Cyclone winding device for distinguished noodle production line

A production line and noodle-eating technology, which is applied in the fields of dough processing, food science, baking, etc., can solve the problems of inability to realize continuous mass production, difficult storage and post-processing, loose dough, etc. Good quality, not easy to loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

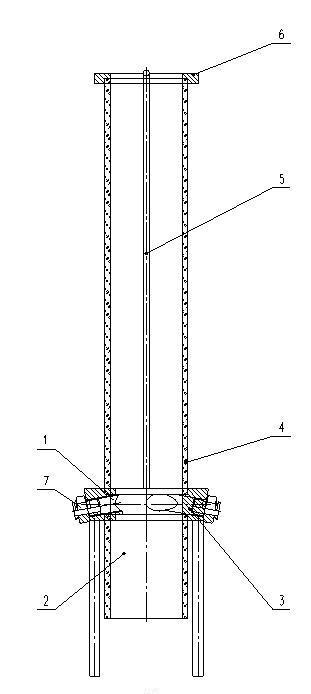

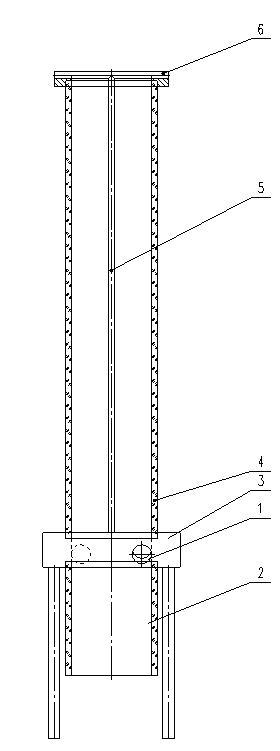

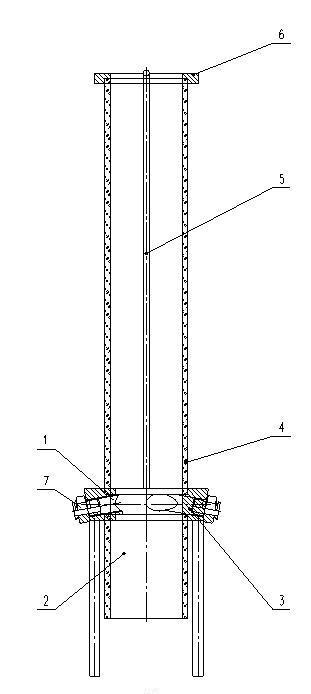

[0015] A cyclone wrapping device for a new food noodle production line, the innovation of which is that it is mainly composed of a bracket 3, a cylinder body, and a mandrel 5, and the cylinder body includes an upper cylinder body 4 and a lower cylinder body vertically installed on the upper and lower parts of the bracket 2. The upper cylinder and the lower cylinder are connected internally, the top of the upper cylinder and the bottom of the lower cylinder are open, and the air inlet 1 connected to the bottom of the upper cylinder is installed on the bracket. The air inlet is symmetrical and arranged on the upper cylinder The tangent position of the body, the mandrel is fixed in the middle of the upper cylinder through the mandrel bracket 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com