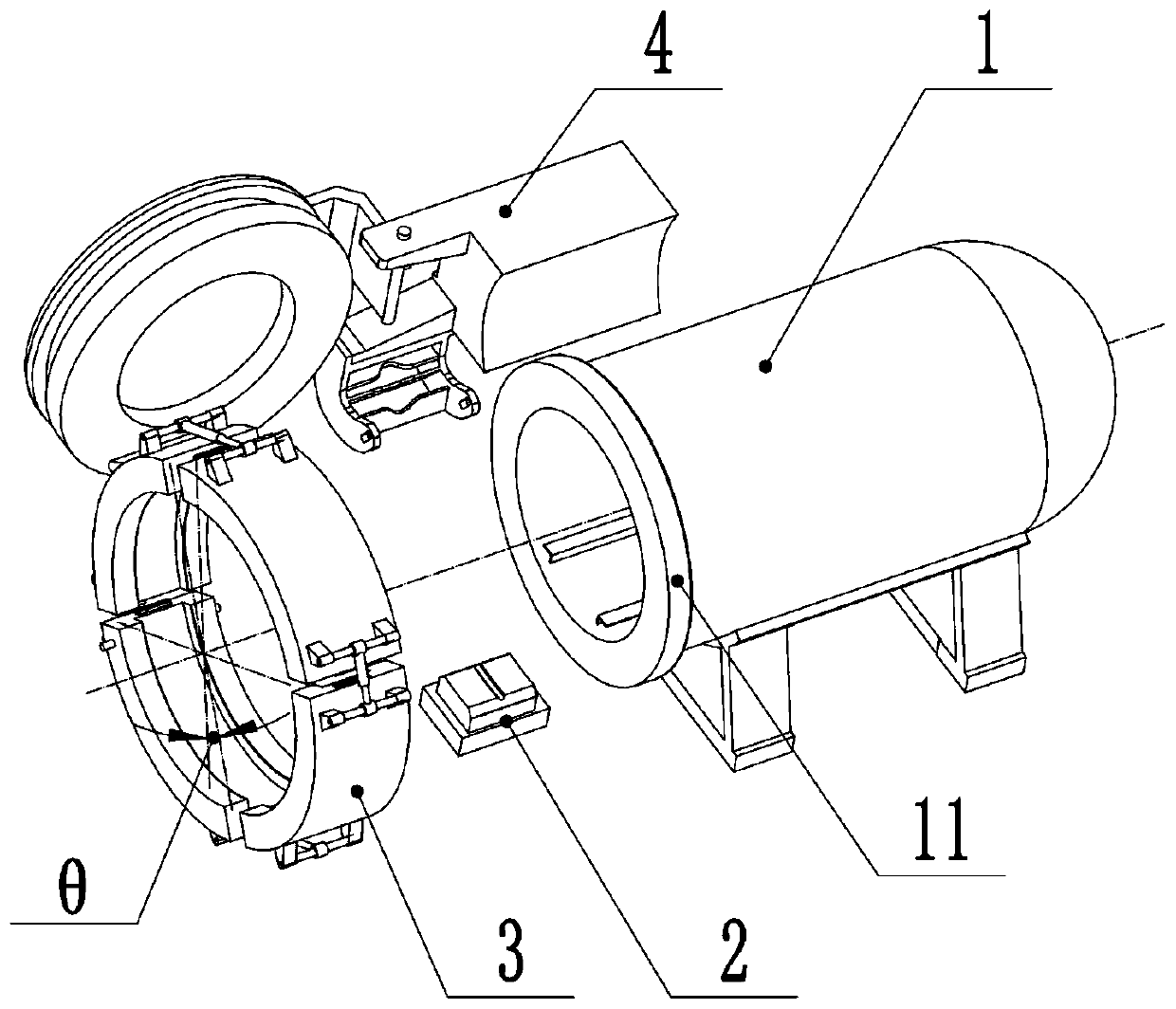

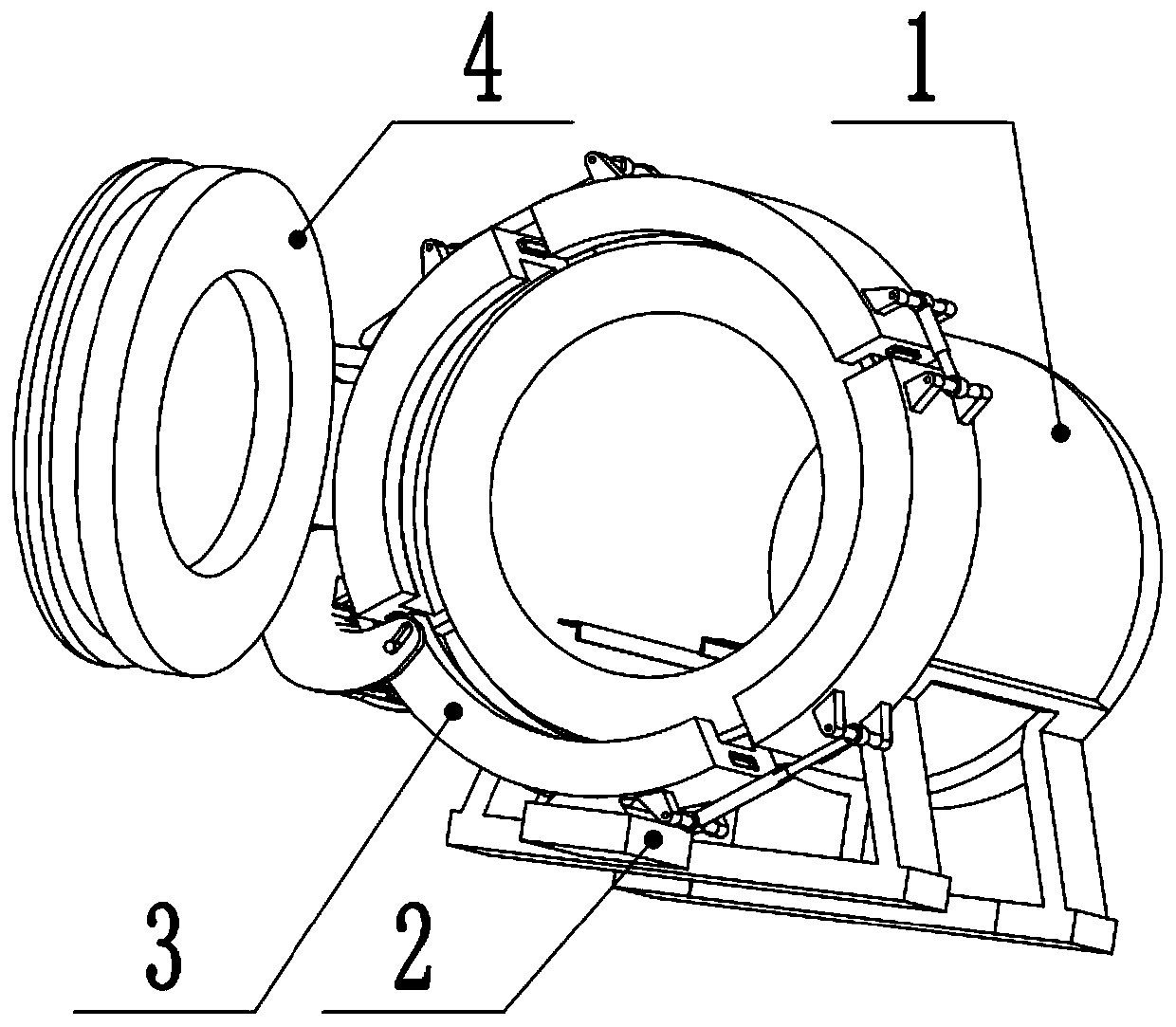

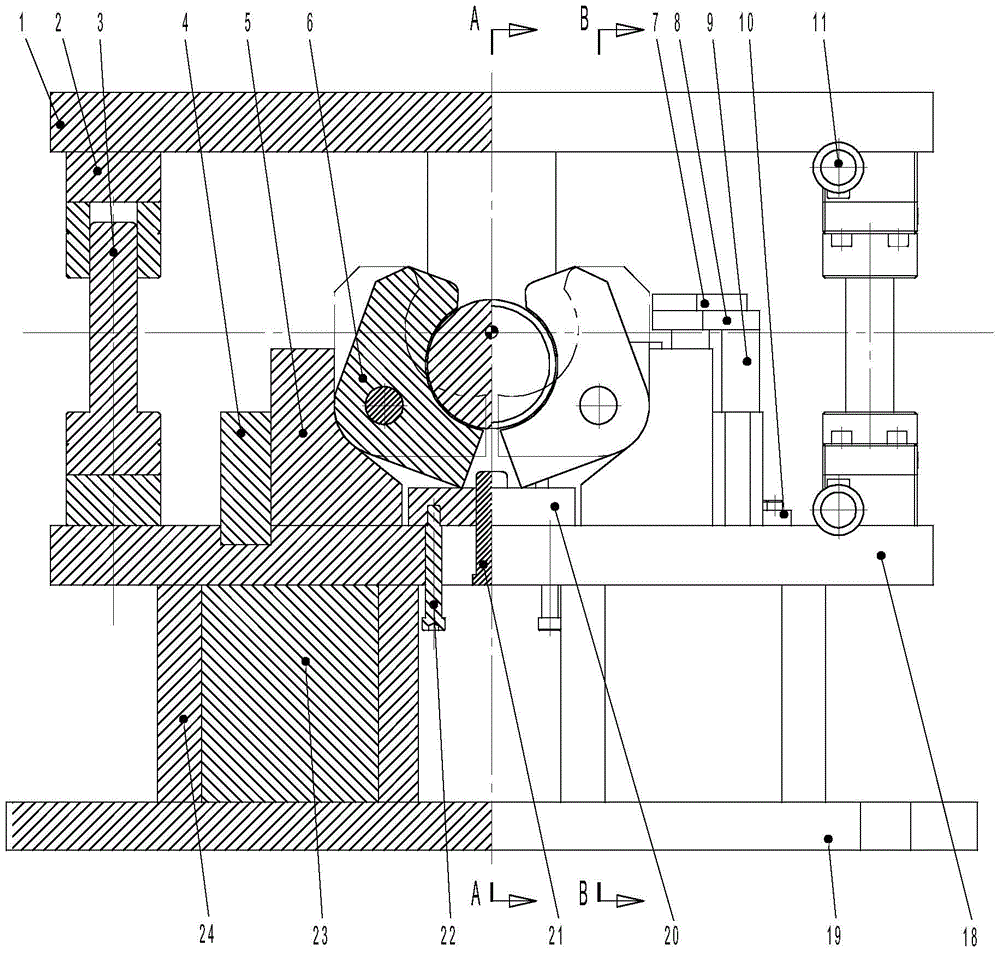

Four-block combination two-way opening and closing clamp horizontal type supercritical fluid foaming quick-opening device

The invention provides a four-block combination two-way opening and closing clamp horizontal type supercritical fluid foaming quick-opening device for the defects that supercritical fluid vertical type kettle bodies are mostly suitable for small experimental devices and the installation and operation space of horizontal type tank body device manhole seal ends is insufficient. Automatic opening andclosing control is adopted for the device. The device is mainly composed of a kettle body assembly, a supporting assembly, a clamp assembly and an end cover opening and closing assembly. The clamp combination face in the clamp assembly and the kettle body longitudinal vertical face of the kettle body assembly are installed in an inclined manner. The clamp assembly is composed of four clamps, a clamping groove is formed in the inner side of each clamp, the warp angle of each clamp is 90 degrees, and each clamp is of a fan-shaped annular structure. Opening and closing of an end cover are achieved through a link mechanism driven by hydraulic push-pull rods. By means of the device, he installation space of equipment is reduced, the operation labor intensity is lowered, and meanwhile the laborefficiency is improved. The four-block combination two-way opening and closing clamp horizontal type supercritical fluid foaming quick-opening device is suitable for supercritical industrialized production of polymer materials.

Owner:QINGDAO UNIV OF SCI & TECH

Automatic rolling die

The invention relates to a mechanical machining die, in particular to an automatic edge rolling die. The automatic edge rolling die comprises an upper die plate, a male die body, a female die body, a lower die fixing plate and a lower base plate. The male die body is connected with the upper die plate through a male die fixing plate and a male die supporting plate. The female die body is composed of a left L-shaped female die block and a right L-shaped female die block, wherein the left L-shaped female die block and the right L-shaped female die block are symmetrical. The inner sides of the two L-shaped female die blocks are provided with inner circular arcs which can surround the male die body. Each L-shaped female die block is installed on the lower die fixing plate through a lower die fixing pin and a lower die fixing pin fixing plate. Female die fixing bases are further arranged on the two sides of the female die body. Each female die fixing base is fixed to the lower die fixing plate. Female die pressing and supporting assemblies fixed to the lower die fixing plate are installed on the two sides of each female die fixing base. The bottom of the lower die fixing plate is connected with the lower base plate through lower plate supporting blocks. The top of the lower die fixing plate is connected with the upper die plate through guide post guide sleeves. A material returning plate is further installed on the lower die fixing plate. The automatic edge rolling die is simple in structure, low in cost, high in production efficiency and suitable for machining and producing small-sized sheet type cylinder parts.

Owner:LIUZHOU LIUHE FANGSHENG MACHINERY

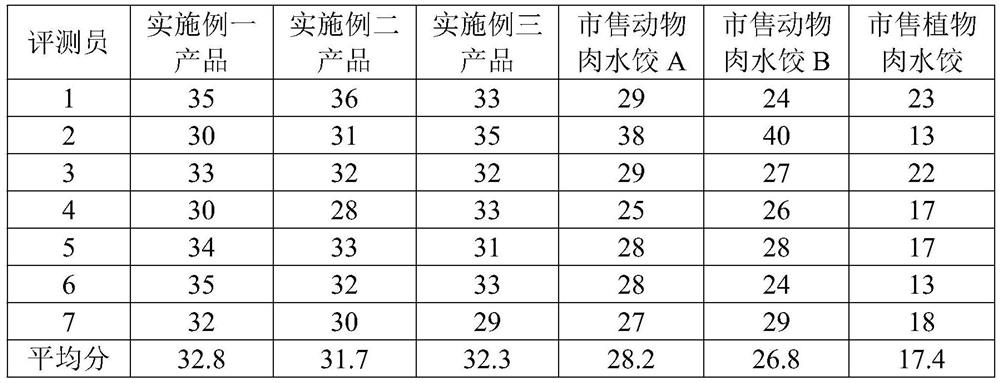

Vegetable meat stuffing and preparation method thereof

The invention belongs to the technical field of food production and processing, particularly relates to plant meat stuffing and a preparation method thereof, and solves the problem that sensory characteristics such as chewiness, cohesiveness, texture and taste of available plant-based products are greatly different from those of animal meat products in the prior art. The plant meat stuffing comprises the following raw materials in percentage by weight: 10-20% of vegetable oil, 20-40% of plant tissue protein, 2-10% of starch, 2-9% of protein isolate powder, 2-11% of a binder, 1-10% of fibre powder, 1-8% of a toner, 1-2% of edible essence, 2-5% of a seasoner and the balance of ice water. The plant meat stuffing in the invention is scientific in formula, rigorous in proportion, simple in process, economical and easily available in raw materials and suitable for processing and production in meat product factories; and products with different sensory indexes can be obtained by adjusting the proportion of the additives.

Owner:上海魅味特食品科技有限公司

Machining method for spare part of punch pin

PendingCN113263401ASuitable for processing and productionImprove processing effectivenessAbrasive surface conditioning devicesGrinding machinesGrinding wheelMachining

The invention discloses a machining method for a spare part of a punch pin. The machining method for the spare part of the punch pin comprises the following steps: obtaining the molded surface of a required grinding wheel according to a pattern of the part to be processed; trimming the forming grinding wheel with the target molded surface through a diamond pen; and directly grinding a part block into a target shape by the forming grinding wheel. According to the machining method for the spare part of the punch pin, the forming grinding wheel is adopted for carrying out grinding treatment on the part block, the desired shape is directly obtained, and compared with a point machining mode of slow wire feeding machining and optical curve grinding machining, the linear machining mode is high in efficiency, and simple in machining and good in forming effect especially for an arc surface and a forming surface with multiple radial size changes; and in addition, even if the grinding wheel needs to be trimmed, the whole machining period still has the advantages, and the machining method for the spare part of the punch pin is particularly suitable for machining and production for batch parts.

Owner:WUXI MICRO RES

Heat treatment method for 55NiCrMoV7 roller bed roller

ActiveCN109468451AInduction heating is sufficientEven and consistent induction heatingIncreasing energy efficiencyFurnace typesWater coolingWear resistance

The invention relates to a heat treatment method for a 55NiCrMoV7 roller bed roller, belonging to the technical field of roller heat treatment, and including the following process steps: 1) inductionpreheating: a roller is inductively heated on a quenching machine tool and heated to 500-700 DEG C, and the whole roller body is preheated; 2) induction heating: the preheated roller is heated to 840-940 DEG C for full austenitization and heat preservation; 3) pre-cooling: the roller is pre-cooled to 760-810 DEG C; 4) water cooling: the pre-cooled roller is water-cooled to 40-110 DEG C; and 5) medium temperature tempering: the roller is heated to 350-450 DEG C, kept for 15-25 h, and air-cooled. The roller bed roller produced by the heat treatment method of the invention has good wear resistance, high accident resistance, high corrosion resistance, long service life, low use cost and good comprehensive performance. The invention has low energy consumption and low production cost.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

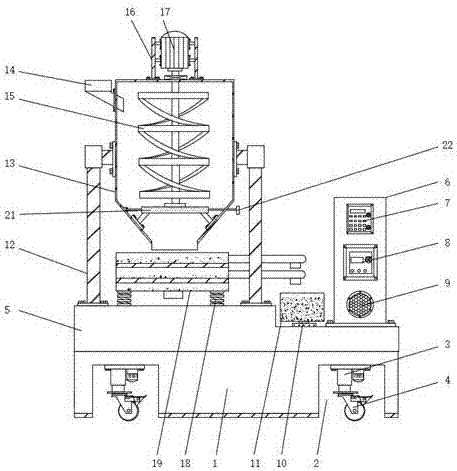

Aquatic feed mixing device for microptenus salmoides

InactiveCN107983201AImprove stabilityAvoid prone to shaking or even moving problemsSievingFeeding-stuffEngineeringElectric control

The invention discloses an aquatic feed mixing device for microptenus salmoides. The aquatic feed mixing device for the microptenus salmoides comprises a supporting seat; an electric hydraulic rod isfixedly mounted at the top end of the interior of a groove; a pressure sensor is fixedly mounted in the position, close to one side of an electric control box, of the upper surface of a pressure bearing plate; a mixing barrel is fixedly mounted at the top of the supporting rod; a feeding trough is mounted on one side of the top of the mixing barrel in an embedded manner; the upper end of a dampingspring is fixedly connected with a screening box; a vibrating motor is fixedly mounted on the front surface of the screening box. According to the aquatic feed mixing device for microptenus salmoides, mixed aquatic feed can be screened through the screening box and the vibrating motor; the stability of the mixing device in normal work is further improved on the premise of not influencing the normal movement of the mixing device; through the pressure sensor, a controller and a buzzer, the buzzer can make a sound when a material receiving box is approximately full, so that an operator can replace the material receiving box conveniently in time.

Owner:ZHANJIANG YUHAO BIOLOGICAL TECH CO LTD

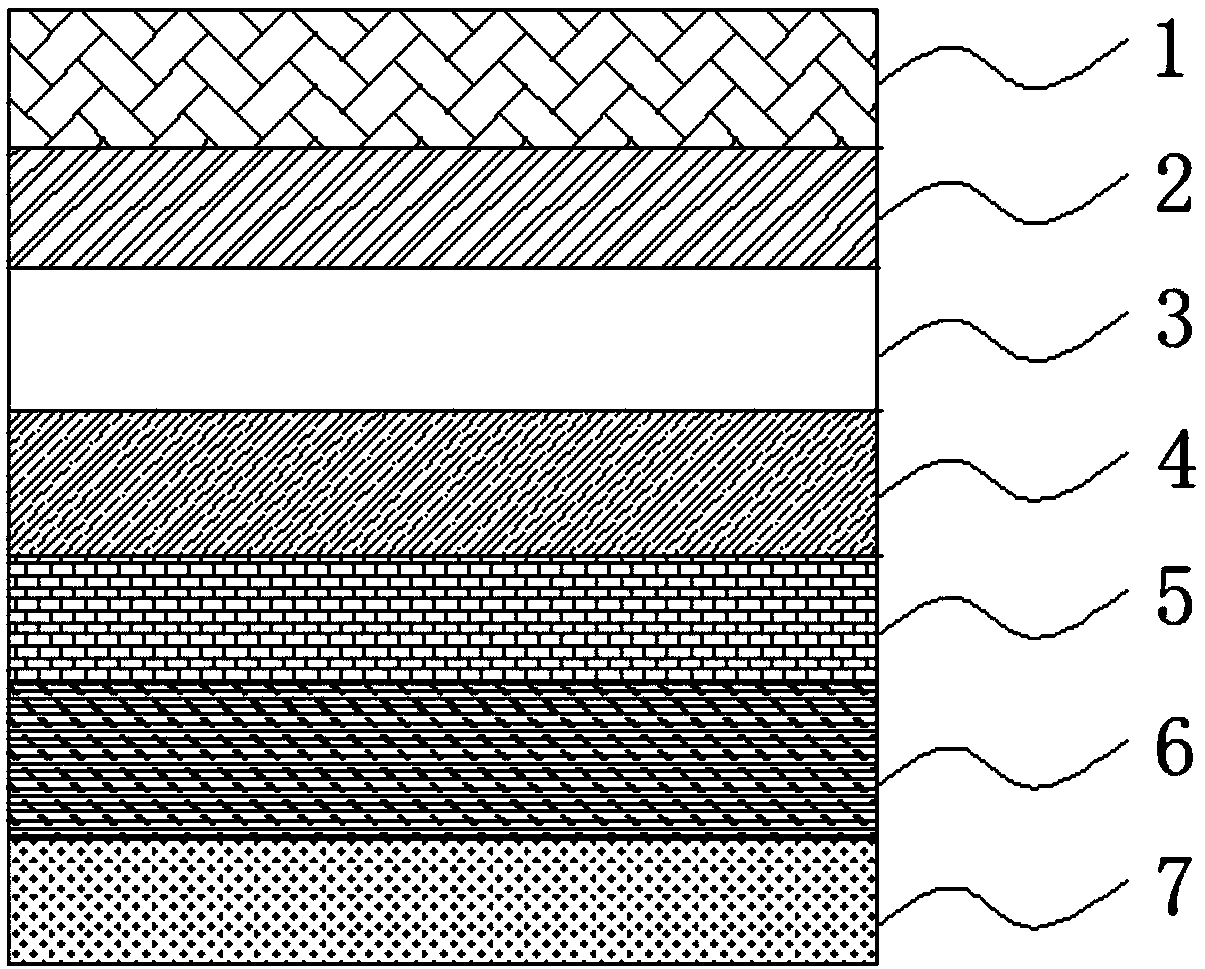

Composite type wallpaper and preparation method thereof

InactiveCN108222403AThe overall thickness is thinImprove fitFireproof paintsCovering/liningsActivated carbonUltimate tensile strength

The invention discloses composite type wallpaper and a preparation method thereof. The composite type wallpaper comprises a substrate layer, wherein a reinforced layer is arranged on any side of the substrate layer, a waterproof layer is arranged on the other side of the substrate layer, a fireproof layer is arranged on the other side of the reinforced layer, a sound absorbing layer is arranged onthe other side of the fireproof layer, a decorative layer is arranged on the other side of the sound absorbing layer, and a protective layer is arranged on the other side of the decorative layer; thereinforced layer is a polyarylester fiber layer; the sound absorbing layer is an activated carbon layer; and the protective layer is a polyvinyl resin layer. The composite type wallpaper disclosed bythe invention adopts green and environment-friendly materials, is excellent in tensile strength, integrates waterproof, fireproof, sound absorbing and dustproof functions into a whole and is optimized for interior decoration.

Owner:昆山市聚光装饰材料有限公司

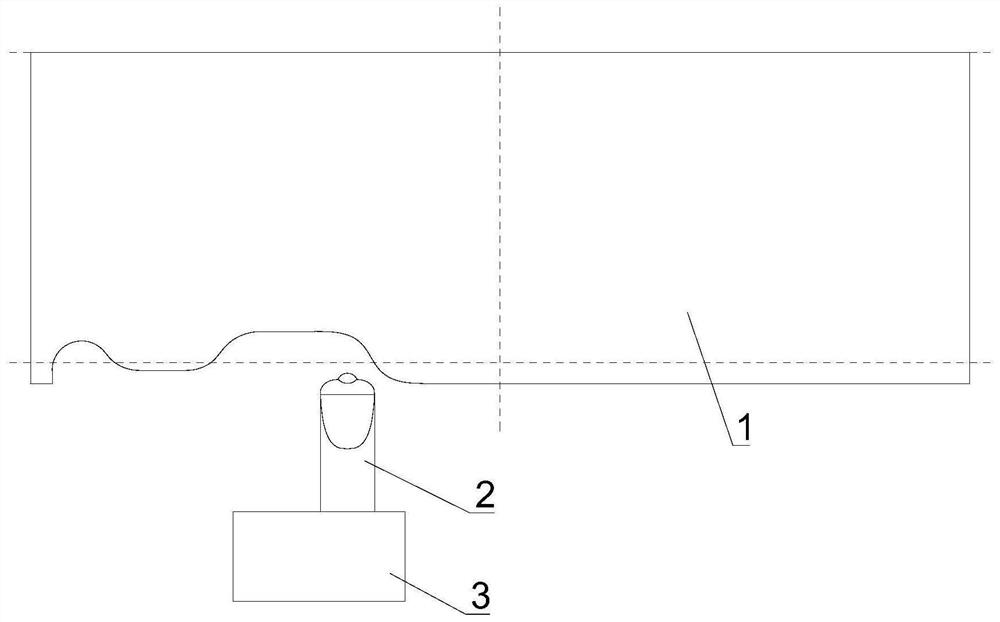

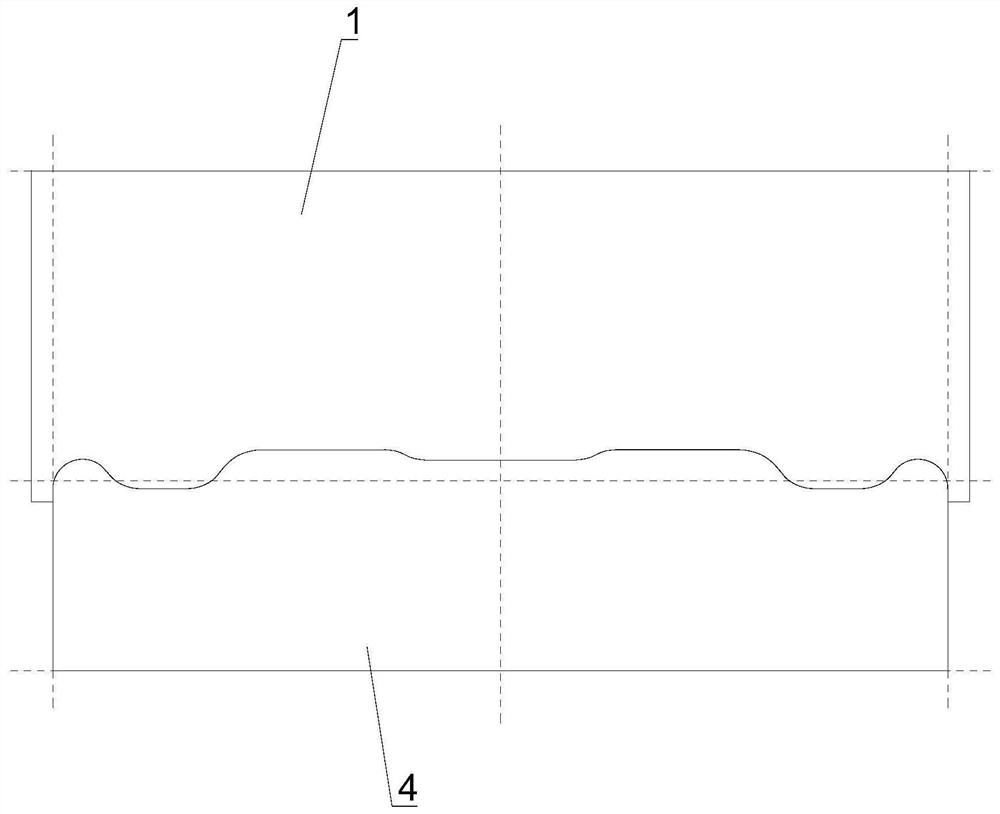

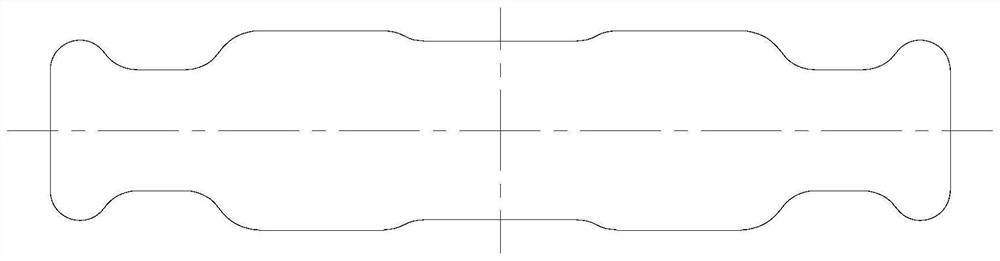

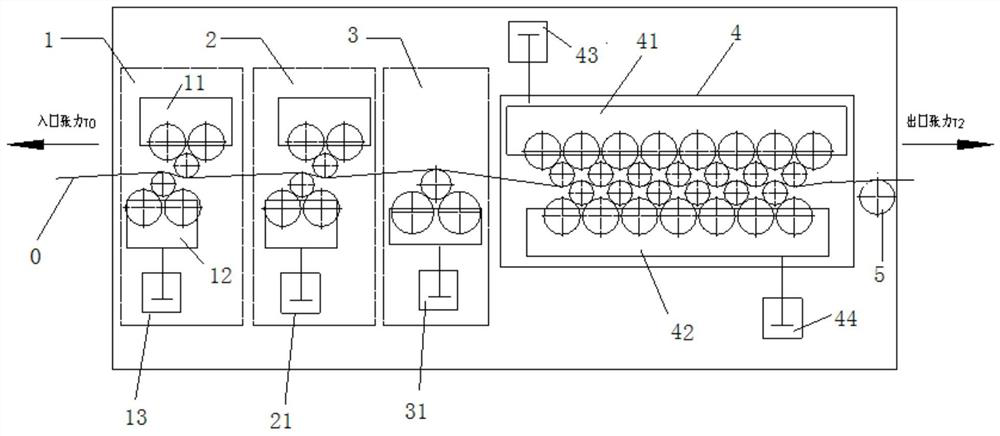

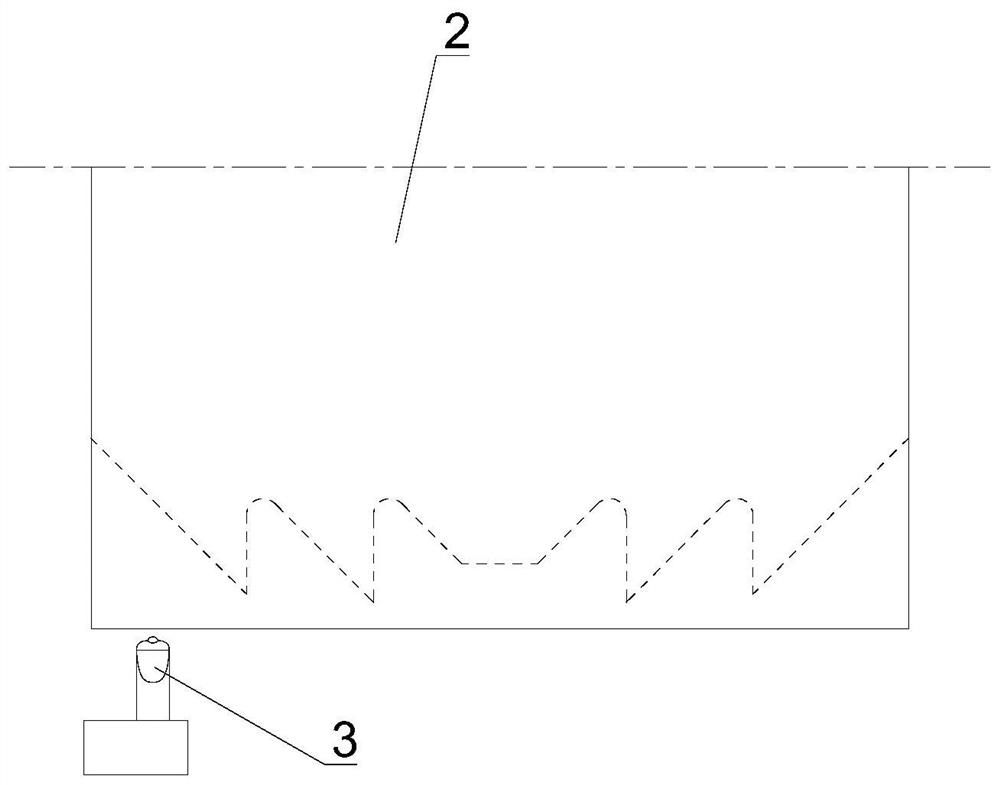

Strip steel straightening method and device

ActiveCN112605166ASuitable for processing and productionEasy to shapeClassical mechanicsStructural engineering

The invention relates to a strip steel straightening method and device. The method comprises the steps: sequentially applying first tension, second tension and third tension to strip steel in the movement direction of the strip steel, and arranging extension roller sets between the action points of the first tension and the second tension; and enabling a flattening roller set to be arranged on the extension roller sets in the moving direction of the strip steel, and enabling a homogenizing roller set to be arranged between the action points of the second tension and the third tension and comprise a first homogenizing roller and a second homogenizing roller which are arranged in a relatively staggered mode, wherein the strip steel penetrates through the homogenizing roller set to form a plurality of continuous arcs with opposite bending directions, and residual stress on the strip steel is homogenized. By means of the method, wave-shaped influence caused by incoming material machining can be eliminated, transverse bending and longitudinal bending generated by uneven extension are eliminated, the residual stress is homogenized, and therefore, the high-strength strip steel is obtained, and the method is particularly suitable for machining production of ultrahigh-strength strip steel.

Owner:WISDRI ENG & RES INC LTD

Processing process for preparing various asphalt and fuel oil with coal tar

ActiveCN101323788BImprove qualityIncrease added valueTar working-up by distillationCoal tar preparationFuel oil

The invention discloses a processing technology for preparing various pitches and fuel oils by coal tar, which comprises the steps that: the coal tar is heated to 350 DEG C to 360 DEG C, rectified at ordinary pressure first and then at reduced pressure, primarily ultracentrifugated and secondarily ultracentrifugated to respectively produce purified pitch, impregnating pitch, modified pitch, high softening point pitch and fuel oils. The invention has simple technology and convenient operation, can produce various high quality pitches and fuel oils and is characterized by less investment in devices and stable quality, thus better solving the problems of low general grade of pitches of China at present, unstable fraction of coal tar pitches and plenty of impurities and being quite applicableto the processing and producing of the coal tar.

Owner:浙江美阳国际工程设计有限公司

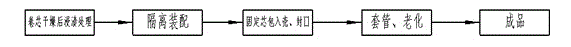

High specific volume electrolytic capacitor roll core isolation assembling method

InactiveCN104882280AEradication of explosive phenomenaDoes not increase internal resistanceElectrolytic capacitorsInternal resistanceEngineering

The invention discloses a high specific volume electrolytic capacitor roll core isolation assembling method; a dipped roll core is isolated from a fixing liquid, and a specific method is to wrap a capacitor paper layer outside the dipped roll core, so black glue and the capacitor roll core can be isolated in the fixing liquid, and copper, iron, chloride ion and impurity in the black glue cannot dip into an anode and a cathode of the capacitor roll core, thus preventing conduction and reaction under high temperature, hydrogen cannot be generated, so blast phenomenon can be eradicated. The capacitor paper is low in tightness, high in intensity, small and uniform in hole diameter, has small accident loss probability in usage, and capacitor internal resistance is not added; the leakage current is small, energy storage effect is good, and capacitor production can be convenient.

Owner:NANTONG HUAYU ELECTRONICS

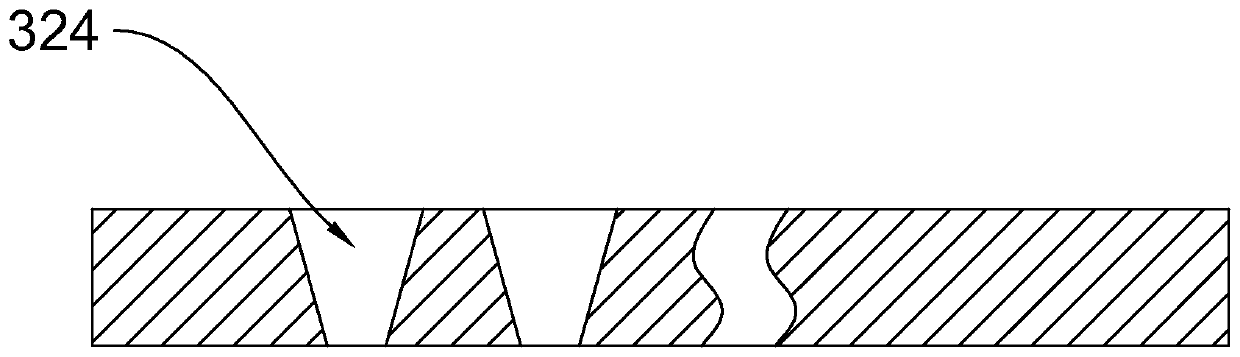

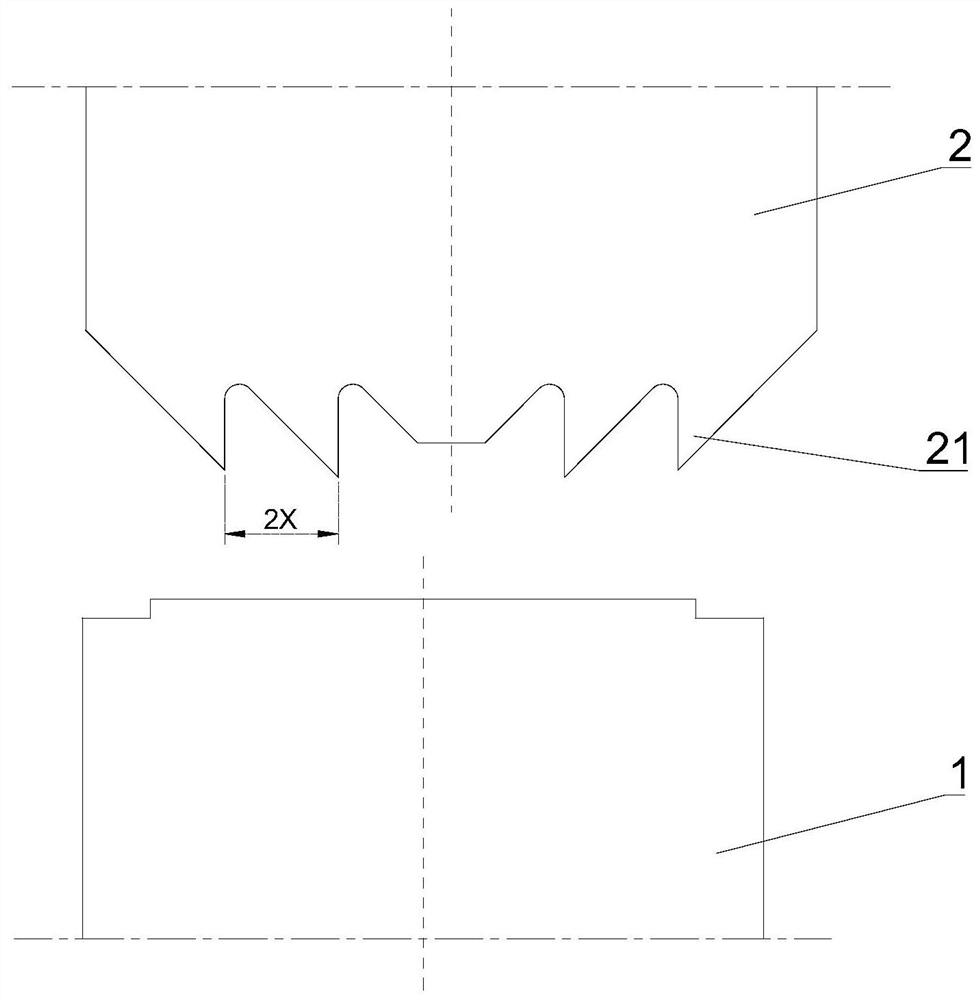

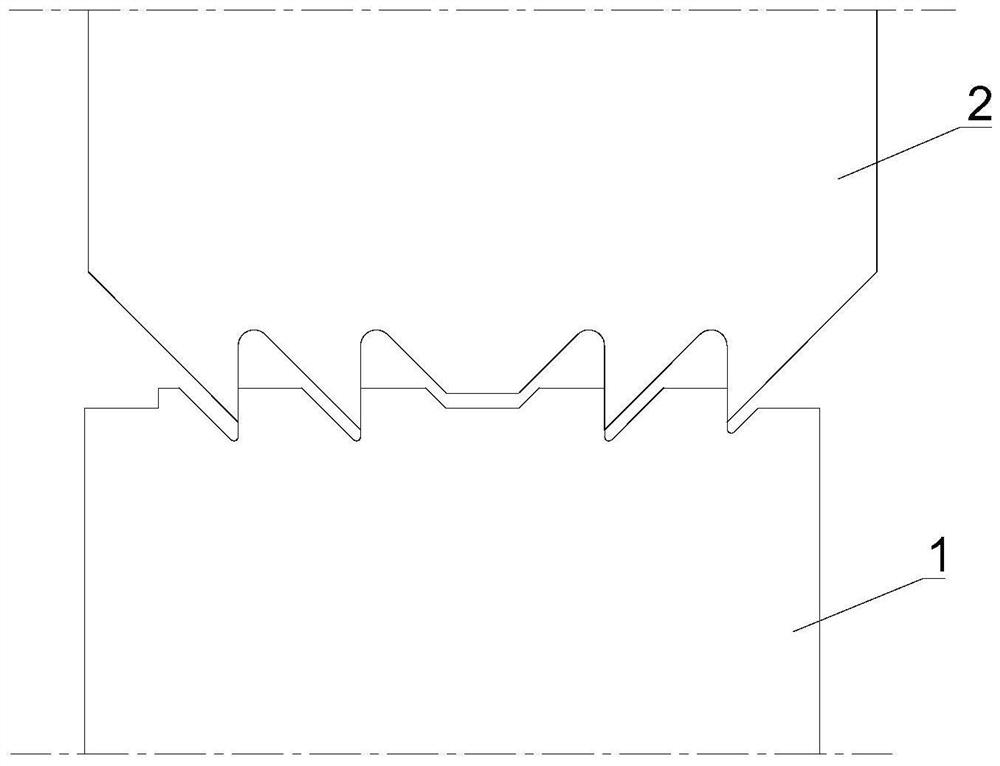

Forming method for cutting edge of shutter punch of air conditioner die

PendingCN113334156AReduce processing difficultySuitable for processing and productionOther manufacturing equipments/toolsAbrasive surface conditioning devicesPunchingStructural engineering

The invention discloses a forming method for a cutting edge of a shutter punch of an air conditioner die. A plurality of punching teeth are arranged on the cutting edge at intervals, the punching teeth on the two sides are in mirror symmetry, the number of the punching teeth on the single side is m, and the distance between the punching teeth is X. The forming method comprises the steps that corresponding grinding teeth are designed on a grinding wheel profile according to the shapes of the punching teeth on the cutting edge, at least one pair of grinding teeth are arranged in a mirror image manner; a formed grinding wheel with a target profile is trimmed through a diamond pen; and the surface of a punch block is directly ground by the forming grinding wheel, grinding is carried out in several times, the grinding wheel transversely deviates by the Y distance relative to the punch block every time, and therefore the target cutting edge shape is formed. According to the forming method for the cutting edge of the shutter punch of the air conditioner die, the forming grinding wheel is used for grinding the punch block, rapid forming is achieved in a linear machining mode, machining is easy, the efficiency is high, the forming effect is good, the final shape is obtained through multiple times of offset grinding especially under the situation that the tooth space is small, the grinding wheel machining difficulty is reduced, and the method is particularly suitable for batch part machining and production.

Owner:WUXI MICRO RES

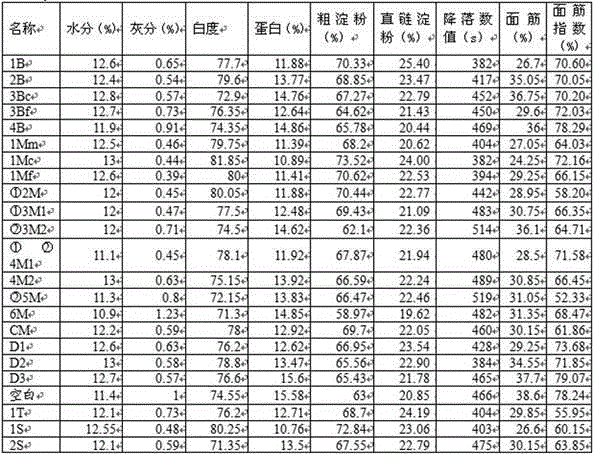

Production method for color-reversion-resisting chilled fresh food tailored flour

ActiveCN104624281AReduce the degree of color returnSuitable for processing and productionGrain treatmentsAleuroneFresh food

The invention discloses a production method for color-reversion-resisting chilled fresh food tailored flour. The production method includes the steps that Zhengmai 7698, Aikang 58,Taikong 6 and Huapei 8 are selected and matched in proportion; sieving, stone removal, winnowing, threshing and secondary sieving are carried out on the mixed wheat to clear out impurities; water is added to the wheat, and then the water content of the wheat reaches 15%; ranking flour is manufactured according to a conventional method and separated to obtain bran pieces, wheat dross, wheat cores and semolina; through grinding, flour flow with the ash content of 0.5-0.8, the whiteness larger than or equal to 80%, the protein of 11-12% and the broken starch of 9-12% is selected out; screening, insect killing and metering are carried out on the flour flow, and the flour flow is conveyed to a screen mesh bulk stock bin to be mixed and then conveyed to a packaging bin to be packaged. The production method has the advantages that the suitable wheat varieties are selected, endosperm, which is prone to color reversion and close to cortexes and the aleurone layers, in wheat grains is separated out, the color reversion degree of the flour is reduced to the maximum extent, the color, luster and interior quality of the flour are effectively controlled, and the production method is more suitable for producing and processing chilled fresh food.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Processing method of step surface of rubber workpiece

ActiveCN104290127BFast processingSuitable for processing and productionMetal working apparatusRapid processingEngineering

The invention discloses a machining process method of a rubber workpiece step surface. The method includes the following steps of firstly, machining an annular end face shear mark on the outer end face of a circular platy rubber blank workpiece through a hollow drill bit, wherein the depth of the end face shear mark is equal to the height of a small-diameter section of the workpiece to be machined, and the diameter of the end face shear mark is equal to the diameter of the small-diameter section of the workpiece to be machined; secondly, machining an annular circumferential shear mark on the outer circumferential face of the blank workpiece through a tool which rotates relative to the blank piece, wherein the mark bottom of the circumferential shear mark and the mark bottom of the end face shear mark coincide; thirdly, removing an annular body, disengaged from the blank workpiece, between the end face shear mark and the circumferential shear mark. In the whole process, the whole unnecessary part of the blank workpiece can be smoothly cut off, and therefore the rubber workpiece step surface is rapidly machined, and the method has the advantages of being low in cost and short in cycle and is quite suitable for machining and producing small batches of workpieces.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

CNC (Computer Numerical Control) four-axis full-automatic foam die-free forming machine

ActiveCN102126231BRealize full circle rotationImprove processing qualityMetal working apparatusNumerical controlTransformer

The invention relates to a foam forming machine, in particular to a CNC (Computer Numerical Control) four-axis full-automatic foam die-free forming machine which comprises a digital control computer, an electric heating wire transformer (54), an electric heating wire (64), a machine body (5), an operating platform (42), a stand column (6), a beam (8) and a Z-direction sliding device (73), whereinan X-direction sliding device (71) is arranged on the beam (8). The CNC four-axis full-automatic foam die-free forming machine also comprises a fixing device (67) for a workpiece to be processed on the operating platform (42). The workpiece to be processed moves linearly forth and back along the Y-axis direction, the electric heating wire (64) moves linearly left and right along the X-axis direction and moves linearly up and down along the Z-axis direction, and the electric heating wire (64) rotates. The invention has the advantages of simple structure, realization of processing various complicated shapes of foams, good processing quality, low cost and wide application range.

Owner:常州市新罗特数控机械有限公司

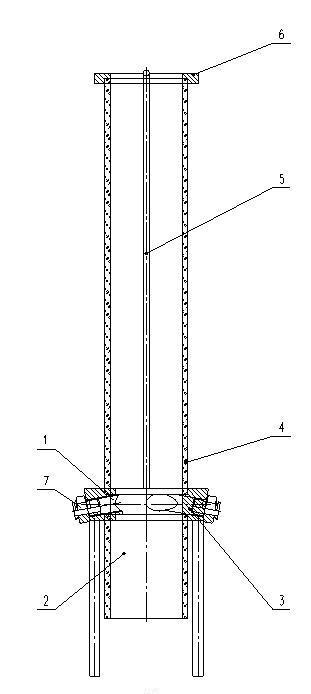

Cyclone winding device for distinguished noodle production line

The invention relates to a cyclone winding device for a distinguished noodle production line, and the device provided by the invention is mainly composed of a bracket, a barrel and a spindle, wherein the barrel comprises an upper barrel and a lower barrel; the upper barrel and the lower barrel are vertically installed on the upper part and the lower part of the bracket; the inner part of the upper barrel and the inner part of the lower barrel are communicated; the top of the upper barrel and the bottom of the lower barrel are opened; the bracket is provided with wind inlets communicated to the inner part of the bottom end of the upper barrel; the wind inlets are symmetrical and are arranged on the tangent position of the upper barrel; and the middle of the upper barrel is fixedly provided with the spindle by a spindle bracket on the top end. The cyclone winding device has the advantages of novel structure, scientific and reasonable design, good winding quality, high efficiency, automatic feeding and discharging, good continuity and the like, does not need manual assistance and is suitable for processing and producing on high-speed production lines.

Owner:SHENGCHANGDA MACHINERY TIANJIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com