Process for firing enamel color not affected by K gold ground color on K gold

A background color and enamel technology, applied in the field of high temperature enamel, can solve the problems of poor color expression of enamel products, no color difference of enamel glaze, complicated process operation, etc., to achieve rich color expression, not easy to burst and peel, rich optional range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

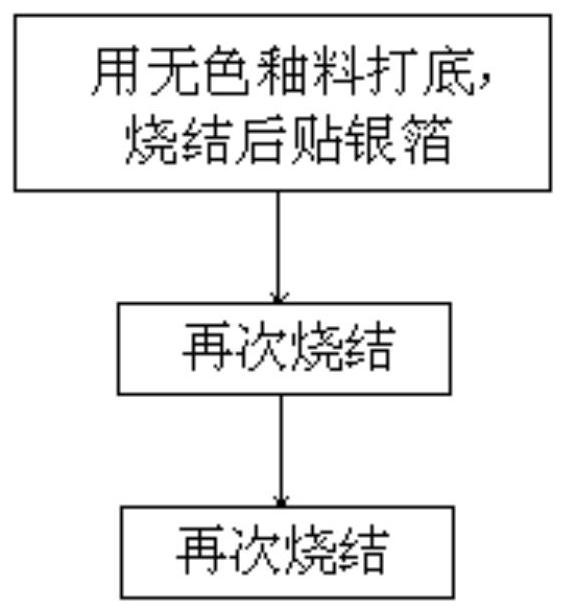

[0036] Such as figure 1 As shown, according to the embodiment of the present invention, the process of burning out the enamel color not affected by the background color of K gold on K gold includes the following steps:

[0037] S1 uses a K gold sheet with a diameter of 2 cm and a thickness of 0.8 mm as the base tire. First, use a colorless transparent glaze (a glaze specially used for gold bases, which is available in the market) to make a uniform base. After sintering in an electric furnace at 815 degrees Celsius for 50 seconds, check whether the entire metal surface of the gold piece is completely covered by the glaze. If there is exposed metal, you need to repair the glaze again and sinter the glaze again at the same temperature and for the same time. Check again after the gold piece is cooled to ensure that the metal surface of the gold piece is completely covered by the glaze, dip a little water with a brush to coat the surface of the glaze, and then paste a layer of 0.02...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com