Mechanical equipment for processing walnut powder

A kind of mechanical equipment and walnut powder technology, which is applied in the field of walnut powder processing machinery and equipment, can solve the problems of time-consuming, labor-intensive, high production costs, etc., and achieve the effects of cost reduction, industry development promotion, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

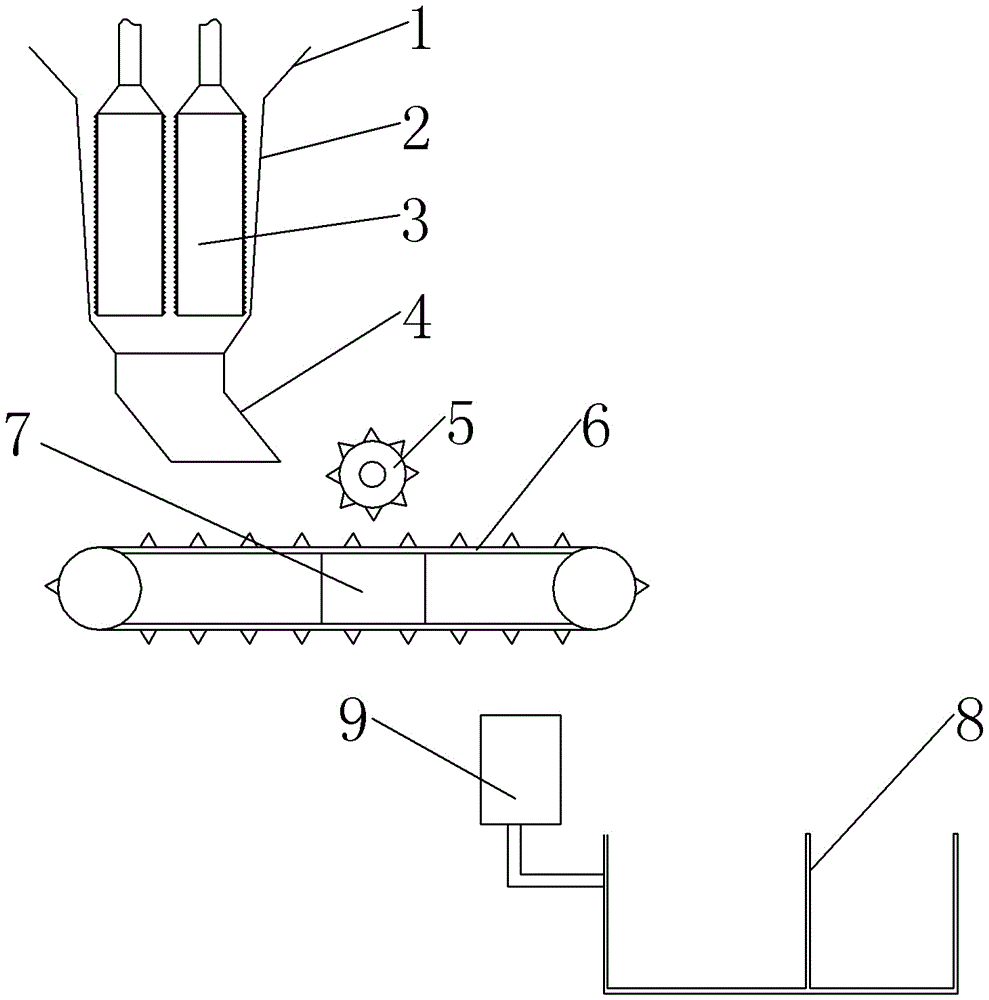

[0014] The reference numerals in the accompanying drawings of the description include: feed channel 1, accommodating chamber 2, shell breaking roller 3, discharge channel 4, additional roller 5, conveying belt 6, support plate 7, partition 8, fan 9.

[0015] The embodiment is basically as figure 1 Shown: mechanical equipment for processing walnut powder, which includes a frame, and also includes a motor fixed on the frame from top to bottom, a drive shaft, and an accommodating chamber 2 that provides space for cracking walnut shells. Shell breaking roller 3, discharge passage 4, additional roller 5, transport belt 6, support plate 7, fan 9 and storage tank, feed passage 1 is arranged on the upper part of the accommodation chamber 2, and the accommodation chamber 2 is in an inverted cone shape, That is, the cone shape gradually shrinks from top to bottom, and the shell br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com