Nickel sulfate evaporative crystallization process

A technology of evaporative crystallization and nickel sulfate, applied in the direction of nickel sulfate, crystallization separation, multi-effect evaporation, etc., which can solve the problems of environmental pollution and non-environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

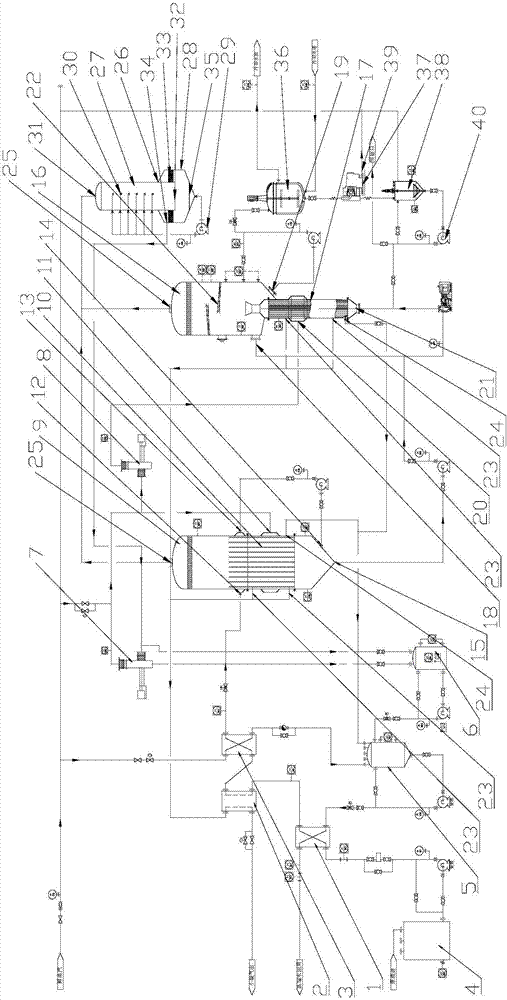

[0024] Depend on figure 1 It can be seen that nickel sulfate evaporation crystallization process of the present invention comprises the following steps:

[0025] Step 1. When the system is started, the fresh steam directly preheats the third plate heat exchanger, the first evaporative concentration device, and the second evaporative concentration device in the heat exchanger group, and generates secondary steam. When the system is in normal operation, the second The temperature of the secondary steam is raised by 12°C, and then part of the heated secondary steam supplies heat to the first evaporation and concentration device, and the temperature of the remaining heated secondary steam is raised by 6°C again to supply heat to the second evaporation and concentration device.

[0026] The first evaporative concentration device comprises a gas-liquid separator 9 and a falling film heat exchanger 10 arranged in the housing of the gas-liquid separator 9, and the falling film heat ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com