Aquatic feed mixing device for microptenus salmoides

A kind of aquatic feed and mixing device technology, which is applied in the direction of feed, mixer, mixer with rotating stirring device, etc., can solve the problems of increasing processing cost, unsaturated working time of workers, single function, etc., and achieve stable performance improvement and improvement Practical performance, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

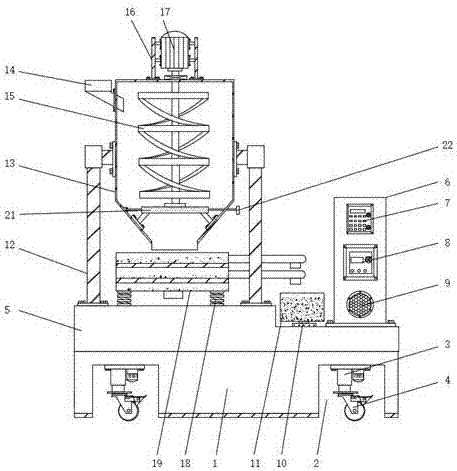

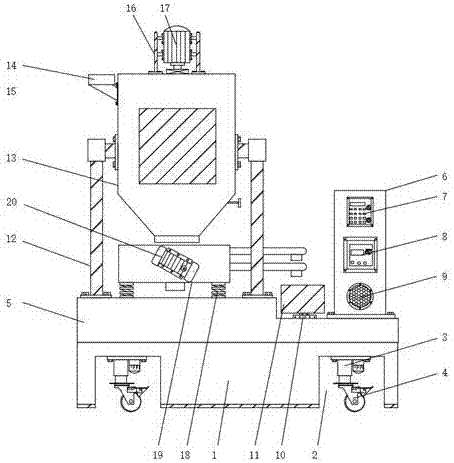

[0026] Example: such as Figure 1-5 As shown, the present invention provides a technical solution, an aquatic feed mixing device for California perch, comprising a support base 1, a groove 2 is provided on the lower surface of the support base 1, and an electro-hydraulic rod is fixedly installed on the inner top of the groove 2 3. A universal wheel 4 is fixedly installed on the lower end of the electro-hydraulic rod 3, a pressure bearing plate 5 is fixedly installed on the upper surface of the support seat 1, an electric control box 6 is fixedly installed on the upper surface of the pressure bearing plate 5, and the pressure bearing plate 5 A control switch 7 is fixedly installed on the front surface, and a MAM-100 controller 8 is fixedly installed on the front surface of the pressure bearing plate 5 close to the lower end of the control switch 7, and the front surface of the pressure bearing plate 5 is close to the MAM-100 controller 8. A buzzer 9 is fixedly installed at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com