High-speed high-power density AC servo motor

A technology of AC servo motor and high power density, which is applied in the preparation of AC servo motor and the field of high-speed and high-power-density AC servo motor preparation. Density of AC servo motor technical solutions and other issues, to achieve good economic and social benefits, easy industrial production, high speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

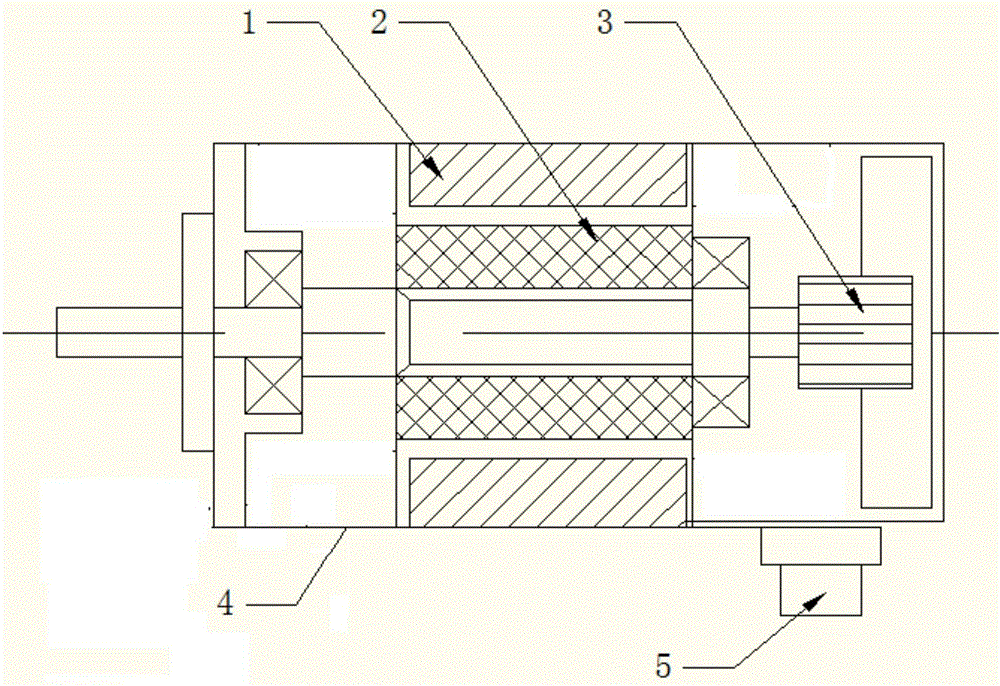

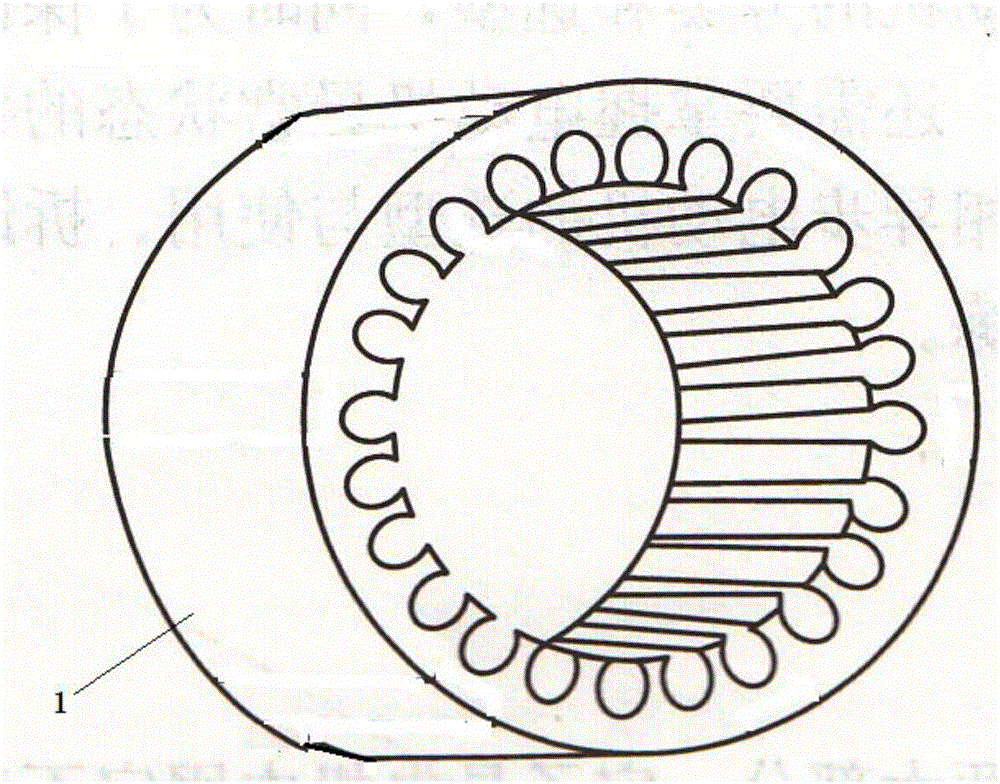

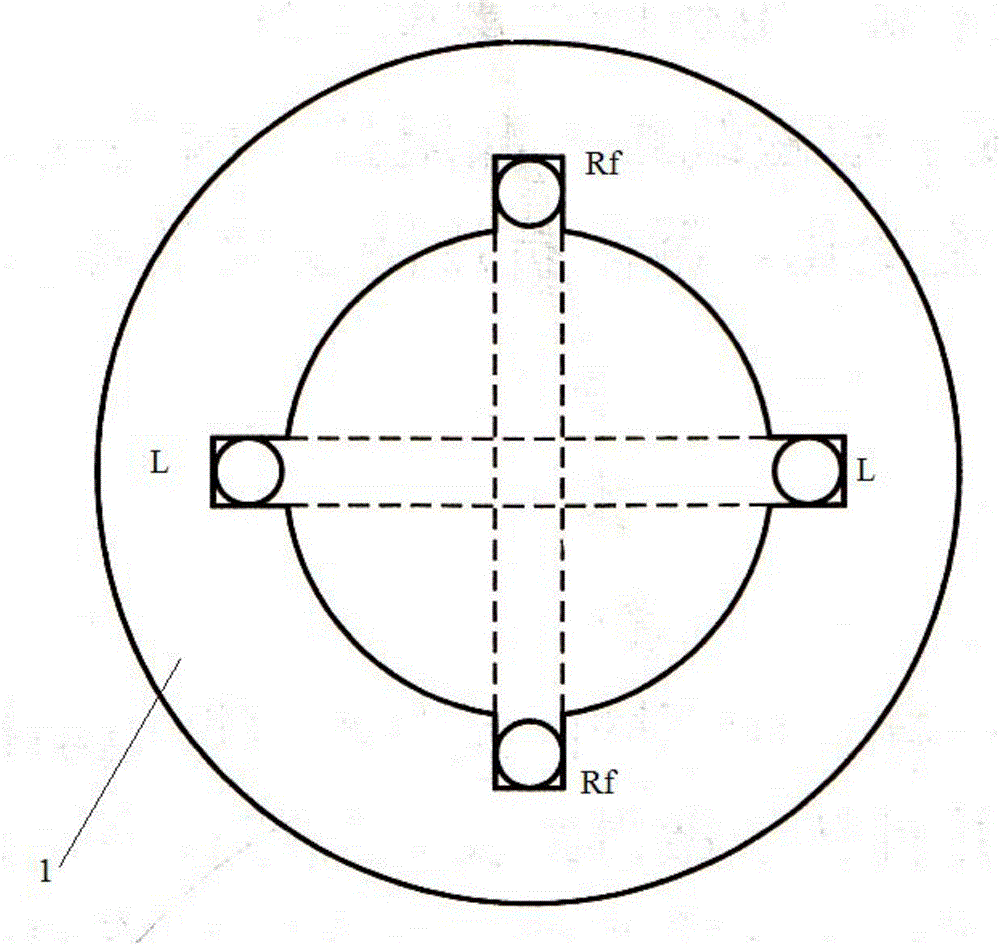

[0031] A kind of high-speed high-power-density AC servo motor (see Figure 1-3 ), the motor is composed of a stator part, a rotor part and a detection element, the stator part includes a machine base 4, a stator core 1, a stator winding, an end cover and a bearing, and the rotor part 2 is composed of a rotating shaft, a rotor magnetizer, a permanent magnet and a stainless steel strip Partial composition, the rotor magnetizer is sleeved on the rotating shaft, and the outer surface of the rotor is bonded with a tile-shaped permanent magnet to generate an air gap magnetic field. The specific preparation method is as follows:

[0032] The cast aluminum alloy is used to pour the machine base and the end cover. The chemical composition and mass fraction of the cast aluminum alloy are 0.009% B, 5.48% Cu, 0.063% Ca, 0.196% Li, 3.01% Mg, 3.07% Ni, 1.13% Si, 0.146% Zr, 1.10% Er, 0.268% Ti, 0.294% Fe, 0.715% Mn, the balance is aluminum and unavoidable impurities; the casting aluminum all...

Embodiment 2

[0036] A kind of high-speed high-power-density AC servo motor (see Figure 1-3 ), the motor is composed of a stator part, a rotor part and a detection element, the stator part includes a machine base 4, a stator core 1, a stator winding, an end cover and a bearing, and the rotor part 2 consists of a rotating shaft, a rotor magnetizer, a permanent magnet and a stainless steel strip Partial composition, the rotor magnetizer is sleeved on the rotating shaft, and the outer surface of the rotor is bonded with a tile-shaped permanent magnet to generate an air gap magnetic field. The specific preparation method is as follows:

[0037] The cast aluminum alloy is used to pour the machine base and the end cover. The chemical composition and mass fraction of the cast aluminum alloy are 0.017% B, 5.04% Cu, 0.128% Ca, 0.152% Li, 3.480% Mg, 2.607% Ni, 1.48% Si, 0.086% Zr, 1.348% Er, 0.220% Ti, 0.384% Fe, 0.519% Mn, the balance is aluminum and unavoidable impurities; the heat treatment proce...

Embodiment 3

[0041] A kind of high-speed high-power-density AC servo motor (see Figure 1-3 ), the motor is composed of a stator part, a rotor part and a detection element, the stator part includes a machine base 4, a stator core 1, a stator winding, an end cover and a bearing, and the rotor part 2 consists of a rotating shaft, a rotor magnetizer, a permanent magnet and a stainless steel strip Partial composition, the rotor magnetizer is sleeved on the rotating shaft, and the outer surface of the rotor is bonded with a tile-shaped permanent magnet to generate an air gap magnetic field. The specific preparation method is as follows:

[0042] The cast aluminum alloy is used to pour the machine base and the end cover. The chemical composition and mass fraction of the cast aluminum alloy are 0.014% B, 5.33% Cu, 0.096% Ca, 0.182% Li, 3.208% Mg, 2.77% Ni, 1.37% Si, 0.125% Zr, 1.206% Er, 0.251% Ti, 0.354% Fe, 0.595% Mn, the balance is aluminum and unavoidable impurities; the casting aluminum allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com