A high-precision CNC centering machine tool spindle

A machine tool spindle, high-precision technology, applied in metal processing mechanical parts, metal processing equipment, manufacturing tools, etc., can solve the problems of late start, blank supporting core components, etc., to achieve safe drainage function, good processing advantages, High rigidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

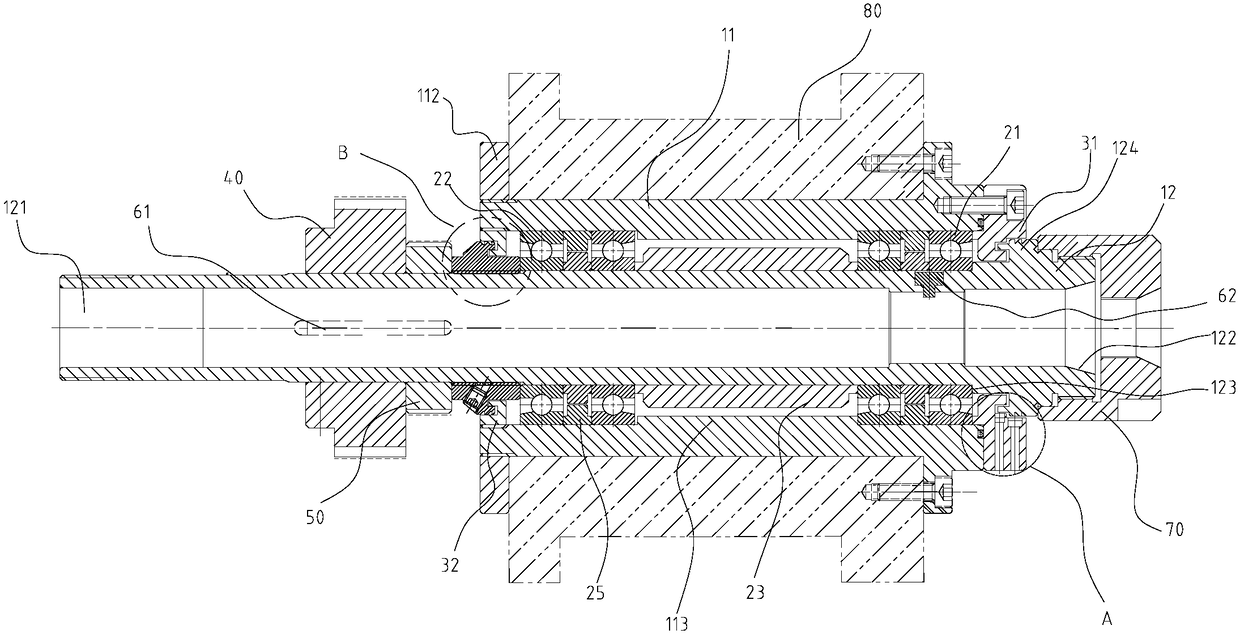

[0037] like Figure 1-3 As shown, it is the spindle of the high-precision CNC centering machine tool of the present invention, including the spindle body 11, the shaft core 12, the bearing assembly, the right end cover 31 and the driving wheel 40 installed on the shaft core 12;

[0038] One end of the spindle body 11 is fixed on the machine tool 80 by a fixing member, and the other end is provided with a spindle locking block 112 , through which the spindle body 11 is tightly locked and fixed on the machine tool 80 .

[0039] The bearing assembly is sleeved on the shaft core 12, the main shaft body 11 is sleeved on the bearing assembly, and the shaft core 12 is rotatably connected to the main shaft body 11 through the bearing assembly.

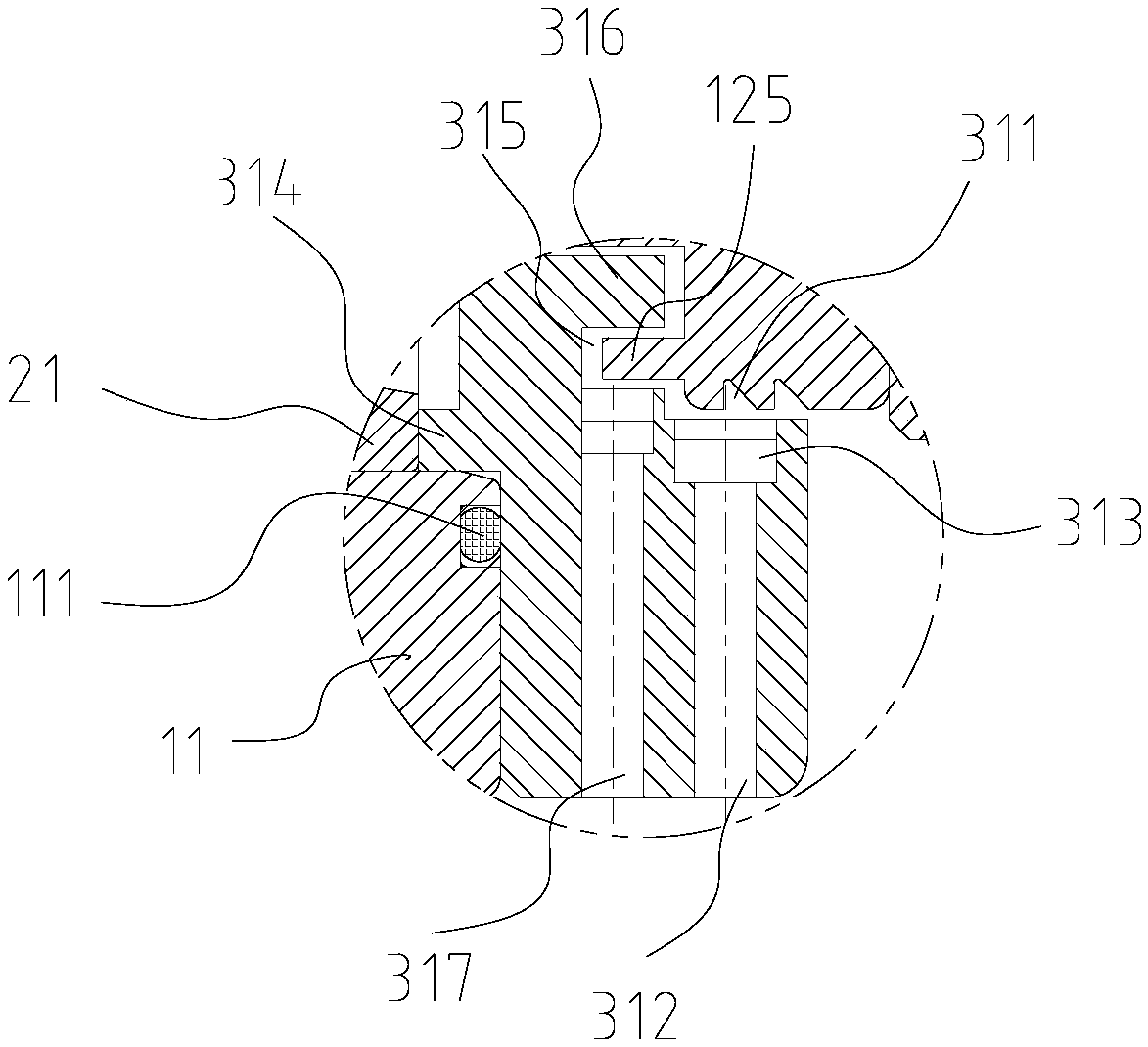

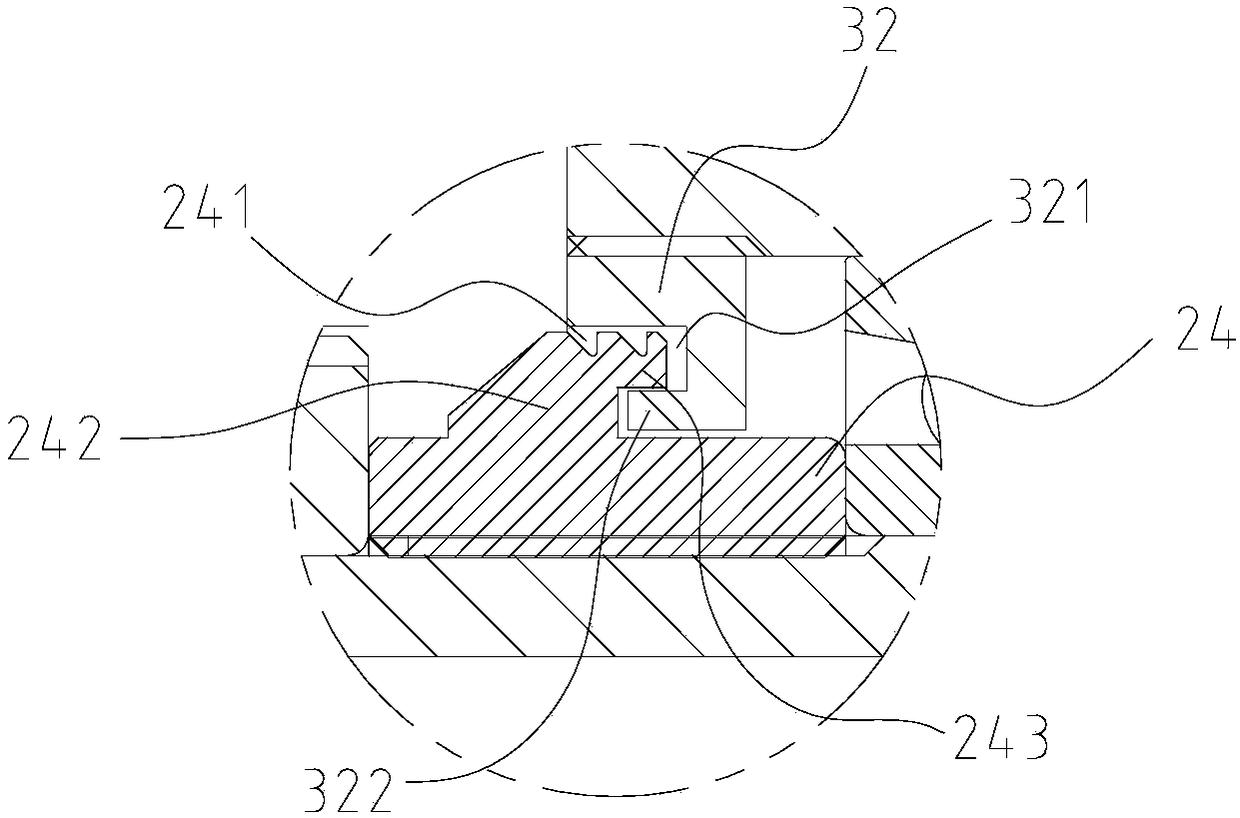

[0040] The bearing assembly includes a first bearing group 21, a bearing spacer 23, and a second bearing group 22 which are arranged side by side on the shaft core 12 from right to left; the first bearing group 21 and the second bearing group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com