Color mixing hose lamp

A hose and color mixing technology, which is applied in the field of hose lamps, can solve the problems of lack of color expression and increase in the cost of hose lamps, and achieve the effect of enriching color expression and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

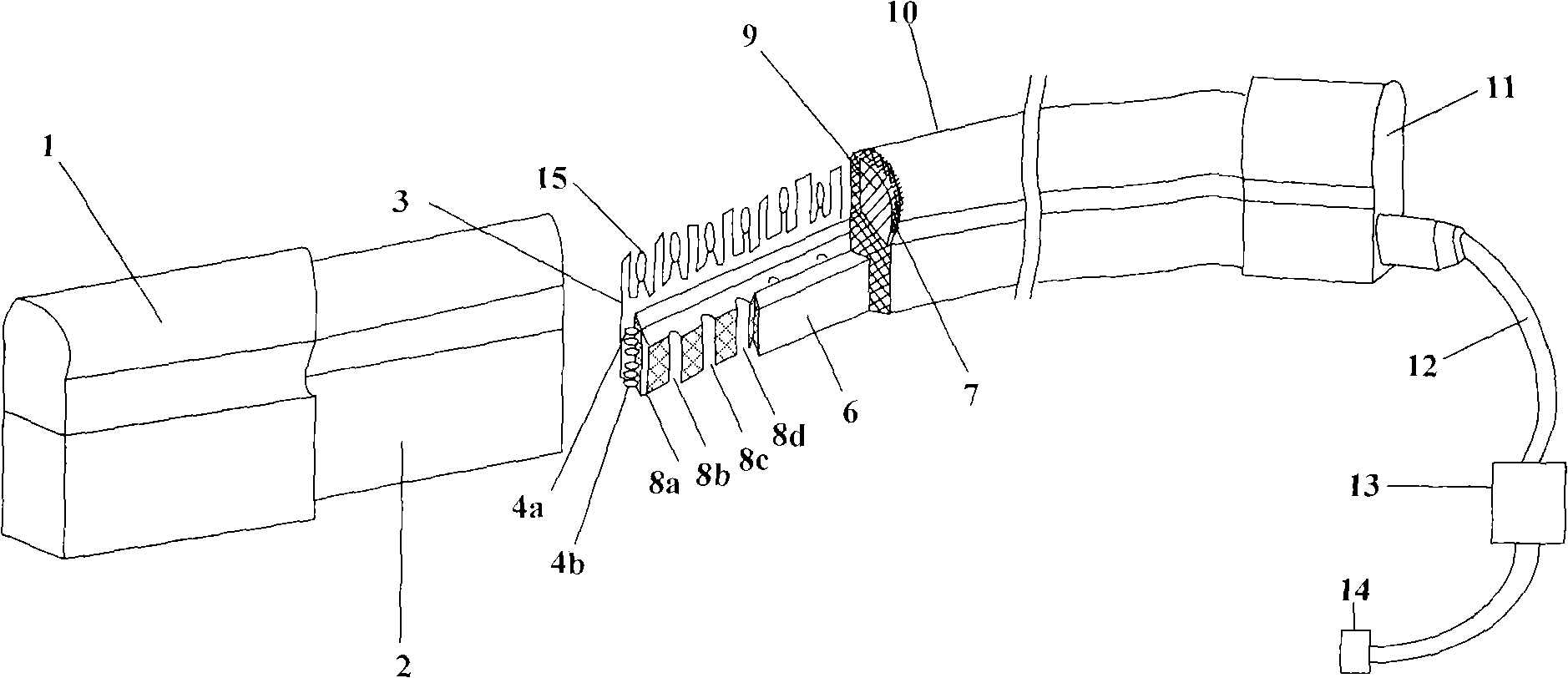

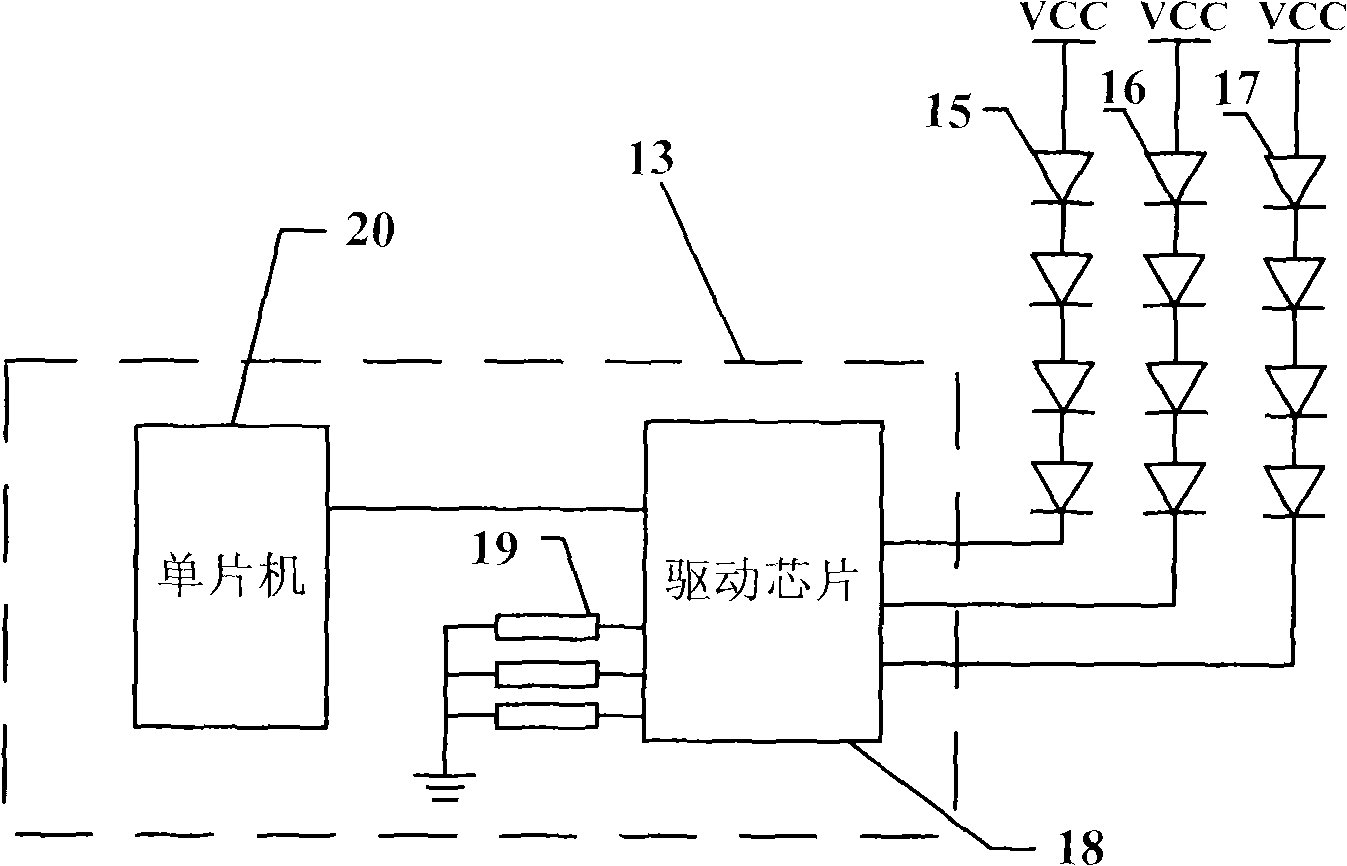

[0030] refer to figure 1 and figure 2 , a color-mixing hose lamp, which contains the following components:

[0031] A core wire 6 is extruded from a soft plastic to form a prefabricated length strip, and on one side of the cross section of the strip, at least 3 pairs of copper stranded wires connected in parallel are arranged at intervals up and down, figure 1 The middle copper stranded wire 4a and the copper stranded wire 4b represent the head end and the end of each pair of copper stranded wires respectively.

[0032] The longitudinal extension of the copper stranded wire is equal to the length of the strip; on the other side of the cross section of the strip, there are several transverse holes parallel to the copper stranded wire, such as figure 1 As shown, it includes a transverse hole 8a, a transverse hole 8b, a transverse hole 8c, and a transverse hole 8d, and each transverse hole is evenly distributed on the entire longitudinal length of the strip at a preset interva...

Embodiment 2

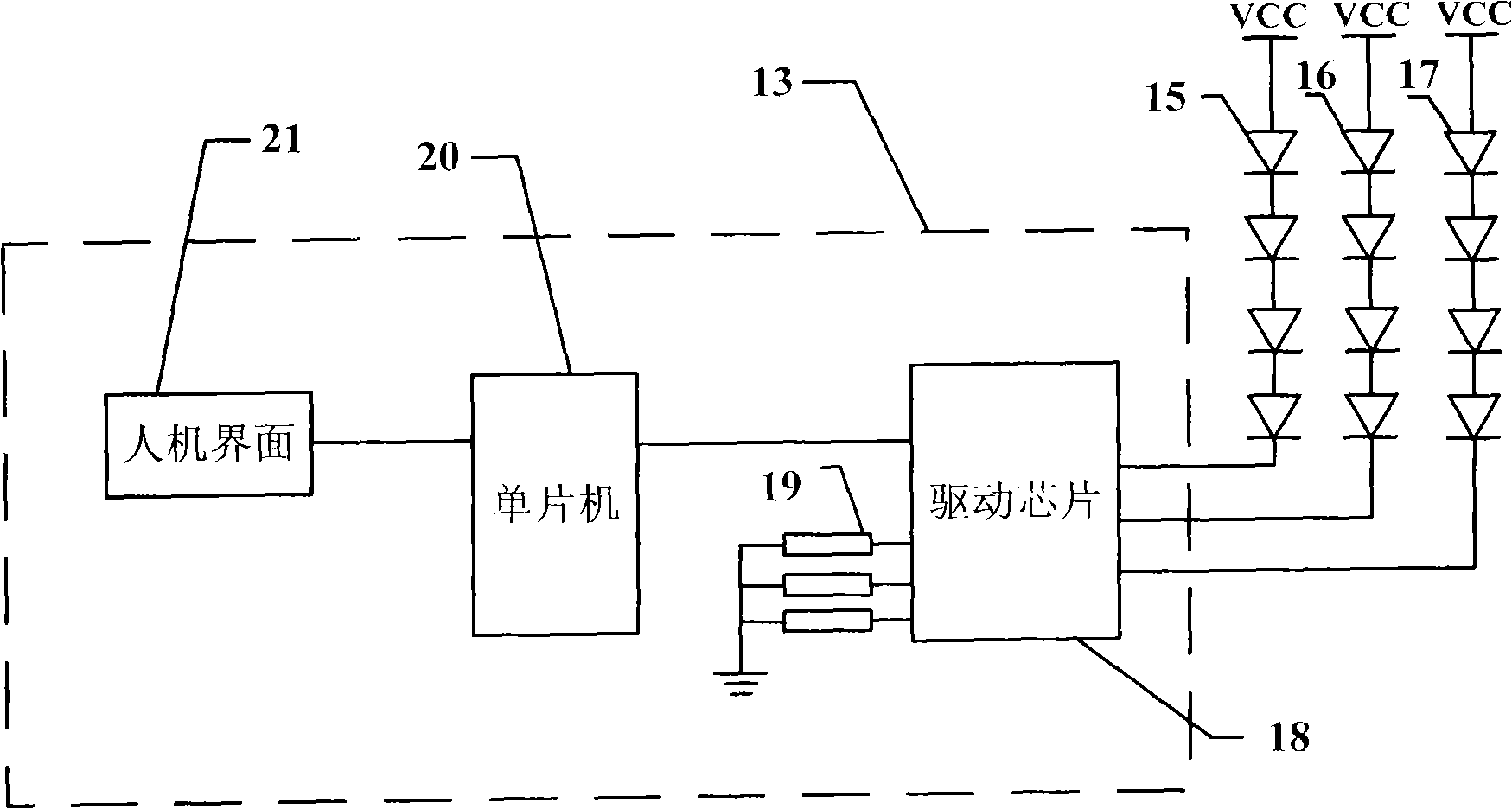

[0047] refer to figure 1 and image 3 In this embodiment, on the basis of Embodiment 1, the single-chip microcomputer 20 also includes a man-machine interface 21 and a control panel, which are used to allow the user to operate the single-chip microcomputer through the control panel, and reflect it to the user through the man-machine interface 21 , to meet the needs of more people. Other principles are the same as those in Embodiment 1, and will not be repeated here.

[0048] With the solution of this embodiment, the editability of the color-mixing hose lamp is greatly improved, and it is suitable for high-end users to control by themselves, and change the lighting mode of the LED lamp at any time according to different needs.

Embodiment 3

[0050] refer to figure 1 and Figure 4 , in this embodiment, the driving chip set 25 in the driving device 13 is composed of a first driving chip 22, a second driving chip 23 and a third driving chip 24, each driving chip drives an LED series light string respectively, and The driving chips are all constant current driving chips, for example, the driving chip adopts Zhongqing's ZQ9712 chip. The rest of the principle is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com