Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Solve fatigue fracture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

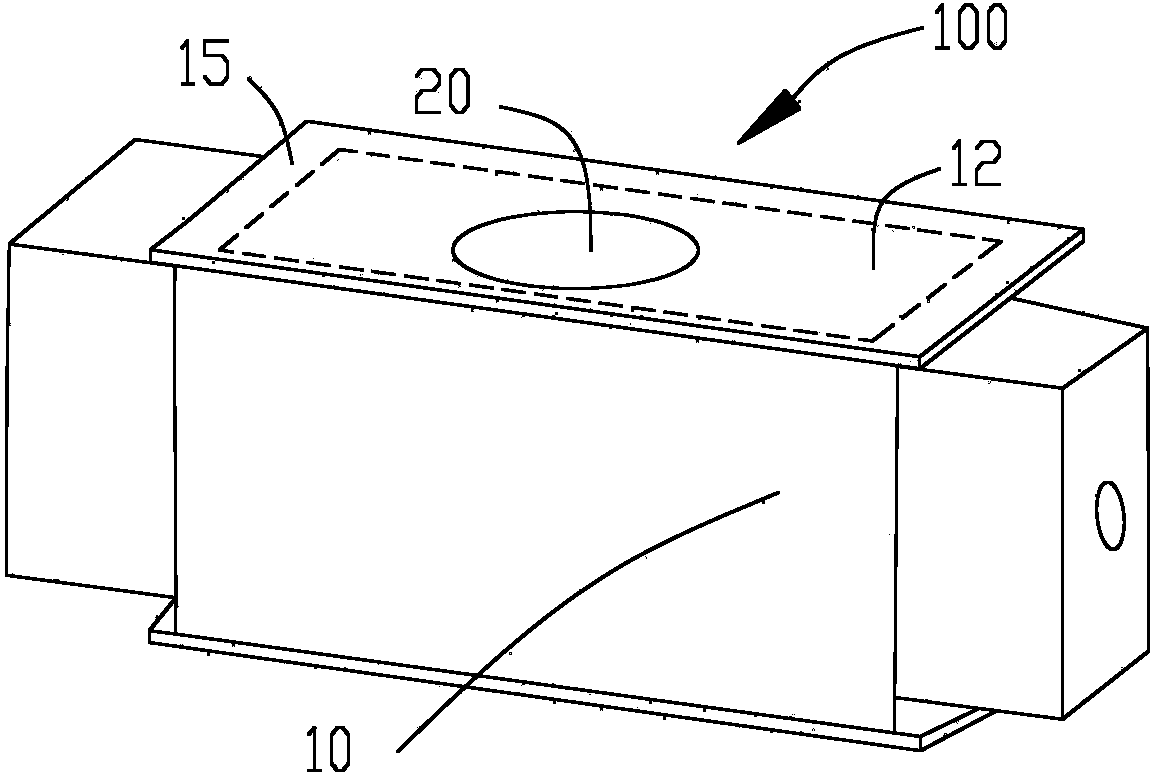

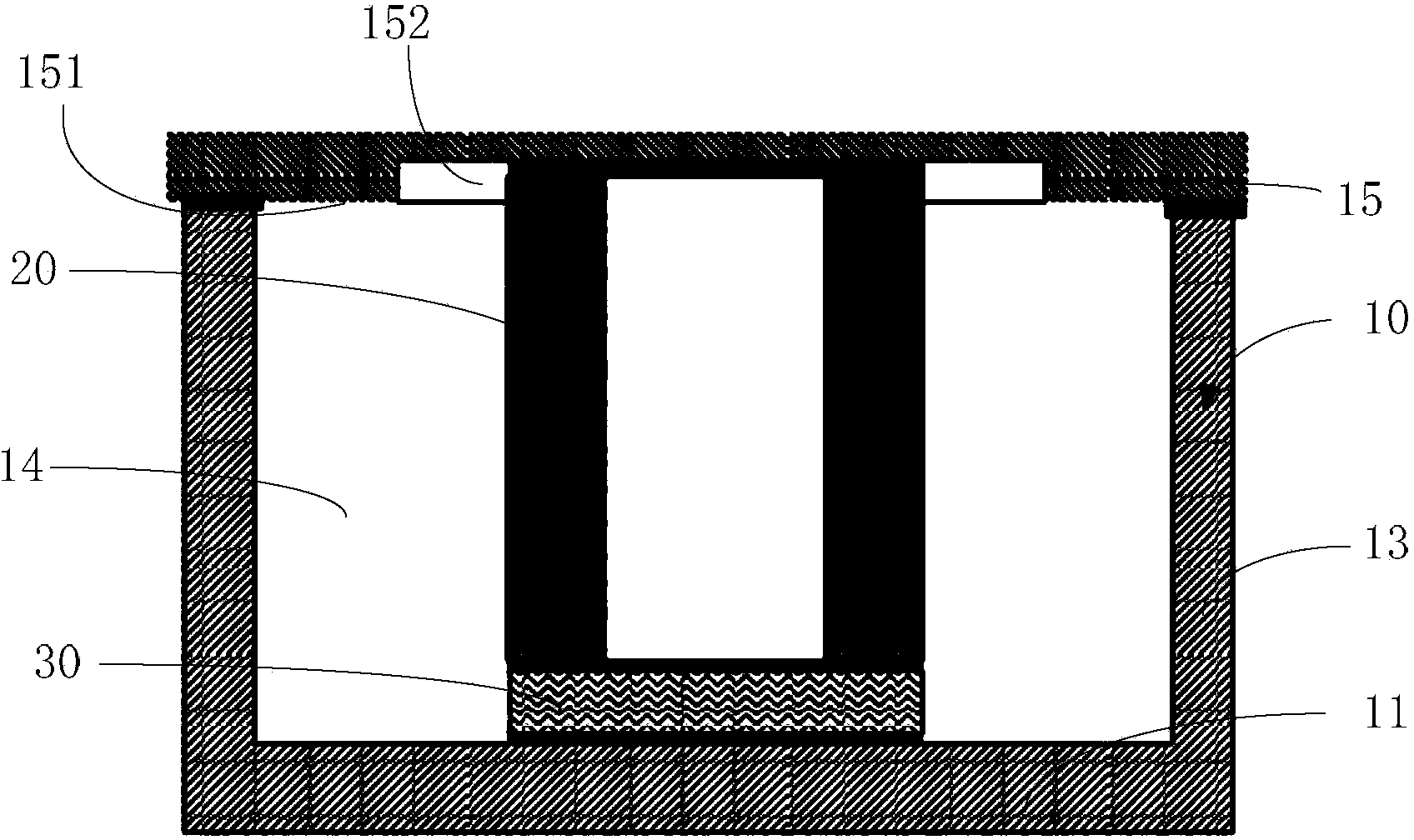

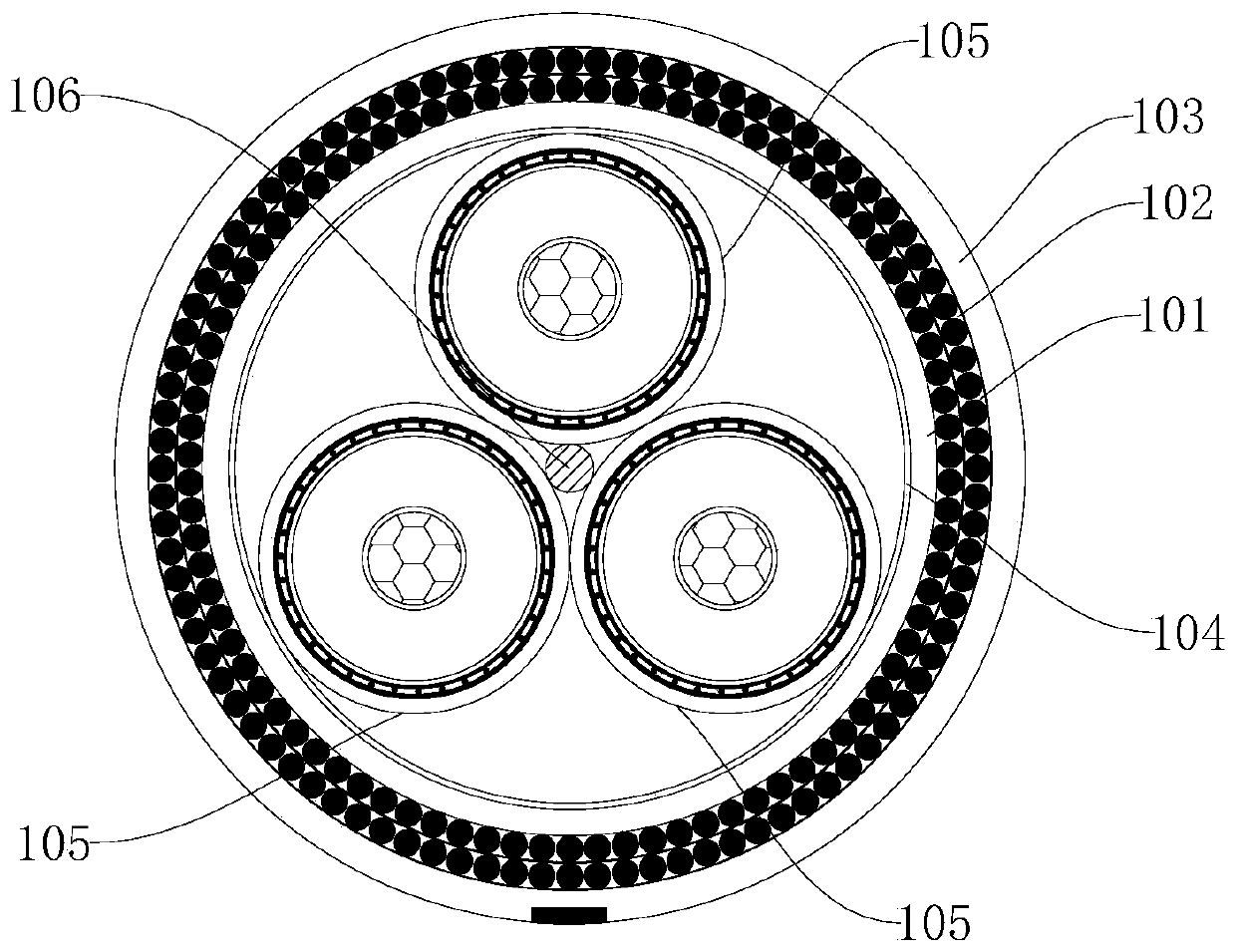

TM (transverse magnetic)-mode dielectric filter

InactiveCN103972618AExtended service lifeImprove solder joint reliabilityWaveguide type devicesDielectricEngineering

The invention provides a TM (transverse magnetic)-mode dielectric filter which comprises a shell, a cover plate, a dielectric filter and a mounting layer. An opening is formed in the shell, the cover plate covers the opening side of the shell, the mounting layer is arranged on the shell, the dielectric filter is positioned between the cover plate and the shell, two opposite ends of the dielectric filter are respectively welded with the cover plate and the mounting layer, and a thermal expansion coefficient of the mounting layer and a thermal expansion coefficient of the cover plate range from a thermal expansion coefficient of the shell and a thermal expansion coefficient of the dielectric filter.

Owner:HUAWEI MACHINERY

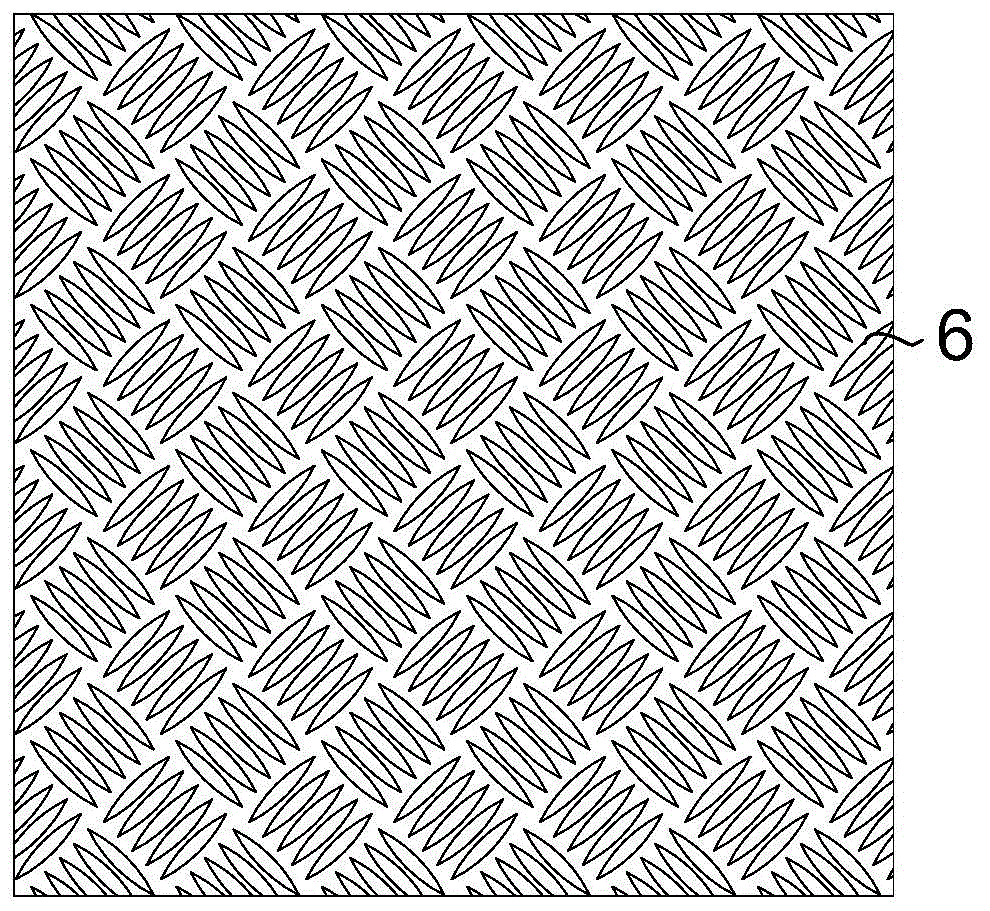

Connector-free steel and ultrahigh-performance concrete combined bridge deck structure and construction method thereof

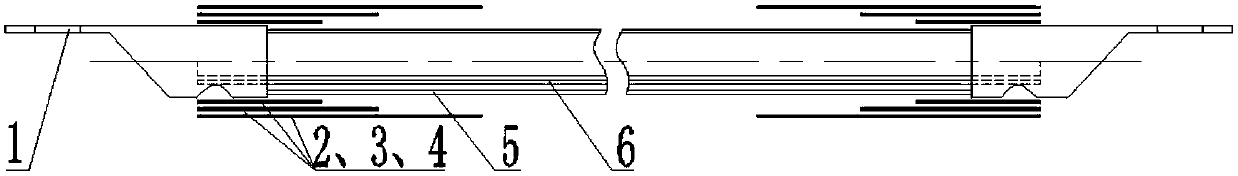

InactiveCN104631319AAvoid connectionReduce the difficulty of repairBridge structural detailsBridge erection/assemblyBridge engineeringBridge deck

The invention belongs to the technical field of bridge engineering and relates to a connector-free steel and ultrahigh-performance concrete combined bridge deck structure and a construction method thereof. The bridge deck structure comprises a steel bridge deck slab, a bridge deck pavement layer is paved on an ultrahigh-performance concrete layer which is paved on the steel bridge deck slab; the upper surface of the steel bridge deck slab is provided with protruding lines, and the lower portion of the steel bridge slab is provided with longitudinal stiffening ribs and transverse stiffening ribs. Compared with a steel and ultrahigh-performance concrete combined bridge deck structure with welding stud connectors, the connector-free steel and ultrahigh-performance concrete combined bridge deck structure has the advantages that welding of a great quantity of shear connectors is avoided, and construction and repair difficulty of bridge decks can be lowered. Compared with a traditional orthotropic steel bridge deck structure, the connector-free steel and ultrahigh-performance concrete combined bridge deck structure has the advantage that technical problems of fatigue rupture of steel structures and proneness to damages of the pavement layers can be effectively solved according to the scheme. Moreover, the connector-free steel and ultrahigh-performance concrete combined bridge deck structure has the advantages of convenience in material acquisition, structural simplicity, quickness in construction, force reasonability and high technical and economical benefits.

Owner:TSINGHUA UNIV

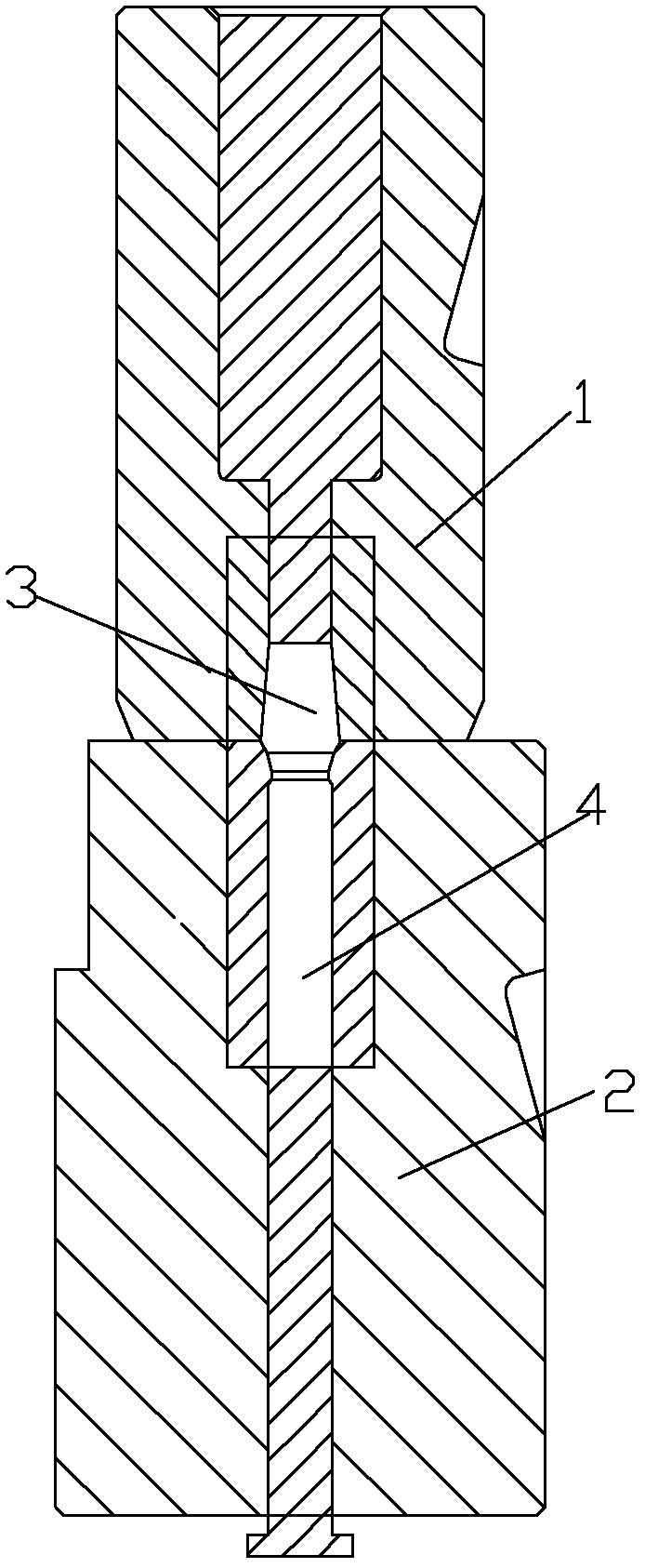

Method for machining T-shaped bolt

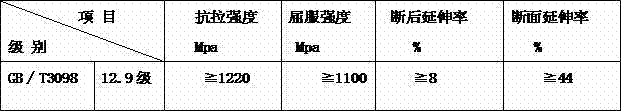

The invention discloses a method for machining a T-shaped bolt. The method comprises the following steps of: a) casting a T-shaped rod material blank and controlling the weight percentage of all chemical components of the rod material blank to ensure that the rod material blank comprises 0.28 to 0.35 percent of C, 0.25 to 0.35 percent of Mn, 0.05 to 0.09 percent of V, 0.15 to 0.35 percent of Si, 0.01 to 0.04 percent of W, less than or equal to 0.025 percent of P, less than or equal to 0.035 percent of S, 0.55 to 1.20 percent of Ni, 0.35 to 0.45 percent of Co, 0.20 to 0.30 percent of Sb and less than or equal to 0.20 percent of Cu; according to the method for machining the T-shaped bolt, the bolt is machined by a cold extruding process, so that the intensity of the bolt is improved, the hardness value and the intensity value required by a 12.9 high-intensity bolt can be acquired, and the delayed fracture and the fatigue crack of the bolt under high intensity can be avoided; and during use, the bolt is reliable in connection, is not prone to break, and meets the using requirements of all industries in society on the high-intensity bolt; and the service life of the bolt is prolonged.

Owner:ANHUI LIUFANG ZHONGLIAN MECHANICAL SHARE

Manufacturing process of high low screws

InactiveCN103302225AHigh strengthResolving Delayed FracturesMetal-working apparatusScrew-threads articlesEngineeringNylon thread

The invention discloses a manufacturing process of high low screws. The manufacturing process comprises the following steps of firstly, cutting a required blank at a room temperature, putting the cut blank into a mould cavity and forming a head part and a rod part required for screws through utilizing the blank by virtue of forging power; then processing threads in a screw rod by utilizing a thread rolling machine, wherein the thread rolling machine is provided with a high low thread rolling plate and can be used for rolling a high thread and a low thread at a step, the height of the high thread is 7.6-8.1mm, and the height of the low thread is 6.0-6.5mm; performing carburizing treatment on the screws formed after thread rolling, wherein the carburizing layer is 0.25-0.35mm; and finally performing thermal rust-preventing treatment on the surface. According to the manufacturing process, on one hand, a cold heading technology is adopted for processing the high low screws, so that the strength of the high low screws is improved, the delayed breakage and fatigue breakage problems of a bolt under a high bolt are solved, and the form and location tolerance and the thread accuracy of finished products of the high low screws can be effectively ensured; and on the other hand, by adopting the cold heading technology for processing, no waste materials can be generated, raw materials are saved, and the production cost is lowered.

Owner:苏州新凌高强度紧固件有限公司

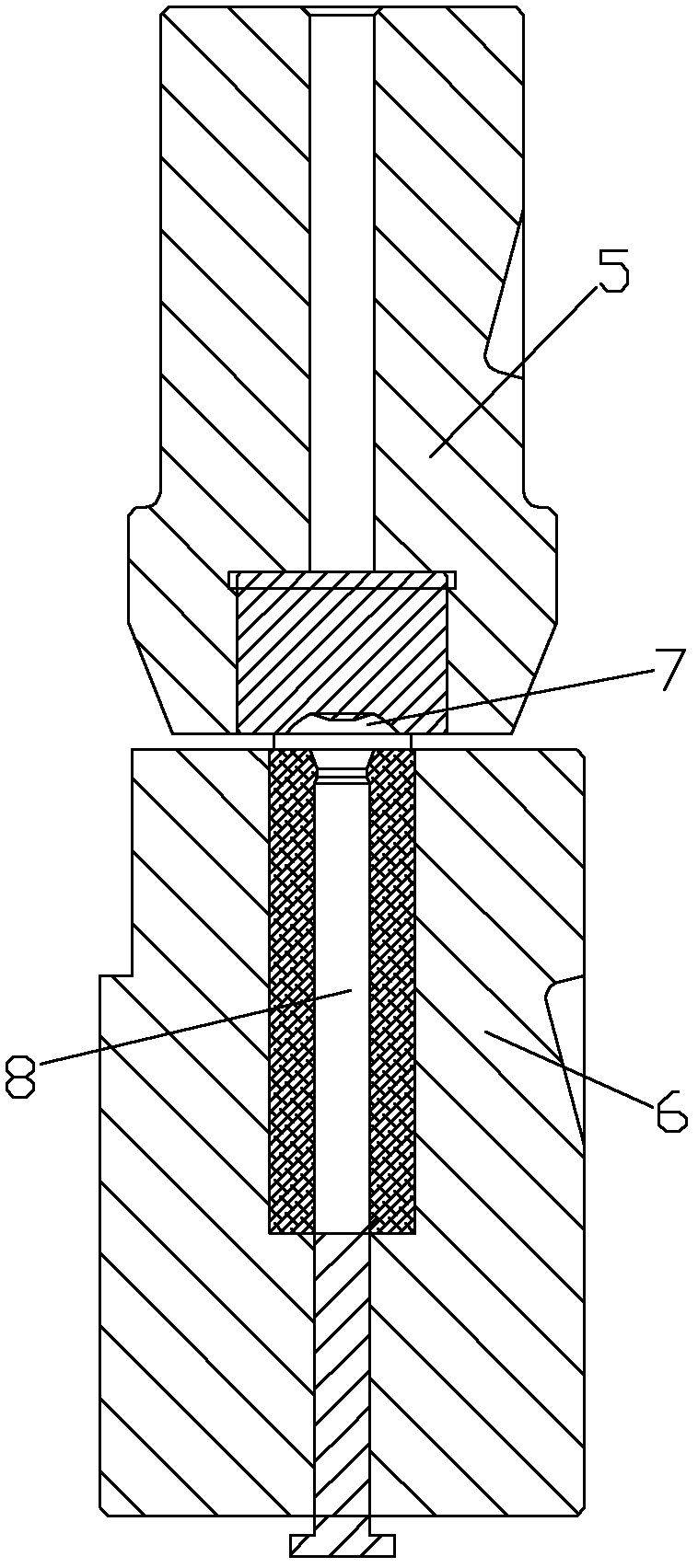

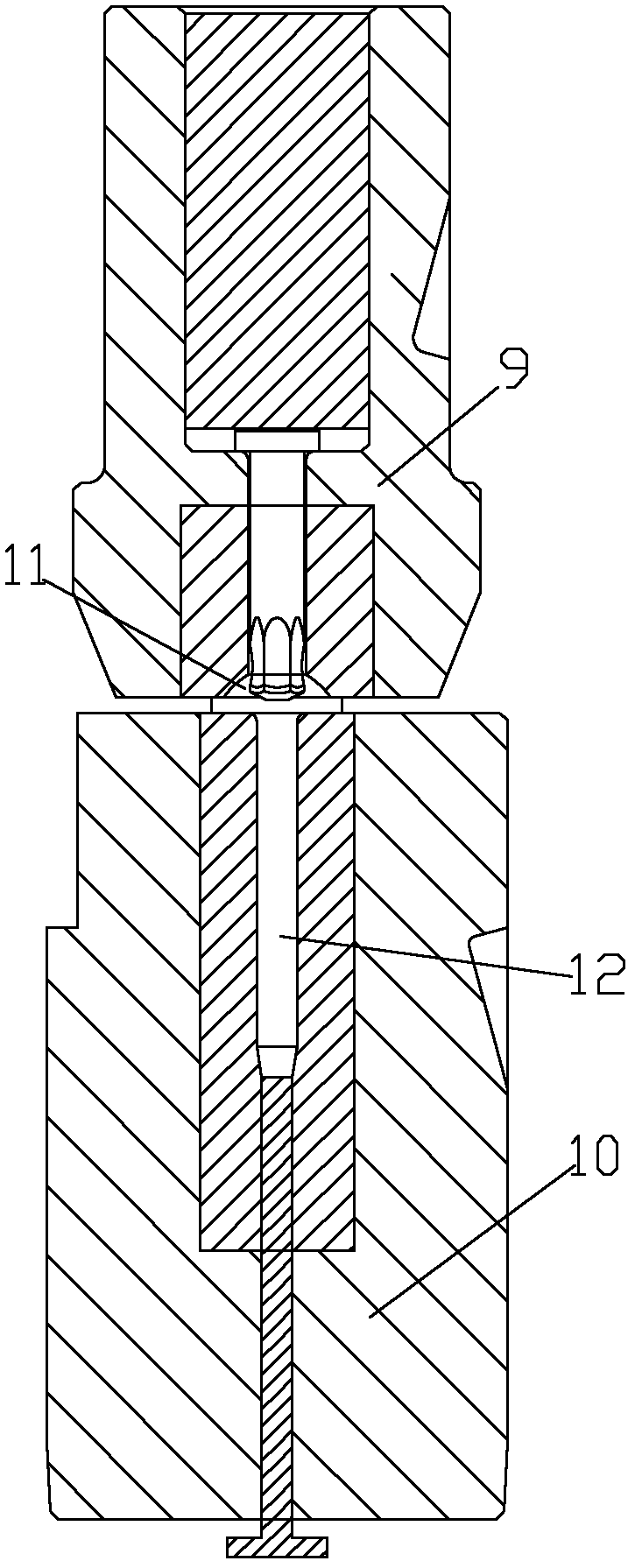

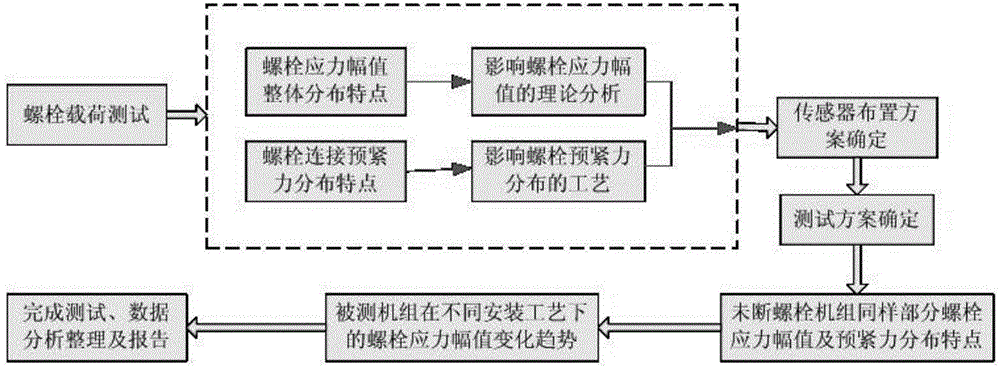

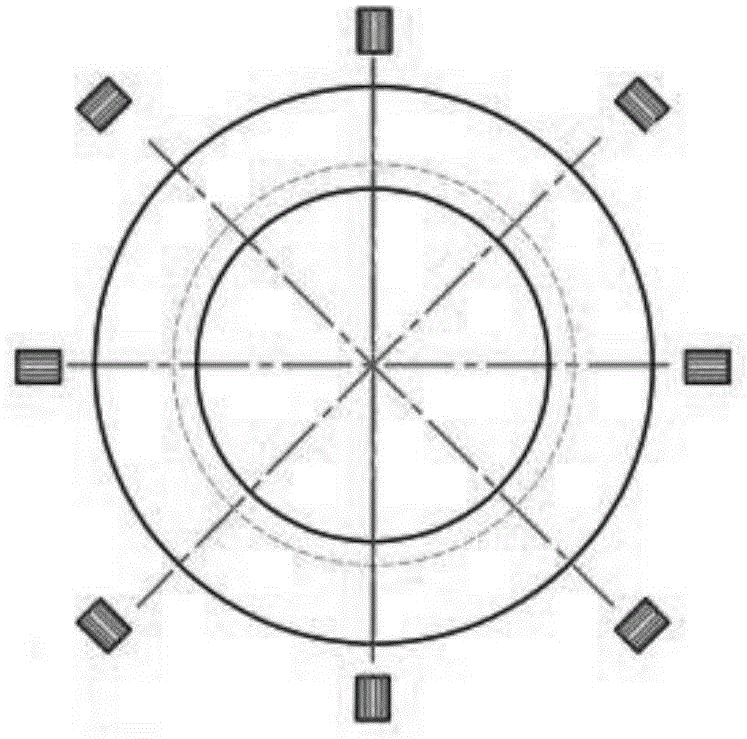

Method and equipment for evaluating technological property of bolt installation

ActiveCN104931185AAvoid fatigue fractureAvoid breakingMeasurement of torque/twisting force while tighteningCommunication interfacePull force

The invention relates to a method and equipment for evaluating the technological property of bolt installation, and the method comprises the steps: determining the fastening sequence of bolts; testing the total pulling force of bolts in an operation process under the condition of different loads; obtaining a real-time stress amplitude value; making a conclusion that an end face of a connected part is cracked when the real-time stress amplitude value is greater than a standard stress amplitude value; and determining the fastening sequence of new bolts till the fastening sequence of the current bolt is judged to be the optimal bolt fastening sequence. The equipment comprises a signal input end module, a signal collection and processing module, and a man-machine interaction module, wherein the signal input end module comprises a strain signal input end, a standard analog input end, and a power circuit. The signal collection and processing module comprises a processing chip. The man-machine interaction module comprises a processor, a communication interface, an operation module, and a display module. The method and equipment can test the bolts, propose a new installation technology, and facilitate the maintenance of the bolts.

Owner:BEIJING TIANYUAN SCI & TECH CREATION WINDPOWER TECH

Nut production process

InactiveCN109531071AReduce contentIncrease contentFurnace typesHeat treatment furnacesChemical compositionHardness

The invention discloses a nut production process. The process comprises the following steps that S1, through a casting process, a workblank part is made, and the workblank part comprises, by weight ratio, 0.28 to 0.32 of C, 0.32 to 0.45 of Mn, 0.05 to 0.09 of Zn, 0.15 to 0.25 of Si, 0.01 to 0.03 of La, not larger than 0.015 of P, not larger than 0.015 of S, 0.50 to 1.20 of Ni, 0.15 to 0.25 of Sn,0.15 to 0.25 of Al, 0.2 to 0.5 of Mo and the balance iron; S2, the workblank part is put into a mold cavity, cold heading extrusion molding is carried out, and the nut workblank is made; S3, the nut workblank is turned and tapped; S4, heat treatment is carried out; S5, surface treatment is carried out, cleaning oil removal is carried out, blackening treatment is carried out, static electricity manner is adopted to spray an anti-corrosion agent to the nut, and the sprayed nut is cured to obtain a nut finished product. The nut produced through the nut production process has the hardness value and strength value needed by the high-strength nut, is not prone to being corroded and long in service life.

Owner:重庆旺达汽车零部件有限公司

Method for producing adsorbable artificial ligaments

InactiveCN101327342ASolve fatigue fractureLong-term useLigamentsMusclesLigament structureHorticulture

Owner:SHANGHAI JIAO TONG UNIV AFFILIATED SIXTH PEOPLES HOSPITAL +1

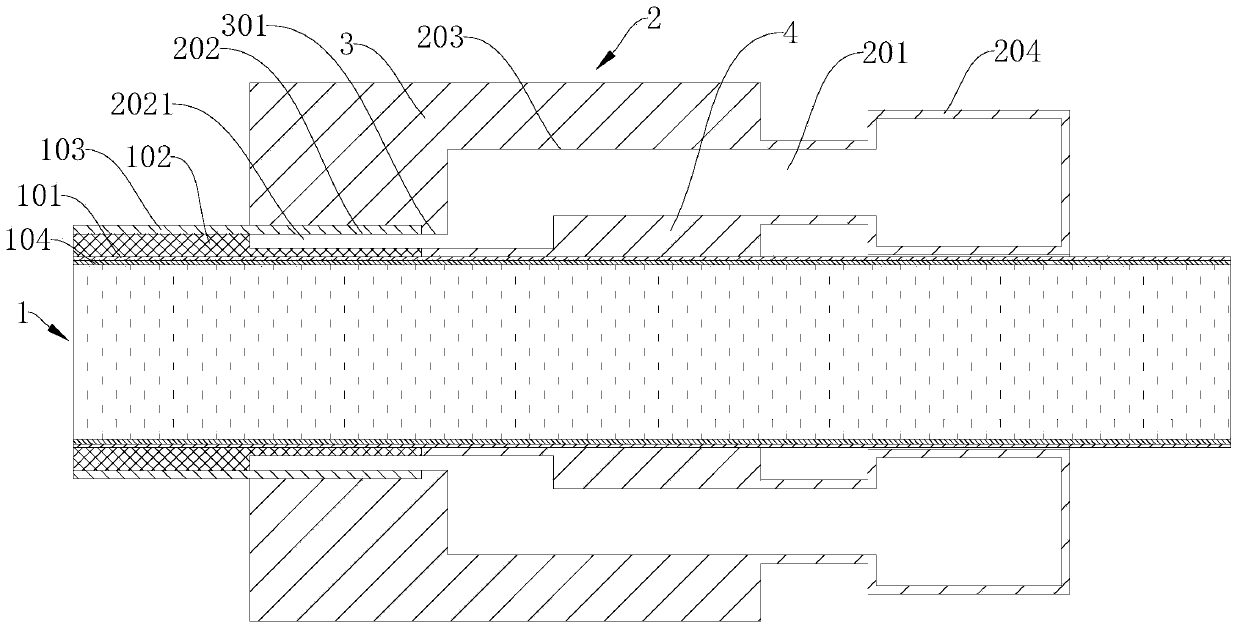

Dynamic submarine cable assembly for deep water

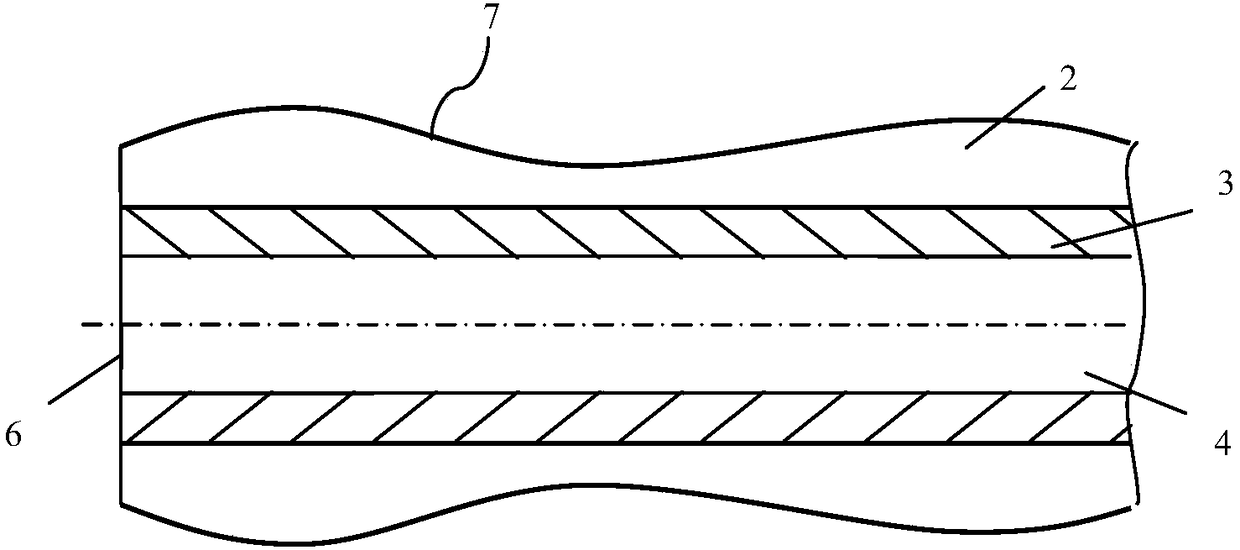

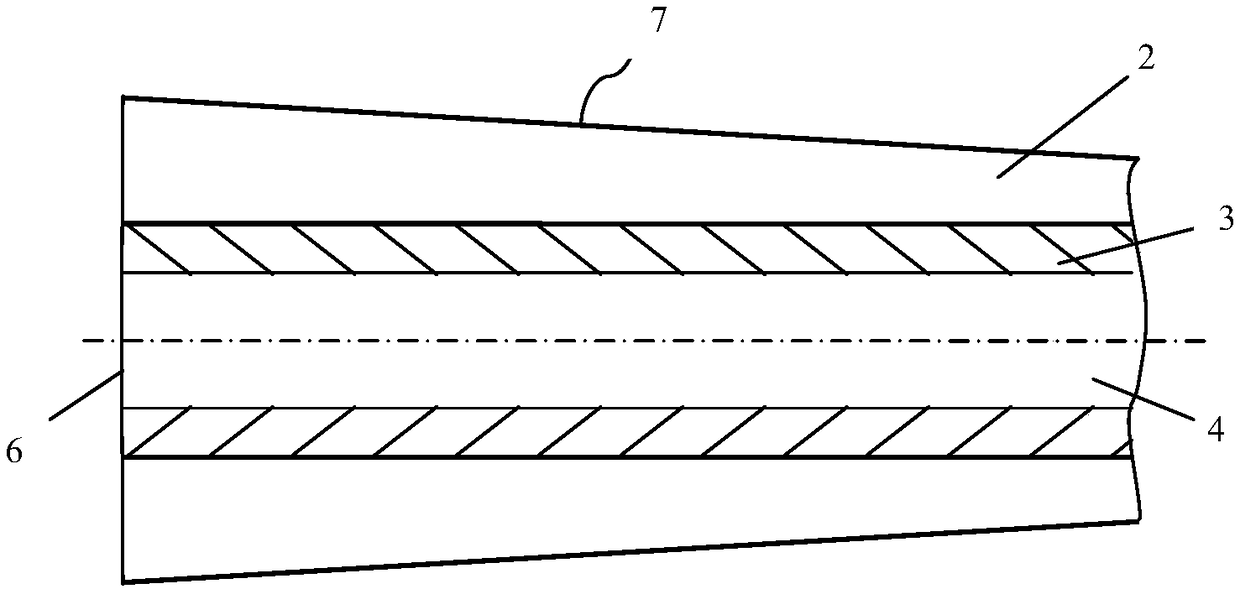

PendingCN110610774APlay a water blocking roleSolve growthClimate change adaptationSubmarine cablesInternal pressureMarine engineering

The invention discloses a dynamic submarine cable assembly for deep water. The dynamic submarine cable assembly comprises a dynamic submarine cable body. The dynamic submarine cable body comprises a cable core. The cable core is coated with an inner sheath. The inner sheath is coated with a steel wire armor layer. The steel wire armor layer is coated with an outer sheath. The dynamic submarine cable assembly is characterized in that the space between the inner sheath and the outer sheath is filled with insulating oil, the insulating oil fills the gaps of the steel wire armor layer, and the dynamic submarine cable body is equipped with a pressure balancing device used for balancing the internal pressure and the external pressure of the dynamic submarine cable body. The dynamic submarine cable assembly for deep water has the advantage that the dynamic submarine cable has better water blocking performance and longer service life because the space between the inner sheath and the outer sheath is filled with the insulating oil and the pressure balancing device is arranged on the dynamic submarine cable body.

Owner:宁波东方电缆股份有限公司

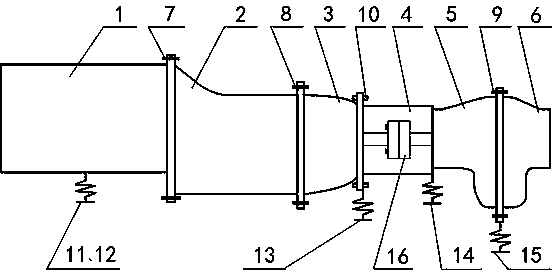

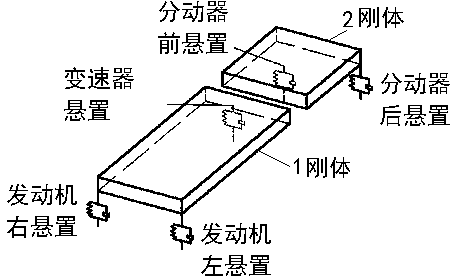

Arrangement method and structure of power assembly for long-wheelbase four-wheel-drive automobile

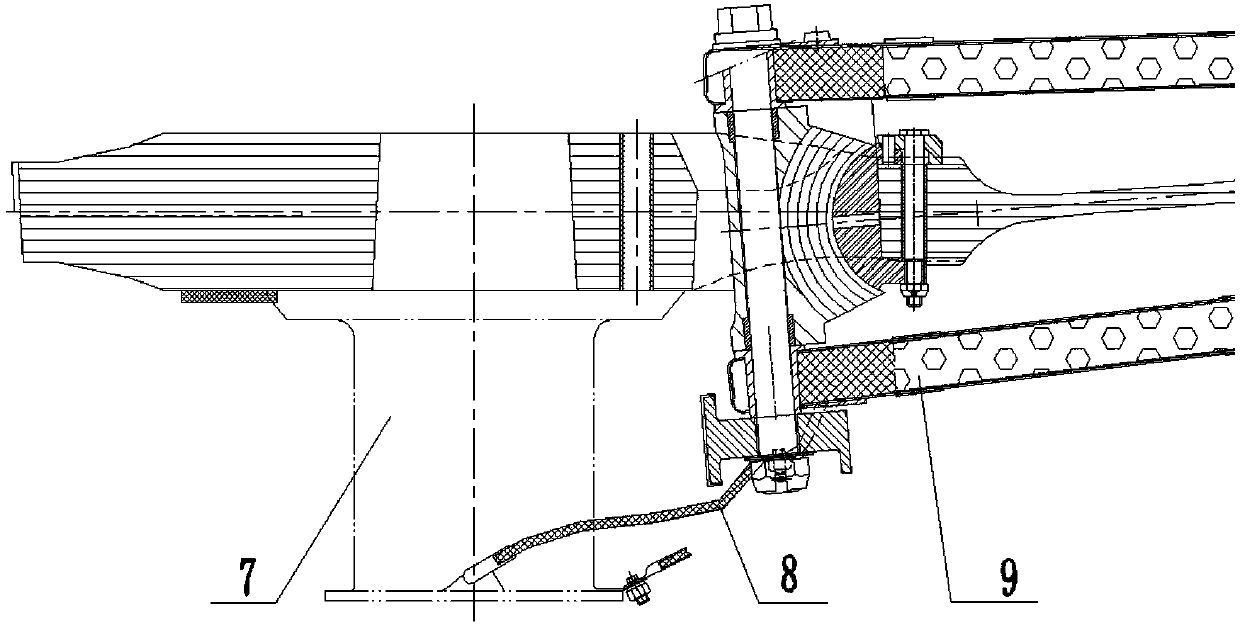

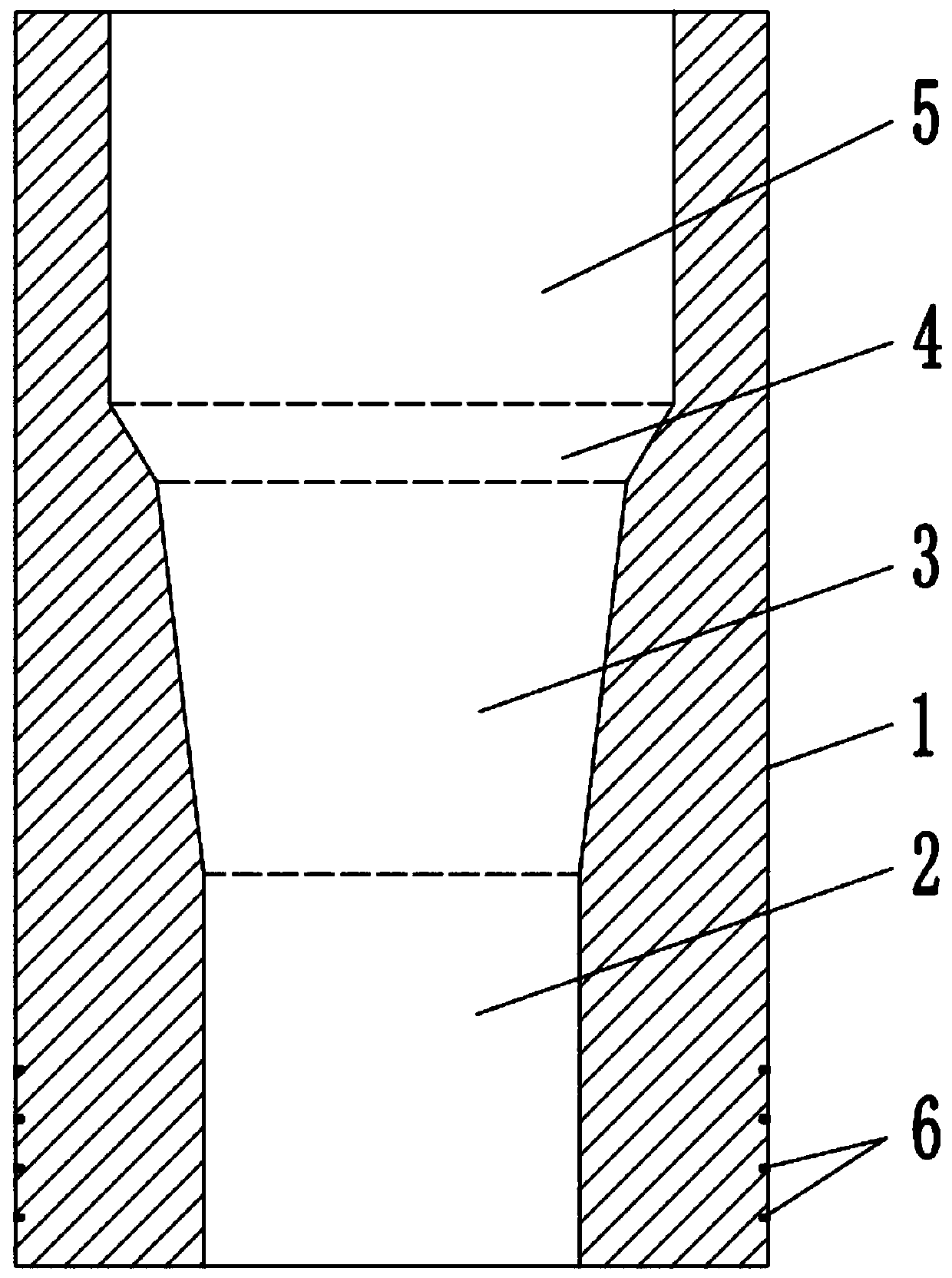

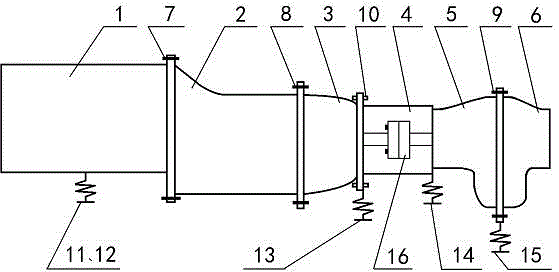

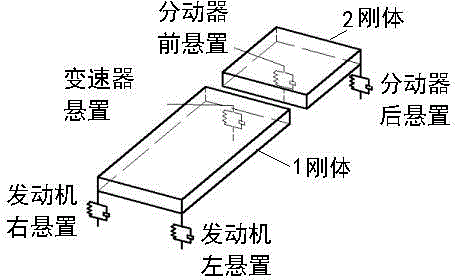

InactiveCN103448525AShorten the cantilever lengthReduce alternating load stress amplitudeJet propulsion mountingInternal combustion mountingTransfer caseBlocked Connection

Disclosed is an arrangement method and structure of a power assembly for a long-wheelbase four-wheel-drive automobile. The structure is characterized by comprising a power assembly suspension system, a power assembly three-shell block connection, and a transmission shaft connection. The power assembly suspension system comprises an engine left suspension, an engine right suspension, a transmission suspension, a transfer case front suspension and a transfer case rear suspension. The power assembly three-shell block connection is characterized in that an engine housing is rigidly connected with a transmission front shell through bolts; the transmission front shell is rigidly connected with a transmission rear shell through bolts; the transmission rear shell is flexibly connected with a transition plate through a rubber elastic bushing added between the bolts and mounting holes; the transition plate is rigidly connected with a transfer case through bolts; a transfer case front shell is rigidly connected with a transfer case rear shell through bolts. The structure has the advantages that vibration reduction and noise reduction are simultaneous, the change range of the amplitude of stress borne by the power assembly three-shell can be reduced greatly, chances for fatigue breakage of the three-shell are slimmed, and vehicles can be comfortable and reliable to use.

Owner:NANJING UNIV OF TECH +1

Preparation method of lengthened bolt

ActiveCN103088267AHigh strengthResolving Delayed FracturesThread cutting machinesBoltsChemical compositionFatigue fractures

The invention discloses a preparation method of a lengthened bolt. The preparation method is characterized by comprising the following processing steps of: a, preparing a rod blank through a casting technology, wherein the rod blank comprises the following chemical components in percentage by weight: 0.25%-0.35% of C, 0.08%-0.15% of Mn, 0.05%-0.15% of Si, 0.01%-0.04% of W, no less than 0.015% and no more than 0.025% of P, no less than 0.015% and no more than 0.035% of S, 0.15%-0.20% of Ni, 0.025%-0.045% of Zn, 0.02%-0.03% of Sn, no more than 0.02% of Cr, and the balance of iron. The preparation method of the lengthened bolt disclosed by the invention has the beneficial effect of improving the strength of the bolt by processing the bolt through a cold extrusion process, the hardness value and the strength value required for a 12.9 high-strength bolt are achieved, the problems of delayed fracture and fatigue fracture of the bolt under high strength are solved, the bolt is reliable for connection and less prone to breaking in use, the service life of the bolt is prolonged, and the use requirement on the high-strength bolt in various industries in society is satisfied.

Owner:重庆冠鹏机车部件有限公司

Preparation method of high-strength anti-corrosion bolt

ActiveCN103088271AHigh strengthExtend your lifeFurnace typesMetallic material coating processesChemical compositionHardness

The invention discloses a preparation method of a high-strength anti-corrosion bolt. The preparation method comprises the following processing steps of: a, casting a rod material which comprises the following chemical components according percentage composition: 0.4%-0.8% of C, 0.02%-0.05% of Si, 0.18%-0.21% of Mn, 0.16%-0.18% of P, 0.05%-0.07% of S, 0.05%-0.15% of Cr, 0.05%-0.12% of Ti, 0.11%-0.13% of Cu, 0.01%-0.02% of Al, 0.02%-0.03% of Mg, and the balance of iron; b, performing acid pickling on the casted rod material, performing wire drawing on the rod material according to the wire diameter requirement of the bolt so as to shrink the rod material to the wire diameter required for the bolt, cutting the rod material with the shrunk wire diameter to a length required for the bolt, placing the cut rod material in a die cavity at a normal temperature, and shaping the rod material to be in the size of the head part and the rod part required for the bolt through forging force. By processing the bolt through the cold extrusion process, the preparation method of the high-strength anti-corrosion bolt provided by the invention has the effects of improving the strength of the bolt, ensuring that the hardness value and the strength value required for a 12.9 high-strength bolt are achieved, and solving the problems of delay fracture and fatigue fracture of the bolt under high strength; and the bolt is reliable for connection and less prone to breaking in use, the service life of the bolt is prolonged, and thus the use requirement on high-strength bolts in various industries in society is satisfied.

Owner:国动科技有限公司

Method for machining connection rod bolt of diesel engine

InactiveCN103084525AHigh strengthResolving Delayed FracturesMetal-working apparatusBoltsChemical compositionHardness

The invention discloses a method for machining a connection rod bolt of a diesel engine. The method comprises the following steps of: manufacturing a rod material blank, and controlling the weight percentage of all chemical components of the rod material blank to ensure that the rod material blank comprises 0.28 to 0.32 percent of C, 0.35 to 0.45 percent of Mn, 0.05 to 0.15 percent of V, 0.15 to 0.35 percent of Si, 0.01 to 0.04 percent of W, less than or equal to 0.025 percent of P, less than or equal to 0.035 percent of S, 0.55 to 1.20 percent of Ni, 0.35 to 0.45 percent of Co, 0.20 to 0.30 percent of Sn and less than or equal to 0.20 percent of Cu. According to the method for machining the connection rod bolt of the diesel engine, the bolt is machined by a cold extruding process, so that the intensity of the bolt is improved, the hardness value and the intensity value which are required by a 12.9 high-intensity bolt can be acquired, and the delayed fracture and fatigue crack of the bolt under high intensity can be overcome; the bolt is reliable in connection during use, and is not prone to break and crack; the service life of the bolt is prolonged; and the using requirements of all industries in society on the high-intensity bolt can be met.

Owner:佛山顺恒鑫科技实业有限公司

Preparation method of anti-fracture engine crankshaft

InactiveCN105420609AHigh strengthExtend your lifeSolid state diffusion coatingFurnace typesChemical compositionMetallurgy

The invention discloses a preparation method of an anti-fracture engine crankshaft. The preparation method comprises the steps that a rod blank is cast; and chemical components of the rod blank are made to meet the requirement that the rod blank is composed of, by weight, 0.28-0.35% of C, 0.25-0.35% of Mn, 0.15-0.35% of Si, 0.01-0.04% of W, 0-0.025% of P, 0-0.035% of S, 0.55-1.20% of Ni, 0.35-0.45% of Co, 0.20-0.30% of Sn, and 0-0.20 of Al. By means of the preparation method, the strength of the engine crankshaft is improved, the hardness value and the strength value which are required by a high-strength engine crankshaft are reached, the problems of delayed fracture and fatigue fracture of the engine crankshaft under high strength are solved, connection is reliable when the engine crankshaft is in use, fracture is unlikely to occur, the service life of the engine crankshaft is prolonged, and using requirements of various industries in the society for the high-strength engine crankshaft are met.

Owner:HEFEI HAIYUAN MACHINERY

Method for manufacturing abrasion-resistant U-shaped bolt

The invention discloses a method for manufacturing an abrasion-resistant U-shaped bolt. Machining steps include: casting a U-shaped rod, by weight, adding 11-14 parts of scrap steel into a medium frequency furnace to melt to form molten steel, adding carburant, when the temperature in the medium frequency furnace rises to 1120-1220 DEG C, adding 0.1-0.2 part of molybdenum, 0.2-0.3 part of magnesium ingot, 5-7 parts of scrap aluminum, 32-34 parts of steel ingot, 30-35 parts of pig iron and 12-16 parts of foundry returns, simultaneously scattering a layer of heat preservation covering agent on the surface of the melt and covering, slagging, after slagging, adding 0.6-0.9 part of ferromanganese and 2-3 parts of ferrosilicon alloy, when the temperature in the medium frequency furnace rises to 1400 DEG C, withdrawing, adding 0.4-0.6 part of copper along with molten iron into a ladle, and casting. The method adopts cold extrusion process to machine the bolt, the strength of the bolt is improved, hardness and strength required by the 12.9 high-strength bolt are met, and delayed fracture and fatigue fracture of the bolt under high strength are avoided. The bolt is reliable in connection and not prone to break, prolongs service life, and meets use requirements of various industries in society for the high-strength bolt.

Owner:浙江艾信汽车零部件股份有限公司

Cold heading formation technology of grid structure bolt

The cold heading forming process of grid bolts disclosed by the present invention includes the steps of material preparation, raw material reformation, cold heading forming, groove milling, quenching, tempering, blackening treatment and post-treatment. The cold heading forming process of grid bolts provided by the invention solves the delayed fracture and fatigue fracture of bolts under high strength. It is not easy to break during use, and the connection is reliable, which improves the service life of bolts and can better meet the needs of today's society. The use of high-strength bolts for steel grid bolt ball joints is required.

Owner:南通安赛乐紧固件有限公司

Saw web forging forming process

InactiveCN107282998AResolving Delayed FracturesSolve fatigue fractureMetal sawing tool makingFurnace typesMaterials preparationHigh intensity

A saw blade forging forming process disclosed by the present invention includes the steps of material preparation, raw material reformation, forging, shot blasting, heat treatment, cryogenic treatment and post-treatment. The saw blade forging forming process provided by the invention solves the delayed fracture and fatigue fracture of the saw blade under high strength, is not easy to break during use, has reliable connection, and improves the service life of the saw blade.

Owner:JIANGSU JUNWEI ELECTRONICS TECH CO LTD

Low-stress high-damping railway fastener elastic strip

ActiveCN108277702AReduce the maximum stress amplitudeReduce the amplitude of the resonance responseClimate change adaptationRail fastenersEngineeringLow stress

The invention relates to a low-stress high-damping railway fastener elastic strip. The elastic strip has a variable cross section in the direction of a center line, the coefficient of the variable cross section of the elastic strip is 1-3, and in other words, the ratio of the maximum cross section area to the minimum cross section area of the elastic strip is 1-3:1. Compared with the prior art, the elastic strip has the advantages that the maximum stress amplitude value of an existing elastic strip is decreased, and the safety coefficient of the elastic strip is increased.

Owner:SHANGHAI UNIV OF ENG SCI

High-strength bolt machining method

The invention discloses a high-strength bolt machining method. The method comprises the step of S1, a rod blank is prepared through a casting process, wherein the rod blank is controlled to comprisesthe following chemical components of, by weight, 0.28-0.32% of C, 0.32-0.45% of Mn, 0.05-0.15% of V, 0.15-0.25% of Si, 0.01-0.03% of W, less than or equal to 0.015% of P, less than or equal to 0.015%of S, 0.50-1.20% of Ni, 0.15-0.25% of Sn, 0.15-0.25% of Cu, 0.15-0.35% of Mo and the balance iron. A bolt produced by the high-strength bolt machining method reaches the hardness value and the strength value which are required by the high-strength bolt, the delay fracture and the fatigue fracture problems of the bolt under the high strength are solved, during use, connection is reliable, breakageis not prone to occurrence, the service life of the bolt is prolonged, and the use requirements of all industries in the society on the high-strength bolt are met.

Owner:重庆旺达汽车零部件有限公司

Cable protecting structure between propeller shaft and propeller hub of helicopter

PendingCN108033028AHigh strengthExcellent fatigue propertiesInstallation of lighting conductorsAircraft lighting protectorsHeat-shrinkable sleevePropeller

The invention relates to a cable protecting structure between a propeller shaft and a propeller hub of a helicopter. The two ends of the cable are connecting ends, one connecting end is connected to the propeller hub, and the other connecting end is connected to the propeller shaft; the cable is provided with an insulating sleeve; the two connecting ends of the cable are each sleeved with three layers of heat-shrinkable sleeves, and the length of the inner layer heat-shrinkable sleeve, the length of the middle layer heat-shrinkable sleeve and the length of the outer layer heat-shrinkage sleeveare gradually increased. The rigidity of the earth wire middle flexible portion is lowered, the rigidity of the whole earth wire is distributed again due to the improved whole structure of the earthwire, and the strength is locally reinforced, so that the fatigue property of the earth wire is improved, and the problem of fatigue cracks of the earth wire is solved.

Owner:AVIC HUIYANG AVIATION PROPELLER

Heat treatment method of connecting rod bolt

InactiveCN107447221AIncreased Strength and RigidityAddressing Delayed and Fatigue FracturesFurnace typesHeat treatment furnacesDegreasingPhosphate treatment

The invention discloses a heat treatment method for connecting rod bolts, which comprises the following steps: A. forming a connecting rod bolt forging blank through die forging; B. extruding the connecting rod bolt forging blank through a thread extrusion knife to obtain a continuous Rod bolts; C. Quenching the threaded portion of the connecting rod bolts, and then quenching the rod portion of the connecting rod bolts; carburizing the quenched connecting rod bolts; D. Alkaline washing and degreasing of the heat-treated connecting rod bolts , pickling, and after drying, immerse the connecting rod bolts in the surface phosphating treatment solution; E. After blackening the connecting rod bolts, the heat treatment of the connecting rod bolts is completed. Compared with the prior art, the invention can solve the delayed fracture and fatigue fracture of the high-strength lower connecting rod bolts, the connection is reliable in use, not easy to break, and the service life of the connecting rod bolts is improved.

Owner:LIUZHOU JINTE NEW WEAR RESISTANT MATERIAL CO LTD

Manufacturing method of water gap die sleeve

InactiveCN110369975ASmall rate of changeHigh strengthFurnace typesHeat treatment furnacesFatigue fracturesHeat resistance

The invention discloses a manufacturing method of a water gap forming die sleeve. The method comprises the steps of A, blank selecting and casting, B, forging, C turning and D heat treatment. According to the manufacturing method of the water gap die sleeve, through burdening selection and manufacturing process optimization, the water gap die sleeve is low in linear change rate, high in strength and good in rapid cooling and heat resistance property after high-temperature burning, and the damage caused by frequent replacing of the water gap die sleeve is avoided; the forging process is adoptedfor machining, the strength of the water gap die sleeve is improved, the delayed fracture and the fatigue fracture of the water gap die sleeve can be solved, during use, connection is reliable, the die sleeve is not prone to cracking damage, the service life of the water gap die sleeve is prolonged, the water gap die sleeve can be recycled, repaired and then used, during recycling, the die sleevecan be recycled after the damage part is cut off according to the positioning ring line, the spare parts stock of an enterprise can be reduced, the enterprise production cost is reduced, and the economic benefit is improved.

Owner:云南濮耐昆钢高温材料有限公司

Weather-proof delayed-fracture-resistant high-strength bolt cold heading forming process

InactiveCN111590005AHigh strengthSolve weather resistanceMetal-working apparatusBoltsWire rodTempering

The invention discloses a weather-proof delayed-fracture-resistant high-strength bolt cold heading forming process. The process comprises the steps of cutting off a wire rod raw material to obtain a metal round rod for bolt forming, wherein the metal round rod comprises a head round rod and a rod round rod; carrying out primary cold heading on the metal round rod to primarily form a bolt head at one end of the round rod; then carrying out secondary cold heading so that the bolt head is completely formed, wherein the width of the completely-formed bolt head is 40-45 mm, and the height of the completely-formed bolt head is 15-20 mm; and carrying out chamfering, rod part shrinking and trimming forming on the tail end of the rod part of the product in the S3, and then carrying out quenching and tempering treatment and surface treatment to obtain a weather-proof delayed-fracture-resistant high-strength bolt.

Owner:ANHUI CHANGJIANG FASTENERS

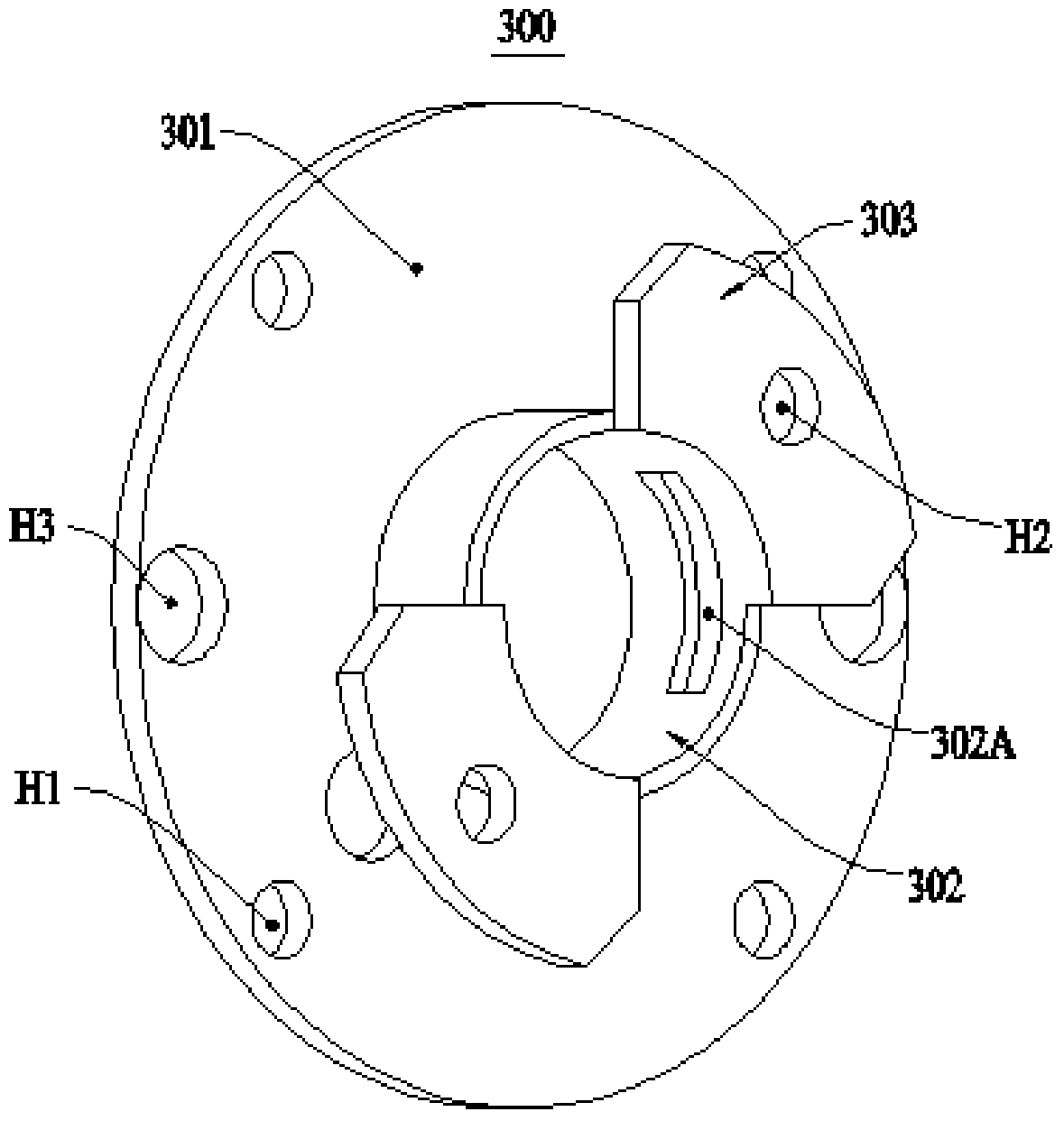

Powertrain Layout Method and Structure of Long Wheelbase Four-Wheel Drive Vehicle

InactiveCN103448525BShorten the cantilever lengthReduce alternating load stress amplitudeJet propulsion mountingInternal combustion mountingTransfer caseBlocked Connection

Disclosed is an arrangement method and structure of a power assembly for a long-wheelbase four-wheel-drive automobile. The structure is characterized by comprising a power assembly suspension system, a power assembly three-shell block connection, and a transmission shaft connection. The power assembly suspension system comprises an engine left suspension, an engine right suspension, a transmission suspension, a transfer case front suspension and a transfer case rear suspension. The power assembly three-shell block connection is characterized in that an engine housing is rigidly connected with a transmission front shell through bolts; the transmission front shell is rigidly connected with a transmission rear shell through bolts; the transmission rear shell is flexibly connected with a transition plate through a rubber elastic bushing added between the bolts and mounting holes; the transition plate is rigidly connected with a transfer case through bolts; a transfer case front shell is rigidly connected with a transfer case rear shell through bolts. The structure has the advantages that vibration reduction and noise reduction are simultaneous, the change range of the amplitude of stress borne by the power assembly three-shell can be reduced greatly, chances for fatigue breakage of the three-shell are slimmed, and vehicles can be comfortable and reliable to use.

Owner:NANJING TECH UNIV +1

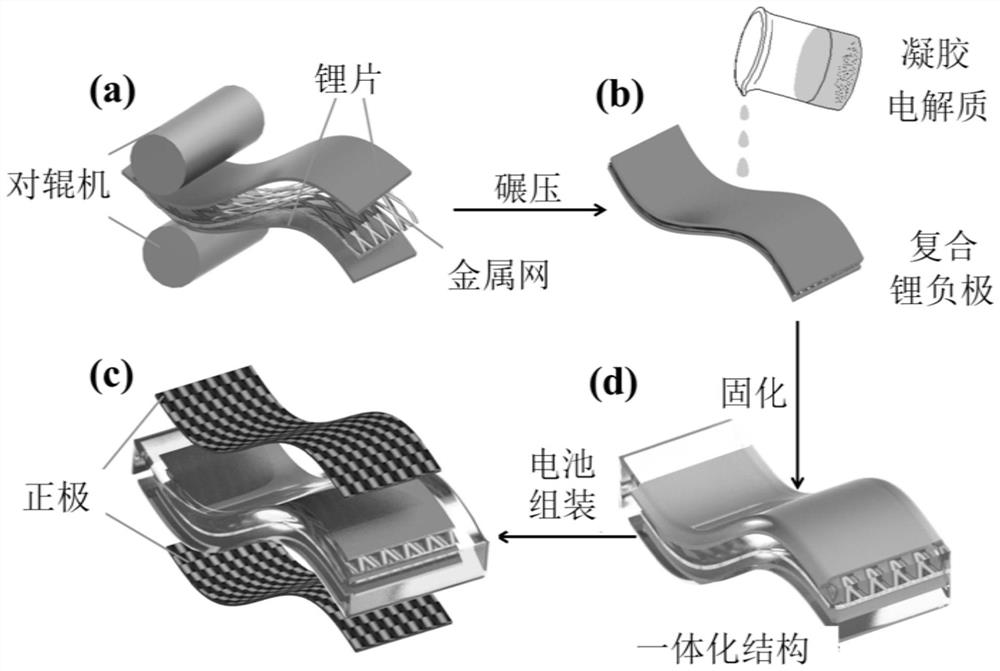

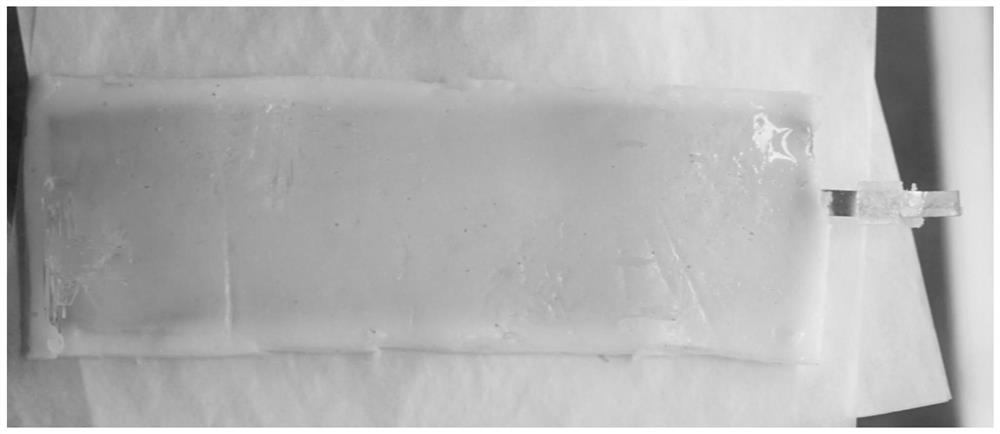

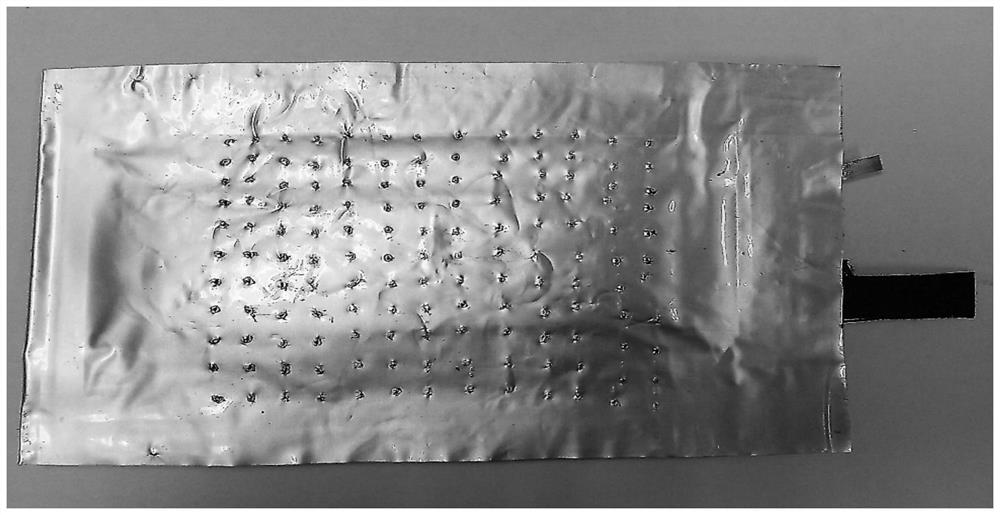

Preparation method of lithium-air battery based on gel electrolyte-lithium negative electrode integrated structure

InactiveCN112467258ASolve fatigue fractureFully contactedFuel and primary cellsCell electrodesComposite materialLithium–air battery

The invention belongs to the technical field of lithium battery devices, and relates to a preparation method of a lithium-air battery based on a gel electrolyte-lithium negative electrode integrated structure. The prepared lithium-air battery comprises a flexible porous metal sheet, two lithium sheets, two positive electrodes and a gel electrolyte, wherein a tab is welded on the flexible porous metal sheet to form a negative electrode current collector; the flexible porous metal sheet is located between the two lithium sheets, the two lithium sheets are implanted to form a composite lithium negative electrode, the gel electrolyte wraps the composite lithium negative electrode to form a gel electrolyte-lithium negative electrode integrated structure, and the positive electrode and the gel electrolyte-lithium negative electrode integrated structure are assembled into the lithium-air battery. The problems that the lithium negative electrode of the flexible lithium-air battery is easy to break due to fatigue, potential safety hazards exist when the lithium negative electrode is exposed to air, electrolyte and the lithium negative electrode cannot be in full contact and are easy to separate in the bending process are solved.

Owner:BEIHANG UNIV

Processing technology for high-strength large hexagon head bolt used for steel structure

The invention discloses a processing technology for a high-strength large hexagon head bolt used for a steel structure and belongs to a processing technology for a high-strength connecting piece. The high-strength large hexagon head bolt is processed by less or non cutting including one time of hot forging forming and three times of cold extrusion forming, wherein the hot forging forming is bolt rail forming. The first time of cold extrusion forming is screw forming, the second time of cold extrusion forming is upper screw thread section forming, and the third time of cold extrusion forming isthread forming. The invention mainly adopts the cold extrusion process for bolt production, improves the strength of the bolt, optimizes the production process of the bolt, overcomes the delay fracture and fatigue fracture of the high-strength bolt, ensures that the bolt is not easy to fracture in the use process and reliably connected, prolongs the service life of the bolt and can more meet theuse requirement for the high-strength large hexagon head bolt used for the steel net frame bolt ball node in modern society.

Owner:扬州狮鹤高强度螺栓有限公司

Preparation method of high-strength corrosion-resistant bolts

ActiveCN103088271BHigh strengthExtend your lifeFurnace typesMetallic material coating processesChemical compositionFatigue fractures

The invention discloses a preparation method of a high-strength anti-corrosion bolt. The preparation method comprises the following processing steps of: a, casting a rod material which comprises the following chemical components according percentage composition: 0.4%-0.8% of C, 0.02%-0.05% of Si, 0.18%-0.21% of Mn, 0.16%-0.18% of P, 0.05%-0.07% of S, 0.05%-0.15% of Cr, 0.05%-0.12% of Ti, 0.11%-0.13% of Cu, 0.01%-0.02% of Al, 0.02%-0.03% of Mg, and the balance of iron; b, performing acid pickling on the casted rod material, performing wire drawing on the rod material according to the wire diameter requirement of the bolt so as to shrink the rod material to the wire diameter required for the bolt, cutting the rod material with the shrunk wire diameter to a length required for the bolt, placing the cut rod material in a die cavity at a normal temperature, and shaping the rod material to be in the size of the head part and the rod part required for the bolt through forging force. By processing the bolt through the cold extrusion process, the preparation method of the high-strength anti-corrosion bolt provided by the invention has the effects of improving the strength of the bolt, ensuring that the hardness value and the strength value required for a 12.9 high-strength bolt are achieved, and solving the problems of delay fracture and fatigue fracture of the bolt under high strength; and the bolt is reliable for connection and less prone to breaking in use, the service life of the bolt is prolonged, and thus the use requirement on high-strength bolts in various industries in society is satisfied.

Owner:国动科技有限公司

Processing technology for high-strength bolt used for steel net frame bolt ball node

InactiveCN101549448BHigh strengthSolve fatigue fractureBoltsFurnace typesFatigue fracturesHigh intensity

The invention discloses a processing technology for a high-strength bolt used for a steel net frame bolt ball node, which belongs to a processing technology for a high-strength connecting piece. The high-strength bolt is processed by taking 40Cr as a billet by less or non cutting including three times of cold extrusion forming and one time of hot forging forming, wherein the first time of cold extrusion forming is screw forming, the second time of cold extrusion forming is upper screw thread section forming, the third time of cold extrusion forming is thread forming and the hot forging formingis bolt rail forming. The invention mainly adopts the cold extrusion process for bolt production, improves the strength of the bolt, optimizes the production process of the bolt, overcomes the delayfracture and fatigue fracture of the bolt under high strength, ensures that the bolt is not easy to fracture in the use process and reliably connected, prolongs the service life of the bolt and can more meet the use requirement for the high-strength bolt used for the steel net frame bolt ball node in modern society.

Owner:扬州狮鹤高强度螺栓有限公司

Processing technology of bolts for steel grid bolt spherical joints

The invention relates to a processing technology of bolts for steel grid bolt spherical joints. The bolts for the joints mainly comprise the components of Ni, Mo, Cr, S, P, Mn, Si, C, Re and Fe. According to the processing method of the bolts, chipless forming is adopted and comprises three times of cold extrusion molding and one time of hot forging molding, wherein the first time of cold extrusion molding is screw rod molding, the second time of cold extrusion molding is screw-rod thread segment molding, the third time of cold extrusion molding is thread molding, and the hot forging molding is screw cap molding. The processing technology mainly adopts a cold extrusion process for bolt production, improves the strength of the bolts, optimizes the production process of the bolts and solvesthe delayed fracture and fatigue fracture of the bolts under high strength, fracture does not happen easily during use, the connection is reliable, the service life of the bolts is prolonged, and userequirements of people in the current society for the high-strength bolts for the steel grid bolt spherical joints can be better met.

Owner:JIANGSU HUAHAI STEEL STRUCTURE CO LTD

Linear compressor and refrigeration equipment having same

ActiveCN106286208BResolve offsetHigh control precisionPositive displacement pump componentsPiston pumpsReciprocating motionLinear compressor

The invention provides a linear compressor and a refrigeration device with the linear compressor. The linear compressor comprises a first cylinder and a second cylinder which are arranged on the two sides inside a shell, and a first piston and a second piston corresponding to the first cylinder and the second cylinder, wherein the first piston and the second piston are fixedly connected through connecting pieces; the first piston, the second piston and the connecting pieces have hollow parts which communicate with one another inside; a linear motor enables the first piston and the second piston to perform reciprocating motion; compressed air is generated in a compression chamber; an elastic part provides elastic restoring force for the first piston and the second piston; and to-be-compressed air entering from air inlets formed in the connecting pieces is alternately compressed and discharged. According to the linear compressor, to-be-compressed air enters the compression chamber from the connecting pieces between the two pistons of the linear compressor, so that suction overheating can be reduced, and the volumetric efficiency of the compressor is improved; and the stroke is small, the service life of the two pistons is long, and the reliability is improved. The invention further provides the refrigeration device with the linear compressor.

Owner:GREE ELECTRIC APPLIANCES INC

Bolt machining method

The invention discloses a bolt machining method. The method comprises the step of S1, a rod blank is prepared through a casting process, wherein the rod blank is controlled to comprises the followingchemical components of, by weight, 0.28-0.34% of C, 0.32-0.43% of Mn, 0.18-0.25% of V, 0.15-0.25% of Si, 0.01-0.03% of W, less than or equal to 0.015% of P, less than or equal to 0.015% of S, 0.50-1.20% of Ni, 0.15-0.25% of Sn, 0.15-0.35% of Mo and the balance iron. A bolt produced by the bolt machining method reaches the hardness value and the strength value which are required by the high-strength bolt, the delay fracture and the fatigue fracture problems of the bolt under the high strength are solved, during use, connection is reliable, breakage is not prone to occurrence, the service life of the bolt is prolonged, and the use requirements of all industries in the society on the high-strength bolt are met.

Owner:重庆旺达汽车零部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com