Connector-free steel and ultrahigh-performance concrete combined bridge deck structure and construction method thereof

An ultra-high-performance, combined bridge deck technology, applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the problems of heavy welding workload of shear connectors, cumbersome construction technology, and difficult repair, etc., to solve the fatigue of steel structures The effect of breaking, simplifying the dismantling process, and reducing the difficulty of repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

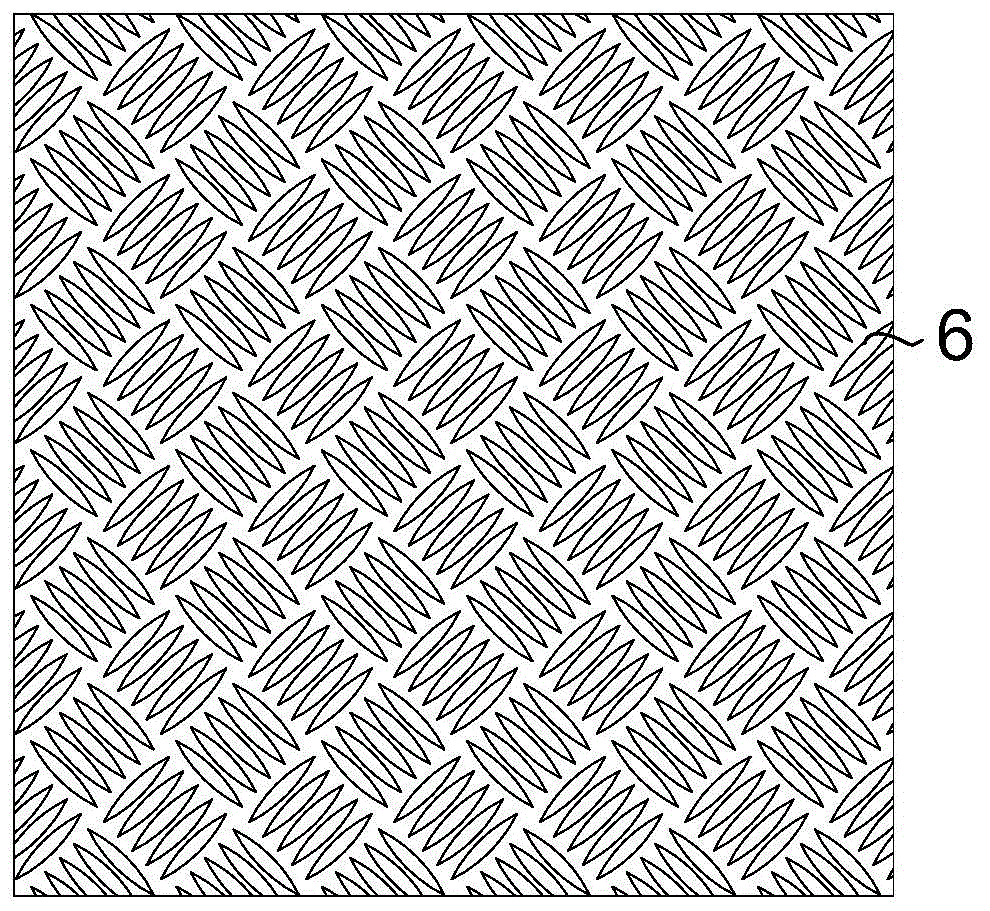

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. The steel-ultra-high-performance concrete composite bridge deck structure without connectors of the present invention comprises a steel bridge deck 1, an ultra-high-performance concrete layer 2, a deck pavement layer 3, longitudinal stiffeners 4, and transverse stiffeners 5. The ultra-high performance concrete layer 2 is laid on the top of the steel bridge deck, and the bridge deck pavement layer 3 is laid on the top of the ultra-high performance concrete layer 2; the upper surface of the steel bridge deck is provided with raised patterns 6, and the lower part of the steel bridge deck is provided with longitudinal stiffeners 4 with transverse stiffeners 5 . Such as figure 1 , 2 shown.

[0022] The ultra-high-performance concrete layer 2 is cast from ultra-high-performance concrete, and steel bars may also be provided therein, which is benef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com