CNC (Computer Numerical Control) four-axis full-automatic foam die-free forming machine

A fully automatic, forming machine technology, applied in metal processing and other directions, can solve the problems of increased production cost, low labor efficiency, poor quality of packaging foam, etc., and achieve the effect of accurate processing, wide application range and high processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

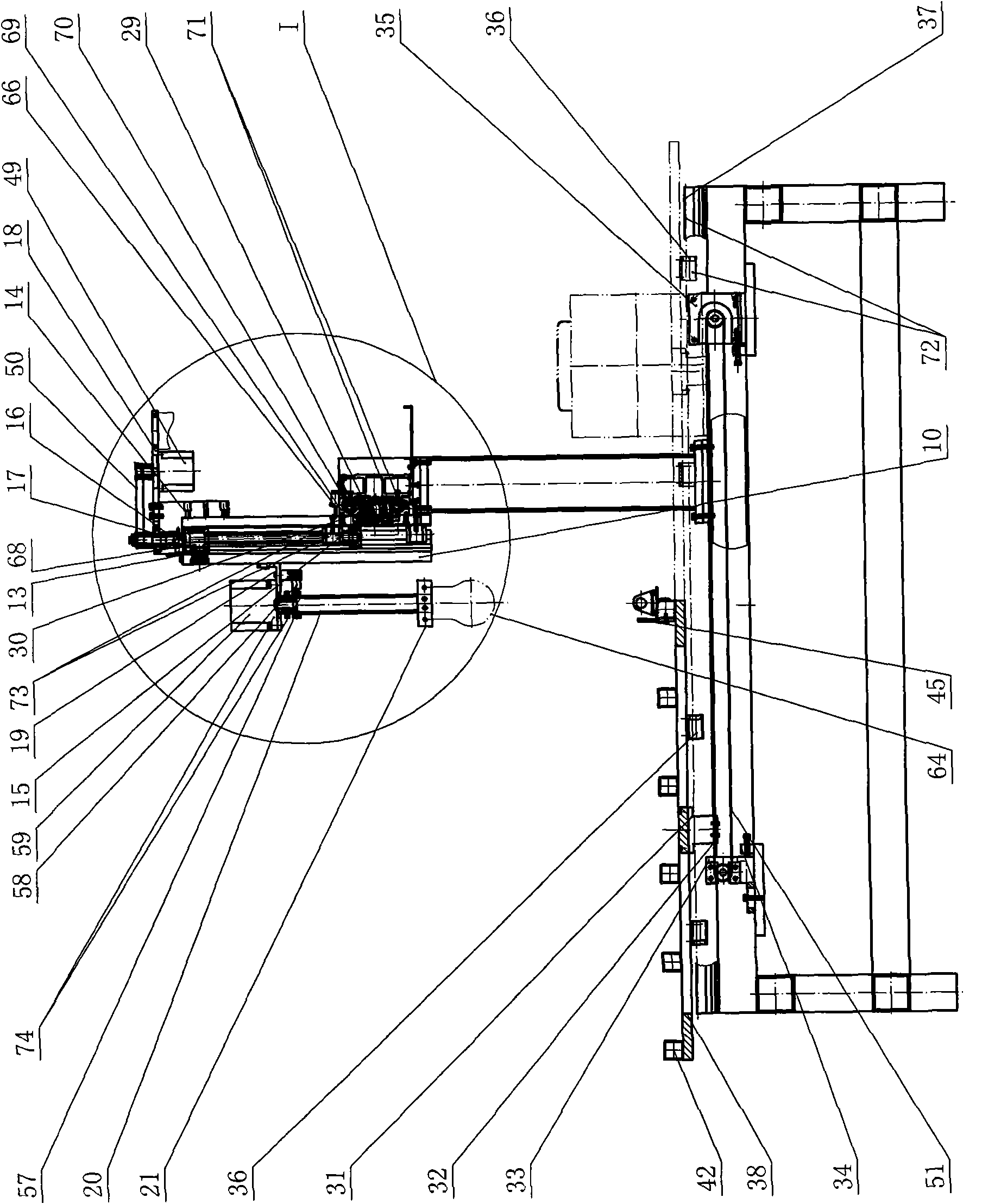

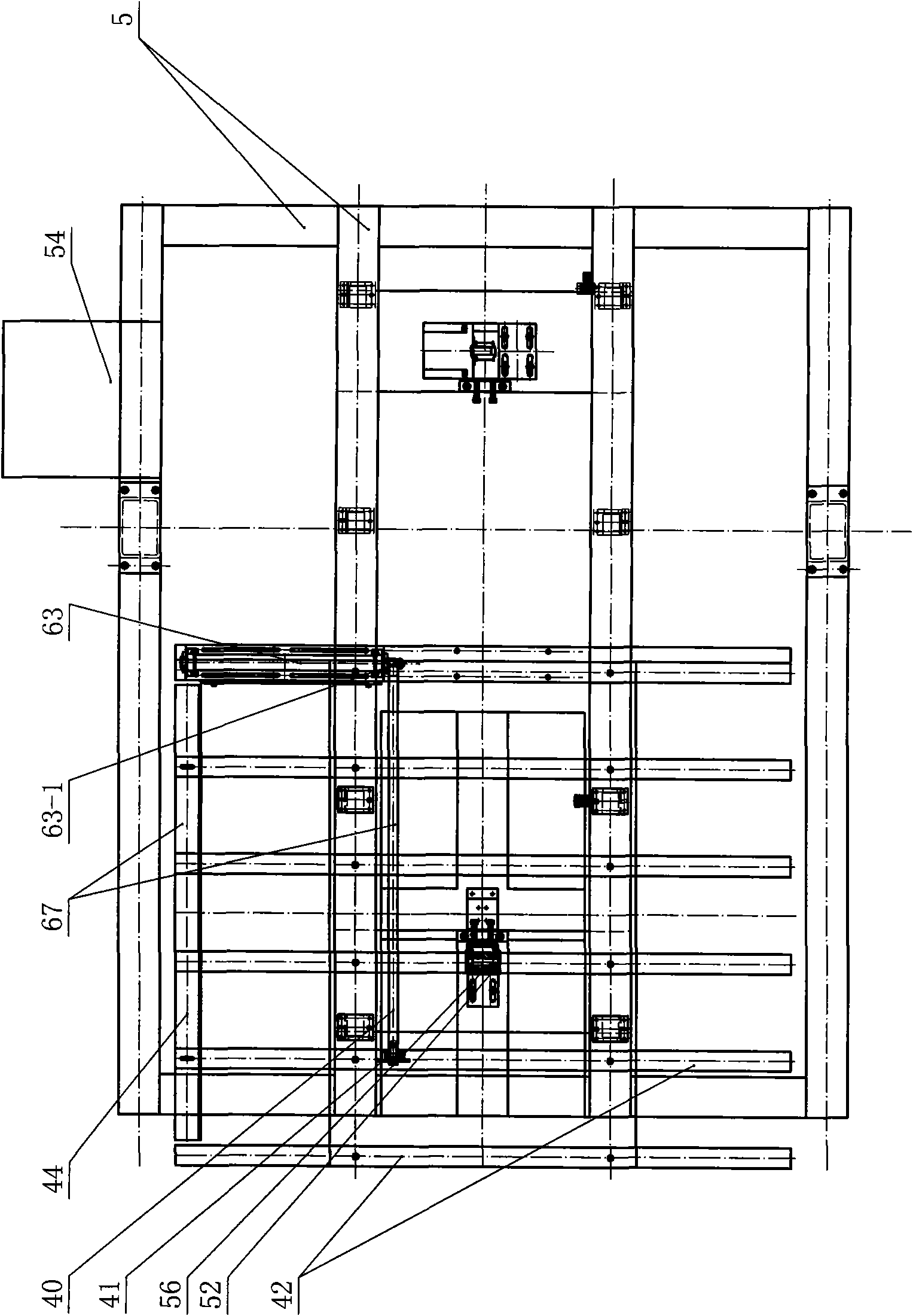

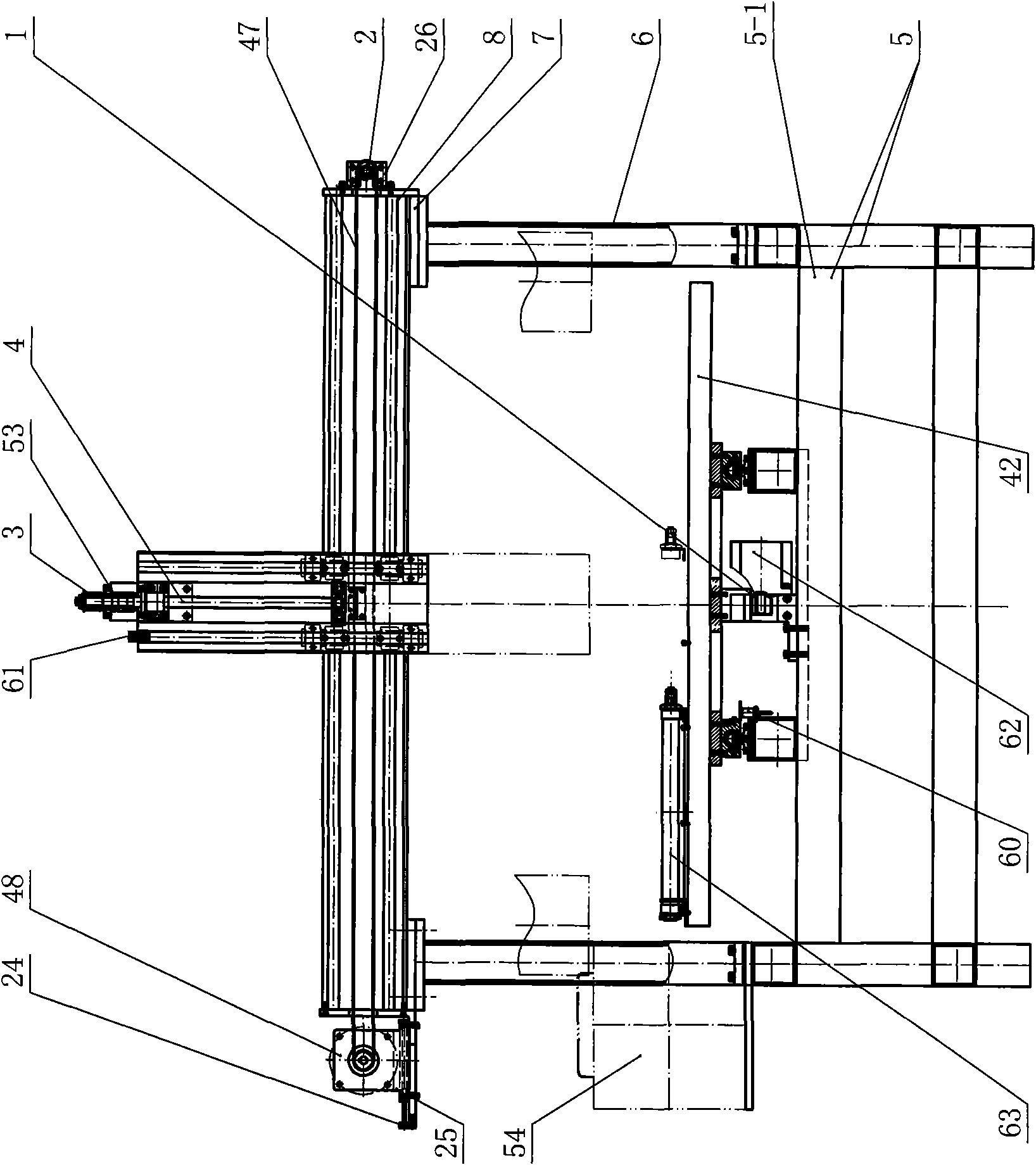

[0023] Such as Figures 1 to 6 As shown, a CNC four-axis automatic foam-free molding machine includes a numerical control computer, a heating wire transformer 54 and a heating wire 64, a bed 5, a workbench 42, a column 6 and a beam 8, and There is a Z-direction sliding device 73, the workbench 42 is set on the bed 5, the beam 8 is suspended above the workbench 42 through two columns 6 at both ends, the beam 8 is connected with the column 6 through the beam bottom plate 7, and the beam 8 is An X-direction sliding device 71 is provided, and the heating wire transformer 54 is connected with the heating wire 64 to make the heating wire 64 generate heat. It also includes a Y-direction sliding device 72 and a heating wire rotating working assembly 74 . The processed workpiece fixture 67, wherein:

[0024] Y to slide device 72 comprises Y to motor 62, Y to slide plate 38, Y to slide block 36, Y to garden guide rail 37, Y to synchronous pulley 1, Y to synchronous belt 51, Y to synchr...

Embodiment 2

[0033] Such as Figures 1 to 6 As shown, a CNC four-axis fully automatic foam-free molding machine, this embodiment is basically the same as Embodiment 1, the difference is the spindle motor 59, X-direction motor 48, Y-direction motor 62 and Z-direction motor 49 All are servo motors, and the servo motors are AC servo motors. That is, the axial movement in the X direction, the Y direction and the Z direction and the driving motor for the rotation of the fourth axis rotating shaft 20 provided with the heating wire 64 are all driven by a servo motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com