A kind of white oil for poultry vaccine injection and preparation method thereof

A technology for injection and vaccine, which is applied in the treatment of hydrocarbon oil, petroleum industry, hydrocarbon oil treatment products, etc. It can solve the problems of low paraffin content, easy inflammatory reaction, poor absorption, etc., and achieve high antibody titer and excellent Color stability and anti-oxidation stability, good absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

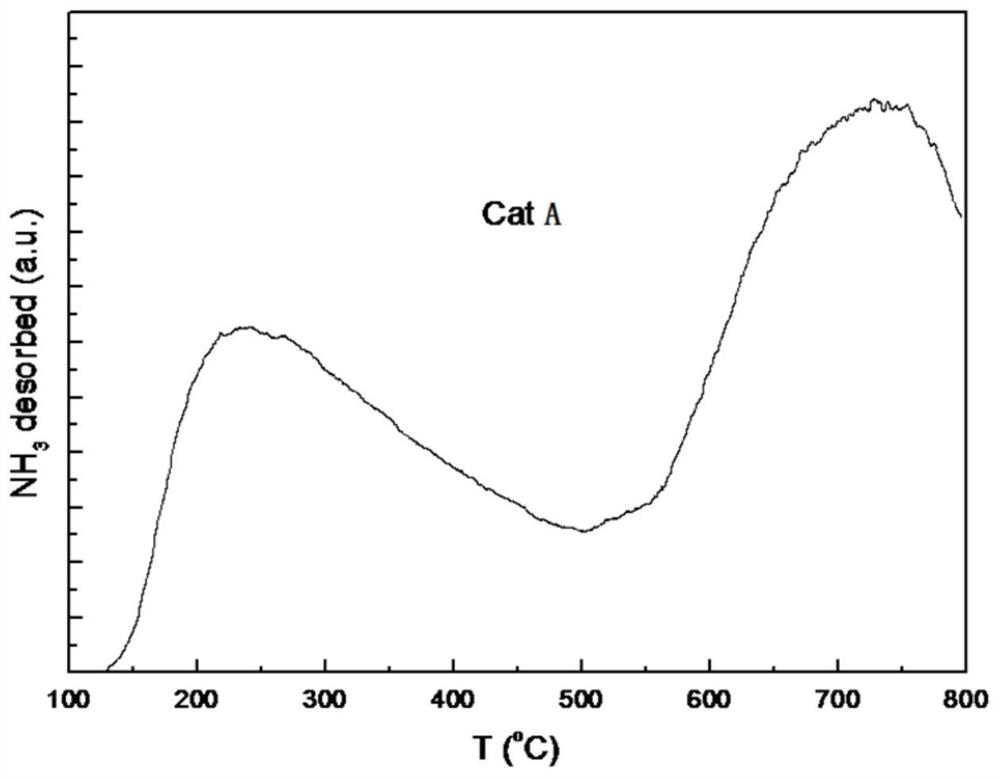

Image

Examples

Embodiment 1

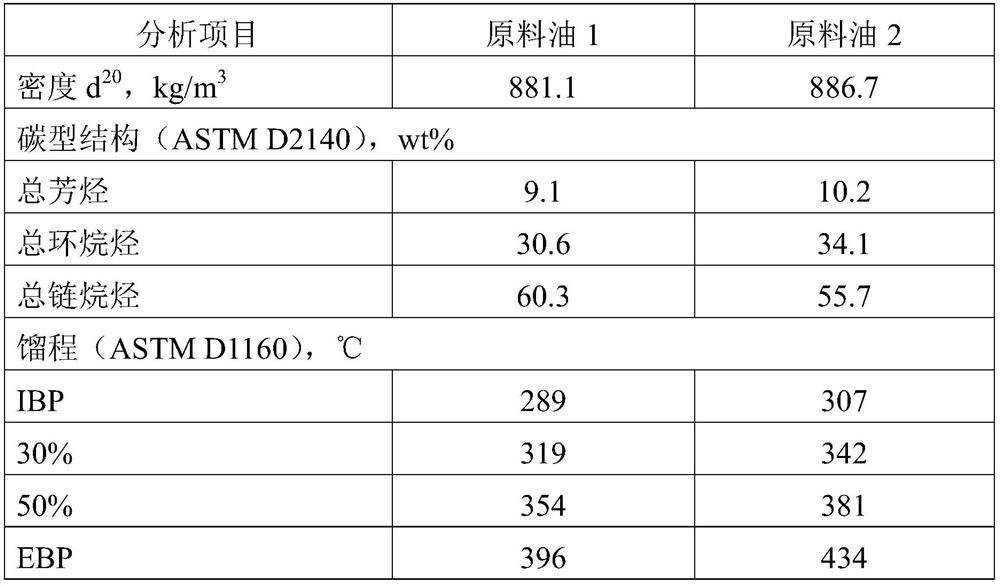

[0049] The atmospheric and vacuum fraction of paraffin-based crude oil and the atmospheric and vacuum fraction of naphthenic crude oil are blended into a mixed fraction according to the mass ratio of 85:15. Atmospheric and vacuum distillate of alkyl crude oil cuts 280~360℃ distillate oil. The mixed fraction in this example is recorded as feed oil 1, and the specific properties of feed oil 1 are shown in Table 1.

[0050] The raw material oil 1 is subjected to hydrogenation pre-refining, so that the hydrogenation pre-refining product meets the limited requirements of the high-pressure hydrogenation process for feed oil: the total metal content is less than 2.0 μg / g, the content of n-heptane insolubles is less than 0.02%, and the salt content The iron content is less than 1.0mg / L, the water content is less than 300μg / g, the iron content is less than 1.5μg / g, and the carbon residue is less than 1%.

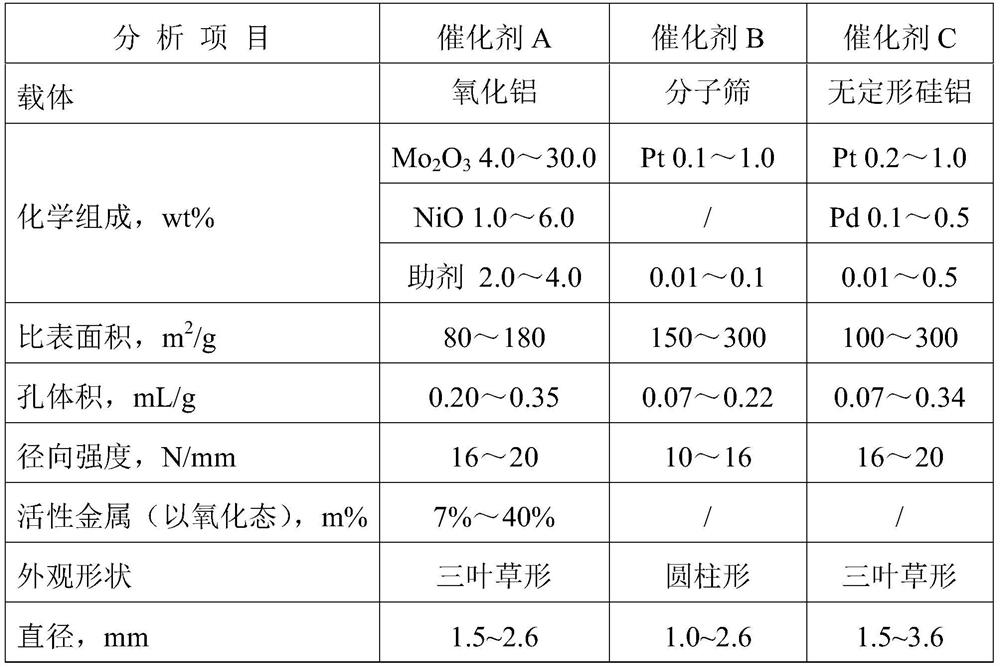

[0051] Under the hydrogen partial pressure of 17MPa, the hydrorefined products ...

Embodiment 2

[0058] This embodiment provides a preparation method of white oil for poultry vaccine injection. The raw material oil and catalyst used are the same as in Example 1. First, the mixed fraction (i.e. raw material oil 1) is hydrogenated and pre-refined to make the hydrogenated pre-refined product Reach the limit requirements of high-pressure hydrogenation process for feed oil; then carry out three-stage high-pressure hydrogenation reaction under the hydrogen partial pressure of 18MPa, in which:

[0059] Hydrotreating: reaction temperature is 380°C, space velocity is 1.0h -1 , The volume ratio of hydrogen to oil is 1500:1;

[0060] Isomerism depreciation: reaction temperature is 350°C, space velocity is 0.5h -1 , The volume ratio of hydrogen to oil is 1500:1;

[0061] Supplementary hydrogenation refining: reaction temperature 300°C, space velocity 2.2h -1 , The volume ratio of hydrogen to oil is 2000:1.

[0062] The reaction product obtained from the three-stage high-pressure ...

Embodiment 3

[0064] Atmospheric and vacuum distillates of paraffinic crude oil and atmospheric and vacuum distillates of naphthenic crude oil are blended into mixed fractions according to the mass ratio of 70:30. Atmospheric and vacuum distillate of alkyl crude oil cuts 300-380°C distillate oil. The mixed fraction in this example is recorded as feed oil 2, and the specific properties of feed oil 2 are shown in Table 1.

[0065] Hydrogenation and pre-refining of raw oil 2, so that the hydro-pre-refining product meets the limit requirements of high-pressure hydrogenation process for feed oil: the total metal content is less than 2.0 μg / g, the content of n-heptane insolubles is less than 0.02%, and the salt content The iron content is less than 1.0mg / L, the water content is less than 300μg / g, the iron content is less than 1.5μg / g, and the carbon residue is less than 1%.

[0066]Under the hydrogen partial pressure of 20MPa, the hydrorefined products are successively entered into the three-sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| UV absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com