Strip steel straightening method and device

A strip and straightening technology, applied in the field of strip straightening methods and devices, can solve the problems of poor strip flatness, uneven distribution of residual stress, and reduced quality grades, and achieves elimination of residual stress and good performance. effect, the effect of improving the shape of the plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

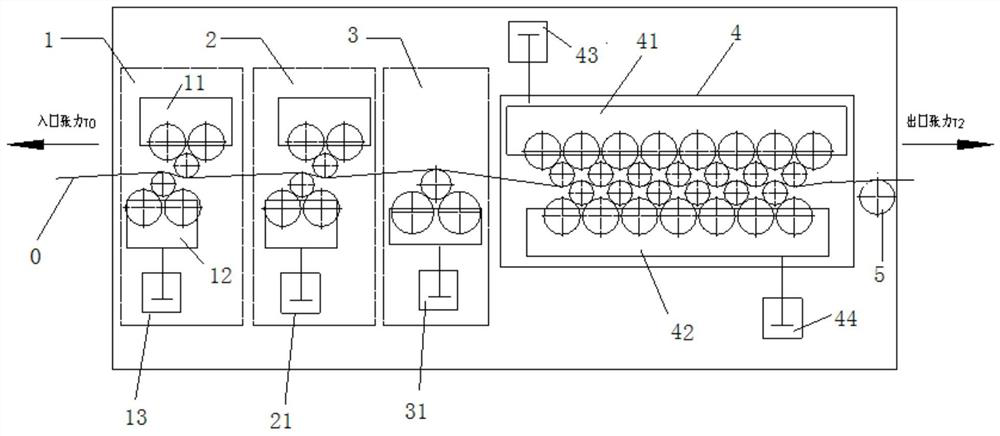

[0042] A strip straightening method, comprising: sequentially applying a first tension, a second tension and a third tension to the strip along the moving direction of the strip, wherein the direction of the first tension is opposite to that of the third tension, And the absolute value of the third tension is greater than the first tension, and the second tension is in the same direction as the third tension;

[0043] a set of stretching rolls is disposed between the point of application of the first tension and the second tension, the set of stretching rolls causes the strip to be stretched;

[0044] A flattening roller set is arranged on the stretching roll set along the moving direction of the strip, and the flattening roller set provides the second tension, so that the strip is flattened;

[0045] A group of homogenizing rollers is arranged between the action points of the second tension and the third tension, and the group of homogenizing rollers includes a first homogeni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com