Driving mechanism with eccentric round cam groove

A technology of eccentric cam and transmission mechanism, which is applied in transmission devices, mechanical equipment, belts/chains/gears, etc. It can solve problems such as energy consumption, complex structure, and large swing friction, and achieve simple structure, reliable transmission, and stable high-speed operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

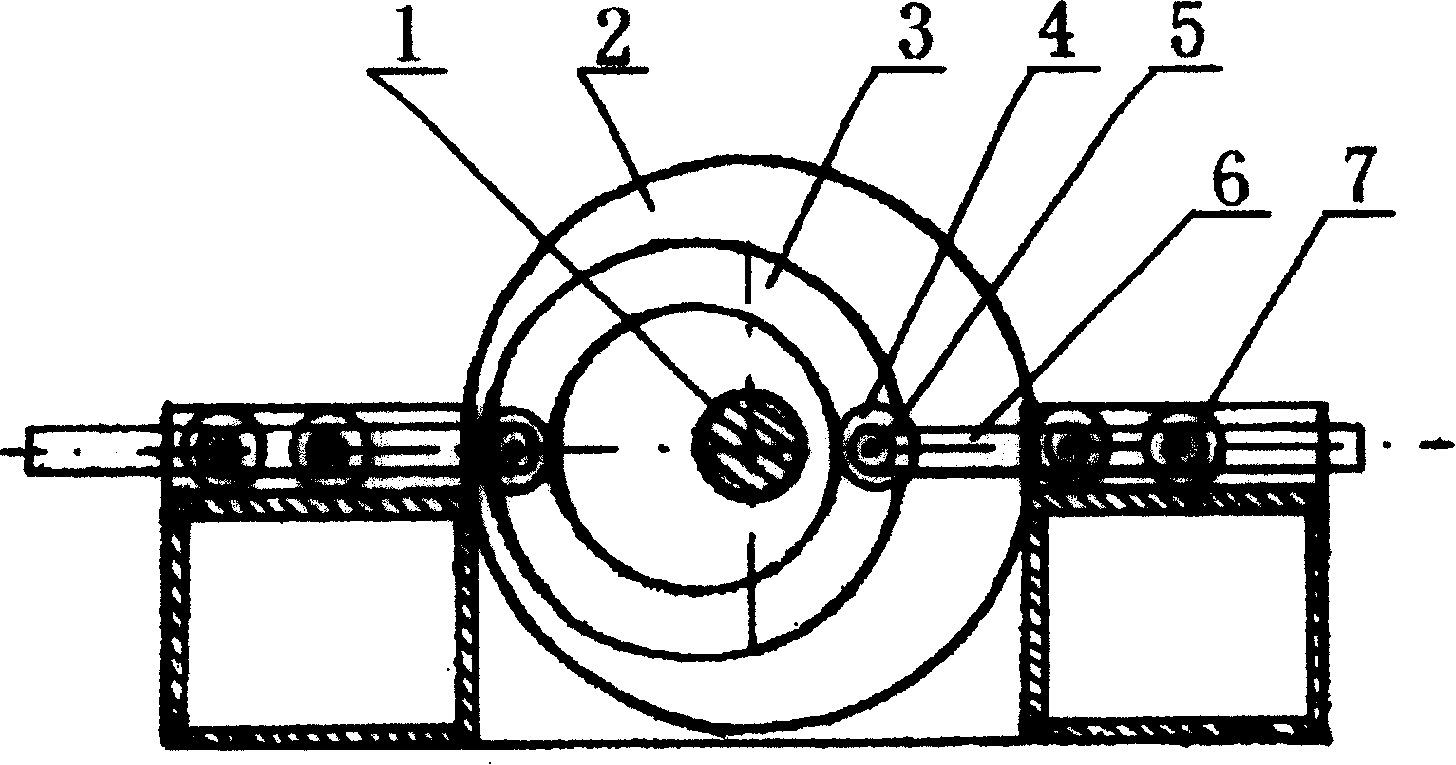

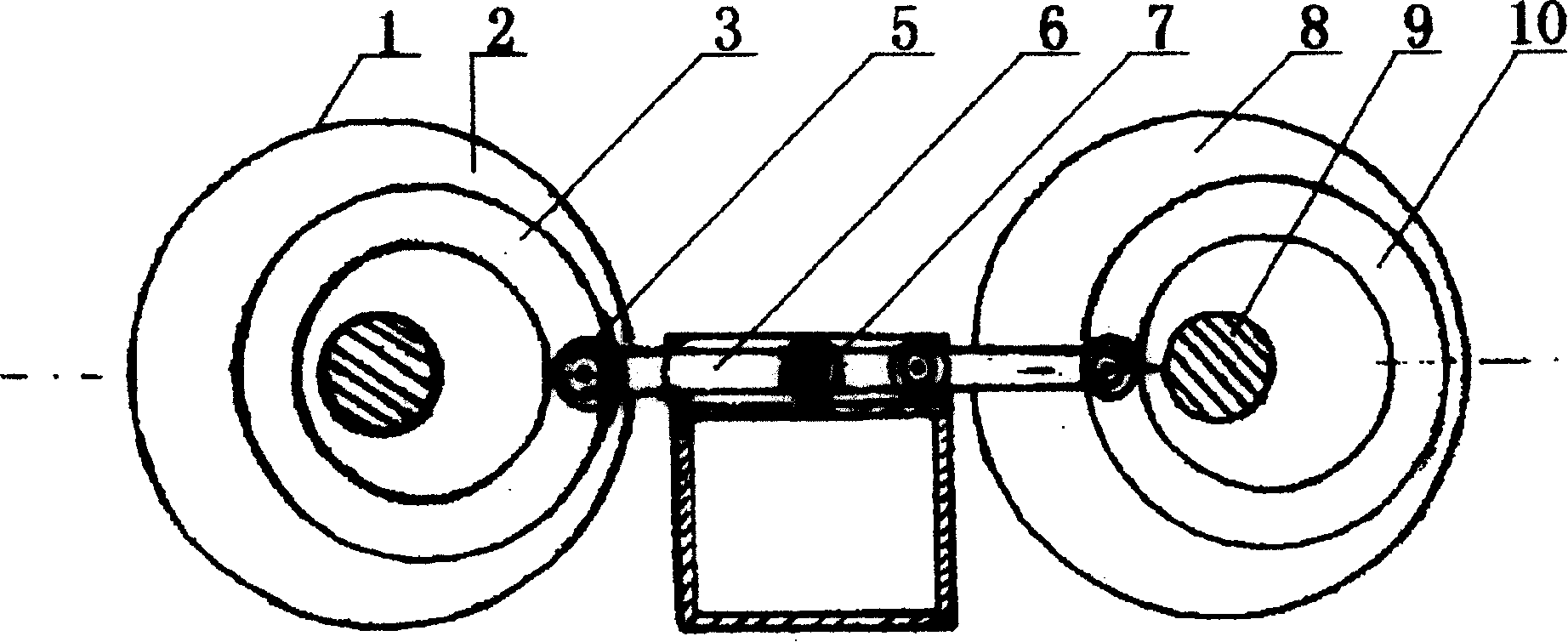

Embodiment 1

[0011] Embodiment 1, by figure 1 It can be seen that the eccentric cam body 2 of the present invention can adopt a circular eccentric cam body, so that its manufacture is more convenient. The rotating shaft 1 passes through the center of the circular eccentric cam body 2, even if the rotating shaft 1 coincides with the axis line of the eccentric cam body 2. The circular eccentric cam body 2 is provided with a circular groove 3 deviated from the axis line of the rotary shaft 1 around the rotating shaft 1, which can be on one side of the circular eccentric cam body 2 or on both sides of the circular eccentric cam body 2. Set round slot 3. Because the transmission rod 6 is set in the guide groove that can only reciprocate longitudinally, when the power device drives the circular eccentric cam disc body 2 to rotate through the rotating shaft 1, so that the circular groove 3 deviated from the axis line of the rotating shaft 1 performs an eccentric circular motion, One end is driv...

Embodiment 2

[0013] Embodiment 2, in order to make the movement smoother, the eccentric cam body 2 adopts a circular eccentric cam body, and the thickness inside the circular groove 3 is greater than the thickness outside the circular groove 3, and the connecting rod 6 is set in the circular groove 3 Roller 5 is sleeved on the axle. In order to make the transmission more reliable, a roller 5 is set at the bottom of the circular groove 3 at the inner end of the connecting shaft of the transmission rod 6. The roller 5 is in contact with the outer wall of the circular groove 3, and a large roller 4 is installed on the outside of the connecting shaft. It is in contact with the inner wall of the circular groove 3, so that the transmission rod 6 and the circular groove 3 are tightly fitted and in smooth contact.

[0014] It is also possible to set rollers 7 on the transmission rod 6, or to set different rollers 7 with different inner diameters on both sides, and the transmission rod 6 is sleeved...

Embodiment 3

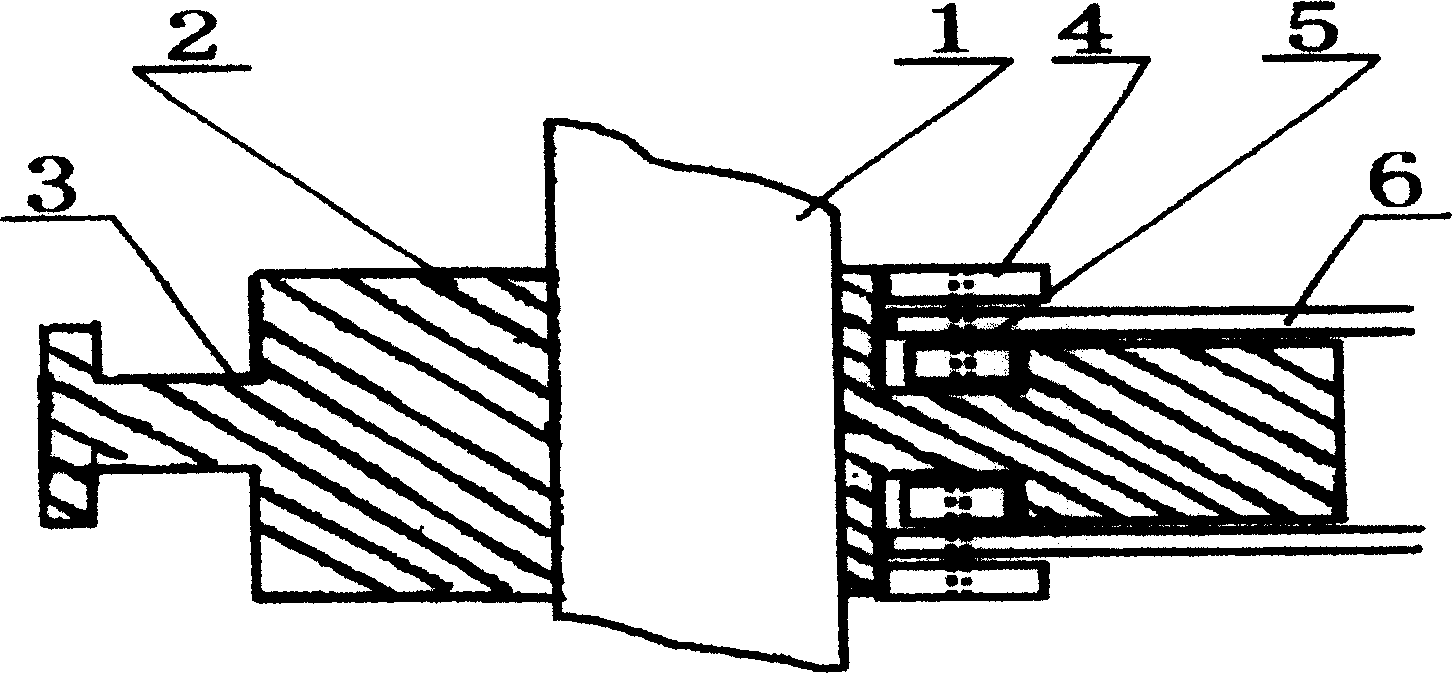

[0015] Embodiment 3, in order to make the movement of the whole mechanism more stable without vibration, the gravity balance can be realized by making the eccentric cam disc body 2 provided with the circular groove 3 take the axis line of the rotating shaft 1 as the axis line, so that the gravity is balanced with the axis line of the rotating shaft 1 is a balanced distribution of the center line, so that when the eccentric cam body 2 rotates around the rotating shaft 1, the movement of the mechanism is very stable. All the other are with embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com