Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Rich color expression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

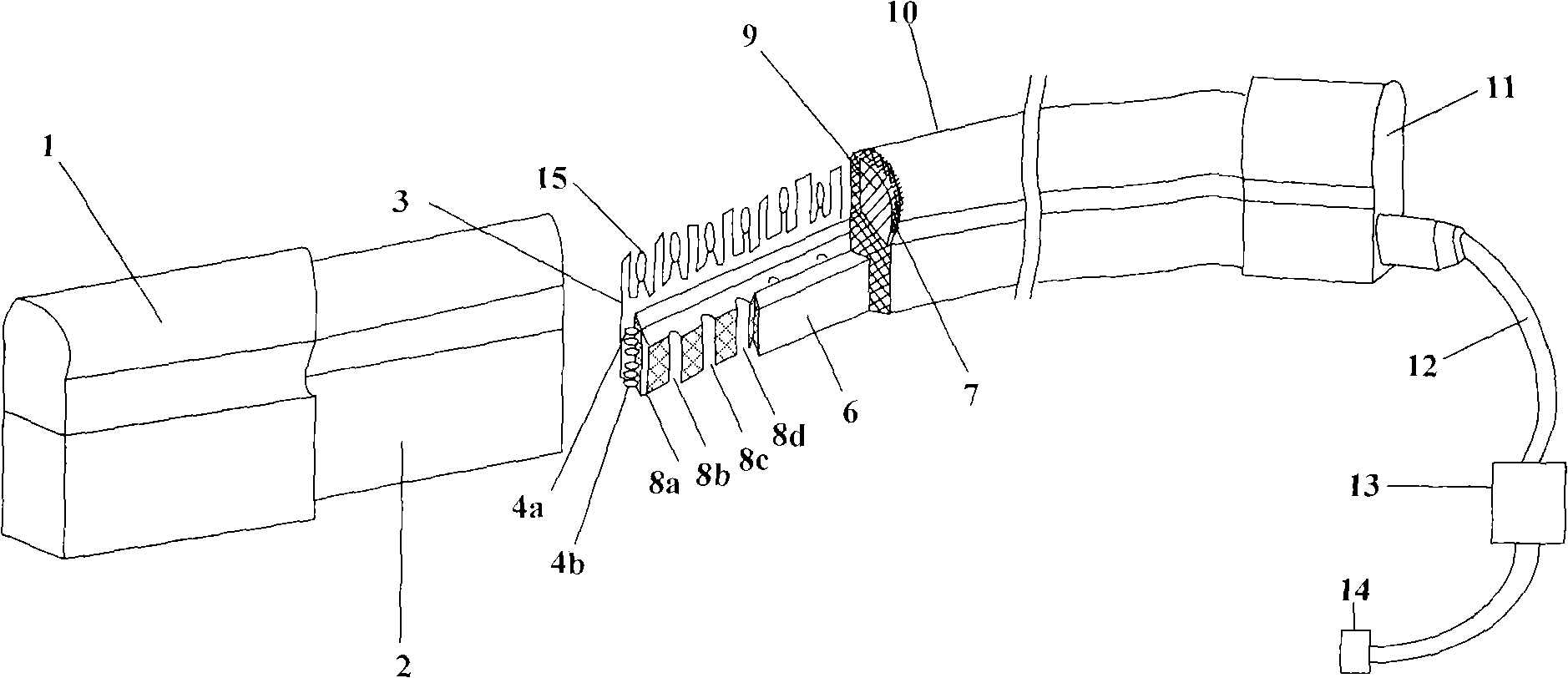

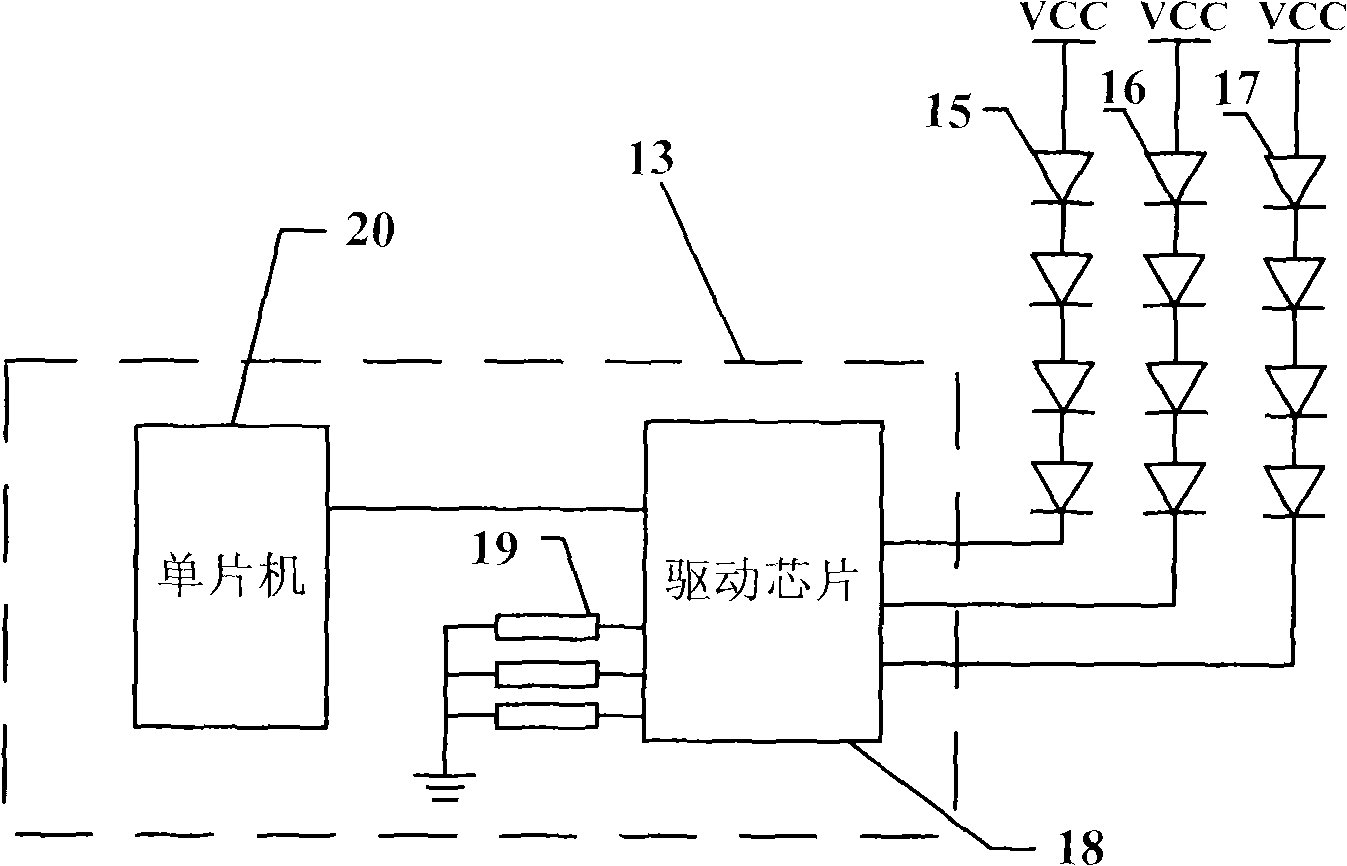

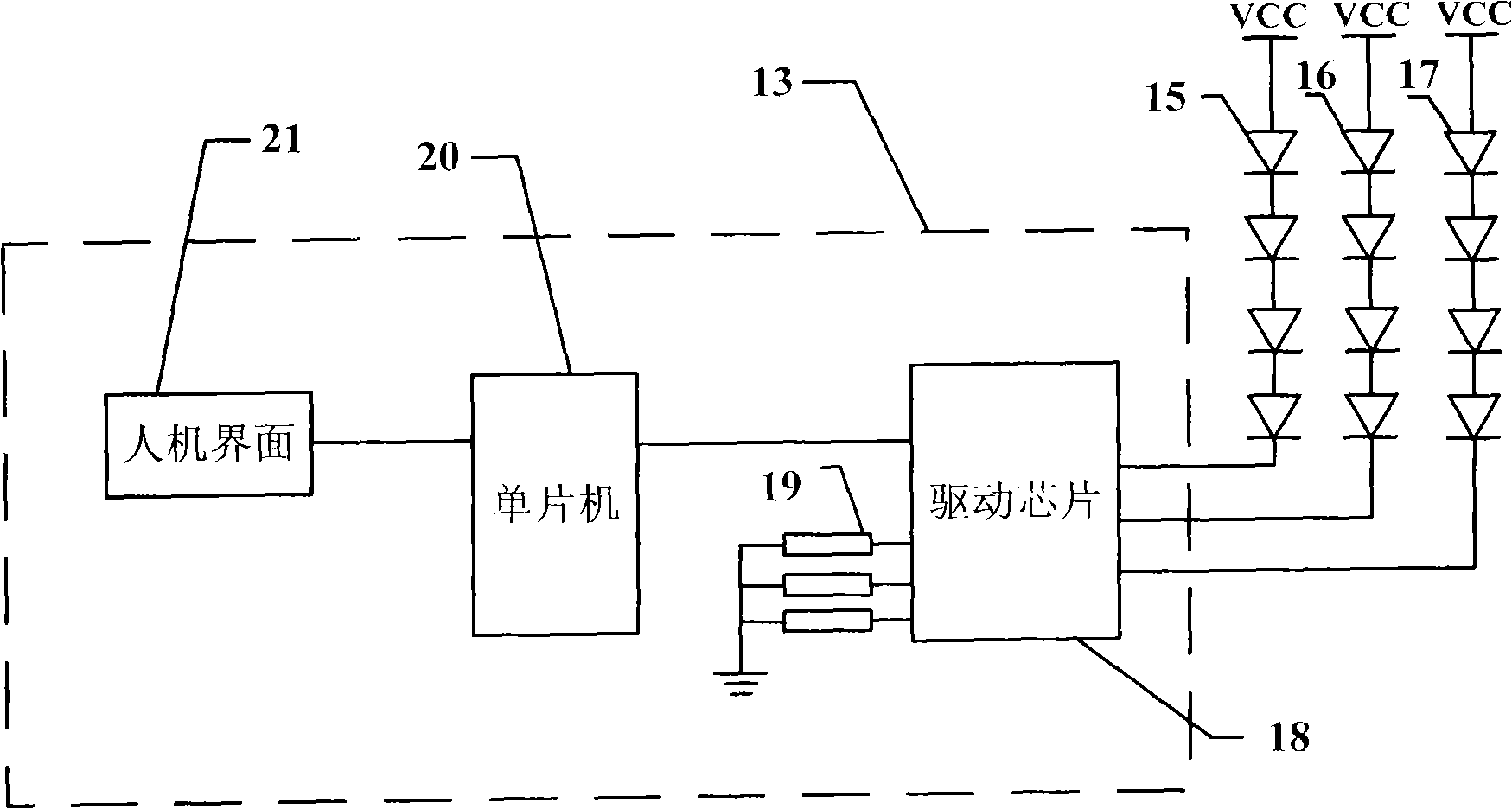

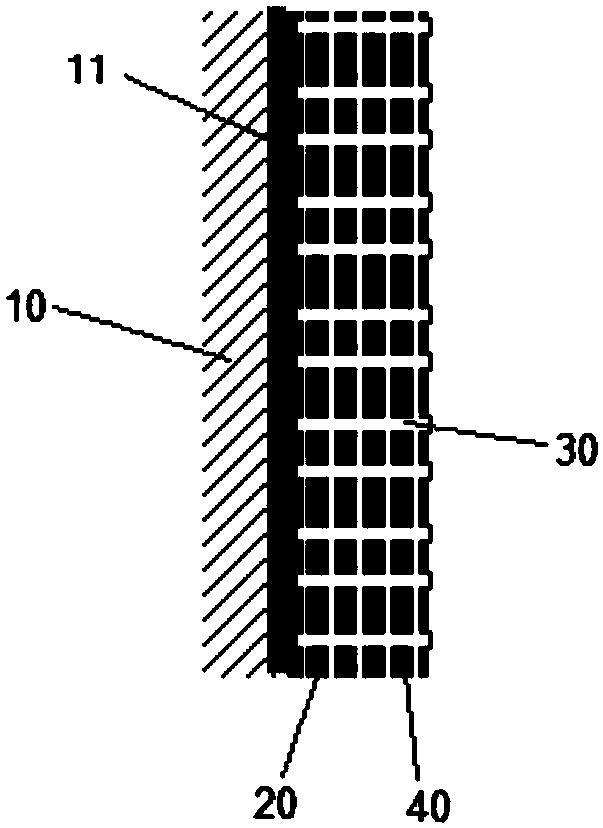

Color mixing hose lamp

InactiveCN101493196ARich color expressionLow costLighting support devicesPoint-like light sourceColor mixingCopper wire

The invention discloses a color mixing hose lamp with a drive device, which comprises a drive chip set and a singlechip; wherein, the output ends of the drive chip set are respectively connected with one end of each pair of copper wires cross for driving each LED lamp string to glow; the singlechip is connected with the input end of the drive chip set for controlling the drive chip set to light each LED lamp string. The color mixing hose lamp can increase the color expressivity of hose lamps and realize multicolored on-off in one hose lamp simultaneously.

Owner:广州艾力普斯制冷设备有限公司

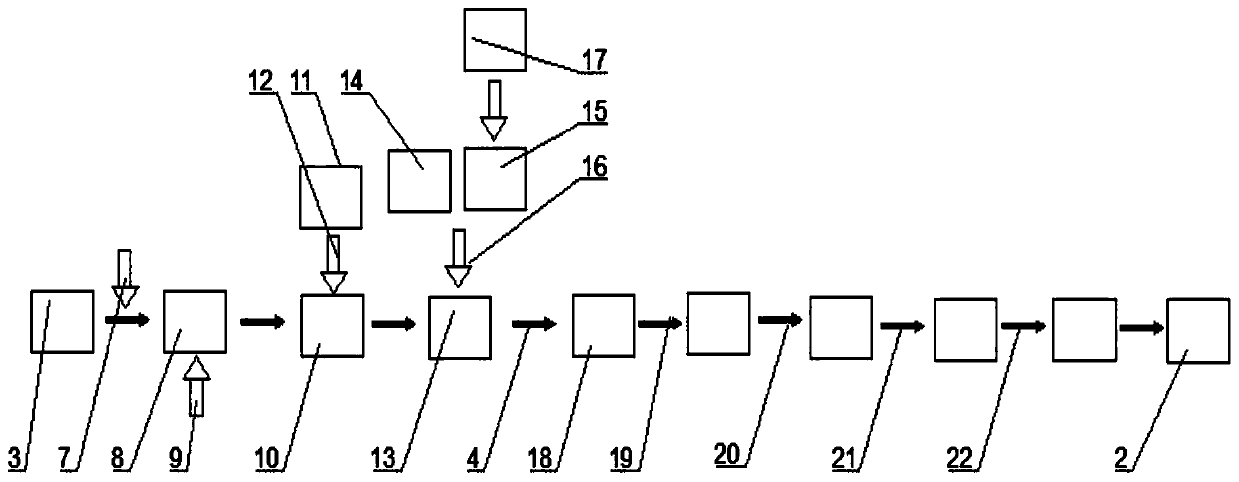

Process for fabricating floss-silk decorative paintings with tridimensional embossment effect

InactiveCN103287190AEasy to masterRich color expressionSpecial ornamental structuresEngineeringSilk fiber

The invention discloses a process for fabricating floss-silk decorative paintings with a tridimensional embossment effect. The process comprises the following steps of: (1) drafting on a drawing board for forming a whole composition of a painting creation; (2) dividing the painting into concave and convex gradations according to characteristics of images of the painting; (3) laying the whole painting with monochromatic or chromatic silk fibers; (4) depicting on details according to the concave-convex gradations of the painting successively, and stacking layer by layer and fixing each layer by spraying glue until the required effect of the painting is achieved; and (5) adjusting the painting overall, and fixing the whole painting overall by spraying glue after the painting is finalized. The process of the invention thoroughly overcomes the above three insoluble defects caused by different processes, so that a brand new species of painting and a ''tridimensional embossment floss-silk painting'' in the true sense are created.

Owner:强军

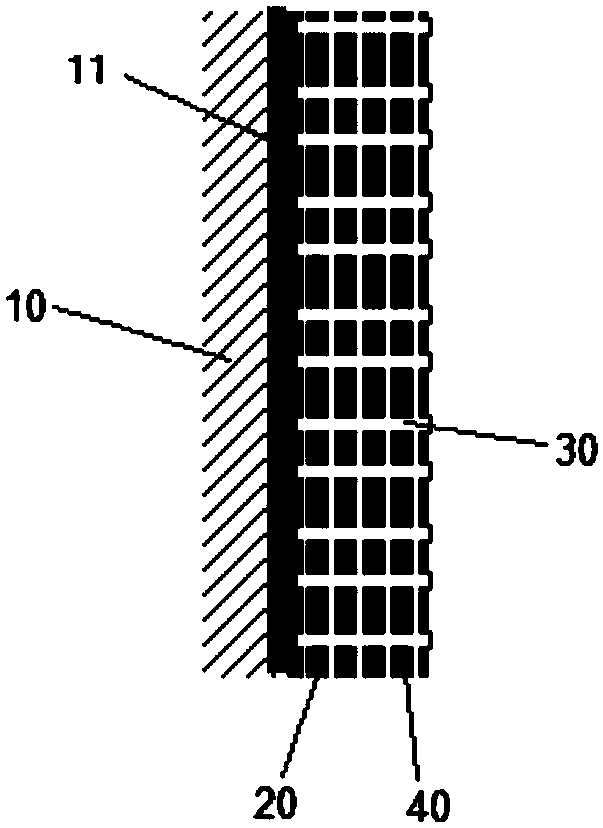

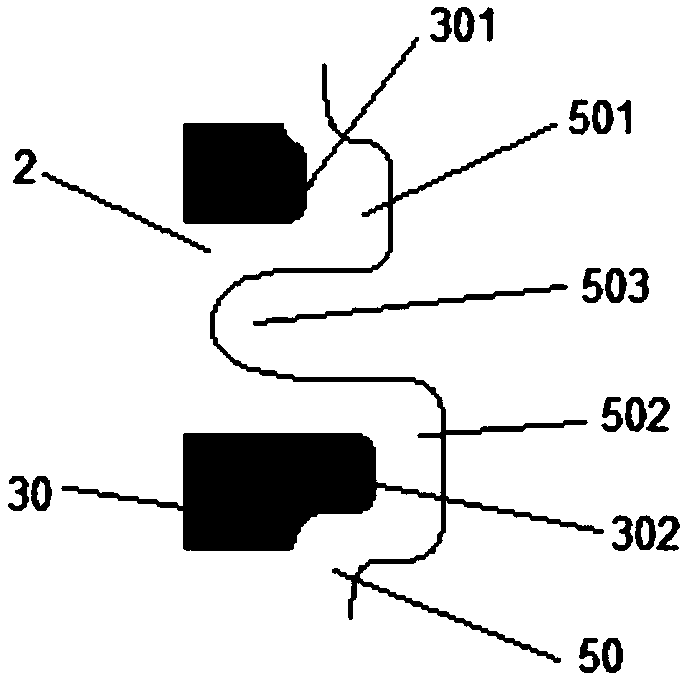

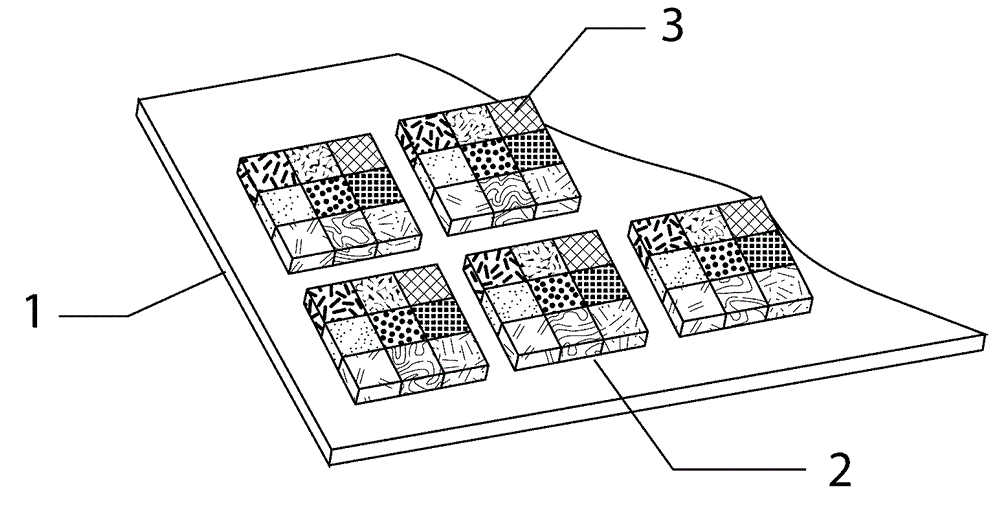

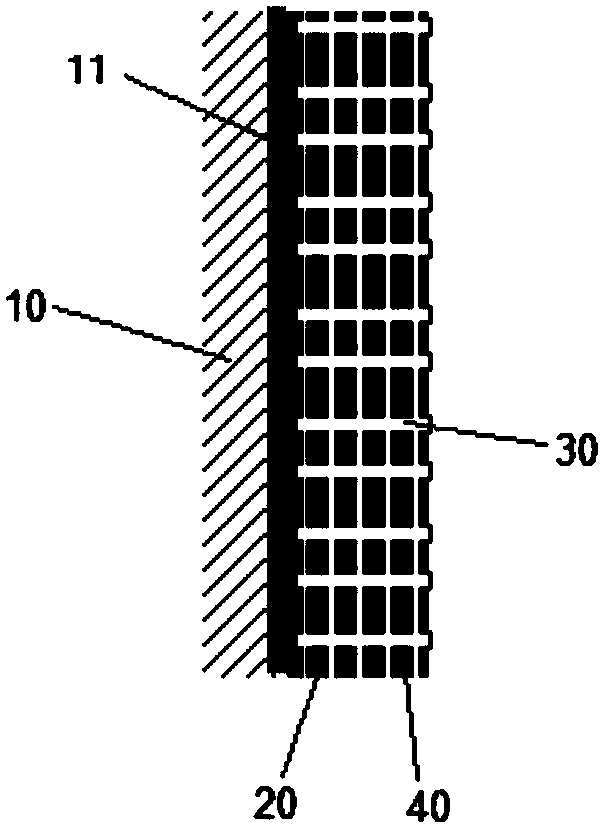

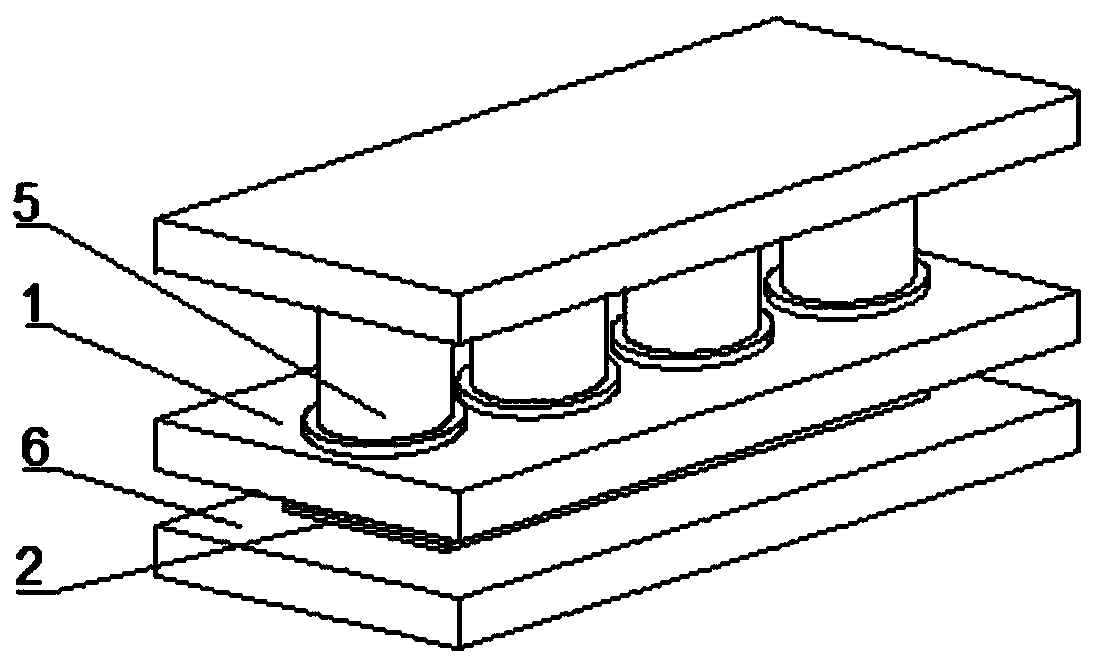

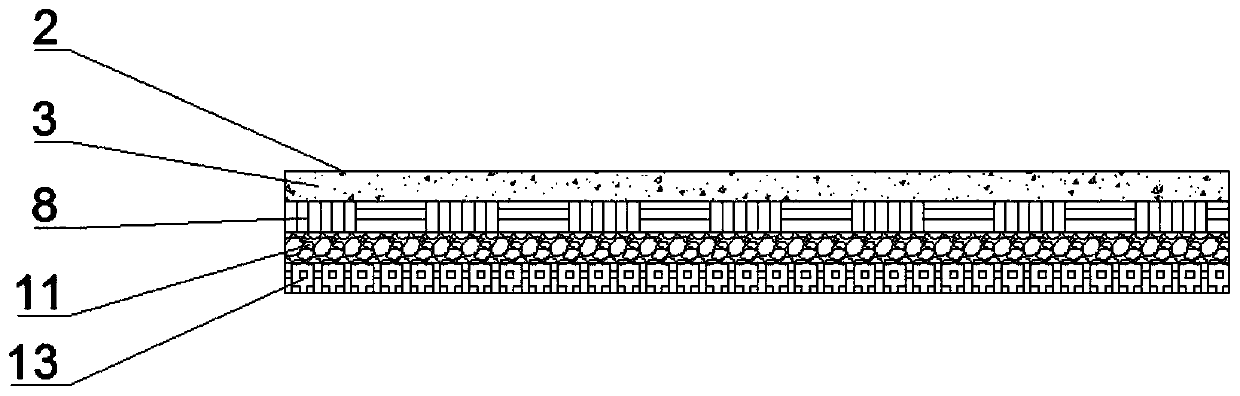

Phase change energy storage infiltration coating sandwich wall cloth and manufacturing method thereof

The invention provides a phase change energy storage infiltration coating sandwich wall cloth, and a method for manufacturing the phase change energy storage infiltration coating sandwich wall cloth,or an object decoration method. The phase change energy storage infiltration coating sandwich wall cloth comprises a bottom coating and an infiltration coating composite sandwich coating compound coated on the surface of the bottom coating; the infiltration coating composite sandwich coating compound comprises a transparent or semi-transparent second coating and a fiber texture network sandwich wrapped by the second coating; the fiber texture network sandwich contains a network structure formed by fibers; the second coating penetrates into meshes of the network structure; and one or more of the second coating, the bottom coating and the fiber texture network sandwich can have a phase change energy storage function. The wall cloth with textures and / or patterns can be manufactured in a standardized and large-scale mode, and has good crack resistance, air permeability and decorative performance.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Fireproof infiltration coating sandwich wall cloth and manufacturing method thereof

PendingCN110158892AAdequate adhesionObvious connection seamCovering/liningsCoatingsFiberCoated surface

The invention provides a fireproof infiltration coating sandwich wall cloth and a method for manufacturing the fireproof infiltration coating sandwich wall cloth or an object decoration method. The fireproof infiltration coating sandwich wall cloth comprises an undercoat layer and an infiltration coating composite sandwich coating composite body, wherein the surface of the undercoat layer is coated with the infiltration coating composite sandwich coating composite body, the infiltration coating composite sandwich coating composite body comprises a transparent or semitransparent second coatinglayer and a fiber texture network sandwich covered with the second coating layer, the fiber texture network sandwich contains a network structure formed by fibers, the second coating layer penetratesinto meshes of the network structure, and one or more of the second coating layer and the undercoat layer can be a fireproof coating layer. The wall cloth with skin textures and / or patterns can be produced in a standardized and large-scale mode, and good crack resistance, air permeability and decoration performance are achieved.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Heat insulation infiltration coating sandwich wall cloth and manufacturing method thereof

PendingCN110158891AAdequate adhesionObvious connection seamCovering/liningsSpecial surfacesFiberCrack resistance

The invention provides a heat insulation infiltration coating sandwich wall cloth, and a method for manufacturing the heat insulation infiltration coating sandwich wall cloth, or an object decorationmethod. The heat insulation infiltration coating sandwich wall cloth comprises a heat insulation coating and an infiltration coating composite sandwich coating compound covering the surface of the heat insulation coating; the infiltration coating composite sandwich coating compound comprises a transparent or semi-transparent second coating and a fiber texture network sandwich wrapped by the secondcoating; the fiber texture network sandwich contains a network structure formed by fibers; and the second coating penetrates into meshes of the network structure. The wall cloth with textures and / orpatterns can be manufactured in a standardized and large-scale mode, and has good crack resistance, air permeability and decorative performance.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Alkali-resistant infiltration coating sandwich wall cloth and manufacturing method thereof

The invention provides an alkali-resistant infiltration coating sandwich wall cloth, and a method for manufacturing the infiltration coating sandwich wall cloth, or an object decoration method. The alkali-resistant infiltration coating sandwich wall cloth comprises a closed bottom coating, a bottom color coating covering the surface of the closed bottom coating and an infiltration coating composite sandwich coating compound covering the surface of the bottom color coating; the infiltration coating composite sandwich coating compound comprises a transparent or semi-transparent second coating and a fiber texture network sandwich wrapped by the second coating; the fiber texture network sandwich contains a network structure formed by fibers; and the second coating penetrates into meshes of thenetwork structure. The wall cloth with textures and / or patterns can be manufactured in a standardized and large-scale mode, and has good crack resistance, air permeability and decorative performance.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Impregnated coated sandwich wall cloth and manufacturing method thereof

The invention provides an impregnated coated sandwich wall cloth and a method for manufacturing the impregnated coated sandwich wall cloth, or an object decoration method. The impregnated coated sandwich wall cloth comprises a bottom coating and an impregnated coated composite sandwich coating complex, wherein the surface of the bottom coating is coated with the impregnated coated composite sandwich coating complex; and the impregnated coated composite sandwich coating complex comprises a transparent or translucent second coating and a fiber texture network sandwich wrapped by the second coating, wherein the fiber texture network sandwich contains a network structure formed by fiber, and the second coating permeates into net holes of the network structure. The wall cloth with textures and / or patterns can be manufactured in standardized and large-scale modes, and the impregnated coated sandwich wall cloth has good anti-cracking performance, air-permeable performance and decoration performance.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Tripolar carbon nanotube display with filtering structure and process for preparing same

InactiveCN1667788AQuality improvementReduce distractionsImage/pattern display tubesCold cathode manufactureFlat glassManufacturing technology

This invention relates to a three-pole two-dimensional display of an anode panel structure applying the method of combining a Sn In oxide film, a color filter layer and a blocking layer and its manufacturing technology including a vacuum cavity made up of flat glasses, an anode panel produced by the method of combining Sn In oxide film the color filter layer and the blocking layer and a cathode panel printed with carbon nm tubes and insulation separating post elements.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Waterproof impregnated coated sandwich wall cloth and manufacturing method thereof

The invention provides a waterproof impregnated coated sandwich wall cloth and a method for manufacturing the impregnated coated sandwich wall cloth, or an object decoration method. The waterproof impregnated coated sandwich wall cloth comprises a bottom coating and an impregnated coated composite sandwich coating complex, wherein the surface of the bottom coating is coated with the impregnated coated composite sandwich coating complex; and the impregnated coated composite sandwich coating complex comprises a transparent or translucent second coating and a fiber texture network sandwich wrapped by the second coating, wherein the fiber texture network sandwich contains a network structure formed by fiber, the second coating permeates into net holes of the network structure, and one or moreof the second coating and the bottom coating can be waterproof coatings. The wall cloth with textures and / or patterns can be manufactured in standardized and large-scale modes, and the waterproof impregnated coated sandwich wall cloth has good anti-cracking performance, air-permeable performance and decoration performance.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Inlaying and clay-strip forming method Nixing pottery

The invention discloses an inlaying and clay-strip forming method for Nixing pottery. The method includes the steps of: preparation of a clay-strip forming blank, preparation of a color clay material, preparation of a clay-strip forming material, painting and carving, and inlaying. The method can realize mutual adsorption of color clay and the blank; in the firing process, the blank is not easy to fall off or crack, so as to reach a high firing rate, enrich color expression of Nixing pottery, and reach better plasticity. The method is a bold innovation on the basis of the inherited Nixing pottery process, develops a school of its own in the world of ceramic art gallery, brings business opportunities to the sustainable development of Nixing pottery industry, and makes creative contribution for the promotion of the inheritance and of development traditional process of Nixing pottery.

Owner:黄剑

Electromagnetic shielding impregnation coating sandwich wall cloth and manufacturing method thereof

The invention provides an electromagnetic shielding impregnation coating sandwich wall cloth and a method of manufacturing the electromagnetic shielding impregnation coating sandwich wall cloth or anobject decoration method. The electromagnetic shielding impregnation coating sandwich wall cloth comprises a bottom coating and an impregnation coating composite sandwich coating composite body applied to the surface of the bottom coating; and the impregnation coating composite sandwich coating composite body comprises a transparent or semitransparent second coating and a fiber texture network sandwich wrapped in the second coating, the fiber texture network sandwich comprises a network structure formed through fibers, the second coating permeates into net holes of the network structure, and one or more of the bottom coating, the second coating and the fiber texture network sandwich have an electromagnetic shielding function. According to the electromagnetic shielding impregnation coatingsandwich wall cloth and the method, the wall cloth with textures and / or patterns can be manufactured in a standardized and large-scale manner, and the wall cloth has the good anti-cracking performance, air permeability and decorative performance.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Scrawling preventing infiltration coating sandwiched wall cloth and manufacturing method thereof

PendingCN110158885AAdequate adhesionAvoid crackingLiquid surface applicatorsCovering/liningsCoated surfaceFiber

The invention provides scrawling preventing infiltration coating sandwiched wall cloth and a method for manufacturing the scrawling preventing infiltration coating sandwiched wall cloth or an object decoration method. The scrawling preventing infiltration coating sandwiched wall cloth comprises a bottom coating and an infiltration coating composite sandwiched coating composite body applied to thesurface of the bottom coating. The infiltration coating composite sandwiched coating composite body comprises a transparent or semitransparent scrawling preventing coating and a fiber texture networksandwiched core wrapped by the scrawling preventing coating, wherein a network structure formed by fiber is contained in the fiber texture network sandwiched core, and the scrawling preventing coatingseeps into meshes of the network structure. By means of the method, the wall cloth with texture and / or patterns can be manufactured in a standard and large-scale manner, and good crack resisting performance, ventilation performance and decoration performance are achieved.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Magnetic attracting wall-mounted infiltrated and coated sandwich wall cloth and manufacturing method thereof

The invention provides a magnetic attracting wall-mounted infiltrated and coated sandwich wall cloth and a manufacturing method thereof or an object decorating method. The magnetic attracting wall-mounted infiltrated and coated sandwich wall cloth comprises a bottom coating and an infiltrated and coated compound sandwich painting complex coated on the surface of the bottom coating; the infiltratedand coated compound sandwich painting complex comprises a transparent or semitransparent second coating and a fiber texture mesh sandwich wrapped by the second coating, wherein the fiber texture meshsandwich includes a mesh structure formed by fibers inside; the second coating infiltrates into mesh openings of the mesh structure; and one or several of the second coating, the bottom coating and the fiber texture mesh sandwich can possess magnetic attracting performance. The manufacturing method disclosed by the invention is capable of manufacturing the wall cloth with textures and / or patternson a large scale in a standardizing manner, and the wall cloth has good anti-cracking ability, air permeability and decorating property.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Color-adjustable kneading molding material micro-sculpture three-dimensional pixel picture and production method thereof

InactiveCN104875542ARich color expressionRich shapesOrnamental structuresSpecial ornamental structuresMonochromeMaterials science

Owner:冯志刚

Long-acting antibacterial infiltration coated sandwich wall covering and manufacturing method thereof

The invention provides a long-acting antibacterial infiltration coated sandwich wall covering and a method for manufacturing the infiltration coated sandwich wall covering, or an object decorating method. The long-acting antibacterial infiltration coated sandwich wall covering comprises a priming coat and an infiltration coated composite sandwich coating composite coated on the surface of the priming coat; and the infiltration coated composite sandwich coating composite comprises a transparent or translucent second coat and a fiber texture network sandwich wrapped with the second coat, whereinthe fiber texture network sandwich contains a network structure formed by fibers, and the second coat infiltrates into meshes of the network structure, meanwhile, the fibers of the fiber texture network sandwich are loaded with an antibacterial substance or a substance capable of releasing an antibacterial substance. The wall covering with textures and / or patterns can be manufactured in large scale in a standardized mode, and has good crack resistance, air permeability and decorative performance. An antibacterial agent is loaded in the fibers and wrapped by coating, and does not fall off, sothat the long-term antibacterial effect can be achieved.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Water-based sand wall-shaped pearly coating and preparation method thereof

InactiveCN109535899AImproved color stabilityRich color expressionMulticolor effect coatingsWater basedMechanical stability

The invention provides a water-based sand wall-shaped pearly coating which comprises pearly colorful sand and a basic coating, wherein the pearly colorful sand is white sand with pearly pigment and resin binder coated on surface. According to the invention, pearly pigment and resin binder are coated on the surface of white sand, so that pearly pigment is uniformly fixed on the surface of white sand; the white sand is combined with the basic coating, so that color difference of coating caused by change on arrangement mode of pearly pigment during the construction process can be prevented, and the acquired water-based sand wall-shaped pearly coating has high color stability, more abundant color expression and colorful pearly effect; and meanwhile, the water-based sand wall-shaped pearly coating has high glossiness, excellent covering property, high water resistance, high mechanical stability, high constructability and high bonding strength, and is capable of meeting the requirements forconstruction external wall coatings.

Owner:上海贝塔建筑科技有限公司

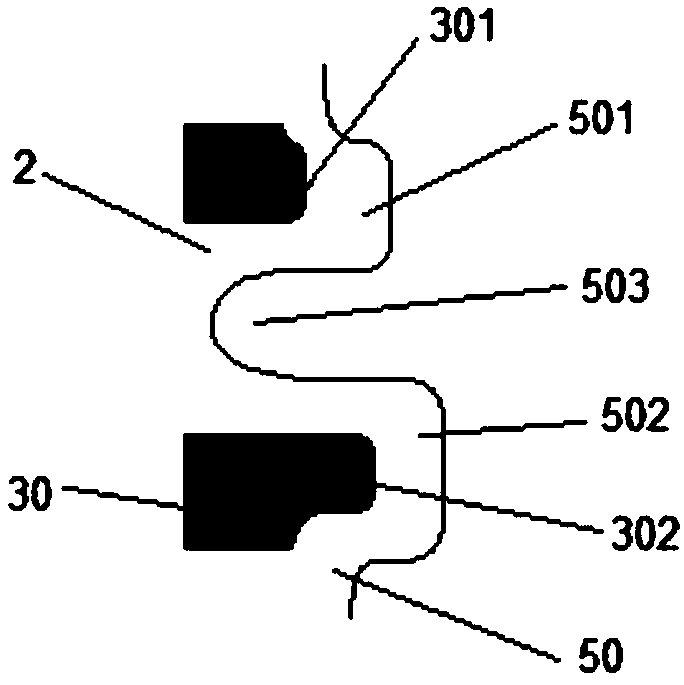

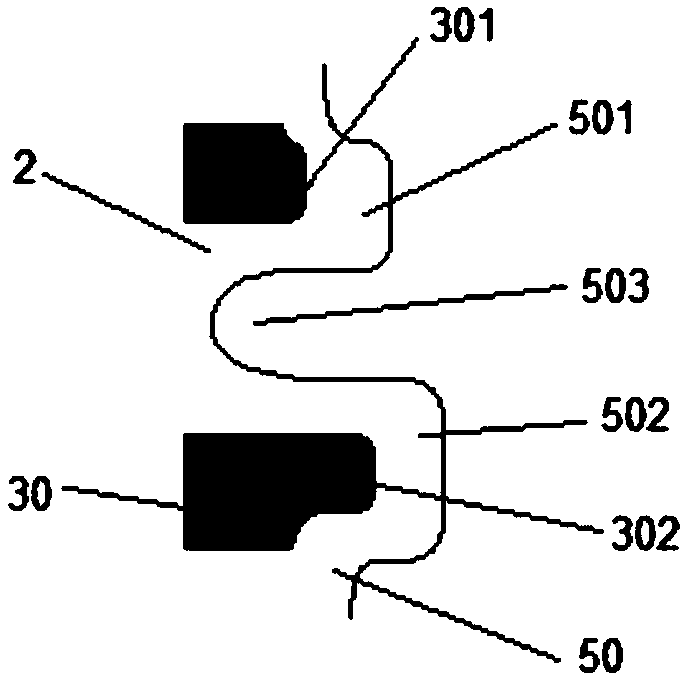

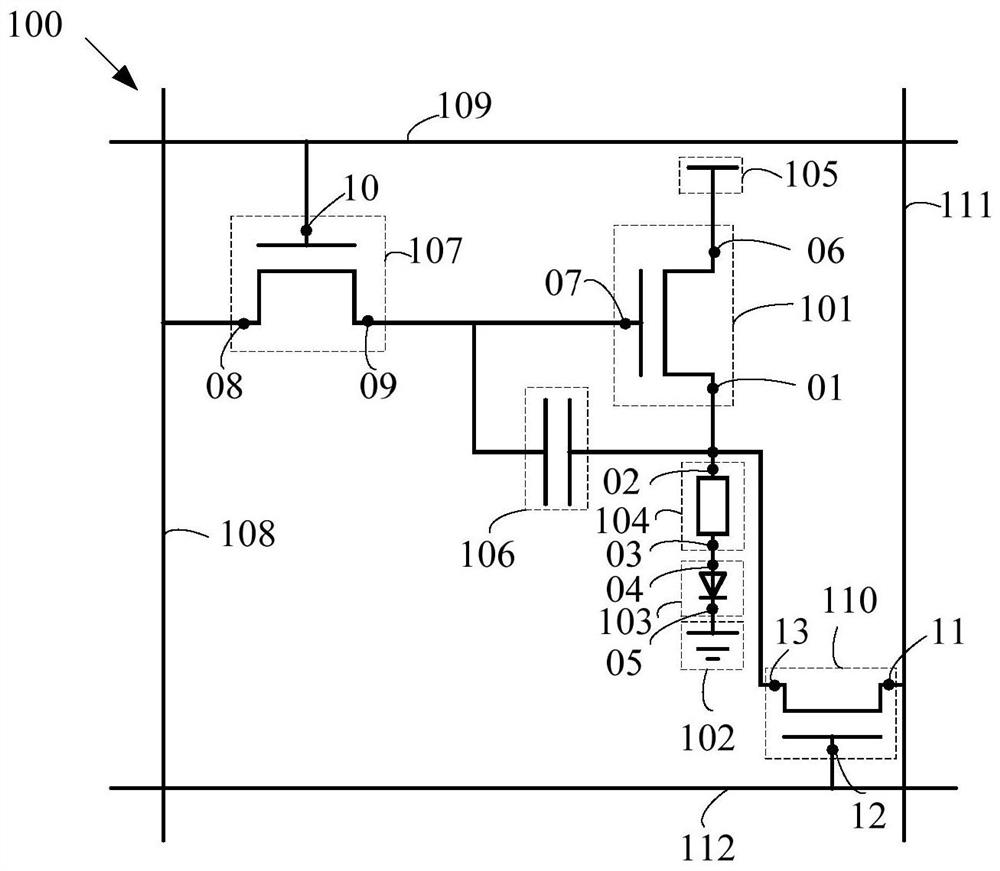

Pixel driving circuit and display panel

InactiveCN112908248ARich color expressionImprove color levelsStatic indicating devicesHemt circuitsLight-emitting diode

The invention provides a pixel driving circuit and a display panel, the pixel driving circuit comprises a driving module, a first voltage module, a light-emitting module and an adjusting module, the two ends of the light-emitting module are electrically connected with the driving module and the first voltage module respectively, the light-emitting module comprises a micro light-emitting diode, and the adjusting module and the light-emitting module are connected in series; and according to the scheme, the adjusting module is connected to the branch of the light emitting module in series, the minimum value of voltage changes at the two ends of the micro light emitting diode can be reduced in an auxiliary mode, the pixel corresponding to the micro light emitting diode can achieve more gray scale levels, the color expressive force of a picture is enriched, and the color level of the picture is increased.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

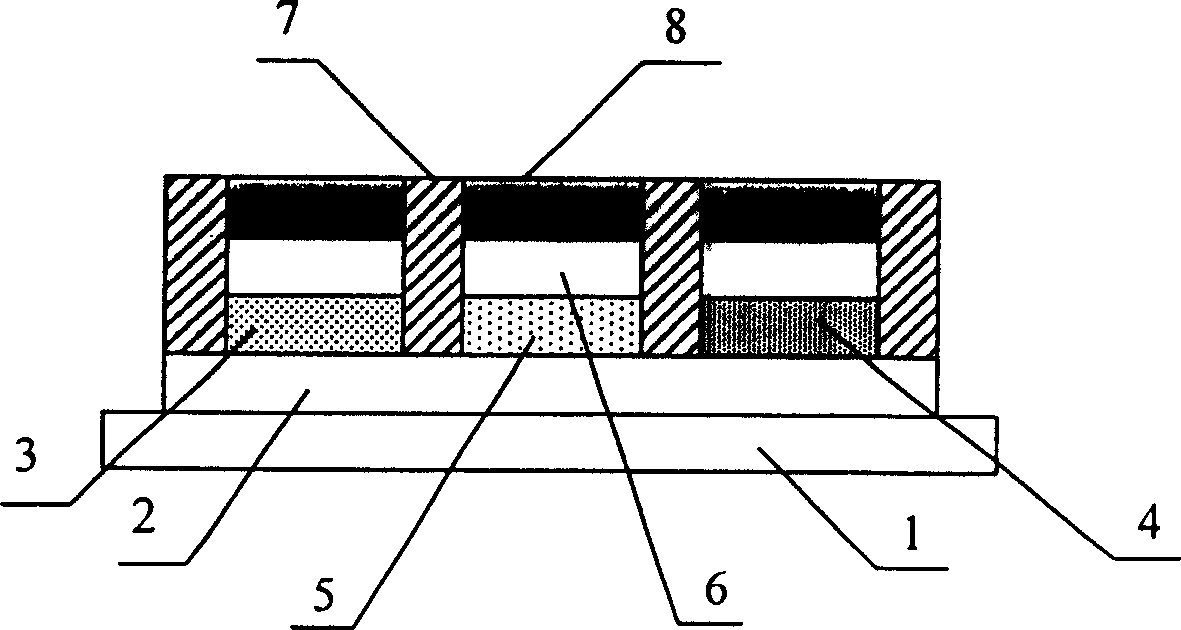

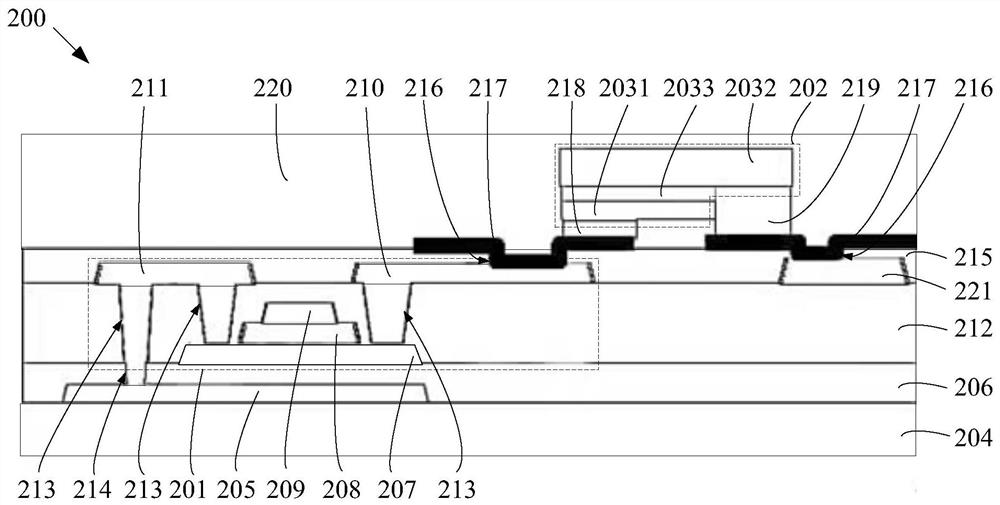

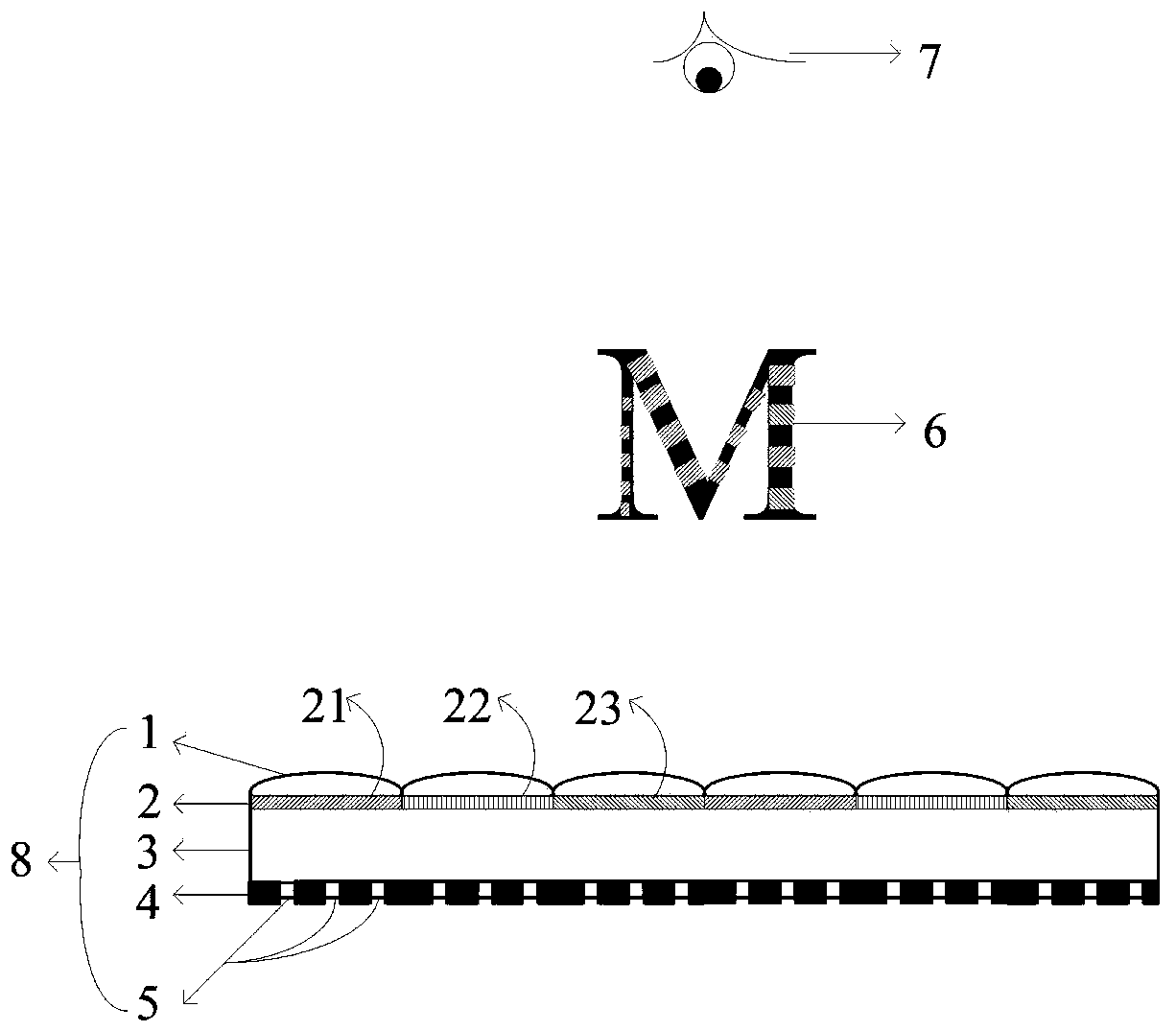

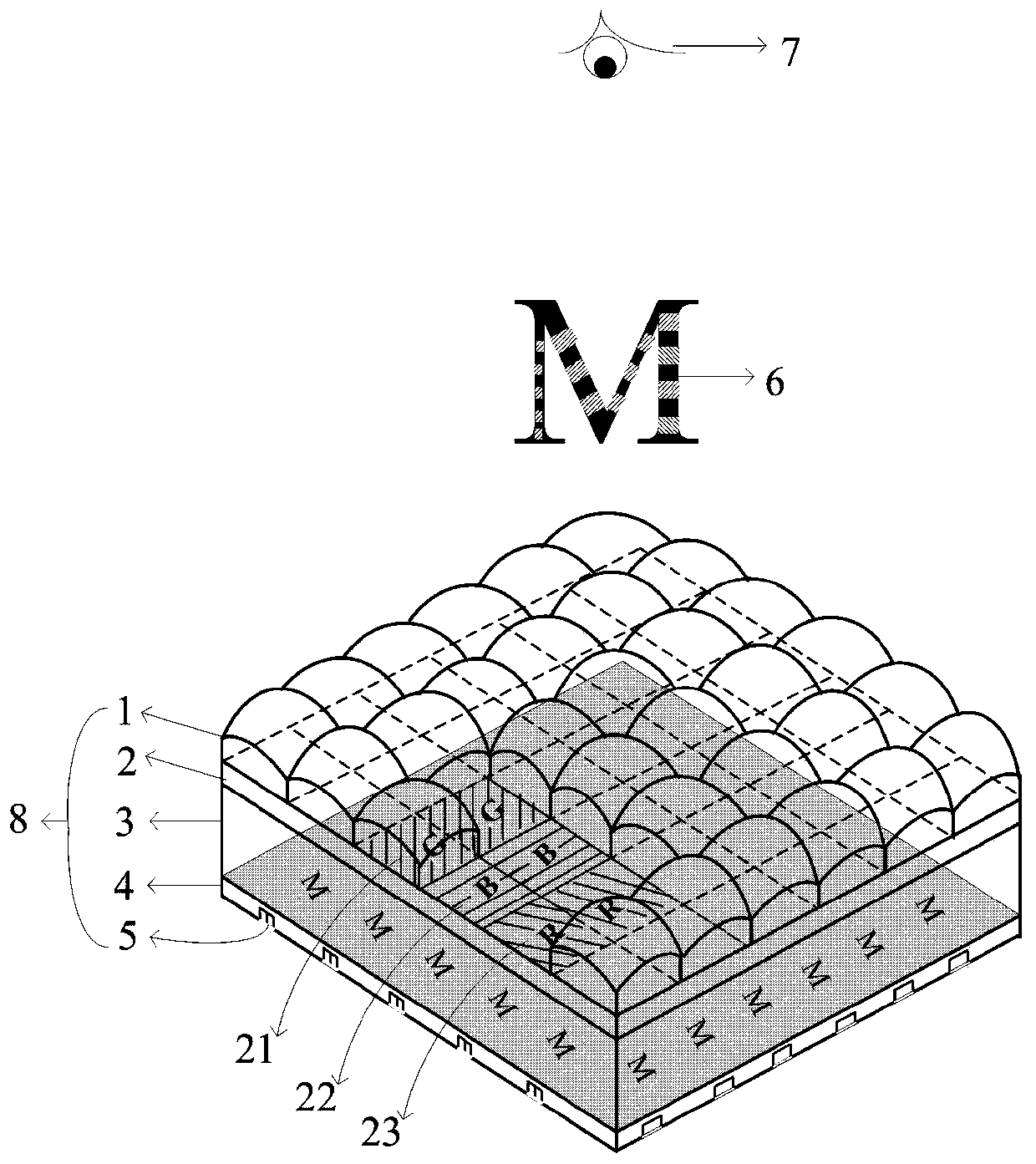

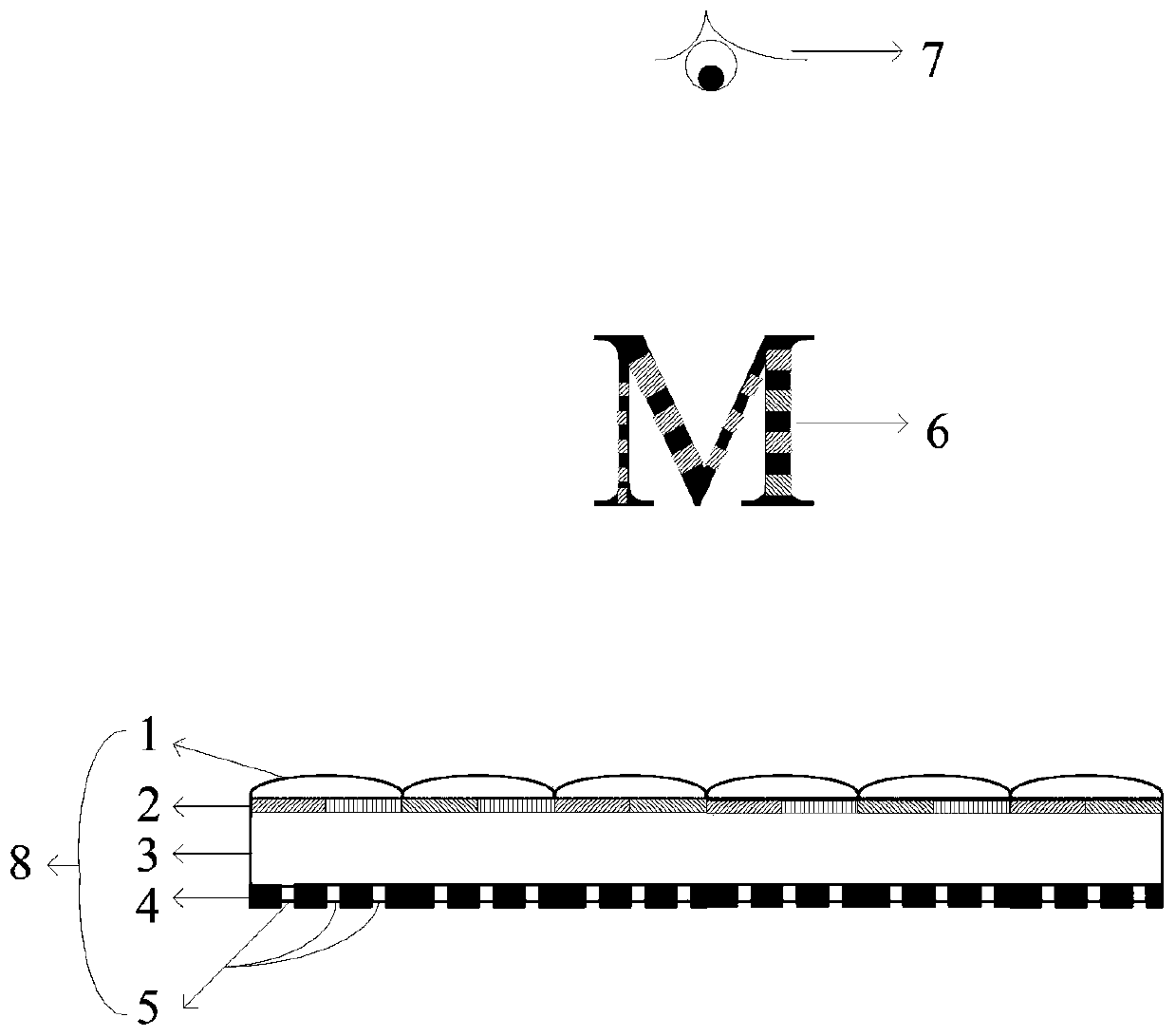

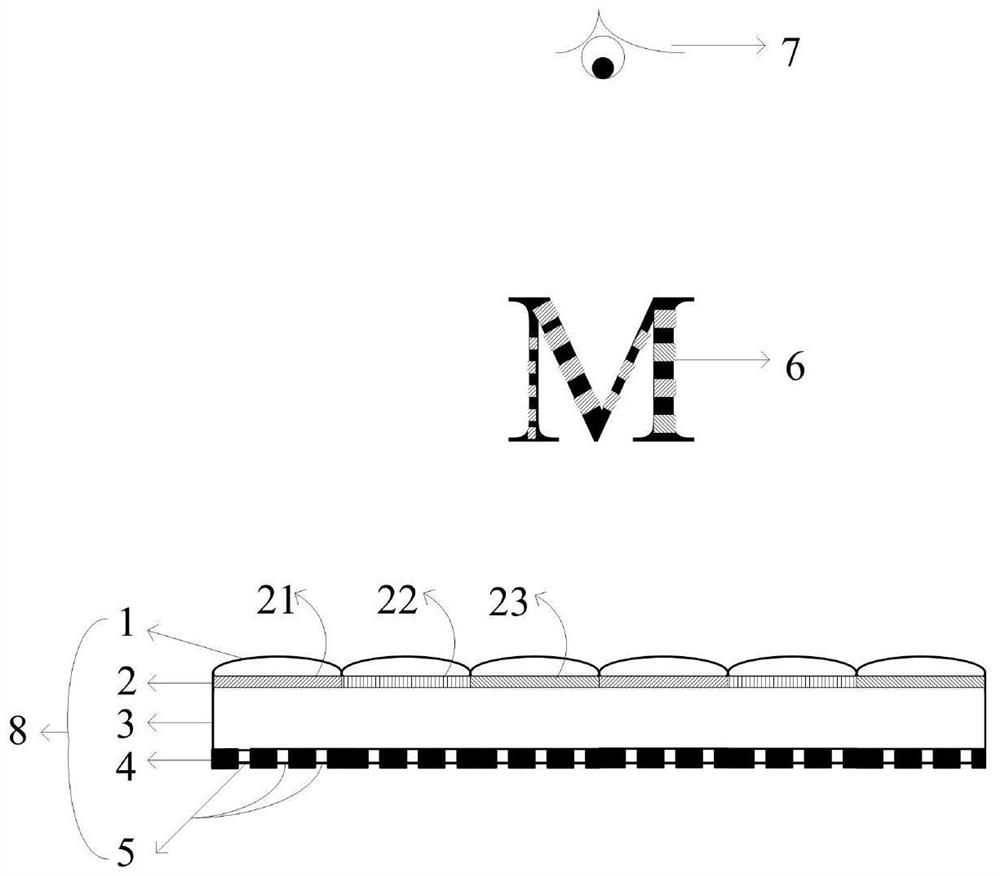

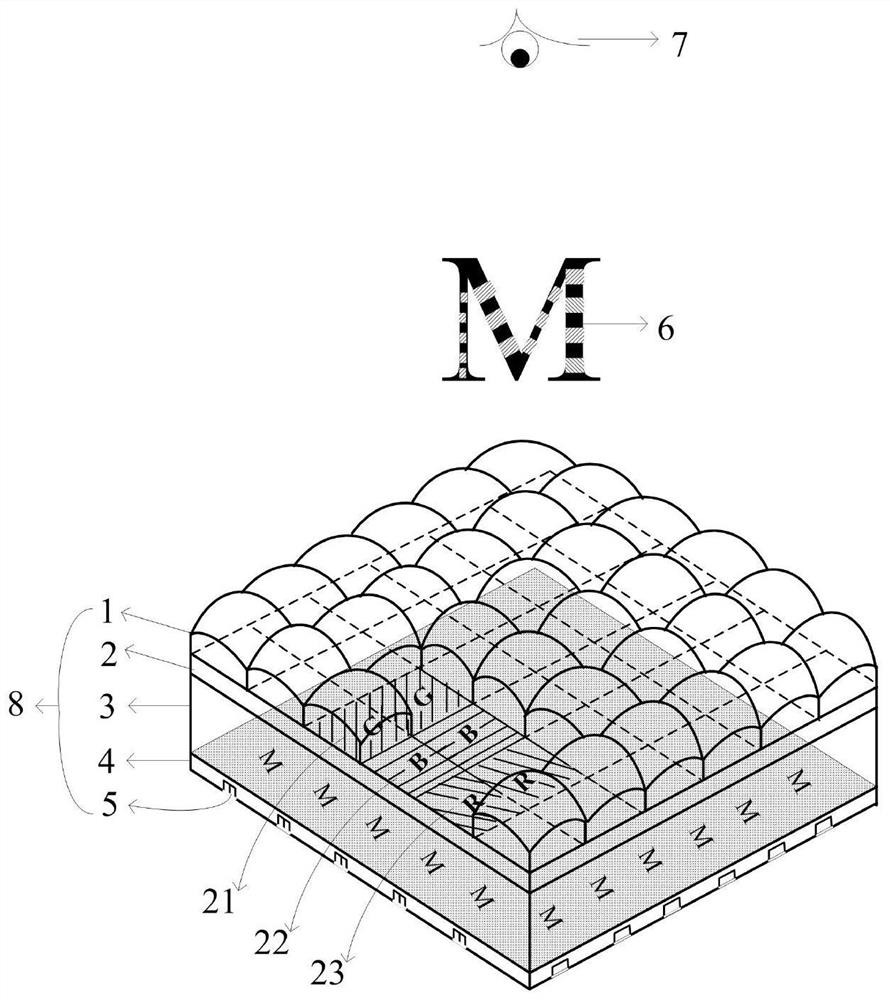

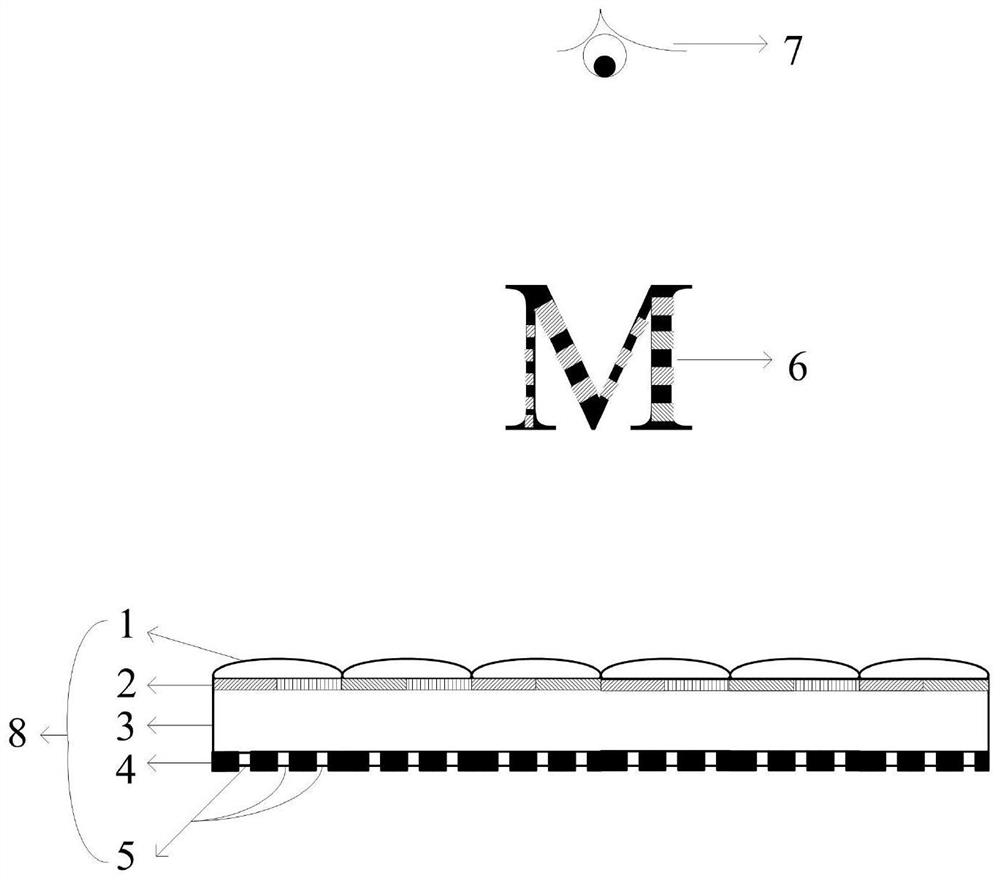

Color image

The invention relates to the field of dyeing and color images, and in particular to a color image, comprising a focusing element array layer, a first dyeing layer, a substrate layer, a micro pattern array layer and a second dyeing layer, which are sequentially disposed, wherein the layers are adhered to each other to form a film type color image; the focusing element array layer is composed of a focusing element array formed by arranging focusing units, the first dyeing layer is formed by arranging color pixel point arrays, the micro pattern array layer is composed of a micro pattern array formed by arranging micro pattern units, and the second dyeing layer is formed by arranging color pixel point arrays. According to the color image provided by the invention, indirect dyeing of two dyeinglayers is adopted, a color image having a pixel unit less than 5 micrometers can be achieved, the resolution of the color image is improved, the color of the color image is enriched, and the displayeffect of the color image is improved. The formed color image has novel effects such as color three-dimensional color, dynamics, optical change, illumination response and the like, and thus has a broad application prospect.

Owner:ZHEJIANG SCI-TECH UNIV

Solid wood paint-free composite single board

InactiveCN109719809AImprove penetrating adhesionHigh glossPlywood pressesVeneer pressesHydraulic cylinderSolid wood

The invention relates to the technical field of composite boards, in particular to a solid wood paint-free composite single board. A pressing-fit machine lower pressing plate, a composite single board, regenerated veneer and a pressing-fit part are included. The outer surface of the upper side of the pressing-fit machine lower pressing plate is fixedly connected with a hydraulic cylinder. A pressing-fit tabletop is arranged on the lower side of the pressing-fit machine lower pressing plate. The regenerated veneer is combined with fiber paper after being subjected to the step of water supplementing, the fiber paper is treated through a melamine glue immersing step, and after being combined with the regenerated veneer, the fiber paper is combined with a thin wood slice. Various valuable woodis selected as a solid wood veneer layer of the third layer, the valuable wood is planed and cut into the thin wood slice with 20-30 filaments, and in the actual effect, the surface solid wood pipe hole texture and grain quality and the abundant color and luster presentation are improved. In the fourth-layer paint glue film technology, during machining, through adding of aluminum oxide in resin,the capability of abrasion and scratching resisting can be improved, and practicability is improved. Integral practicability is high, and the usage effect is better compared with a traditional manner.

Owner:临沂大瑞木业有限公司

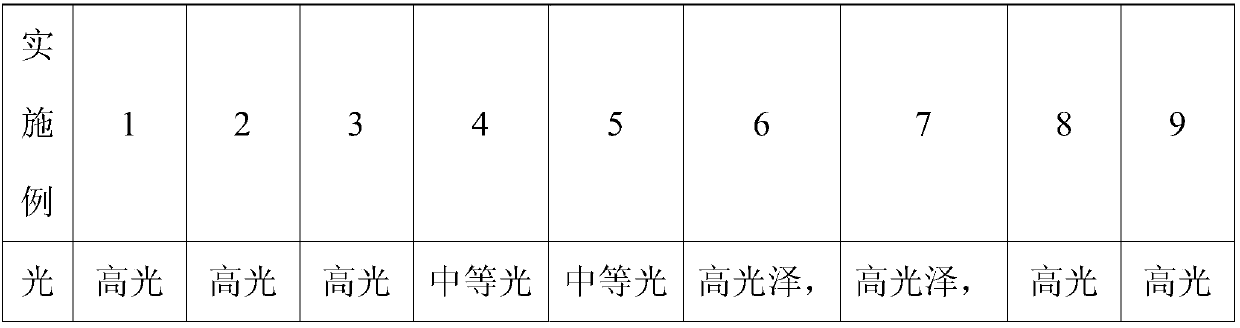

Method for manufacturing glazed interior wall bricks with two glazed effects

The invention discloses a method for manufacturing glazed interior wall bricks with two glazed effects. The method is characterized by comprising the following process steps of: selecting biscuit raw materials, performing ball milling, removing iron, spraying and manufacturing powder, performing compression molding, biscuiting to form biscuit, coating a ground coat, spraying glue water, performing dry glazing, performing inkjet printing and performing glaze firing, wherein the step of performing dry glazing comprises the following sub-steps of distributing matte overglaze and distributing gloss overglaze, or distributing gloss overglaze and distributing matte overglaze. The invention provides a method for manufacturing the glazed interior wall bricks, which is low in cost, clear in pattern texture and enriched in color application and through which the gloss difference between gloss and matte is obvious on the same non-standard product.

Owner:FOSHAN SANSHUI NEW PEARL CONSTR CERAMICS IND +1

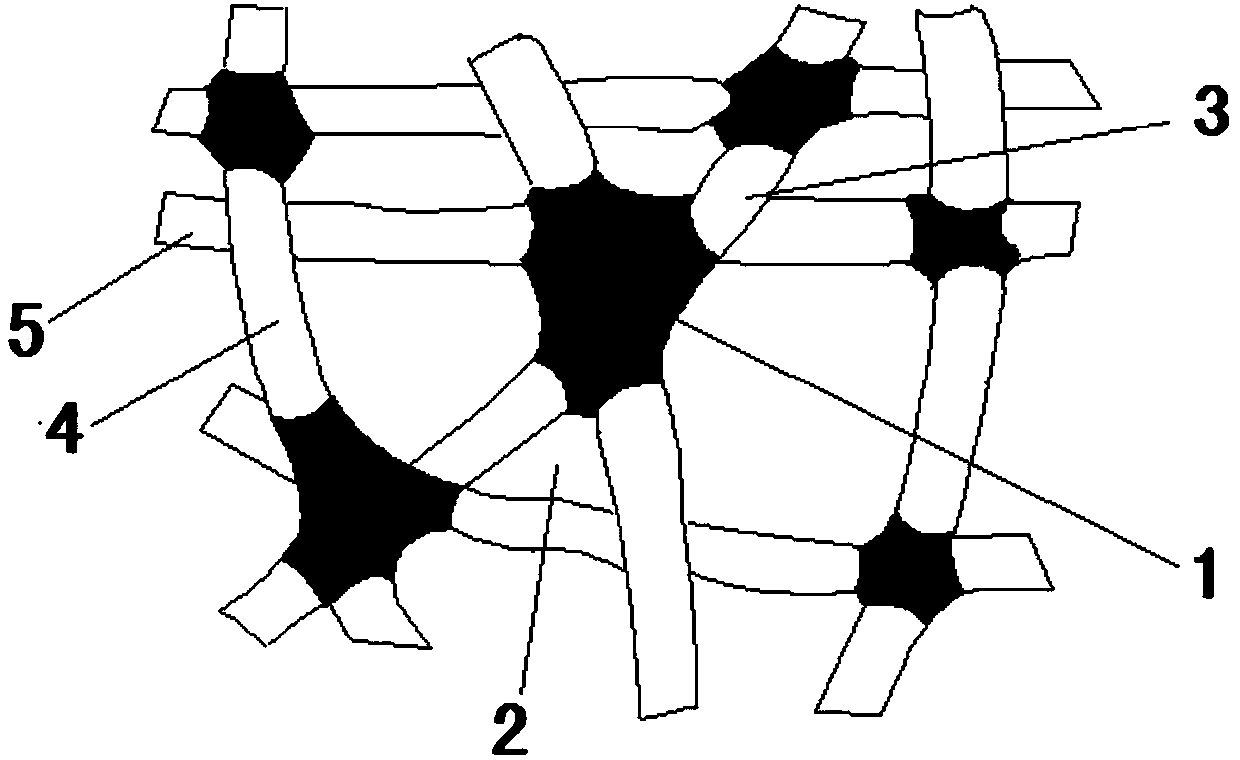

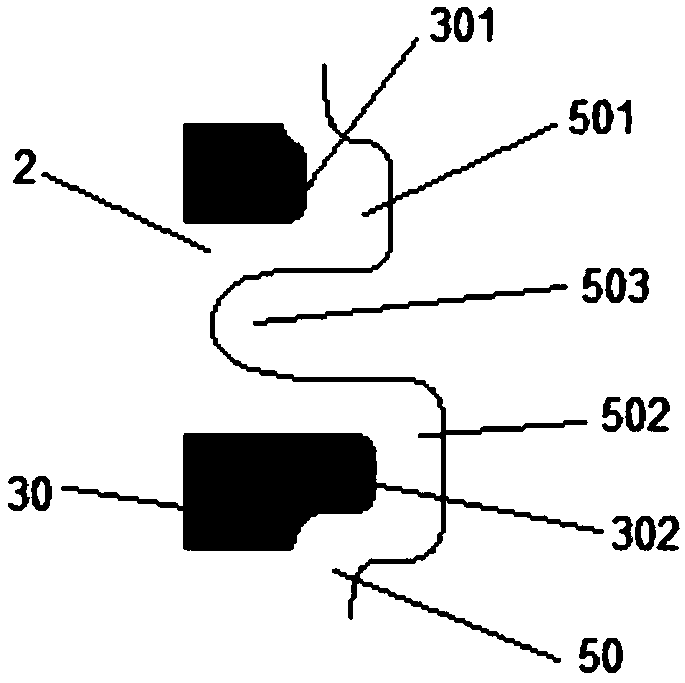

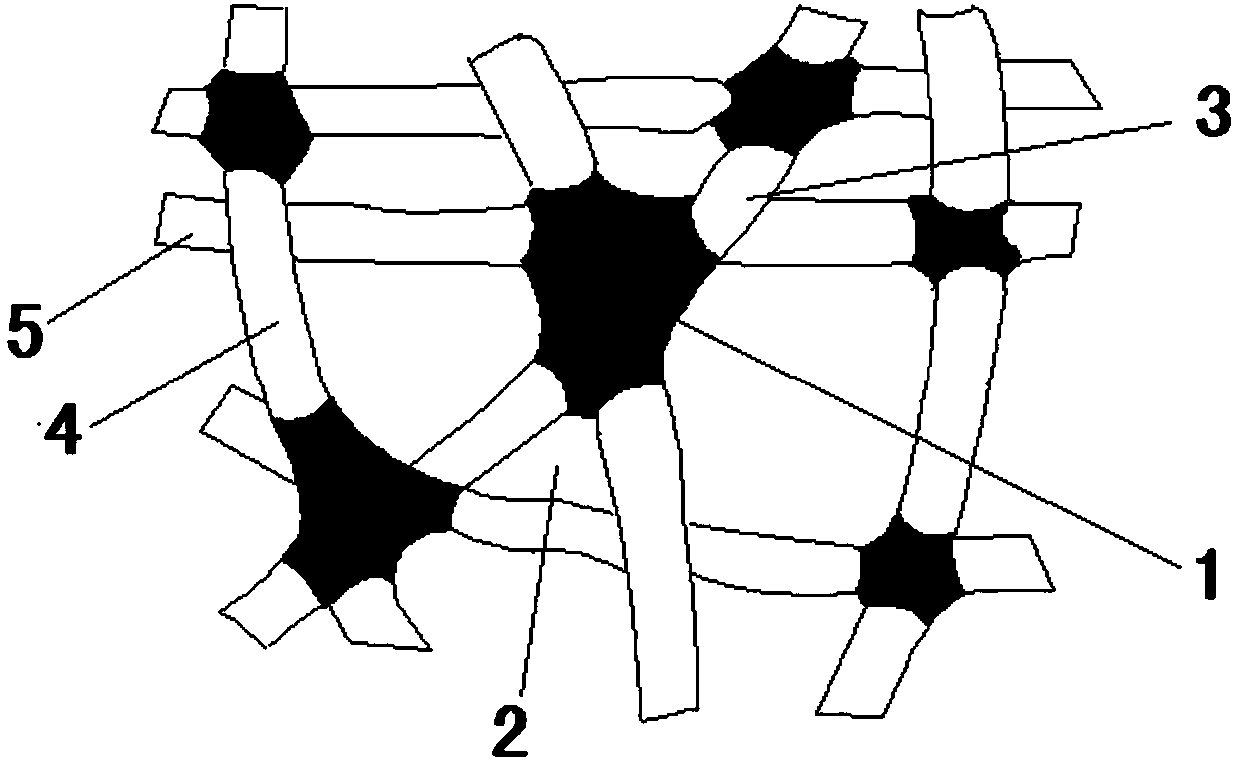

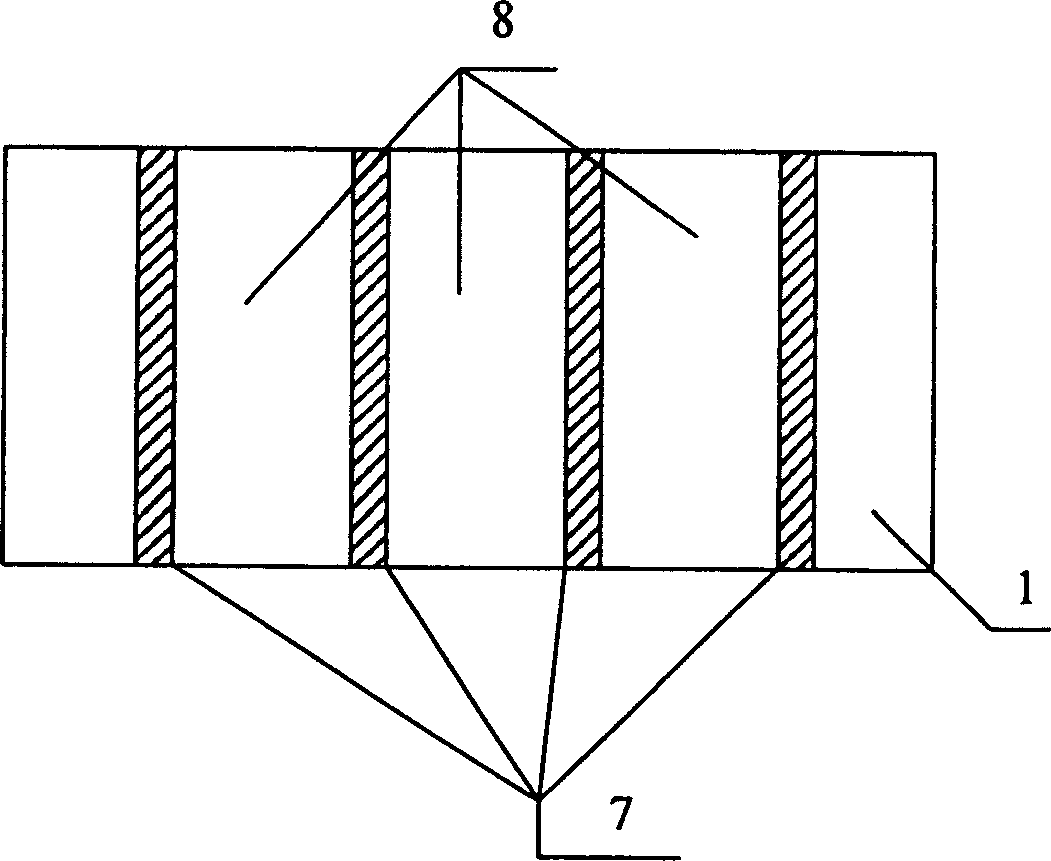

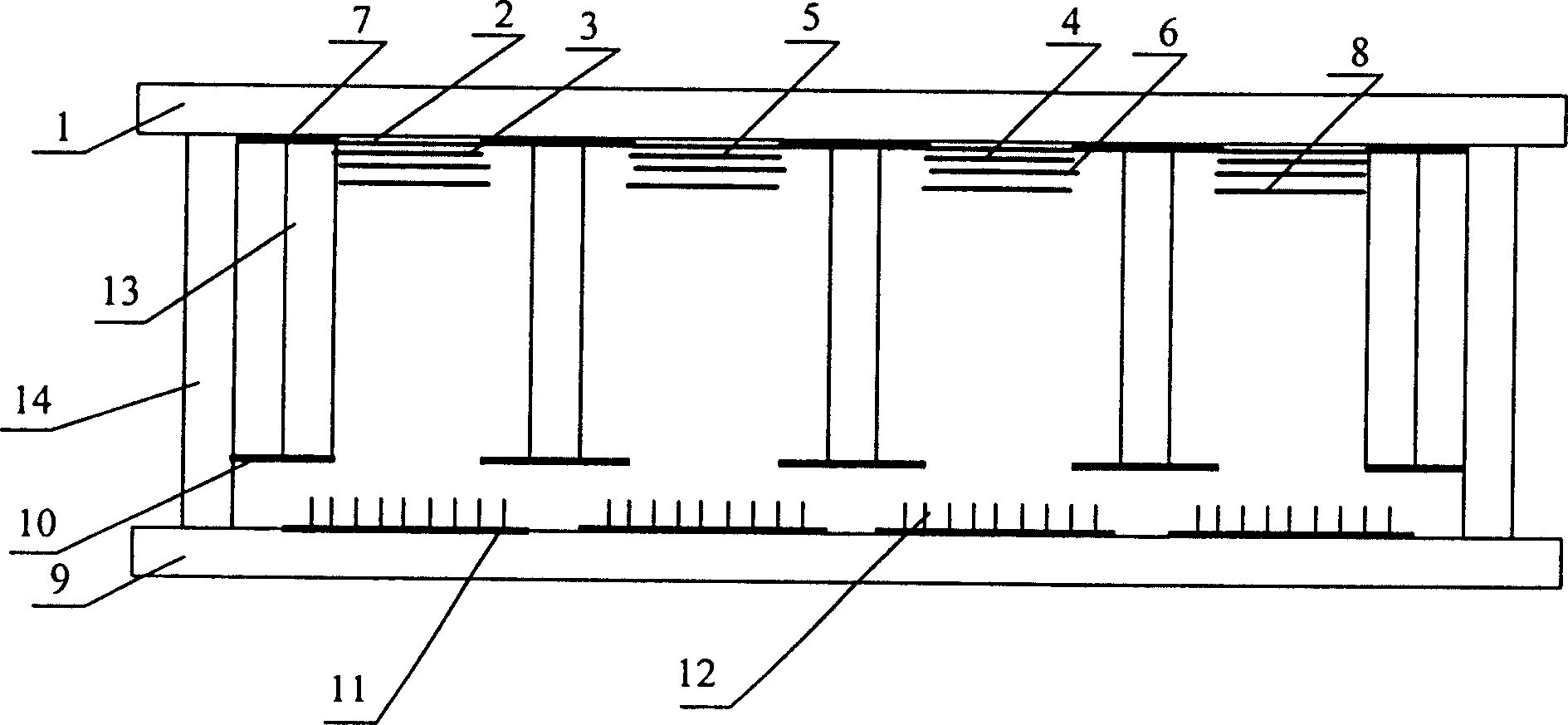

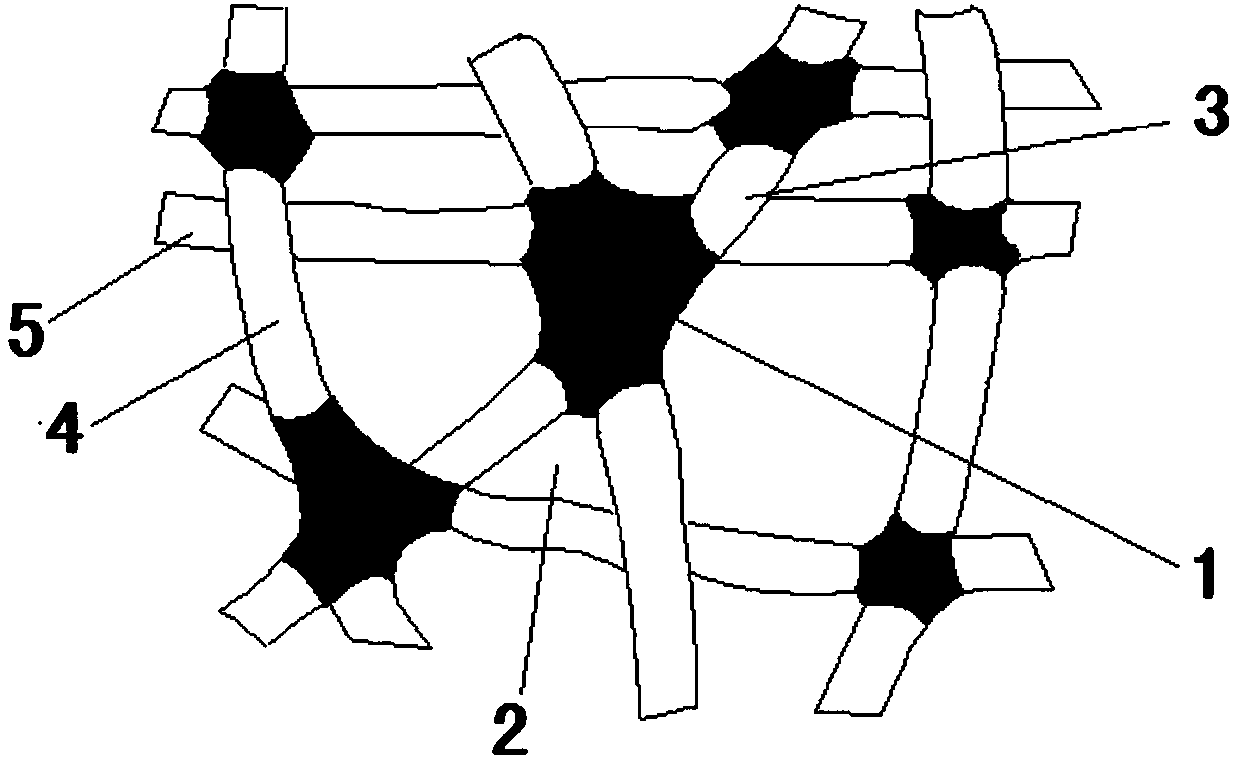

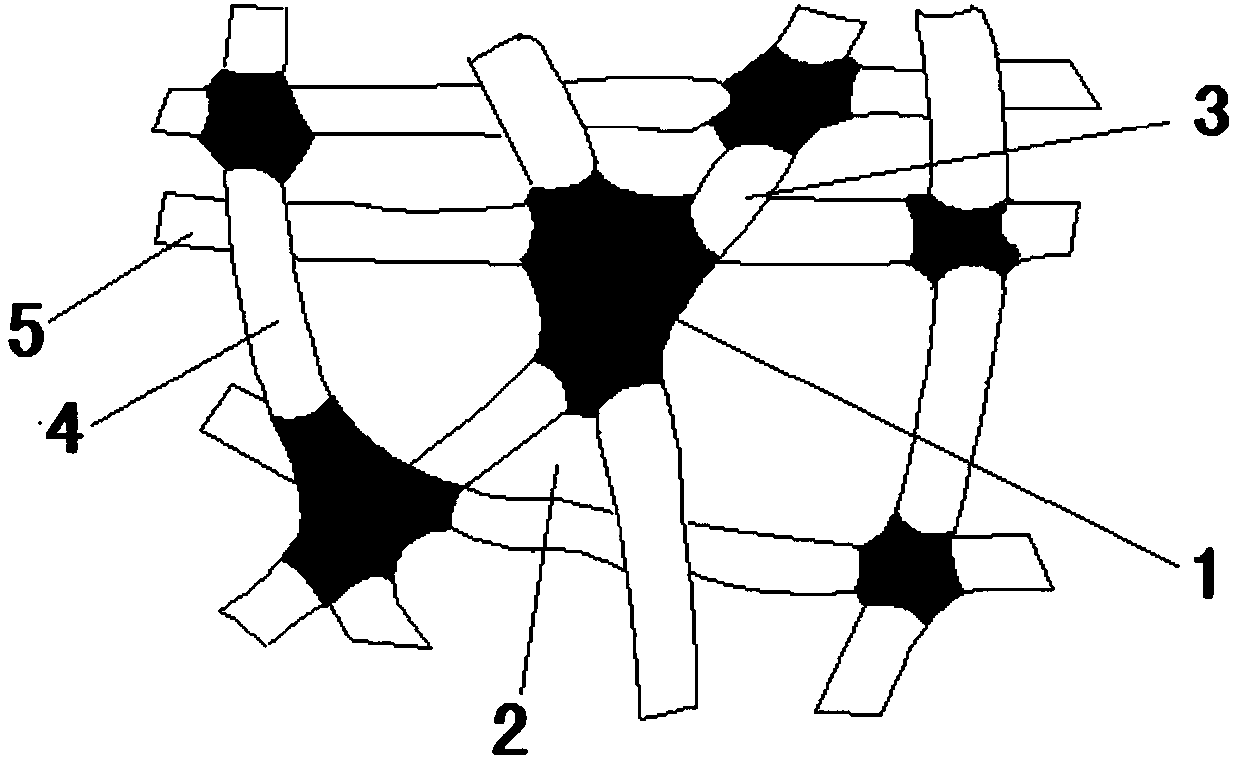

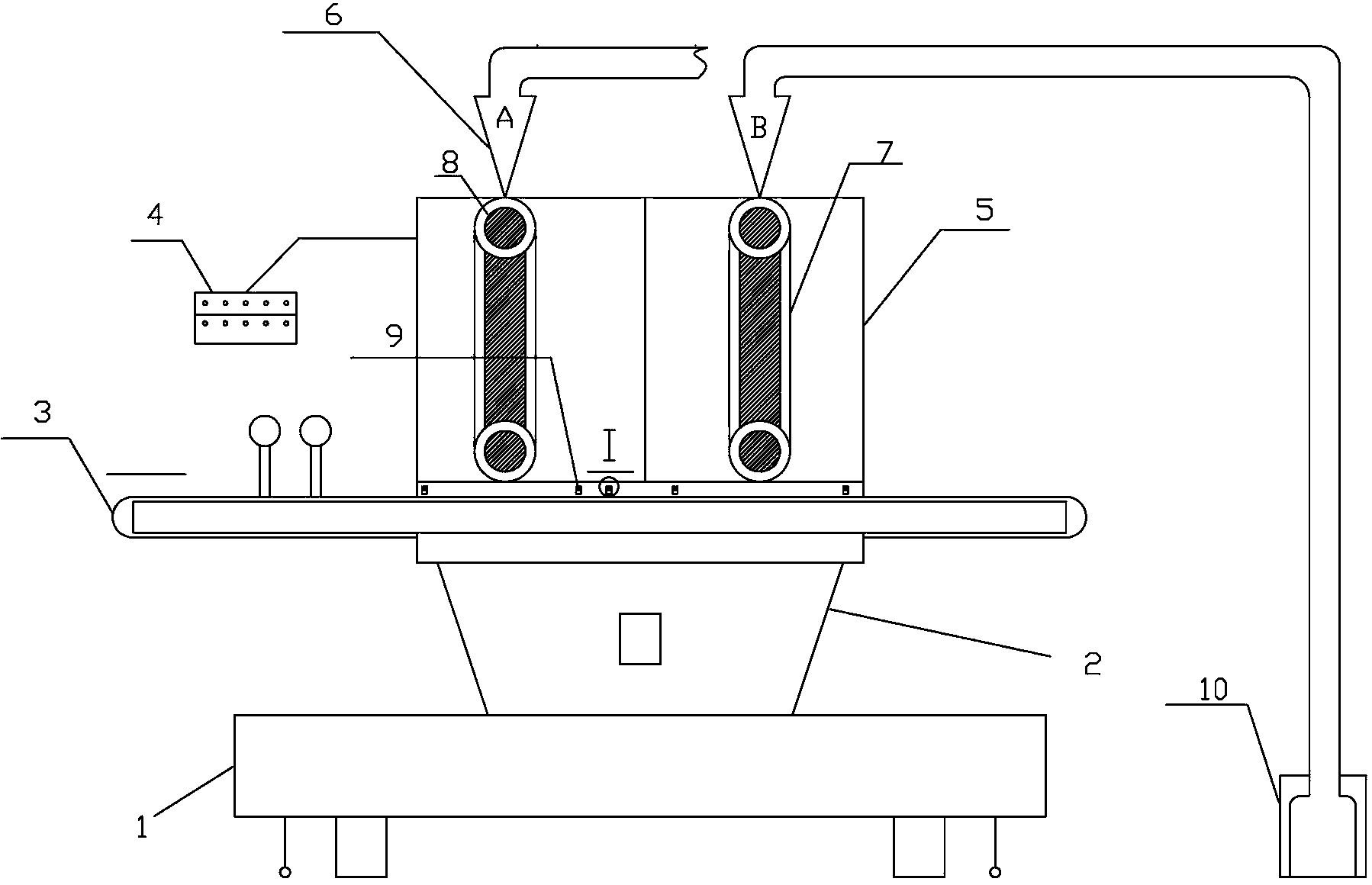

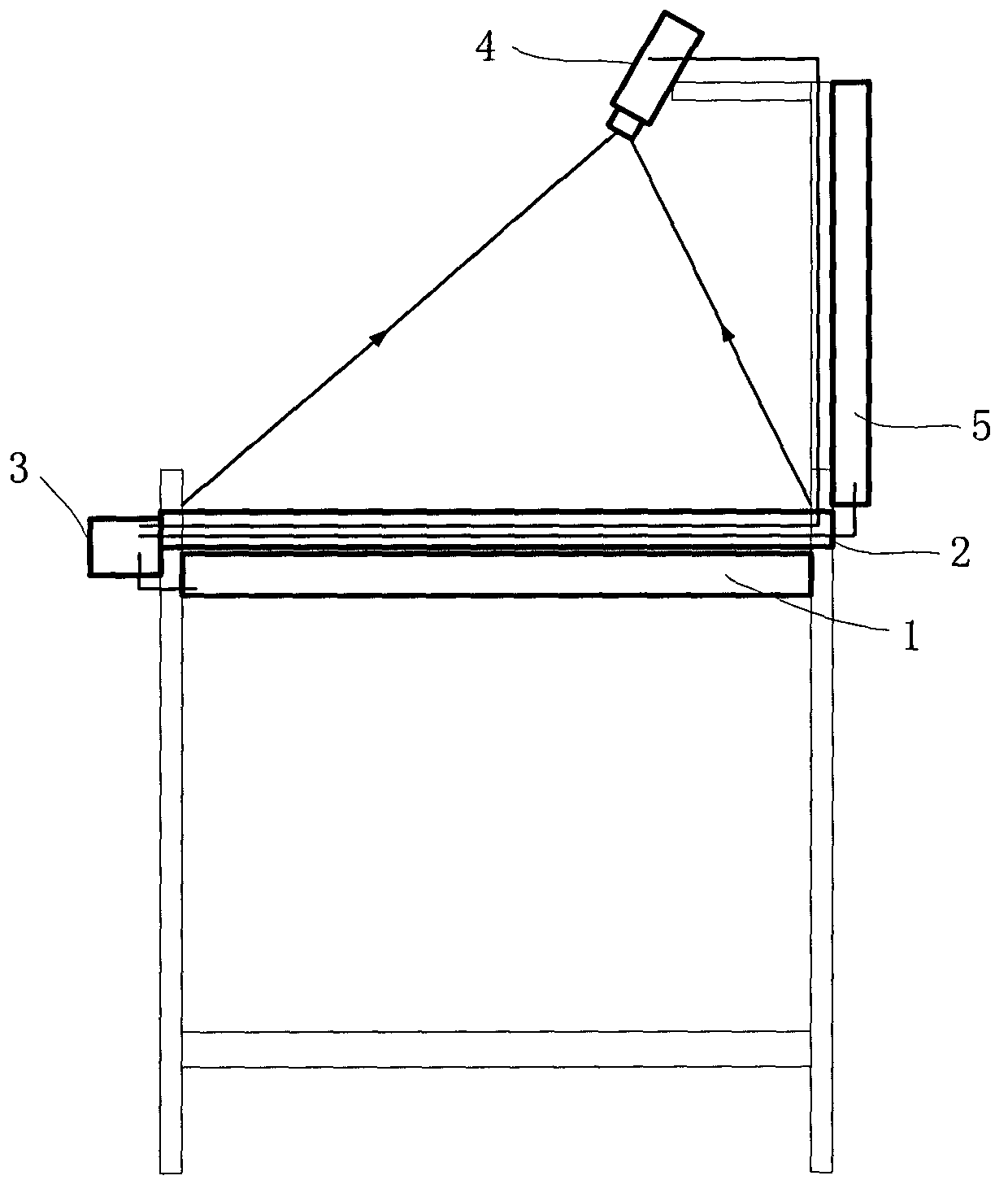

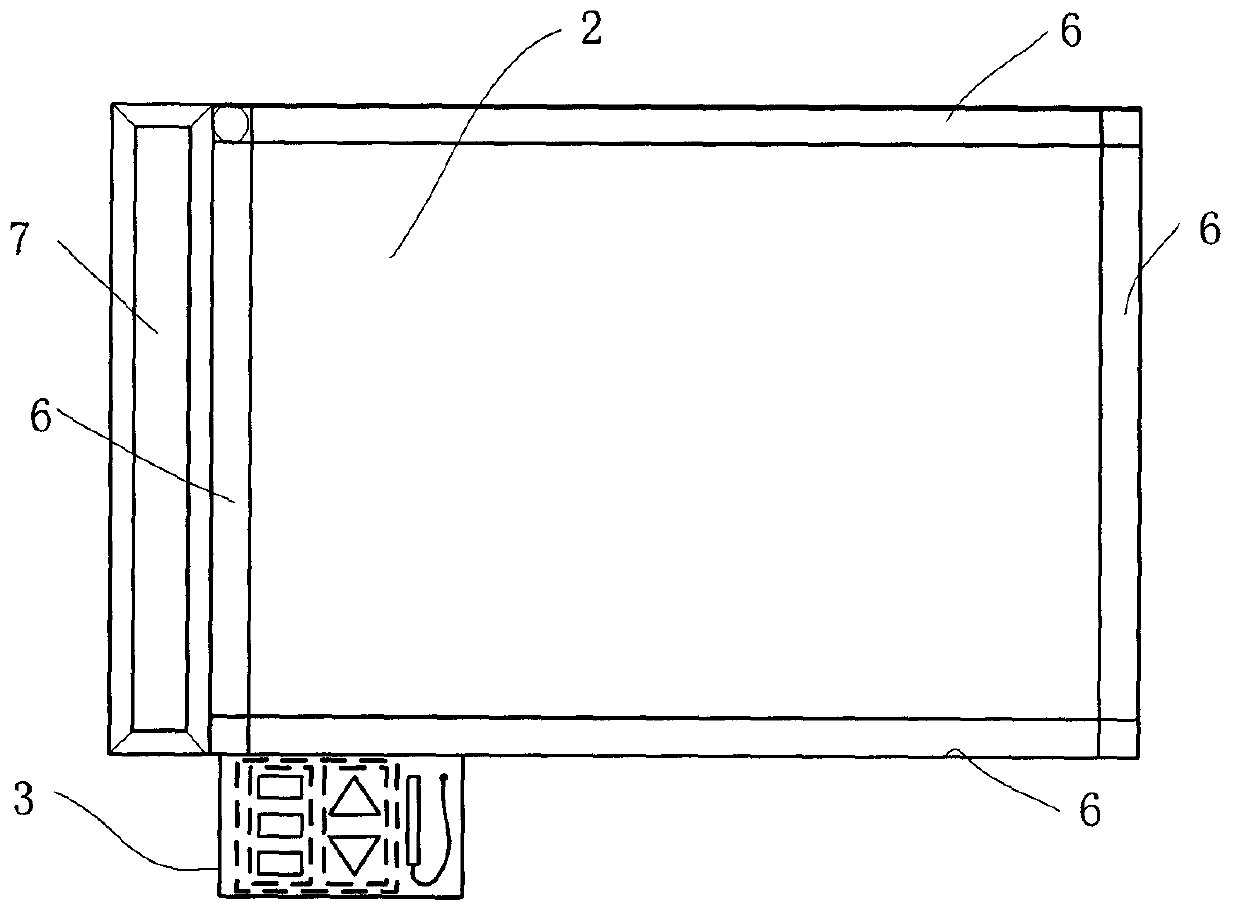

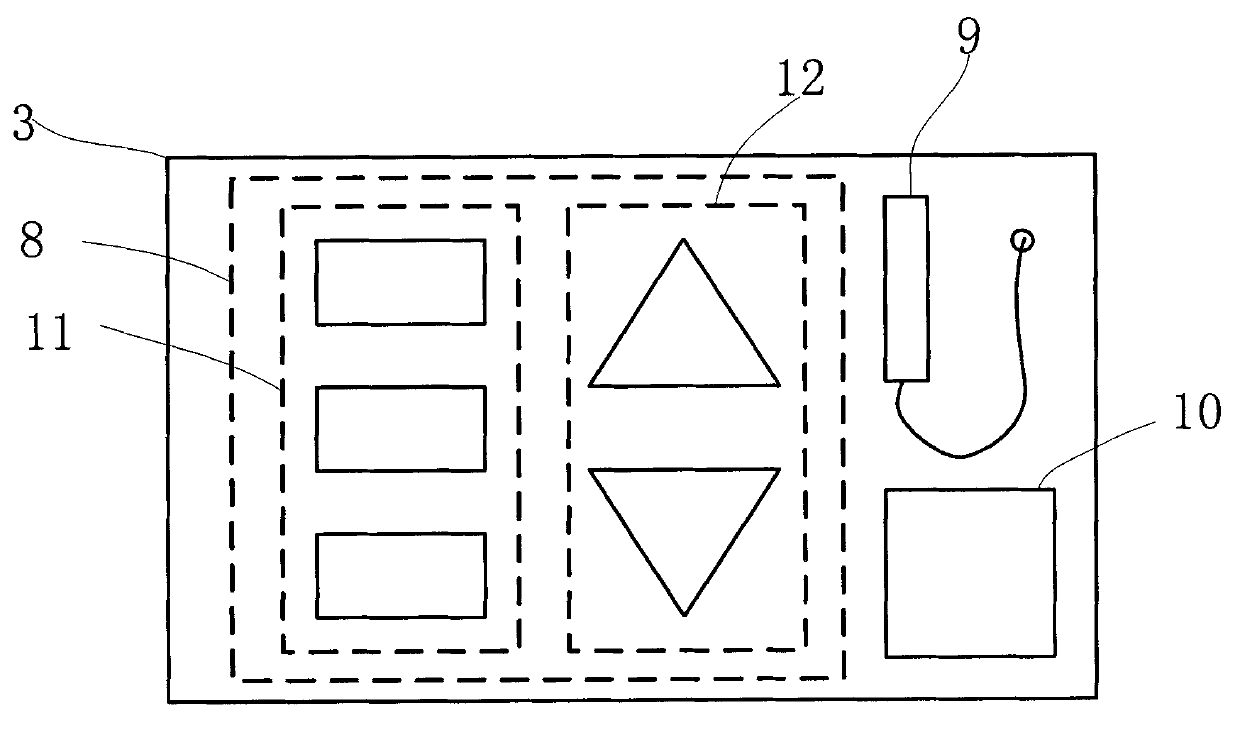

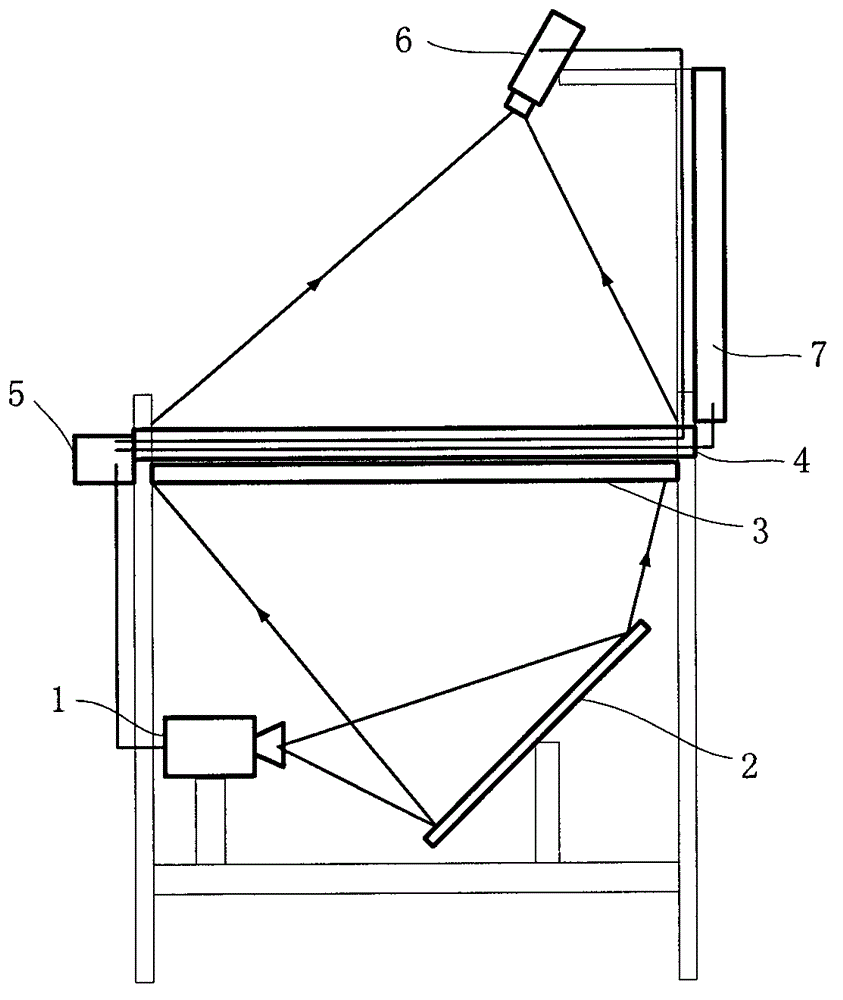

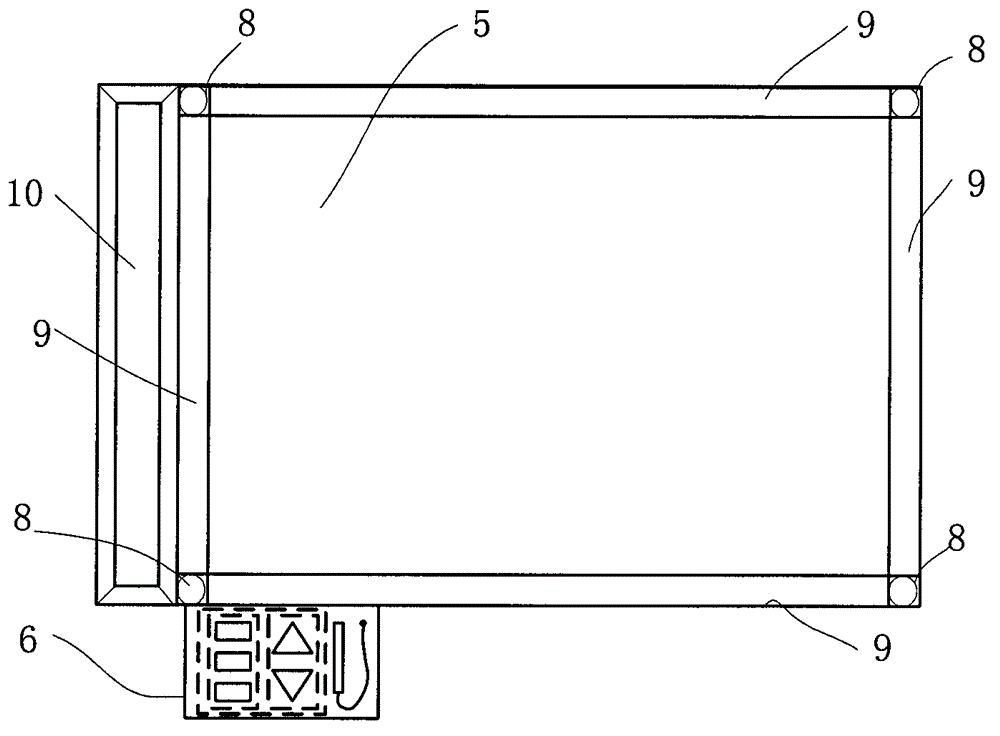

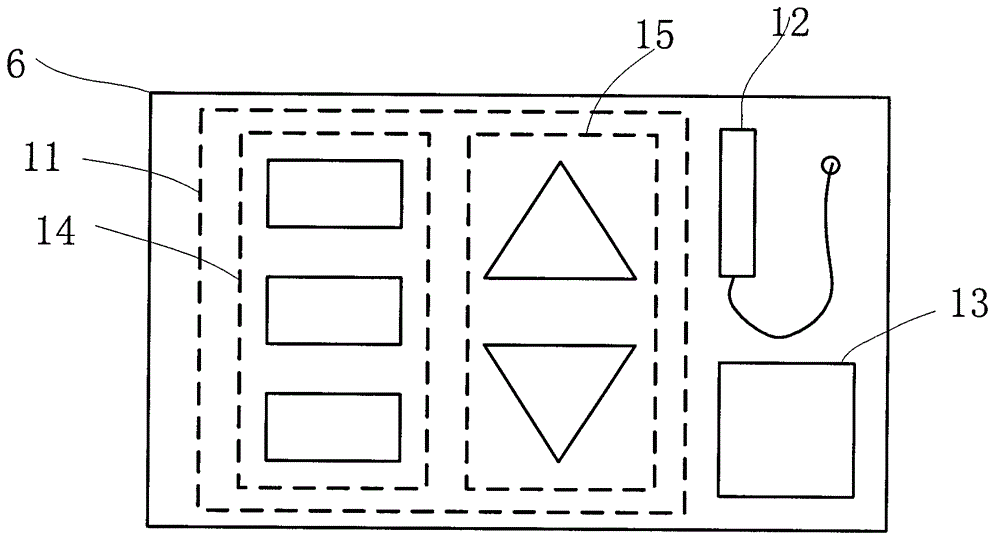

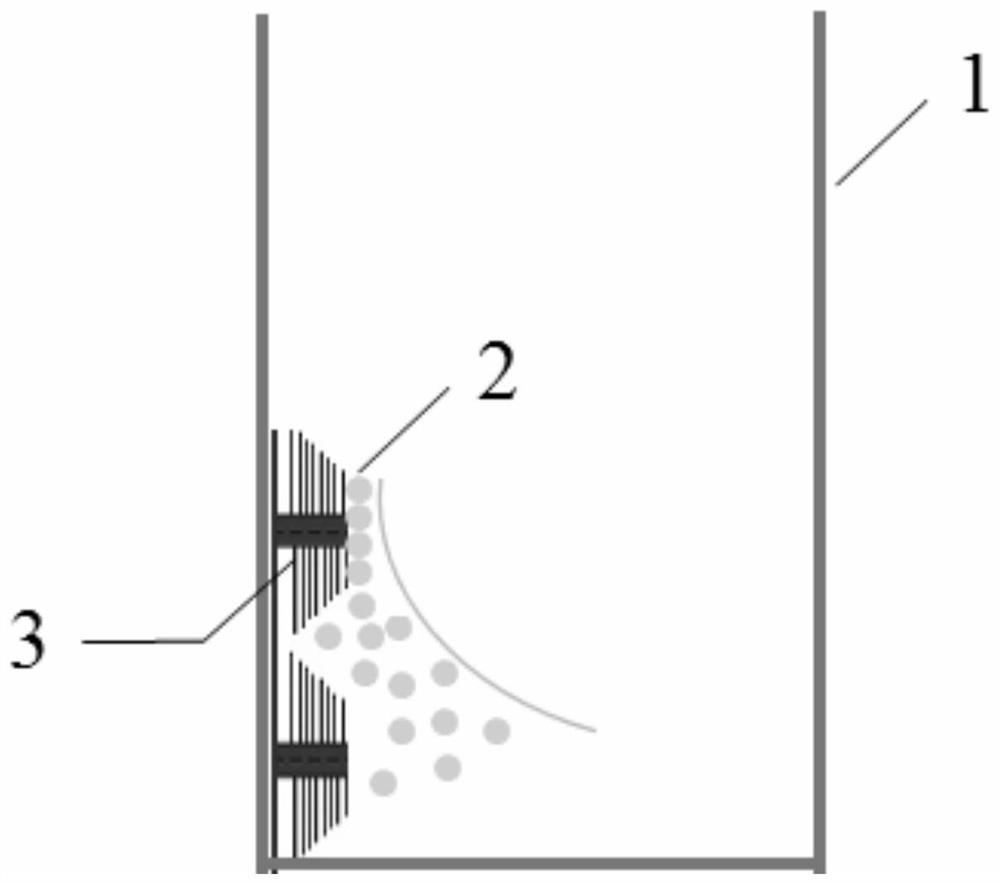

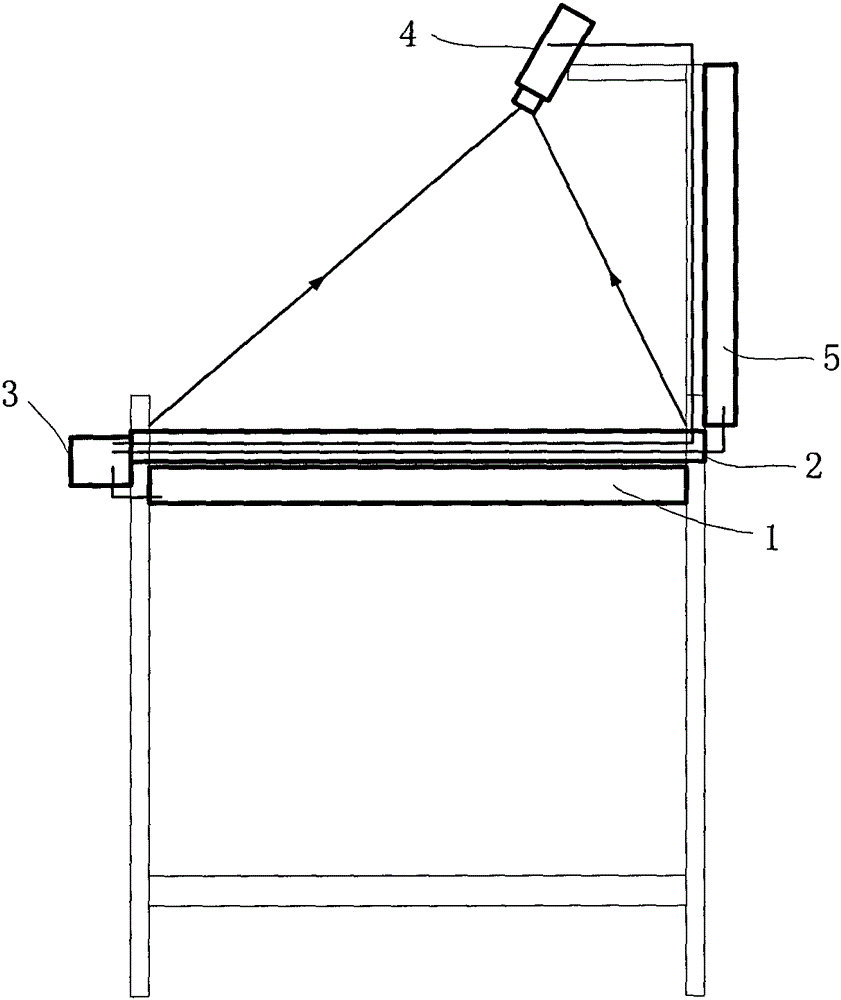

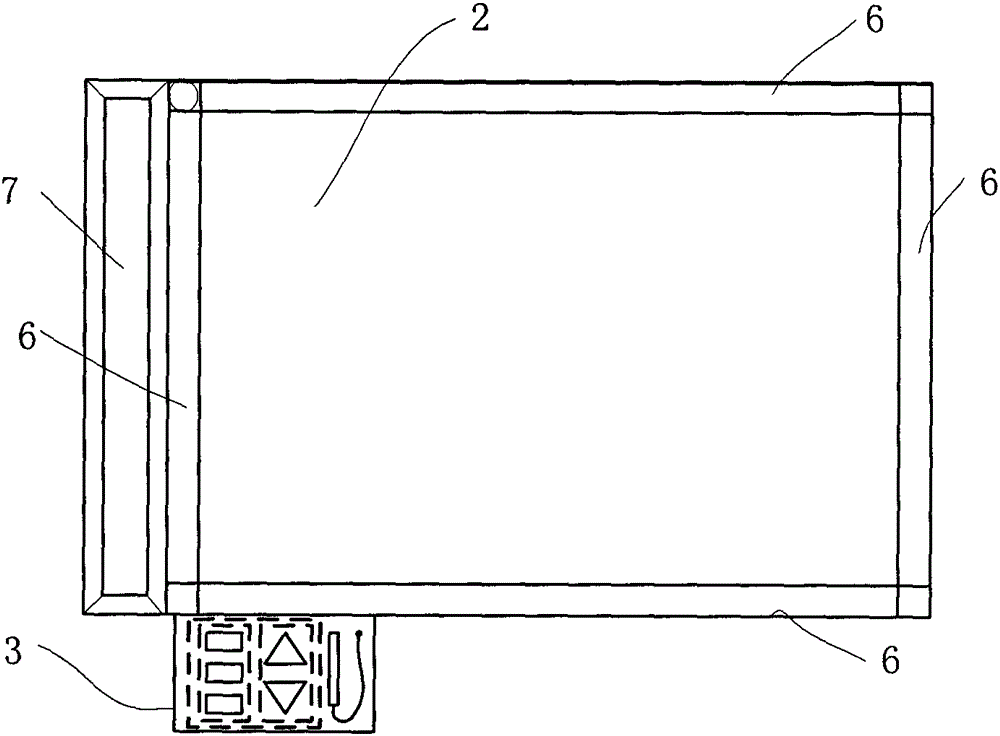

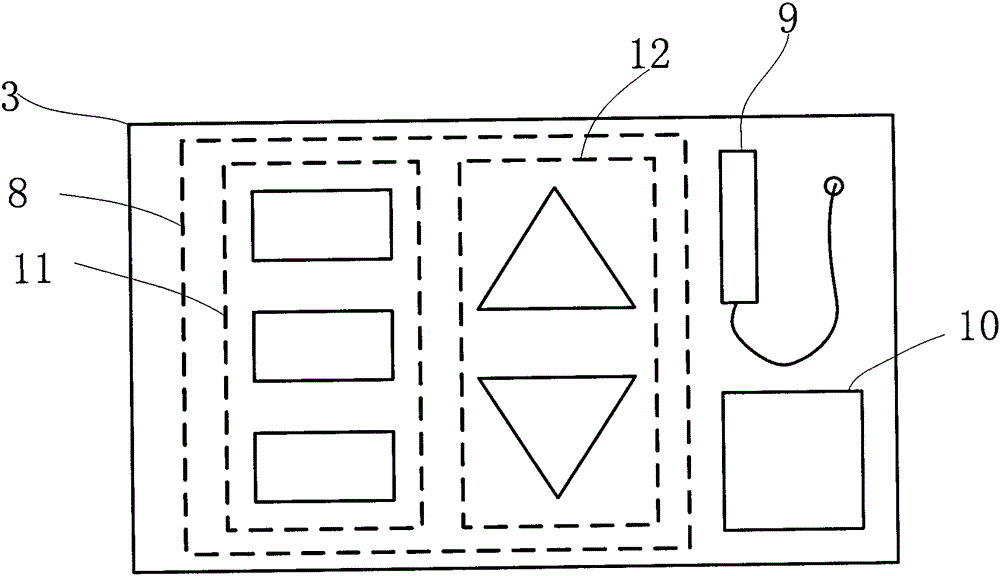

Sand painting device based on liquid crystal displayer and capable of adjusting colors

InactiveCN103273794AEasy to operateRich color expressionLight effect designsSpecial artistic techniquesColor imageLiquid-crystal display

A sand painting device based on a liquid crystal displayer and capable of adjusting colors comprises a first displayer (1), a sand painting workbench (2), a control panel (3), a camera system (4) and a second displayer (5). The first displayer (1) is located below the sand painting workbench (2), displays color images, and casts color light rays towards the sand painting workbench (2), and the color light rays are blocked by sand on the sand painting workbench (2), so that sand painting works in different colors are presented on the sand painting workbench (2). A user can change emergent light rays of the first displayer (1) through the control panel (3) so that brightness and colors in different areas on the sand painting workbench (2) can be adjusted, and the sand painting works in different colors are achieved. Meanwhile, the camera system (4) shoots the painting process and the works so as to enable the painting process and the works to be displayed on the second displayer (5) for appreciation of audience. The sand painting device enables the sand painting works to present different colors, brings great convenience for a designer and brings visual experience of high art value for the audience.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Projector-based sand painting platform device with adjustable color

InactiveCN103273795BEasy to operateRich color expressionHand artistic toolsOther artistic work equipmentsDisplay deviceVisual perception

Owner:ZHEJIANG FORESTRY UNIVERSITY

Return lamp with double light sources

PendingCN107062091AKeep solid colorIncrease light sourceLighting applicationsMechanical apparatusEngineeringLamp shell

The invention discloses a return lamp with double light sources, and relates to stage lamp equipment and facilities. The return lamp comprises a lamp shell, wherein the lamp shell is a hollow cylinder; a reflective cup is arranged inside the lamp shell; a bulb fixed plate is arranged inside the reflective cup; a bulb support base is arranged on the bulb fixed plate; a halogen bulb is arranged on the bulb support base; the reflective cup is connected with an LED fixed plate; the LED fixed plate is fixed with an LED substrate; an LED lamp is arranged on the LED substrate; an LED light barrier plate is arranged on the LED substrate; a cover plate is arranged on the LED light barrier plate and is connected with the lamp shell by a bolt; a light source of the LED lamp is added in the return lamp so that the return light is turned into a halogen light source which is combined with the LED light source to form new double light sources; the two light sources are used alternately and also can be used separately, so that the pure color of the traditional return lamp is maintained; because various colors of the LED are added, the using forms are varied, and the color representation is rich.

Owner:GUANGZHOU PENGLIN LIGHTING CO LTD

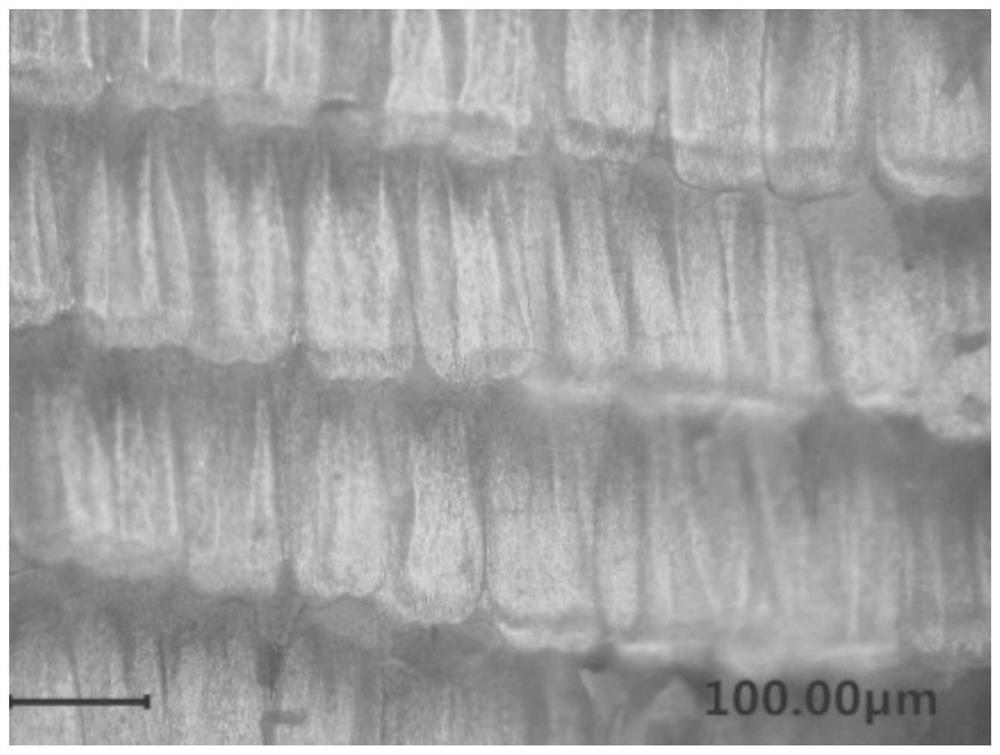

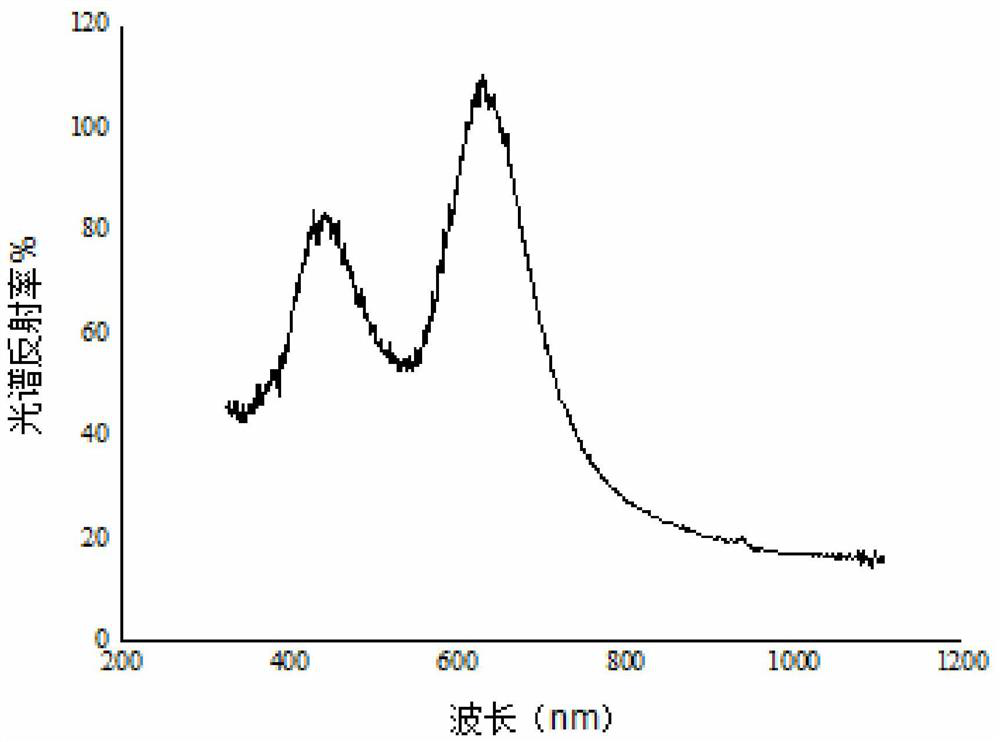

Method for preparing butterfly wing/colloidal crystal microsphere composite structure color film by vertical deposition method

ActiveCN110328131BWide color gamutRich color expressionLiquid surface applicatorsCoatingsMicrosphereMorpho

The invention relates to a method for preparing a butterfly wing / colloid crystal microsphere composite structural color film by a vertical deposition method, and belongs to the technical field of structural color film preparation. The butterfly wing with periodic structure was selected as a template, and the surface of the butterfly wing was pretreated; the colloidal crystal microsphere dispersion liquid was prepared and ultrasonically dispersed to make it in a uniformly dispersed state; after the butterfly wing was cut, it was placed vertically In the petri dish, slowly add the microsphere dispersion to completely submerge the butterfly wings, then place the petri dish in a constant temperature and humidity box, and assemble it by vertical deposition method. After the solvent is completely evaporated, butterfly wings / colloidal crystals are obtained The microsphere composite structure achieves specific color rendering effects in different viewing directions. The invention also discloses a batch preparation method of the film. The invention can realize structural color display with wide color gamut, narrow band gap, high brightness and special color rendering effect, and not only has important scientific research value, but also has great application value.

Owner:SHENZHEN JINJIA GRP +1

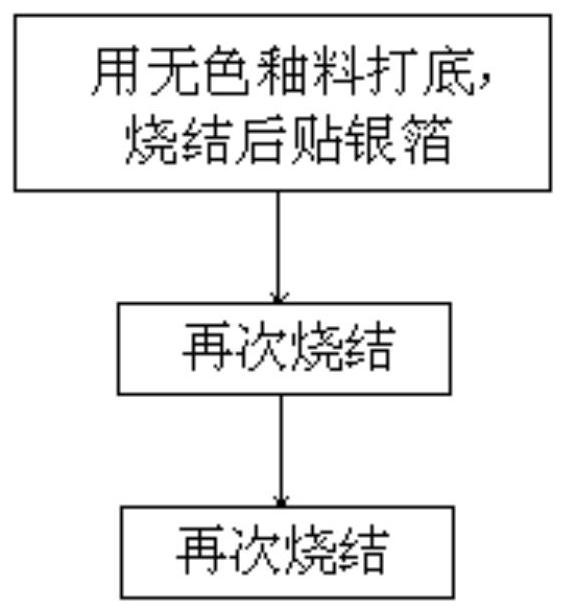

Process for firing enamel color not affected by K gold ground color on K gold

The invention discloses a process for firing an enamel color unaffected by a K gold ground color on K gold. The process comprises the following steps of conducting bottoming by using colorless transparent glaze, and pasting a layer of silver foil after sintering; conducting sintering again after the silver foil is pasted, so that the silver foil can be tightly attached to the surface of the K gold; checking the fitting degree of the glaze and the silver foil to ensure that the silver foil is sintered again under the conditions of no bulge and no dislocation; and checking the fitting degree of the glaze and the silver foil again, and dispensing enamel glaze after it is confirmed that the glaze and the silver foil are completely fitted. According to the process for firing the enamel color unaffected by the K gold ground color on the K gold, pure-color enamel, various light-color enamel and all design schemes needing to be transited from transparent white to colored enamel are successfully fired in a local silver foil applying manner; and by adopting the process, the pure blue enamel can be fired, so that the problem that the blue enamel is greenish is solved, the technical problem that the enamel is used as high-grade jewelry is solved to a great extent, and the expression form of the enamel is enriched.

Owner:孔氏(北京)国际钟表有限责任公司

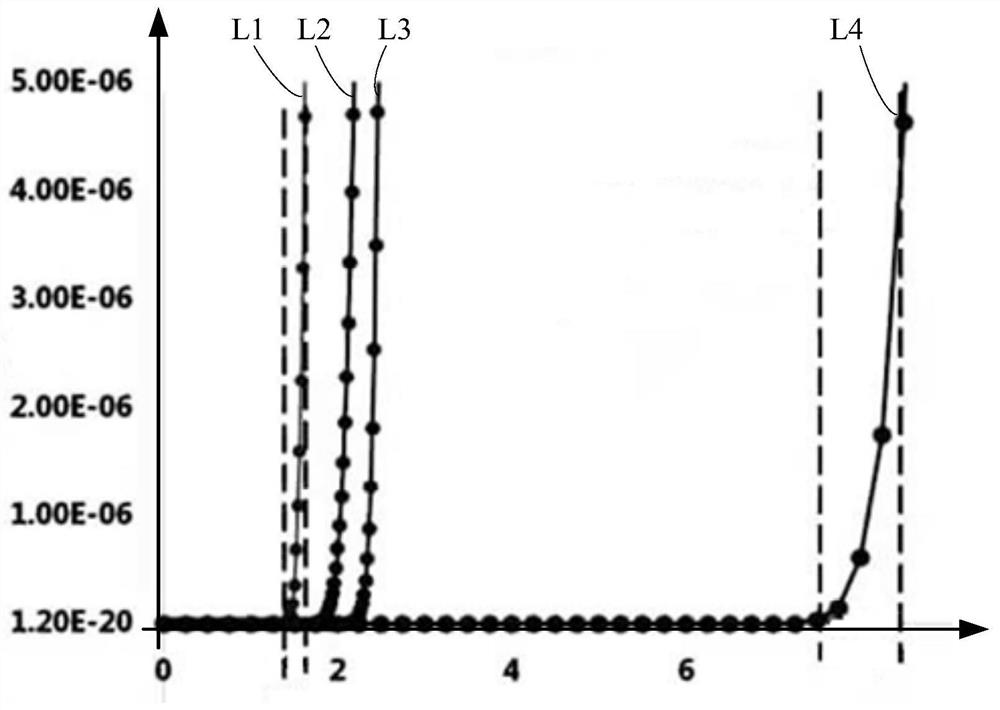

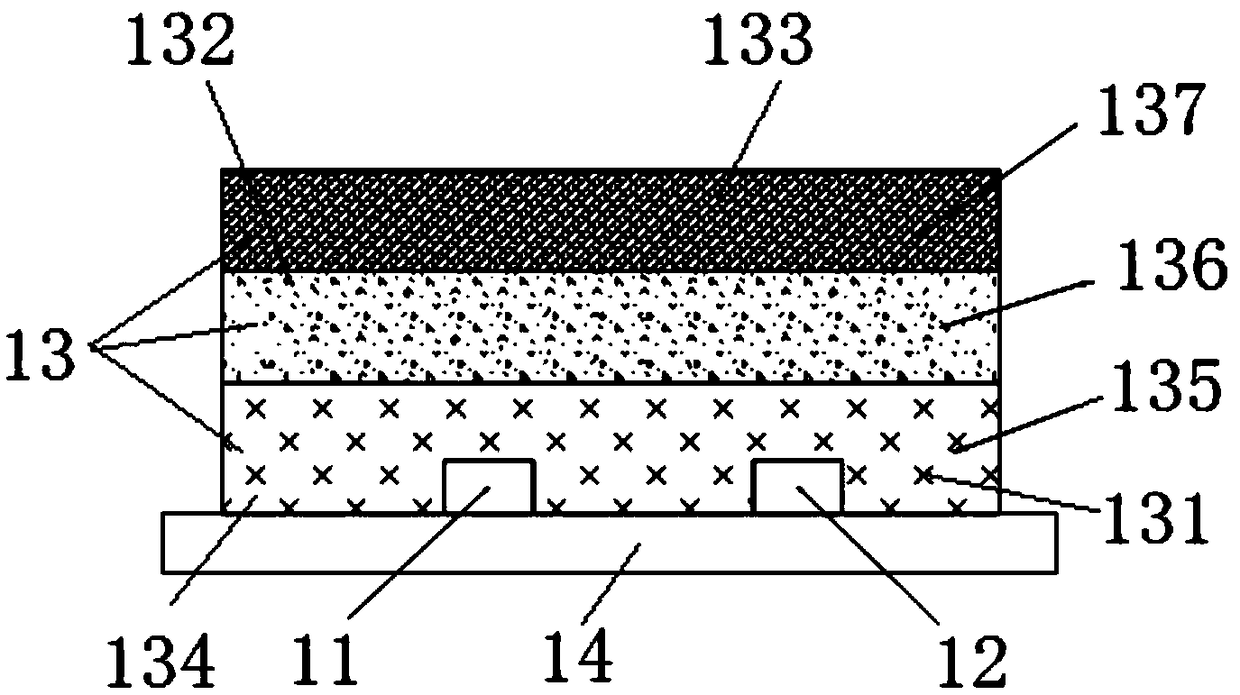

LED light emitting device and backlight module using the LED light emitting device

ActiveCN105810674BBreak through the limit of color gamut coverageRich color expressionSolid-state devicesSemiconductor devicesAdhesiveFluorescence

The invention discloses a light emitting diode (LED) luminous device. The LED luminous device comprises a purple-light LED chip, a blue-light LED chip and a fluorescent adhesive, wherein the fluorescent adhesive covers the purple-light LED chip and the blue-light LED chip and comprises nitrogen oxide green fluorescent powder, green fluorescent powder with half-wave width below 40 nanometers, Mn<4+> activated fluoride red fluorescent powder and silica gel, and the mass percent of the weight of the nitrogen oxide green fluorescent powder in the total weight of the nitrogen oxide green fluorescent powder, the green fluorescent powder with half-wave width below 40 nanometers and the Mn<4+> activated fluoride red fluorescent powder is less than or equal to 25%. The invention also discloses a backlight module employing the LED luminous device. By the LED luminous device, high color gamut can be acquired, mass production also can be achieved, and the reliability is high. When the LED luminous is applied to the backlight module, a fabricated LED television is approximate to a quantum dot (QD) television in national television system committee (NTSC) gamut, and audience acquires favorable visual experience.

Owner:APT ELECTRONICS

a color image

The invention relates to the field of dyeing and color images, in particular to a color image, which comprises a focusing element array layer, a first dyeing layer, a base material layer, a micrographic array layer and a second dyeing layer arranged in sequence, and each layer is adhered to each other. forming a film-type color image; the focusing element array layer is composed of a focusing element array formed by focusing units, the first dyed layer is formed by a color pixel dot matrix, and the micro-pattern array layer is composed of micro-pattern units The array of arranged micro graphics is formed, and the second dyed layer is formed by an array of colored pixels. The color image of the present invention adopts indirect dyeing of two dyeing layers, can realize the color image with the pixel unit smaller than 5 microns, improves the resolution of the color image, enriches the color of the color image, and improves the display effect of the color image. The formed color image has novel effects such as color three-dimensional, dynamic, light change, light response, etc., and has wide application prospects.

Owner:ZHEJIANG SCI-TECH UNIV

an ink with metallic luster

The invention relates to the field of ink, and provides an ink with metallic luster. In terms of weight percentage, the preparation raw materials at least include: 10-30% of dye, 5-25% of auxiliary agent, 5-20% of gold powder, and the balance of water.

Owner:上海鱼圆文具有限公司 +1

Color-adjustable sand painting platform device based on liquid crystal display

InactiveCN103273794BEasy to operateRich color expressionLight effect designsSpecial artistic techniquesColor imageLiquid-crystal display

A sand painting device based on a liquid crystal displayer and capable of adjusting colors comprises a first displayer (1), a sand painting workbench (2), a control panel (3), a camera system (4) and a second displayer (5). The first displayer (1) is located below the sand painting workbench (2), displays color images, and casts color light rays towards the sand painting workbench (2), and the color light rays are blocked by sand on the sand painting workbench (2), so that sand painting works in different colors are presented on the sand painting workbench (2). A user can change emergent light rays of the first displayer (1) through the control panel (3) so that brightness and colors in different areas on the sand painting workbench (2) can be adjusted, and the sand painting works in different colors are achieved. Meanwhile, the camera system (4) shoots the painting process and the works so as to enable the painting process and the works to be displayed on the second displayer (5) for appreciation of audience. The sand painting device enables the sand painting works to present different colors, brings great convenience for a designer and brings visual experience of high art value for the audience.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com