Automatic rolling die

A rolling die, automatic technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of high cost, increase production cost, large volume, etc., and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

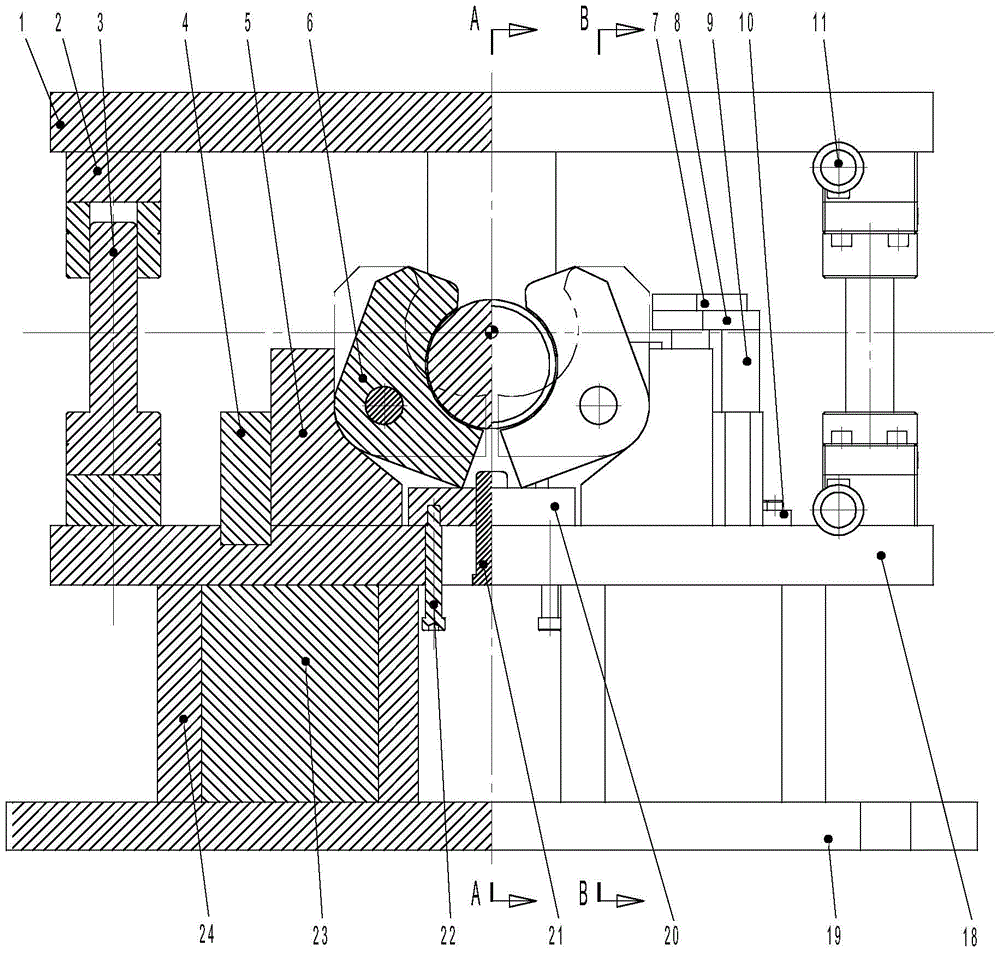

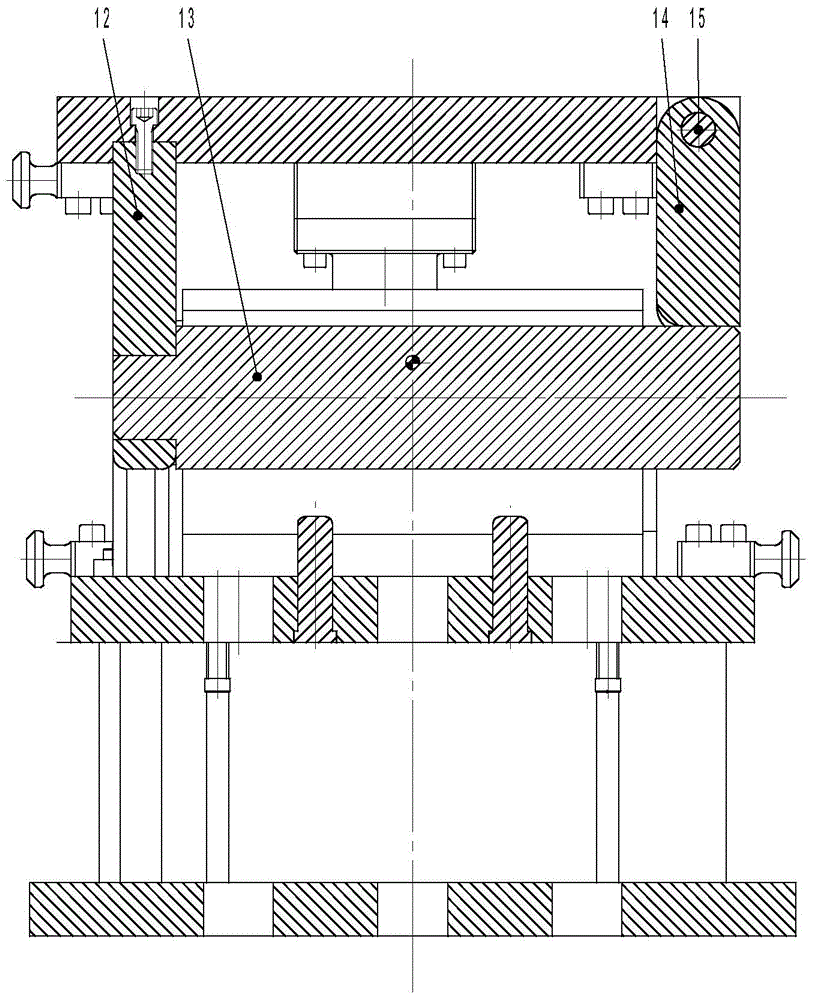

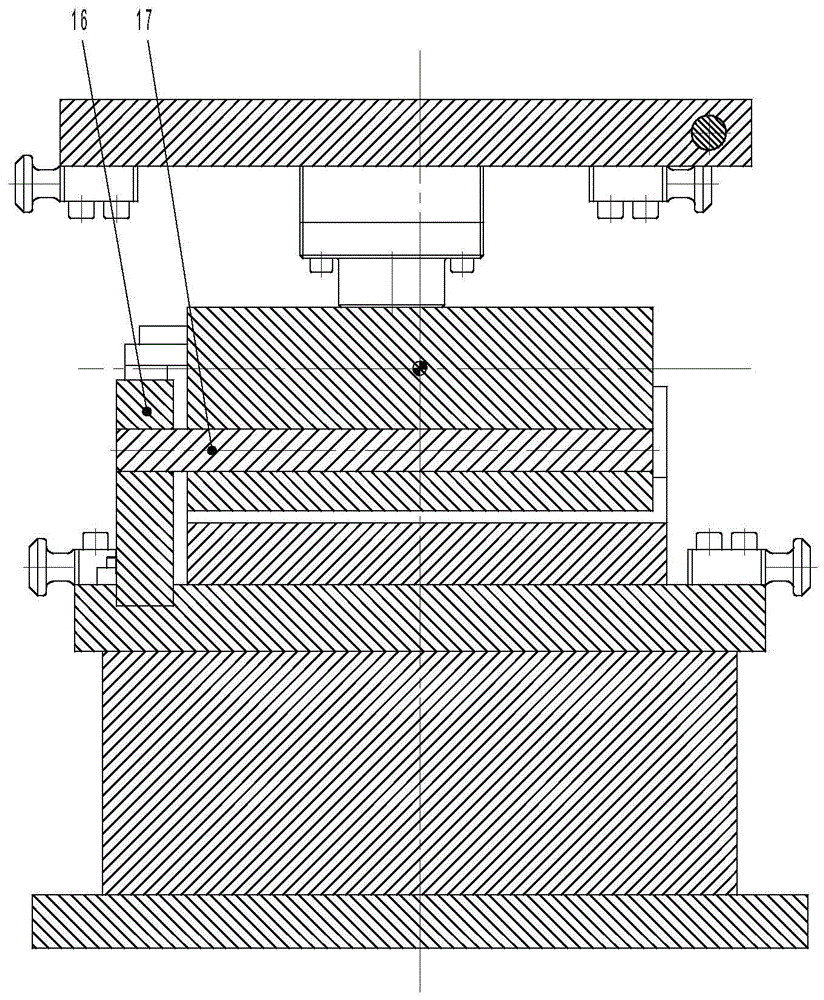

[0028] A kind of automatic rolling round mold, comprises upper template 1, punch 13, die 6, lower mold fixing plate 18 and lower bottom plate 19, described punch 13 one end is connected with the bottom of upper template 1 through punch fixing plate 12 , the top of the other end is provided with a punch support plate 14, the top of the punch support plate 14 is connected to the upper template 1 through the upper mold fixing pin 15; the die 6 is composed of two symmetrical L-shaped concave modules on the left and right The inner side of the two L-shaped concave modules is provided with an inner arc that can surround the punch 13, and the corner of each L-shaped concave module is provided with a lower mold fixing pin 17, and one end of the lower mold fixing pin 17 passes through the Lower die fixed pin fixed plate 16 is installed on the lower mold fixed plate 18; said die 6 both sides are also provided with die fixed seat 5, and this die fixed seat 5 is fixed on the lower mold fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com