Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Smooth operation at high speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

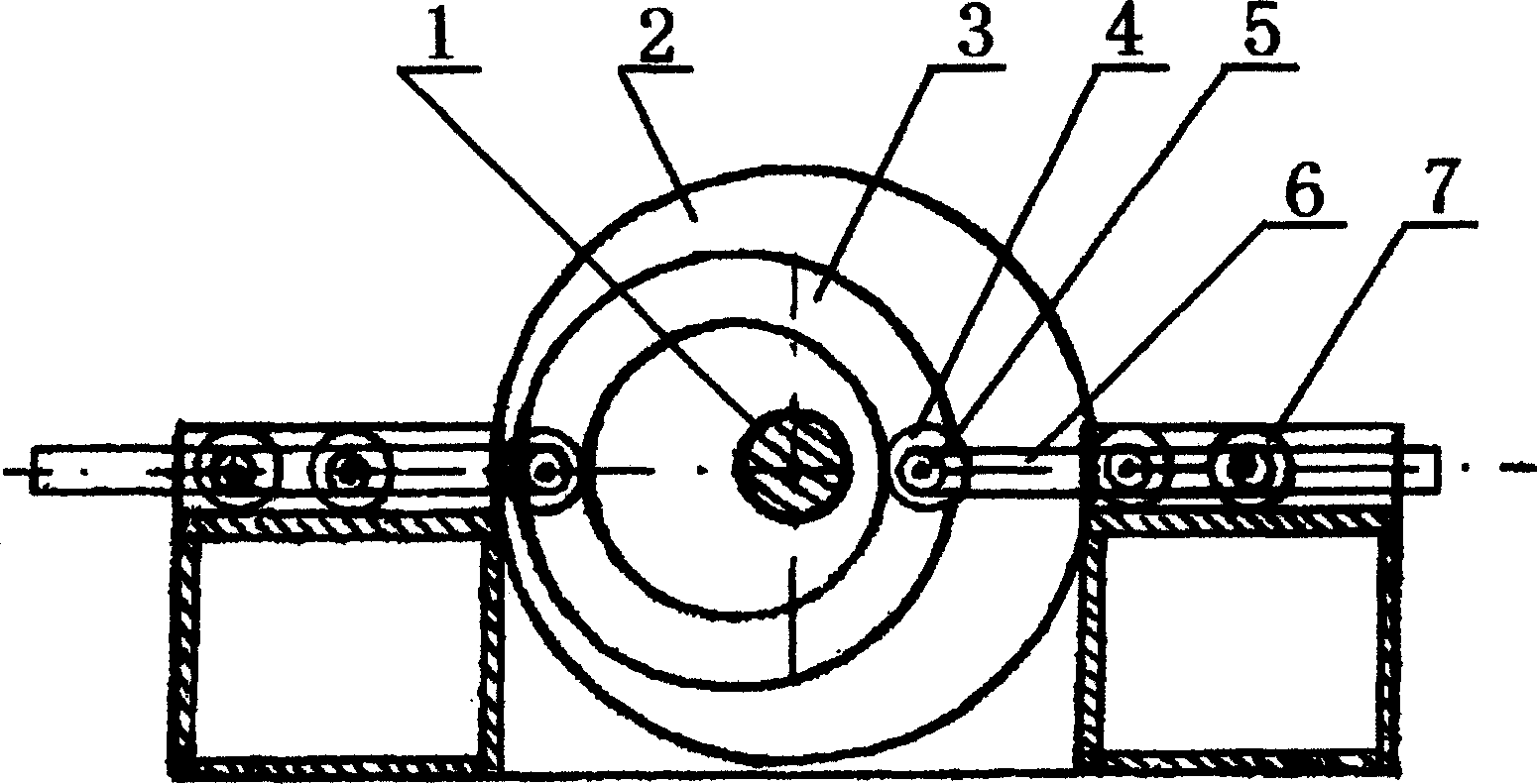

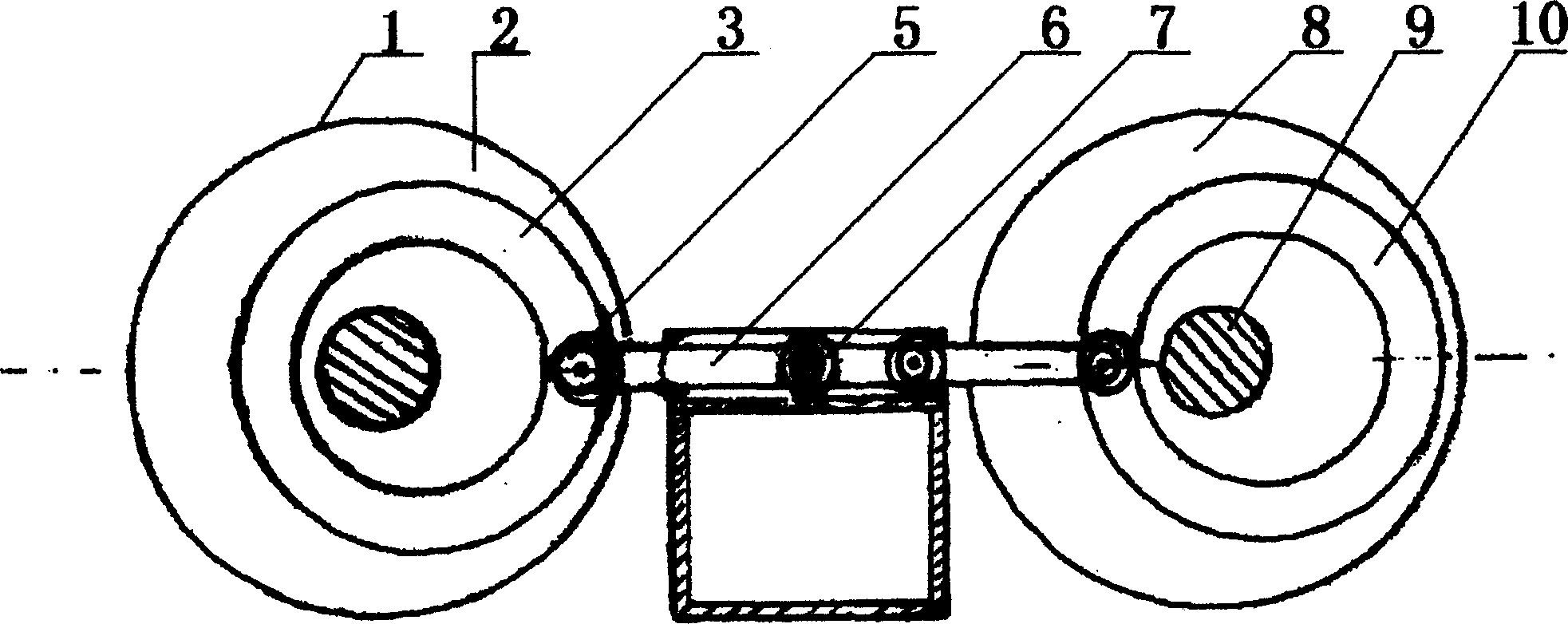

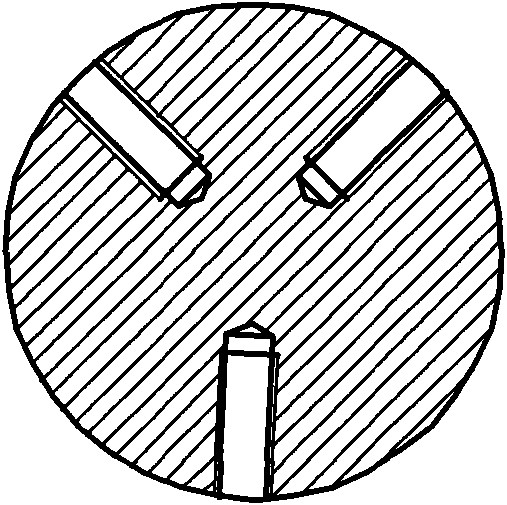

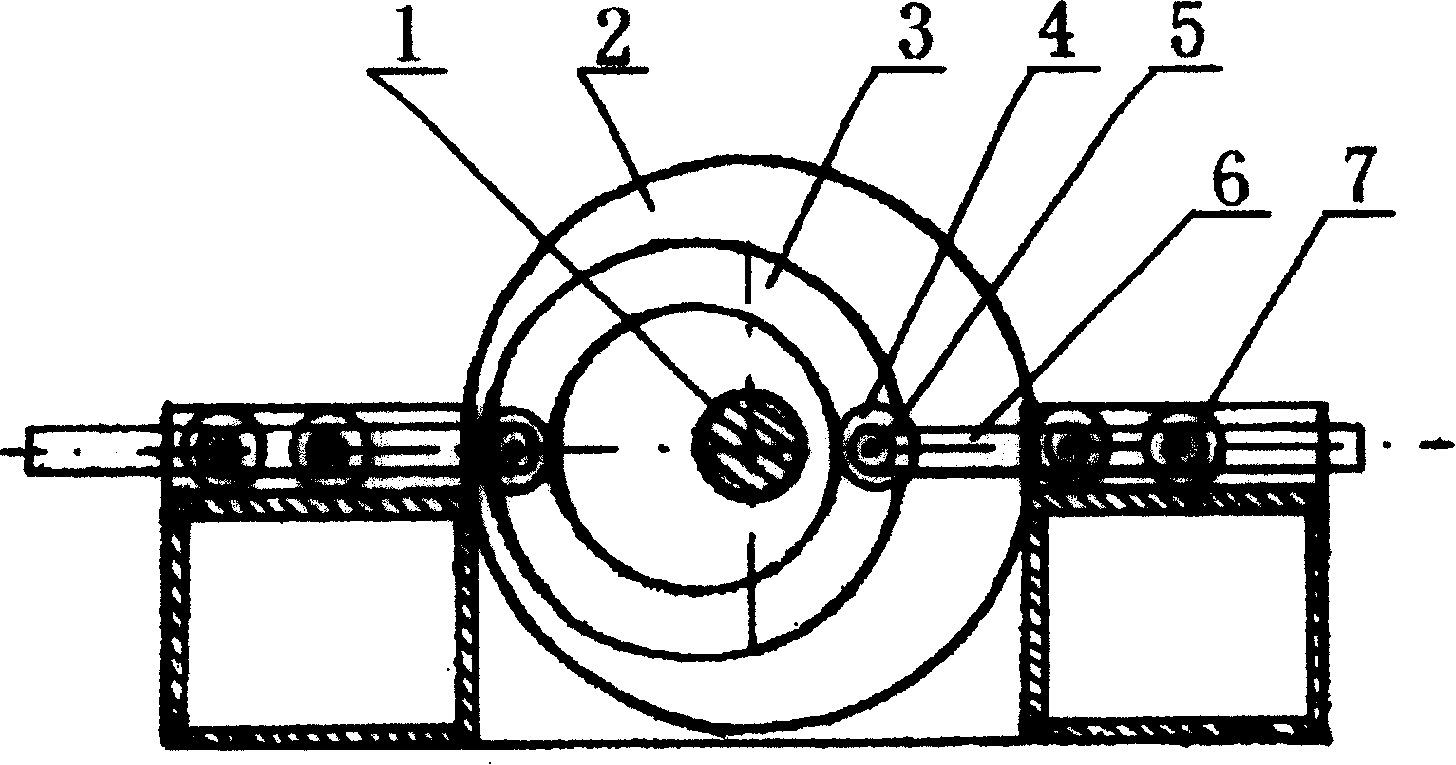

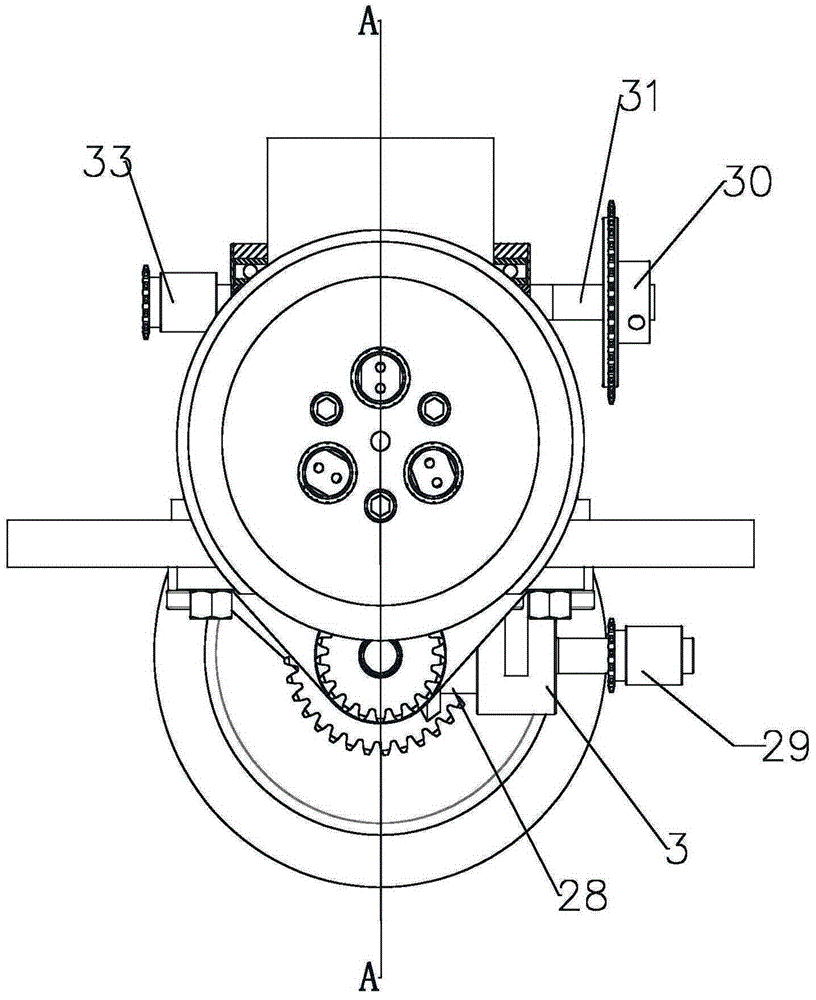

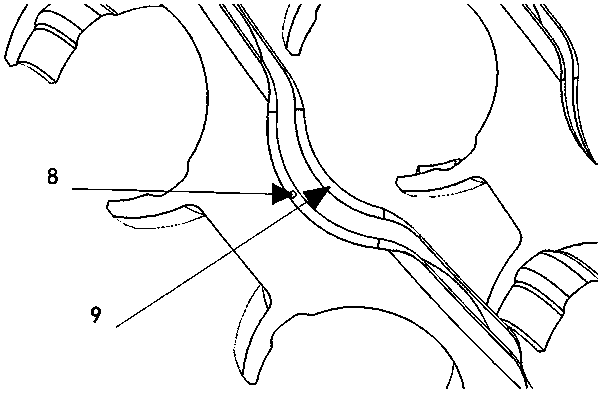

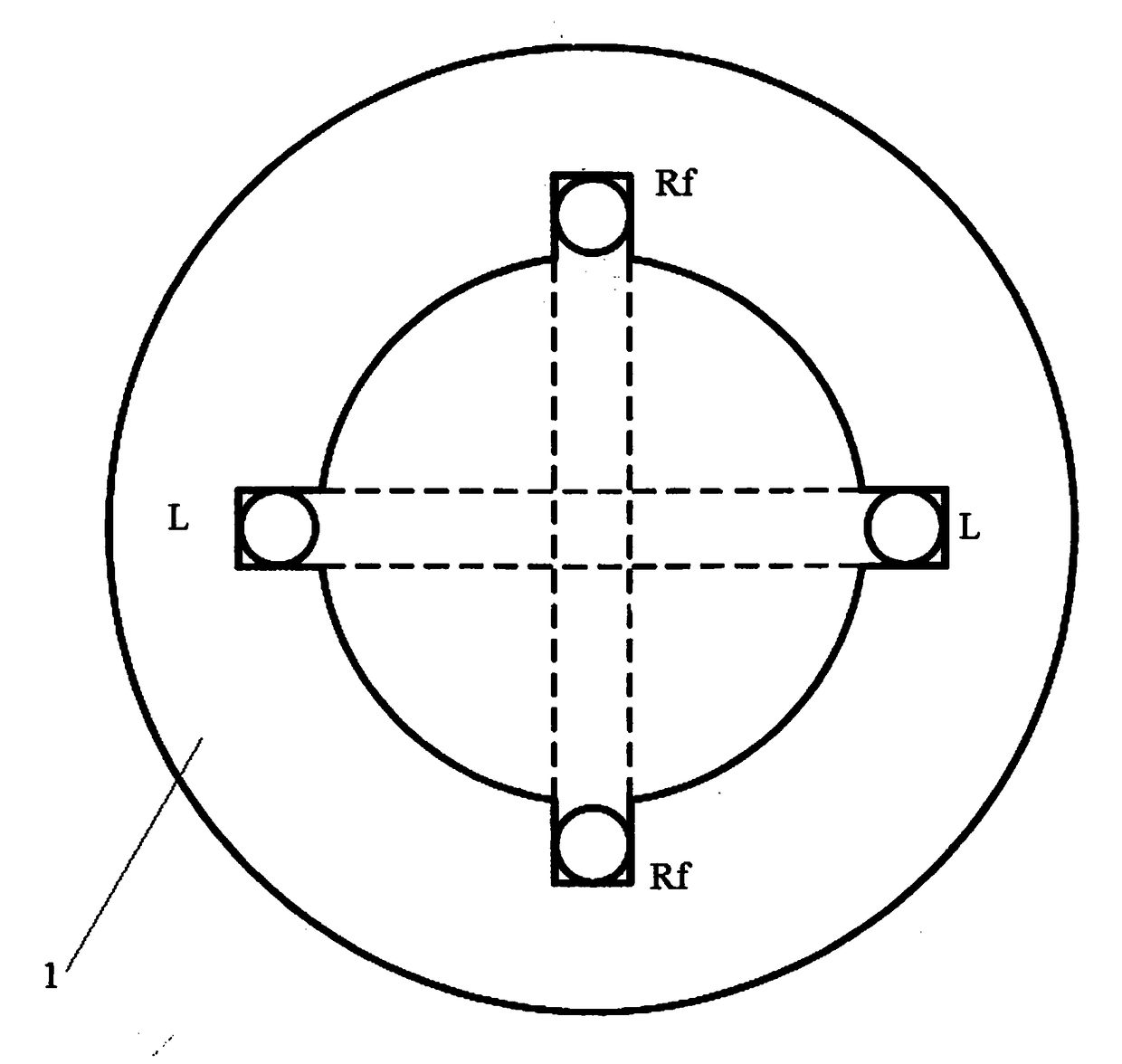

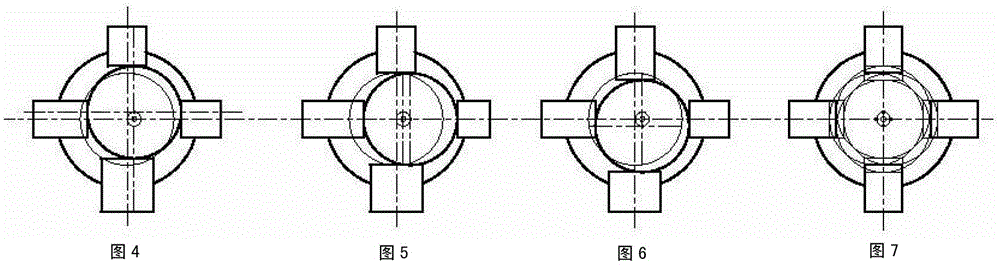

Driving mechanism with eccentric round cam groove

A slotted eccentrical circular cam type drive mechanism features that an eccentrical wheel installed to central axle has an eccentrical ring slot on its circumferential surface, the longitudinally reciprocating drive rods are respectively installed in their guide tubes, and the sleeved end of said drive rod is arranged vertically in said ring slot on eccentrical cam. Its advantages are simple structure, and high stability and reliability.

Owner:王良知

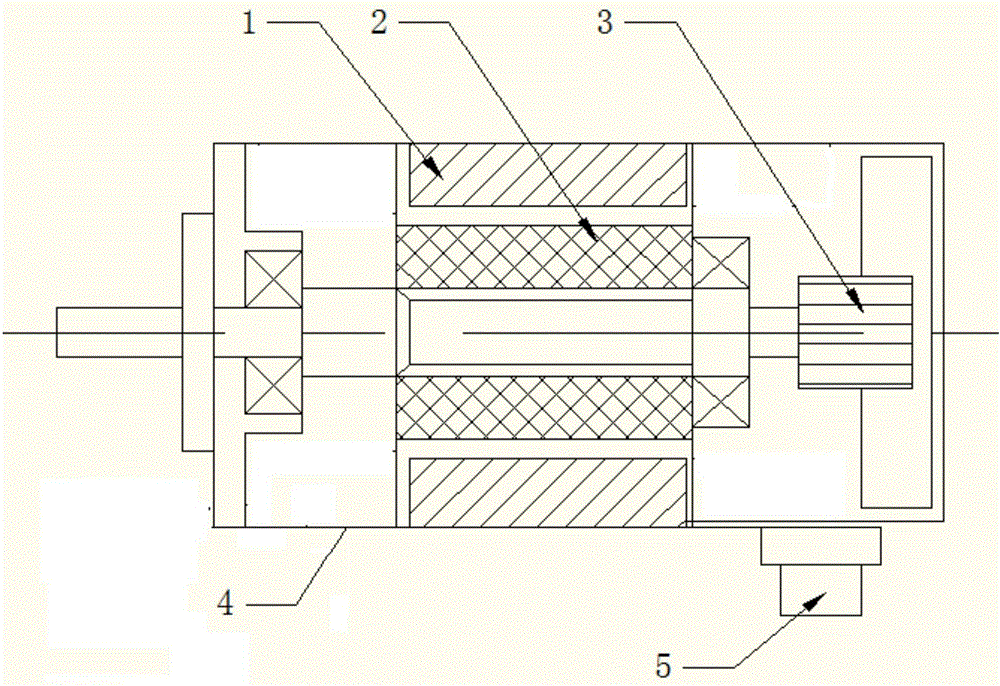

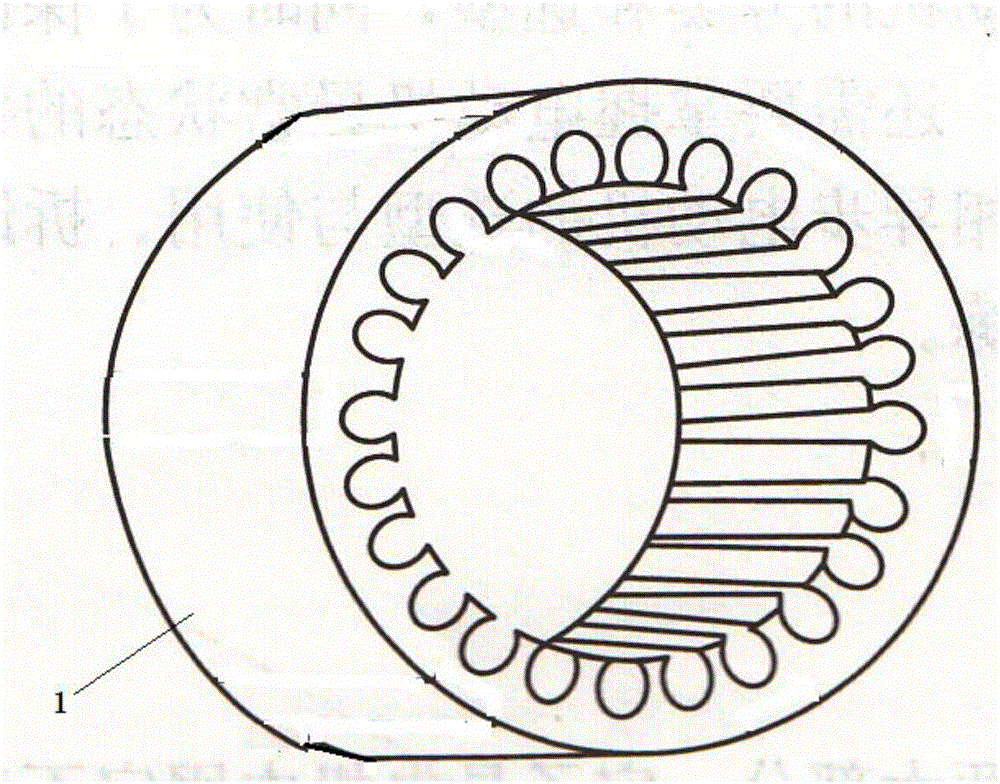

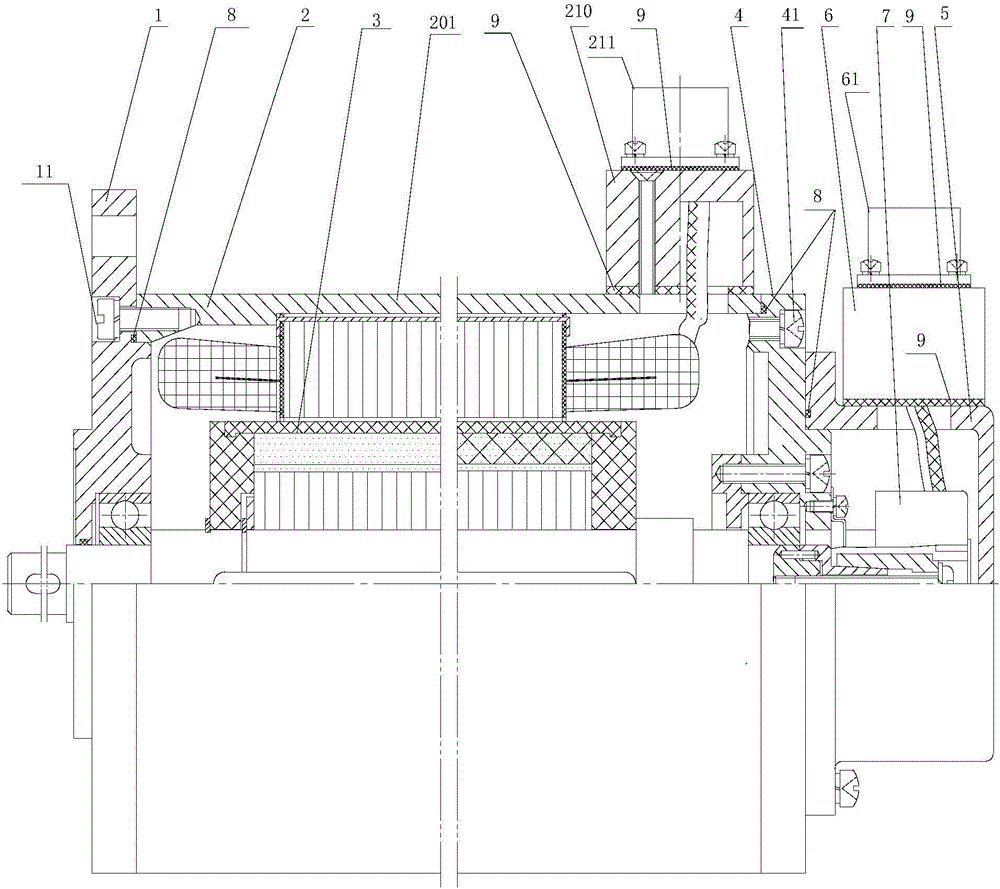

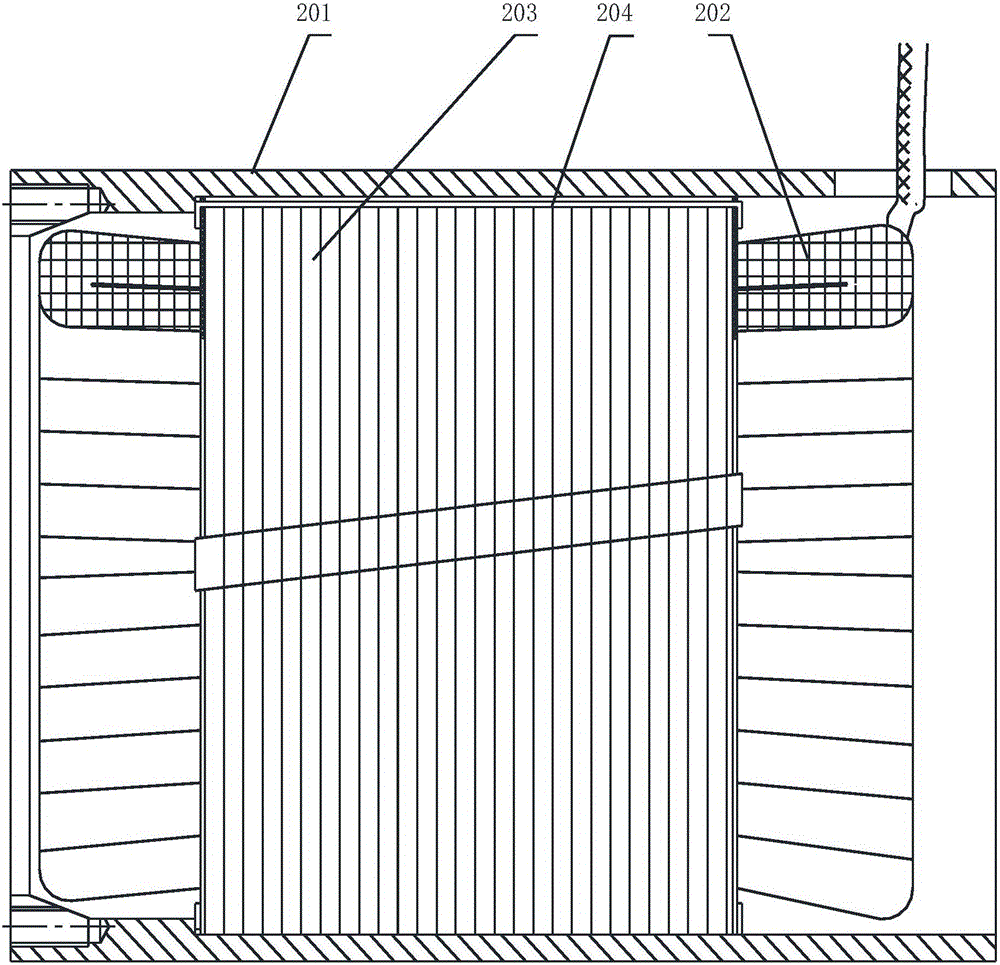

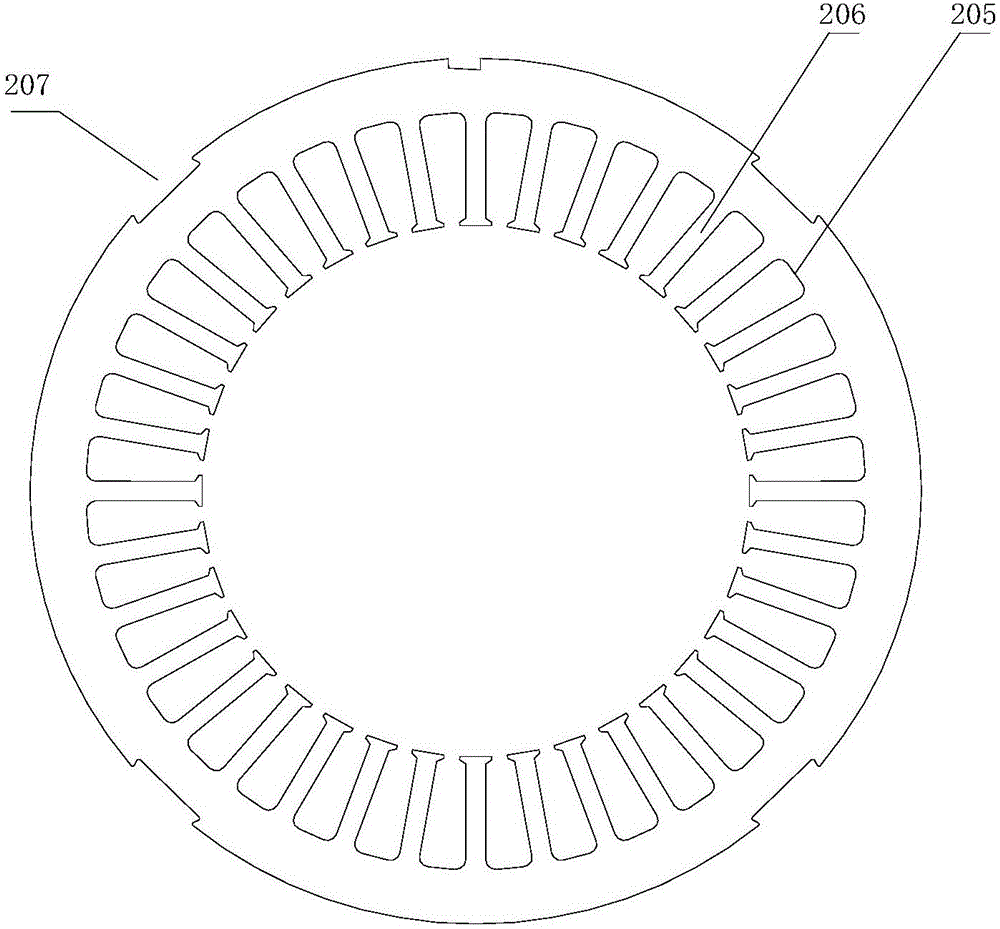

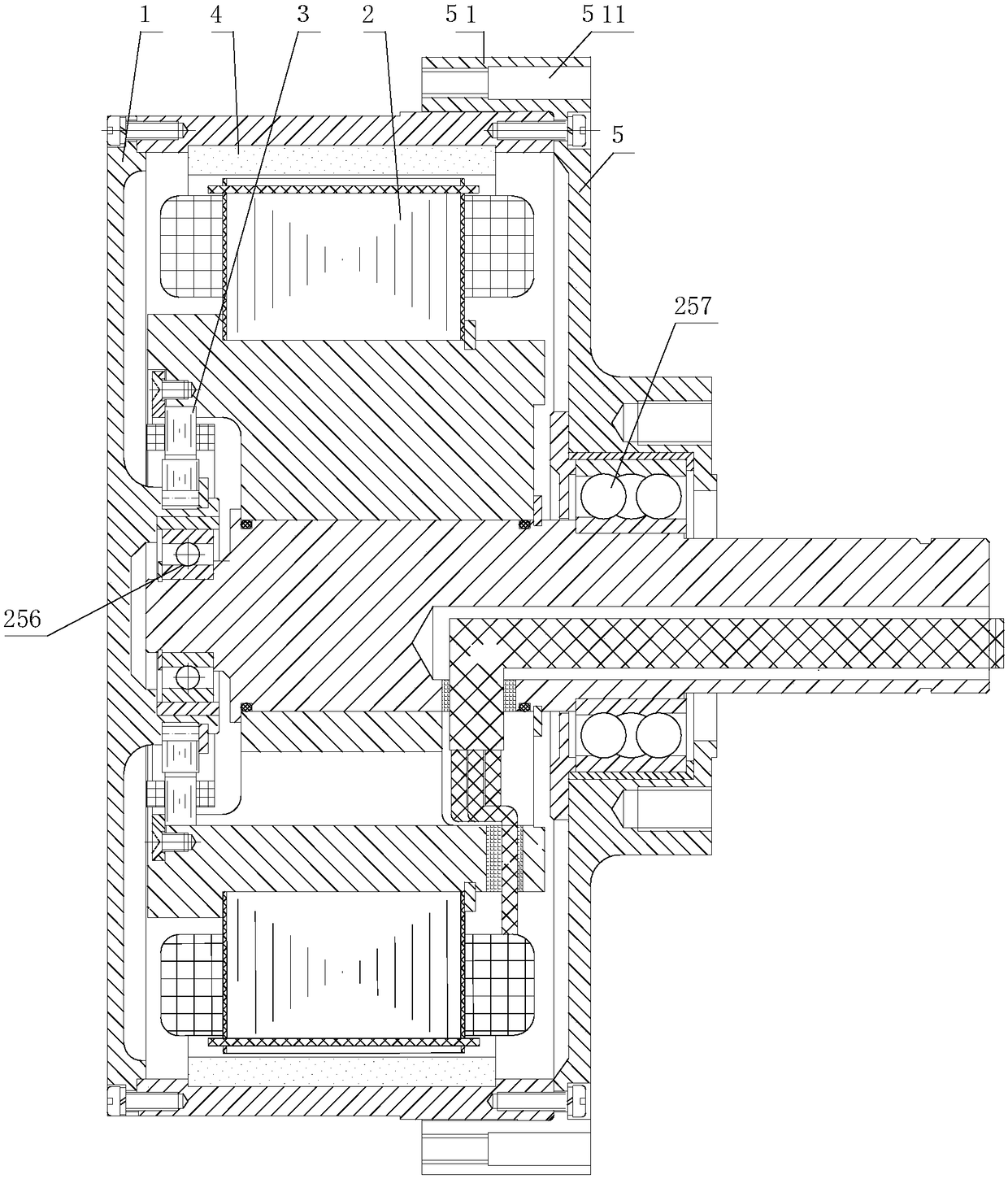

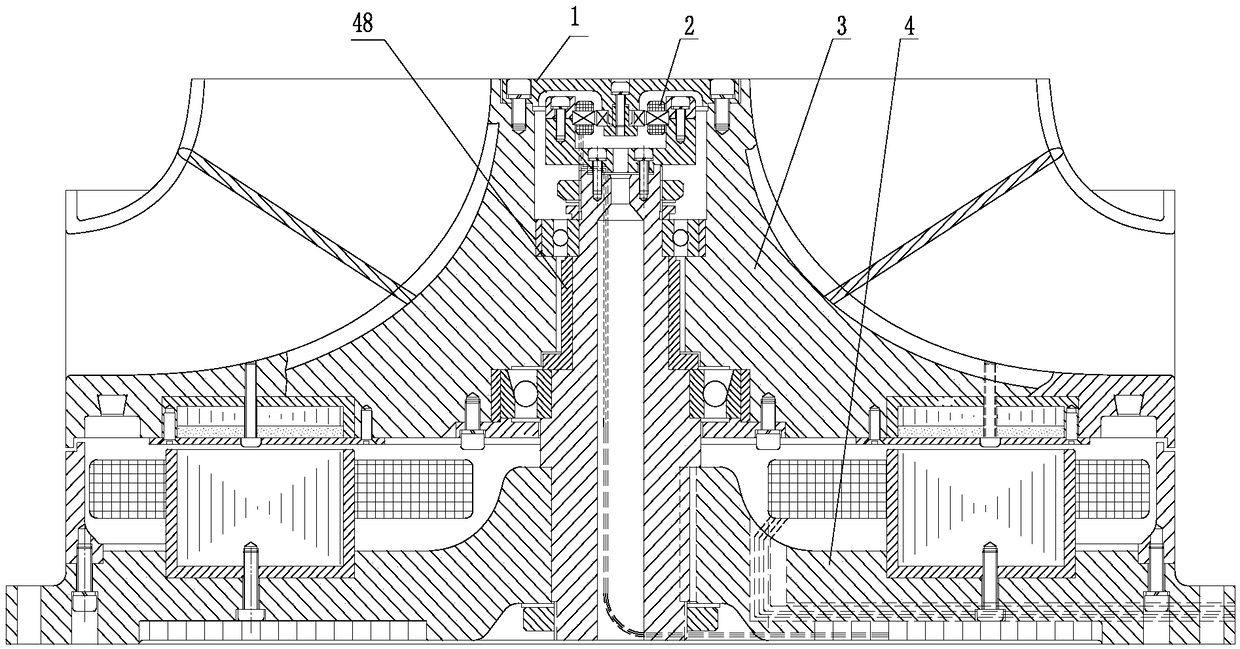

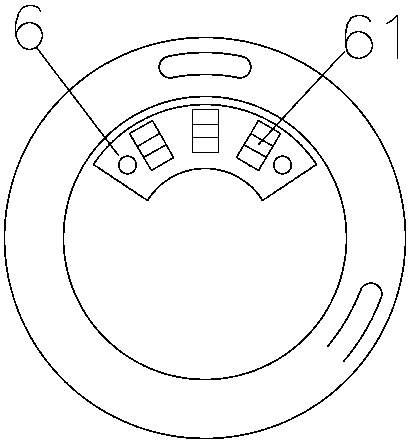

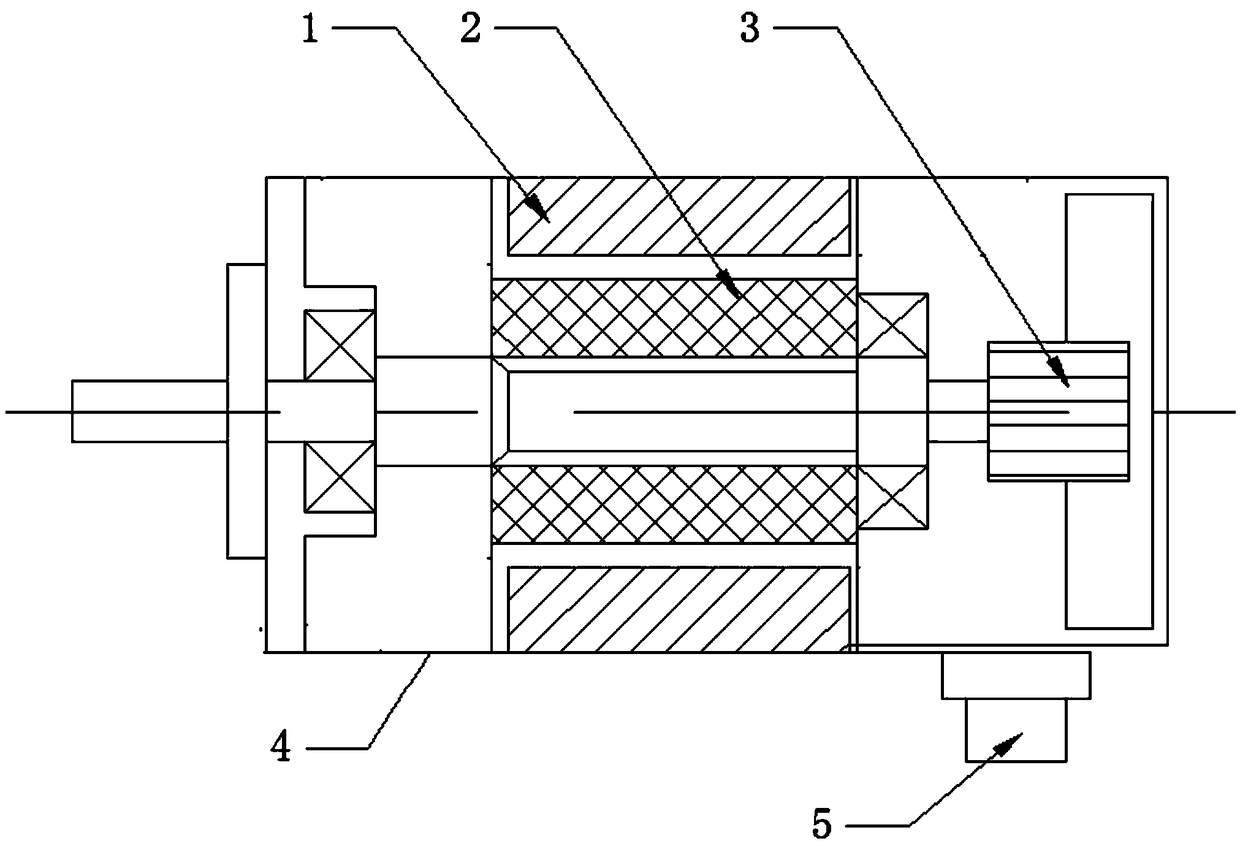

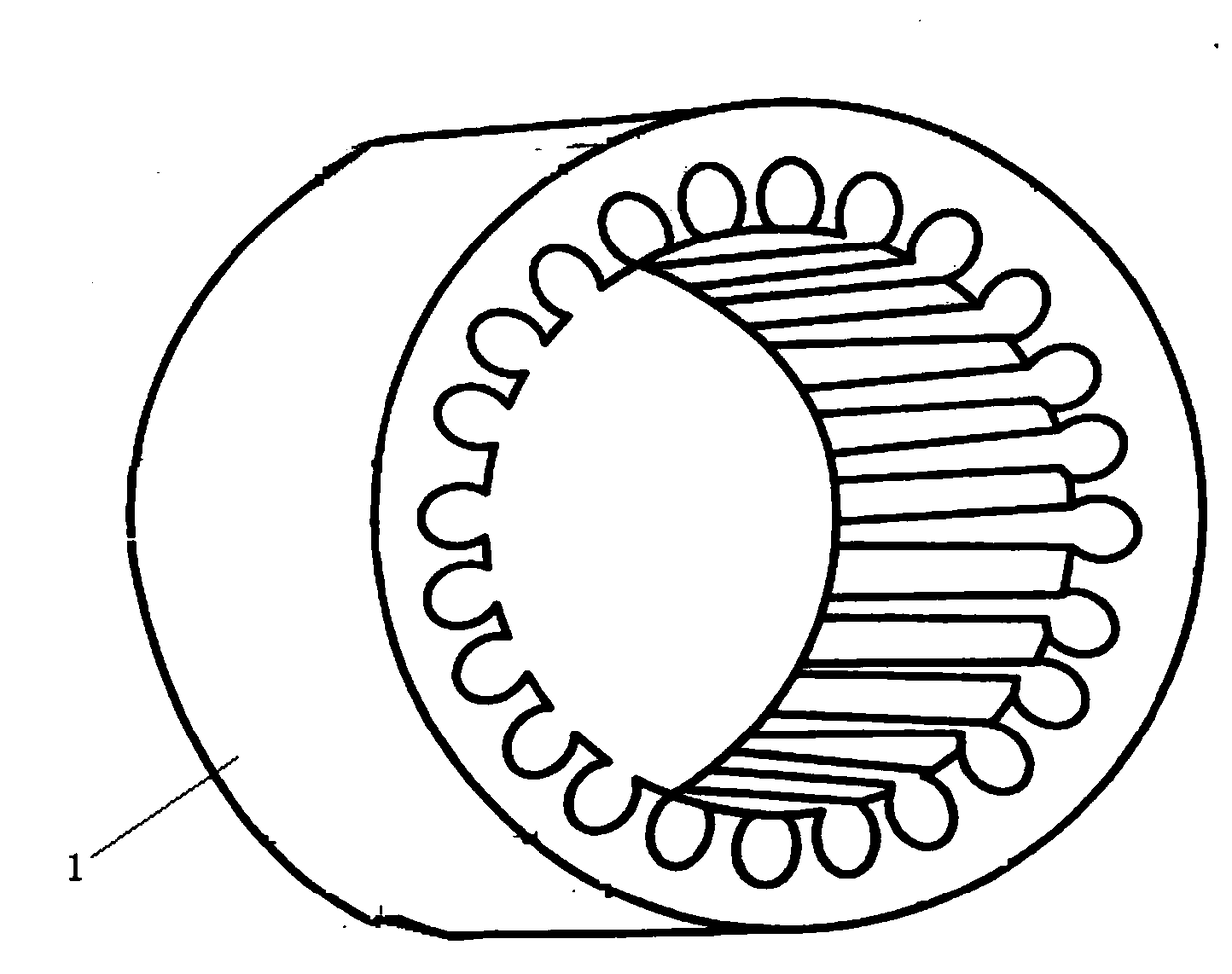

High-speed high-power density AC servo motor

ActiveCN106655649AIncrease speedSmooth operation at high speedManufacturing stator/rotor bodiesCopper wireEngineering

The invention discloses a high-speed high-power density AC servo motor, which belongs to the technical field of motors. The high-speed high-power density AC servo motor comprises a stator part and a rotor part, wherein the stator part comprises a frame, a stator iron core, stator windings, end covers and bearings; the rotor part comprises a rotation shaft, rotor magnetizers, permanent magnets and a stainless steel band; two ends of the frame are provided with the front end cover and the rear end cover; the frame is internally provided with the rotation shaft, the stator iron core, the stator windings and the rotor part; the rotor magnetizers sleeve the rotation shaft, the tile-shaped permanent magnets are adhesive to the outer surface, and an air gap magnetic field is generated; cast aluminum alloy is adopted to cast the frame, the front end cover and the rear end cover, and thermal processing is carried out; silicon steel sheets are adopted to process the stator iron core, and the oxide layer on the surface of the silicon steel sheet serves as inter-sheet insulation; the inner circle of the iron core ring is uniformly provided with grooves parallel with the axis, the stator windings are embedded in the grooves, and each stator winding adopts a high temperature-resisting copper wire; the rotor part is assembled; and the stator part and the rotor part are combined together. The rotation speed of the motor is high, the power density is large, and the operation is steady.

Owner:AVIC POWER SCI & TECH ENG

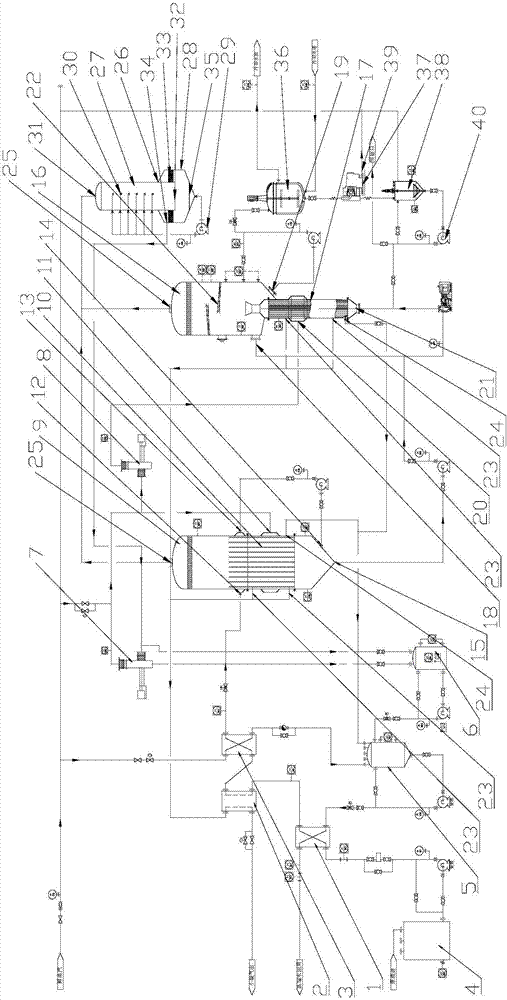

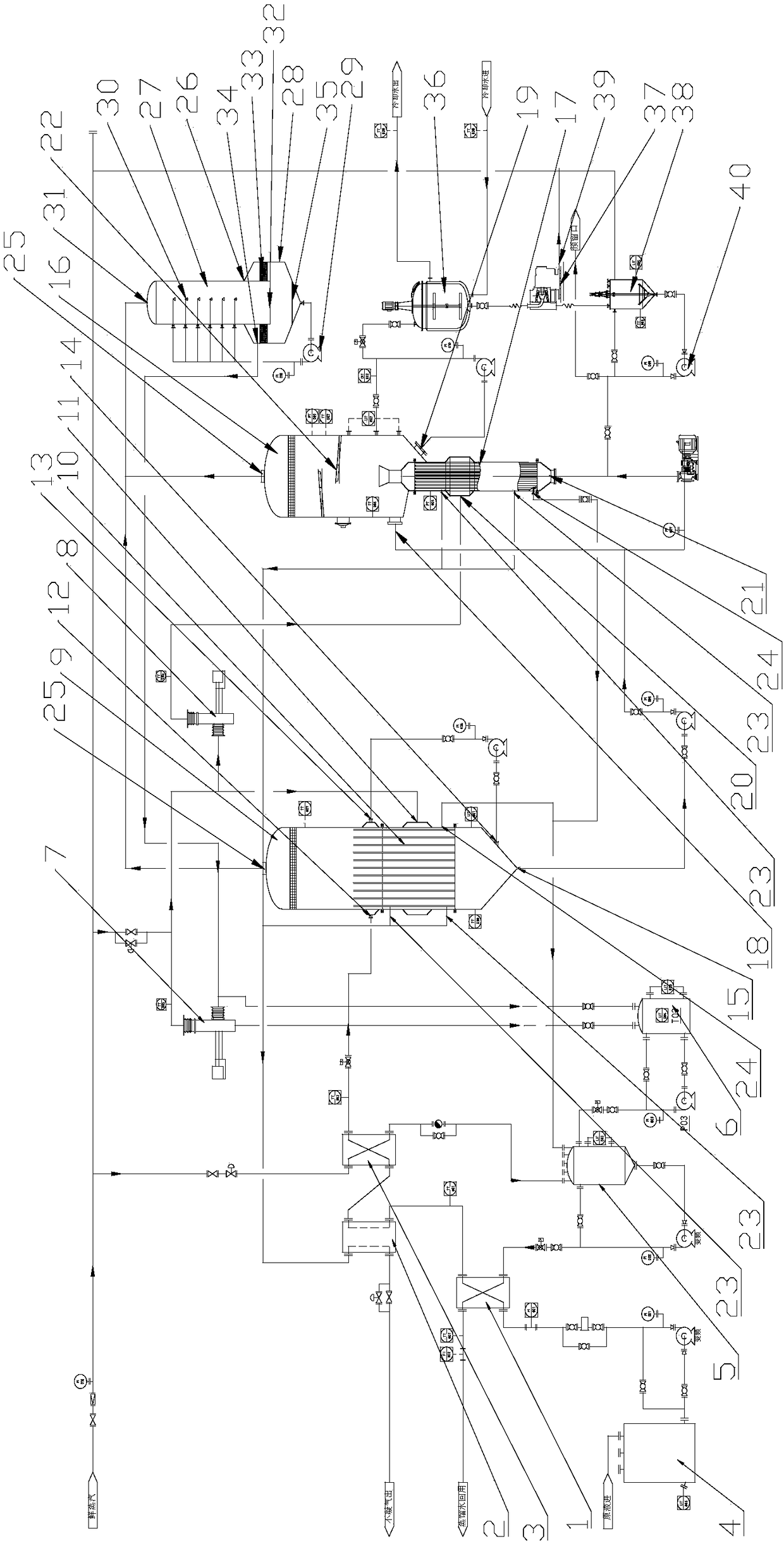

Nickel sulfate evaporative crystallization process

ActiveCN107008026ASmall footprintLow costChemical industrySolution crystallizationVapor–liquid separatorSulfate

The invention relates to a nickel sulfate evaporative crystallization process which comprises the following steps: S1, fresh steam supplies heat to a heat exchanger group, a first evaporation and concentration device and a second evaporation and concentration device; S2, a material enters the heat exchanger group to be pre-heated, then enters the first evaporation and concentration deice after being preheated, and when the material reaches an expected concentration in a gas-liquid separator, the material enters the second evaporation and concentration device to be further evaporated and concentrated; and S3, the material meeting the expected concentration value in the second evaporation and concentration device is discharged from a discharge port and enters a cooling kettle to be cooled, then enters a centrifugal machine to be separated and crystallized, and finally, a product is discharged from the centrifugal machine, and the separated mother liquor is stored in a mother liquor tank. The nickel sulfate evaporative crystallization process provided by the invention is stable and reliable, energy-saving and emission-reducing, small in occupied area and low in cost.

Owner:JIANGSU RUISHENGHUA ENERGY TECH CO LTD

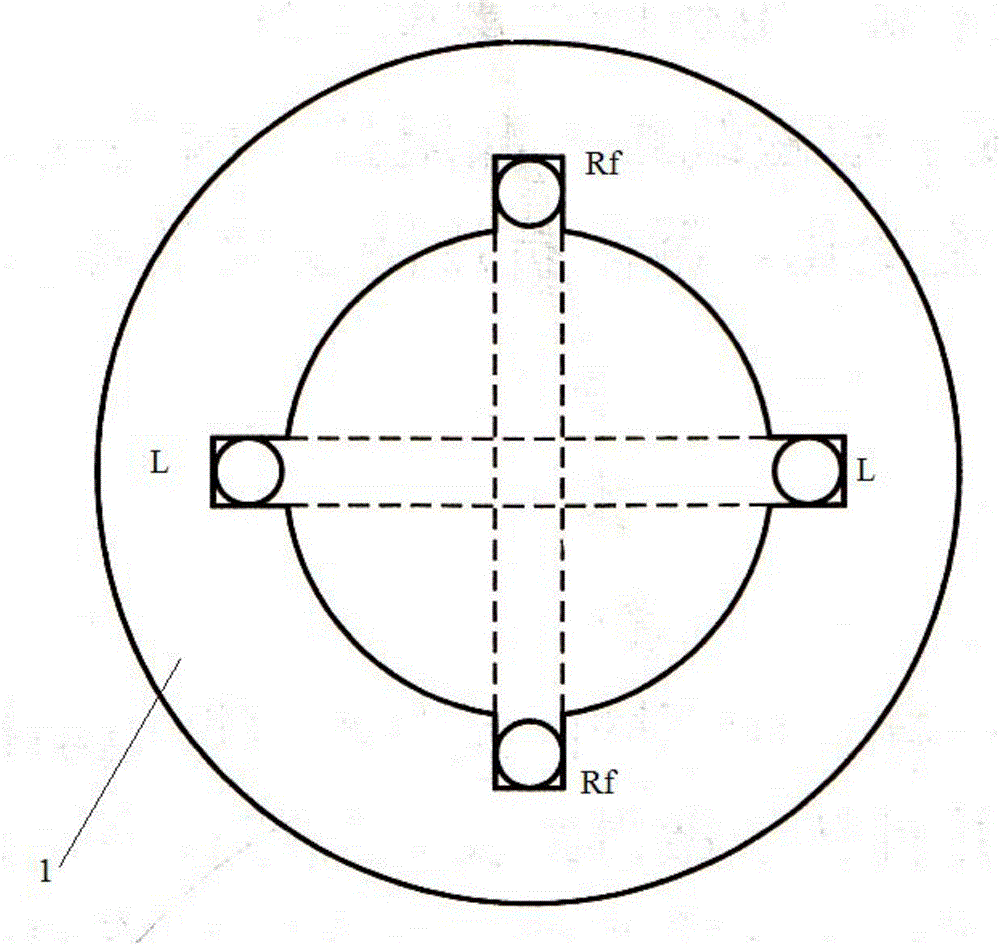

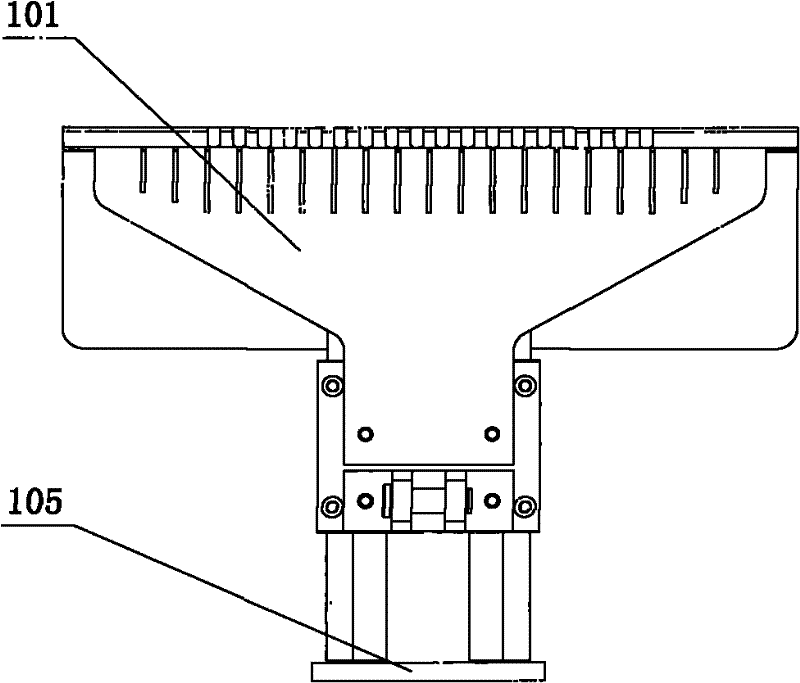

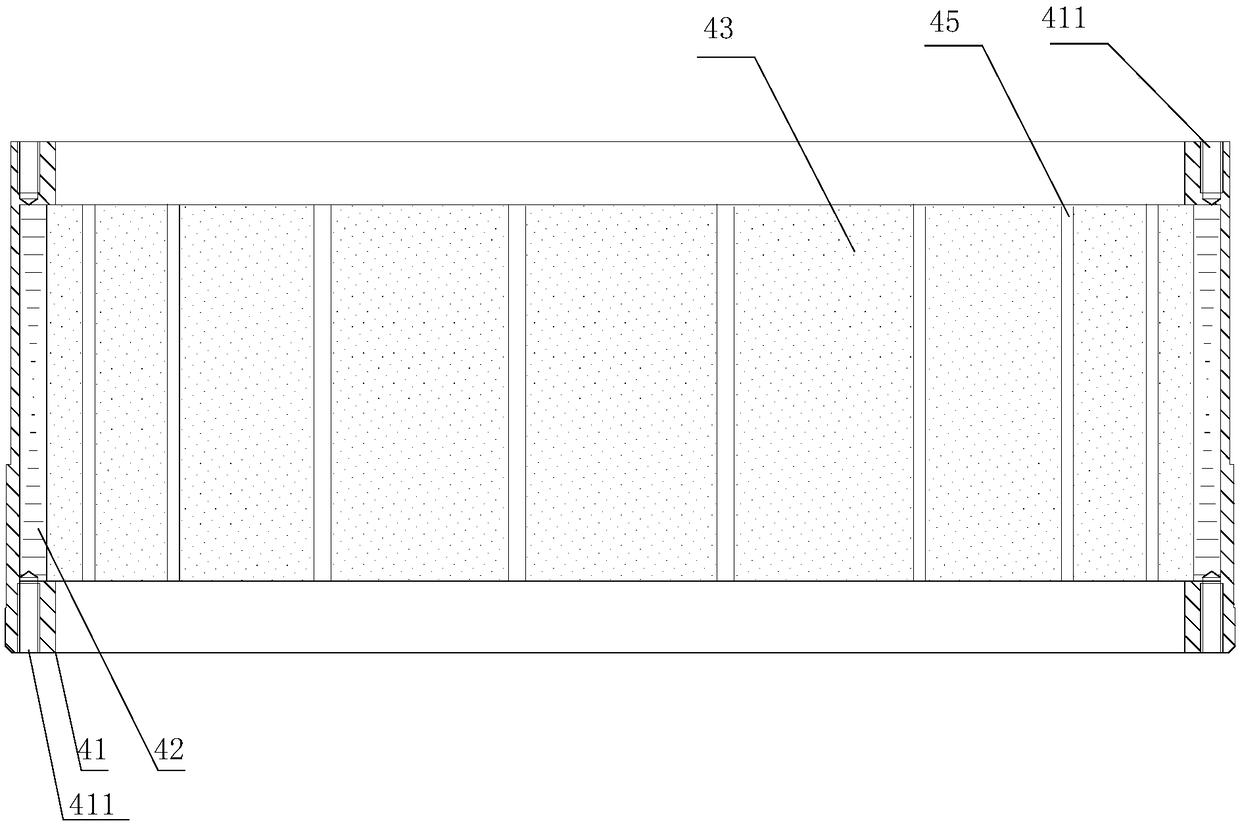

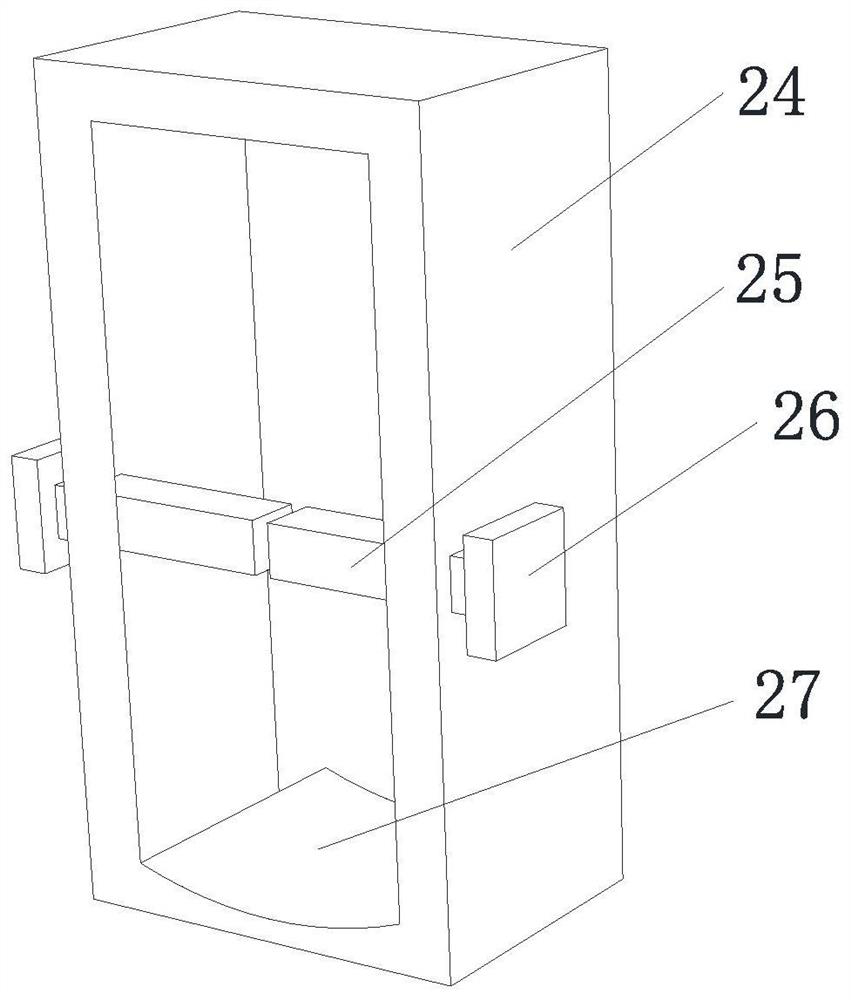

Solid beating-up device

The invention belongs to the technical field of an air-jet loom. In the existing air-jet loom, a device comprising a hollow shaft and an iron bracket is utilized as a beating-up shaft, so the beating-up mechanism is bad in rigidity, weak in beating-up strength, small in weaving range, large in noise and vibration when beating-up, and is not suitable for high-speed rotation. The solid beating-up device provided by the invention comprises an aluminum bracket, a solid beating-up shaft and a counter weight, wherein the aluminum bracket is mounted in two holes which are mutually vertical on the beating-up shaft, and is fixed by bolts; the counter weight is mounted at the eccentric opposite direction of the aluminum bracket and fixed on the beating-up shaft by a bolt. By using the device provided by the invention, the rigidity of the beating-up mechanism is increased and the beating-up strength is improved; the device is suitable for knitting fabrics with high intensity and large thickness, so the knitting range is correspondingly expanded; the noise when beating-up is greatly reduced; the balanced beating-up mechanism can work stably when rotating at a high speed and the ground vibration is reduced by more than 35%.

Owner:杨明江

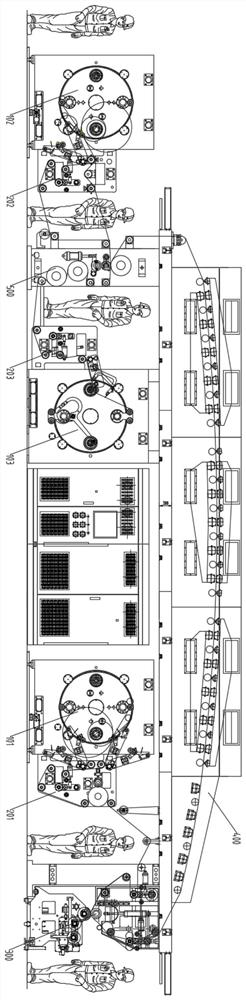

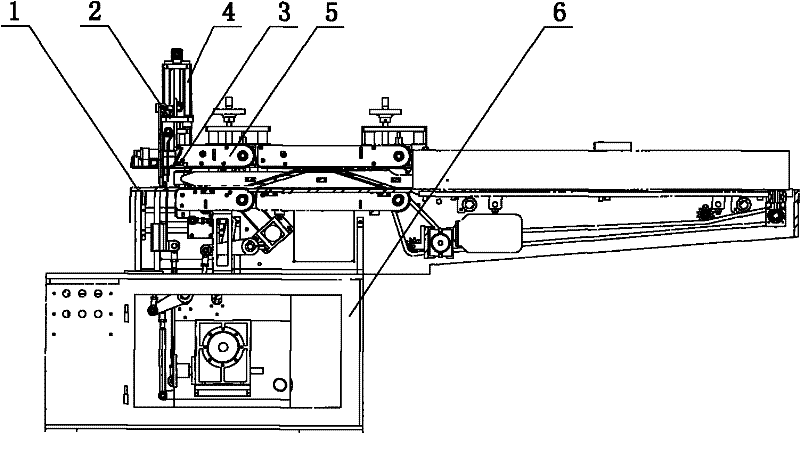

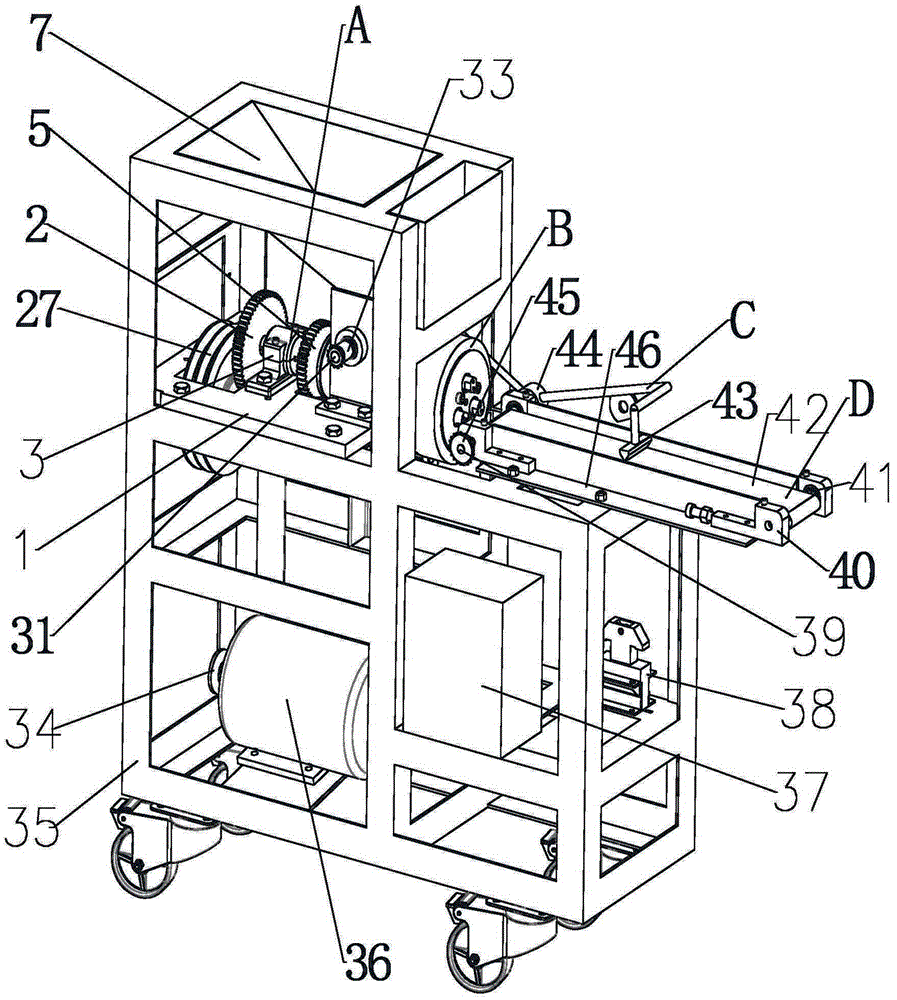

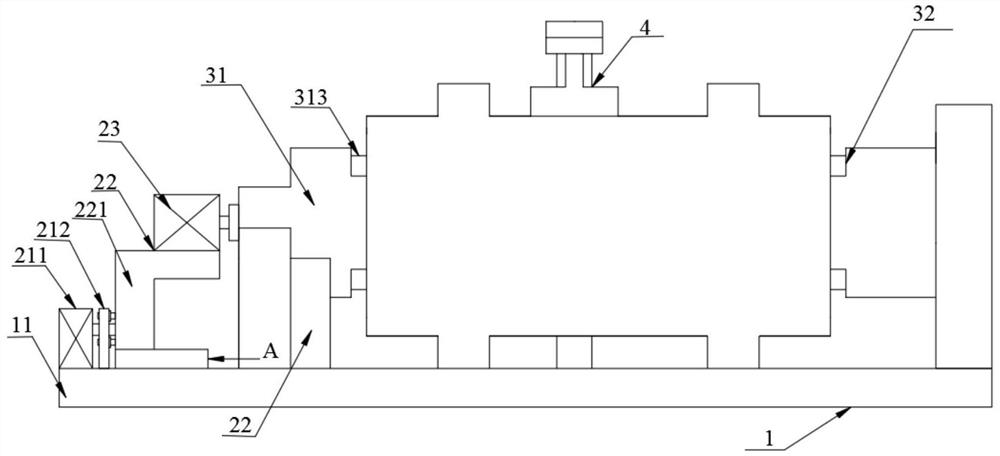

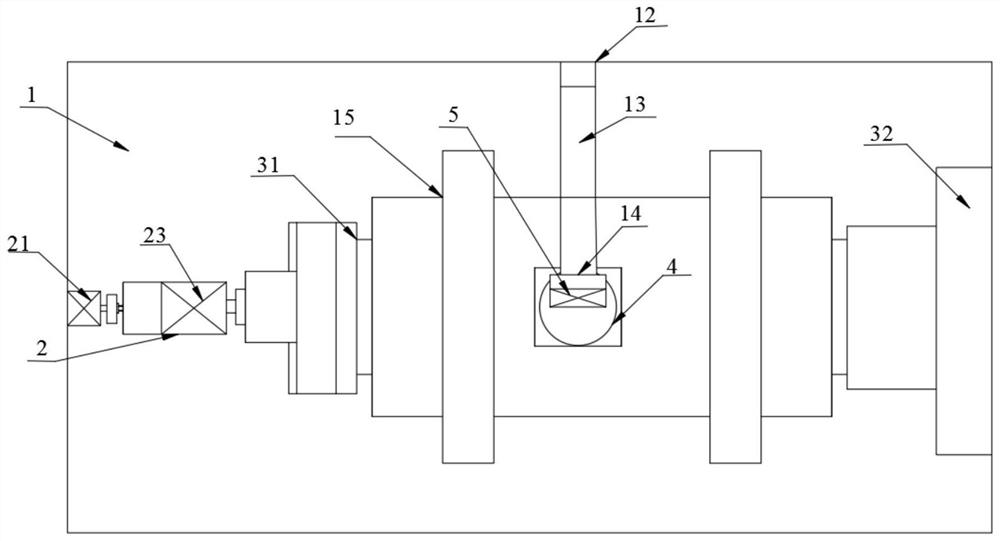

Full-servo control high-speed multifunctional dry-type coating compound machine

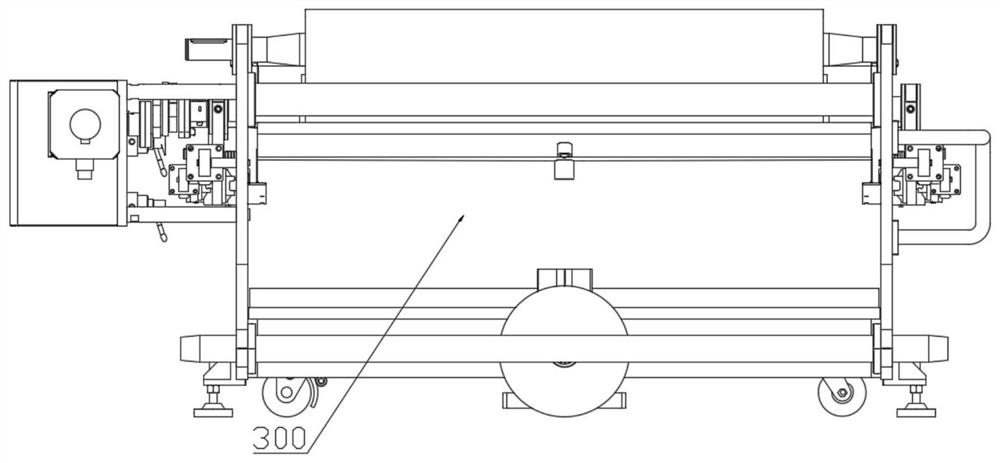

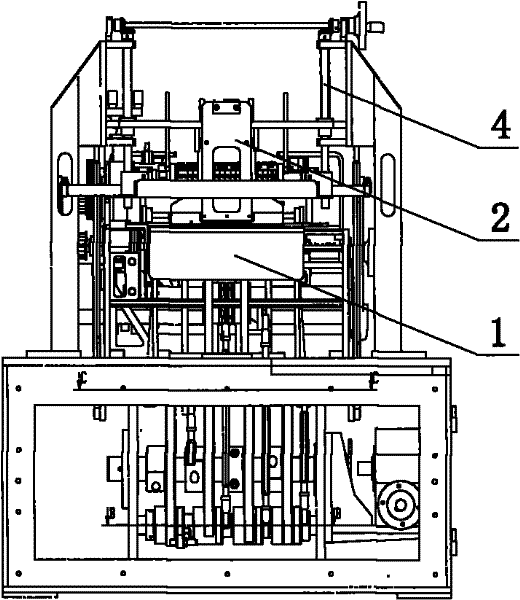

PendingCN112959796AHigh speedImprove yieldLamination ancillary operationsLaminationCircular discAdhesive glue

The invention discloses a full-servo control high-speed multifunctional dry type coating compound machine. The compound machine comprises disc gear shaftless charging winding and unwinding equipment for winding a coating base material, a movable semi-flexographic plate coating device for coating glue on the surface of the coating base material, a drying system for drying the base material coated with the glue by the movable semi-flexographic plate coating device, and a composite cooling unit which is used for laminating and bonding the coated base material coated with the glue and dried with other base materials; the disc gear shaftless charging winding and unwinding equipment comprises three groups of high-speed disc gear shaftless charging winding and unwinding devices; a first disc unwinding device works to release a first coating base material wound on the first disc unwinding device, and one side of the released first coating base material is coated with glue through a movable semi-flexographic plate coating device; and after being coated with glue, the base material is fed into the drying system for drying treatment and is simultaneously fed to the composite cooling unit together with a second coating base material wound on the second disc unwinding device, and the two base materials are laminated by the composite cooling unit.

Owner:广东汕樟轻工股份有限公司

Three-phase-shielded permanent magnet synchronous motor

PendingCN106849515AWon't leakWill not cause electromagnetic interferenceSupports/enclosures/casingsShielding from electromagnetic fieldsPermanent magnet rotorElectric machine

The invention discloses a three-phase-shielded permanent magnet synchronous motor which comprises a back end cap, a stator, a permanent magnet rotor, a front end cap, a protective cover, a terminal block, an encoder and a conductive sealing material. According to the three-phase-shielded permanent magnet synchronous motor, electromagnetic waves which are generated by the motor can be totally shielded in the motor so that leakage of the electromagnetic wave to outside of the motor is prevented, thereby preventing electromagnetic interference to other systems.

Owner:包头天工电机有限公司

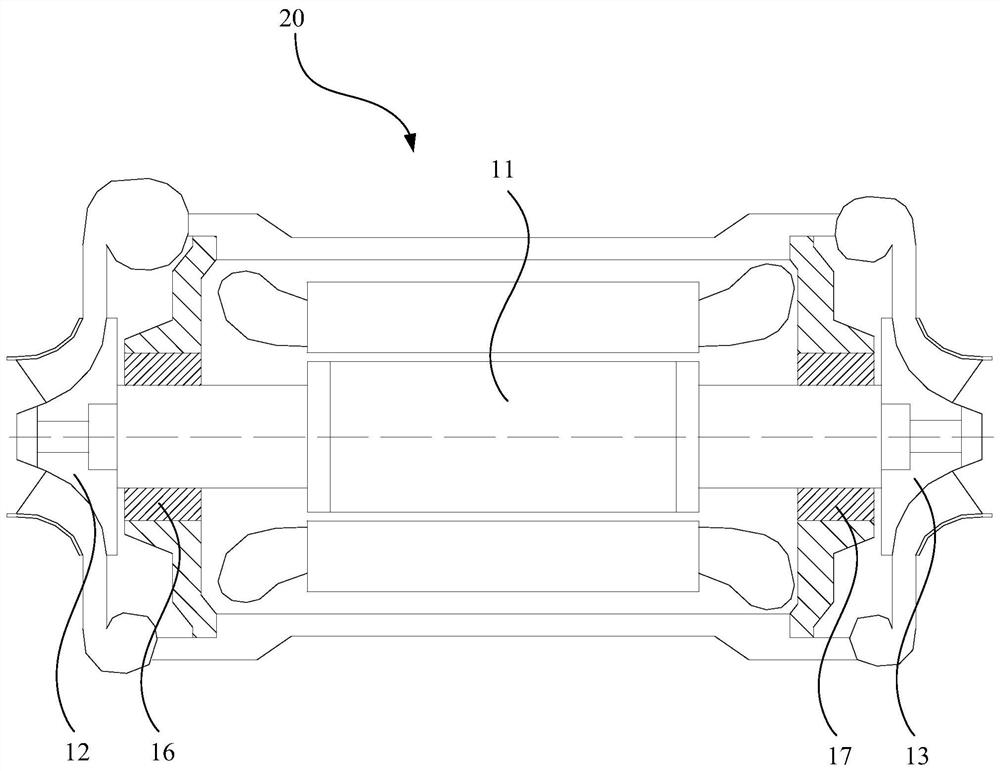

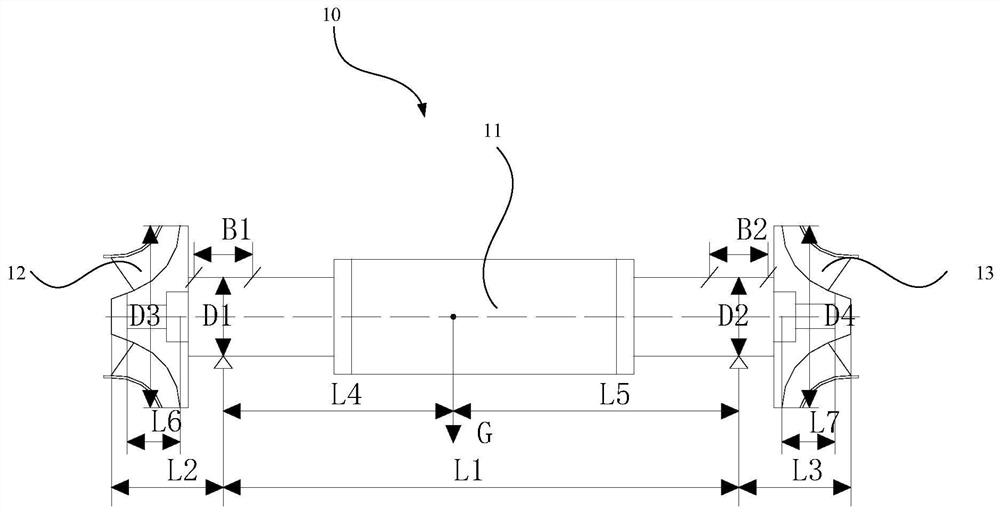

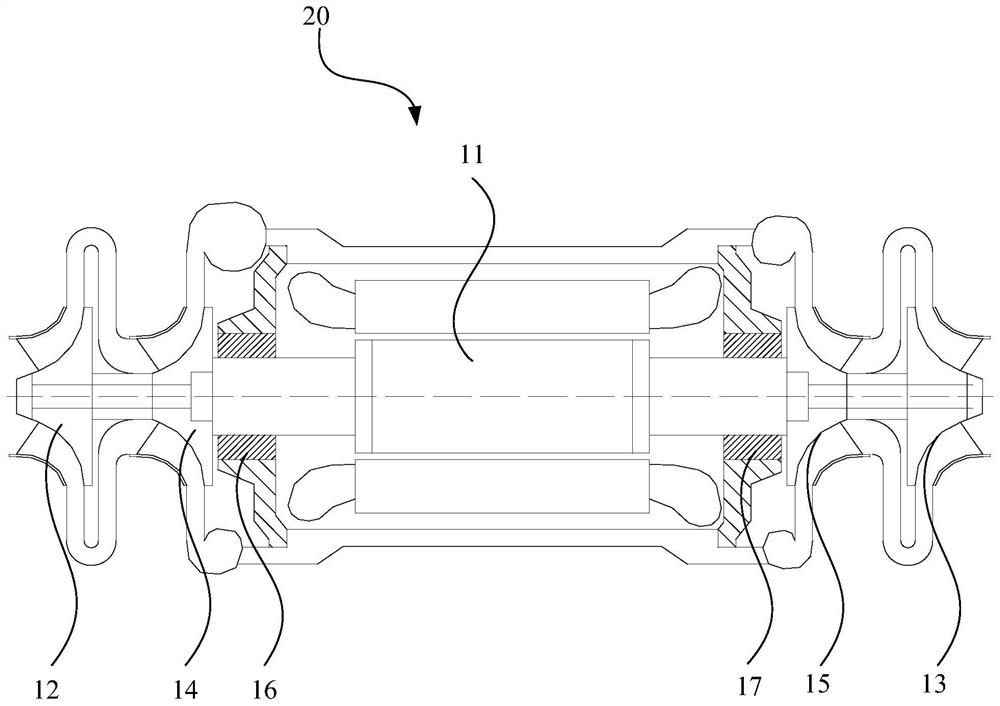

Centrifugal compressor shaft system, centrifugal compressor and air conditioner

PendingCN113847270AEasy to operateImprove stabilityCompressorPump componentsGravity centerCantilever

The invention relates to a centrifugal compressor shaft system, a centrifugal compressor and an air conditioner. Through matching design of all geometric parameters of the shaft system, the shaft system can stably operate even under the conditions of high rotating speed and high load, and the use stability and reliability are improved. Specifically, the cantilever length ratios L2 / L1 and L3 / L1 of the shaft system, the installation width ratios B1 / L2 and B2 / L3 of a supporting piece, the width-diameter ratios B1 / D1 and B2 / D2 of the supporting piece, the gravity center shift rate abs (L4-L5) / (L1 / 2) of the shaft system, and the length-diameter ratios L6 / D3 and L7 / D4 of an impeller are designed.

Owner:GREE ELECTRIC APPLIANCES INC

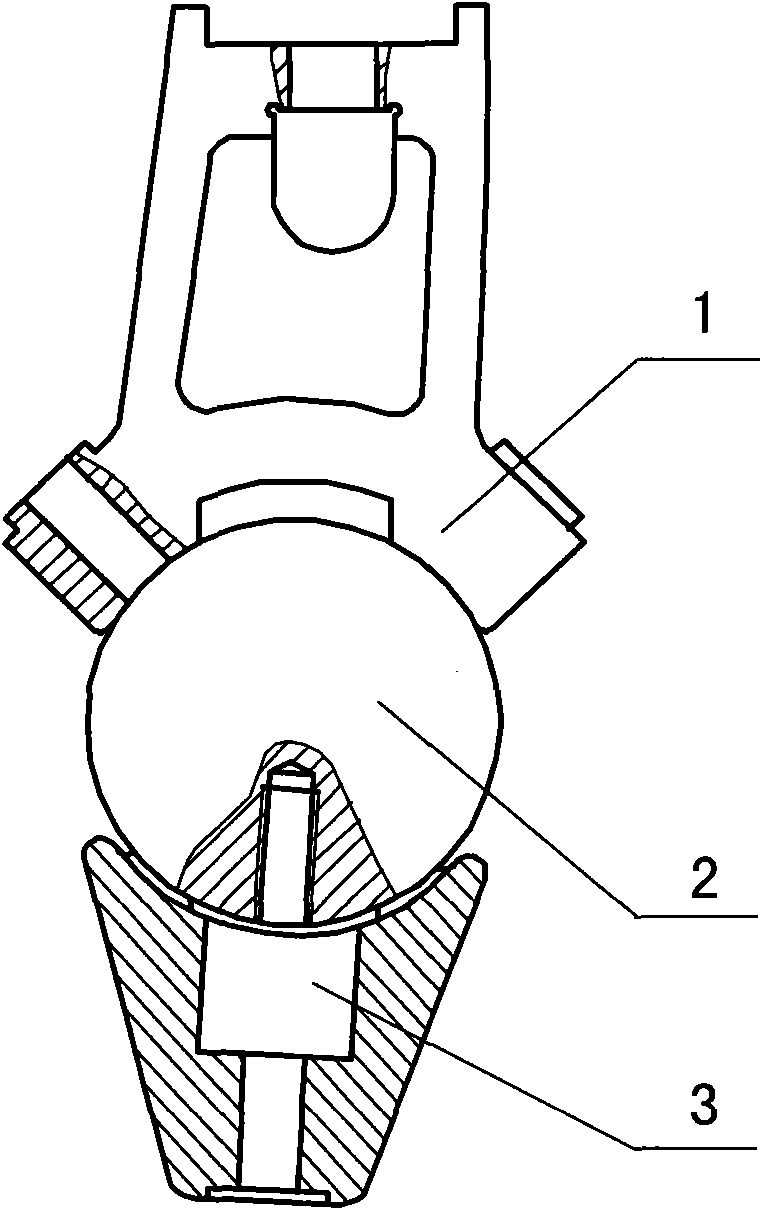

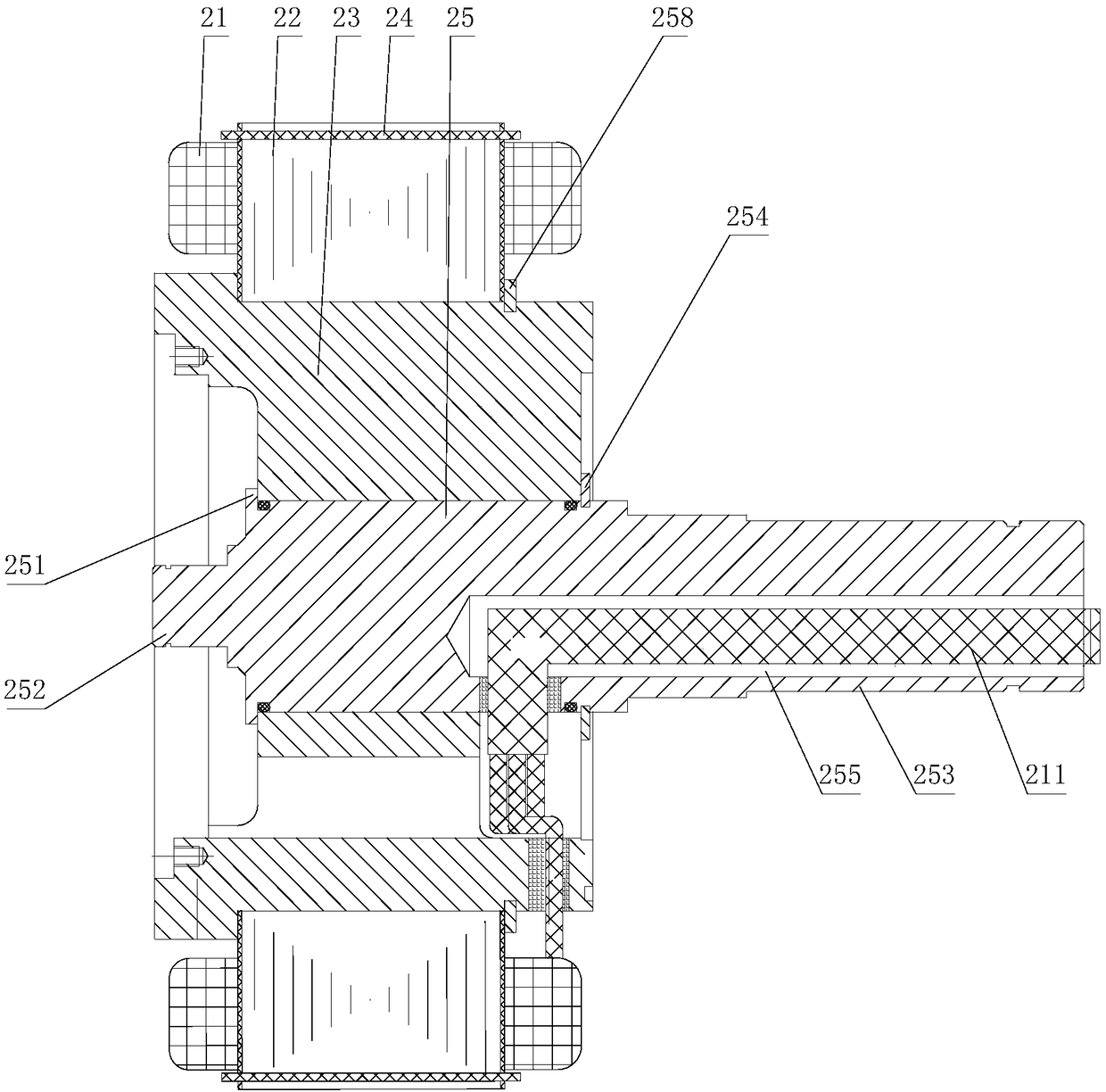

Novel oil cylinder clamping device

InactiveCN103769928AExtended service lifeLow costPositioning apparatusMetal-working holdersCouplingPiston

The invention relates to a lathe oil cylinder clamping device and aims at providing a novel oil cylinder clamping device which does not need an oil cylinder coupling block, and is low in processing precision, low in process cost and long in service life. The novel oil cylinder clamping device comprises a fixed pipe, a main shaft arranged in the front part of the fixed pipe, a clamping pull rod arranged in the inner cavity of the main shaft, an oil cylinder arranged at the rear end of the fixed pipe and an oil cylinder shaft arranged in the oil cylinder and connected with a clamping pull rod, wherein a piston is arranged on the oil cylinder shaft in the oil cylinder to divide the inner cavity of the oil cylinder into a front cavity and a rear cavity, the main shaft is rotatably connected with the fixed pipe, one end, located in the inner cavity of the main shaft, of the clamping pull rod is rotatably connected with the oil cylinder shaft, the oil cylinder and the fixed pipe are further provided with oil inlets leading to the inner cavity of the oil cylinder, respectively, and the oil inlet formed in the oil cylinder leads to the rear cavity of the oil cylinder, while the oil inlet formed in the fixed pipe leads to the front cavity of the oil cylinder.

Owner:泉州利达机器有限公司

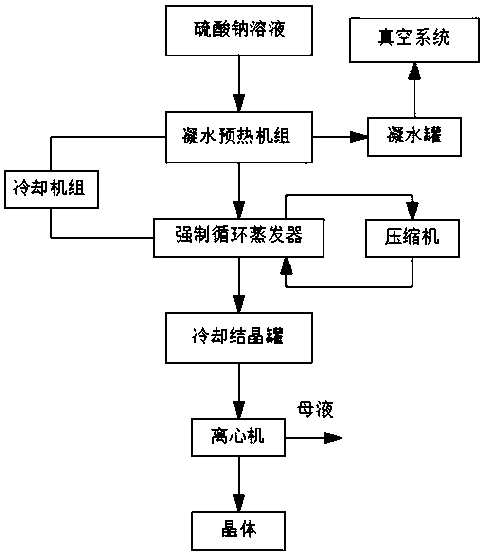

Processing process for evaporating and concentrating sodium sulfate aqueous solution to crystallize

InactiveCN107867709ARecovery of latent heatImprove efficiencyChemical industryAlkali metal sulfite/sulfate dehydrationChemistryHeating efficiency

The invention discloses a processing process for evaporating and concentrating sodium sulfate aqueous solution to crystallize in the technical field of chemical equipment. The processing process has the following specific steps that: (S1) the sodium sulfate aqueous solution to be treated is evaporated and concentrated; (S2) materials are sent into a forced circulation evaporator, and are then sentinto a centrifugal machine for separation, and qualified mother liquid returns the forced-circulation evaporator again for secondary evaporation; (S3) secondary steam enters a compressor unit after passing through a gas-liquid separator; (S4) the secondary steam then enters an MVR (Mechanical Vapor Recompression) compressor; (S5) when the temperature of secondary-steam condensation water is reduced to be about 40 DEG C, the secondary-steam condensation water is discharged out of the system; (S6) heat-exchange evaporation is carried out and the whole system reaches heat balance. The processingprocess disclosed by the invention has the beneficial effects that steam to be abandoned originally is fully utilized, so that latent heat is recovered, the heat efficiency is improved, and the production cost is reduced; the phenomenon of pipe blocking is not easy to occur and full reuse of the secondary-steam condensation water can be achieved.

Owner:广州叶林环保科技有限公司

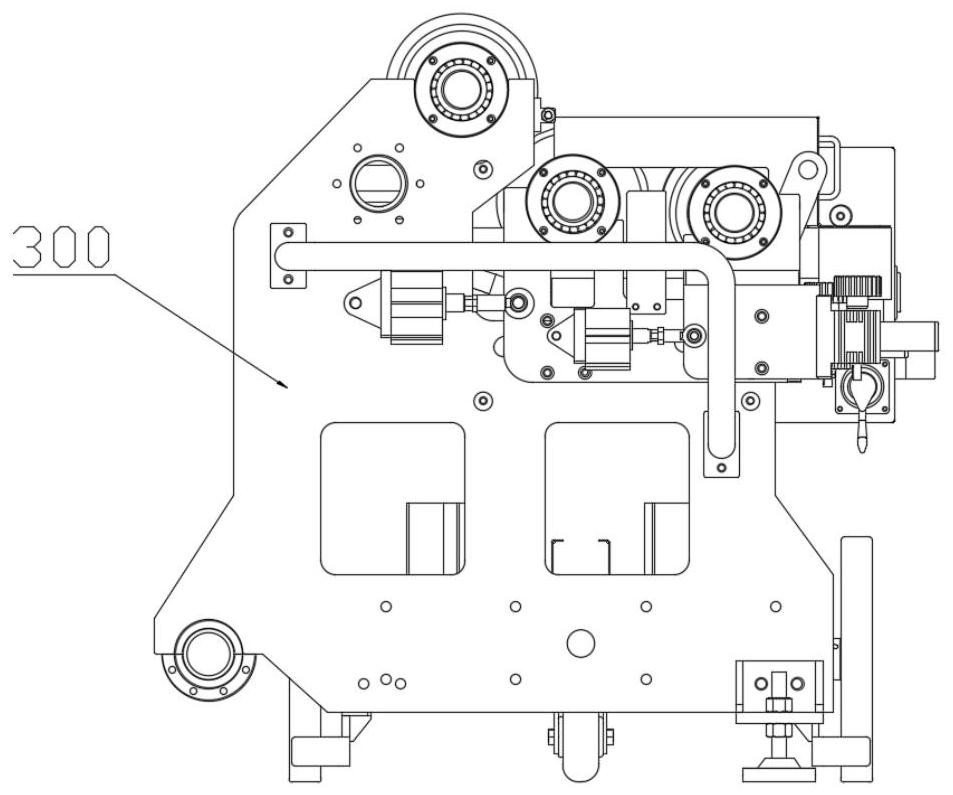

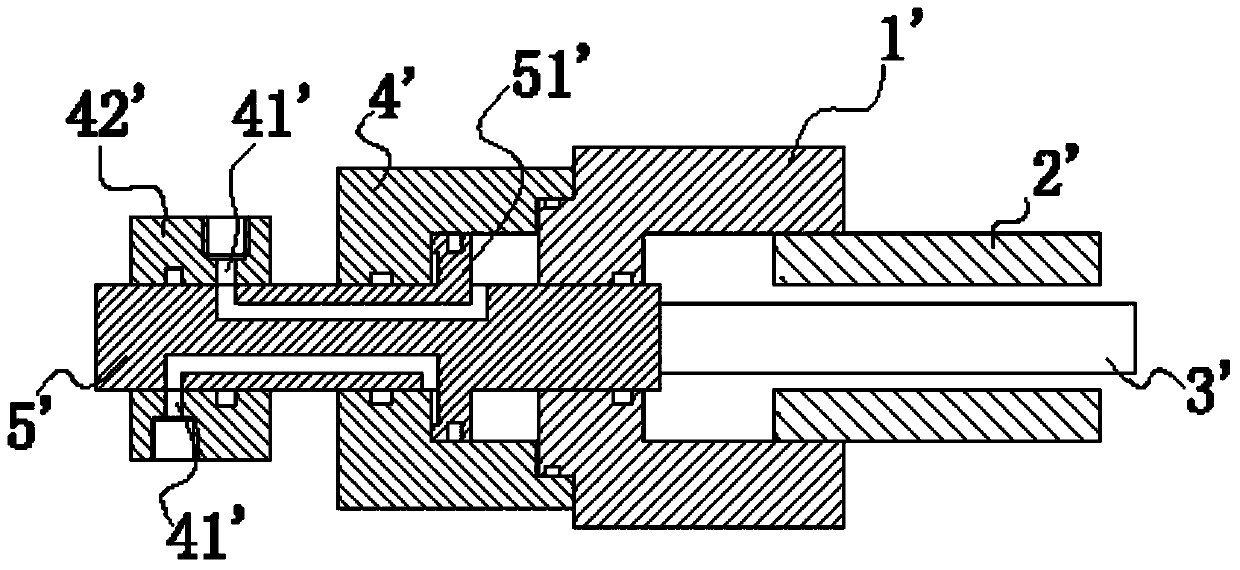

Modularized independent transmission rolling mill and unit thereof

PendingCN110842030AEasy to repair and replaceEasy to installRolling mill drivesMetal rolling arrangementsGear wheelControl engineering

The invention discloses a modularized independent transmission rolling mill and a unit thereof, and belongs to the field of metallurgical rolling equipment. The modularized independent transmission rolling mill comprises a module rolling mill body, a gear box and a motor, wherein the rolling mill body comprises two mutually independent machine frames arranged in a box body; the gear box comprisestwo mutually independent gear trains; and the two machine frames on the module rolling mill body are connected with two mutually independent motor bodies through the two gear trains on the gear box. The unit comprises one or more modular independent transmission rolling mills, wherein each machine frame of the single or multiple module rolling mill bodies is capable of adjusting an extension coefficient between the machine frames based on the speed change of the corresponding motor bodies. The modularized independent transmission rolling mill can solve the problems that the speed ratio betweenthe two machine frames in a single module rolling mill cannot be flexibly adjusted, and solves the problems that the equipment structure is complex and the dead-load power consumption is high and thelike in the prior art.

Owner:CISDI RES & DEV CO LTD

Wrapping device for domestic paper packaging machine

InactiveCN102219065AHigh transmission precisionReduce noisePaper article packagingWrapper folding/bending apparatusPulp and paper industryPackaging machine

The invention provides a wrapping device for a domestic paper packaging machine. Due to the adoption of the device, the production efficiency is improved greatly to fulfill the aim of saving production cost. The wrapping device consists of a lower paper folding mechanism, an upper paper folding scald-sealing mechanism, a pushing mechanism, a middle conveying mechanism and a first guide pillar, wherein the lower paper folding mechanism and the middle conveying mechanism are fixed on a machine frame of the packaging machine; the upper paper folding scald-sealing mechanism is sleeved on the first guide pillar and can move freely; and the pushing mechanism is arranged on the middle conveying mechanism. The wrapping device is mainly used in the field of the domestic paper packaging machines.

Owner:昆山信义恒企业管理顾问有限公司

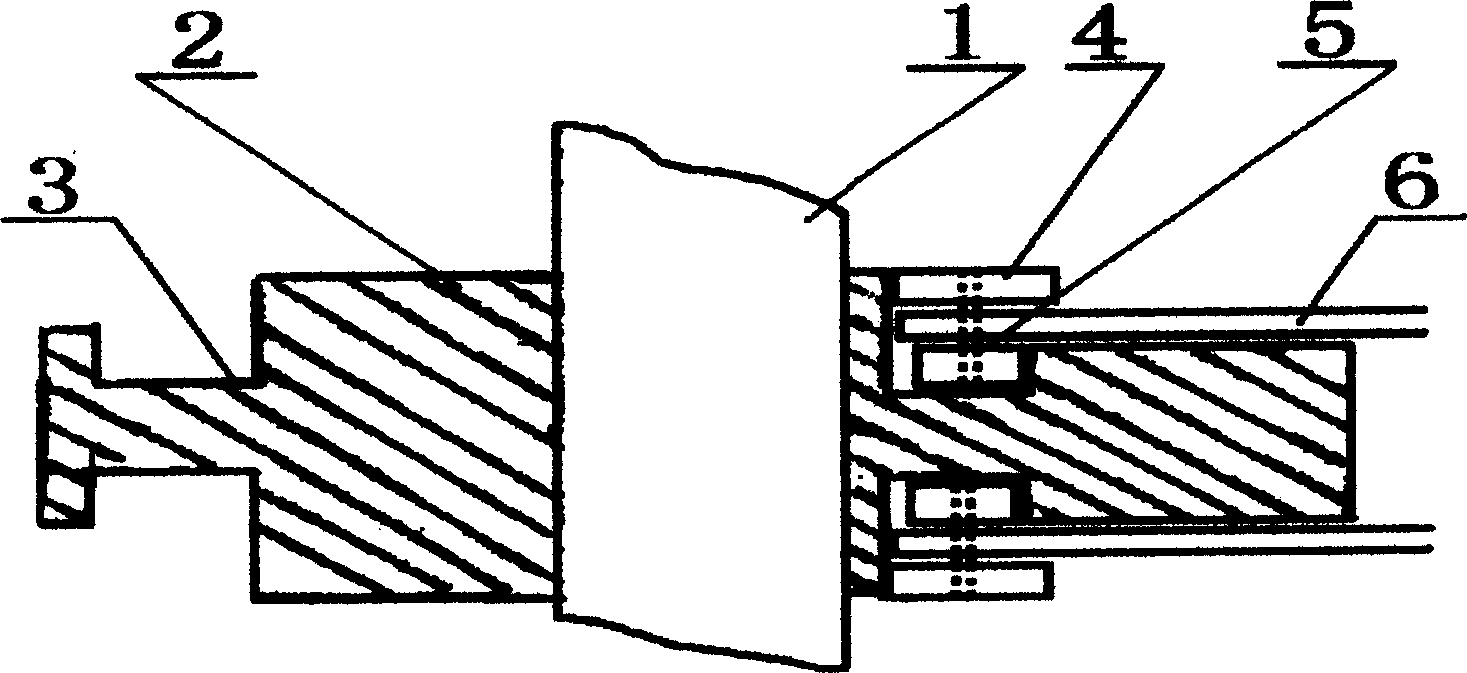

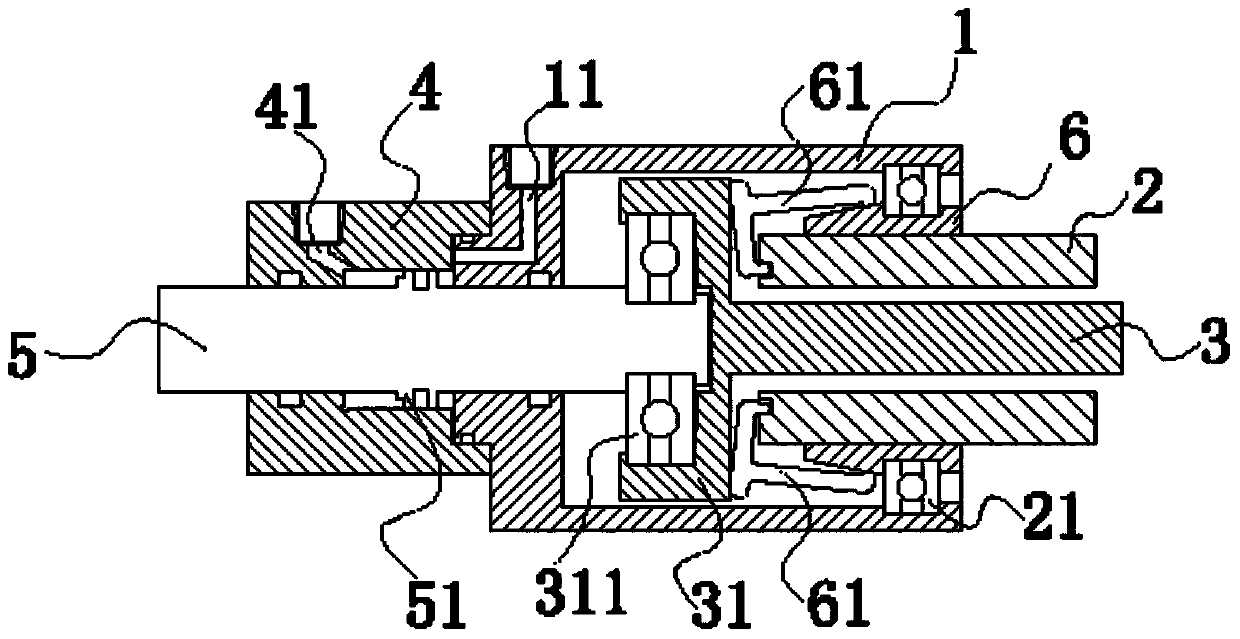

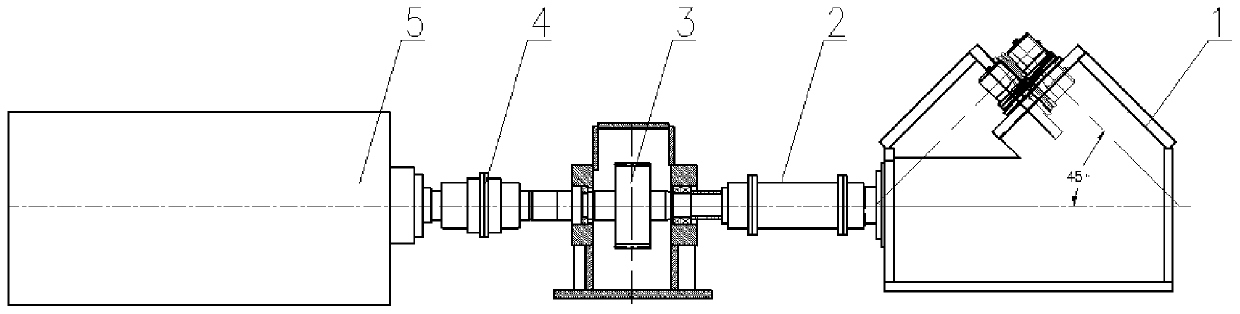

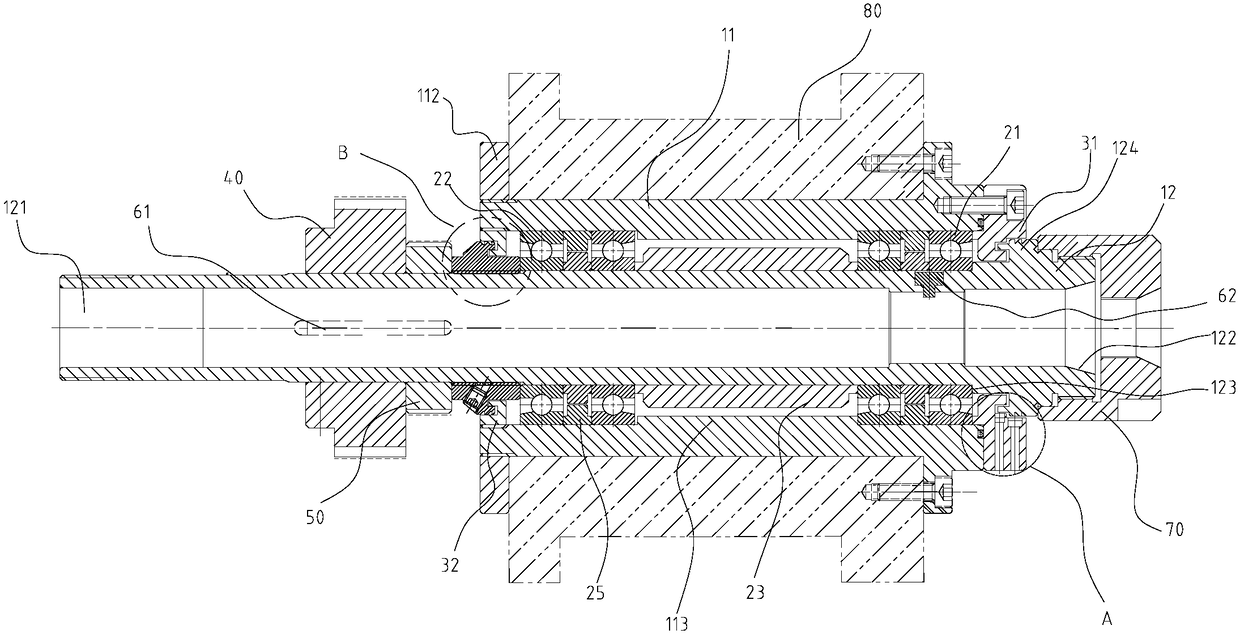

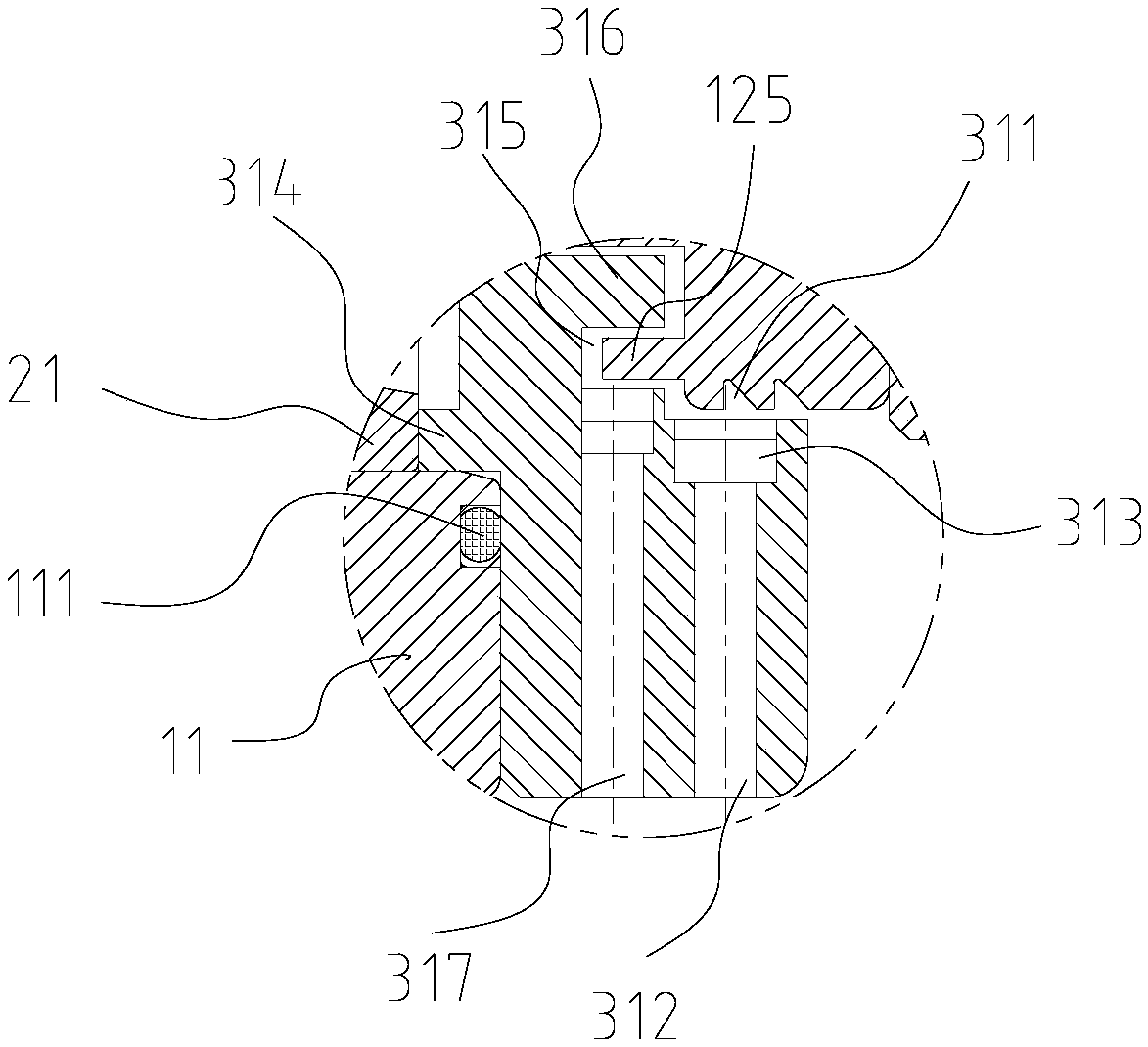

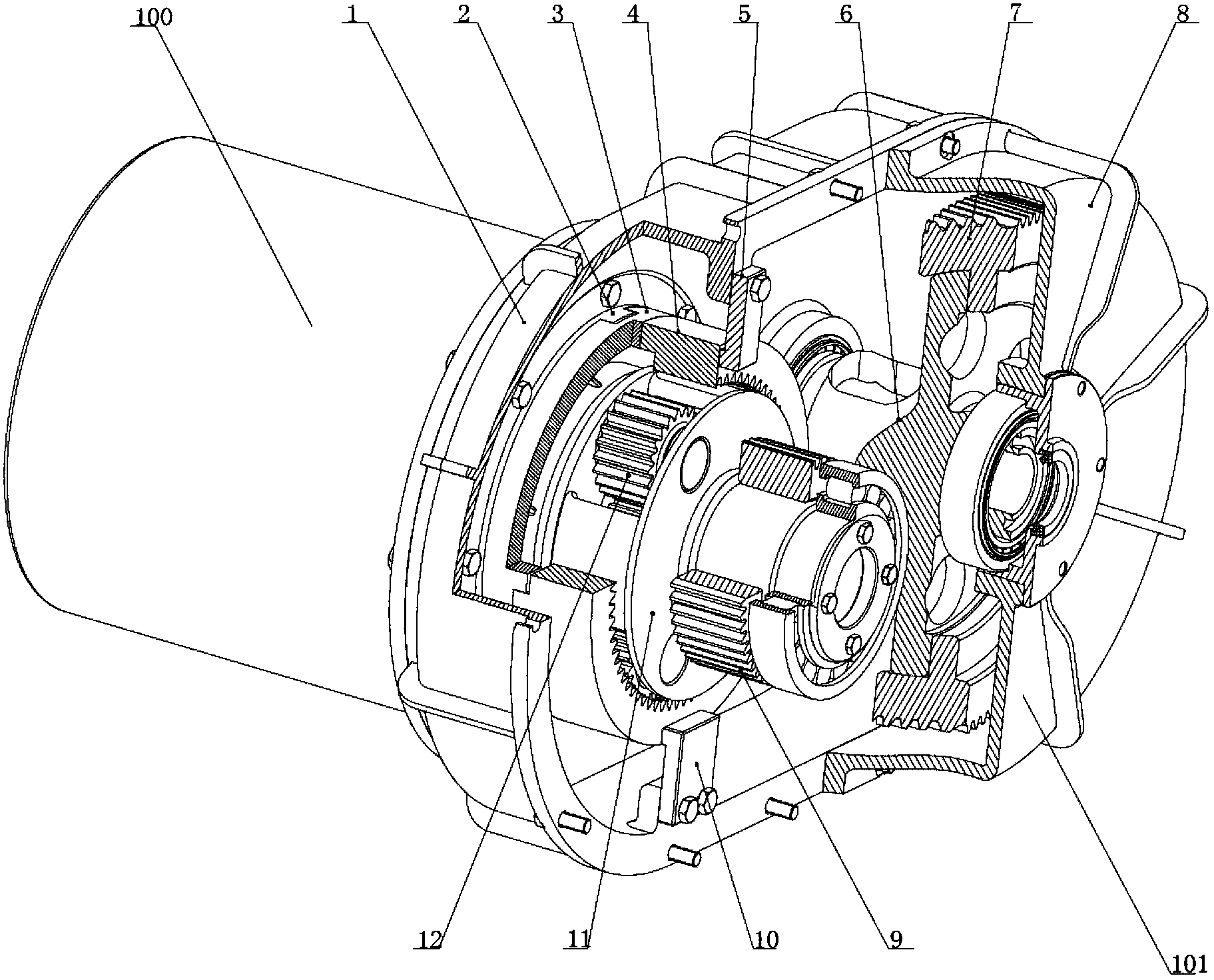

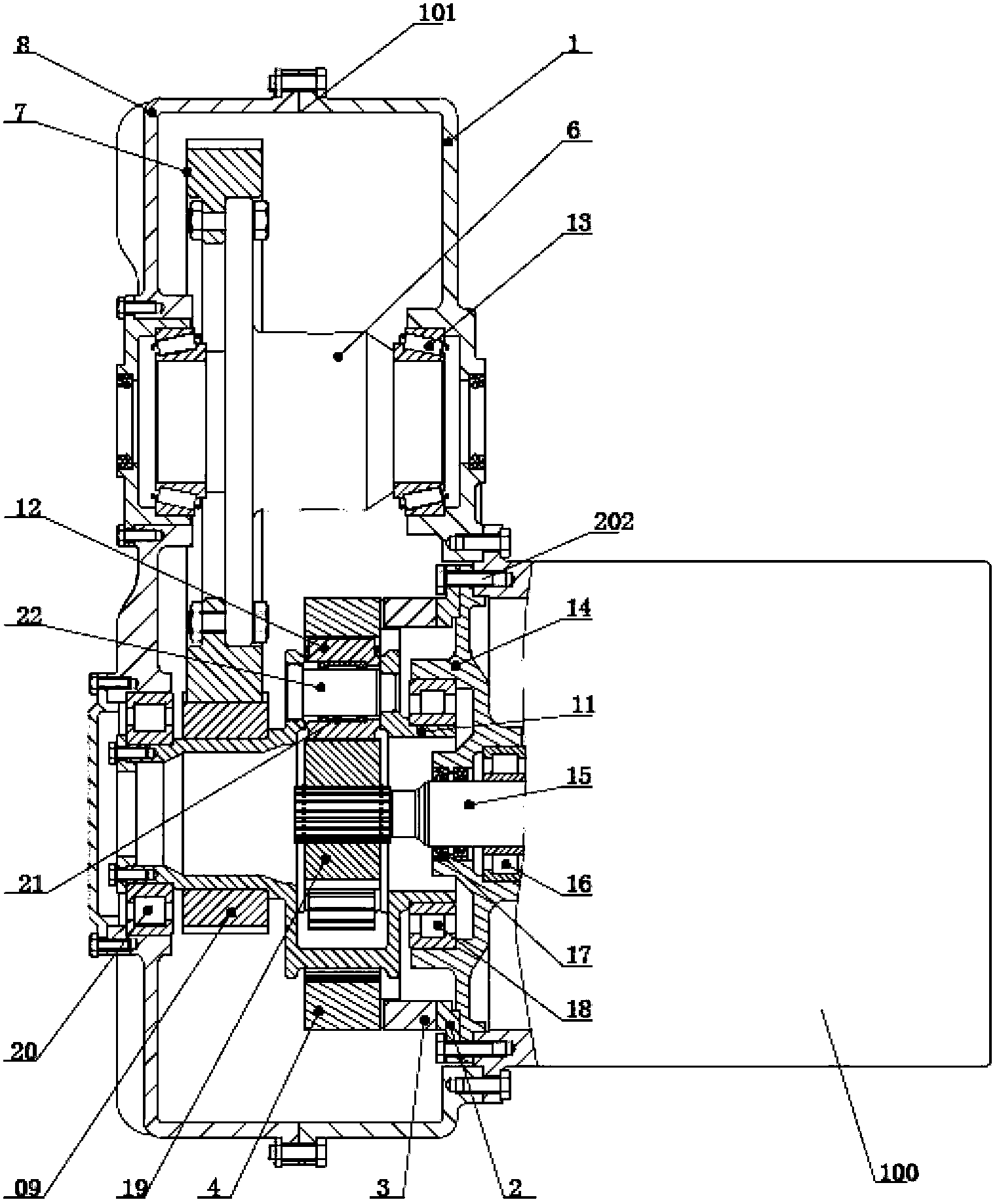

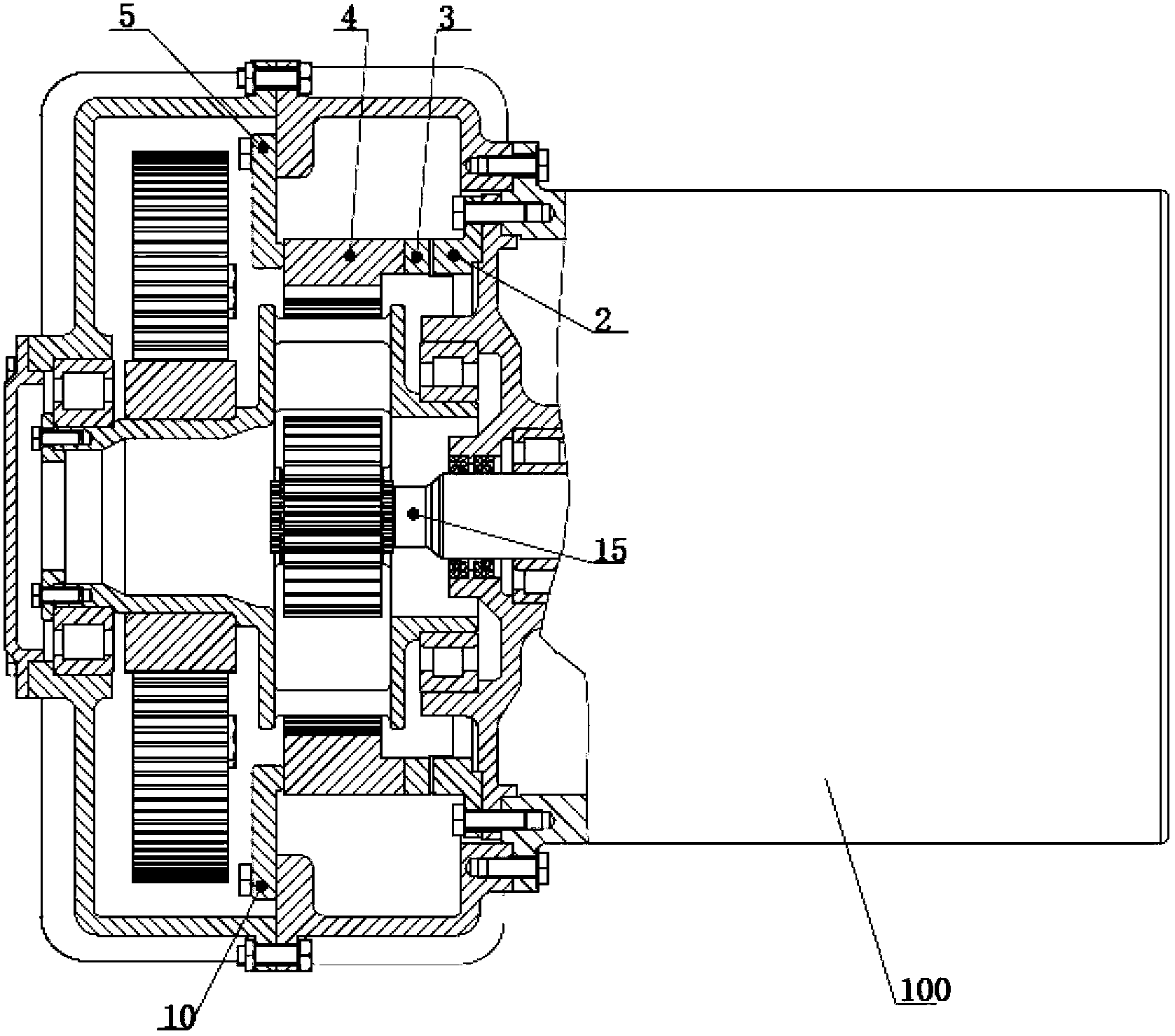

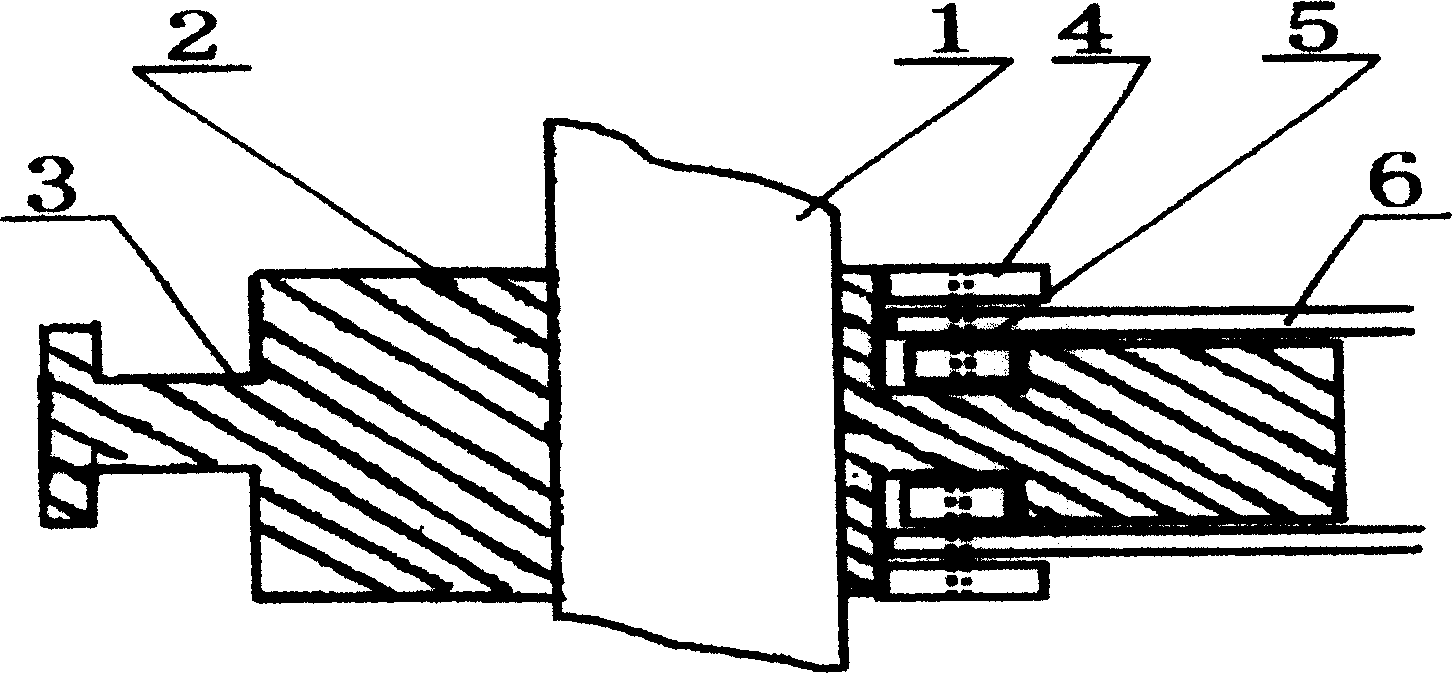

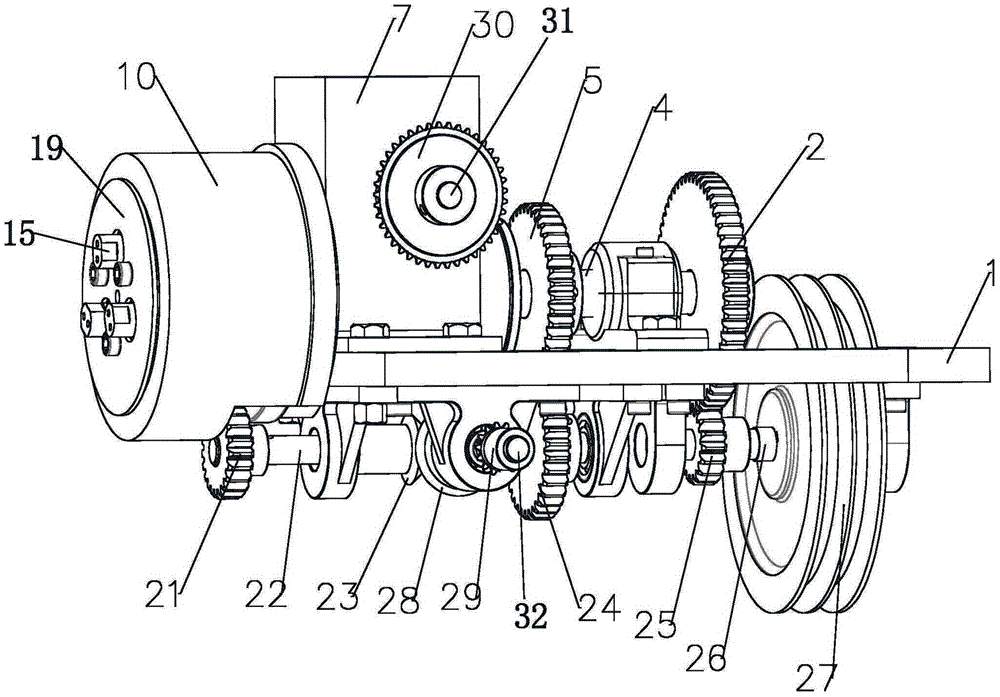

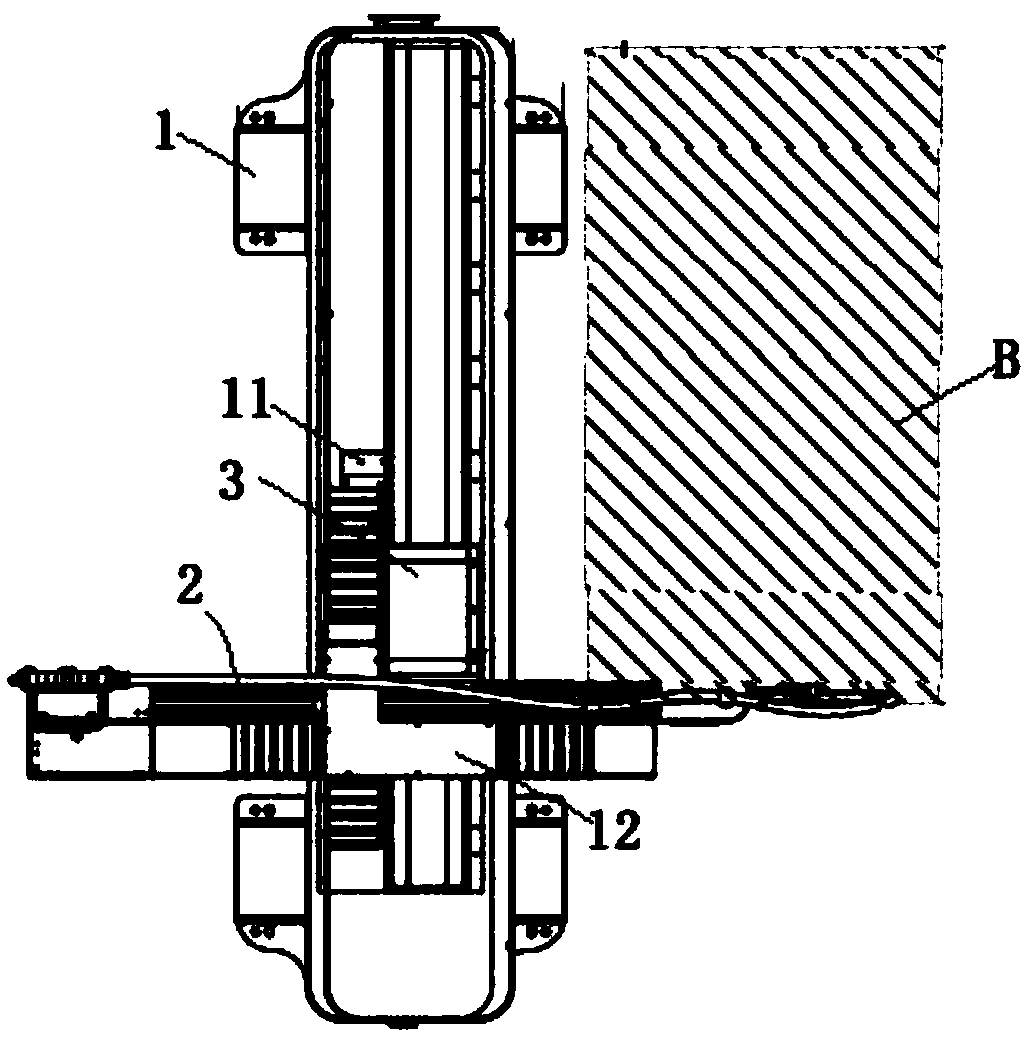

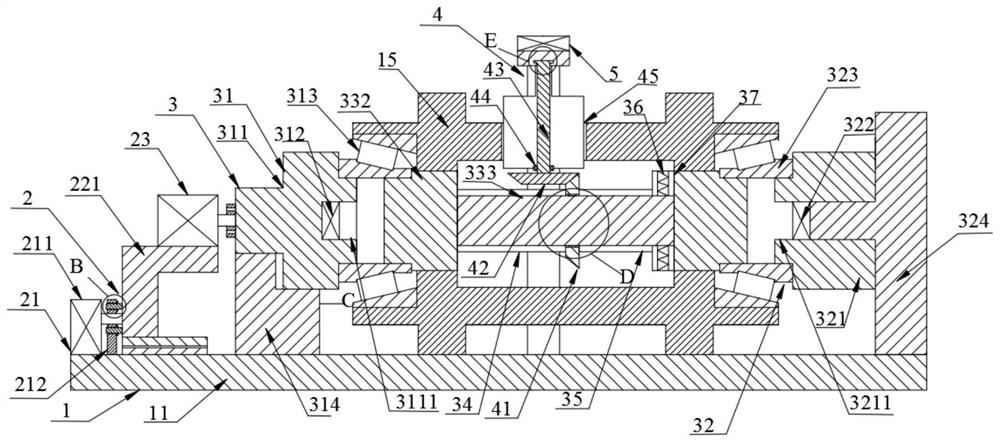

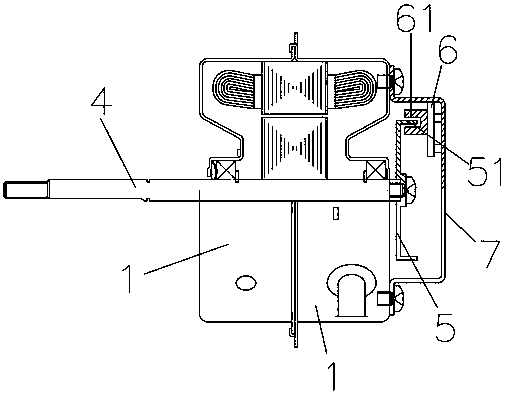

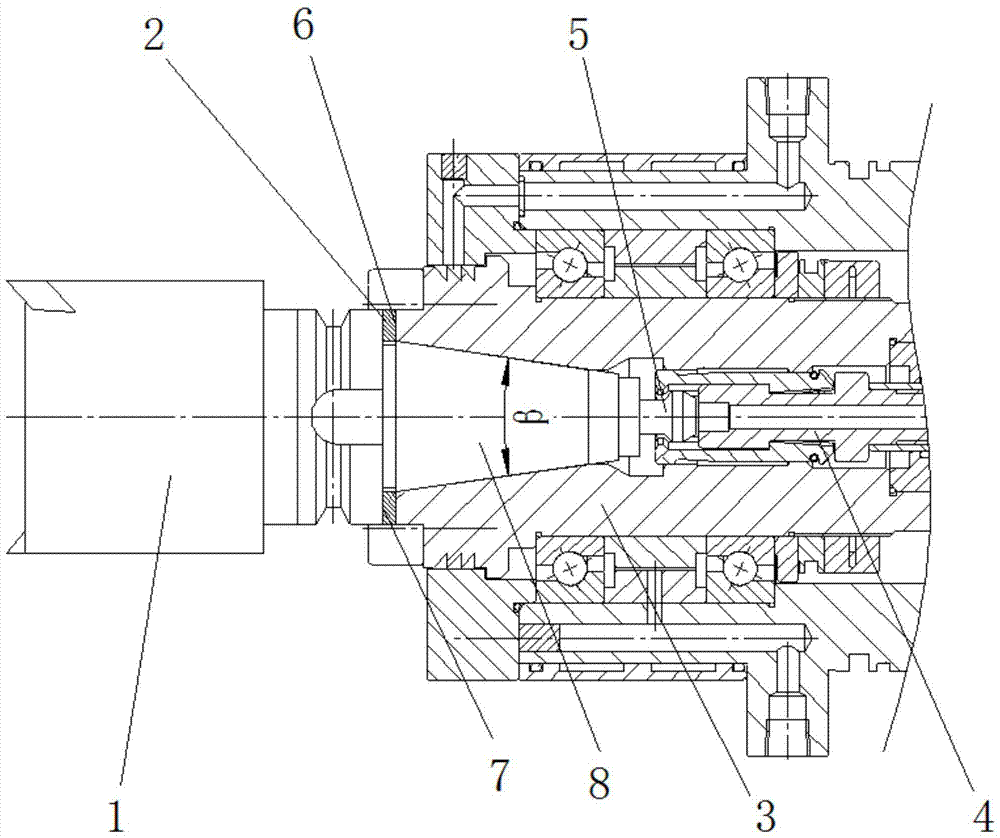

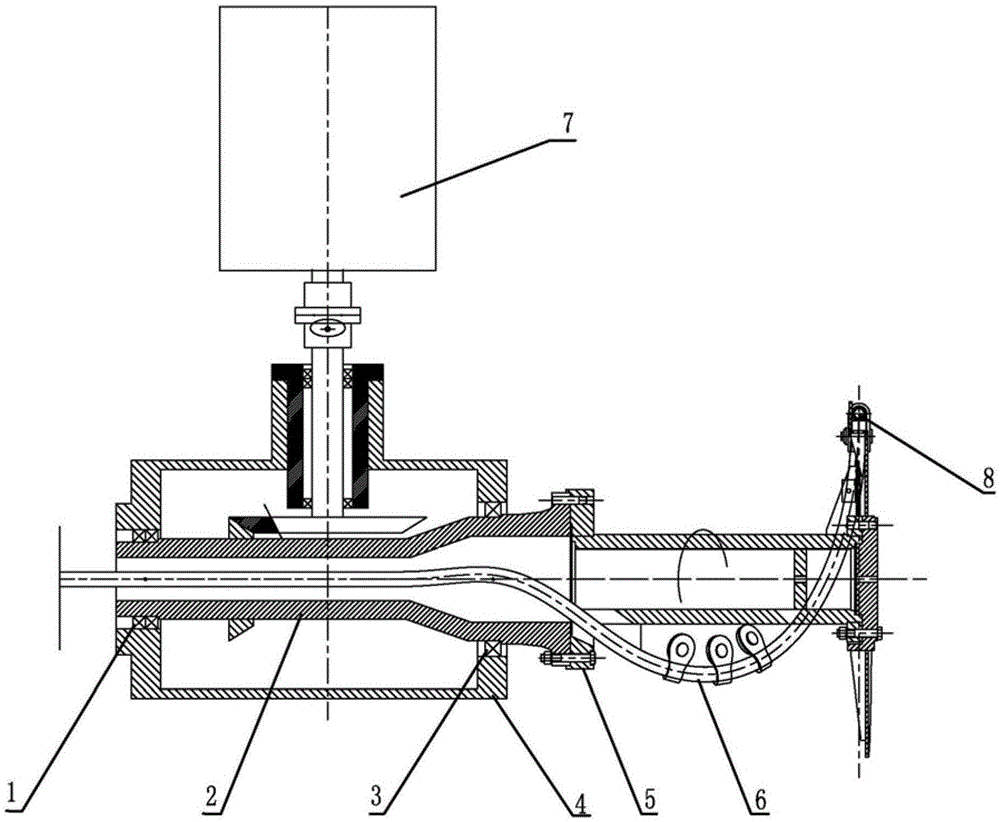

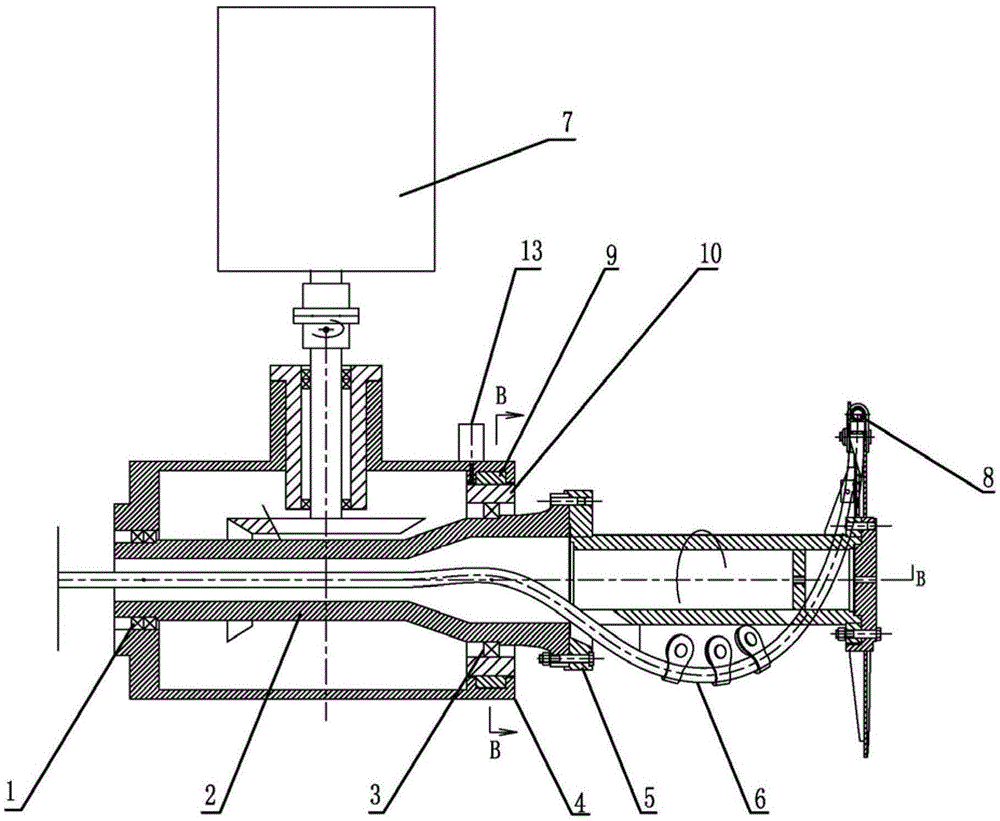

A high-precision CNC centering machine tool spindle

ActiveCN106270575BImprove rigiditySmooth operation at high speedLarge fixed membersNumerical controlDrive wheel

The invention discloses a high-precision numerical-control centerless machine tool spindle. The high-precision numerical-control centerless machine tool spindle comprises a spindle engine body, a central spindle, a bearing component, a right end cover and a driving wheel, wherein one end of the spindle engine body is fixed on a machine tool through a fixing part, and the other end of the spindle engine body is locked on the machine tool through a spindle locking block; the bearing component is sleeved on the central spindle, and the spindle engine body is sleeved on the bearing component; the bearing component comprises a first bearing pack, a bearing distance sleeve and a second bearing pack which are sleeved on the central spindle in sequence and in parallel; a first step and a bearing locking block propped against the bearing component are respectively arranged at two ends of the bearing component; the right end cover is sleeved on the central spindle and fixed on the right end face of the spindle engine body; a stop block propped against the first bearing pack is arranged on the right end cover; a convex wall is arranged on the inner wall of the spindle engine body, the right end of the convex wall is propped against the left end face of the first bearing pack, and the left end of the convex wall is in clearance fit with the right end face of the second bearing pack. The high-precision numerical-control centerless machine tool spindle disclosed by the invention has the characteristics of high precision, stable high-speed operation, and long service life.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

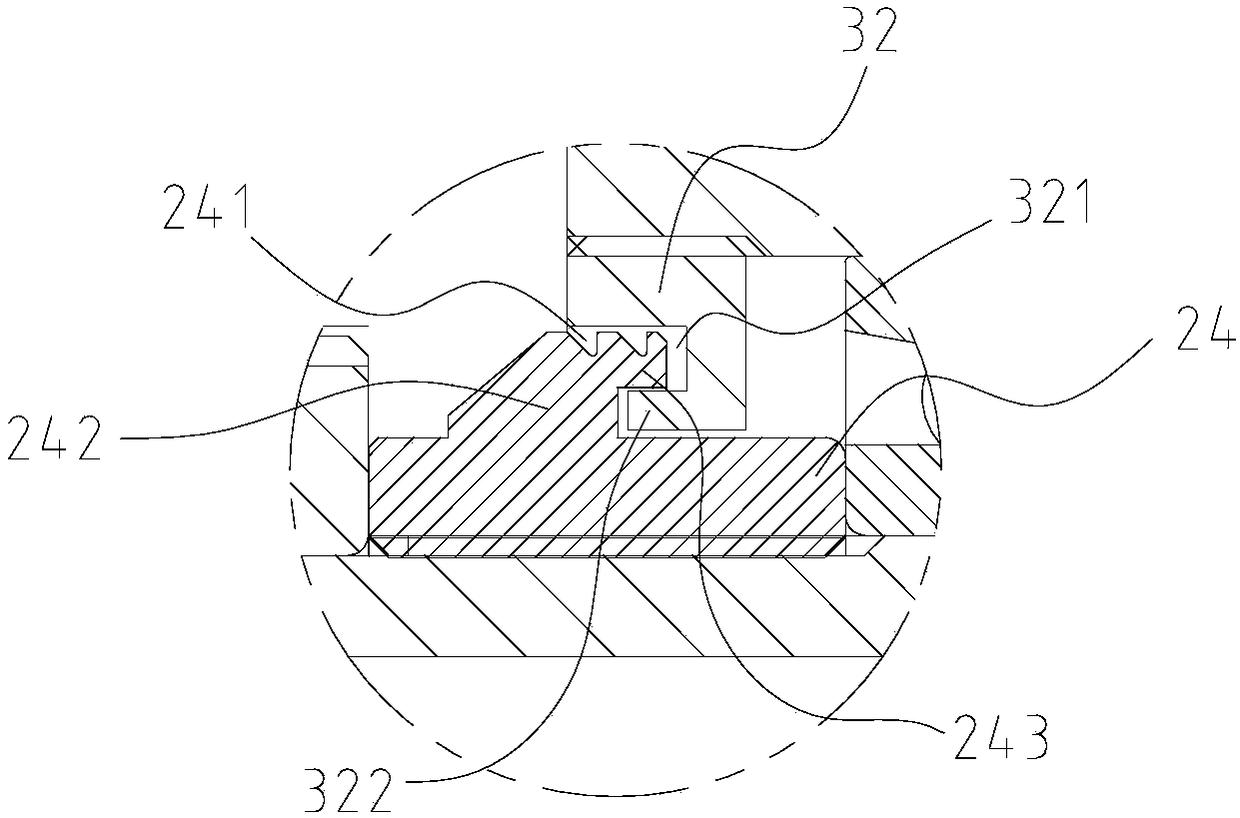

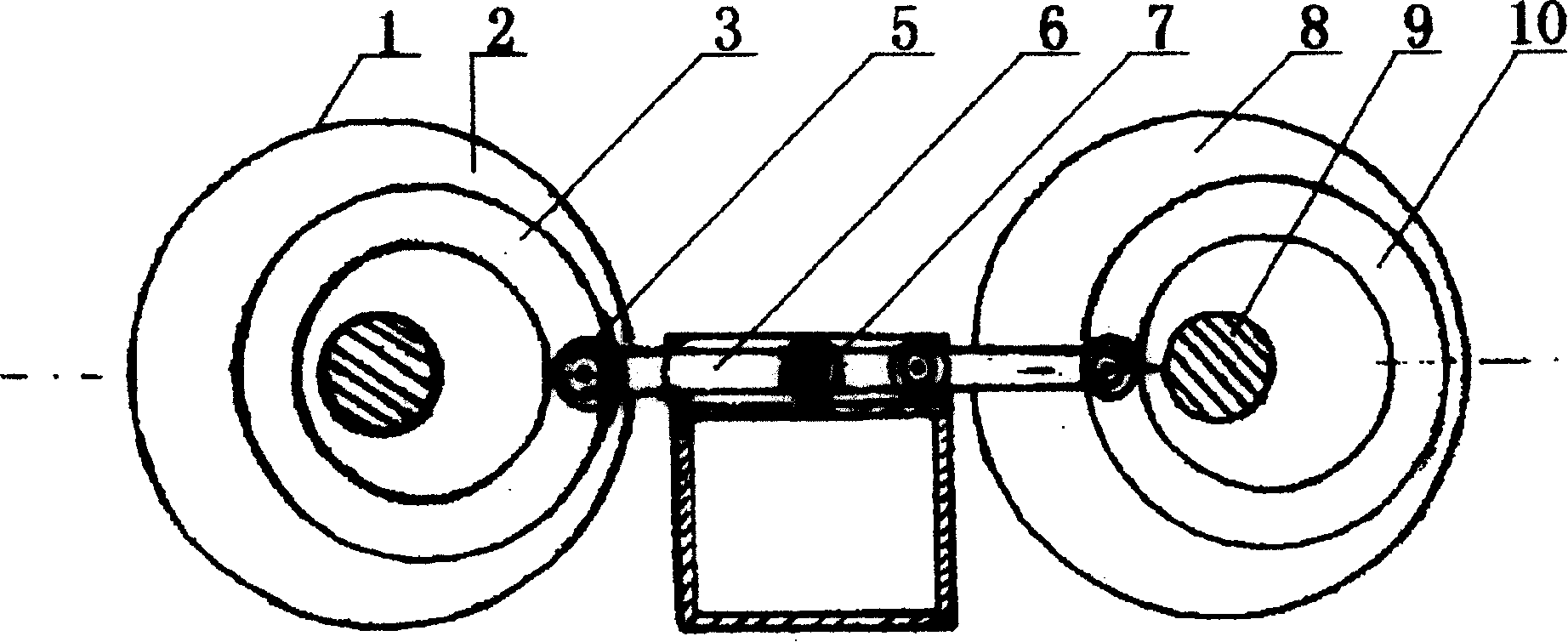

Electric vehicle transmission system

ActiveCN103660929ASmooth operation at high speedSimple structureControl devicesElectric machineryElectric vehicle

The invention provides an electric vehicle transmission system. The electric vehicle transmission system comprises a motor and a speed reducer. The motor is provided with an output shaft. The speed reducer is provided with a box and comprises a planetary gear train and a differential mechanism, wherein the planetary gear train is driven by the output shaft and arranged coaxial with the output shaft, and the differential mechanism is driven through the output end of the planetary gear train to rotate. The central axis of the differential mechanism and the axis of the output shaft are arranged in parallel. The electric vehicle transmission system has the advantages that the planetary mechanism is adopted for the speed reducer input stage, so that vibration force arms are offset mutually, and better smoothness and stability are achieved in the process of high-speed running; the output stage of the speed reducer and the differential mechanism are integrated together, the simple in structure, occupied space is small, the overall structure of the speed reducer is compact, the weight is lighter, and the overall running is smooth and stable.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Driving mechanism with eccentric round cam groove

A slotted eccentrical circular cam type drive mechanism features that an eccentrical wheel installed to central axle has an eccentrical ring slot on its circumferential surface, the longitudinally reciprocating drive rods are respectively installed in their guide tubes, and the sleeved end of said drive rod is arranged vertically in said ring slot on eccentrical cam. Its advantages are simple structure, and high stability and reliability.

Owner:王良知

Wheel hub permanent magnet synchronous motor

PendingCN108429422AFast startupGood low speed performanceMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsPermanent magnet rotorPermanent magnet synchronous motor

The invention discloses a wheel hub permanent magnet synchronous motor. The motor comprises a front end cover, a stator, a rotary transformer, a permanent magnet rotor and a rear end cover; the frontend cover and the rear end cover are installed at the two ends of the permanent magnet rotor respectively, one end of the stator is movably connected to the inner side of the front end cover, the other end of the stator protrudes out from a shaft hole of the rear end cover, and the rotary transformer is fixed to the end of the stator; the front end cover, the permanent magnet rotor, the rear end cover and the stator are coaxially installed. The motor has the advantages of high starting speed, good low-speed performance, high overload capacity, stable high-speed running, wide speed regulation range, wide efficient working area and the like.

Owner:包头天工电机有限公司

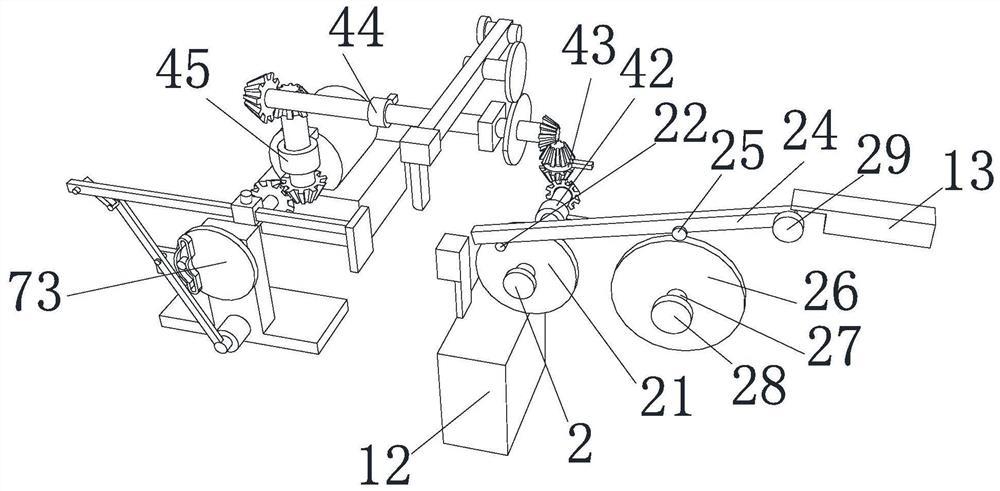

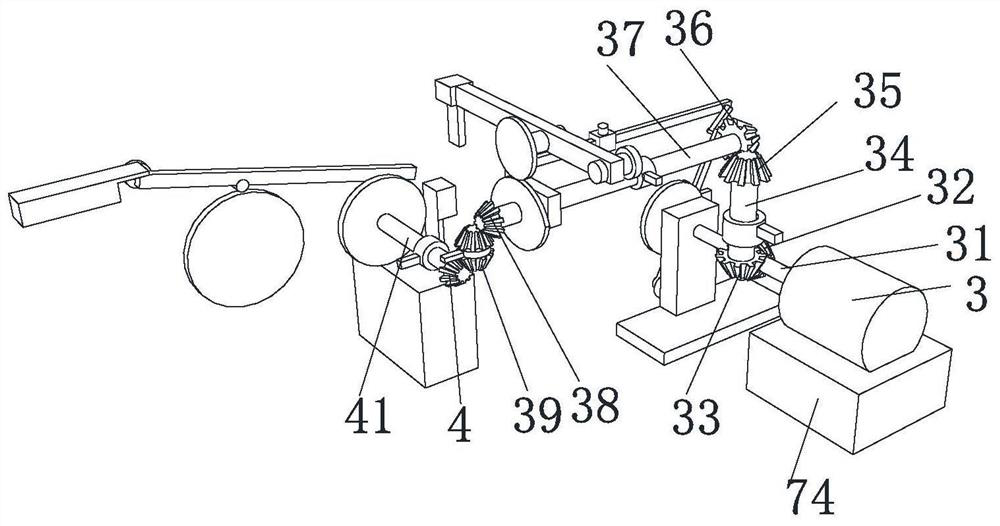

Optimum-speed full-automatic fried dough twist machine

InactiveCN105076282ABarrier extrusionGuaranteed to workEngine sealsGearingTransmitted powerEngineering

The invention provides an optimum-speed full-automatic fried dough twist machine which has a rack. A formation mechanism is arranged on the rack and is fixed at the middle position of the rack. The formation mechanism comprises a transmission mechanism, a head device, a cut-off mechanism and a conveying mechanism. The transmission mechanism transmits power to the head device and the conveying mechanism, and fried dough twist produced from the head device is conveyed through the conveying mechanism to below a cut-off head of the cut-off mechanism and is cut off by the cut-off head. By arranging a sealing device between large outer teeth of the head and a boss, flour inside a flour box is effectively prevented from entering the head device, and normal operation of parts inside the head device is guaranteed. In addition, foreign materials are effectively prevented from entering the head device. Meanwhile, a bearing pedestal of the head and the boss fixed on the flour box are in threaded connection. Thus, the head device is convenient to dismantle and maintain when parts inside the head device break down. The machine provided by the invention has a simple structure and has high transmission accuracy. Service life of parts inside the head device is long. The machine provided by the invention has high use value.

Owner:罗丽丽

High-consistency in-mold injection molding precision structural part

The invention discloses a high-consistency in-mold injection molding precision structural part, and relates to the technical field of in-mold injection molding precision structural parts. The high-consistency in-mold injection molding precision structural part comprises a machine box, a product falling table is arranged in the machine box, a rectangular table is fixedly connected to the upper surface of the bottom in the machine box, a product placing table is fixedly connected to the right face in the machine box, and a printing device is arranged in the machine box. According to the high-consistency in-mold injection molding precision structural part, a third cylindrical connecting rod is driven to rotate through rotation of a fourth bevel gear, a fifth bevel gear is driven to rotate through rotation of the third cylindrical connecting rod, two sixth bevel gears are driven to rotate through rotation of the fifth bevel gear, a seventh bevel gear is driven to rotate through rotation ofthe sixth bevel gear at the lower end, a fourth cylindrical connecting rod is driven to rotate through rotation of the seventh bevel gear, and through multiple linkage structures, one motor can driveother structures to operate during operation, so that the linkage among the devices is greatly improved.

Owner:SEAFLYER MOLDING SHENZHEN CO LTD

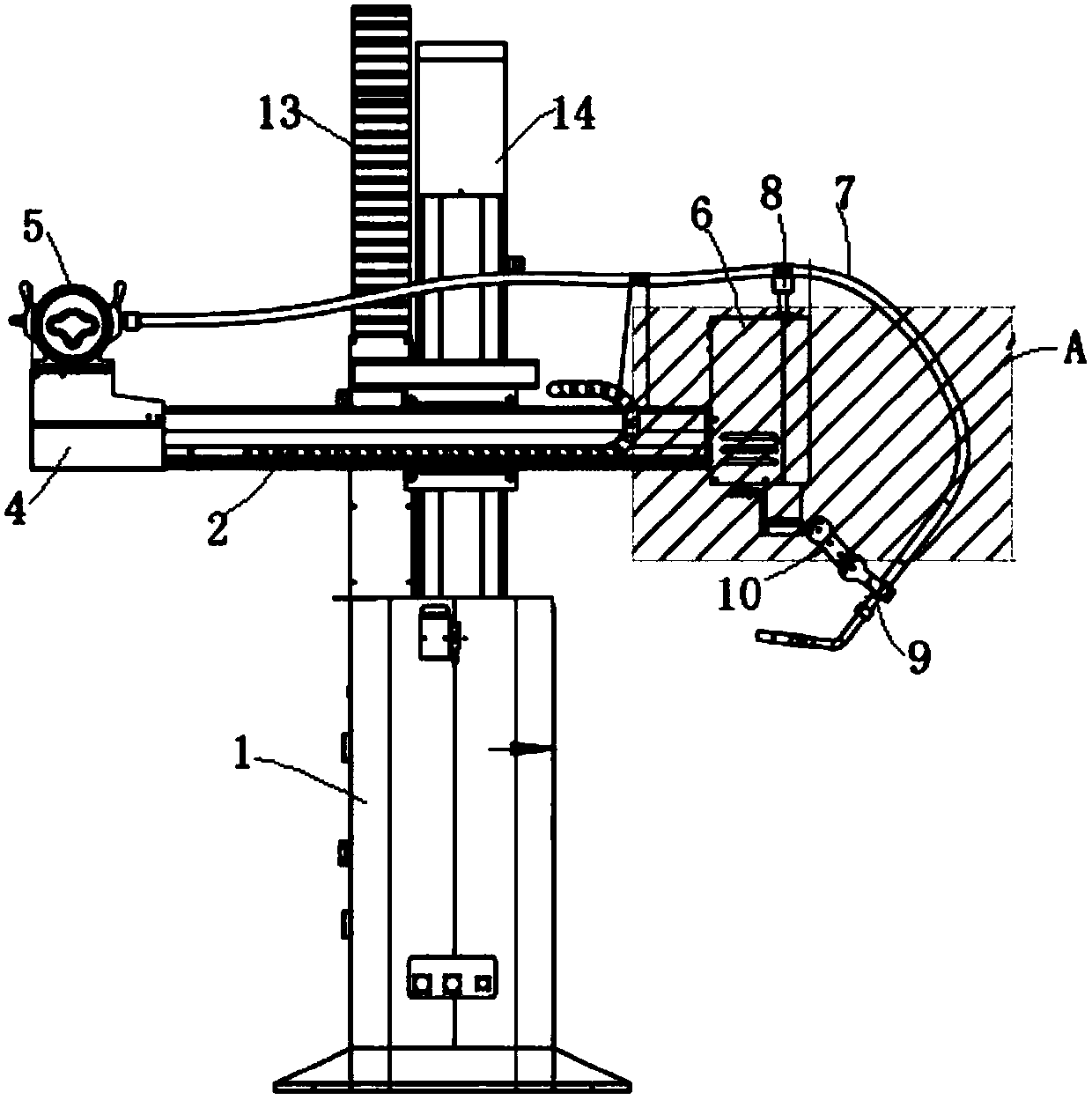

Welding manipulator

PendingCN107627052AExtended service lifeIncrease profitProgramme-controlled manipulatorGripping headsManipulatorEngineering

The invention relates to a welding manipulator. The welding manipulator comprises a rack. An X-axis linear module, a Y-axis linear module and a Z-axis linear module are arranged on the rack. The X-axis linear module comprises an X-axis guide rail arranged on the rack. The X-axis guide rail is connected with a transmission component and a driving component. The end of the X-axis guide rail is provided with a sliding block. A welding machine is fixed to the sliding block. The other side of the X-axis guide rail is provided with a fixed block. A welding hose is connected to the welding machine. The end head of the welding hose is provided with a welding head. The middle portion of the welding hose is connected with the top of the fixed block through an upper fixing foot. The position, close to the end head, of the welding hose is provided with a first movable hinge piece. The bottom of the fixed block is provided with a second movable hinge piece. The first movable hinge piece and the second movable hinge piece are connected movably. The mass-produced linear modules developed independently are adopted for the X-axis, the Y-axis and the Z-axis. Through secondary structure combination design, the strength of equipment is improved, high-speed operation is smoother and steadier.

Owner:浙江斯柯特科技有限公司

Nickel sulfate evaporation and crystallization process

ActiveCN107008026BSmall footprintLow costChemical industrySolution crystallizationVapor–liquid separatorSulfate

The invention relates to a nickel sulfate evaporative crystallization process which comprises the following steps: S1, fresh steam supplies heat to a heat exchanger group, a first evaporation and concentration device and a second evaporation and concentration device; S2, a material enters the heat exchanger group to be pre-heated, then enters the first evaporation and concentration deice after being preheated, and when the material reaches an expected concentration in a gas-liquid separator, the material enters the second evaporation and concentration device to be further evaporated and concentrated; and S3, the material meeting the expected concentration value in the second evaporation and concentration device is discharged from a discharge port and enters a cooling kettle to be cooled, then enters a centrifugal machine to be separated and crystallized, and finally, a product is discharged from the centrifugal machine, and the separated mother liquor is stored in a mother liquor tank. The nickel sulfate evaporative crystallization process provided by the invention is stable and reliable, energy-saving and emission-reducing, small in occupied area and low in cost.

Owner:JIANGSU RUISHENGHUA ENERGY TECH CO LTD

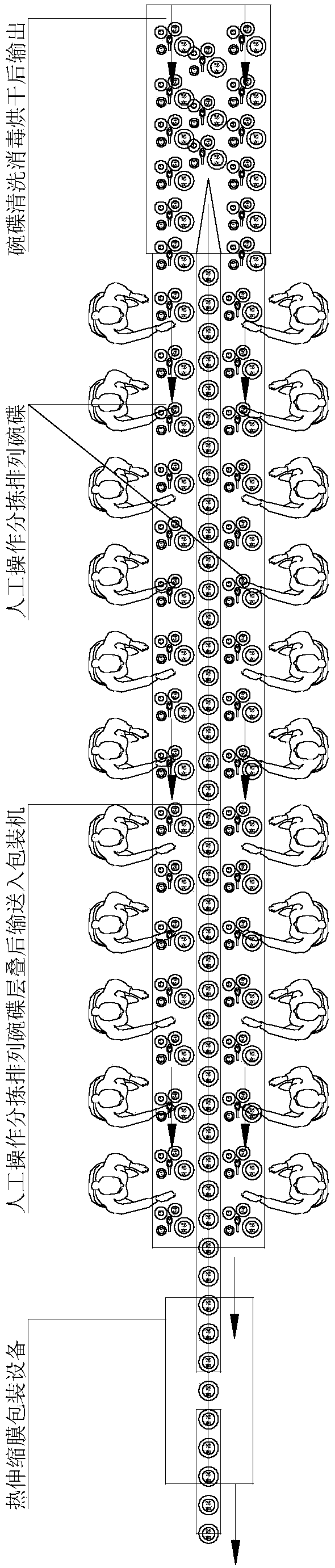

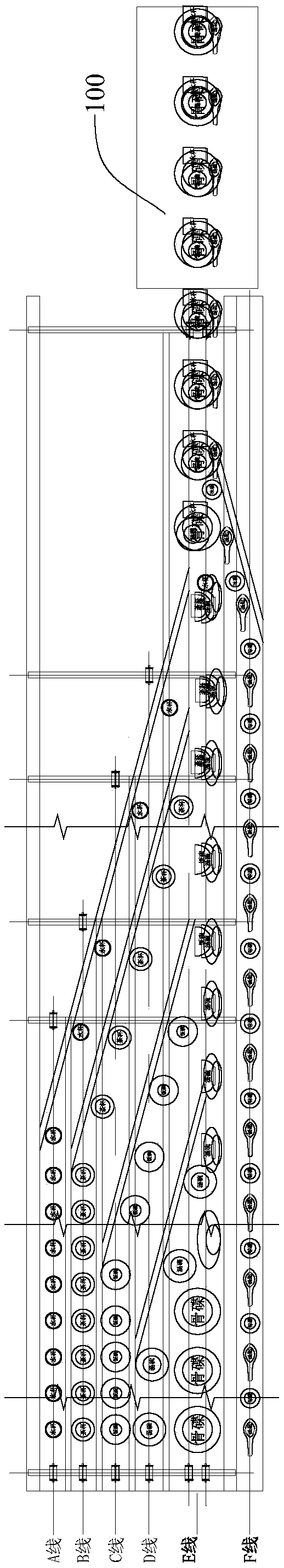

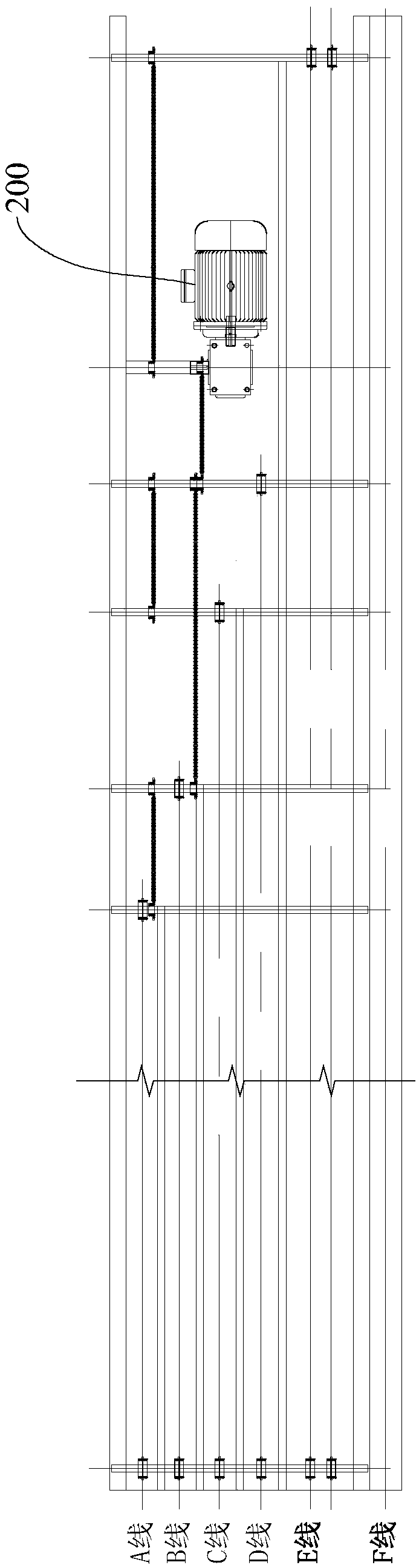

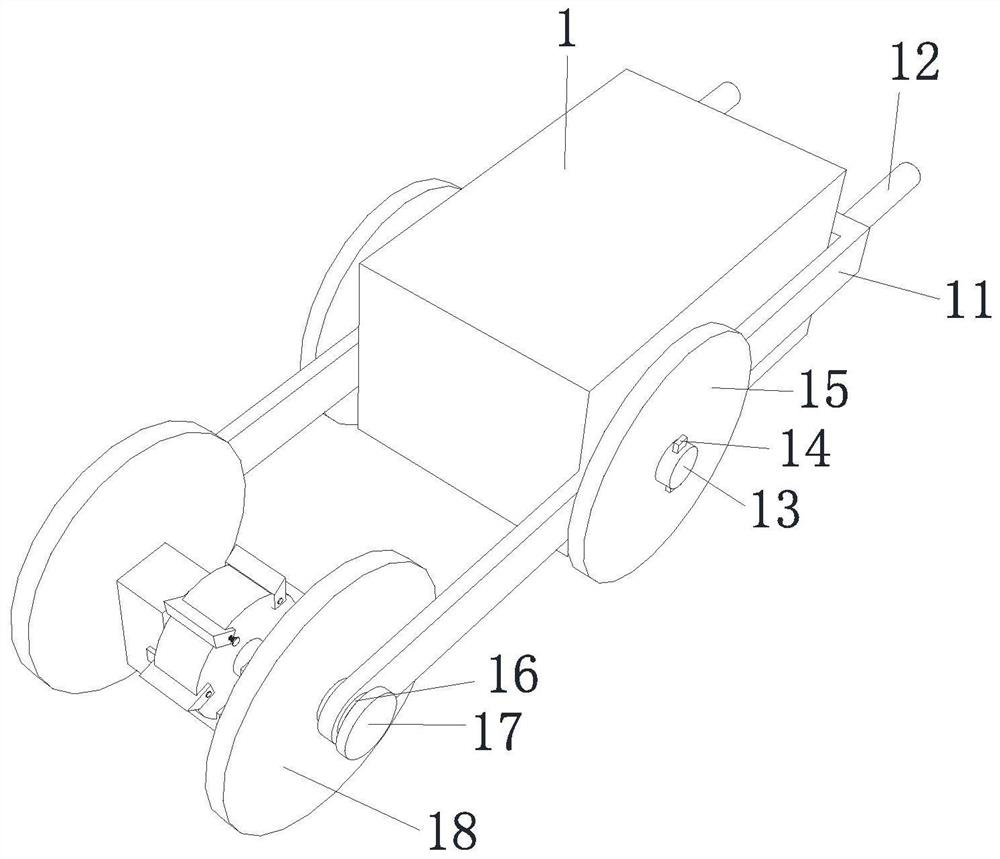

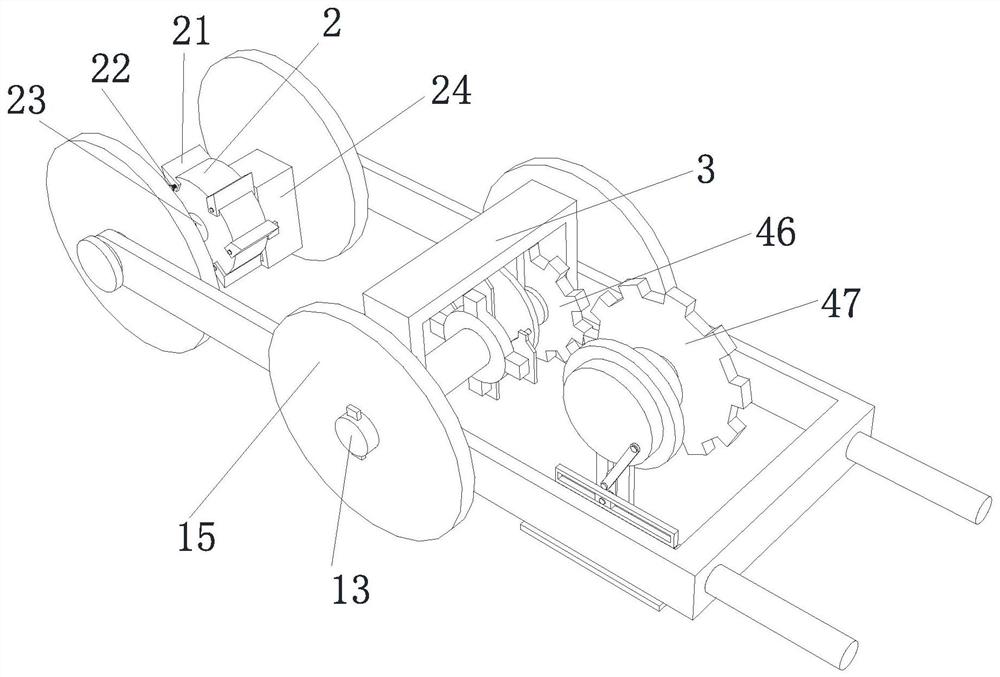

A fully automatic vertical dish bowl cup confluence conveying equipment and its application method

ActiveCN106809437BSolve the shortcomings of manual operation of combined packaging equipmentRealize six-in-one fully automaticPackagingProduction lineEngineering

Owner:台山市远博机械科技有限公司

Agricultural pinpoint control device for fertilizer application for agricultural Intelligence

The invention discloses an agricultural pinpoint control device for fertilizer application for agricultural intelligence. The agricultural pinpoint control device comprises a machine box, wherein a vehicle frame is fixedly connected to the front side and the rear side of the machine box, and comprises a front part, a rear part and a right part, and rotating shafts II are respectively and movably connected to the inner surfaces of the vehicle frame of the front part, the rear part and the right part in a sleeving manner. According to the agricultural pinpoint control device for fertilizer application for agricultural intelligence, eight wedge-shaped cutter heads are in contact with the ground, and the surfaces of the eight wedge-shaped cutter heads are wedge-shape, so that when the eight wedge-shaped cutter heads are in contact with the bottom surface, the earth on the ground can be turned up, and when the eight wedge-shaped cutter heads are not in contact with the bottom surface, fixing screws are rotated to enable the fixing screws to be separated from the wedge-shaped cutter heads; and at this moment, the wedge-shaped cutter heads can be taken down to be replaced with other wedge-shaped cutter heads, so that the control device can operate on different grounds, and the availabilities of the device can be greatly improved.

Owner:京山俊平机电科技有限公司

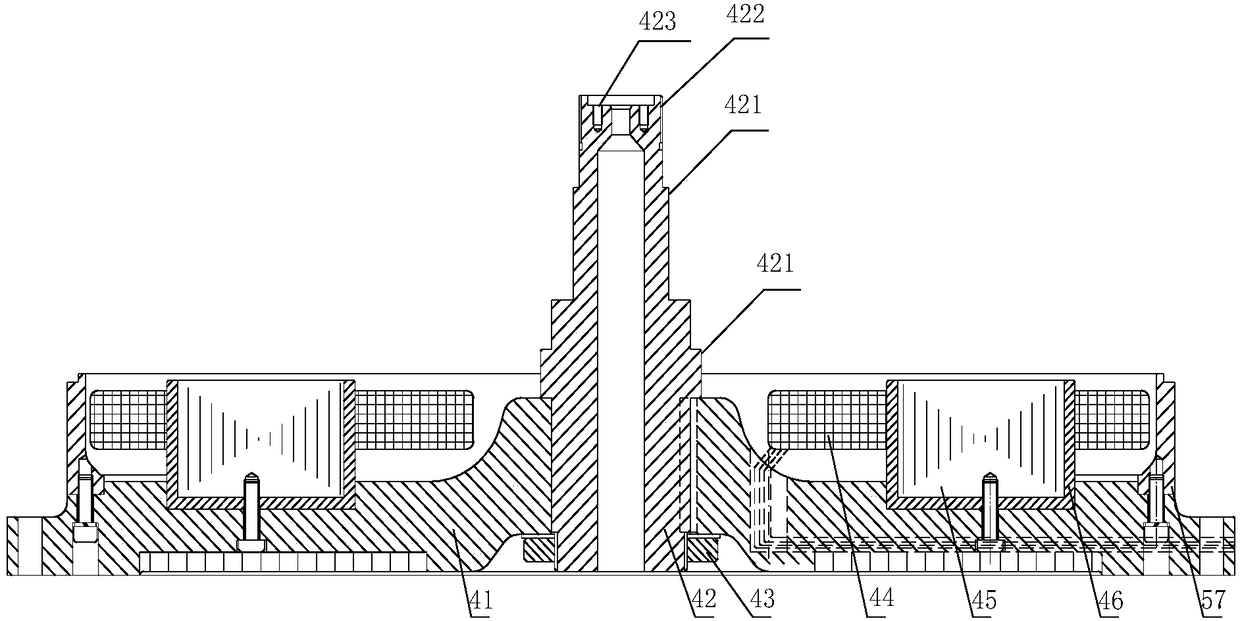

Disc type permanent magnet synchronous exhaust fan motor

PendingCN108539944AImprove reliabilityFew partsMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsPermanent magnet rotorEngineering

The invention discloses a disc type permanent magnet synchronous exhaust fan motor. The motor comprises a rotary transformer cover plate, a rotary transformer, a fan permanent magnet rotor and a stator. With the adoption of an axial magnetic circuit, the axial length of the motor is reduced, and the motor is suitable for being used in a place with small axial space and large radial space.

Owner:包头天工电机有限公司

Instrument for rapidly measuring total thickness of cone bearing

InactiveCN112857198APrevent leakageHigh precisionMachine bearings testingUsing electrical meansTotal thicknessBevel gear

The invention discloses a cone bearing total thickness rapid measuring instrument, which comprises a mounting frame, a power device, a clamping device, a transmission assembly and an ampere meter, wherein one side of the mounting frame is fixedly connected with the power device, one side of the power device is fixedly connected with the clamping device, one side of the clamping device is movably connected with the transmission assembly, one side of the mounting frame is fixedly connected with the clamping device, one side of the transmission assembly is movably connected with the mounting frame, the mounting frame comprises a mounting base plate, a mounting frame body and a fixing plate, one side of the mounting frame body is fixedly connected with the mounting base plate, the transmission assembly comprises a first bevel gear, a second bevel gear and a gear shaft, the tooth surfaces of the first bevel gear and the second bevel gear are meshed, the side, away from the first bevel gear, of the second bevel gear is fixedly connected with the gear shaft, a fixing block is arranged on the side, away from the second bevel gear, of the gear shaft, a rotation groove is formed in one side of the fixing plate, a fixing block is inserted into the rotation groove, and the gear shaft is movably connected with the fixing plate.

Owner:杭州聚森科技有限公司

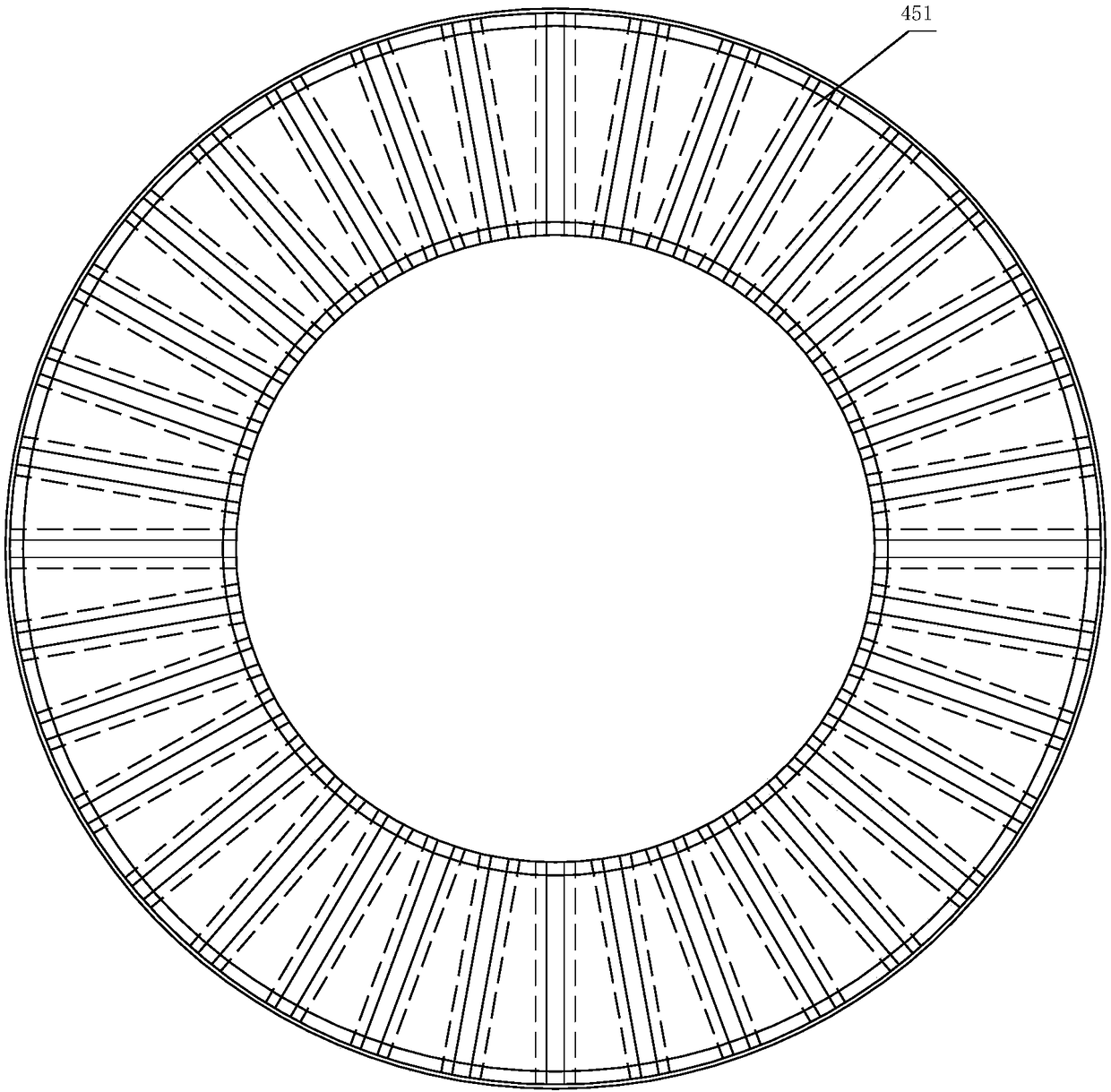

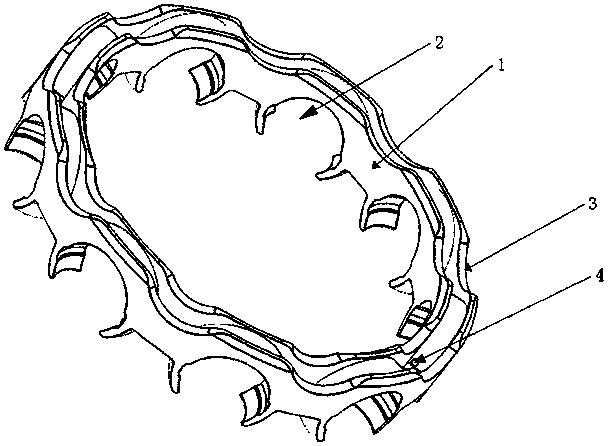

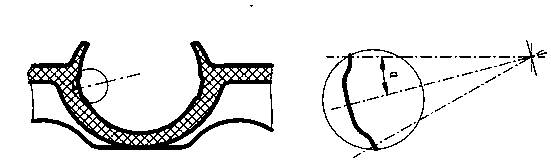

Bearing cage and bearing

ActiveCN109027009BReduce weightSmooth operation at high speedBearing componentsClassical mechanicsStructural engineering

A bearing cage and a bearing are provided. The invention relates to the technical field of bearing, by designing a bearing cage with a conical arc structure at the bottom between pockets and a groovestructure at the bottom, the technical problem of reducing the service life of the bearing due to factors such as instability of the cage during high-speed operation, uneven distribution of internal lubricating grease, instability of the pocket shape and the like existing in the prior art is solved. The bearing cage includes a cage body provided with a plurality of pocket holes and a groove structure at the bottom of the cage; the bottom between adjacent pockets is provided with a conical arc structure. The bearing cage is used for the bearing, can keep the stable running of the bearing cage.The grease is distributed uniformly, the wall thickness between the arc surface at the bottom of the outer diameter and the inner surface of the pocket is consistent (close) with the wall thickness between the arc surface at the bottom of the cage and the inner surface of the pocket, so that the expansion amounts of the two materials are consistent (close) to ensure the shape of the pocket to be stable, so that the steel ball is guided normally and the service life of the bearing is prolonged.

Owner:邓四二 +1

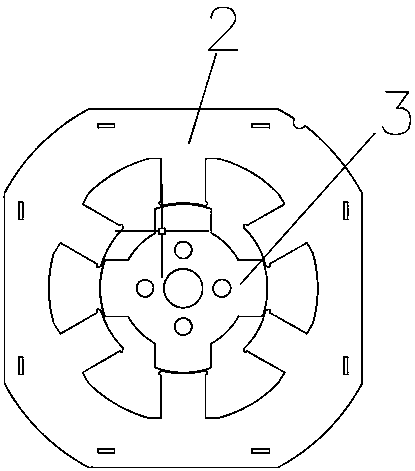

A Low Noise Switched Reluctance Motor

ActiveCN105978190BNot easily affected by vibrationNot easy to shiftMagnetic circuit rotating partsStructural associationLow noiseMotor vibration

The invention relates to the field of household appliances, and specifically relates to a low-noise switched reluctance motor. The motor comprises an end cover as well as a stator and a rotor arranged in the end cover; a rotating shaft connected with the end cover via a bearing penetrates through the rotor, and one end of the rotating shaft stretches out of the end cover to form an output shaft; the rotor comprises a rotor body and a plurality of teeth surrounding the rotor body, an anti-vibration de-noising block is filled between the adjacent teeth, the anti-vibration de-noising blocks are fixedly connected via connectors on two end faces of the rotor, and reinforcing engagement structures are arranged between the rotor and the anti-vibration de-noising blocks. The whole rotor forms a complete cylinder via the anti-vibration de-noising blocks, connecting discs and the like, and gaps between the teeth are filled, so that the dynamic balance of the rotor is improved and then vibration and noise of the motor are reduced. Meanwhile, the rotating inertia of the rotor is increased, the wind resistance is reduced, the noise of air power is reduced and vibration and noise of the motor are greatly reduced.

Owner:HUZHOU YONGCHANG BEISHITUO ELECTRIC APPLIANCE INDAL

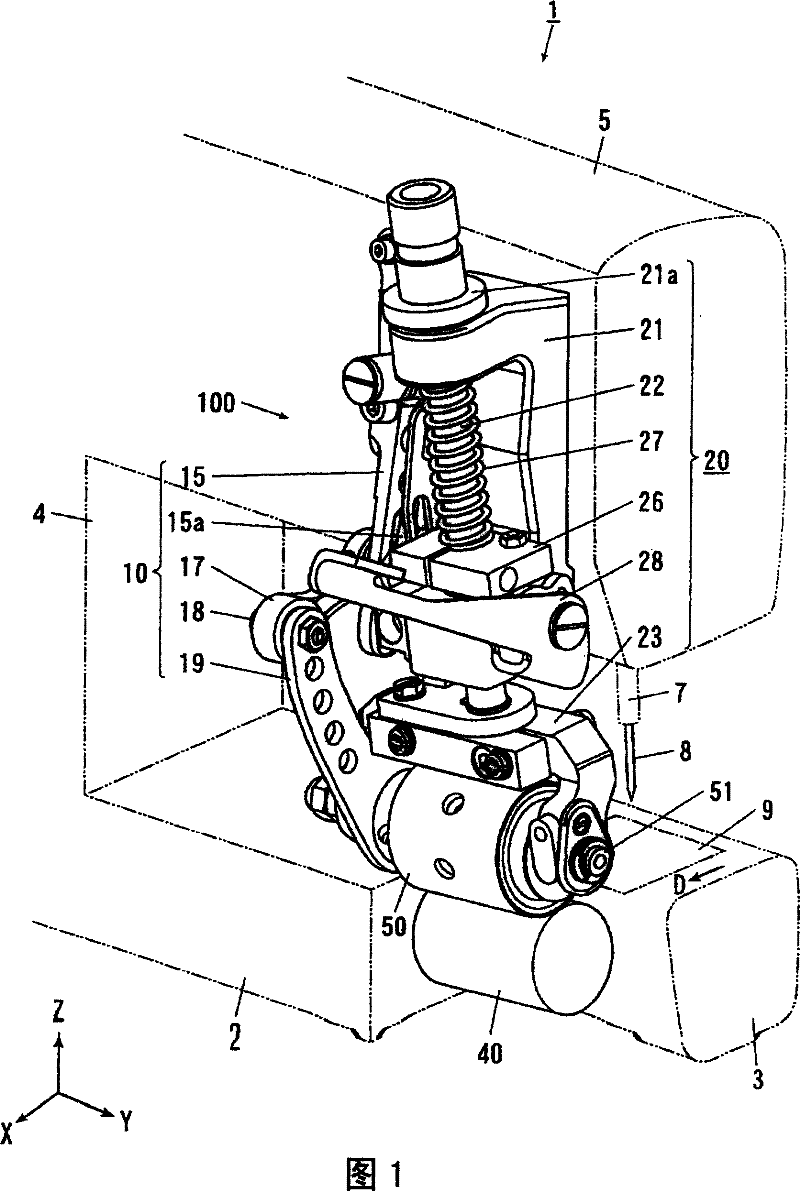

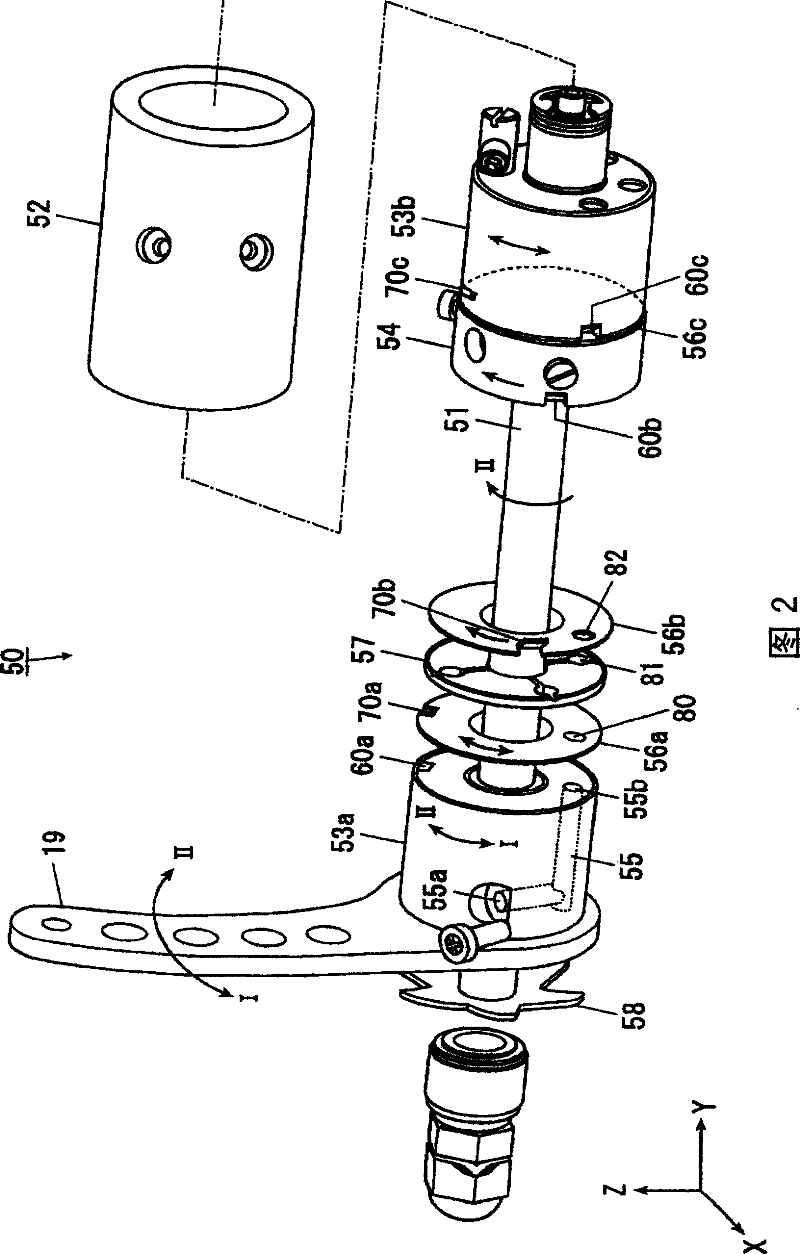

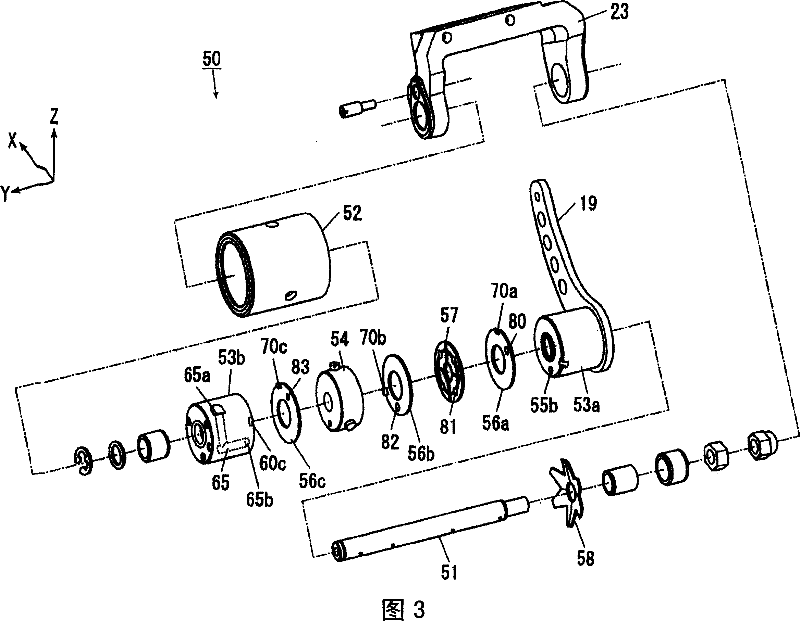

Pulling device of sewing machine

ActiveCN1854369BPrevent direct slidingAvoid feverLubrication/cooling devicesWork-feeding meansClutchSewing machine

The invention discloses a drawing device of seamer to rotate seamer at high speed stably, which is characterized by the following: setting two pieces of first thrust plate (56a, 56b) of phosphor bronze in the drawing device (100) of gap part (54) and clutch cylinder (53a, 53b) with one-way transcendental clutch as well as opposite end surface of clutch cylinder (53a) and gap part (54) separately;placing a piece of second thrust plate (57) of steel material between two pieces of first thrust plate; chucking each first thrust plate to the opposite end surface of clutch cylinder (53a) and gap part to rotate along axis direction integrally; forming oil-supplying path (55) on the clutch cylinder (53a) and through-hole on each first and second thrust plates; setting guiding grooves (A, B, C) to guide lubricating grease on the end surface of second thrust plate.

Owner:JUKI CORP

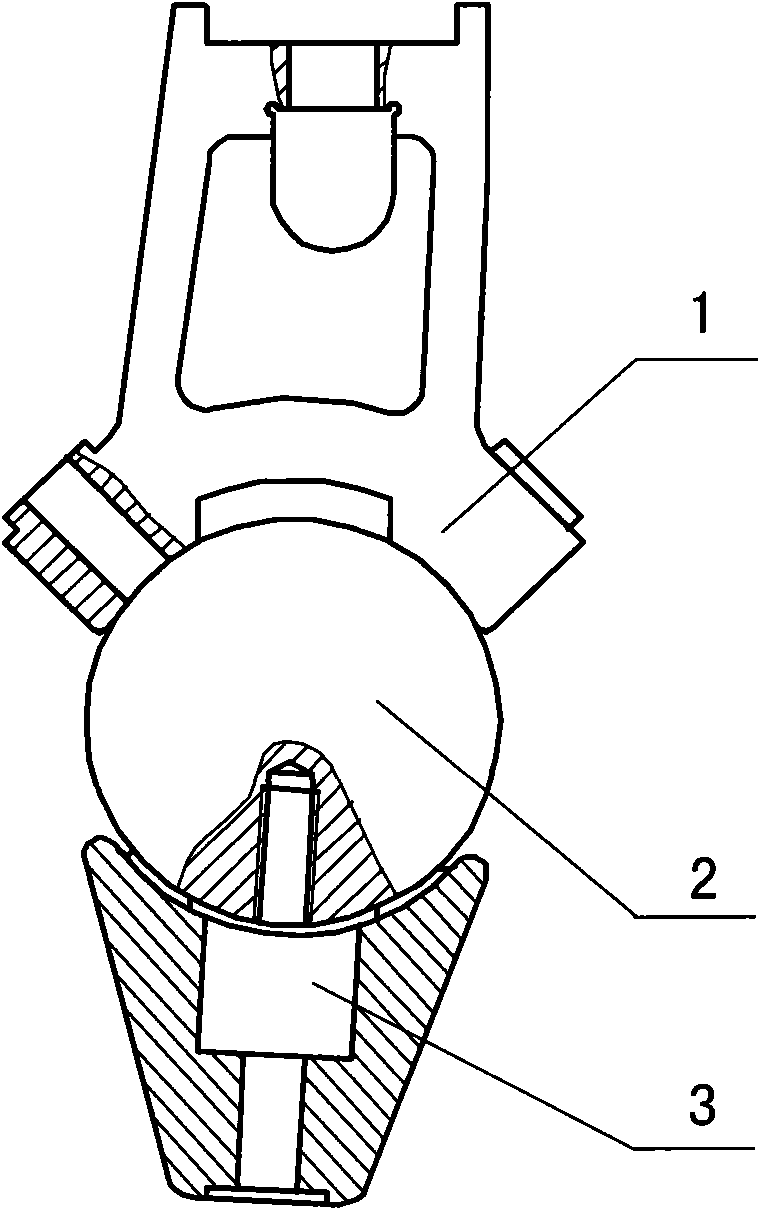

A kind of high-speed cutting mechanism and using method of bt tool holder

ActiveCN104924136BImprove contact stiffnessHigh repeat positioning accuracyPositioning apparatusMetal-working holdersNumerical controlCircular cone

The invention discloses a BT knife handle high-speed cutting mechanism and a use method and belongs to the technical field of numerically-controlled machine tool cutting machining. The BT knife handle high-speed cutting mechanism comprises a BT knife handle, a main shaft, a knife pulling mechanism, a pop-rivet and a cushion cover, wherein the end face of the non tool installation end of the BT knife handle is a knife handle rear end face, a circular cone frustum is arranged on the center position of the knife handle rear end face, the pop-rivet is installed on the center position of the end face of the circular cone frustum, the main shaft is a hollow shaft, the end face of the end, close to the rear end face of the knife handle, of the main shaft is a main shaft front end face, a taper hole is formed in the center portion of the main shaft front end face, the shape of the taper hole is matched with that of the circular cone frustum, the circular cone frustum is installed in the taper hole, the cushion cover is arranged between the knife handle rear end face and the main shaft front end face, the knife pulling mechanism is installed in a main shaft center cavity, and the knife pulling mechanism is connected with the pop-rivet in a clamped mode. By means of the BT knife handle high-speed cutting mechanism and the use method, the high-speed cutting of the BT knife handle is achieved, the contact rigidity and the repeated positioning accuracy of the BT knife handle are high, the high-speed cutting machining precision and the efficiency are high, the service lives of a tool and a machine tool are prolonged, and the BT knife handle can replace an HSK knife handle to be used.

Owner:JIANGSU YUANLI AVIA PRECISION MACHINE TOOL

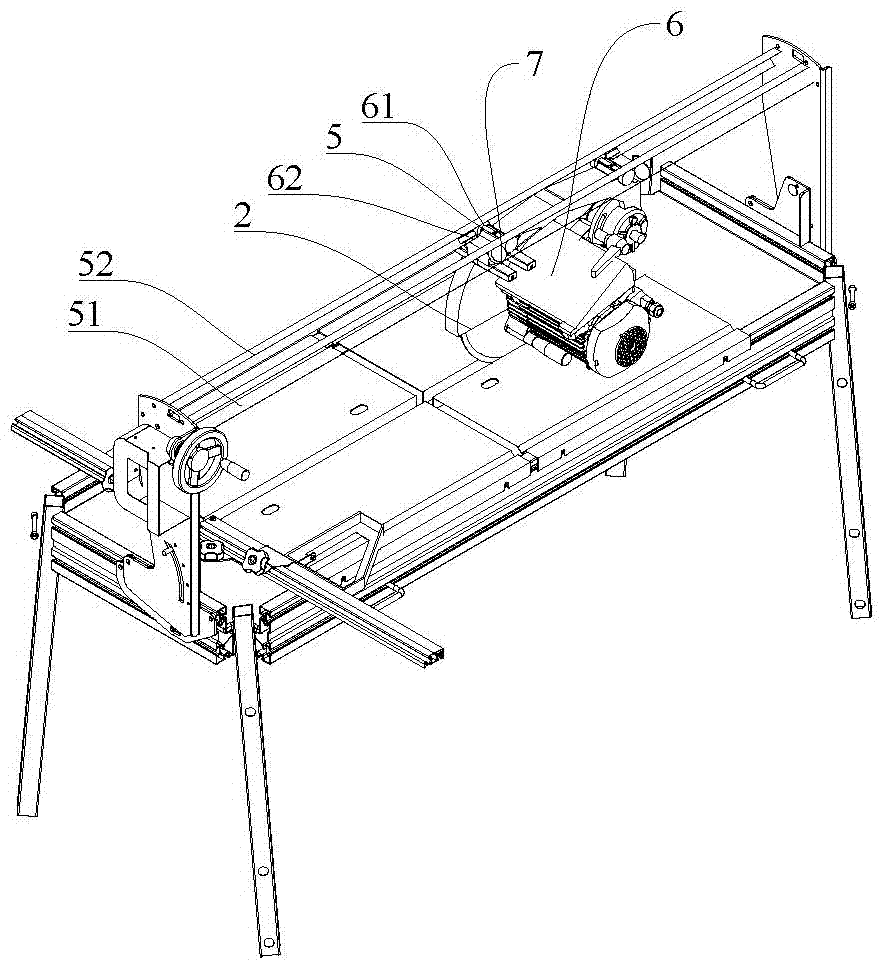

Desk type cutting machine for cutting stones

PendingCN107953462AGuaranteed accuracyShaking phenomenon does not occurWorking accessoriesStone-like material working toolsEngineeringPrism

The invention discloses a desk type cutting machine for cutting stones. The desk type cutting machine for cutting the stones includes a cutting handpiece, a sliding rail and a connecting frame; the cutting handpiece drives a blade to reciprocate along the sliding rail through the connecting frame, the sliding rail is a half of a multi-prismatic rail which includes a pair of vertical rails and a pair of slant rails, and the top portion, in correspondence with the vertical rails and the slant rails, of the connecting frame is provided with two pair of vertical parallel wheels and slant wheels; and the parallel wheels and the slant wheels can separately slide in the vertical rails and the slant rails. Two pairs of sliding rails are arranged at the desk type cutting machine for cutting the stones to prevent the cutting handpiece from swinging and the stable of the cutting handpiece in vertical direction and in lateral direction can both be ensured and especially when the cutting handpieceis under stress, the cutting handpiece can be stressed uniformly under the balance force of the sliding rails in lateral and vertical directions, the rapid running can be stable, and the accuracy forcutting the stones can be ensured.

Owner:YANCHENG CITY HAITONG MACHINERY MFG PLANT

High speed and high power density AC servo motor

ActiveCN106655649BIncrease speedSmooth operation at high speedManufacturing stator/rotor bodiesCopper wireElectric machine

The invention discloses a high-speed high-power density AC servo motor, which belongs to the technical field of motors. The high-speed high-power density AC servo motor comprises a stator part and a rotor part, wherein the stator part comprises a frame, a stator iron core, stator windings, end covers and bearings; the rotor part comprises a rotation shaft, rotor magnetizers, permanent magnets and a stainless steel band; two ends of the frame are provided with the front end cover and the rear end cover; the frame is internally provided with the rotation shaft, the stator iron core, the stator windings and the rotor part; the rotor magnetizers sleeve the rotation shaft, the tile-shaped permanent magnets are adhesive to the outer surface, and an air gap magnetic field is generated; cast aluminum alloy is adopted to cast the frame, the front end cover and the rear end cover, and thermal processing is carried out; silicon steel sheets are adopted to process the stator iron core, and the oxide layer on the surface of the silicon steel sheet serves as inter-sheet insulation; the inner circle of the iron core ring is uniformly provided with grooves parallel with the axis, the stator windings are embedded in the grooves, and each stator winding adopts a high temperature-resisting copper wire; the rotor part is assembled; and the stator part and the rotor part are combined together. The rotation speed of the motor is high, the power density is large, and the operation is steady.

Owner:AVIC POWER SCI & TECH ENG

a spinning machine

ActiveCN104174792BImprove work rateIncrease spinning speedMetal rollingWire rodHigh frequency vibration

The invention provides a wire discharging machine. The wire discharging machine comprises a box body and a wire discharging head, wherein the wire discharging head comprises a main shaft, and the main shaft is mounted in a bore hole of the box body through a main bearing. The wire discharging machine further comprises an elastic mounting member, wherein the elastic mounting member is arranged on the box body, supports the main bearing and is used for enabling the main bearing to drive the main shaft to achieve the movement of a predetermined range in the bore hole along a predetermined direction. The elastic mounting member can offset vibration generated during the operation of the main bearing; a load caused by the high-frequency vibration and shock of the main bearing is reduced, the service life of the main bearing and the service life of the wire discharging head are prolonged, the operating efficiency of the wire discharging head is increased, and the production and repair costs are reduced. According to the embodiments of the invention, a flexible support is increased by the main bearing, and the high-speed operation is more stable, so that the wire discharging speed of the wire discharging machine can be increased, and then, the yield of a high-speed wire production line is increased.

Owner:BEIJING JINGCHENG RUIXINCHANGCAI ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com