Solid beating-up device

A solid, beating-up shaft technology, used in textiles, textiles, papermaking, looms, etc., can solve the problems of poor rigidity of the beating-up mechanism, unsuitable for high-speed operation, and insufficient beating-up strength, so as to increase the beating-up strength, improve Rigidity, the effect of expanding the weaving range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

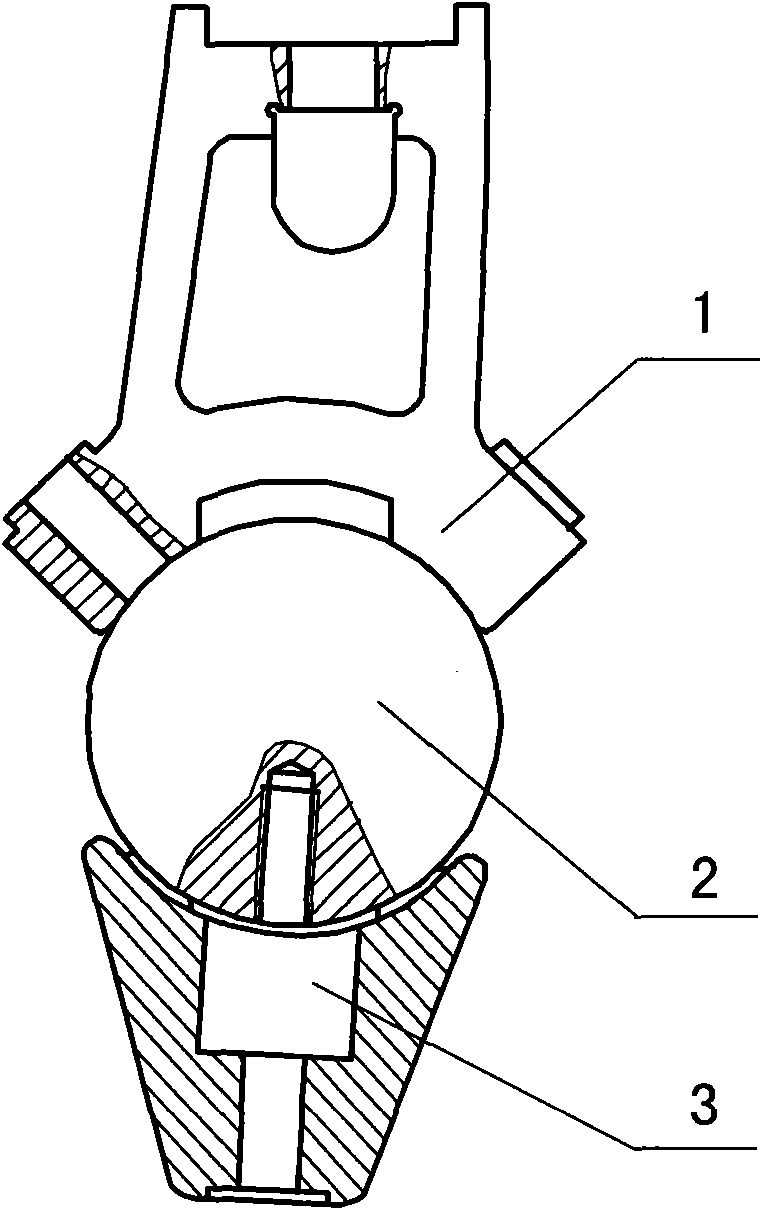

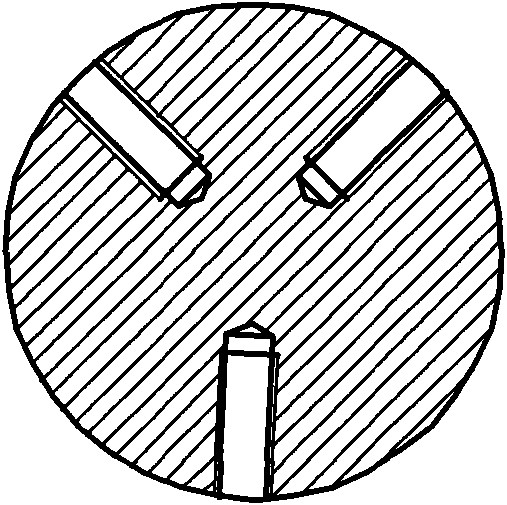

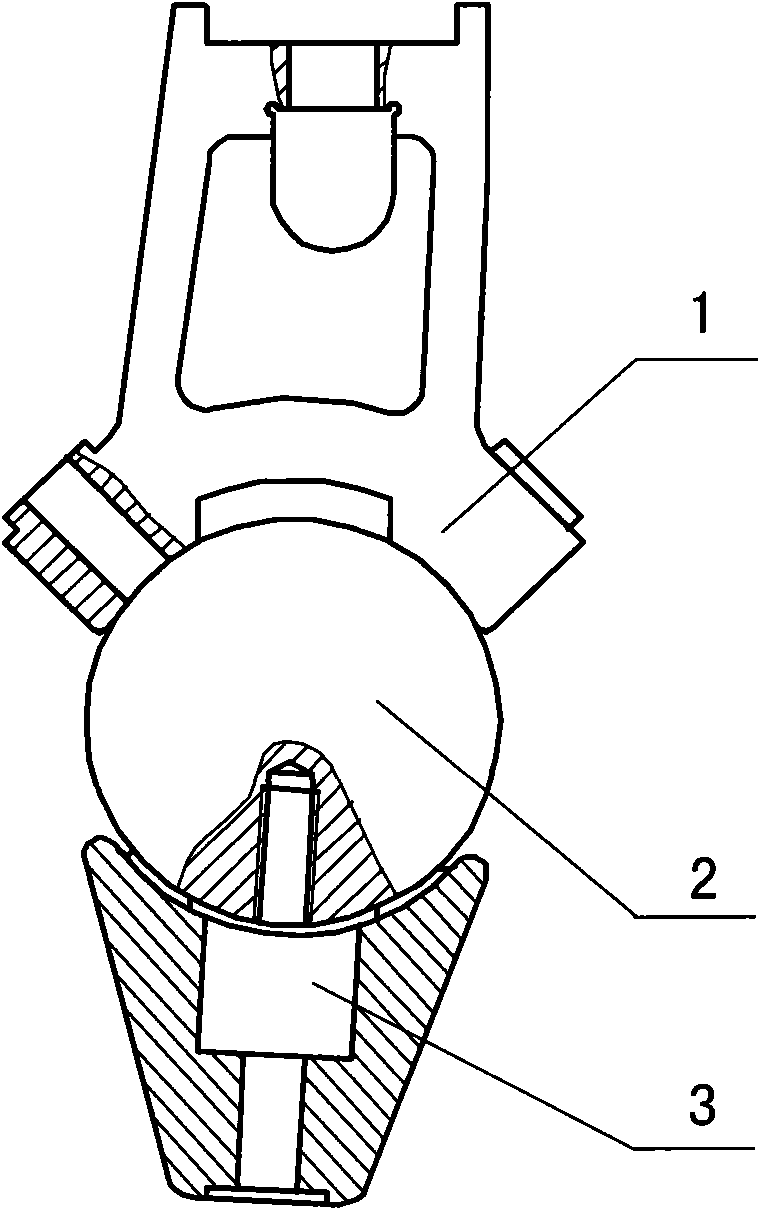

[0016] Such as Figure 1-Figure 2 Shown, the present invention comprises aluminum support 1, beating-up shaft 2 and counterweight 3, installs aluminum support 1 on the two holes that mutually form 90 ° of angles on the beating-up shaft 2, and fixes with bolts, on the aluminum support 1 Counterweight 3 is installed in the opposite direction of eccentricity, and is fixed on the beating-up shaft 2 with bolts. The beat-up shaft 2 is a solid shaft, and the number of counterweights 3 and aluminum supports 1 is configured according to the reed width of the loom.

[0017] When the present invention is in use, the beating shaft 2 connects the gearboxes on both sides through the coupling joints at both ends. According to the size of the reed width of the loom, the number of counterweights 3 is installed, and the guide rail beam device is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com