Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Good Phosphate Film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of fastening bolt for automobile wheel

ActiveCN103088268AModerate hardnessImprove the lubrication effectThread cutting machinesBoltsChemical compositionFatigue fractures

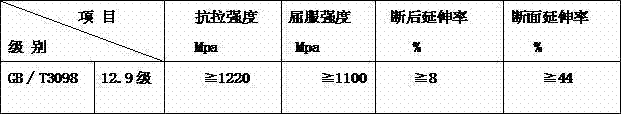

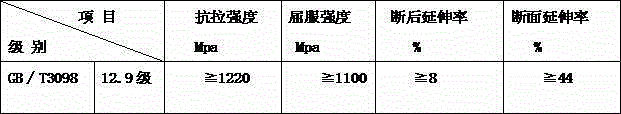

The invention discloses a preparation method of a fastening bolt for an automobile wheel. The preparation method comprises the following processing steps: a, casting a raw material, wherein the raw material comprises the following chemical components in percentage by weight: 0.4 to 0.8% of C, 0.02 to 0.05% of Si, 0.18 to 0.21% of Mn, 0.16 to 0.18% of P, 0.05 to 0.07% of S, 0.05 to 0.15% of Cr, 0.05 to 0.12% of Ti, 0.11 to 0.13% of Cu, 0.01 to 0.02% of Al, 0.02 to 0.03% of Mg, and the balance of iron; and b, scouring the casted and formed rod material; carrying out line drawing on the rod material according to the requirement of the line diameter of the bolt, so that the rod material shrinks to the line diameter required by the bolt; cutting the rod material which is shrunk to the required line diameter to the length required by the bolt; placing the cut rod material into a die cavity at normal temperature; and using upsetting force to enable the dimensions of a head part and a rod part of the rod material to reach the requirements of the bolt. According to the preparation method of the fastening bolt for the automobile wheel, the bolt is processed by cold extruding process, so that the strength of the bolt is improved, the hardness value and the strength value required by the 12.9 high-strength bolt can be realized, and the delayed fracture and the fatigue fracture of the bolt at high strength can be solved; the fastening bolt is reliable in connection and hardly broken during use, prolongs the service life, and meets the usage demand of various industries in the society to high-strength bolts.

Owner:湖北友谦汽车零部件有限公司

Preparation method for high-strength foundation bolt

InactiveCN103205641AModerate hardnessImprove the lubrication effectMetal-working apparatusSolid state diffusion coatingFatigue fracturesHigh stress

The invention discloses a preparation method for a high-strength foundation bolt. Processing steps comprise a step of casting of a rod material, wherein chemical components of a rod material blank comprise, by weight, 0.27 to 0.36% of C, 0.25 to 0.33% of Mn, 0.05 to 0.08% of V, 0.25 to 0.35% of Si, 0.01 to 0.04% of W, no more than 0.025% of P, no more than 0.035% of S, 0.45 to 0.60% of Ni, 0.20 to 0.30% of Sn and 0.45 to 0.65% of Cu, with the balance being Fe. According to the invention, a cold extruding process is used for processing of the bolt, so strength of the bolt is improved, a hardness number and a strength value required by a 12.9 high-strength bolt are reached, the problems of delayed fracture and fatigue fracture of the bolt under high stress are overcome, and the bolt has reliable connection and hardly breaks during usage, has a prolonged service life and meets usage demands for high strength bolts by a variety of industries in society.

Owner:繁昌县琪鑫铸造有限公司

Method for machining T-shaped bolt

The invention discloses a method for machining a T-shaped bolt. The method comprises the following steps of: a) casting a T-shaped rod material blank and controlling the weight percentage of all chemical components of the rod material blank to ensure that the rod material blank comprises 0.28 to 0.35 percent of C, 0.25 to 0.35 percent of Mn, 0.05 to 0.09 percent of V, 0.15 to 0.35 percent of Si, 0.01 to 0.04 percent of W, less than or equal to 0.025 percent of P, less than or equal to 0.035 percent of S, 0.55 to 1.20 percent of Ni, 0.35 to 0.45 percent of Co, 0.20 to 0.30 percent of Sb and less than or equal to 0.20 percent of Cu; according to the method for machining the T-shaped bolt, the bolt is machined by a cold extruding process, so that the intensity of the bolt is improved, the hardness value and the intensity value required by a 12.9 high-intensity bolt can be acquired, and the delayed fracture and the fatigue crack of the bolt under high intensity can be avoided; and during use, the bolt is reliable in connection, is not prone to break, and meets the using requirements of all industries in society on the high-intensity bolt; and the service life of the bolt is prolonged.

Owner:ANHUI LIUFANG ZHONGLIAN MECHANICAL SHARE

Preparation method of high-strength T-shaped bolt

InactiveCN103131948AModerate hardnessImprove the lubrication effectBoltsMedium frequencyHigh intensity

The invention discloses a preparation method of a high-strength T-shaped bolt. The preparation method is mainly characterized in that machining steps comprise T-shaped rod material casting and the like. The T-shaped rod material casting comprises that 12-14 parts by weight of waste iron are first fed into a medium frequency furnace to be melted into molten iron, when temperature inside the medium frequency furnace rises to 1000-1200 DEG C, 30-35 parts by weight of steel ingot, 30-35 parts by weight of cast iron and 12-16 parts by weight of foundry returns are then fed into the molten iron, and at the same time, a layer of warm-keeping covering agent is sprinkled on the surface of the solution for covering, then slagging is conducted, and when temperature inside the medium frequency furnace rises to 1400 DEG C for discharging, pouring is conducted. According to the preparation method of the high-strength T-shaped bolt, cold extruding technology bolt machining is adopted, so that the strength of the bolt is improved, a hardness value and a strength value needed by the high-strength bolt are achieved, and the problems of delayed fracture and fatigue fracture of the bolt under high strength are solved, and in the use process, connection is reliable, the bolt is not prone to fracture, service life of the bolt is prolonged, and use demands to the high-strength bolt in all industries in the society are satisfied.

Owner:繁昌县琪鑫铸造有限公司

Method for machining high-strength double end bolt

The invention discloses a method for machining a high-strength double end bolt. The method comprises the following steps of: a, manufacturing a rod blank, and controlling the weight percentage of each chemical component of the rod blank to meet the following requirements: 0.28 to 0.35 percent of C, 0.25 to 0.35 percent of Mn, 0.05 to 0.09 percent of V, 0.15 to 0.35 percent of Si, 0.01 to 0.04 percent of W, less than or equal to 0.025 percent of P, less than or equal to 0.035 percent of S, 0.55 to 1.20 percent of Ni, 0.35 to 0.45 percent of Co, 0.20 to 0.30 percent of Sb and less than or equal to 0.20 percent of Cu; and b, forging a cast rod at the temperature of between 850 and 800 DEG C for not more than 20 times, wherein a thin layer of fly ash is coated on the inner wall of an impression of a forging die; and turning an external thread at each of two ends of the bolt by using a precision lathe after forging. According to the method for machining the high-strength double end bolt, the bolt is machined by adopting a cold extrusion process, so that the strength of the bolt is improved, the hardness value and the strength value required by the 12.9 high-strength bolt are achieved, the problems of delayed fracture and fatigue fracture of the bolt under high strength are solved, the bolt is reliable in connection during use and difficult to break, the service life of the bolt is prolonged, and the using requirement of each industry in the society for the high-strength bolt is met.

Owner:ANHUI LIUFANG ZHONGLIAN MECHANICAL SHARE

Preparation method of fracture-resistant steel rope bolt

InactiveCN103131954AModerate hardnessImprove the lubrication effectMetal-working apparatusSolid state diffusion coatingChemical compositionFatigue fractures

The invention discloses a preparation method of a fracture-resistant steel rope bolt. The process includes following steps: a. casting rod material, wherein a blank of the rod material comprises, in terms of chemical component, by weight, 0.132%-0.260% of C, 0.62%-1.30% of Si, 0.25%-0.35% of Mn, 0.010%-0.030% of P, 0.010%-0.030% of S, 1.10%-1.50% of Cr, trace quantity-0.0018% of B, 0.012%-0.030% of Cu, and the balances are Fe and inevitable impurities; b. washing the rod material after casting molding in acid, conducting thread drawing for the rod material according to the requirement of thread diameter of the bolt to enable the rod material to shrink to the required thread diameter, cutting the rod material after thread diameter shrinks to the required length of the bolt, placing the cutting-off rod material into a mould shaped cavity which is covered by plant ashes at normal temperature, enabling the rod material to form a required head part and required size of a rod part of the bolt by applying upset forging force, and making screw threads on the periphery face of the rod part of the rod material through turning by using a precision lathe. According to the preparation method of the fracture-resistant steel rope bolt, cold extrusion process is applied to process the bolt, so that the strength of the bolt is improved, required hardness and strength of a high-strength bolt are reached, and the problem that delayed fracture and fatigue fracture of the bolt under high strength is solved. The bolt is reliable to use in connection, not easy to break, and the service life of the bolt is prolonged.

Owner:繁昌县琪鑫铸造有限公司

Preparation method of high-strength steel cable bolt

The invention discloses a preparation method of a high-strength steel cable bolt. The method includes the following steps: casting a rod material, throwing 10-14 parts by weight of waste steel into a medium frequency furnace, enabling the steel to be melted into liquid steel, adding a carbon addition agent, throwing 30-35 parts by weight of steel ingot, 30-35 parts by weight of cast iron and 12-16 parts by weight of returns into the medium frequency furnace after temperature in the medium frequency furnace is increased to 1120-1220 DEG C, conducting slagging and adding 0.4-0.6 part by weight of copper and liquid iron into a ladle to conduct pouring when temperature in the medium frequency furnace increases to 1450 DEG C and the iron is discharged. The preparation method of the high-strength steel cable bolt adopts the cold extrusion process to process the bolt, improves bolt strength, achieves the hardness and the strength required by 12.9 high-strength bolt, resolves the problems of delaying breaking and fatigue breaking of the bolt under high strength, prolongs service life of the bolt due to the fact that the bolt is reliable in connection and not easy to break in use, and meets using requirements of social industries for the high-strength bolt.

Owner:青龙船务工程(南通)有限公司

Method for machining high-strength U-shaped bolt

ActiveCN103084523AModerate hardnessImprove the lubrication effectMetal-working apparatusBoltsChemical compositionGranularity

The invention discloses a method for machining a high-strength U-shaped bolt. The method comprises the following steps of: a, casting a U-shaped rod blank, and controlling the weight percentage of each chemical component of the rod blank to meet the following requirements: 0.28 to 0.35 percent of C, 0.25 to 0.35 percent of Mn, 0.05 to 0.09 percent of V, 0.15 to 0.35 percent of Si, 0.01 to 0.04 percent of W, less than or equal to 0.025 percent of P, less than or equal to 0.035 percent of S, 0.55 to 1.20 percent of Ni, 0.35 to 0.45 percent of Co, 0.20 to 0.30 percent of Sn, less than or equal to 0.20 percent of Al and the balance of iron; and b, forging a cast U-shaped rod at the temperature of between 650 and 700 DEG C for not more than 25 times, wherein a thin layer of graphite powder is coated on the inner wall of an impression of a forging die, and the granularity of the graphite powder is controlled to be 200 to 300 meshes; and turning an external thread of the bolt by using a precision lathe after forging. According to the method for machining the high-strength U-shaped bolt, the bolt is machined by adopting a cold extrusion process, so that the strength of the bolt is improved, the hardness value and the strength value required by the 12.9 high-strength bolt are achieved, the problems of delayed fracture and fatigue fracture of the bolt under high strength are solved, the bolt is reliable in connection during use and difficult to break, the service life of the bolt is prolonged, and the using requirement of each industry in the society for the high-strength bolt is met.

Owner:舟山德玛吉实业有限公司

Preparation method of high-strength aluminum alloy flange bolt

The invention discloses a preparation method of a high-strength aluminum alloy flange bolt. Machining steps comprise rod material casting and the like. The rod material casting comprises that 11-14 parts by weight of waste aluminum sectional materials are first fed into a medium frequency furnace to be melted into molten steel, carbon adding agents are then added into the molten steel, when temperature inside the medium frequency furnace rises to 650-700 DEG C, 32-42 parts by weight of A356 aluminium ingot, 30-35 parts by weight of cast iron and 12-16 parts by weight of foundry returns are then fed and at the same time, a layer of warm-keeping covering agent is sprinkled on the surface of the solution for covering, then slagging is conducted, after the slagging, alloy is added, and when temperature inside the medium frequency furnace rises to 1400 DEG C for discharging, pouring is conducted. According to the preparation method of the high-strength aluminum alloy flange bolt, cold extruding technology is adopted to machine the bolt, so that the strength of the bolt is improved, a hardness value and a strength value needed by the high-strength bolt are satisfied, and the problems of delayed fracture and fatigue fracture of the bolt under high strength are solved, and in the use process, connection is reliable, the bolt is not prone to fracture, service life of the bolt is prolonged, and use demands to the high-strength bolt in all industries in the society are satisfied.

Owner:繁昌县琪鑫铸造有限公司

Processing method for high-class bolt

ActiveCN103028685AModerate hardnessImprove the lubrication effectMetal-working apparatusBoltsChemical compositionHigh intensity

The invention discloses a processing method for a high-class bolt. The processing method comprises the following steps: a) casting a rod blank and controlling the weight percent of all chemical components of the rod blank as follows: 0.27-0.34% of C, 0.45-0.65% of Mn, 0.05-0.15% of V, 0.15-0.35% of Si, 0.01-0.04% of W, less than or equal to 0.025% of P, less than or equal to 0.025% of S, 1.55-2.00% of Ni, 0.65-0.95% of Co, 0.20-0.30% of Sn and less than or equal to 0.20% of Cu. According to the processing method for the high-class bolt provided by the invention, a cold extrusion process is adopted for processing the bolt, so that the strength of the bolt is increased, the hardness value and strength value required by the bolt with the strength being 12.9 are achieved, the problems of delay breakage and fatigue breakage of the bolt under high strength are solved, the connection is reliable during a use process, the bolt is difficult to break, the service life of the bolt is prolonged and the use requirement for the high-strength bolt in various industries is met.

Owner:ANHUI LIUFANG ZHONGLIAN MECHANICAL SHARE

Preparation method of lengthened bolt

ActiveCN103088267AHigh strengthResolving Delayed FracturesThread cutting machinesBoltsChemical compositionFatigue fractures

The invention discloses a preparation method of a lengthened bolt. The preparation method is characterized by comprising the following processing steps of: a, preparing a rod blank through a casting technology, wherein the rod blank comprises the following chemical components in percentage by weight: 0.25%-0.35% of C, 0.08%-0.15% of Mn, 0.05%-0.15% of Si, 0.01%-0.04% of W, no less than 0.015% and no more than 0.025% of P, no less than 0.015% and no more than 0.035% of S, 0.15%-0.20% of Ni, 0.025%-0.045% of Zn, 0.02%-0.03% of Sn, no more than 0.02% of Cr, and the balance of iron. The preparation method of the lengthened bolt disclosed by the invention has the beneficial effect of improving the strength of the bolt by processing the bolt through a cold extrusion process, the hardness value and the strength value required for a 12.9 high-strength bolt are achieved, the problems of delayed fracture and fatigue fracture of the bolt under high strength are solved, the bolt is reliable for connection and less prone to breaking in use, the service life of the bolt is prolonged, and the use requirement on the high-strength bolt in various industries in society is satisfied.

Owner:重庆冠鹏机车部件有限公司

Method for machining connection rod bolt of diesel engine

InactiveCN103084525AHigh strengthResolving Delayed FracturesMetal-working apparatusBoltsChemical compositionHardness

The invention discloses a method for machining a connection rod bolt of a diesel engine. The method comprises the following steps of: manufacturing a rod material blank, and controlling the weight percentage of all chemical components of the rod material blank to ensure that the rod material blank comprises 0.28 to 0.32 percent of C, 0.35 to 0.45 percent of Mn, 0.05 to 0.15 percent of V, 0.15 to 0.35 percent of Si, 0.01 to 0.04 percent of W, less than or equal to 0.025 percent of P, less than or equal to 0.035 percent of S, 0.55 to 1.20 percent of Ni, 0.35 to 0.45 percent of Co, 0.20 to 0.30 percent of Sn and less than or equal to 0.20 percent of Cu. According to the method for machining the connection rod bolt of the diesel engine, the bolt is machined by a cold extruding process, so that the intensity of the bolt is improved, the hardness value and the intensity value which are required by a 12.9 high-intensity bolt can be acquired, and the delayed fracture and fatigue crack of the bolt under high intensity can be overcome; the bolt is reliable in connection during use, and is not prone to break and crack; the service life of the bolt is prolonged; and the using requirements of all industries in society on the high-intensity bolt can be met.

Owner:佛山顺恒鑫科技实业有限公司

Method for manufacturing abrasion-resistant foundation bolt

The invention discloses a method for manufacturing an abrasion-resistant foundation bolt. Machining steps include: casting a rod, by weight, adding 12-14 parts of scrap iron into a medium frequency furnace to melt to form molten iron, adding carburant, when the temperature in the medium frequency furnace rises to 1000-1220 DEG C, adding 0.1-0.2 part of molybdenum, 30-35 parts of steel ingot, 30-35 parts of scrap steel and 12-16 parts of foundry returns, simultaneously scattering a layer of heat preservation covering agent on the surface of the melt and covering, slagging, after slagging, adding 0.5-0.8 part of ferro-nickel alloy and 1-2 parts of ferrosilicon alloy, when the temperature in the medium frequency furnace rises to 1450 DEG C, withdrawing, adding 0.4-0.6 part of magnesium powder along with molten iron into a ladle, and casting. The method adopts cold extrusion process to machine the bolt, the strength of the bolt is improved, hardness and strength required by the 12.9 high-strength bolt are met, and delayed fracture and fatigue fracture of the bolt under high strength are avoided. The bolt is reliable in connection and not prone to break, prolongs service life, and meets use requirements of various industries in society for the high-strength bolt.

Owner:浙江同力重型机械制造有限公司

Method for manufacturing abrasion-resistant U-shaped bolt

The invention discloses a method for manufacturing an abrasion-resistant U-shaped bolt. Machining steps include: casting a U-shaped rod, by weight, adding 11-14 parts of scrap steel into a medium frequency furnace to melt to form molten steel, adding carburant, when the temperature in the medium frequency furnace rises to 1120-1220 DEG C, adding 0.1-0.2 part of molybdenum, 0.2-0.3 part of magnesium ingot, 5-7 parts of scrap aluminum, 32-34 parts of steel ingot, 30-35 parts of pig iron and 12-16 parts of foundry returns, simultaneously scattering a layer of heat preservation covering agent on the surface of the melt and covering, slagging, after slagging, adding 0.6-0.9 part of ferromanganese and 2-3 parts of ferrosilicon alloy, when the temperature in the medium frequency furnace rises to 1400 DEG C, withdrawing, adding 0.4-0.6 part of copper along with molten iron into a ladle, and casting. The method adopts cold extrusion process to machine the bolt, the strength of the bolt is improved, hardness and strength required by the 12.9 high-strength bolt are met, and delayed fracture and fatigue fracture of the bolt under high strength are avoided. The bolt is reliable in connection and not prone to break, prolongs service life, and meets use requirements of various industries in society for the high-strength bolt.

Owner:浙江艾信汽车零部件股份有限公司

Method for machining T-shaped bolt

ActiveCN103084532BModerate hardnessImprove the lubrication effectBoltsChemical compositionHigh intensity

Owner:ANHUI LIUFANG ZHONGLIAN MECHANICAL SHARE

Method for machining high-strength double end bolt

The invention discloses a method for machining a high-strength double end bolt. The method comprises the following steps of: a, manufacturing a rod blank, and controlling the weight percentage of each chemical component of the rod blank to meet the following requirements: 0.28 to 0.35 percent of C, 0.25 to 0.35 percent of Mn, 0.05 to 0.09 percent of V, 0.15 to 0.35 percent of Si, 0.01 to 0.04 percent of W, less than or equal to 0.025 percent of P, less than or equal to 0.035 percent of S, 0.55 to 1.20 percent of Ni, 0.35 to 0.45 percent of Co, 0.20 to 0.30 percent of Sb and less than or equal to 0.20 percent of Cu; and b, forging a cast rod at the temperature of between 850 and 800 DEG C for not more than 20 times, wherein a thin layer of fly ash is coated on the inner wall of an impression of a forging die; and turning an external thread at each of two ends of the bolt by using a precision lathe after forging. According to the method for machining the high-strength double end bolt, the bolt is machined by adopting a cold extrusion process, so that the strength of the bolt is improved, the hardness value and the strength value required by the 12.9 high-strength bolt are achieved, the problems of delayed fracture and fatigue fracture of the bolt under high strength are solved, the bolt is reliable in connection during use and difficult to break, the service life of the bolt is prolonged, and the using requirement of each industry in the society for the high-strength bolt is met.

Owner:ANHUI LIUFANG ZHONGLIAN MECHANICAL SHARE

Method for forging torsional shear type high-strength bolt

ActiveCN103084533BModerate hardnessImprove the lubrication effectBoltsUltimate tensile strengthMaterials science

The invention discloses a method for forging a torsional shear type high-strength bolt. The method comprises the step of: manufacturing a rod blank by a casting process, wherein the rod blank comprises the following chemical ingredients in percentage by weight: 0.25 to 0.35 percent of C, 0.15 to 0.25 percent of Mn, 0.15 to 0.35 percent of Si, 0.01 to 0.04 percent of W, less than or equal to 0.025 and more than or equal to 0.015 percent of P, less than or equal to 0.035 and more than or equal to 0.015 percent of S, 0.15 to 0.20 percent of Ni, 0.025 to 0.045 percent of Zn, 0.02 to 0.03 percent of Sn, less than or equal to 0.02 percent of Cr and the balance of Fe. According to the method for forging the torsional shear type high-strength bolt, the bolt is machined by using a cold extrusion process, so that the strength of the bolt is enhanced, a hardness value and a strength value which are required by the high-strength bolt of which the strength is 12.9 are reached, and the delayed breakage and fatigue breakage of the bolt are avoided under high strength; and the torsional shear type high-strength bolt is reliable in connection and difficult to break in the using process, so that the service life of the bolt is prolonged, and the using demand of each industry in society on the high-strength bolt is met.

Owner:ANHUI LIUFANG ZHONGLIAN MECHANICAL SHARE

Processing method of high-grade bolts

ActiveCN103028685BModerate hardnessImprove the lubrication effectMetal-working apparatusBoltsChemical compositionUltimate tensile strength

The invention discloses a processing method for a high-class bolt. The processing method comprises the following steps: a) casting a rod blank and controlling the weight percent of all chemical components of the rod blank as follows: 0.27-0.34% of C, 0.45-0.65% of Mn, 0.05-0.15% of V, 0.15-0.35% of Si, 0.01-0.04% of W, less than or equal to 0.025% of P, less than or equal to 0.025% of S, 1.55-2.00% of Ni, 0.65-0.95% of Co, 0.20-0.30% of Sn and less than or equal to 0.20% of Cu. According to the processing method for the high-class bolt provided by the invention, a cold extrusion process is adopted for processing the bolt, so that the strength of the bolt is increased, the hardness value and strength value required by the bolt with the strength being 12.9 are achieved, the problems of delay breakage and fatigue breakage of the bolt under high strength are solved, the connection is reliable during a use process, the bolt is difficult to break, the service life of the bolt is prolonged and the use requirement for the high-strength bolt in various industries is met.

Owner:ANHUI LIUFANG ZHONGLIAN MECHANICAL SHARE

Anti-fracture bolt forging method

The invention discloses a method for forging a fracture-resistant bolt. The method comprises the following steps of: a) casting a U-shaped rod material blank, and controlling the weight percentage of all chemical components of the rod material blank to ensure that the fracture-resistant bolt comprises 0.28 to 0.35 percent of C, 0.25 to 0.35 percent of Mn, 0.05 to 0.09 percent of V, 0.15 to 0.35 percent of Si, 0.01 to 0.04 percent of W, less than or equal to 0.025 percent of P, less than or equal to 0.035 percent of S, 0.55 to 1.20 percent of Ni, 0.35 to 0.45 percent of Co, 0.20 to 0.30 percent of Sn, and less than or equal to 0.20 percent of Al; and b) forging and forming the U-shaped rod material formed by forging, wherein the forging temperature is controlled to be 650 to 700 DEG C, thin-layered graphite powder covers on the inner wall of an impression of the forging die, the particle size of the graphite powder is controlled to be 200 to 300 meshes, and the forging frequency is less than or equal to 25 times, and turning an outer thread of the bolt by using a fine turning lathe after forging and forming. According to the method for forging the fracture-resistant bolt, the bolt is machined by a cold extruding process, so that the intensity of the bolt is improved, the harness value and the intensity value which are required by a 12.9 high-intensity bolt can be acquired, and the delayed fracture and the fatigue fracture of the bolt under high intensity are avoided; during use, the bolt is reliable in connection, is not prone to break, and meets the using requirements of all industries in the society on the high-intensity bolt; and the service life of the bolt is prolonged.

Owner:淮安倍特锻造有限公司

Preparation method of fastening bolts for automobile wheels

ActiveCN103088268BModerate hardnessImprove the lubrication effectThread cutting machinesBoltsChemical compositionHardness

The invention discloses a preparation method of a fastening bolt for an automobile wheel. The preparation method comprises the following processing steps: a, casting a raw material, wherein the raw material comprises the following chemical components in percentage by weight: 0.4 to 0.8% of C, 0.02 to 0.05% of Si, 0.18 to 0.21% of Mn, 0.16 to 0.18% of P, 0.05 to 0.07% of S, 0.05 to 0.15% of Cr, 0.05 to 0.12% of Ti, 0.11 to 0.13% of Cu, 0.01 to 0.02% of Al, 0.02 to 0.03% of Mg, and the balance of iron; and b, scouring the casted and formed rod material; carrying out line drawing on the rod material according to the requirement of the line diameter of the bolt, so that the rod material shrinks to the line diameter required by the bolt; cutting the rod material which is shrunk to the required line diameter to the length required by the bolt; placing the cut rod material into a die cavity at normal temperature; and using upsetting force to enable the dimensions of a head part and a rod part of the rod material to reach the requirements of the bolt. According to the preparation method of the fastening bolt for the automobile wheel, the bolt is processed by cold extruding process, so that the strength of the bolt is improved, the hardness value and the strength value required by the 12.9 high-strength bolt can be realized, and the delayed fracture and the fatigue fracture of the bolt at high strength can be solved; the fastening bolt is reliable in connection and hardly broken during use, prolongs the service life, and meets the usage demand of various industries in the society to high-strength bolts.

Owner:湖北友谦汽车零部件有限公司

Preparation method of wear-resistant U-bolt

ActiveCN103133485BModerate hardnessImprove the lubrication effectScrewsFerrosiliconMaterials science

Owner:浙江艾信汽车零部件股份有限公司

Preparation method of high-strength steel cable bolts

The invention discloses a preparation method of a high-strength steel cable bolt. The method includes the following steps: casting a rod material, throwing 10-14 parts by weight of waste steel into a medium frequency furnace, enabling the steel to be melted into liquid steel, adding a carbon addition agent, throwing 30-35 parts by weight of steel ingot, 30-35 parts by weight of cast iron and 12-16 parts by weight of returns into the medium frequency furnace after temperature in the medium frequency furnace is increased to 1120-1220 DEG C, conducting slagging and adding 0.4-0.6 part by weight of copper and liquid iron into a ladle to conduct pouring when temperature in the medium frequency furnace increases to 1450 DEG C and the iron is discharged. The preparation method of the high-strength steel cable bolt adopts the cold extrusion process to process the bolt, improves bolt strength, achieves the hardness and the strength required by 12.9 high-strength bolt, resolves the problems of delaying breaking and fatigue breaking of the bolt under high strength, prolongs service life of the bolt due to the fact that the bolt is reliable in connection and not easy to break in use, and meets using requirements of social industries for the high-strength bolt.

Owner:青龙船务工程(南通)有限公司

Preparation method of anti-yield anchor bolts

The invention discloses a manufacturing method of an anti-yield foundation bolt. A processing step includes: a, casting a rod blank, wherein the rod blank comprises chemical components, by weight, 0.196%<=C<=0.250%, 0.20%<=Si<=1.90%, 0.35%<=Mn<=1.35%, 0.010%<=P<=0.030%, 0.010%<=S<=0.030%, 1.50%<=Cr<=1.50%, trace amount <=B<=0.0018%, 0.012%<=Cu<=0.030% and the balance Ferrum and inevitable impurities; and cooling temperature of casting molded blank to 350 DEG C, heating to 670-780 DEG C, keeping warm for 3-5 hours, cooling a furnace to 300 DEG C, keeping warm for 3 hours, heating to 650-760 DEG C, keeping warm for 10 hours, cooling to 400 DEG C at 45 DEG C / hour, and cooling to 150 DEG C at 25 DEG C / hour. The manufacturing method of the anti-yield foundation bolt adopts cold extrusion technology bolt processing, improves strength of the bolt, reaches a hardness value and a strength value required by the anti-yield foundation bolt, solves delay breakage and fatigue breakage of the bolt under high strength, is reliable to connect in use and not prone to break, prolongs service life of the bolt, and meets using requirements of various industries in society on high-strength bolts.

Owner:浙江同力重型机械制造有限公司

Forging method of anchor bolts

ActiveCN103088266BModerate hardnessImprove the lubrication effectBoltsFurnace typesFatigue fracturesMaterials science

Owner:NANTONG QIANQIANHUI CHEM

Flange bolt forging method

ActiveCN103084524BModerate hardnessImprove the lubrication effectMetal-working apparatusBoltsGranularityThin layer

The invention discloses a method for forging a flange bolt. The method comprises the following machining steps of: (a) manufacturing a rod blank by a casting process, wherein the rod blank comprises the following chemical ingredients in percentage by weight: 0.25 to 0.35 percent of C, 0.15 to 0.25 percent of Mn, 0.15 to 0.35 percent of Si, 0.01 to 0.04 percent of W, less than or equal to 0.025 and more than or equal to 0.015 percent of P, less than or equal to 0.035 and more than or equal to 0.015 percent of S, 0.15 to 0.20 percent of Ni, 0.025 to 0.045 percent of Ba, 0.02 to 0.03 percent of Sn, less than or equal to 0.02 percent of Mg and the balance of Fe; and (b) casting a cast rod for forming, forging at the temperature of between 600 and 650 DEG C for less than or equal to 25 times, covering thin-layer plant ash on the inner wall of a die cavity of a forging die, and turning the forged rod by utilizing a precision lathe to form external threads of the bolt, wherein the granularity of the plant ash is 200 to 300 meshes. According to the method for forging the flange bolt, the bolt is machined by using a cold extrusion process, so that the strength of the bolt is enhanced, a hardness value and a strength value which are required by the high-strength bolt of which the strength is 12.9 are reached, and the delayed breakage and fatigue breakage of the bolt under high strength are avoided; and the flange bolt is reliable in connection and difficult to break in the using process, so that the service life of the bolt is prolonged, and the using requirement of each industry in society on the high-strength bolt is met.

Owner:ANHUI LIUFANG ZHONGLIAN MECHANICAL SHARE

Preparation method of extended bolt

ActiveCN103088267BModerate hardnessImprove the lubrication effectThread cutting machinesBoltsMetallurgyMaterials science

The invention discloses a preparation method of a lengthened bolt. The preparation method is characterized by comprising the following processing steps of: a, preparing a rod blank through a casting technology, wherein the rod blank comprises the following chemical components in percentage by weight: 0.25%-0.35% of C, 0.08%-0.15% of Mn, 0.05%-0.15% of Si, 0.01%-0.04% of W, no less than 0.015% and no more than 0.025% of P, no less than 0.015% and no more than 0.035% of S, 0.15%-0.20% of Ni, 0.025%-0.045% of Zn, 0.02%-0.03% of Sn, no more than 0.02% of Cr, and the balance of iron. The preparation method of the lengthened bolt disclosed by the invention has the beneficial effect of improving the strength of the bolt by processing the bolt through a cold extrusion process, the hardness value and the strength value required for a 12.9 high-strength bolt are achieved, the problems of delayed fracture and fatigue fracture of the bolt under high strength are solved, the bolt is reliable for connection and less prone to breaking in use, the service life of the bolt is prolonged, and the use requirement on the high-strength bolt in various industries in society is satisfied.

Owner:重庆冠鹏机车部件有限公司

Processing method of connecting rod bolts of diesel engine

InactiveCN103084525BModerate hardnessImprove the lubrication effectMetal-working apparatusBoltsChemical compositionHigh intensity

The invention discloses a method for machining a connection rod bolt of a diesel engine. The method comprises the following steps of: manufacturing a rod material blank, and controlling the weight percentage of all chemical components of the rod material blank to ensure that the rod material blank comprises 0.28 to 0.32 percent of C, 0.35 to 0.45 percent of Mn, 0.05 to 0.15 percent of V, 0.15 to 0.35 percent of Si, 0.01 to 0.04 percent of W, less than or equal to 0.025 percent of P, less than or equal to 0.035 percent of S, 0.55 to 1.20 percent of Ni, 0.35 to 0.45 percent of Co, 0.20 to 0.30 percent of Sn and less than or equal to 0.20 percent of Cu. According to the method for machining the connection rod bolt of the diesel engine, the bolt is machined by a cold extruding process, so that the intensity of the bolt is improved, the hardness value and the intensity value which are required by a 12.9 high-intensity bolt can be acquired, and the delayed fracture and fatigue crack of the bolt under high intensity can be overcome; the bolt is reliable in connection during use, and is not prone to break and crack; the service life of the bolt is prolonged; and the using requirements of all industries in society on the high-intensity bolt can be met.

Owner:佛山顺恒鑫科技实业有限公司

Preparation method of high-strength excavator bolts

ActiveCN103203593BModerate hardnessImprove the lubrication effectChemical compositionFatigue fractures

The invention discloses a method for manufacturing bolts for a high-strength excavator. The manufacturing process includes rod material blank casting, wherein the rod material blank comprises the follow chemical components by weight: 0.221%<=C<=0.262%, 0.32%<=Si<=0.90%, 0.25%<=Mn<=0.35%, 0.013%<=P<=0.030%, 0.023%<=S<=0.030%, 20%<=Cr<=1.50%, trace<=B<=0.0018%, 0.012%<=Cu<=0.030%, and the allowance of iron and inevitable impurities. By means of the method, the bolts are processed through a cold extrusion process, so that the strength of the bolts are improved, the required hardness value and strength value of the high-strength bolts can be achieved, delayed fracture and fatigue fracture of the bolts under high strength can be avoided, the bolts can be connected reliably and are not apt to be broken during usage, the service life of the bolts are prolonged, and the using requirements on the high-strength bolts in all industries of the society can be met.

Owner:浙江艾信汽车零部件股份有限公司

High Strength Bolt Forging Method

ActiveCN103084798BModerate hardnessImprove the lubrication effectMetal-working apparatusFurnace typesFatigue fracturesGranularity

The invention discloses a method for forging a high-strength bolt. The method comprises the following steps of: a, manufacturing a rod blank through a casting process, and controlling the weight percentage of each chemical component of the rod blank to meet the following requirements: 0.28 to 0.35 percent of C, 0.15 to 0.25 percent of Mn, 0.15 to 0.35 percent of Si, 0.01 to 0.04 percent of W, more than or equal to 0.015 and less than or equal to 0.025 percent of P, more than or equal to 0.015 and less than or equal to 0.035 percent of S, 0.15 to 0.20 percent of Ni, 0.025 to 0.045 percent of Ba, 0.02 to 0.03 percent of Sn, less than or equal to 0.02 percent of Mg and the balance of iron; and b, forging a cast rod at the temperature of between 630 and 680 DEG C for not more than 25 times, wherein a thin layer of graphite powder is coated on the inner wall of an impression of a forging die, and the granularity of the graphite powder is controlled to be 200 to 300 meshes; and turning an external thread of the bolt by using a precision lathe after forging. According to the method for forging the high-strength bolt, the bolt is machined by adopting a cold extrusion process, so that the strength of the bolt is improved, the hardness value and the strength value required by the 12.9 high-strength bolt are achieved, the problems of delayed fracture and fatigue fracture of the bolt under high strength are solved, the bolt is reliable in connection during use and difficult to break, the service life of the bolt is prolonged, and the using requirement of each industry in the society for the high-strength bolt is met.

Owner:NANTONG QIANQIANHUI CHEM

Preparation method of fastening bolt

InactiveCN111254365AHigh strengthResolving Delayed FracturesSolid state diffusion coatingFurnace typesMachiningMaterials science

The invention discloses a preparation method of a fastening bolt. The preparation method comprises the following processing steps of a, casting a rod material, and controlling the following chemical components in percentage by weight of 0.4%-0.8% of C, 0.02%-0.05% of Si, 0.18%-0.21% of Mn, 0.16%-0.18% of P, 0.05%-0.07% of S, 0.05%-0.15% of Cr, 0.05%-0.12% of Ti, 0.11%-0.13% of Cu, 0.01%-0.02% of Al, 0.02%-0.03% of Mg and the balance iron; and b, carrying out acid pickling treatment on the rod material subjected to casting molding, conducting wire drawing according to the wire diameter requirement of the bolt so that the rod material is shrunk to the wire diameter required by the bolt, cutting off the rod material with the shrunk wire diameter to the length needed by the bolt, placing the cut-off rod material in a mold cavity at the normal temperature, and using upsetting force to enable the rod material to form the head and rod part sizes needed by the bolt. According to the preparation method of the fastening bolt, a cold extrusion process is adopted for bolt machining, the strength of the bolt is improved, the hardness value and the strength value needed by the 12.9 high-strengthbolt are achieved, delayed fracture and fatigue fracture of the bolt under high strength are avoided, connection is reliable and not prone to fracture in the using process, the service life of the bolt is prolonged, and the use requirements of various industries in society on the high-strength bolt are met.

Owner:余姚市晶易光伏发电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com