Water-based sand wall-shaped pearly coating and preparation method thereof

A sand-wall-like pearlescent pigment technology, which is applied in the field of water-based sand-wall-like pearlescent paint and its preparation, can solve the problems of inability to protect the exterior walls of buildings, high specific gravity of white sand particles, poor crack resistance, etc., and achieve excellent color stability, Enrich color expression and prevent paint color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

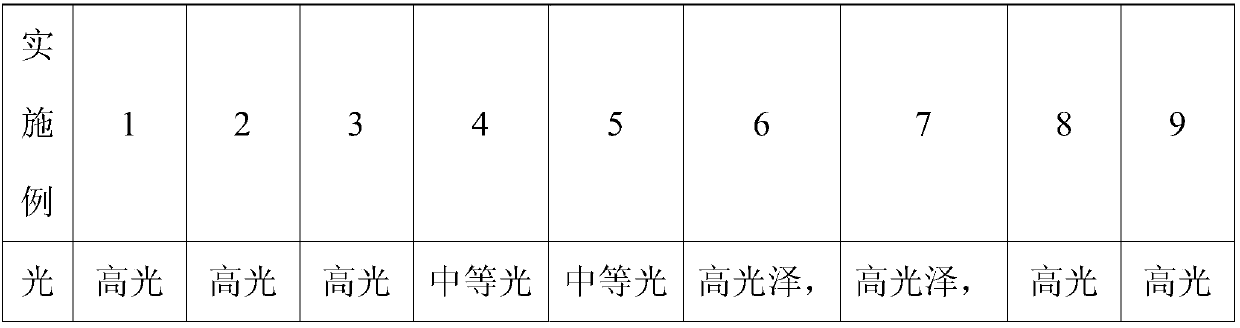

Examples

Embodiment 1

[0070] Prepare water-based sand wall shape pearlescent coating 1 by following steps:

[0071] First add 3kg of basic paint in the reaction kettle, stir at a speed of 200 rpm, add 7kg of pearlescent colored sand while stirring, and continue stirring for 10min to make the two mix evenly, and then obtain the water-based sand wall-shaped pearlescent paint 1.

[0072] The pearlescent colored sand is prepared through the following steps:

[0073] In step (1), 1000kg particle diameter is 25 mesh quartz sand and 30kg particle diameter is 40~60 μ m pearlescent pigment (average particle diameter is 50 μ m, is the mica flake that surface is coated with titanium dioxide film layer), mixes, with 400~500 Stir for 3 minutes at a speed of rev / min, so that the pearlescent pigment is adsorbed on the surface of the quartz sand, then add 30kg of epoxy resin binder to it, keep the stirring speed constant, and continue stirring to obtain a mixture;

[0074] Step (2), the mixture obtained in step (...

Embodiment 2

[0081] Prepare water-based sand wall shape pearlescent paint 2 by following steps:

[0082] The only difference from Example 1 is that in the preparation process of the pearlescent colored sand, the particle diameter of the pearlescent pigment in step (1) is 5-20 μm (the average particle diameter is 12 μm).

[0083] Embodiment 2 obtains water-based sand wall shape pearlescent paint 2.

Embodiment 3

[0085] Prepare water-based sand wall shape pearlescent coating 3 by following steps:

[0086]The only difference from Example 1 is that in the preparation process of the pearlescent colored sand, the particle diameter of the pearlescent pigment in step (1) is 20-40 μm (the average particle diameter is 30 μm).

[0087] Embodiment 3 obtains water-based sand wall shape pearlescent paint 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com