Forming method for cutting edge of shutter punch of air conditioner die

A molding method and shutter technology, applied in abrasive surface adjustment devices, other manufacturing equipment/tools, parts of grinding machine tools, etc., can solve the problems of unsuitable batch parts processing and production, long processing cycle, increasing processing difficulty, etc. The effect of reducing the difficulty of processing, good forming effect and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

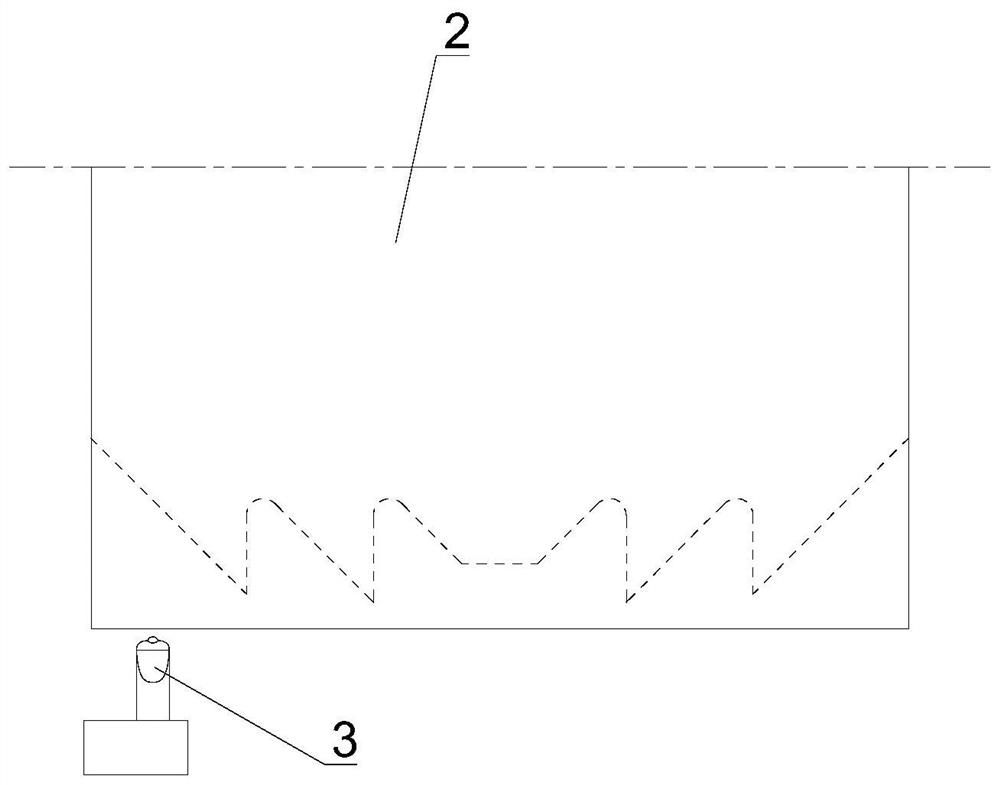

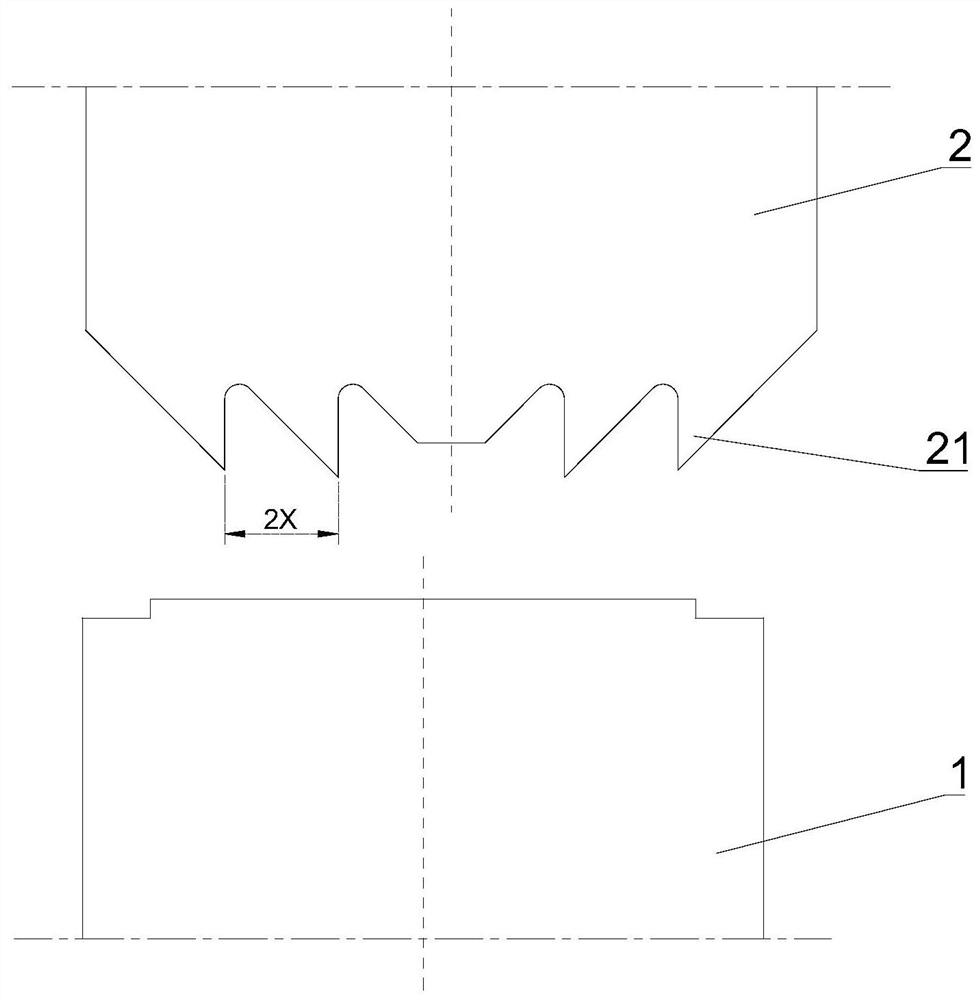

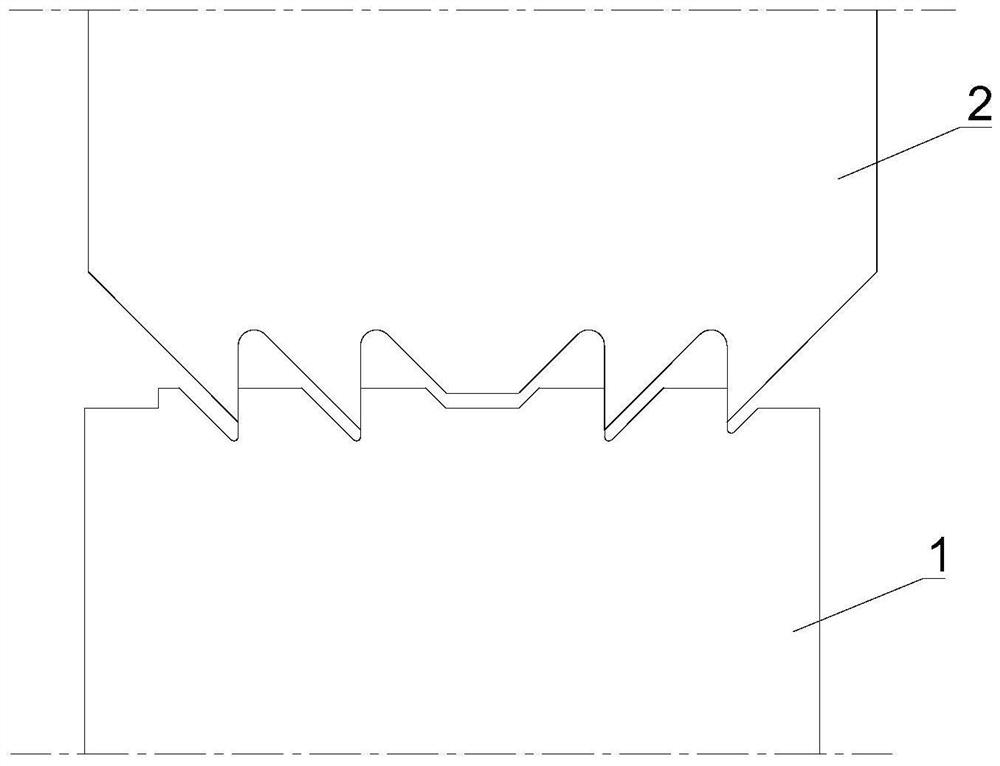

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0023] This embodiment provides a method for forming the edge of the louver punch of an air-conditioning mold. Specifically, the lower punch of the louver in an air-conditioning mold is used as an example. On this basis, the upper punch and other similar punch structures are applicable.

[0024] A plurality of stamping teeth 11 are arranged at intervals on the cutting edge of the punch, and the stamping teeth 11 on both sides are mirror-image symmetrical. There are m stamping teeth 11 on one side (m=2, 3, 4, ...), and the tooth spacing is X . In this embodiment, a total of eight stamping teeth on the cutting edge and four stamping teeth on each side are taken as an example to further illustrate the forming process. The processing steps are as follows:

[0025] Step 1: According to the shape of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com