Membrane processing equipment

A processing equipment and diaphragm technology, applied in metal processing, sorting, etc., can solve the problems of dependence on labor, poor product quality consistency, low production efficiency, etc., achieve the effect of regular layout of finished products and avoid secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

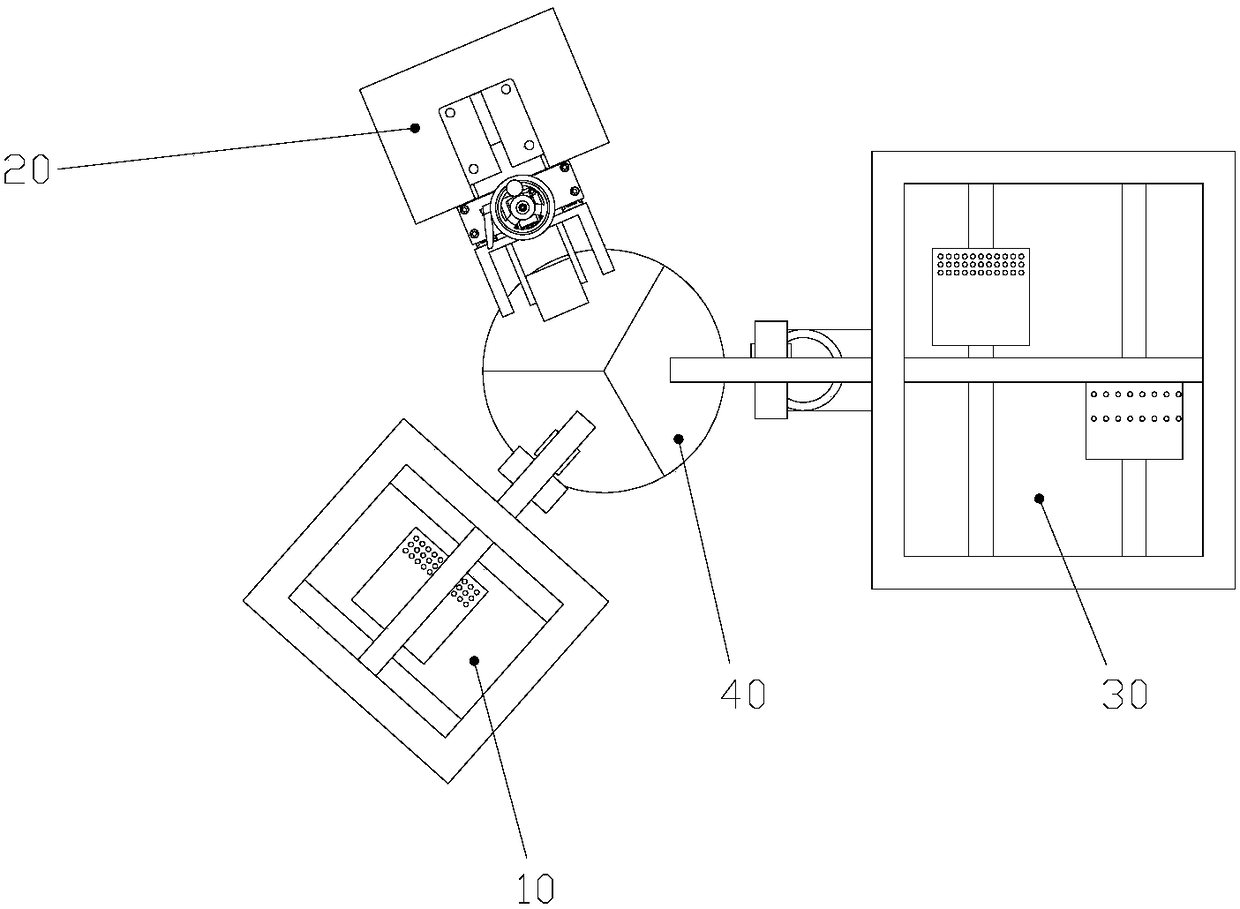

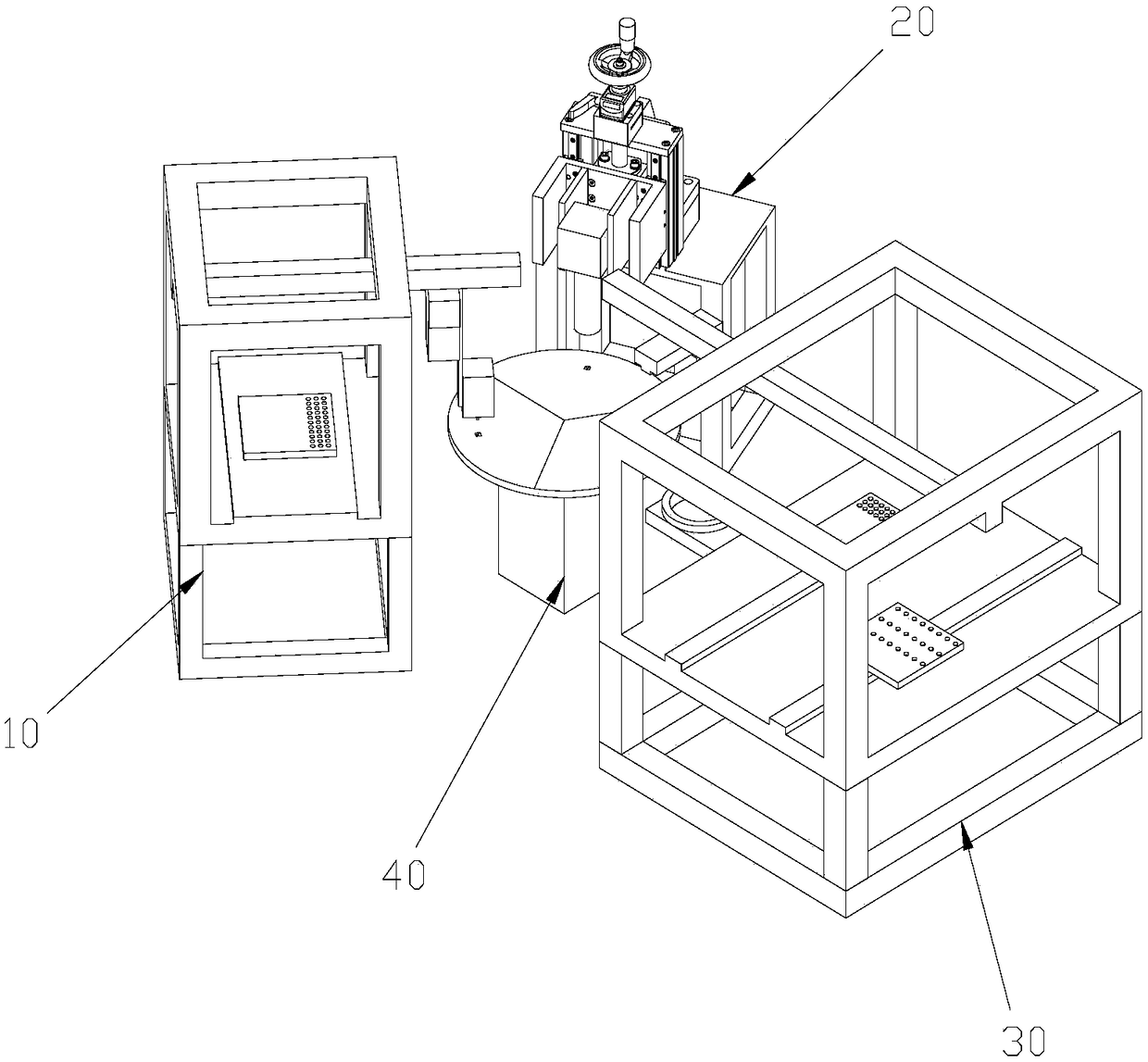

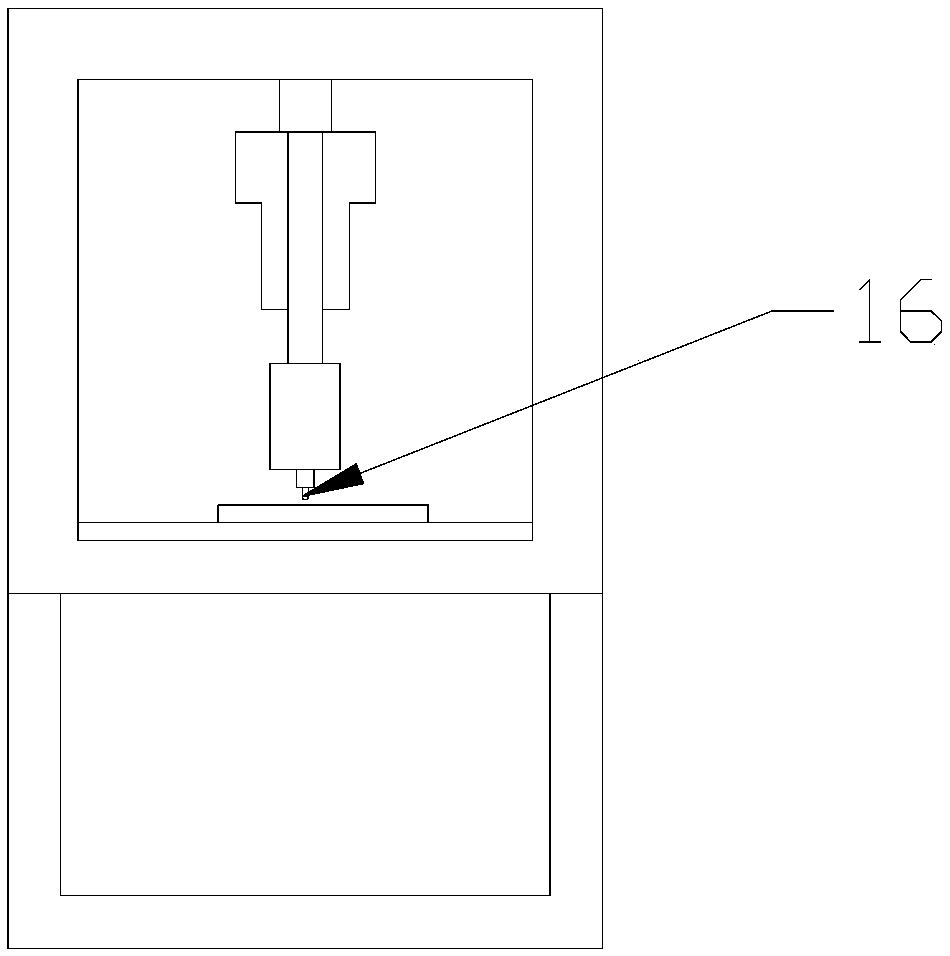

[0051] The film processing equipment according to the first embodiment of the present invention includes at least a cutting mechanism 10 for cutting the film into a finished film of a predetermined size; a detection mechanism 20 for receiving the finished film and detecting The film of the finished product is tested to obtain a test result; the typesetting mechanism 30 is used to receive the tested film of the finished product and perform classification and typesetting on the film of the finished product according to the test result.

[0052] Through the membrane processing equipment according to the first embodiment of the present invention, automatic operations can be realized in each process stage of membrane processing such as cutting, detection, and typesetting, so that the dependence on labor in the production process is reduced, and the production efficiency is improved. Avoid the contamination of the product caused by too much manual participation, and improve the consi...

no. 2 approach

[0054] The film processing equipment of the second embodiment of the present invention is the same as the film processing equipment of the first embodiment, at least including a cutting mechanism 10 , a detection mechanism 20 , and a typesetting mechanism 30 . In addition, the film processing equipment of the second embodiment further includes a conveying mechanism 40, which is used to convey the cut film of the finished product to the detection mechanism 20 for detection, and / or is used to pass all the detected The finished films are sent to the typesetting mechanism 30 for sorting and typesetting. Preferably, the transfer mechanism 40 adopts an index plate mechanism.

[0055] Through the film processing equipment according to the second embodiment of the present invention, it is not only possible to realize automatic operations in each process stage of film processing such as cutting, detection and typesetting, but also to transfer the film processed in each process between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com