Touch display screen and manufacture method thereof

A technology for a touch display screen and a manufacturing method, which is applied to semiconductor/solid-state device manufacturing, static indicators, optics, etc., can solve the problem of high manufacturing cost, and achieve the effects of reducing manufacturing cost, improving quality and manufacturing efficiency, and simplifying manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

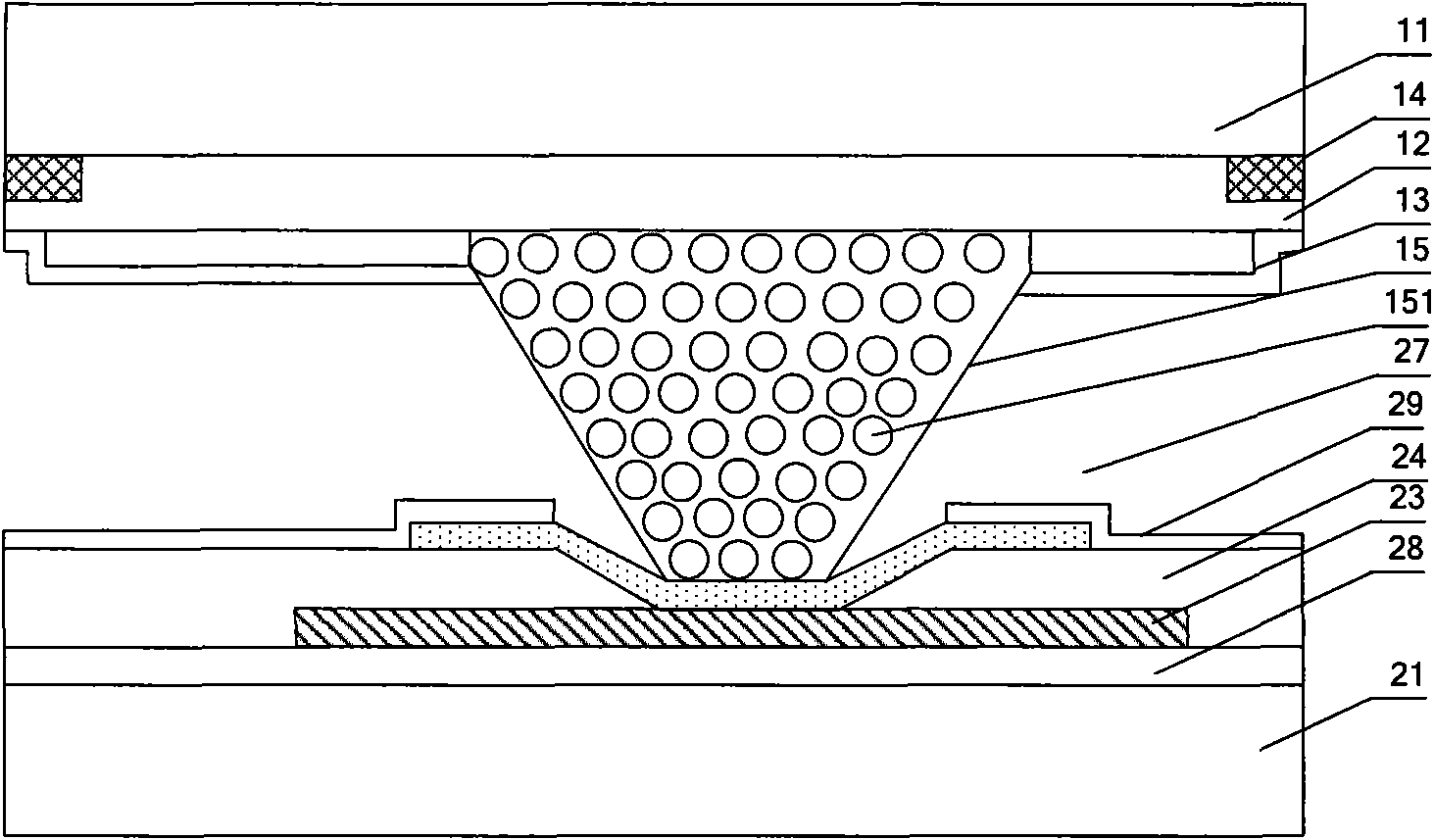

[0080] Figure 8 The flow chart of manufacturing the array substrate for Embodiment 2 of the touch display screen manufacturing method of the present invention, as shown in Figure 8 As shown, different from method embodiment 1, forming a color filter substrate with several spacers connected to a common electrode through a patterning process includes:

[0081] Step 1011', forming a black matrix pattern on the upper substrate;

[0082] Step 1012', forming a color resin unit pattern on the upper substrate on which the black matrix pattern is formed;

[0083] Step 1013', forming a common electrode pattern on the upper substrate on which the color resin unit pattern is formed;

[0084] Step 1014', forming several spacer patterns capable of conducting electricity under pressure on the upper substrate on which the common electrode pattern is formed, and the spacer is connected to the common electrode.

[0085] The manufacturing method of the array substrate in this embodiment is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com