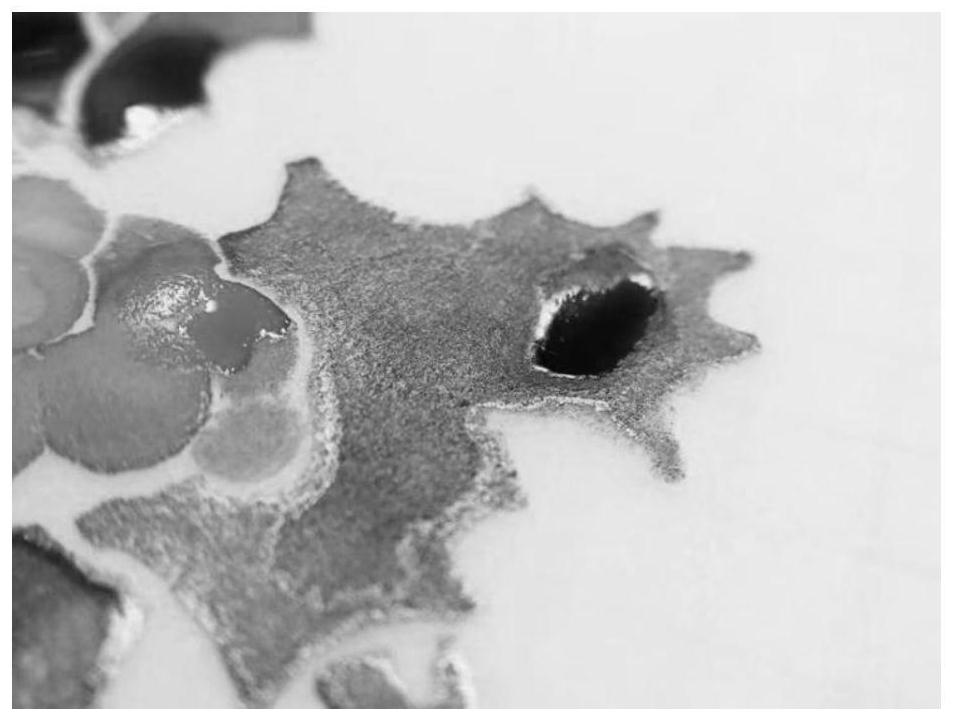

an ink with metallic luster

A technology of metallic luster and ink, applied in the field of ink, can solve the problems of poor performance of color ink metallic luster and metallic texture, and achieve the effect of rich color performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] A kind of ink with metallic luster, by weight percentage, its preparation raw material comprises:

[0067] Dye 20%,

[0068] Auxiliary 15%,

[0069] Gold Dust 12%,

[0070] water balance;

[0071] The dyes are rhodamine B and orange G; the weight ratio of rhodamine B and orange G is 3:1; the weight percentage of thickener, lubricant, surfactant and preservative in the auxiliary agent is 1 : 1.5: 0.7: 0.5; the plasticizer is gum arabic; the lubricant is 1,2-propylene glycol; the surfactant is sodium lauryl sulfate; the preservative is phenoxyethanol; The weight ratio of copper-gold powder and pearl powder in the gold powder is 4:1.

Embodiment 2

[0073] A kind of ink with metallic luster, by weight percentage, its preparation raw material comprises:

[0074] Dye 10%,

[0075] Auxiliary 5%,

[0076] Gold Dust 5%,

[0077] water balance;

[0078] The dyes are rhodamine B and orange G; the weight ratio of rhodamine B and orange G is 0.5:1; the weight percentage of thickener, lubricant, surfactant and preservative in the auxiliary agent is 1 : 1:0.5:0.1; the plasticizer is pectin; the lubricant is 1,2-propylene glycol; the surfactant is sodium dodecylbenzenesulfonate; the preservative is phenoxyethanol ; The weight ratio of copper-gold powder and pearl powder in the gold powder is 3:1.

Embodiment 3

[0080] A kind of ink with metallic luster, by weight percentage, its preparation raw material comprises:

[0081] Dye 15%,

[0082] Auxiliary 10%,

[0083] Gold Dust 9%,

[0084] water balance;

[0085] The dyestuff is carmine and orange G; the weight ratio of carmine and orange G is 2:1; the weight percentage of thickener, lubricant, surfactant and preservative in the auxiliary agent is 1 : 1.3: 0.6: 0.4; the plasticizer is gum arabic; the lubricant is glycerol; the surfactant is sodium lauryl sulfate; the preservative is phenoxyethanol; the gold powder The weight ratio of medium copper gold powder and pearl powder is 3.5:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com