Welding manipulator

A technology for welding manipulators and racks, which is applied in the direction of manipulators, program-controlled manipulators, welding equipment, etc., which can solve the problems of inability to achieve high precision, high speed, high stability, and small welding space, so as to provide welding quality and improve work efficiency , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

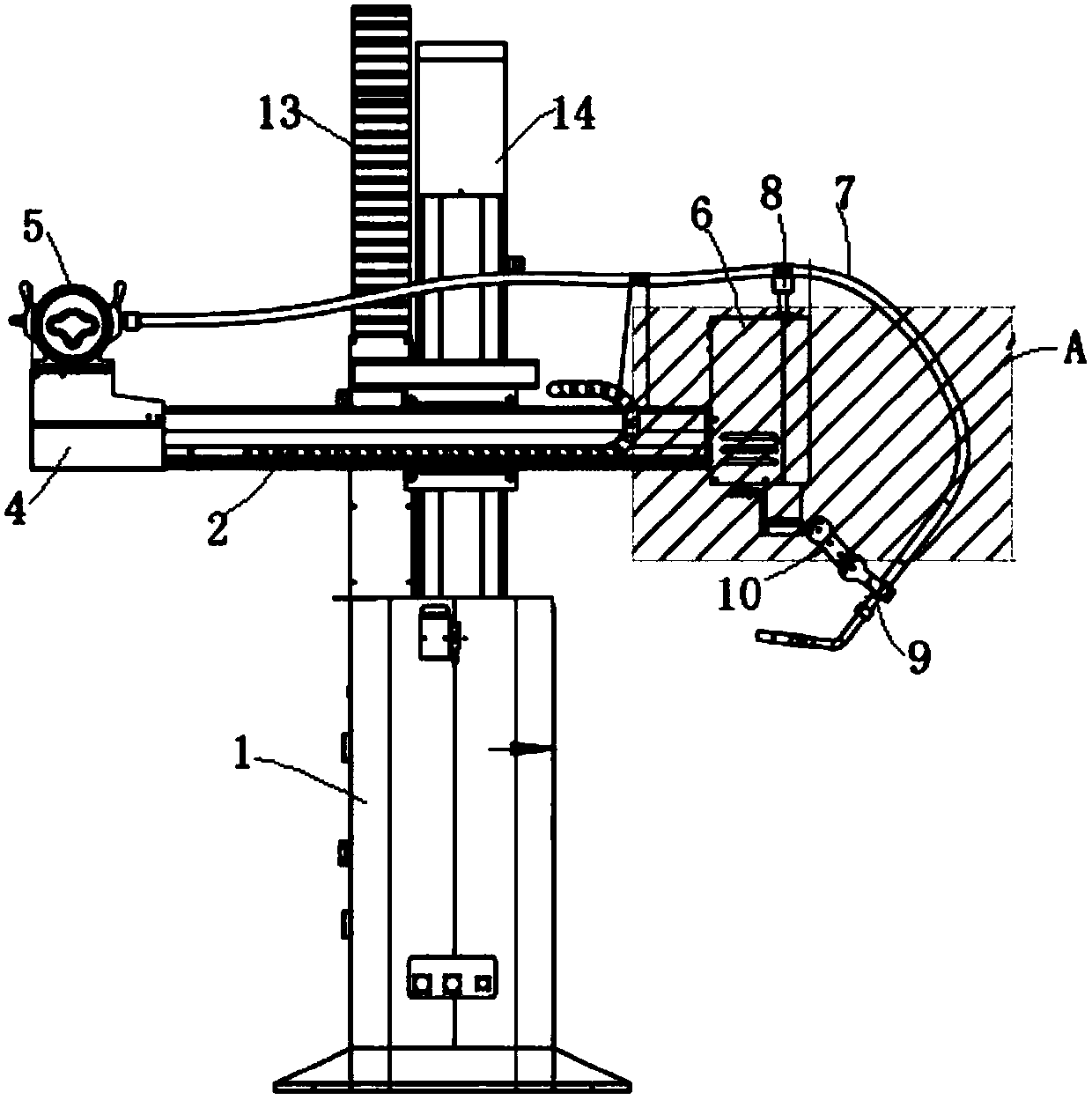

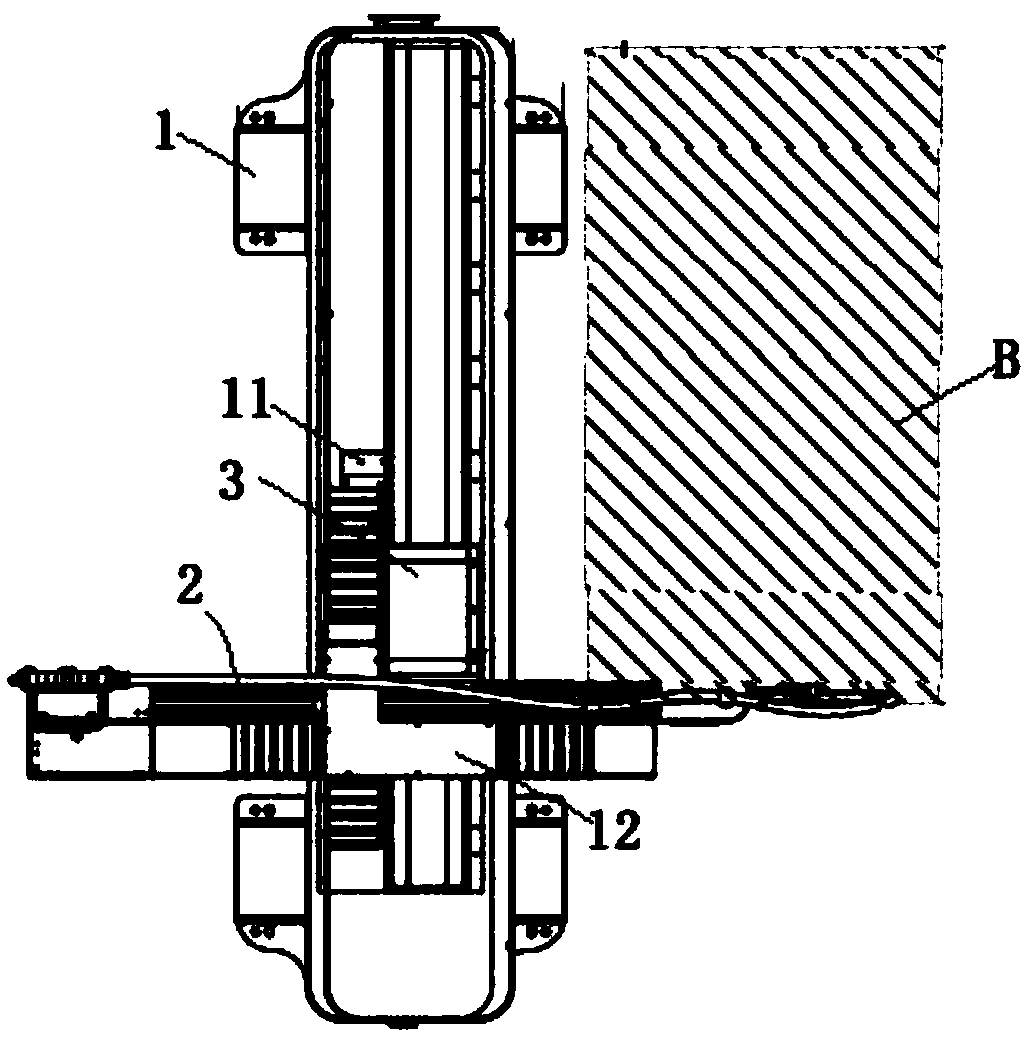

[0022] Such as figure 1 , figure 2 As shown, a welding manipulator includes a frame 1 on which an X-axis linear module, a Y-axis linear module and a Z-axis linear module are arranged. The X-axis linear module includes a The X-axis guide rail 2, the X-axis guide rail 2 connects the transmission part 3 and the driving part, the end of the X-axis guide rail 2 is provided with a sliding block 4, the welding machine 5 is fixed on the sliding block 4, and the other side of the X-axis guide rail 2 is provided with Fixing block 6, welding hose 7 is connected to welding machine 5, welding head is placed at the end of welding hose 7, the middle part of welding hose 7 is connected with the top of fixing block 6 through upper fixing foot 8, welding hose 7 is close to the end The position of the head is provided with a first living hinge 9, the bottom of the fixed block 6 is provided with a second living hinge 10, and the first living hinge 9 is movably connected with the second living h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com